Operator's manual

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

Operator's manual

3522A - HTA13P - 4527A - HTA16P - 5533A

- HTA19P

3522A - HTA13P - 4527A - HTA16P -

5533A - HTA19P

24203 0

X

USA

4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

2 4000670470 E 04.19 USA / GB

Operator's manual

CONTENTS

A

FOREWORD

1 - User responsibility . . . . . . . . . . . . . . . . . . . . . . .

1.1 - Owner's responsibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 - Employer's responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 - Trainer's responsibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 - Operator's responsibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 - Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 - Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1.1 - Misuse Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1.2 - Falling Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.3 - Overturning / Tip-over Hazards . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1.4 - Electrocution Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.1.5 - Explosion / Fire Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1.6 - Crushing / Collision Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1.7 - Uncontrolled movement Hazards . . . . . . . . . . . . . . . . . . . . . . . . 16

3 - Safety inquiries. . . . . . . . . . . . . . . . . . . . . . . . .

4 - Incident notification . . . . . . . . . . . . . . . . . . . . .

5 - Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 - Product information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.1 - Change of Ownership Notification . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.2 - Owner information update form . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2 - Product specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8

10

17

17

18

B

FAMILIARIZATION

1 - General safety. . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 - Intended use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.2 - Decal content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.3 - Symbols and colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.4 - Level of severity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.5 - Symbols legend and definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2 - Models description. . . . . . . . . . . . . . . . . . . . . .

3 - Primary machine components . . . . . . . . . . . .

3.1 - Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

CONTENTS

3.2 - Ground control box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.2.1 - Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.3 - Platform control box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.3.1 - Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4 - Performance Specifications . . . . . . . . . . . . . .

4.1 - Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.2 - Working area / Range of motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5 - Decals and markings locations. . . . . . . . . . . .

21

25

26

36

45

3

Operator's manual

C

PRE-OPERATION INSPECTION

1 - Recommendations . . . . . . . . . . . . . . . . . . . . . .

2 - Working area assessment . . . . . . . . . . . . . . . .

3 - Inspection and Functional test . . . . . . . . . . . .

3.1 - Daily inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3.2 - Inspection Form. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4 - Safety functional checks . . . . . . . . . . . . . . . . .

4.1 - E-Stop button check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.2 - Activation of controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4.3 - Fault detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4.3.1 - Indicators/LED's test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4.4 - Automatic engine cut-out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4.5 - Outriggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

D

71

72

73

79

OPERATION INSTRUCTIONS

1 - Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 - Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

1.2 - Operation from the ground control box. . . . . . . . . . . . . . . . . . . . . . . . . . . 85

1.3 - Operation from the platform control box. . . . . . . . . . . . . . . . . . . . . . . . . . 86

2 - Ground control box . . . . . . . . . . . . . . . . . . . . .

2.1 - Boom and arm controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

3 - Platform control box . . . . . . . . . . . . . . . . . . . .

3.1 - To start and stop the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3.2 - Platform box controls (Primary station). . . . . . . . . . . . . . . . . . . . . . . . . . . 90

3.3 - Additional controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4 - Outriggers extension . . . . . . . . . . . . . . . . . . . .

5 - Rescue and emergency procedures. . . . . . . .

5.1 - In case of power loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

5.1.1 - Manual Boom Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

5.1.1.1 - Manual retraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

5.1.1.2 - Manual rotation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

5.1.1.3 - Manual Boom Lowering Procedure . . . . . . . . . . . . . . . . . . . . . . 96

5.2 - To rescue operator in platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

5.3 - No power available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

83

87

89

92

94

4

Operator's manual

6 - Transportation . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 - Putting in transport position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6.1.1 - Machine layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6.1.2 - Transporting on to a truck bed . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6.1.3 - Unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6.2 - Towing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6.2.1 - Procedure to hitch and tow. . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6.3 - Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.4 - Lifting operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7 - Cold Weather Recommendations . . . . . . . . .

7.1 - Engine oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

7.2 - Hydraulic oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

E

GENERAL SPECIFICATIONS

1 - Machine dimensions . . . . . . . . . . . . . . . . . . .

2 - Major component masses . . . . . . . . . . . . . . .

3 - Acoustics and vibrations. . . . . . . . . . . . . . . .

4 - Wheel/Tire assembly . . . . . . . . . . . . . . . . . . .

4.1 - Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

4.2 - Inspection and maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

5 - Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 - Important . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

5.2 - Drive and set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

5.2.1 - Drive and set safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

5.2.2 - Drive and set controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

5.2.3 - Drive and set use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

5.2.3.1 - Initial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

5.2.3.2 - During Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

5.3 - Platform rotator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

98

104

106

108

108

109

114

CONTENTS

5

Operator's manual

F

MAINTENANCE

1 - General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 - Maintenance Schedule. . . . . . . . . . . . . . . . . .

3 - Inspection program . . . . . . . . . . . . . . . . . . . .

3.1 - General program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

3.2 - Daily inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

3.3 - Periodic inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

3.4 - Reinforced inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

3.5 - Major inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

4 - Repairs and adjustments. . . . . . . . . . . . . . . .

G

OTHER INFORMATION

1 - HAULOTTE® new product warranty

North America . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 - Warranty claims procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

1.2 - Warranty registration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

2 - Subsidiary contact information. . . . . . . . . . .

2.1 - California warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

121

122

123

125

127

131

6

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

A

- Foreword

You have just purchased a HAULOTTE® product and we would like to thank you for your business.

Foreword

The Aerial Work Platform is a mechanical device primarily designed and manufactured with the intent to position people

with the necessary tools and material to overhead elevated temporary workplaces. All other uses or alterations/

modifications to the aerial work platform must be approved by HAULOTTE®.

This equipment is designed and manufactured in compliance with the duties, responsiblities and standards set forth for

manufacturers in the ANSI, CSA and AS standards in effect at the time of manufacture.

This equipment meets or exceeds applicable ANSI and CSA standards when operated in accordance with

manufacturer's recommendations.

This manual shall be considered a permanent component of the machine and shall be kept with the aerial work platform

in the designated Manual Holder, at all times.

Safe operation of this product can only be assured if you follow the operating instructions contained in this manual. To

ensure proper and safe use of this equipment, only trained and authorized personnel must operate and maintain the

aerial work platform.

We would particularly like to draw your attention to 2 essential points :

• Comply with safety instructions.

• Use the equipment within the specified/published performance limits.

With regard to the designation of our equipment, we stress that this is purely for commercial purposes and not to be

confused with the technical specifications. Only the specifications in this manual should be used to study the suitability

of the equipment for the intended use.

This operator's manual is specific to the HAULOTTE® products listed on the cover page of this manual.

Original language and version :

Manuals in English and French are the original instructions. Manuals in other languages are translations

of the original instructions.

The operator's manual does not replace the basic training required for equipment operators. HAULOTTE® has compiled

this manual to assist in safe and efficient operation of the products covered in the manual.

The manual must be available to all operators and must be kept in a legible condition. Additional copies can be ordered

from HAULOTTE Services®.

Stay Safe and keep working with HAULOTTE® !

7 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

A

- Foreword

1 - User responsibility

1.1 - OWNER'S RESPONSIBILITY

The owner (or hirer) has the obligation :

• To inform operators of the instructions contained in the Operator's Manual.

• For applying the local regulations regarding operation of the machine.

• To replace all manuals or decals that are either missing or not legible. Additional copies can

be ordered from HAULOTTE Services®.

• To establish a preventive maintenance program in accordance with the manufacturer's

recommendations, taking into account the environment and severity of use of the machine.

• To perform periodic inspections in accordance with HAULOTTE® recommendations and

local regulations.

All malfunctions and problems identified during the inspection shall be corrected before the

aerial work platform is returned to service.

1.2 - EMPLOYER'S RESPONSIBILITY

The employer has the obligation :

• To authorize the operator to use the machine.

• To inform and familiarize the operator with the local regulations.

Forbid anyone from operating the machine if :

• Under the influence of drugs, alcohol, etc.

• Subject to fits, loss of motor skills, dizziness, etc.

1.3 - TRAINER'S RESPONSIBILITY

The trainer must be qualified to provide training to operators in accordance with applicable

local regulations. The training must be given in an obstacle-free area until the trainee is

considered competent as defined by the training program undertaken.

8 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

A

- Foreword

1.4 - OPERATOR'S RESPONSIBILITY

The operator has the obligation to :

• Read and understand the contents of this manual and familiarize himself with the decals

affixed on the machine.

• To inspect the machine before use according to HAULOTTE®'s recommendations..

• Inform the owner (or hirer) if the manual or any decals are missing or are not legible.

• To inform of any malfunctioning of the machine.

The operator shall ensure that frequent inspections were conducted by the owners and the

operator may only operate the machine for the purpose intended by the manufacturer.

Only authorized and qualified operators may operate HAULOTTE® machines.

All operators must become familiar with and fully understand the emergency controls and be

able to operate the machine in an emergency.

The operator has the obligation to stop using the machine in the event of malfunction or safety

problems on the machine or in the work area and report the problem immediately to his/her

supervisor.

9 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

A

- Foreword

2 - Safety

2.1 - SAFETY INSTRUCTIONS

2.1.1 - Misuse Hazards

• Do not use the machine for any other purpose than to position

people, their tools and material to the overhead/elevated

temporary work places.

• Do not use the machine as a crane, material lift or elevator.

Only use the machine as it was intended.

• Do not attach overhanging loads when raising or lowering the platform.

• Do not tie the boom or platform to an adjacent fixed or mobile structure.

• Do not use/operate the machine when alone. A survey person or immediate Supervisor must

be present on the ground in case of emergency.

• Do not use a faulty or poorly maintained machine. Remove defective/damaged machine

from service.

• Do not climb onto the compartment covers of the machine.

• Do not replace items critical to machine stability with items of different weight or specification.

• Do not replace factory-installed tires with tires of different specifications or ply rating.

• Do not alter or disable machine components that in any way affect safety and stability.

• Do not disable the safety devices.

• Do not deface, modify or obscure any decals or markings on the aerial work platform.

10 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

307P216290 b

x 1

A

- Foreword

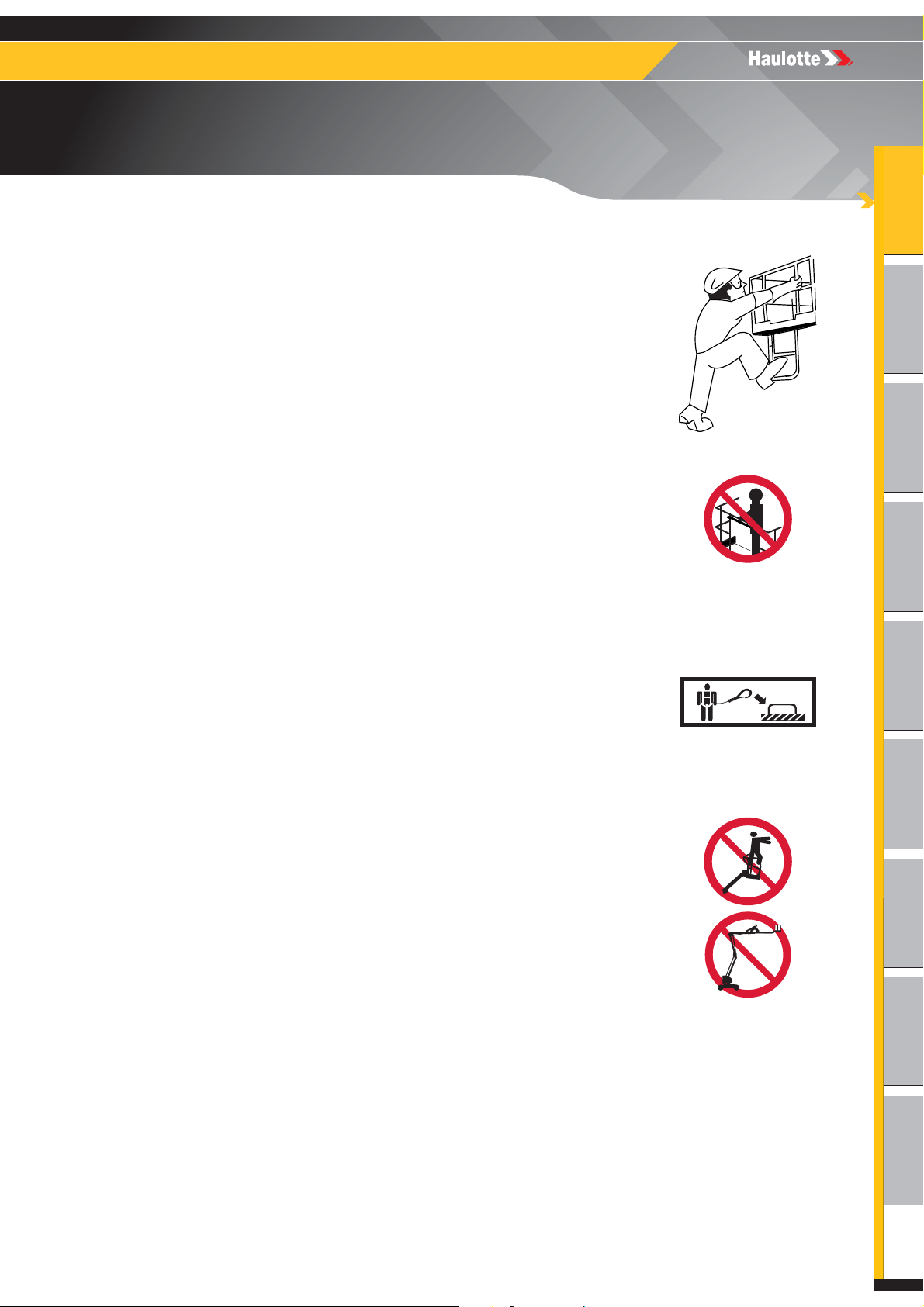

2.1.2 - Falling Hazards

To enter or exit from the platform :

• The machine must be completely stowed.

• Face the machine to access the entry opening to the platform.

• Keep 3 points of contact (both hands and a foot) on the steps

and the guardrail.

Before commencing operation :

• Ensure that guard rails are correctly installed and secured.

• Ensure that gate or sliding bar is in it’s proper closed position.

• Remove oil or grease from the steps, floor, handrail and the

guardrails.

• Clear the platform floor free of debris.

When in the platform :

• Occupants must wear a fall arrest harness with energy

absorber, in accordance with applicable governmental

regulations. Attach the lanyard to the designated fall arrest

anchor provided in the platform.

• The correct use of the harness requires the lanyard to be

connected to an anchorage point designated by the decals.

Refer to this decal located on the platform.

• Hold on securely to the guardrails.

• Always keep your feet firmly on the floor of the platform.

• Do not sit, stand, or climb on the platform guard rails.

• Work only within the platform guardrails area and do not lean

over guardrails to perform work.

• Do not exit the platform until it is in the completely stowed

position.

• Do not use the guardrail as a means of access to climb in or

out of the platform.

11 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

A

- Foreword

2.1.3 - Overturning / Tip-over Hazards

Before positioning and operating the machine :

• Ensure that the surface is capable of supporting the machine weight

including the rated capacity. Check the load bearing capacity of the

supporting ground.

• Do not operate on surfaces that do not support force exerted by the

outriggers during aerial work platform operation.

• Do not exceed the maximum rated capacity that includes the weight

of both material and allowed number of occupants. Do not exceed

the allowable number of occupants.

• Place the loads uniformly distributed on the platform floor.

• Do not increase the working height (using extensions, ladder, etc.).

• Do not place ladders or scaffolds in the platform or against any part

of this machine.

• Do not use the machine in winds exceeding the permissible limit.

• Do not increase the surface area of the platform exposed to wind.

This includes adding panels, mesh, banners. Be aware when

working with materials with a large surface area. This will add to the

wind load on the machine.

• Do not replace components critical to stability with components of

different weight or specification.

• Do not use the machine with material or objects hanging from the

guardrail or the boom.

• Do not pull or push towards any object outside of the platform. Do not

exceed the maximum allowable side force stated in the performance

specifications.

• Do not use boom or platform to push or pull or to lift any part of the

trailer.

• Do not use the machine to support any external structure.

• Do not use the machine to drag materials.

• Do not operate aerial work platform without outriggers fully extended

or when platform is not level.

• Do not raise the outriggers or move the trailer with materials or

personnel on board, or while boom is raised or extended.

12 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

A

- Foreword

WIND : The aerial work platform can operate up to a maximum wind speed as indicated in the

specifications. To identify the local wind speed, use the Beaufort scale below, use a wind

gauge or an anemometer.

N.B.-:-T

COMMUNICATING

CLEAR LAND IS ASSOCIATED WITH EACH DEGREE.

Force

0 Calm Smoke rises vertically. 0 - 0,3 0 - 1 1

1 Very light breeze Smoke indicates the wind direction. 0,3 - 1,5 1 - 5 1 - 3

2 Light breeze

3 Slight breeze

4 Nice breeze

5 Nice breeze

6 Cool wind

7 Near gale

8 Gale

9 Strong gale

10

Storm, Violent Storm,

Hurricane

HE BEAUFORT SCALE OF WIND FORCE IS ACCEPTED INTERNATIONALLY AND IS USED WHEN

WEATHER CONDITIONS. A WIND SPEED RANGE AT 10 M (32 FT 9 IN) ABOVE FLAT,

Beaufort scale

Meteorological

description

Wind felt on the face. Leaves rustle.

Weather vanes turn.

Leaves and small twigs in constant

motion. Flags move slightly.

Raised dust and loose papers. Small

branches are moved.

Small trees in leaf to sway. Crested

wavelets form on inland waterways.

Large branches in motion. Power

lines and chimneys 'sing'. Umbrellas

used with difficulty.

Whole trees in motion. Inconvenience

felt when walking against wind.

Some branches break. Generally we

cannot walk against the wind.

The wind causes slight damage to

buildings. Tiles and chimney stacks

are blown off.

Trees uprooted, widespread damage

to structures, widespread

devastation.

Observed effects m/s km/h mph

1,6 - 3,3 6 - 11 4 - 7

3,4 - 5,4 12 - 19 8 - 12

5,5 - 7,9 20 - 28 13 - 17

8,0 - 10,7 29 - 38 18 - 24

10,8 - 13,8 39 - 49 25 - 30

13,9 - 17,1 50 - 61 31 - 38

17,2 - 20,7 62 - 74 39 - 46

20,8 - 24,4 75 - 88 47 - 54

More

than 24,5

More

than 89

More

than 55

13 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

A

- Foreword

2.1.4 - Electrocution Hazards

The machine is not electrically insulated and does not provide protection from contact or

proximity to electrically charged conductors.

Always position the lift at a safe distance from electrically charged conductors to ensure that

no part of the machine is within an unsafe area.

Respect the local rules and the minimum safety distance from power lines.

Minimum safe approach distances

Electric voltage Minimum safety distance

Mètre Feet

0 - 300 V Avoid contact

300 V - 50 kV 3 10

50 - 200 kV 5 15

200 - 350 kV 6 20

350 - 500 kV 8 25

500 - 750 kV 11 35

750 - 1000 kV 14 45

N.B.-:-U

• Do not operate the machine when close to live power lines,

consider the movement of the machine and the sway of the

electric power lines particularly in windy conditions.

• Do not operate the machine during lightning, thunderstorms,

snow/ice or any weather condition that could compromise

operator safety.

• Do not use the machine as a ground for welding.

• Do not weld on the machine without first disconnecting the

battery terminals.

• Always disconnect ground cable first.

• The machine must not be used while charging the batteries.

• When using the AC power supply, ensure it is protected with a

circuit breaker and residual current device.

Keep away from the machine if it contacts energized power

lines. Personnel on the ground or in the platform must not touch

or operate the machine until energized power lines are shut off.

SE THIS TABLE EXCEPT WHERE LOCAL REGULATIONS INDICATE OTHERWISE.

14 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

A

- Foreword

2.1.5 - Explosion / Fire Hazards

Always wear protective clothing and eye wear when working with

batteries and power sources/systems.

N.B.-:-A

• Do not start the engine if you smell or detect liquid propane gas

(LPG), gasoline, diesel fuel or other explosive substances.

• Do not work on or operate a machine in an explosive or flammable

atmosphere / environment.

• Do not touch hot components.

• Do not bridge the battery terminals with metallic objects.

• Do not service the battery in proximity of spark, open flame, lit

cigarettes.

• Do not fill up the fuel tank, when the engine is running and/or near

a flame.

• Avoid contact with battery acid. Battery acid causes serious burns

and should be kept away from skin or eyes. If contact occurs, flush

with water and consult a physician immediately.

2.1.6 - Crushing / Collision Hazards

CID IS NEUTRALIZED WITH SODIUM BICARBONATE AND WATER.

When in the platform :

• Check the work area for clearance overhead, beside and below

the platform when lifting and lowering the platform.

• During movement, keep all the parts of the body inside the

platform. Hold onto the guardrails on the opposite side to any

surrounding structures. Take care to avoid trapping hands whilst

holding the guardrails.

• Ensure there are no obstacles (structure) in the work area.

• Always cordon off the area around the base of the machine to keep personnel and other

equipment away from the machine while in use.

• Warn personnel not to work, stand, or walk under a raised boom/platform.

• Do not drive in reverse direction (opposite the field of vision).

• Be aware of the boom position and tail swing when rotating the turret (turntable).

• Always ensure that the chassis is never driven any closer than 1 m (3 ft 3 in) to holes,

bumps, slopes, obstructions, debris and ground coverings that may hide holes and other

dangers.

• Keep non-operating personnel at least 5 m (16 ft 5 in) away from the machine when driving

and slewing.

15 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

A

- Foreword

• Be aware of driving direction.

• When changing the driving direction (Forward <> Reverse) the joysticks or switches must return to the neutral

position before reversing the drive direction and for movement to occur.

• When driving, position the platform so as to provide the best possible visibility and to avoid

any blind spots.

• Hold on securely to the guardrails.

• Occupants must wear a fall arrest harness with energy absorber, in accordance with

applicable governmental regulations. Attach the lanyard to the designated fall arrest anchor

provided in the platform.

• Avoid contact with fixed or mobile obstacles (other machines).

• Other machines (crane, aerial work platform, etc.) operating in the work area increase the

risk of crushing or collision. Restrict the operation of machines moving within the aerial work

platform work area.

• Take into consideration the stopping distance, reduced visibility and blind spots of the

machine.

• Limit travel speed to suit the ground surface condition, slope (incline), and people in the

vicinity.

2.1.7 - Uncontrolled movement Hazards

Do not use a damaged or malfunctioning machine.

Be aware of uncontrolled movement and always respect the following :

• Maintain clearance from high voltage lines.

• Maintain clearance from generators, radar, electromagnetic fields.

• Never expose the batteries or electrical components to water (high pressure washer, rain).

• Never tow the machine over extended distances.

• In case of a machine breakdown, it is possible to tow short distance to load it onto a trailer.

• Never leave the hydraulic cylinders fully extended before switching off the machine, or when

stationary for an extended period of time.

• Retract the boom and lower the arms to the stowed position.

• Select a safe parking location, on a firm level surface, clear of obstruction and traffic.

• Ensure all compartments are closed and secured.

• Chock the wheels.

• Do not leave keys in the aerial work platform while unattended or not in use.

16 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

A

- Foreword

3 - Safety inquiries

Inquiries relating to design criteria/specifications of a product, standards compliance, or overall

machine safety should be sent to the HAULOTTE® PRODUCT SAFETY department.

Each inquiry or request should include all relevant information; including contact name, telephone

number, mailing address, email address, plus the machine model and serial number.

The HAULOTTE® Product Safety department will evaluate each request/inquiry and will provide a

written response.

4 - Incident notification

Notify HAULOTTE® immediately when a HAULOTTE® product has been involved in an incident/

accident leading to personal injury or death, or when there is a major property damage.

HAULOTTE Group - EUROPE

Product Safety Department

Address : La Péronnière - BP 9 42152 L'Horme - France

Tel : +33 (0)4 77 29 24 24

HAULOTTE Group - Australia, India and

Asia Product Safety Department

Address : No.26 Changi North Way Singapore 498812 - Singapore

Tel : +65 6546 0123

HAULOTTE Group - North & South

America Product Safety Department

Address : 3409 Chandler Creek Rd. Virginia Beach, VA 23453 - United States

Tel : +1 757 689 2146

Email : ProductSafety@haulotte.com

Email : ProductSafety@haulotte.com

Email : ProductSafety@haulotte.com

17 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

A

- Foreword

5 - Compliance

5.1 - PRODUCT INFORMATION

Without the written permission from Haulotte, modifying a HAULOTTE® product is a Safety

concern. Any modification may violate Haulotte design parameters, government regulations

and industry standards.

If you desire a modification to the product, submit a request in writing to HAULOTTE®.

With the utmost care to ensure enhanced reliability and greater safety of the HAULOTTE®

products, it is pertinent that when a "Service or Safety Bulletin" is issued, action is taken

immediately. Once the bulletin has been addressed, make sure that the completed form is

submitted to HAULOTTE®.

Do not hesitate to contact HAULOTTE Services®, should you have any questions relating to

the issued bulletin(s) or with questions on the policy itself.

5.1.1 - Change of Ownership Notification

It is important and necessary to keep HAULOTTE Services® updated with current ownership

of the machine. This way, HAULOTTE® will be able to provide the necessary support for the

product. If you have sold or transferred this machine(s); it is your responsibility to

notify HAULOTTE Services®. It is not required to include Lessees/Renters of Leased/Rented

machines on this form.

Use the HAULOTTE® Product Status Notification form to report scrapped, stolen, missing or

recovered machine(s).

18 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

A

- Foreword

5.1.2 - Owner information update form

Owner information update form

Complete this form and mail or fax it to :

HAULOTTE® subsidiary Name : Address 1 :

Fax : Address 2 :

e.mail address : Address 3 :

Product information :

Model : Machine serial number :

Owner / Servicing information :

Do not include leased or rented units in this form

Current product owner 1 : Current product owner 2 :

Name : Name :

Company : Company :

Address 1 : Address 1 :

Address 2 : Address 2 :

Country : Country :

Phone : Phone :

Date of ownership : Date of ownership :

Signature : Signature :

Date : Date :

Company stamp is mandatory : Company stamp is mandatory :

Check here if the machine has been permanently removed from service (scrapped). The manufacturer's

nameplate must be removed and returned to HAULOTTE Group when the unit is removed from service.

Reason for removal :

19 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

A

- Foreword

5.2 - PRODUCT SPECIFICATIONS

HAULOTTE® cannot be held liable for any changes to the technical characteristics/

specifications contained in this manual. HAULOTTE® has a continuous improvement policy

in place for its product range. Given this policy, the Company reserves the right to modify

products technical characteristics / specifications without notice.

Certain options/accessories can modify the machine's operating characteristics and its'

associated safety. If your machine was originally delivered with options fitted, replacing a

safety component associated with a particular option does not require any particular

precaution other than those associated with the installation itself (static test).

Otherwise, it is essential to follow the manufacturer's recommendations as stated below :

• Installation by authorised HAULOTTE® personnel only.

• Update the manufacturer's identification plate.

• Have stability tests carried out by a certified agency/competent person.

• Ensure decals are updated.

20 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

Familiarization

1 - General safety

1.1 - INTENDED USE

Do not operate the product in the following situations :

• On soft, unstable or cluttered ground.

• With wind blowing faster than the permissible limit.

• Check the allowable wind speed specified in the performace specifications tabulation.

• Consult the Beaufort scale.

• Close to power lines. Keep a safe distance.

• If the machine is stored at a temperature out of range - 20°C / + 50°C (- 4°F / + 122°F).

• In an explosive atmosphere / environment.

• During storms.

• In the presence of strong electromagnetic fields.

N.B.-:-U

MACHINE

TEMPERATURES, SALINITY, CORROSIVENESS, ATMOSPHERIC PRESSURE), CONTACT HAULOTTE

ERVICES®. REDUCE INTERVALS BETWEEN SERVICING.

S

SE THE MACHINE UNDER "NORMAL" CLIMATIC CONDITIONS. IF YOU NEED TO USE THE

IN CLIMATIC CONDITIONS LIKELY TO CAUSE DETERIORATION (EXTREME : HUMIDITY,

N.B.-:-W

FULLY

CONTROL

HILE THE MACHINE IS NOT IN USE, CARE MUST BE TAKEN TO BRING THE MACHINE TO THE

STOWED POSITION. ENSURE THAT THE MACHINE IS LOCKED IN A SECURE LOCATION, AND THE

KEY IS REMOVED TO PREVENT UNAUTHORISED USE OF THE MACHINE.

21 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

DANGER

CRUSH HAZARD

Do not stand or walk behind or in front

of the machine while in use.

Stay clear from the path of boom

rotation and platform lowering.

Failure to comply will result in death

or in serious injury

1

3

2

4

B

- Familiarization

1.2 - DECAL CONTENT

Decals are provided to alert the user of hazards inherent with the Aerial Work Platforms.

Decals provide the following information :

• The level of severity.

• The specific hazard.

• A method to avoid, suppress or reduce the hazard.

• Descriptive text (where required).

Familiarize yourself with the decals and the hazard severity levels.

Decals must be kept in good legible condition.

Familiarize yourself with the decals and their respective color codes.

Additional decals can be ordered from HAULOTTE Services®.

AS standard

1

DANGER

ANSI and CSA standards

Marking Description

1 Hazard symbol

2 Level of severity

3 Avoidance symbol pictorial

4 Avoidance text

2

3

22 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

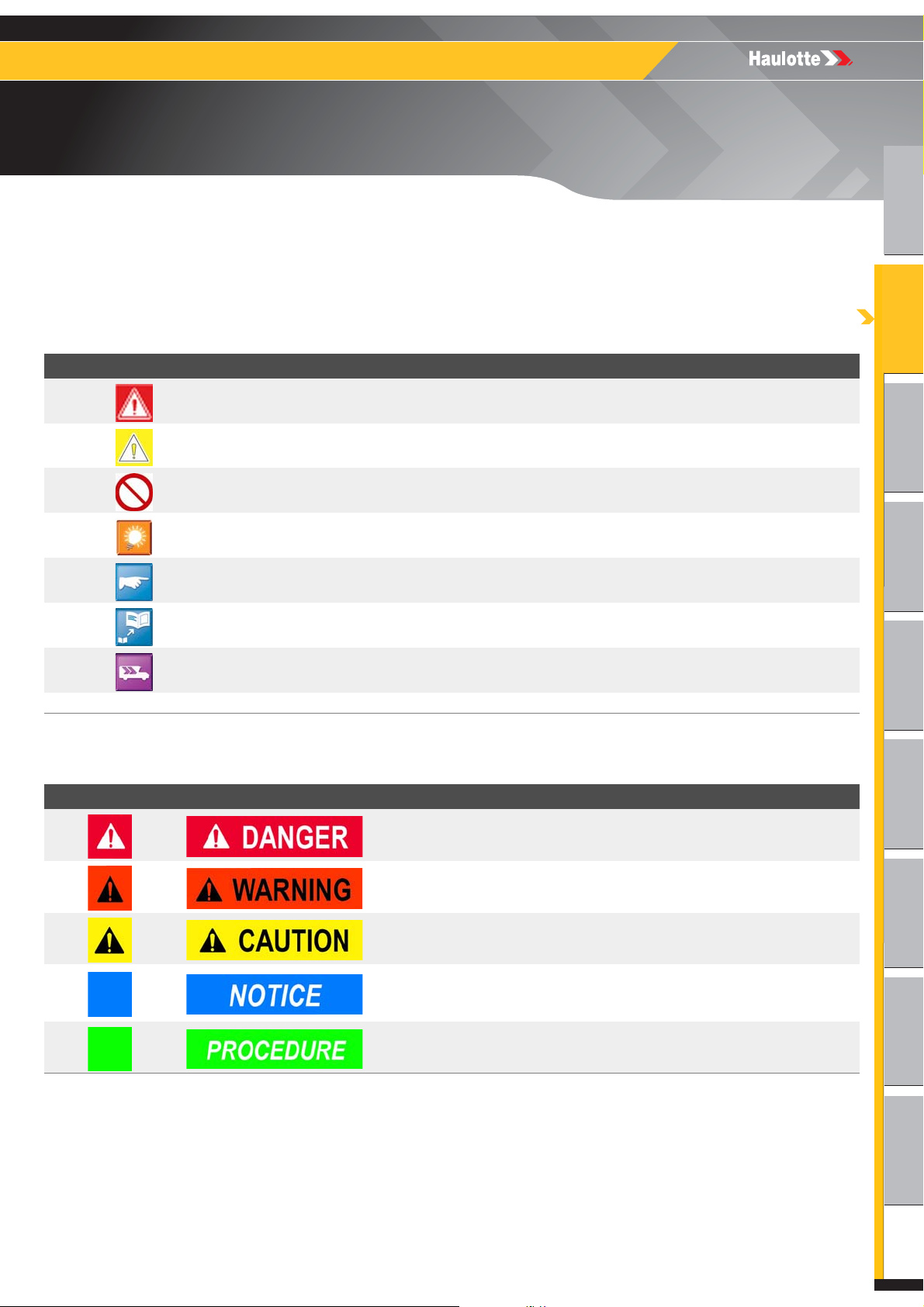

1.3 - SYMBOLS AND COLORS

Symbols and colors are used to alert the operator of safety precautions and/or to highlight

important safety information.

The following safety symbols are used throughout this manual to indicate specific hazards and

the hazard severity level when operating or maintaining the Aerial Work Platform.

Symbol Description

Danger : Risk of injury or death

Caution : Risk of material damage

Prohibited action

Reminder to use good practice or follow pre-operation checks

Cross-reference to another part of the manual

Cross-reference to another manual

Cross-reference to repair (contact HAULOTTE Services®)

N.B. : Additional technical information

1.4 - LEVEL OF SEVERITY

Color Title Description

Danger : Indicates a hazardous situation which if not avoided,

WILL result in death or serious injury.

Warning : Indicates a hazardous situation which if not avoided,

COULD result in death or serious injury.

Caution : Failure to comply could result in minor or moderate

injury.

Notice : Indicates recommended practices if not followed, may

result in a malfunction or damage the machine or its

components.

Procedure : Indicates a maintenance operation.

23 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

x 1

B

- Familiarization

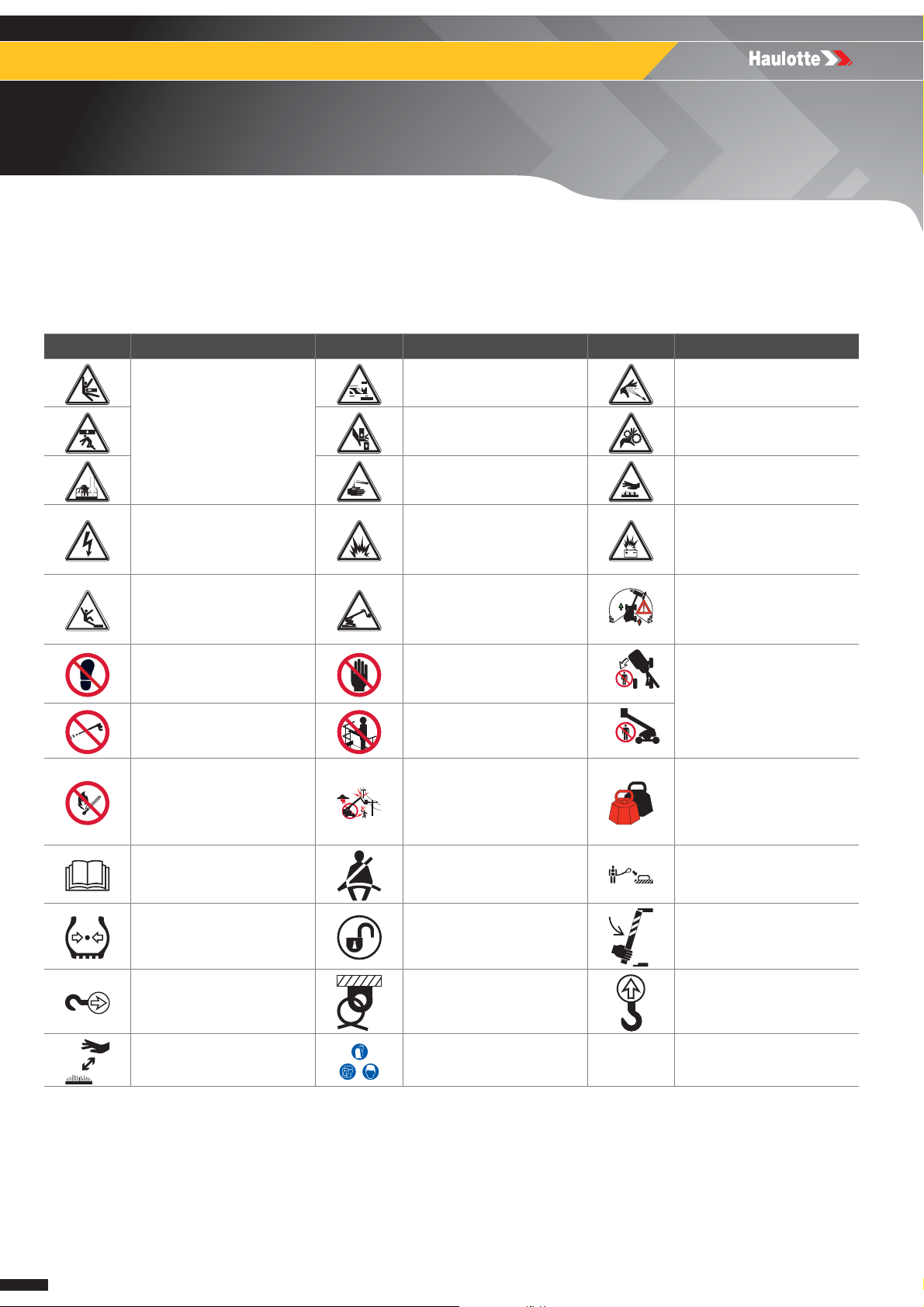

1.5 - SYMBOLS LEGEND AND DEFINITIONS

Symbols are used throughout this manual to depict hazards, avoidance measures and indicate

when information is required.

Refer to the following table to familiarize yourself with these symbols.

Symbol Description Symbol Description Symbol Description

Foot crushing hazard

Body crushing hazard

Electrical contact or lightning

strike

Risk of operator(s) falling

Do not put foot in this area

Never expose batteries and

electrical component to high

pressure washer

Flames prohibited

Refer to operator manual Safety belt

Hand crushing hazard Entanglement hazard

Health/safety hazards

related to chemicals

Burns and scalds from

contact with flames,

explosion or radiation from

heat sources

Tip over due to excessive

loading / wind load and

excessive ground slope

Do not put your hand in this

area

Ensure entry drop rail is

down

Maintain safe clearance from

high voltage electrically

charged conductors as

described in manual - Do not

use in thunderstorms

High pressure fluid ejection

hazard

Health-damaging effects

from hot work environment

Injury from Electric arcs Energy supply disconnecting

devices - Batteries fire,

emissions, etc

Relate and coordinate

directional arrows on the

chassis with those on the

control box

Keep away from product

working area

Overload

Use appropriate lanyard

attached to dedicated

anchor point.

Use safety prop before

Wheel pressure Enable switch

Tow point Tie down point Lift point

Keep away from hot surfaces Wear protective equipment

24 4000670470 E 04.19 USA / GB

attempting any maintenance

work

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

2 - Models description

Regulations Models

ANSI and CSA standards

AS standard

3522A

4527A

5533A

HTA13P

HTA16P

HTA19P

25 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

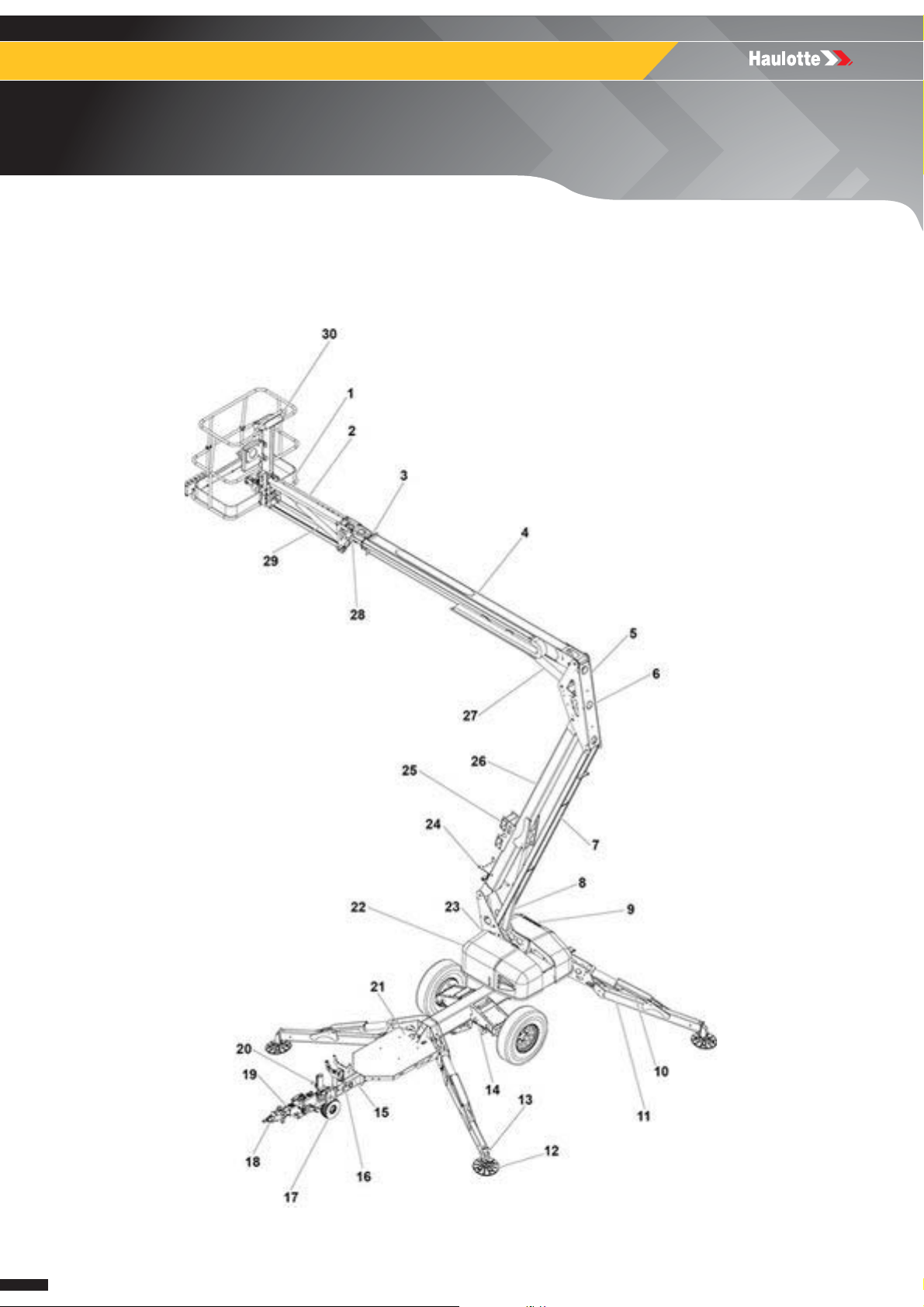

3 - Primary machine components

3.1 - LAYOUT

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

26 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

Marking Description Marking Description

C1 Platform C16 Latch release

C2 Jib boom C17 Dolly wheel

C3 Extension boom C18 Trailer hitch

C4 Secondary boom C19 Coupler

C5 Knuckle C20 Jack

C6 Master cylinder C21 Generator interface plate

C7 Lower link C22 Power unit compartment

C8 Primary lift cylinder C23 Turntable

C9 Ground control box C24 Secondary boom rest

C10 Outrigger cylinder C25 Forklift pocket

C11 Outrigger leg C26 Primary boom

C12 Outrigger pad C27 Secondary lift cylinder

C13 Outrigger foot C28 Slave cylinder

C14 Axle C29 Jib lift cylinder

C15 Primary boom rest C30 Platform control box

27 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

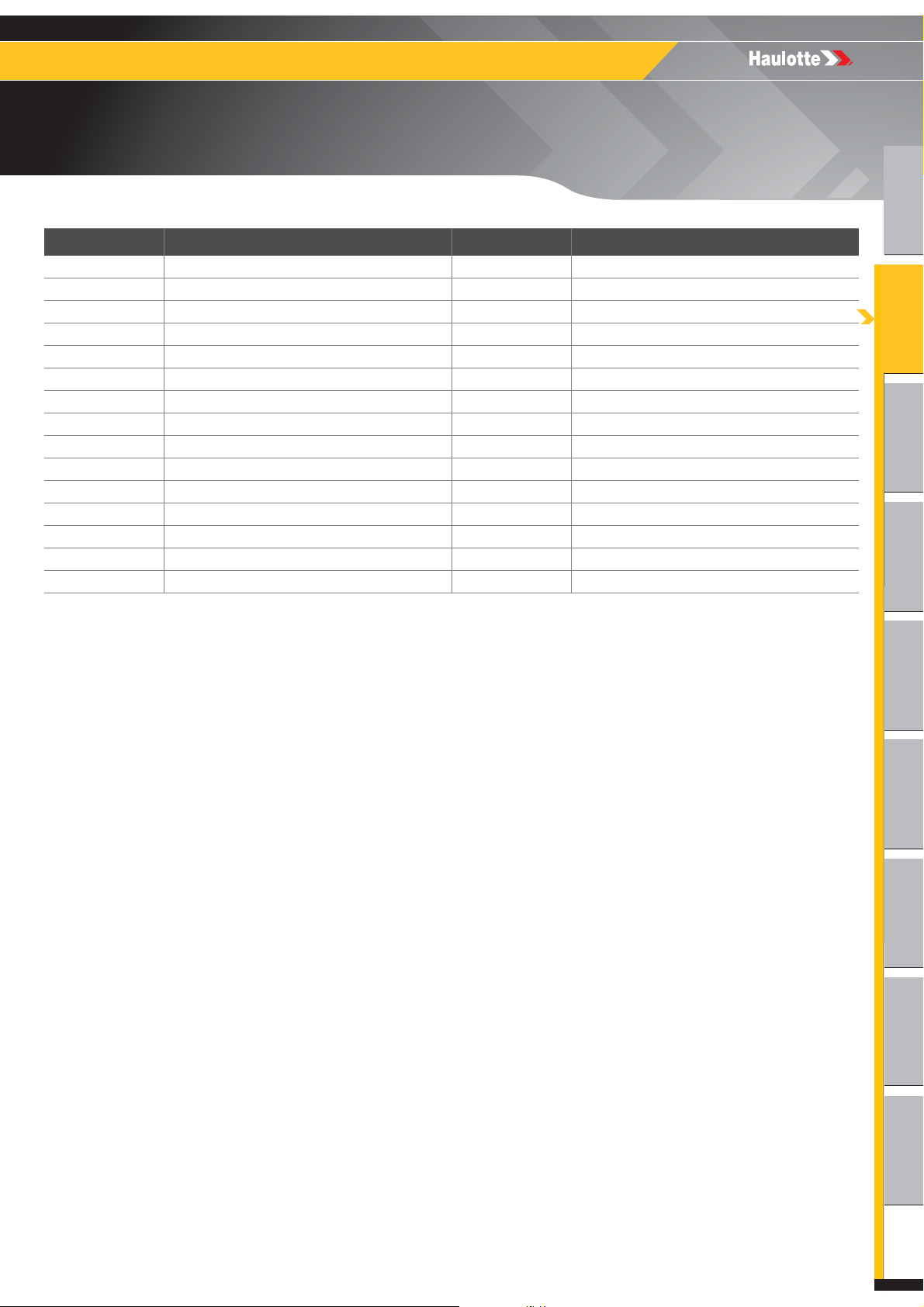

3.2 - GROUND CONTROL BOX

3.2.1 - Layout

General view

28 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

Controls and indicators

Marking Description Function

• Turn the KEY SWITCH ( 1 ) to the GROUND ( 1a ) to select operation from the

ground control box.

• Turn the KEY SWITCH ( 1 ) to the PLATFORM ( 1b ) to select operation from

1 Key Switch

2 Battery Condition Indicator

3 - 4

5 Display panel

6 Emergency stop button

7 - 8

9 - 14

15 Speed/Enable buttons

Engine Start and Choke /

Glow Plug

Boom Extend / Retract

Buttons

Boom Raise / Down Buttons

and Jib Raise / Down

Buttons

1

the platform control box.

• Turn the KEY SWITCH ( 1 ) to the off position . Power supply is now

switched off.

• Remove the key to protect against unauthorized operation.

Indicator LEDs light up to indicate the level of charge in the batteries :

• A lighted green LED indicates an adequate charge level.

• A lighted yellow LED indicates the need for charging soon.

• A lighted red LED warns that the battery charge level is low; all functional

operations become non-functional until the batteries are recharged.

• Start a cold engine : Press and hold the CHOKE ( 4 ) then press the ENGINE

START ( 3 ). To start/restart a warm engine, press the ENGINE START ( 3 ).

• Press and hold the GLOW PLUG ( 4 ) for 30 - 60 seconds then press the

ENGINE START ( 3 ).

The DISPLAY PANEL is a lighted text window that displays the current operating

status or an existing error condition when the KEY SWITCH ( 1 ) is positioned at

either(1a) or(1b).

• When pushed in, the EMERGENCY STOP ( 6 ) button disconnects electrical

power to the ground (lower) and platform (upper) control boxes

• The EMERGENCY STOP button should only be pressed (pushed) in to

immediately stop all aerial work platform motion.

• To resume control, “pull out” the EMERGENCY STOP ( 6 ).

• Pressing (pushing) in and holding a desired SPEED/ENABLE ( 15 ) button,

and the BOOM EXTEND ( 7 ) button at the same time extends the secondary

boom.

• Pressing (pushing) in and holding a desired SPEED/ENABLE ( 15 ) button,

and the BOOM RETRACT ( 8 ) button at the same time retracts the secondary

boom.

• Telescopic boom motion continues until the buttons are released, or until the

boom reaches a hard stop, or a safe travel limit.

• Pressing (pushing) and holding a desired SPEED/ENABLE ( 15 ) button, and

the PRIMARY BOOM RAISE ( 9 ) button at the same time will raise the primary

boom. Pressing (pushing) and holding a desired SPEED/ENABLE ( 15 ) button,

and the PRIMARY BOOM DOWN ( 10 ) button at the same time will retract the

primary boom.

• Pressing (pushing) and holding a desired SPEED/ENABLE ( 15 ) button, and

the SECONDARY BOOM RAISE ( 11 ) button at the same time will raise the

secondary boom. Pressing (pushing) and holding a desired SPEED/

ENABLE ( 15 ) button, and the SECONDARY BOOM DOWN ( 12 ) button at the

same time will retract the secondary boom.

• Pressing (pushing) and holding a desired SPEED/ENABLE ( 15 ) button, and

the JIB BOOM RAISE ( 13 ) button at the same time will raise the JIB BOOM,

pressing (pushing) and holding a desired SPEED/ENABLE ( 15 ) button, and

the JIB BOOM DOWN ( 14 ) button at the same time will retract the JIB BOOM.

• The selected Boom motion continues until the buttons are released or until the

selected boom reaches a hard stop or a safe travel limit.

• The SPEED/ENABLE ( 15 ) buttons are located along the lower right side of

the control panel, one of the speed/enable buttons must be pressed (pushed) in

and held while selecting any boom function.

• There are four speeds that range from fast (RABBIT), to slow (TURTLE),

available to help control the positioning of the Boom and the Jib.

29 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

Marking Description Function

• Press (push) and hold any SPEED/ENABLE ( 15 ) button, and the desired

16 - 17 Platform Leveling Buttons

18 - 19 Turret Rotation Buttons

20 Booms stowed LED

21 - 26 Outrigger controls

27 Power • The LED ( 27 ) lights up when power is On.

1. For machines with engines only

PLATFORM TILT UP ( 16 ) or PLATFORM TILT DOWN ( 17 ) button at the

same time to level the work platform.

• This levels the platform only, NOT the aerial work platform.

• Pressing (pushing) and holding a desired SPEED ( 15 ) button, and the

TURRET ROTATION ( 18 ) button at the same time enables the turret to rotate

in the CLOCKWISE direction.

• Pressing (pushing) and holding a desired SPEED ( 15 ) button, and the

TURRET ROTATION ( 19 ) button at the same time enables the turret to rotate

in the COUNTER CLOCKWISE direction.

• The turret will rotate through 700° of Non-Continuous rotation until the buttons

are released or the stop is reached.

• When this LED is "FLASHING" it indicates that the booms are not in the

"stowed" position, and the outriggers cannot be operated (non-functional).

• When this LED is "ON SOLID" it indicates that the booms are in the "stowed"

position, and the outriggers can be operated (functional).

For simultaneous automatic outrigger extension / retraction of all four ( 4 )

outriggers :

• Select the EXTEND ( 21 ) button or RETRACT ( 22 ) button and the AUTO

LEVEL ( 23 ) button at the same time.

To individually extend or retract the outriggers :

• Select the EXTEND ( 21 ) button or RETRACT ( 22 ) button, and one of the

four OUTRIGGER ( 24 ) buttons at the same time.

• The outrigger indicator LEDs ( 20 ) and ( 23 ) light up when the outriggers are

properly deployed and the aerial work platform weight is on the outrigger foot

pads.

• Each of the outer outrigger LEDs ( 25 ) indicates load is on the outrigger foot

pad.

• Each of the inner outrigger LEDs ( 26 ), when flashing, indicate that side is

low, and needs to be further raised for leveling.

30 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

Notes

31 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

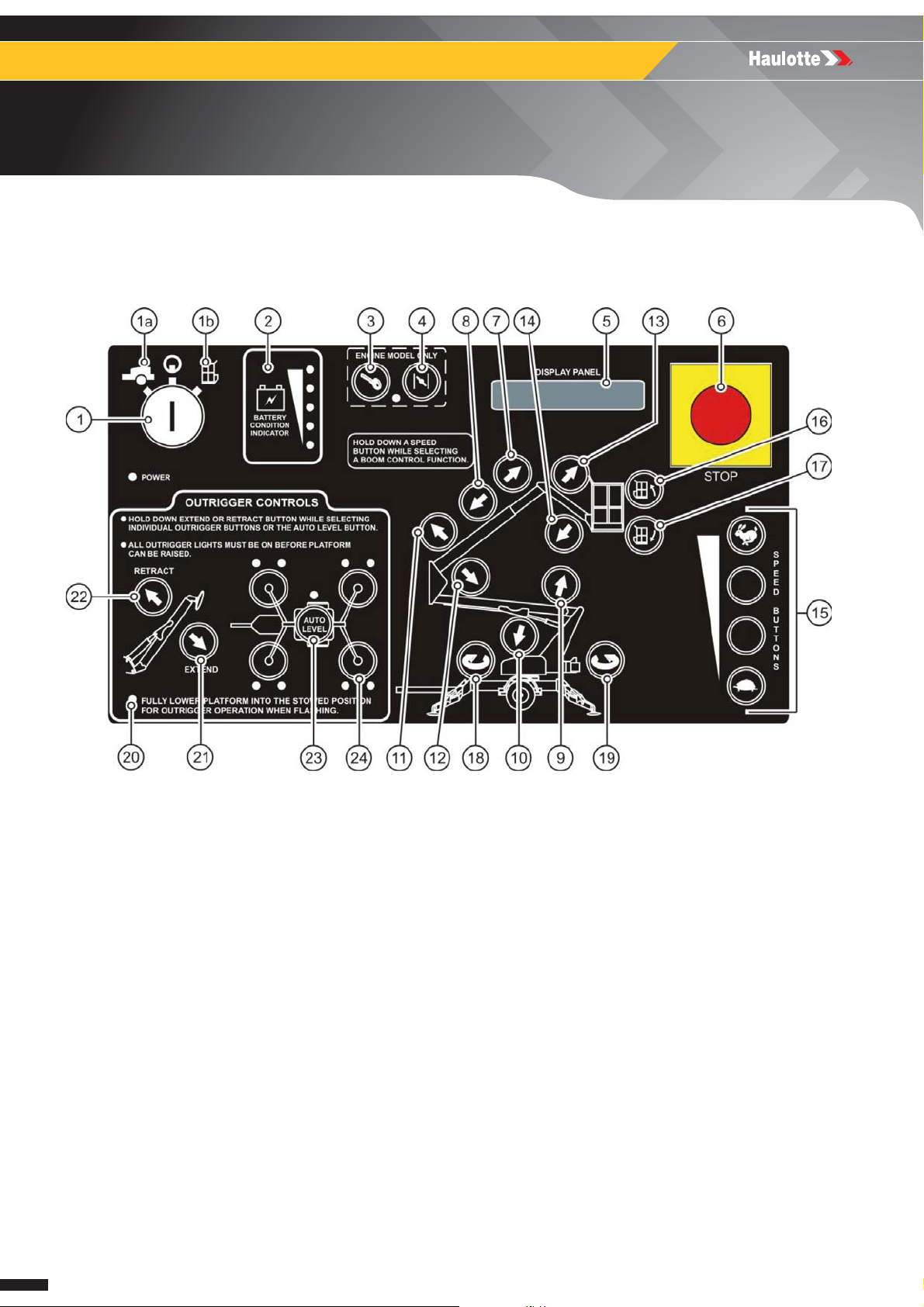

3.3 - PLATFORM CONTROL BOX

3.3.1 - Layout

General view

32 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

Controls and indicators

Marking Description Function

• Start a cold engine by pressing (pushing) in and holding the CHOKE ( 2 ) button

1-2

3 Horn button

4

5 Emergency stop button

6 Speed/Enable buttons

7-8 Boom Rotation Buttons

9-14

Engine Start and Choke /

Glow Plug

Battery Condition

Indicator

Boom Raise / Down

Buttons and Jib Raise /

Down Buttons

1

then press (push) the ENGINE START ( 1 ) button. To start / restart a warm engine,

press (push) the ENGINE START ( 1 ) button only.

• Glow plug operation : Press (push) the GLOW PLUG ( 2 ) button and hold for 30 60 seconds then press (push) the ENGINE START ( 1 ) button

Pressing (pushing) the HORN button ( 3 ) will sound the HORN.

Use the horn button to warn personnel in the area of a falling object hazard,

impending boom motions or the need for assistance.

Indicator LEDs light up to indicate the level of charge in the batteries :

• A lighted green LED indicates an adequate charge level.

• A lighted yellow LED indicates the need for charging soon.

• A lighted red LED warns that the battery charge level is low; all functional

operations become non-functional until the batteries are recharged.

• When pushed in, the EMERGENCY STOP ( 5 ) button disconnects electrical

power to the ground (lower) and platform (upper) control boxes

• The EMERGENCY STOP button ( 5 ) should only be pressed (pushed) to

immediately stop all boom functions.

• To resume control, “pull out” the EMERGENCY STOP ( 5 ).

• The SPEED/ENABLE ( 6 ) buttons are located along the lower right side of the

control panel, one of the speed/enable buttons must be pressed (pushed) in and

held while selecting any boom function.

• There are four speeds that range from fast (RABBIT), to slow (TURTLE), available

to help control the positioning of the Boom and the Jib.

• Pressing (pushing) and holding a desired SPEED/ENABLE ( 6 ) button, and the

BOOM ROTATION ( 7 ) button at the same time enables the boom to rotate in the

CLOCKWISE direction.

• Pressing (pushing) and holding a desired SPEED/ENABLE ( 6 ) button, and the

BOOM ROTATION ( 8 ) button at the same time enables the boom to rotate in the

COUNTER CLOCKWISE direction.

• The boom will rotate through 700° of Non-Continuous rotation until the buttons

are released or the stop is reached.

• Pressing (pushing) and holding a desired SPEED/ENABLE ( 6 ) button, and the

PRIMARY BOOM RAISE ( 9 ) button at the same time will raise the primary boom.

Pressing (pushing) and holding a desired SPEED/ENABLE ( 6 ) button, and the

PRIMARY BOOM DOWN ( 10 ) button at the same time will retract the primary

boom.

• Pressing (pushing) and holding a desired SPEED/ENABLE ( 6 ) button, and the

SECONDARY BOOM RAISE ( 11 ) button at the same time will raise the secondary

boom. Pressing (pushing) and holding a desired SPEED/ENABLE ( 6 ) button, and

the SECONDARY BOOM DOWN ( 12 ) button at the same time will retract the

secondary boom.

• Pressing (pushing) and holding a desired SPEED/ENABLE ( 6 ) button, and the

JIB BOOM RAISE ( 13 ) button at the same time will raise the JIB BOOM, pressing

(pushing) and holding a desired SPEED/ENABLE ( 6 ) button, and the JIB BOOM

DOWN ( 14 ) button at the same time will retract the JIB BOOM.

• The selected Boom motion continues until the buttons are released or until the

selected boom reaches a hard stop or a safe travel limit.

33 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

Marking Description Function

• Pressing (pushing) in and holding a desired SPEED/ENABLE ( 6 ) button, and the

BOOM EXTEND ( 15 ) button at the same time extends the secondary boom.

15-16

17-18

1. For machines with engines only

Boom Extend / Retract

Buttons

Platform Leveling

Buttons

Outlet

• Pressing (pushing) in and holding a desired SPEED/ENABLE button, and the

BOOM RETRACT ( 16 ) button at the same time retracts the secondary boom.

• Telescopic boom motion continues until the buttons are released, or until the

boom reaches a hard stop, or a safe travel limit.

• Press (push) and hold any SPEED/ENABLE ( 6 ) button, and the desired

PLATFORM TILT UP ( 17 ) or PLATFORM TILT DOWN ( 18 ) button at the same

time to level the work platform.

• This levels the platform only, NOT the aerial work platform.

An outlet has been provided as a power source for running electrical power tools,

while in the work platform. The power plug is located on the trailer frame, in front of

the accessory equipment stowage plate. A connecting power cord must be plugged

into a suitable power source. The outlet is rated for a 15 A load. Do not overload

the accessory power circuit.

34 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

Notes

35 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

4 - Performance Specifications

4.1 - TECHNICAL CHARACTERISTICS

Use the table to select the right Haulotte machine for the job.

ANSI, CSA and AS standards

Machine 3522A - HTA13P

Characteristics - Dimensions SI Imp.

Maximum working height 12,9 m 41 ft 9 in

Maximum platform height 10,9 m 35 ft 9 in

Up and over height 5,8 m 19 ft 0 in

Maximum horizontal outreach :

• From centerline of rotation

• From outrigger footpad edge

Rated platform capacity :

• Without platform rotator option

• With platform rotator option

Maximum number of occupants 2

Maximum wind speed allowed 45 km/h 28 mph

Total weight :

• Without option

• Drive and set option adds 113 kg (250 lb), Engine option adds 86 kg (190

lb), all other options add 68 kg (150 lb) to weight

Turntable rotation 700° non continuous

Leveling capability 12.5°

Manual force 400 N - 90 lbf

Platform dimensions :

• Height

• Length

• Width

Platform rotation / Type (Optional) 120° / Manual

Machines stowed dimensions :

• Height

• Length

• Width

Jib dimensions :

• Length

• Vertical Motion

Outrigger footprint (To center of pad) :

• Length

• Width

• Footpad diameter

Parking brake Mechanical

Towing brake

Rated towing speed 105 km/h 65 mph

Tire size ST 205/75 R14C

Control system 24V DC

Battery 4 x 6V 245 amp-hr

Charger

Hydraulic pressure 207 bar (20684 kPa) 3000 psi

6,9 m

5,3 m

227 kg

200 kg

1542 kg 3400 lb

1,1 m

0,8 m

1,2 m

2 m

5 m

1,7 m

1,3 m

150° (+70° / -80°)

3,4 m

3 m

0,25 m

Hydraulic Surge

Mechanical

Electrical

110 Volt 60 Hz

220 Volt 50 Hz

150° (+70° / -80°)

22 ft 6 in

17 ft 5 in

500 lb

440 lb

3 ft 7 in

2 ft 6 in

4 ft 0 in

6 ft 5 in

16 ft 3 in

5 ft 5 in

4 ft 3 in

11 ft 1 in

9 ft 11 in

10 in

36 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

Machine 3522A - HTA13P

Reservoir capacity 11,7 l 3.1 Gallons

Hydraulic system capacity 19,3 l 5.1 Gallons

Hydraulic oil (Standard) HVI AW32

Localized Pressure per Outrigger 1,8 kg/cm2 (176,5 kPa) 25 psi

Operating Temperature Range From -20 °C(-4 °F) to 50 °C(122 °F)

Engine ( IC generator option)

Function speeds :

• Boom - Primary Up

• Boom - Primary Down

• Boom - Secondary Up

• Boom - Secondary Down

• Boom - Jib Up

• Boom - Jib Down

• Extension boom - Boom extend

• Extension boom - Boom retract

• Turntable 700° Non Continuous Rotation

• Platform Leveling Up

• Platform Compensation Down

• Outriggers (Auto level) - Outrigger extend

• Outriggers (Auto level) - Outrigger retract

• Engine

• Model

• Horsepower rating

• Torque (Ft-Lbs)

• Fuel tank capacity

• Oil capacity

154-158 sec

Honda

GX270

8.4@3600 RPM

14.1@2500 RPM

6.4 US qt

1.16 US qt

14-18 sec

14-18 sec

12-16 sec

18-22 sec

16-10 sec

10-14 sec

10-14 sec

14-18 sec

8-12 sec

5-9 sec

12-16 sec

22-26 sec

37 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

ANSI, CSA and AS standards

Machine 4527A - HTA16P

Characteristics - Dimensions SI Imp.

Maximum working height 15,7 m 51 ft 0 in

Maximum platform height 13,7 m 45 ft 0 in

Up and over height 6,3 m 20 ft 9 in

Maximum horizontal outreach :

• From centerline of rotation

• From outrigger footpad edge

Rated platform capacity :

• Without platform rotator option

• With platform rotator option

Maximum number of occupants 2

Maximum wind speed allowed 45 km/h 28 mph

Total weight :

• Without option

• Drive and set option adds 113 kg (250 lb), Engine option adds 86 kg (190

lb), all other options add 68 kg (150 lb) to weight

Turntable rotation 700° non continuous

Leveling capability 12.5°

Manual force 400 N - 90 lbf

Platform dimensions :

• Height

• Length

• Width

Platform rotation / Type (Optional) 120° / Manual

Machines stowed dimensions :

• Height

• Length

• Width

Jib dimensions :

• Length

• Vertical Motion

Outrigger footprint (To center of pad) :

• Length

• Width

• Footpad diameter

Parking brake Mechanical

Towing brake

Rated towing speed 105 km/h 65 mph

Tire size ST 225/75 R15D

Control system 24V DC

Battery 4 x 6V 245 amp-hr

Charger

Hydraulic pressure 207 bar (20684 kPa) 3000 psi

Reservoir capacity 16,3 l 4.3 Gallons

Hydraulic system capacity 23,9 l 6.3 Gallons

Hydraulic oil (Standard) HVI AW32

Localized Pressure per Outrigger 1,8 kg/cm2 (176,5 kPa) 25 psi

Operating Temperature Range From -20 °C(-4 °F) to 50 °C(122 °F)

8,2 m

6,4 m

227 kg

200 kg

1905 kg 4200 lb

1,1 m

0,8 m

1,2 m

2 m

5,9 m

1,7 m

1,3 m

150° (+70° / -80°)

3,8 m

3,5 m

0,3 m

Hydraulic Surge

Mechanical

Electrical

110 Volt 60 Hz

220 Volt 50 Hz

150° (+70° / -80°)

27 ft 0 in

21 ft 0 in

500 lb

440 lb

3 ft 7 in

2 ft 6 in

4 ft 0 in

6 ft 5 in

19 ft 6 in

5 ft 5 in

4 ft 3 in

12 ft 4 in

11 ft 4 in

12.5 in

38 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

Machine 4527A - HTA16P

Engine ( IC generator option)

Function speeds :

• Boom - Primary Up

• Boom - Primary Down

• Boom - Secondary Up

• Boom - Secondary Down

• Boom - Jib Up

• Boom - Jib Down

• Extension boom - Boom extend

• Extension boom - Boom retract

• Turntable 700° Non Continuous Rotation

• Platform Leveling Up

• Platform Compensation Down

• Outriggers (Auto level) - Outrigger extend

• Outriggers (Auto level) - Outrigger retract

• Engine

• Model

• Horsepower rating

• Torque (Ft-Lbs)

• Fuel tank capacity

• Oil capacity

Honda

GX270

8.4@3600 RPM

14.1@2500 RPM

6.4 US qt

1.16 US qt

24-28 sec

22-26 sec

20-24 sec

34-38 sec

8-12 sec

24-28 sec

24-28 sec

28-32 sec

205-209 sec

8-12 sec

6-10 sec

16-20 sec

30-34 sec

39 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

ANSI, CSA and AS standards

Machine 5533A - HTA19P

Characteristics - Dimensions SI Imp.

Maximum working height 8,8 m 61 ft 3 in

Maximum platform height 16,8 m 55 ft 3 in

Up and over height 7 m 23 ft 1 in

Maximum horizontal outreach :

• From centerline of rotation

• From outrigger footpad edge

Rated platform capacity :

• Without platform rotator option

• With platform rotator option

Maximum number of occupants 2

Maximum wind speed allowed 45 km/h 28 mph

Total weight :

• Without option

• Drive and set option adds 113 kg (250 lb), Engine option adds 86 kg (190

lb), all other options add 68 kg (150 lb) to weight

Turntable rotation 700° non continuous

Leveling capability 12.5°

Manual force 400 N - 90 lbf

Platform dimensions :

• Height

• Length

• Width

Platform rotation / Type (Optional) 120° / Manual

Machines stowed dimensions :

• Height

• Length

• Width

Jib dimensions :

• Length

• Vertical Motion

Outrigger footprint (To center of pad) :

• Length

• Width

• Footpad diameter

Parking brake Mechanical

Towing brake

Rated towing speed 105 km/h 65 mph

Tire size ST 225/75 R15D

Control system 24V DC

Battery 4 x 6V 245 amp-hr

Charger

Hydraulic pressure 207 bar (20684 kPa) 3000 psi

Reservoir capacity 21,2 l 5.6 Gallons

Hydraulic system capacity 32,2 l 8.5 Gallons

Hydraulic oil (Standard) HVI AW32

Localized Pressure per Outrigger 1,8 kg/cm2 (176,5 kPa) 25 psi

Operating Temperature Range From -20 °C(-4 °F) to 50 °C(122 °F)

10,2 m

8,2 m

227 kg

200 kg

2177 kg 4800 lb

1,1 m

0,8 m

1,2 m

2 m

7 m

1,7 m

1,3 m

150° (+70° / -80°)

3,93 m

3,88 m

0,3 m

Hydraulic Surge

Mechanical

Electrical

110 Volt 60 Hz

220 Volt 50 Hz

33 ft 5 in

27 ft 4 in

500 lb

440 lb

3 ft 7 in

2 ft 6 in

4 ft 0 in

6 ft 6 in

22 ft 11 in

5 ft 5 in

4 ft 3 in

150° (+70° / -80°)

12 ft 11 in

12 ft 9 in

12.5 in

40 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

Machine 5533A - HTA19P

Engine ( IC generator option)

Function speeds :

• Boom - Primary Up

• Boom - Primary Down

• Boom - Secondary Up

• Boom - Secondary Down

• Boom - Jib Up

• Boom - Jib Down

• Extension boom - Boom extend

• Extension boom - Boom retract

• Turntable 700° Non Continuous Rotation

• Platform Leveling Up

• Platform Compensation Down

• Outriggers (Auto level) - Outrigger extend

• Outriggers (Auto level) - Outrigger retract

• Engine

• Model

• Horsepower rating

• Torque (Ft-Lbs)

• Fuel tank capacity

• Oil capacity

Honda

GX270

8.4@3600 RPM

14.1@2500 RPM

6.4 US qt

1.16 US qt

18-22 sec

18-22 sec

14-18 sec

24-28 sec

6-10 sec

20-24 sec

24-28 sec

26-30 sec

200-204 sec

10-14 sec

7-11 sec

25-29 sec

42-46 sec

41 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

4.2 - WORKING AREA / RANGE OF MOTION

The following information is based on ideal working conditions. Machine performance may

vary based on work environment and on machine options. Only one boom function is permitted

at a time, this function is only operable as long as the boom is within the safe operating zone.

Once a boom motion exceeds its safe operating limit, that function ceases, another boom

function within the safe operating zone must be selected.

3522A - HTA13P

42 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

4527A - HTA16P

43 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

5533A - HTA19P

44 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

5 - Decals and markings locations

• Decals contain information that is required for the safe and proper use of the aerial work platform.

• Decals should be considered necessary components of the machine and should be checked before each

use to verify that they are correctly attached and legible.

• Promptly replace all decals that are no longer legible.

45 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

Decal placement - Decal kit - ANSI/CSA/AS - 3522A - HTA13 -

Used on machines with serial numbers prior to XXX only

46 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

Decal placement - Decal kit - ANSI/CSA/AS - 3522A - HTA13 -

Used on machines with serial numbers prior to XXX only

Marking Color Description Quantity 3522A - HTA13

1 Orange Decal - Warning - Unhitch To Operate 2 B06-00-0550

2 Yellow Decal - Caution - Latch / Jack / Brake 1 B06-00-0551

3 Orange Decal - Warning - Hand Pinch Point 16

4 Blue Decal - Emergency Lower Valve 6

5 Red Decal - Danger - Tip Over Hazard 6 B06-00-0521

6 Orange Decal - Warning - Outrigger Crush Foot 8

7 Other Decal - HAULOTTE Biljax - 5 inBlack / Red on clear 2 B06-00-0161B

8 Orange Decal - Warning - Fork Lift Use 2 B06-00-0477

9 Other Decal 3522A - HTA13 - Black clear vinyl with black letters 2 B06-00-0538

10 Other Decal - Transport latch 1 B06-00-0481

11 Blue

12 Red Decal - Danger - Electrocution 2

13 Other Decal - Lubricate Semi - Annually 1 B06-00-0037

14 Red Decal - Danger - Main Instruction / Hazard - Platform 1 B06-00-0471

15 Orange Decal - Warning - Read / Understand Manual 1

16 Blue Decal - Notice - Operator Manual Missing 1 B06-00-0473

17 Orange Decal - Warning - Platform operation 1 B06-00-0534

18 Blue Decal - Notice - AC Power 2

19 Other Decal - Air - 120 PSI 2 B06-00-0530

20 Other Decal - Water - 3000 PSI 2 B06-00-0531

21 Blue Decal - Notice - Lanyard attachment 1 B06-00-0552

22 Blue Decal - Notice - Platform maximum load 1

23 Other Decal - Flag, Made In USA 1 0202-0523

24 Blue Decal - Notice - Handle applications 1 B06-00-0503

25 Blue Decal - Notice - Emergency hand pump 1 B06-00-0504

26 Blue Decal - Notice - Low Foam Hyd Oil 1

27 Blue Decal - Notice - Contains hazardous material 1 B06-00-0494

28 Other Decal - Manual Rotate / Retract 1 B06-00-0541

29 Yellow Decal - Caution - Compartment Access 2

30 Red Decal - Danger - Main instruction / Hazard - Base 1 B06-00-0505

31 Red Decal - Danger - Battery / Charger Safety 1

32 Orange

33 Red Decal - Danger - Battery / Charger instruction 1 B06-00-0484

34 Orange Decal - Warning - Crush hazard 2 B06-00-0543

35 Other Decal - Generator Plate Maximum 200 1 B06-00-0496

36 Blue Decal - Notice - AC Power Connection 1 B06-00-0478

37 Orange Decal - Warning - Maximum Tow Speed 65 1 B06-00-0542

38 Orange Decal - Warning - Tow hazard 65 mph 2 B06-00-0544

Decal - Notice - Working area / Range of motion - 3522A

- HTA13

Decal - Warning - Ground operation instructions Articulating

2 B06-00-0535

2 B06-00-0533

For ANSI : B06-00-0405

For AS : B06-00-0405-CE

For ANSI : B06-00-0403

For AS : B06-00-0403-CE

For ANSI : B06-00-0404

For AS : B06-00-0404-CE

For ANSI : B06-00-0482

For AS : B06-00-0482-CE

For ANSI : B06-00-0475

For AS : B06-00-0475-CE

For ANSI : B06-00-0062

For AS : B06-00-0062-CE

For ANSI : B06-00-0474

For AS : B06-00-0474-CE

For ANSI : B06-00-0068

For AS : B06-00-0068-CE

For ANSI : B06-00-0495

For AS : B06-00-0495-CE

For ANSI : B06-00-0034

For AS : B06-00-0034-CE

47 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

Identification plates and optional equipment - ANSI/CSA/AS -

3522A - HTA13-Used on machines with serial numbers prior to XXX only

48 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

Identification plates and optional equipment - ANSI/CSA/AS - 3522A - HTA13-

Used on machines with serial numbers prior to XXX only

Marking Color Description Quantity 3522A - HTA13

39 Other Key ring tag 1 B06-00-0526

40 Orange Annual Inspection Plate 1 B06-00-0524

41 Other VIN Plate 1 B06-00-0490

42 Other ANSI ID Plate 1 B06-00-0499

Replacement decals for optional equipment - ANSI/CSA/AS - 3522A - HTA13-

Used on machines with serial numbers prior to XXX only

Marking Color Description Quantity 3522A - HTA13

43 Blue Decal - Notice - Platform rotate - (Manual rotation option) 1 B06-00-0529

44 Orange Decal - Warning - Drive and set - (Drive and set option) 1 B06-00-0527

45 Blue Decal - Notice - Drive and set - (Drive and set option) 1 B06-00-0528

46 Orange Decal - Warning - Jockey wheel - (Drive and set option) 1 B06-00-0553

47 Blue Decal - Notice - Material Lift Set-Up - (Material lift option) 1 B06-00-0485

48 Blue

49 Blue Decal - Notice - Unleaded fuel only - (Gas engine option) 1 B06-00-0487

50 Yellow

51 Blue Decal - Notice - Engine specifics - (Gas engine option) 1 B06-00-0486

52 Orange

Decal - Notice - Material lift max 500 - (Material lift

option)

Decal - Caution - Component damage - (Gas engine

option)

Decal - Warning - Engine operate - Hot - (Gas engine

option)

1 B06-00-0497

1 B06-00-0488

1 B06-00-0547

49 4000670470 E 04.19 USA / GB

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

Decal placement - Decal kit - ANSI/CSA/AS - 3522A - HTA13 -

Used on machines with serial numbers after XXX only

50 4000670470 E 04.19 USA / GB

A

B

C

D

E

F

G

H

I

3522A - HTA13P - 4527A - HTA16P - 5533A - HTA19P

B

- Familiarization

Decal placement - Decal kit - ANSI/CSA/AS - 3522A - HTA13 -

Used on machines with serial numbers after XXX only

Marking Color Description Quantity 3522A - HTA13

1 Orange Decal - Warning - Unhitch To Operate 2 B06-00-0550

2 Yellow Decal - Caution - Latch / Jack / Brake 1 B06-00-0551

3 Orange Decal - Warning - Hand Pinch Point 17 B06-00-0405

4 Blue Decal - Emergency Lower Valve 4 B06-00-0403

5 Red Decal - Danger - Tip-over Hazards 7 B06-00-0521

6 Orange Decal - Warning - Outrigger Crush Foot 8 B06-00-0404

7 Other Decal - HAULOTTE® 2 B06-00-0161B

8 Orange Decal - Warning - Fork Lift Use 2 B06-00-0477

9 Other Decal - 3522A Transfer - Black 2 B06-00-0538

10 Yellow Decal - Caution - Transport latch 2 B06-00-0481

11 Red Decal - Danger - Electrocution Hazard 2 B06-00-0482

12 Other Decal - Lubricate Semi - Annually 1 B06-00-0037

13 Red Decal - Danger - Platform maximum load 3 B06-00-0474

14 Blue Decal - Operator Manual Missing 1 B06-00-0473

15 Orange Decal - Read / Understand Manual 1 B06-00-0475

16 Other Decal - Flag, Made In USA 1 B06-00-0660

17 Other Decal - AC Power 2 B06-00-0062

18 Other Decal - Fall arrest harness 2 307P216290

19 Red Decal - Danger - Main Instruction / Hazard - Platform 1 B06-00-0471

20 Blue Decal - Notice - Range of Motion 2 B06-00-0535

21 Orange Decal - Warning - Platform operation - Articulating 1 B06-00-0534

22 Blue Decal - Notice - Handle applications 1 B06-00-0503

23 Blue Decal - Notice - Emergency hand pump 1 B06-00-0504

24 Blue Decal - Notice - Low Foam hydraulic oil 1 B06-00-0068

Decal - Fluid Level for 4000109360 and 4000110000

25 Other

26 Yellow

27 Yellow Decal - Caution - Compartment Access 2 B06-00-0495

28 Orange

29 Red Decal - Danger - Battery / Charger Instruction 1 B06-00-0484

30 Red Decal - Danger - Main Instruction / Hazard - Base 1 B06-00-0505

31 Red Decal - Danger - Battery / Charger Safety 1 B06-00-0034

32 Orange Decal - Warning - Crush hazard 2 B06-00-0543

33 Red Decal - Danger - Cage pin 2 B06-00-0669

34 Blue Decal - Notice - AC Power Connection 1 B06-00-0478

35 Yellow Decal - Caution - Generator Plate Maximum 200 1 B06-00-0496

36 Other Decal - Air - 8.3 BAR / 120 PSI 1 B06-00-0530

37 Other Decal - Water - 207 BAR / 3000 PSI 1 B06-00-0531

38 Orange Decal - Warning - Tow hazard 65 mph 2 B06-00-0544

39 Orange Decal - Warning - Maximum Tow Speed 65 1 B06-00-0542

Hydraulic pumps only - No fuel level decal for A0025HA

pump

Decal-Caution-Manual Rotate / Retract for 4000109380

and 4000110000 Hydraulic pumps

Decal - Warning - Ground operation instructions Articulating