Keep for future use!

Mini Jet Ionisator II 04.7614.000

Mini Jet Ionisator II with air gun 04.7618.000

Mini Jet Ionisator II

Air Line

Operating instructions

Table of contents

1 Operator instructions........................................................................ 4

2 Safety ................................................................................................. 5

3 Intended use...................................................................................... 8

4 Description of unit............................................................................. 9

5 Installation ....................................................................................... 10

6 Maintenance .................................................................................... 13

7 Troubleshooting .............................................................................. 15

8 Accessories ..................................................................................... 16

9 Technical data ................................................................................. 17

9.1 Supply voltage ............................................................................................ 17

9.2 Air supply system........................................................................................ 17

9.3 Ambient conditions ..................................................................................... 17

9.4 Dimensions ................................................................................................. 18

10 Decommissioning ........................................................................... 19

11 Disposal ........................................................................................... 20

3

1 Operator instructions

1 Operator

instructions

Make sure you read the complete

operatin

and commissioning the "Mini Jet

Ionisator II". They form a constituent

part of the "Mini Jet Ionisator II" and

must be retained for later use or a

subsequent owner.

Safety instructions must be observed

and followed at all times.

For reasons of convenience, “Mini Jet

Ionisator II” is abbreviated MJ II

below.

The MJ II is an air-assisted ionizing

unit which is available in two versions:

• With compressed air connection

• With air gun

The MJ II is operationally safe when

used as intended.

g instructions before installing

The following signal words are

used:

WARNING!

If ignored

• severe personal injury.

• or death may result.

CAUTION!

If ignored

• light personal injury may result.

ATTENTION!

If ignored

• light material damage may occur

as a consequence which might

lead to damage to the ionizing

unit.

NOTE: Important notes and additional

information.

4

2 Safety

All activities must be performed only

by persons authorized by the owner.

Such persons must

• have basic knowledge in the field

of electrical engineering.

• have basic knowledge in the field

of mechanical engineering.

• have been instructed in the

installation and handling of

compressed air devices and the

resulting dangers.

• have read and understood the

operator instructions.

Make sure to switch off the

compressed air and power supply

before starting work on the MJ II, and

protect against inadvertent activation.

In the event of damage to the ionizing

unit, the risk of electric shocks arises.

Immediately take the ionizing unit out

of operation in the event of visible

damage and suspected electrical

failure, and protect against reuse.

2 Safety

Never use air-asissted ionizing units

without pressure reducer and

compressed air filter, and never

exceed the permissible maximum

pressure. The compressed air must be

filtered (< 20 μm), dry and oil-free.

Secure air hoses with suitable clamps.

The ionizing unit does not contain any

parts which can be repaired by the

operator.

For reasons of safety, unauthorized

conversions and modifications of the

MJ II are not permitted.

5

2 Safety

WARNING!

The ionizing unit may influence heart

pacemakers.

The electric high voltage in the ionizing

unit results in an electric alternating

field of 50 Hz which may influence the

function of the heart pacemaker.

Malfunction of the heart pacemaker

may result in ventricular fibrillation or

cardiac arrest.

• Persons wearing heart

pacemakers must maintain a

safety distance of more than 50

cm from the ionizing unit.

• The operator must mark the

danger zone around the ionizing

unit by means of a warning sign.

• The accident prevention

regulations according to BGV A8

must be observed.

• An expert study on the influence of

ionization systems on implanted

heart pacemakers is available from

HAUG GmbH & Co. KG.

CAUTION!

Injuries may be caused by the ionizing

pins of the ionizing unit.

When touched, the ionizing pins may

lead to stab or tear injuries to the

hands.

• Protective gloves must be worn

when working on the ionizing unit

(EN 388 3122).

During operation, small amounts of

ozone are generated by the ionizing

units.

A very high ozone concentration and

prolonged continuous exposure times

may result in headache, irritation to the

eyes, circulatory problems etc.

• To ensure that the maximum

permissible ozone concentration

at the workplace is not exceeded,

adequate ventilation must be

provided during operation of the

ionizing units.

• An expert study on ozone

emissions of ionization systems is

available from HAUG

GmbH & Co. KG.

6

ATTENTION!

Wetness and moisture may result in

spark-overs and leakage paths.

Damage to the ionizing unit and shortcircuits are a likely consequence.

• Protect the ionizing units from

moisture and wetness.

• Never use high-pressure cleaners

to clean the units.

Insertion/removal of the high-voltage

plug into/from the ionizing unit while

the power pack is switched on may

result in contact or separation

sparkovers.

This may result in damage to the

power pack or defects.

• Always switch off the power pack

before plugging in/unplugging the

high-voltage plug.

Pulling the high-voltage cable of the

ionizing unit may result in gaps at the

contact points within the high-voltage

plug and connection of the unit.

Arcing may occur at the gaps due to

the high voltage. Resulting in damage

to the unit.

• Do not pull the high-voltage cable.

2 Safety

7

3 Intended use

3 Intended use

The MJ II is intended for the contactfree cleaning of surfaces in industrial

production processes. It removes

electrostatic charges and

contamination (e.g. dust or similar)

from paper, film, textiles, glass,

plastics etc.

The MJ II must be operated with

filtered (< 20 μm), dry and oil-free

compressed air only.

Never exceed the maximum operating

pressure of 6 bar.

This ionizing unit is only approved for

alternating high voltage.

The high-voltage connector (system

X-2000) of the ionizing unit matches all

popular HAUG power packs. The

ionizing unit must only be connected

to a HAUG power pack. Any warranty

only extends to the units and

accessories of HAUG

GmbH & Co. KG.

The installation and operating

conditions indicated in these

Operating Instructions must be

adhered to.

WARNING

Risk of explosion!

Ignitable sparks may form at the

ionizing units.

• Do not install or use the ionizing

units in area with potentially

explosive atmosphere.

8

4 Description of unit

High-voltage plug

System X-2000

The high-voltage plug system can be

taken apart. This allows the high-voltage

plug to be assembled or dismantled.

Mini Jet Ionisator II:

1. Ionizer

2. Flat jet nozzle

3. High-voltage cable

4. Compressed air connection

Mini Jet Ionisator II with air gun:

1. Ionizer

2. Flat jet nozzle

3. High-voltage cable

4. Air gun

4 Description of unit

5. Ionizing pins

9

5 Installation

5 Installation

1. Check whether the MJ II

corresponds to the ordering data.

• In the event of any damage to

the MJ II, contact

HAUG GmbH & Co. KG.

2. Prepare the installation site with

regard to the following installation

parameters:

ATTENTION!

No ionization is possible at locations

where the ionizing pins are covered by

fixing elements or machine parts. At the

covered points, an arc or leakage path

may form due to contamination of

electrically conductive materials, and

damage the ionizing unit.

• Never attach mounting elements or

machine parts over the ionizing pins.

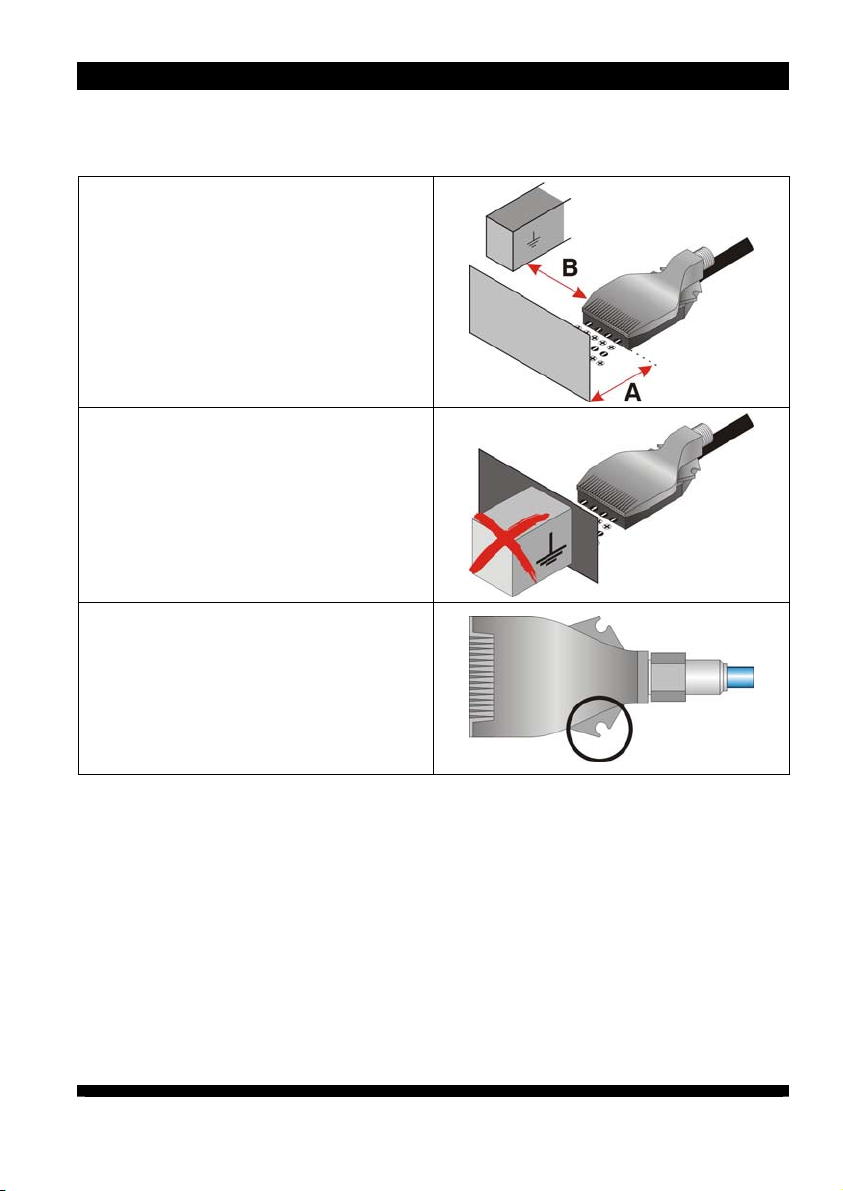

The most favourable distance of the MJ II

to the material to be ionized is approx.

20 – 300 mm.

The limit values for the ionizing effect are

at 10 mm min. and 500 mm max.

10

The distance o

machine part (B) must be greater than

the distance to the material to be ionized

(A).

No earthed machine parts must lie

behind the material to be ionized.

3. Pick up and attach the MJ II in the

machine using the grooves.

f the MJ II to an earthed

5 Installation

11

5 Installation

ATTENTION!

The shielding and insulation of the cable

may be damaged if the cable is kinked or

bent. This will result in a short-circuit.

• The high-voltage cable must not be

kinked.

• When routing around bends, the

bending radius must not be smaller

than 50 mm.

4. Switch off power pack and secure

against inadvertent operation.

5. Insert the ionizing unit’s highvoltage plug in the high-voltage

socket of the power pack and press

the high-voltage cable until it

reaches the stop.

6. Screw the screw cap onto the highvoltage socket and tighten by hand.

12

6 Maintenance

Clean the MJ II at intervals of no more

than 14 days.

The dirtier the enviroment, the shorter

the cleaning interval. Once the ionizing

and cleaning effect drops off, clean the

unit to bring the ionization and

cleaning effect back to normal.

ATTENTION

The ionizing unit may be damaged if

inappropriate brushes or cleaning

agents are used.

• We strongly recommend the

exclusive use of cleaning

accessories from HAUG

GmbH & Co. KG. Refer to Section

Accessories.

6 Maintenance

Dry cleaning

1. Switch off power pack and secure

against inadvertent operation.

2. Switch off the compressed air

supply.

3. Disconnect the ionizing unit from

the power pack.

4. Brush the ionizing pins of the

ionizing unit using special

cleaning brush RB1.

5. Blow off the MJ II with clean

compressed air (max. 6 bar).

6. Check the high-voltage

connections and high-voltage

plugs for contamination. The

connections must be clean and

dry.

7. Reconnect the ionizing unit to the

power pack.

8. Switch the compressed air supply

back on.

NOTE: If dry cleaning does not yield

the desired result, continue by using a

wet cleaning process.

13

6 Maintenance

Moist cleaning

1. Switch off power pack and secure

against inadvertent operation.

2. Switch off the compressed air

supply.

3. Disconnect the ionizing unit from

the power pack.

4. Wet the special cleaning brush

RB1 with the special cleaning

agent SRM1. The special cleaning

system RS2 may also be used for

cleaning.

5. Brush the ionizing pins of the

ionizing unit.

6. Blow off the MJ II with clean

compressed air (max. 6 bar) and

allow to dry.

7. Check the high-voltage

connections and high-voltage

plugs for contamination. The

connections must be clean and

dry.

8. Reconnect the ionizing unit to the

power pack.

9. Switch the compressed air supply

back on.

14

7 Troubleshooting

7 Troubleshooting

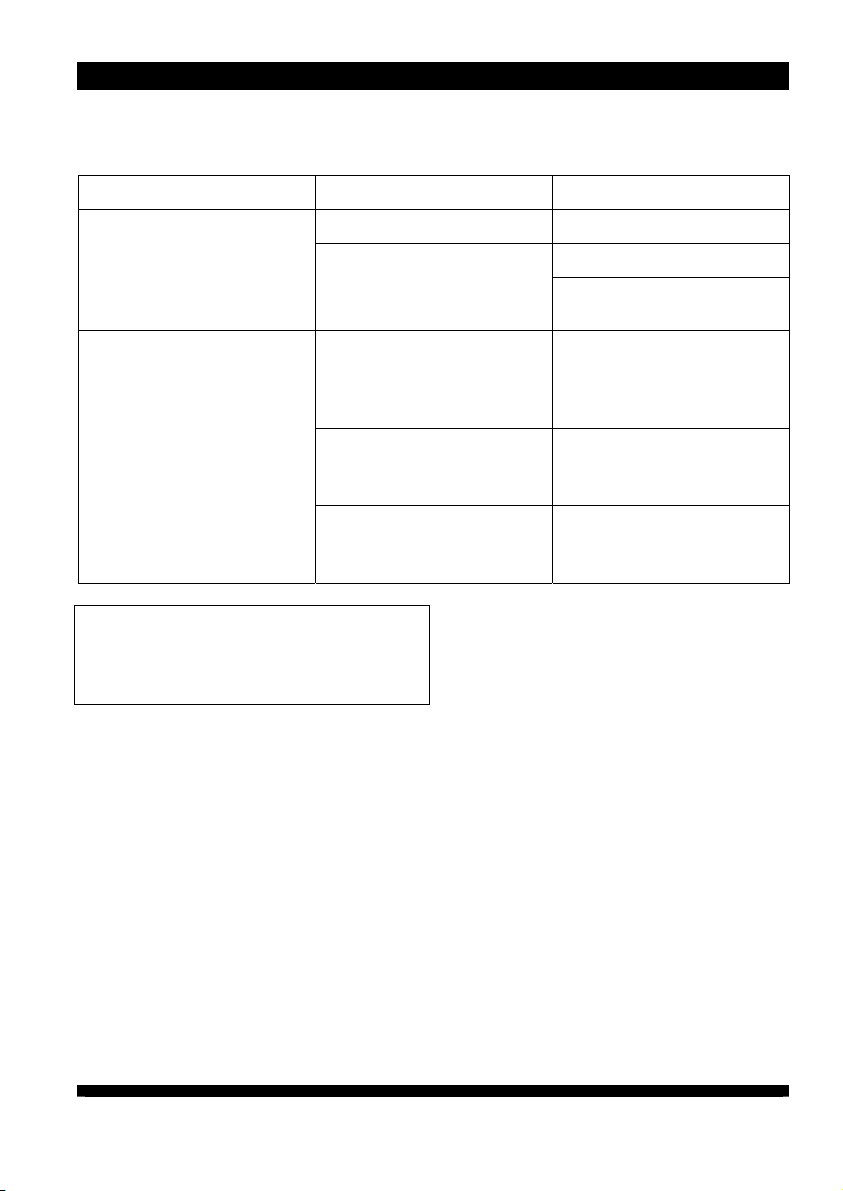

Error Cause Measure for elimination

No ionization

The ionizing unit is dirty. Clean the ionizing unit.

No high voltage.

Check power pack.

Check connections.

Sparks-over

NOTE: If the error cannot be removed in

this way, return the power pack and MJ II

for checking to HAUG GmbH & Co. KG

(for address, see reverse).

The ionizing unit is

covered with an

electrically conductive

deposit.

The ionizing pins are too

close to an electrically

conductive material.

The ionizing unit is

damaged.

Clean the ionizing unit.

Increase distance to the

cause.

Switch off the MJ II

automatically and secure

against switching on.

15

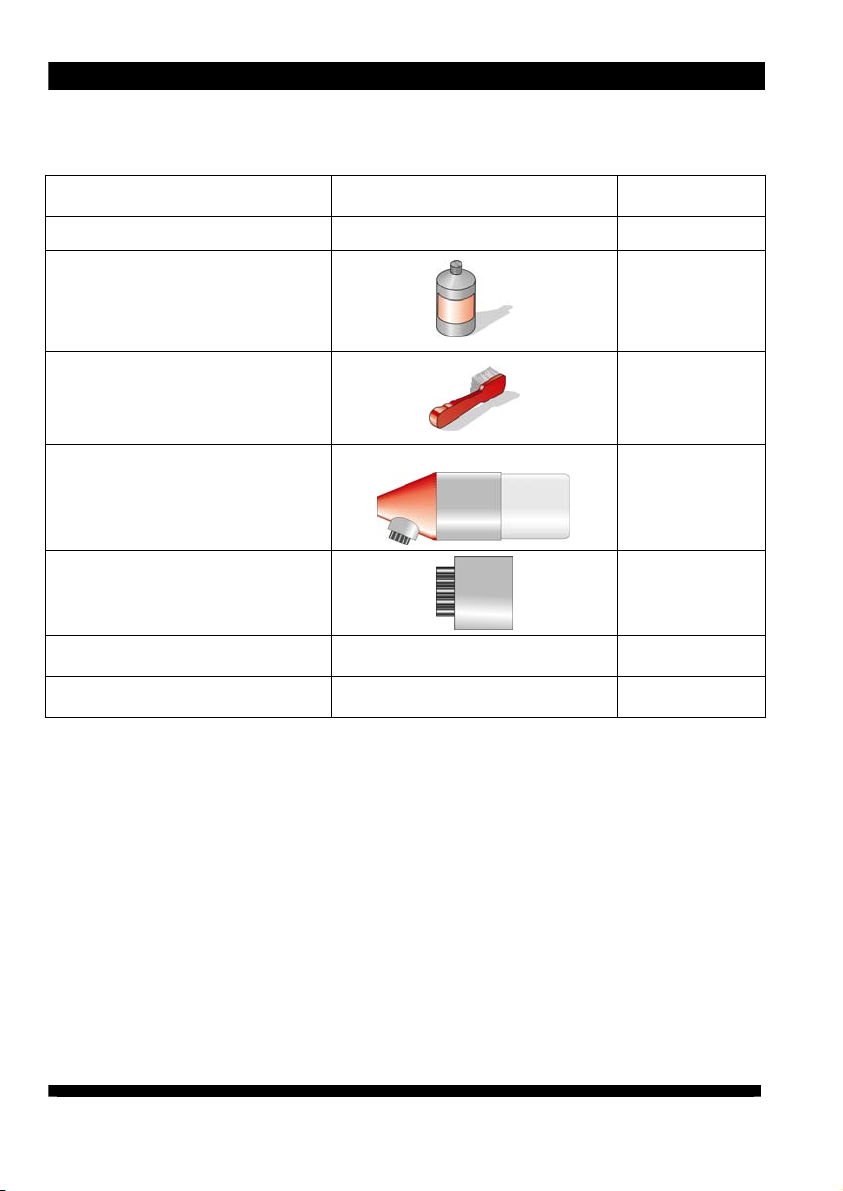

8 Accessories

8 Accessories

Article Illustrations Order number

HAUG power pack On request

Special cleaning fluid SRM1

Special cleaning brush RB1

10.7220.000

10.7218.000

Special cleaning system RS2

Circular brush for special

cleaning system

Compressed air service station 11.7210.001

Compressed air hose X – 3310

10.7218.004

X – 5677

16

9 Technical data

9 Te c h n i c a l d a t a

9.1 Supply voltage

Electric connection to HAUG power pack 7 – 8 kVAC

9.2 Air supply system

Compressed air Filtered (< 20 μm), dry and oil-free.

Maximum pressure 6 bar

Air consumption 315 l/min at 2 bar

9.3 Ambient conditions

Do not use in areas with potentially

explosive atmospheres.

Only for inside use.

Temperature:

Rated application range +5 °C to +45 °C

Extreme range for storage and transport -15 °C to +60 °C

Humidity:

Rated application range 20 % to 65 % RF

Extreme range for storage and transport 0 % to 85 % RF

17

9 Technical data

9.4 Dimensions

Dimensions:

Height approx. 28 mm

Width approx. 50 mm

Depth approx. 75 mm

High-voltage cable Length customer-specific

Compressed air hose Length customer-specific

18

10 Decommissioning

1. Switch off the machine and secure

against unintended switching on.

2. Switch off power pack and secure

against inadvertent operation.

3. Switch off the compressed air

supply.

4. Disconnect the MJ II from the

power pack.

5. Disconnect the MJ II from the air

supply system.

6. Dismantle the MJ II from the

machine.

10 Decommissioning

19

11 Disposal

11 Disposal

Observe and maintain national and

regional waste disposal regulations for

the disposal of the MJ II.

20

NOTES:

made by

MJI2 v02gb.doc

D – 0281 – GB

V02

2010-03-04

Loading...

Loading...