These instructions are intended for use only by experienced, qualified combustion startup personnel. Adjustment of this equipment by unqualified personnel can result in fire,

explosion, severe personal injury or even death.

To make changes to the burner or adjust firing inputs: 1. Shut the burner down; 2. Make

changes; 3. Restart the burner. STAND CLEAR OF THE BURNER UNDER ANY

FIRING CONDITIONS.

MEGASTARTMBURNER

MS-50 – MS-150

WARNING

INSTRUCTIONS

TABLE OF CONTENTS

These instructions are intended to serve as guidelines covering the installation, operation, and maintenance of Hauck equipment. While

every attempt has been made to ensure completeness, unforeseen or unspecified applications, details, and variations may preclude

covering every possible contingency. WARNING: TO PREVENT THE POSSIBILITY OF SERIOUS BODILY INJURY, DO NOT USE OR

OPERATE ANY EQUIPMENT OR COMPONENT WITH ANY PARTS REMOVED OR ANY PARTS NOT APPROVED BY THE

MANUFACTURER. Should further information be required or desired or should particular problems arise which are not covered

sufficiently for the purchaser's purpose, contact Hauck Mfg. Co.

HAUCK MANUFACTURING CO., 100 North Harris Street Cleona, PA 17042 717-272-3051

1/15 www.hauckburner.com Fax: 717-273-9882

Subject

A. General Information…………………………………………………………………… 2

B. Receiving & Inspection……………………………………………………………….. 2

C. Burner Capacities……………………………………………………………………... 3

D. Dimensions…………………………………………………………………………….. 5

E. Component Identification…………………………………………………………….. 6

F. Combustion Flighting…………………………………………………………………. 7

G. Burner Mounting………………………………………………………………………. 7

H. Fuel Manifold Installation……………………………………………………………... 8

I. Natural Gas Fuel Piping System…………………………………………………….. 9

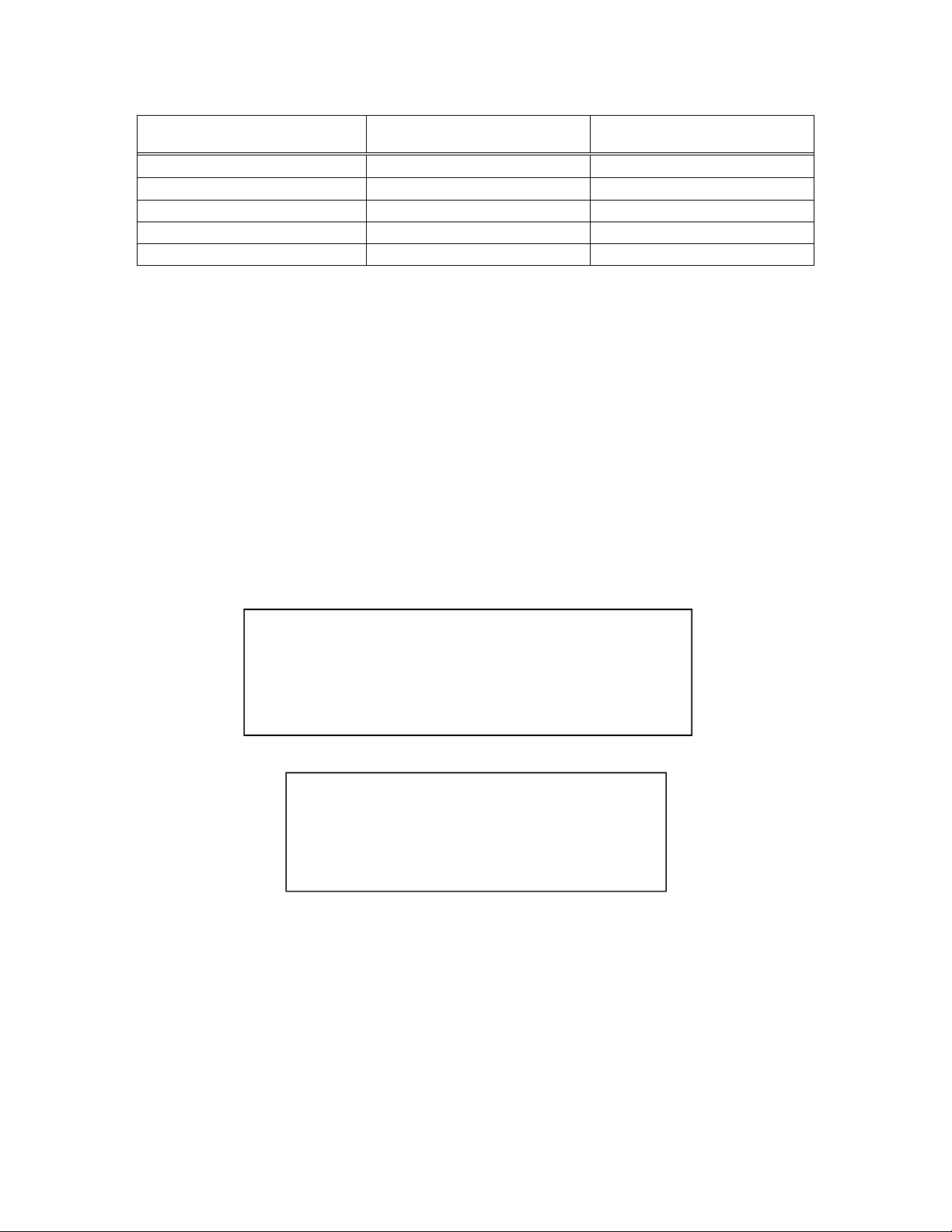

J. Light Fuel Oil Piping System…………………………………………………………. 13

K. Heavy Fuel Oil Piping System……………………………………………………….. 15

L. Oil Manifold Heat Tracing…………………………………………………………….. 18

M. Heavy Oil Insert Heater………………………………………………………………. 18

N. Fuel Oil Nozzle………………………………………………………………………… 20

O. Compressed Air/Oil Atomizer………………………………………………………… 21

P. Liquid Propane (LP) Fuel Piping System…………………………………………… 26

Q. Liquid Propane (LP) Nozzle………………………………………………………….. 31

R. Burner Pilot System…………………………………………………………………… 33

S. Primary Air……………………………………………………………………………... 34

T. Burner Setup…………………………………………………………………………… 34

U. Operation………………………………………………………………………………. 35

V. Adjustments……………………………………………………………………………. 36

W. Maintenance…………………………………………………………………………… 37

X. Recommended Spare Parts…………………………………………………………. 38

Appendix: Field Installation Weld-In Type flights, Y7100……………………….. 39

Required Reference: Appropriate Burner Data Sheet

GJ73 Dryer Drum Gas Analysis

GJ75 MegaStar Application Sheet

Page

MS-9

Page 2

MS-9

WARNING

This equipment is potentially dangerous with the possibility of serious personal injury

and property damage. Hauck Manufacturing Company recommends the use of flame

supervisory equipment and fuel safety shutoff valves. Furthermore, Hauck urges rigid

adherence to National Fire Protection Association (NFPA) standards and insurance

underwriter’s requirements. Operation and regular preventative maintenance of this

equipment should be performed only by properly trained and qualified personnel.

Annual review and upgrading of safety equipment is recommended.

A. GENERAL INFORMATION

The MegaStar

TM

Burner is the next generation of total air aggregate drying burners. It has the

same quiet operation and ecological benefits as its predecessors, with the improved efficiency,

emissions, and ease of operation. It is available with low pressure atomization for light fuel oils

or LP, and is a highly efficient natural gas or vaporous propane burner. It features our lowest

construction profile allowing for easier installation and easier access to working components on

the burner. Flame adjustability allows a tailored fit to any drum configuration. Air/fuel ratio for the

MegaStar burner can be maintained more precisely than ever before over the entire operating

range by an energy saving VFD for maximum efficiency.

The MegaStar

TM

can be supplied with fuel manifolds as an integral part of the burner, or with

optional remote rack mounted fuel manifolds. Natural gas firing does not require a primary air

blower.

The MegaStar

ultraviolet flame scanner. If an alternate flame scanner is

required, consult Hauck.

TM

is supplied with a Honeywell C7027A

NOTE

B. RECEIVING AND INSPECTION

Upon receipt, check each item on the bill of lading and/or invoice to determine that all

equipment has been received. A careful examination of all parts should be made to ascertain if

there has been any damage in shipment.

If the installation is delayed and the equipment is stored outside,

provide adequate protection as dictated by climate and period of

exposure. Special care should be given to all motors and

bearings, if applicable, to protect them from rain or excessive

moisture.

IMPORTANT

Page 3

MS-9

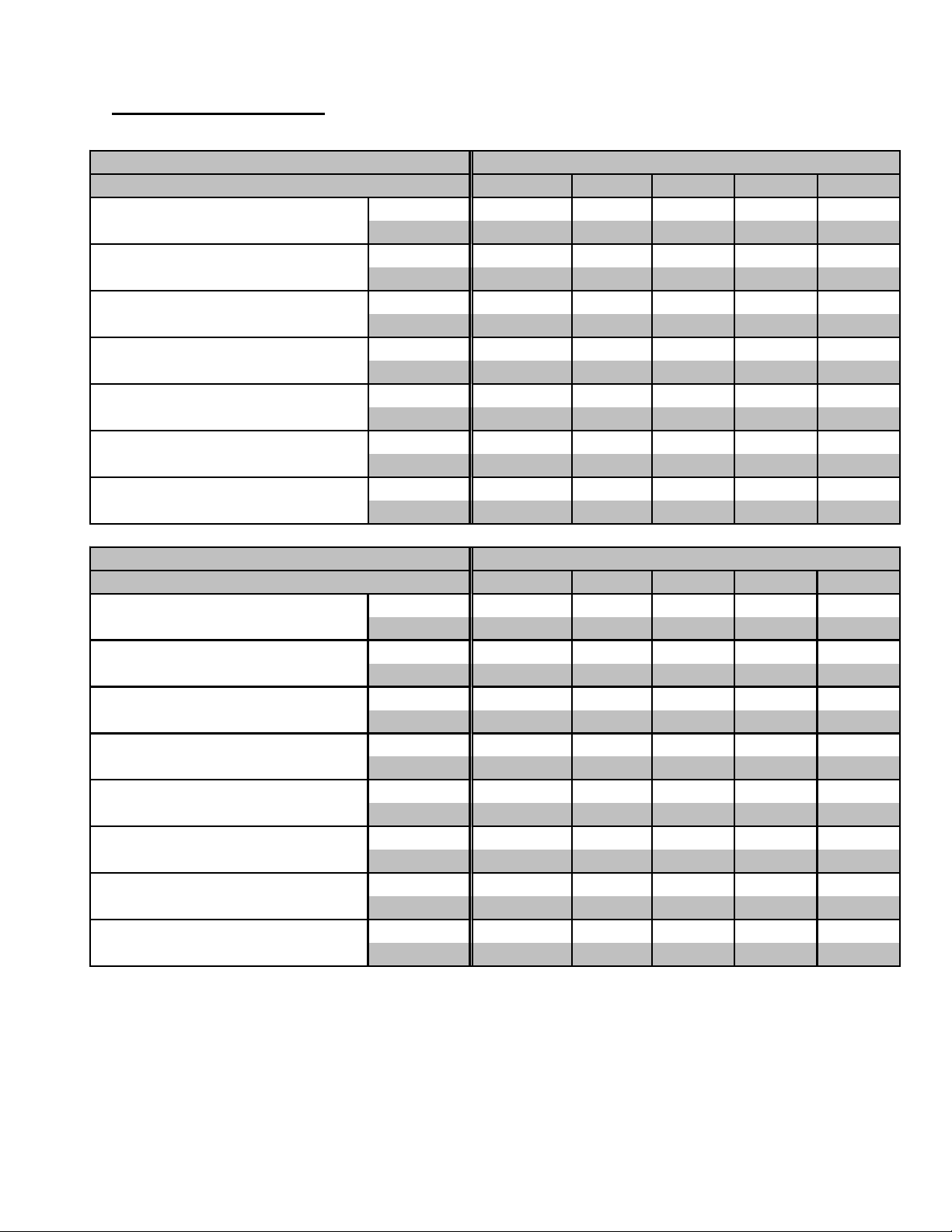

C. BURNER CAPACITIES

Capacity

Main Ai r Flow

Main Air Pressure

Gas Flow Rate

Capacity with Flue Gas Recirc

Flame Length @ 30° Spin

Flame Diameter @ 30° Spin

MEGASTAR BURNER MODEL

GAS SPECIFICATIONS

(MMBTU/hr)

(MW) 14.7 24.2 29.3 39.6 45.2

(scfh) 636,600 1,050,000 1,270,000 1,720,000 1,960,000

3

/hr)

(nm

(in.w.c.) 14.3 12.6 15.3 13.8 14.5

(mbar) 35.6 31.3 38.1 34.3 36.1

(scfh) 52,300 86,200 104,300 141,300 161,000

3

(nm

/hr)

(MMBTU/hr)

(MW) 11.0 16.8 22.2 27.9 33.6

(ft) 12 14 9 11 15

(m) 3.7 4.1 2.7 3.4 4.6

(ft) 4 7587

(m) 1.2 2.0 1.5 2.4 2.1

50 75 100 125 150

54 89 108 146 166

17,100 28,100 34,000 46,100 52,500

1,400 2,300 2,800 3,800 4,300

40.5 62 82 103 124

Capacity

LIGHT OIL SPECIFICATIONS

Main Ai r Flow

Main Air Pressure

Primary Air Flow

Primary Air Pressure

Oil Flow Rate

Flame Length @ 30° Spin

Flame Diameter @ 30° Spin

MEGASTAR BURNER MODEL

50 75 100 125 150

(MMBTU/hr)

(MW) 14.3 22.3 27.2 36.5 41.5

(scfh) 643,300 1,030,000 1,270,000 1,720,000 1,960,000

3

/hr)

(nm

(in.w.c.) 14.3 12.0 16.2 13.7 144.0

(mbar) 35.6 29.9 40.3 34.1 358.3

(scfh) 46,500 46,500 46,500 46,500 46,500

3

/hr)

(nm

(in.w.c.)62 62626262

(mbar) 154 154 154 154 154

(gal) 370 580 710 950 1,080

(lph) 1,400 2,200 2,690 3,600 4,090

(ft) 10 12 12 10 12

(m) 3.1 3.7 3.7 3.1 3.7

(ft) 4 5545

(m) 1.2 1.5 1.5 1.2 1.5

53 82 100 135 153

17,200 27,600 34,000 46,100 52,500

1,200 1,200 1,200 1,200 1,200

Table 1. Burner Capacity Data For Natural Gas & Light Oil

Page 4

MS-9

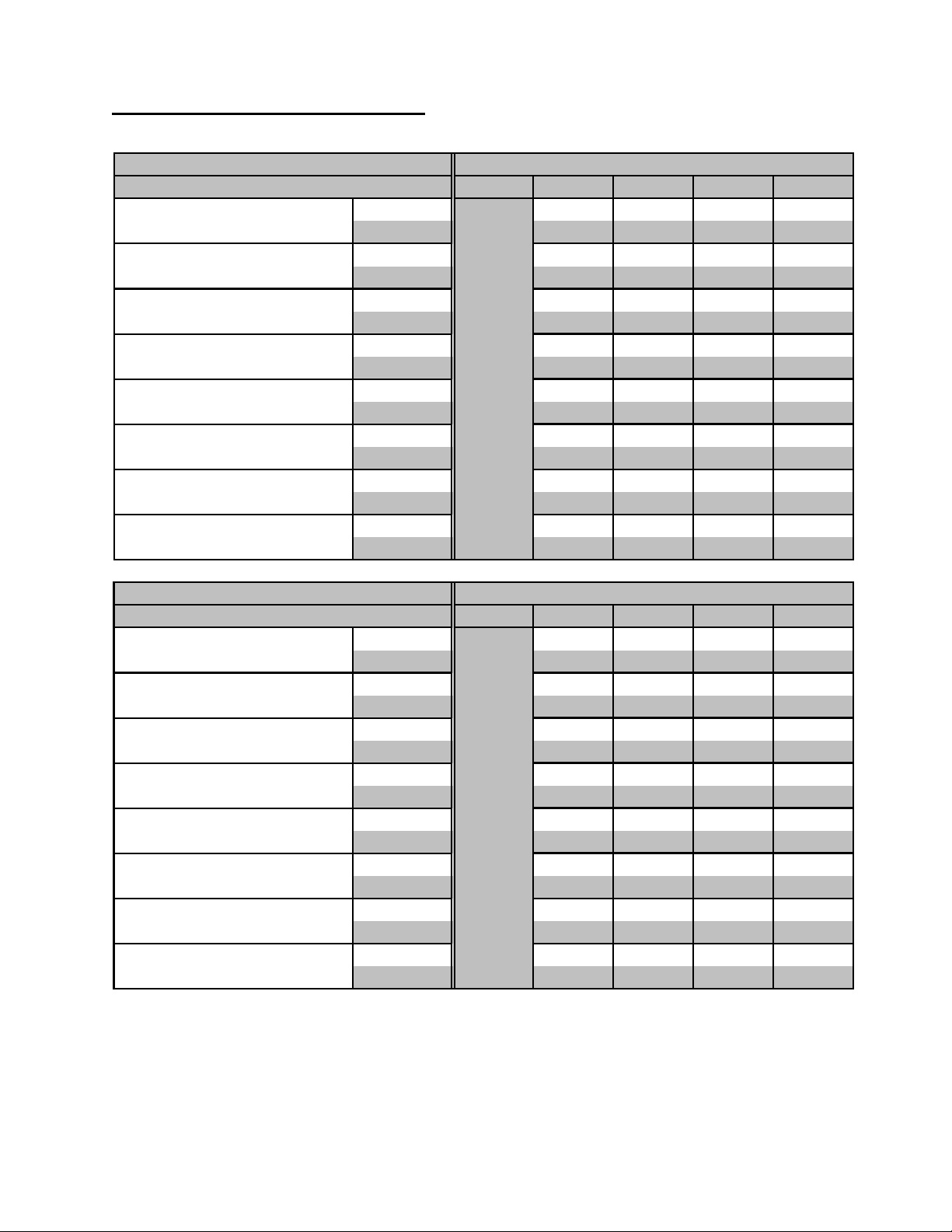

C. BURNER CAPACITIES (Continued)

LIQUID PROPANE SPECIFICATIONS

Capacity

Main Air Flow

Main Air Pressure

Primary Air Flow

Primary Air Pressure

Propane Flow Rate

Flame Length @ 30° Spin

Flame Diameter @ 30° Spin

MEGASTAR BURNER MODEL

50 75 100 125 150

(MMBTU/hr)

(MW) 21.7 26.4 34.6 39.3

(scfh) 980,000 1,200,000 1,590,000 1,810,000

3

/hr)

(nm

(in.w.c.) 12.8 18.5 15.0 18.3

(mbar) 31.8 46.0 37.3 45.5

(scfh) 46,500 46,500 46,500 46,500

3

/hr)

(nm

(in.w.c.) 62626262

(mbar) 154 154 154 154

(gal) 880 1,070 1,400 1,590

(lph) 3,330 4,050 5,300 6,020

(ft) 14 15 13 15

(m) 4.3 4.6 4.0 4.6

(ft) 5566

(m) 1.5 1.5 1.8 1.8

P

e

n

d

i

n

g

80 97 128 145

26,300 32,100 42,600 48,500

1,200 1,200 1,200 1,200

COMPRESSED AIR SPECIFICATIONS

Capacity

Main Air Flow

Main Air Pressure

Compressed Air Flow

Compressed Air Pressure

Oil Flow Rate

Flame Length @ 30° Spin

Flame Diameter @ 30° Spin

MEGASTAR

BURNER MODEL

50 75 100 125 150

(MMBTU/hr)

(MW) 21.4 27.2 35.3 40.7

(scfh) 1,030,000 1,310,000 1,700,000 1,960,000

3

/hr)

(nm

(in.w.c.) 12.0 16.2 13.2 14.4

(mbar) 29.9 40.3 32.8 35.8

(scfh) 3,600 3,600 5,400 5,400

3

/hr)

(nm

(psig) 60 60 60 60

(bar) 4444

(gal) 560 710 920 1,060

(lph) 2,120 2,690 3,480 4,010

(ft) 9 9 10 10

(m) 2.7 2.7 3.1 3.1

(ft) 5555

(m) 1.5 1.5 1.5 1.5

N

o

t

A

v

a

i

l

a

b

l

e

79 100 130 150

27,600 35,100 45,500 52,500

100 100 100 100

Table 2. Burner Capacity Data For Liquid Propane & Compressed Air

Page 5

MS-9

C. BURNER CAPACITIES (Continued)

Table 1 & 2 Notes:

1. Burner capacity is based on 60Hz power and scfh (nm3/hr) 60F (0°C) air at sea level.

Correction factors must be applied for variations in altitude, temperature, or frequency;

consult Hauck. An altitude correction table is available in Hauck Application Sheet GJ75.

2. Natural gas capacities based on higher heating value of 1,034 Btu per cubic foot (lower

heating value of 36.74 MJ/nm

air, and stoichiometric ratio of 9.74:1.

3)

, 2-4 psig (138 – 276 mbar) manifold pressure, 25% excess

3. No. 2 fuel oil capacities based on higher heating value of 141,146 Btu per gallon (lower

heating value of 36.99 MJ/liter), 35% excess air, and stoichiometric ratio of 1371.1 cubic feet

air/gallon of No. 2 oil (9.7 nm

3

air/liter).

4. Liquid propane capacities based on higher heating value of 90,912 Btu per gallon (lower

heating value of 23.83 MJ/liter), 35% excess air, and stoichiometric ratio of 864 cubic feet

air/gallon of liquid propane (6.1 nm3 air/liter).

5. The exhaust fan must be able to provide a slight negative pressure, suction in the range of

0.25 to 1” wc (.6 to 2.5 mbar), at the burner breech plate to exhaust the products of

combustion.

6. MegaStar

TM

Burner airflow can be accurately monitored using the body pressure tap on

either side of the burner air plenum. An accurate device capable of reading up to 15" wc (75

mbar) will be required for this measurement.

7. All burner fuel manifolds are supplied with fuel flow measuring devices. Liquid fuel

manifolds are equipped with an inline flow meter. Gaseous fuel manifolds are equipped with

a gas orifice meter that can be accurately checked for gas flow by measuring the differential

pressure across the orifice meter with a U-tube device (manometer) capable of reading in

the range of 0 to 20"wc (0 to 50 mbar).

8. Low pressure atomizing air, used for firing low pressure fuel oil or LP, is provided by a 36 osi

(155 mbar) Hauck high efficiency Turbo Blower. The low pressure air is used to not only

atomize liquid fuels, but also improve mixing speed in the combustion zone.

9. High pressure compressed air, used for firing heavy oils or any fuel oil at high elevations,

must be supplied by the customer at a nominal 60 psig (4140 mbar) to the burner nozzle for

optimum fuel oil atomization.

D. DIMENSIONS

See appropriate section of MS-3 for detailed dimensional information.

Page 6

MS-9

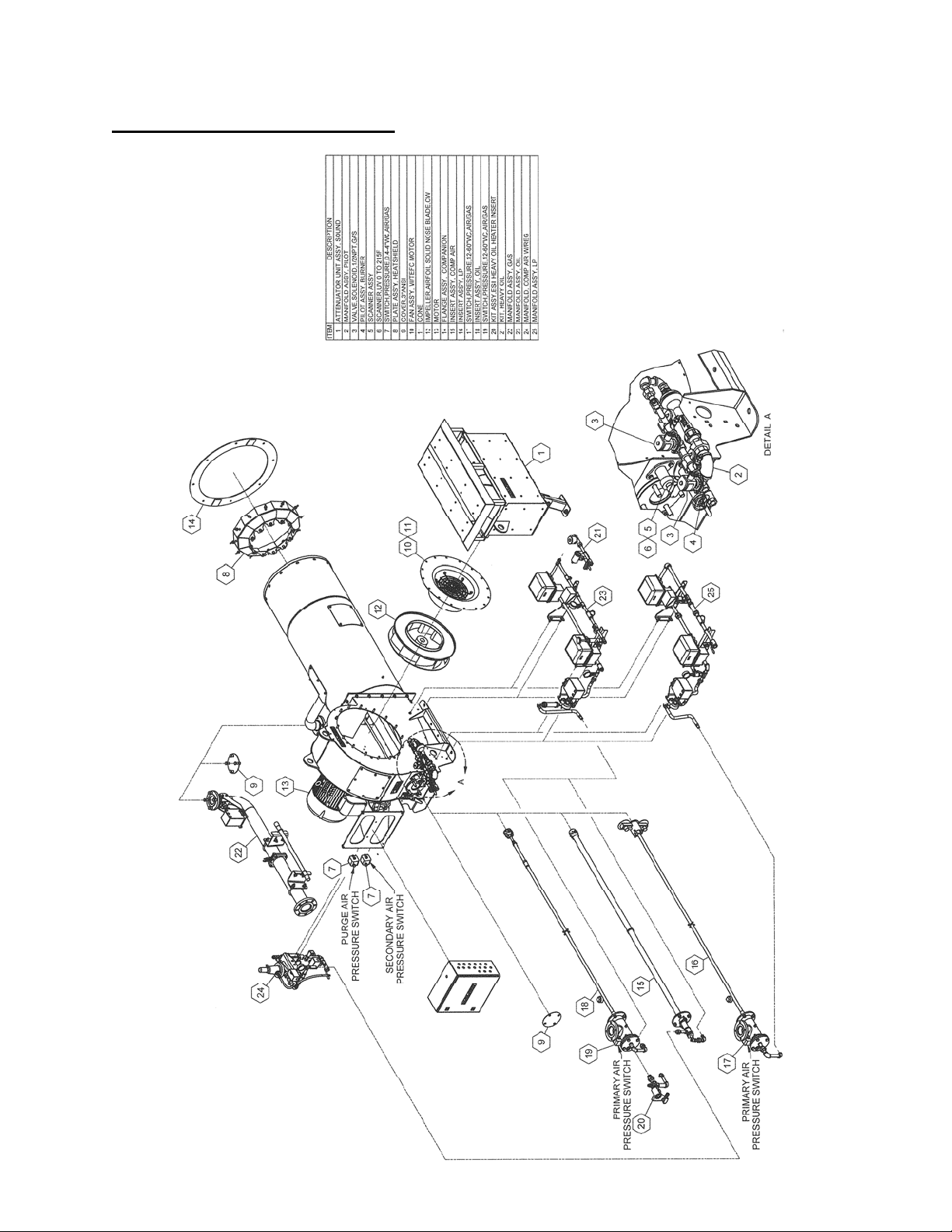

E. COMPONENT IDENTIFICATION

Y8978

Figure 1. MegaStarTM Burner Components

(NOT TO SCALE)

Page 7

TM

MS-9

F. COMBUSTION FLIGHTING

Flight design in the combustion zone is very important. Correct flighting can minimize pollutant

emissions, and provide heat shielding to keep the drum surface temperature down. To obtain

complete combustion, the combustion zone must be sized to provide enough combustion

volume for the flame to burn, and it should also be clear of veiling material that can quench the

flame, resulting in poor combustion efficiency.

Combustion flights provide protection for the drum by shielding it from direct flame radiation.

Construction of the combustion flights should be such that no material is allowed to fall through

the flame. Combustion flights should also have a means of dissipating heat to prevent their

destruction by the flame. This is typically done by plowing material over the fights and keeping

the flights as low as possible to the drum. Consult Hauck for details on flight design and

combustion zone requirements.

Flights are available from Hauck to optimize performance of the MegaStar™ on a rotary dryer;

for detailed installation instructions of Hauck weld-in type flights, see Y7100 in the Appendix.

For additional information on application issues for an MegaStar™ on a rotary dryer, see Hauck

Application Sheet GJ75.

G. BURNER MOUNTING

For MegaStar™ burners with an extended burner nose length, the nose must be

supported to avoid undue strain on the burner housing. Consult dryer

manufacturer for extended burner nose support recommendations.

IMPORTANT

1. The burner should be mounted on the drum centerline at the same pitch as the drum. Install

a structure to support the burner. Refer to dimensional drawings in the Section D. The

support structure must be able to support the weight of the burner (see Table 3). If the

optional primary air turbo blower (TBA) is to be mounted on the same structure as the

burner, allow for the additional weight. Consult Hauck for recommended burner mounting

options. If applicable, choose a suitable location for the optional remote mounted fuel rack

and primary air TBA blower. The fuel rack should be firmly attached to the base structure or

concrete pad. The fuel rack is supplied with mounting holes in the base angle iron. Consult

Hauck for the remote mounted fuel rack dimensional drawing Y6967 if applicable. Consult

TBA blower instruction sheet (TBA-9) for proper mounting instructions for the primary air

TBA blower.

2. The burner is supplied with lifting eyes to facilitate lifting the burner into place. Do not use

the lifting eye on the main blower motor for lifting the entire burner unit. The optional

TBA blower is also supplied with lifting eyes on the blower frame. Do not use the motor

lifting eye to lift the entire blower unit.

MegaStar

Approx. Net Weight* (lb)

[kg]

Model No. 50 75 100 125 150

2,500

[1,130]

5,000

[2,270]

5,800

[2,630]

6,500

[2,950]

6,500

[2,950]

Table 3. MegaStar™ Approximate Burner Net Weights

Page 8

MS-9

3. The burner can be ordered with a split-mounting companion flange that can be bolted onto

the dryer breech plate (see Table 4). This allows positioning the burner at various insertion

depths past the breech plate. Typical burner insertion depth is 18 to 24" (460 to 610mm).

Cut out a hole in the breech plate 2" (50mm) in diameter larger than the burner tube. Do not

weld the split-mounting flange to the burner body, as the breech will expand and contract

with changes in temperature. If the split-mounting flange is welded to the burner, heat and

stress will damage the burner. Tightly seal the burner to the breech. If using oil as a primary

fuel, the insertion depth may have to extend more than 24" (610mm) due to the amount of

radiant heat from an oil flame depending on the application.

MegaStar

TM

Model No. 50 75-100 125-150

Companion Flange Part No. 407091 56548x001 56549x008

Table 4. MegaStarTM Burner Recommended Split-Mounting Companion Flange

4. Bolt the burner to the support structure.

5. Wire the main fan motor and the optional TBA blower motor (if applicable) per instructions

on the motor.

6. Rotation of all blowers must be checked prior to burner startup. The rotation is marked with

an arrow on the blower housings. Do not operate the burner until all blowers are

checked for rotation and are rotating correctly.

All rotating components were balanced from factory at a level meeting ISO 1940-2. A variety

of external causes such as handling, installation, or misalignment may cause imbalance prior

to use. To ensure the intended long life of the equipment and components, and to meet

warranty requirements, equipment and vibration levels should be checked by experienced

personnel and trim balanced if no longer meeting ISO 1940-2 requirements. Under no

circumstances should equipment with excessive vibration be operated at the risk of damaging

that equipment or the personnel operating it.

NOTE

H. FUEL MANIFOLD INSTALLATION

The MegaStarTM burner can be supplied with integral fuel manifolds on the burner or with

optional remote rack mounted fuel manifolds. The fuel manifold has all modulating fuel valves

mounted on it. In addition to modulating fuel valves, the manifold includes the automatic oil, gas

and LP safety shutoff valves.

Fuel manifolds must be mounted in a horizontal position. Safety shutoff valves will not function

properly if mounted vertically. Liquid fuel manifolds should not be mounted above the burner

centerline. Oil and LP manifolds should be mounted as close to the burner as possible. For heavy

fuel oil applications, i.e., any fuel requiring heating for use, oil piping must be heat traced (electric

or steam) and insulated. Self-regulating heat tracing is recommended to maintain the desired

temperature of a given fuel oil to achieve 90 SSU (1.8x10

heat tracing with a nominal rating of 12W/ft (39W/m) covered with a nominal 2" (50mm) fiberglass

type insulation is sufficient for most applications. Fuel oil temperature should not exceed 250°F

(120°C). Oil viscosity should be checked prior to burner operation.

Hauck recommends the use of schedule 40 iron pipe and fittings rated for 150 psig (10.3 bar) for

natural gas and oil system interconnecting piping. LP applications require the use of schedule 80

pipe and fittings rated for 350 psig (24.1 bar).

IMPORTANT

-5 m2

/sec) or less at the burner. Electric

Page 9

MS-9

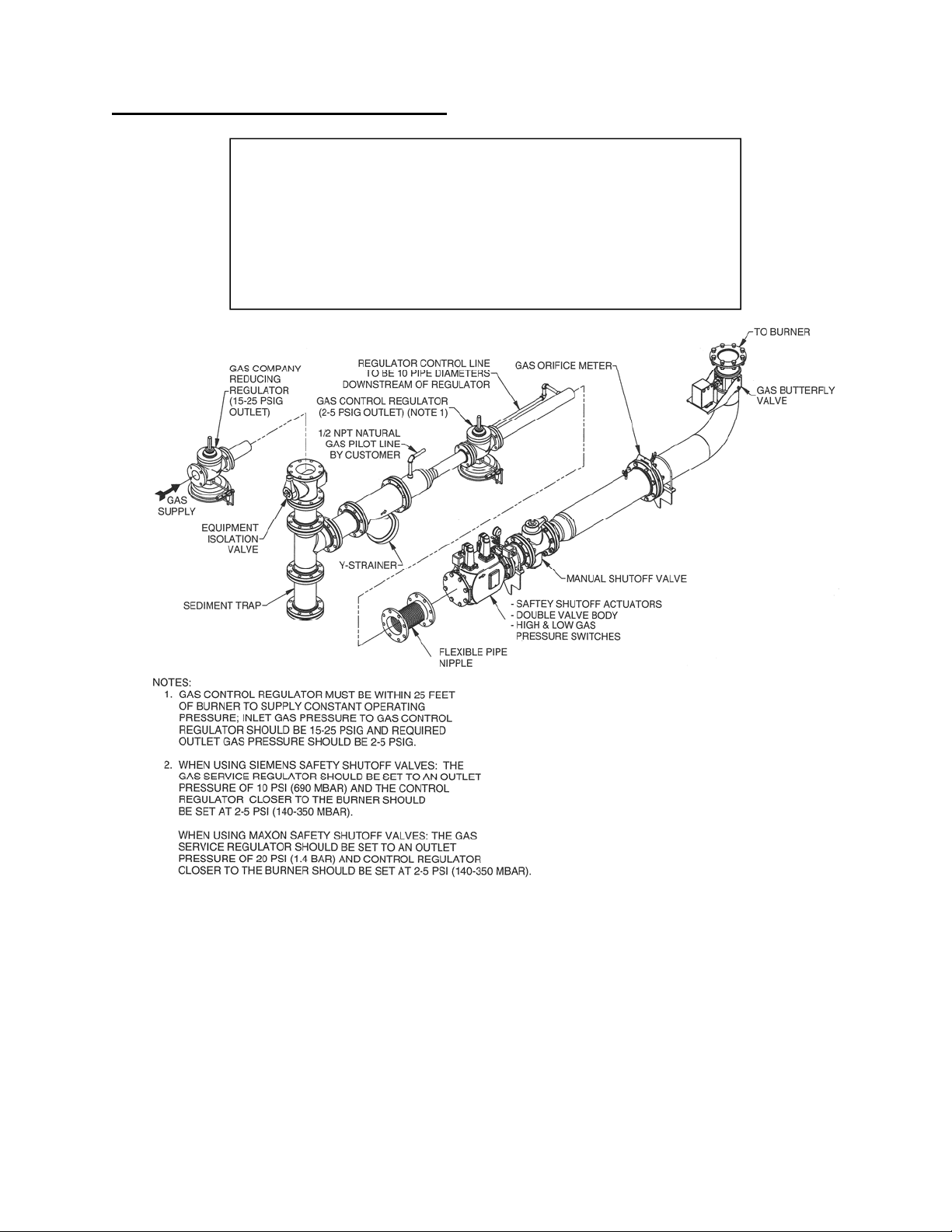

I. NATURAL GAS FUEL PIPING SYSTEM

NOTE

Hauck recommends the use of gas manifolds that meet NFPA

guidelines. NFPA requires two fuel safety shutoff valves wired

in series and a shutoff valve downstream of the second

(blocking) safety shutoff valve, and high and low pressure

switches that are interlocked with the burner's safety shutoff

valves. Hauck gas manifolds have been designed to ensure

compliance to NFPA requirements.

Y7863

(NOT TO SCALE)

Figure 2. Typical Schematic of Burner Gas Piping

1. Install a controlling gas regulator in the main gas line within 25 ft (7.6m) of the burner. This

regulator should be sized to provide the required gas flow at the inlet of the burner manifold.

Exact gas pressure must be set at the initial start-up depending on piping configuration,

burner size, and maximum capacity desired. Regular settings are designed for best

operation and compliance with NFPA 54 (see Figure 2).

2. A manual equipment isolation valve, sediment trap and gas strainer must be installed

upstream of the gas control regulator to ensure compliance to NFPA requirements. The

manual equipment isolation valve facilitates servicing of the gas control regulator, sediment

trap, strainer, and other components in the gas manifold.

3. The gas company should purge the main gas line to remove scale and dirt before it is

attached to the burner gas manifold.

Page 10

MS-9

4. Connect the main gas line (see Figure 2). A flexible pipe nipple should be used to

connect the gas line to the burner gas manifold (see Table 5 for sizes).

Install a flexible fitting between the gas

manifold and the burner gas connection to

reduce vibration stress on the manifold.

IMPORTANT

MegaStar™ Model No. 50 75-100 125-150

FPN Part No. 800598 800599 800600

Size 3” (DN 80) 4" (DN 100) 6" (DN 150)

Table 5. MegaStar™ Burner Recommended Flexible Pipe Nipples

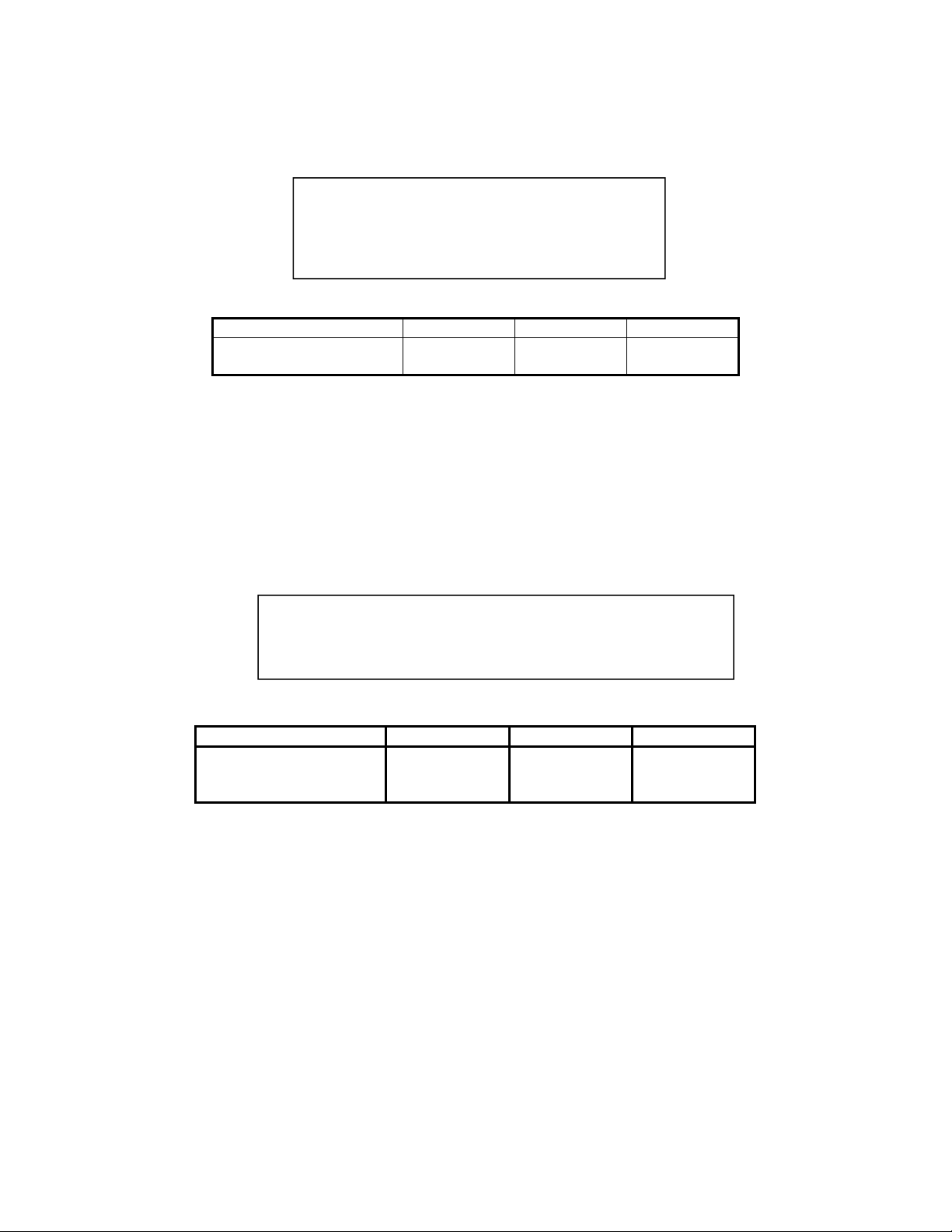

5. The piping from the gas regulator outlet to the burner gas manifold should be sized to

minimize pressure losses. See Figure 3 for pipe pressure losses.

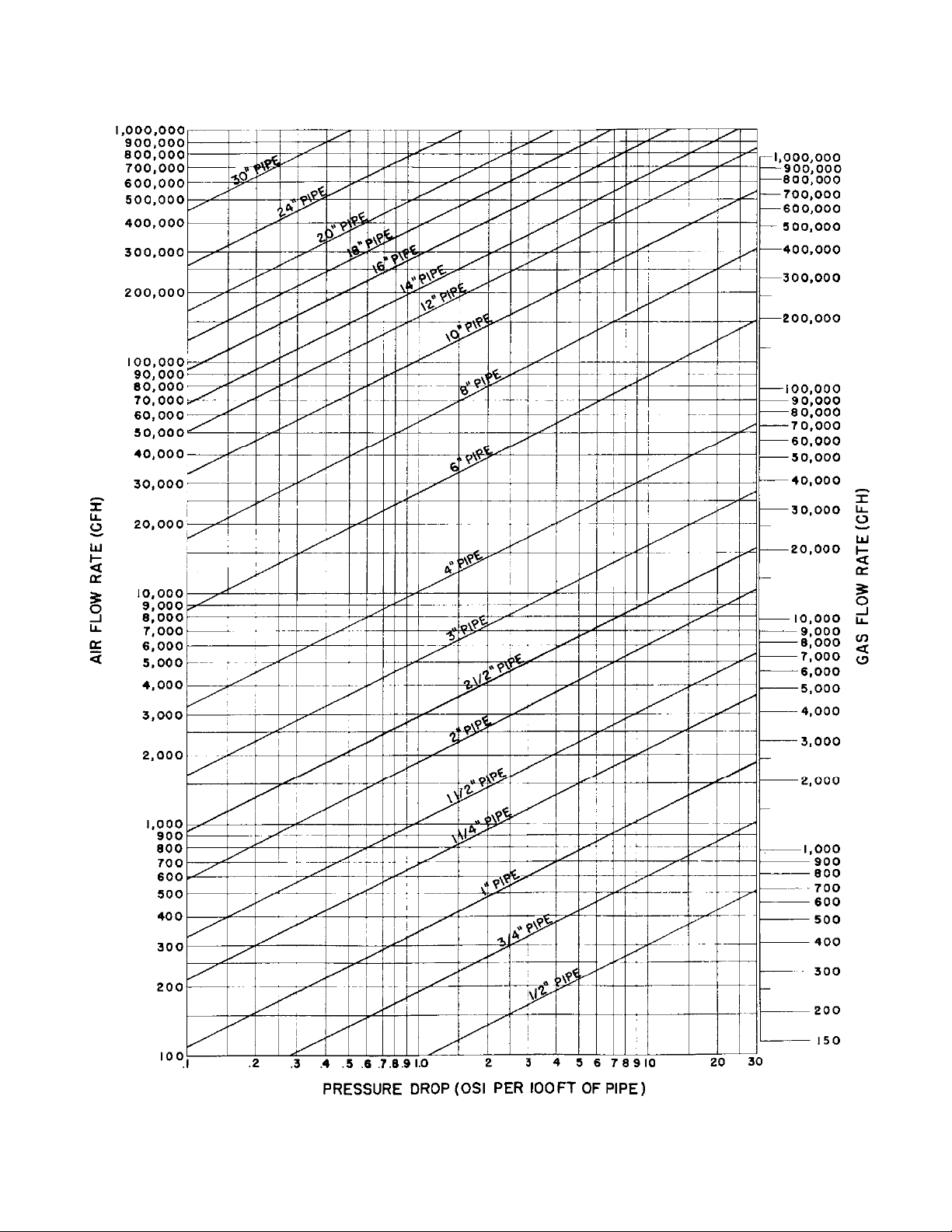

6. The OMG gas orifice meter is an integral part of the gas manifold located on the burner

(refer to Figure 2). Refer to individual burner gas orifice meters graph for gas flows through

the gas orifice meter (see Figure 4). Orifice meter sizes and part numbers are shown below

in Table 6.

Failure to use the gas orifice meter assembly to measure

gas flow will make initial setup and tuning difficult.

IMPORTANT

MegaStar™ Model No. 50 75-100 125-150

OMG Part No. 19816 48242x001 47181x005

Pipe Size 4” (DN 100) 6" (DN 150) 8" (DN 200)

Orifice Size 3.25” (82.5mm) 4.8" (122 mm) 6.0" (152 mm)

Table 6. MegaStar™ Burner Natural Gas Orifice Meter Assemblies

Page 11

MS-9

GL86

Figure 3. Simplified Gas and Air Flow Chart

(@ Atmospheric Conditions)

Page 12

MS-9

Figure 4. MegaStar™ Gas Orifice Meters Graph

Page 13

p

MS-9

J. LIGHT FUEL OIL PIPING SYSTEM

Adjustment of this equipment and its components by

unqualified personnel can result in fire, explosion,

severe

ersonal injury, or even death.

WARNING

Hauck recommends the use of oil manifolds that meet

NFPA guidelines. NFPA requires two safety shutoff

valves piped in series in the burner’s main oil line. A

low/high oil pressure switch must be interlocked with

the burner’s safety shutoff valves. Hauck oil manifolds

have been designed to ensure compliance to NFPA

requirements.

NOTE

1. Hauck recommends using a flexible connection to connect the oil line to the oil manifold

on the burner. A flexible connection will reduce vibration stress on the oil manifold.

Refer to Table 7 for recommended flex connection.

MegaStar™ Model No. 50 75-150

Flex Oil Hose Part No. 11078 20518

Size 1/2" (DN 15) 1" (DN 25)

Table 7. Recommended Flexible Oil Hose Size

2. For recommended piping sizes see Table 8. Before attaching fuel lines, purge the

piping to remove scale and dirt that could clog and damage oil equipment. Follow Figure 5

for the suggested piping layout.

Discharge Piping, Light Oil

MegaStar

Model No.

50 1"

75 1"

100 1"

125 1"

150 1"

Up to 25'

(Up to

7.6m)

(DN25)

(DN25)

(DN25)

(DN25)

(DN25)

Up to 100 SSU

(Up to 2.1 x 10

25'– 49'

(7.6-

14.9m)

1"

(DN25)

1"

(DN25)

1"

(DN25)

1 ¼"

(DN32)

1 ¼"

(DN32)

-5 m2

/sec)

50' – 100'

(15.2-

30.5m)

1 ¼"

(DN32)

1 ¼"

(DN32)

1 ¼"

(DN32)

1 ½"

(DN40)

1 ½"

(DN40)

Return Piping, Light Oil

Up to 100 SSU

(Up to 2.1 x 10-5 m2/sec)

Up to 25'

(Up to

7.6m)

1"

(DN25)

1"

(DN25)

1 ¼"

(DN32)

1 ¼"

(DN32)

1 ¼"

(DN32)

25' – 49'

(7.6-

14.9m)

1 ¼"

(DN32)

1 ¼"

(DN32)

1 ¼"

(DN32)

1 ¼"

(DN32)

1 ¼"

(DN32)

50' – 100'

(15.2-

30.5m)

1 ¼"

(DN32)

1 ¼"

(DN32)

1 ¼"

(DN32)

1 ½"

(DN40)

1 ½"

(DN40)

Up to 25'

(Up to

7.6m)

1 ¼"

(DN32)

1 ¼"

(DN32)

1 ¼"

(DN32)

1 ½"

(DN40)

1 ½"

(DN40)

Return Piping

Heavy Oil

25'– 49'

(7.6-

14.9m)

1 ½"

(DN40)

1 ½"

(DN40)

1 ½"

(DN40)

2"

(DN50)

2"

(DN50)

50' – 100'

(15.2-

30.5m)

2"

(DN50)

2"

(DN50)

2"

(DN50)

2"

(DN50)

2"

(DN50)

Table 8. Minimum Pipe Size For Hauck Oil Supply Pumping Units

3. Adjust the bypass relief valve until required oil pressure is achieved. See Table 9 for

approximate settings. Final oil pressure will have to be adjusted to attain desired burner

output and stack exhaust gas analysis.

Page 14

MS-9

MegaStar™

Model No.

50 75 psig (5.15 bar) 90 psig (6.20 bar)

75 75 psig (5.15 bar) 90 psig (6.20 bar)

100 85 psig (5.85 bar) 100 psig (6.90 bar)

125 65 psig (4.50 bar) 90 psig (6.20 bar)

150 80 psig (5.50 bar) 100 psig (6.90 bar)

Nominal Oil Pressure

w/Low Pressure Atomizer

Nominal Oil Pressure

w/Compressed Air Atomizer

Table 9. Nominal Light and Heavy Fuel Oil Pressure to Burner Manifold Inlet

4. The low/high oil pressure switch is factory set at a low set point of 15 psig (1.03 bar)

and a high set point of 80 psig (5.5 bar). Set point adjustments may be required

depending on the burner and fuel piping specifics.

5. Inspect the complete fuel oil system for oil leaks and repair as necessary. Do not

operate the burner until all fuel leaks are repaired.

6. The burner oil flow control (metering) valve is preset to travel from position 2 to 11.

The low fire oil flow setting can be changed by loosening the coupling connecting the oil

valve to the control motor, adjusting the oil valve pointer, and re-tightening the coupling. The

high fire oil flow setting can be changed via the burner control system, or if necessary, by

increasing or decreasing fuel oil pressure. See the individual burner performance sheets for

fuel oil flow data.

Any adjustment to the fuel oil flow settings should be

made as a minor incremental change and verified that it

has not resulted in any detrimental effect to plant

operation prior to making another adjustment.

CAUTION

Fuel oil flow settings per the individual burner

performance sheets are for initial set-up only.

Final settings may have to be readjusted for

required operation.

NOTE

7. Fuel oil flow rates can be checked with the in-line oil flow meter on the burner fuel

oil manifold. The flow meter glass can be rotated to view the scale if required.

Page 15

MS-9

X7864

(NOT TO SCALE)

Figure 5. Typical Schematic of Burner Light Fuel Oil Piping

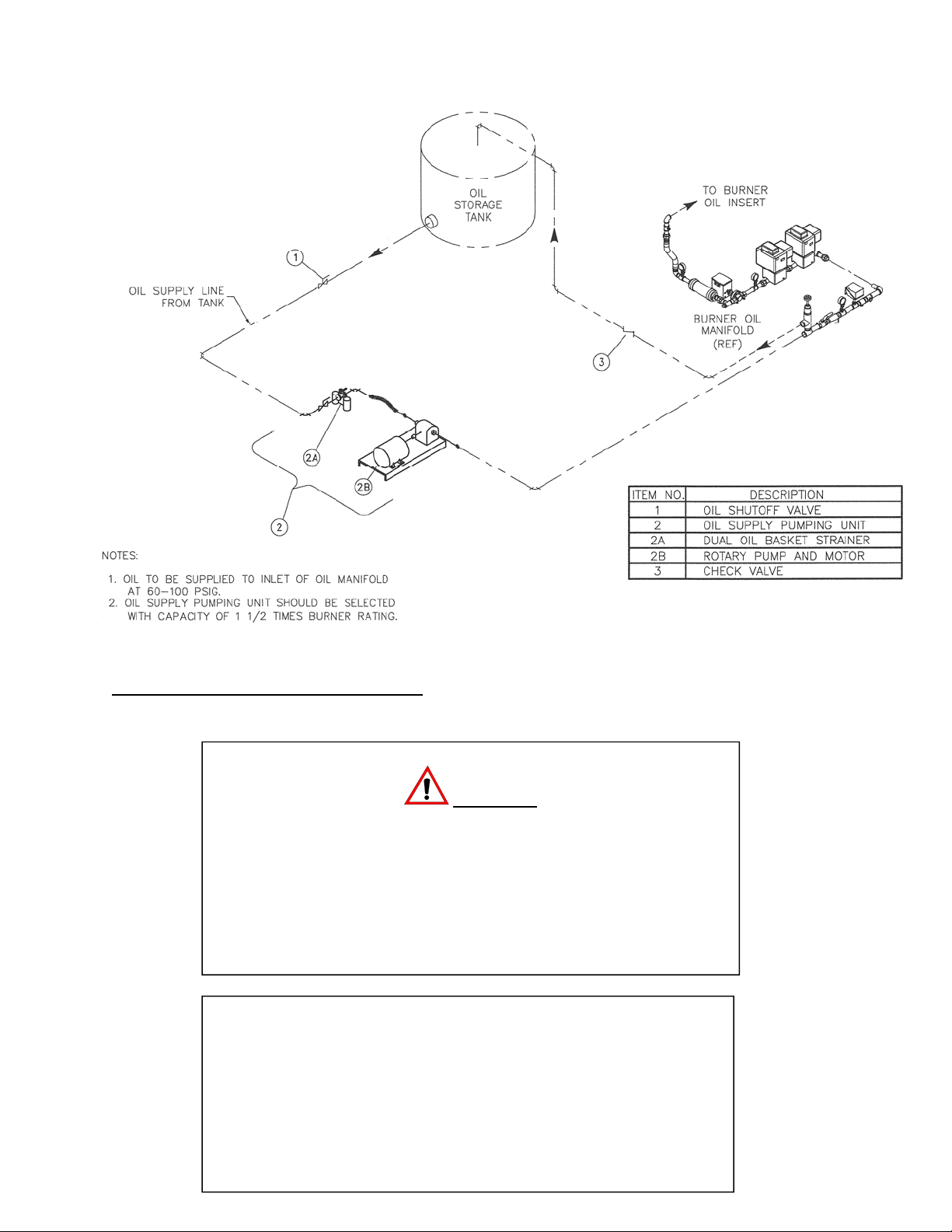

K. HEAVY FUEL OIL PIPING SYSTEM

Adjustment of this equipment and its components by unqualified

personnel can result in fire, explosion, severe personal injury, or

even death.

Heated fuel oil and piping is hot. Precautions should be taken to

avoid contact with heated oil and piping. Proper insulation should

be installed on hot oil pipes. Protective gloves, clothing and a face

shield are recommended when working with heated oil.

IMPORTANT

For all heavy fuel oil applications, i.e., any oil requiring heating for

use, oil piping must be heat traced (electric or steam) and

insulated. Self-regulating heat tracing is recommended to

maintain the desired temperature of a given fuel oil to achieve 90

SSU (1.8 x 10

-5 m2

/sec) or less at the burner. Electrical heat tracing

with a nominal rating of 12W/ft (39W/m) covered with a nominal 2"

(50mm) fiberglass type insulation is sufficient for most applications.

WARNING

Page 16

MS-9

Hauck recommends the use of oil manifolds that meet NFPA

guidelines. NFPA requires two safety shutoff valves piped in series in

the burner’s main oil line. A low/high oil pressure switch must be

interlocked with the burner’s safety shutoff valves. When preheated oil

is used, a low/high oil temperature limit switch must be interlocked with

the burner’s safety shutoff valves. Hauck oil manifolds have been

designed to ensure compliance to NFPA requirements. Hauck

recommends the use of a ‘Heavy Oil Kit’ whenever heavy fuel oil is

used. The components of the heavy oil kit are identified in Figure 6.

NOTE

1. For recommended piping sizes see Table 8. Before attaching fuel lines, purge the piping

to remove scale and dirt that could clog and damage oil equipment. See Figure 6 for the

suggested piping layout.

2. Heavy fuel oil must be 90 SSU (1.8 x 10

-5 m2

/sec) or less for proper atomization and

burning. Use a Hauck viscometer kit (order separately - Part No. 36931) to determine

proper oil temperature to achieve this viscosity. Refer to the instructions that are supplied

with the kit for proper use. In general, the viscosity can be lower than 90 SSU (which

means higher oil temperature) if the fuel is not forming vapor (or steam) pockets in the oil

lines. Vapor pockets can cavitate the pumps used on suction type oil heaters.

3. Set the fuel oil heater temperature set point and the indicating low oil temperature switch

(located on the burner’s oil manifold) to the temperature determined from step 2.

4. Adjust the bypass relief valve until the required oil pressure is achieved. See individual

burner performance sheets for approximate settings. Final oil pressure will have to be

adjusted to attain desired burner output and stack exhaust gas analysis.

5. The low/high oil pressure switch is factory set at a low set point of 15 psig (1.03 bar) and a

high set point of 80 psig (5.5 bar). Set point adjustments may be required depending on

the burner and fuel piping specifics.

6. Inspect the complete fuel oil system for oil leaks and repair as necessary. Do not operate

the burner until all leaks are repaired.

7. The burner oil flow control (metering) valve is preset to travel from position 2 to 11. The low

fire oil flow setting can be changed by loosening the coupling connecting the oil valve to the

control motor, adjusting the oil valve pointer, and re-tightening the coupling. The high fire oil

flow setting can be changed via the burner control system, or if necessary, by increasing or

decreasing fuel oil pressure. See the individual burner performance sheets for fuel oil flow

data.

Any adjustment to the fuel oil flow settings should be

made as a minor incremental change and verified that it

has not resulted in any detrimental effect to plant

operation prior to making another adjustment.

CAUTION

Page 17

MS-9

Fuel oil flow settings per the individual burner

performance sheets are for initial set-up only.

Final settings may have to be readjusted for

required operation.

NOTE

8. Fuel oil flow rates can be checked with the in-line oil flow meter on the burner fuel oil

manifold. The flow meter glass can be rotated to view the scale if required.

X7872

(NOT TO SCALE)

Figure 6. Typical Schematic of Burner Heavy Fuel Oil Piping

Page 18

MS-9

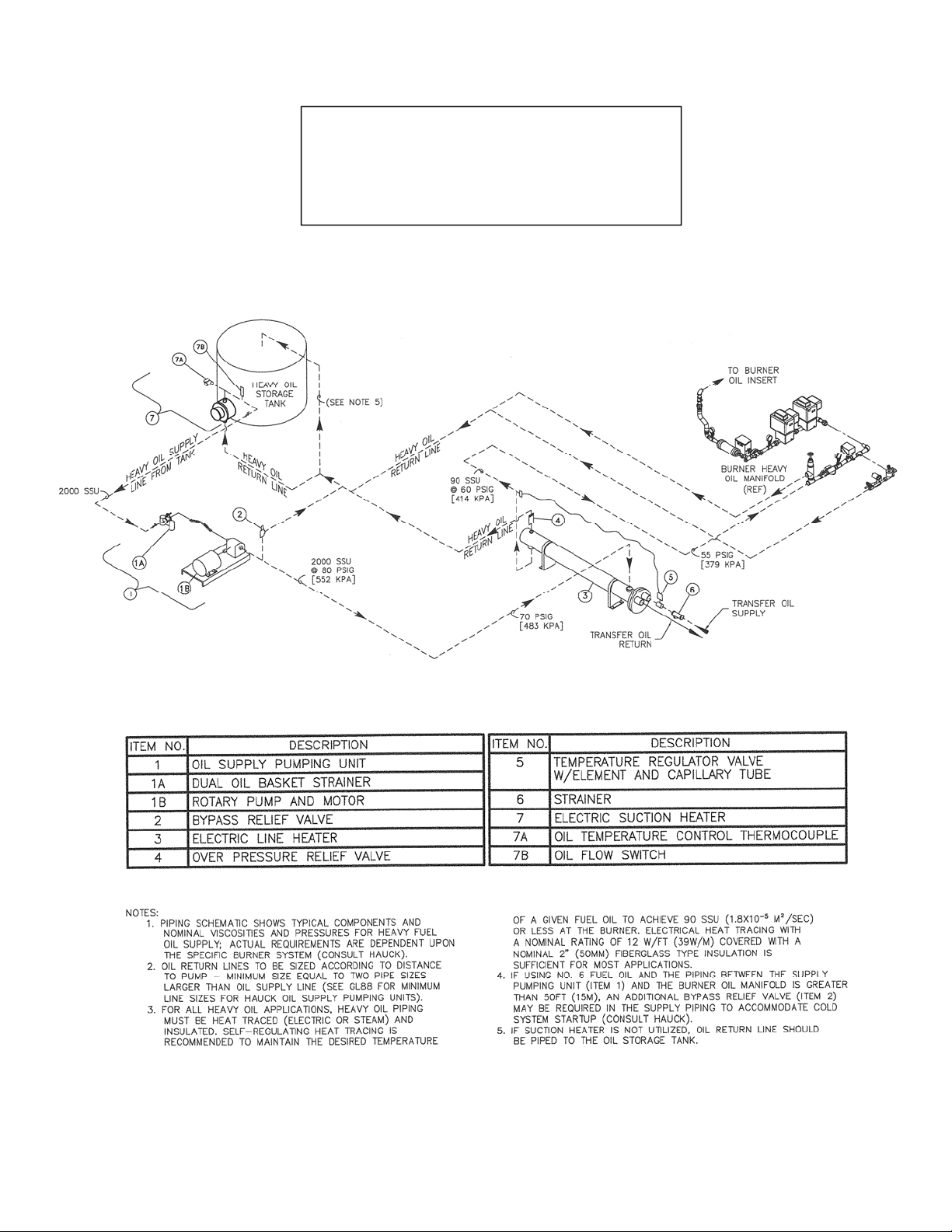

L. OIL MANIFOLD HEAT TRACING

For heavy, waste, or recycled oil applications, the oil manifold piping must be heat traced and

insulated to maintain the desired temperature, and hence, viscosity, of the fuel oil (see Figure

7). The Hauck heat tracing kit installed on the heavy oil manifold will aid in viscosity control and

reliable main flame ignition of the burner. The oil manifold heat tracing kit consists of heat

tracing cable which is wrapped around all piping, and covered with fiberglass insulation and

jacketing.

X8046

(NOT TO SCALE)

Figure 7. Heavy Oil Manifold Heat Tracing Kit

120V/60Hz power for the oil manifold heat tracing kit

must be supplied separately by the customer and wired

into the heat tracing power connection box.

NOTE

The heat tracing cable is self-regulating with a nominal rating of 12 W/ft (39 W/m). When the

circuit breaker switch to the oil manifold heat tracing kit is energized, the self-regulating heat

tracing will automatically switch on and off based on heat demand.

M. HEAVY OIL INSERT HEATER

Heavy, waste, or recycled fuel oils require some means of viscosity control. The Hauck heavy

oil insert heater installed in the burner’s oil tube (see Figure 8) is a perfect solution to the

viscosity control problem and reliable main flame ignition of the burner at cold temperatures.

The heavy oil insert heating element, in conjunction with the oil temperature indicating

controller, will maintain an optimum oil temperature in the oil tube to ensure a reliable burner

main flame ignition after an extended shutdown of the burner.

Page 19

MS-9

V7867

(NOT TO SCALE)

Figure 8. Heavy Oil Insert Heater

120V/60Hz power for the heavy oil insert heater

must be supplied separately by the customer

and wired into the heater junction box.

NOTE

Operation of the heavy oil insert kit is as follows (see Figure 8):

1. Adjust the low oil temperature controller to the desired temperature as determined in Section

K from testing of the heavy fuel oil viscosity.

Adjusting the trip setpoint above the required temperature, as

determined by fuel oil viscosity testing, may result in coking of

the fuel oil in the oil insert assembly piping.

NOTE

2. Energize the insert heater circuit breaker switch.

3. When the oil temperature exceeds the setpoint on the oil temperature indicating controller,

the oil temperature indicating controller switch contact will open and power to the heater

element is removed.

4. When the oil temperature drops below the setpoint on the oil temperature indicating

controller, the oil temperature indicating controller switch contact will close and the heater

element will energize.

See ESII-9.2 Heavy Oil Insert Heater Kit Instructions for more specific detail on the operation

and maintenance of the heavy oil insert heater.

Page 20

MS-9

N. FUEL OIL NOZZLE

The position of the fuel oil atomizer affects its ability to atomize the oil. The compressed air

atomizer or low pressure atomizer should be positioned as shown in Figure 9.

Ensure that the correct atomizer

is being used when firing oil.

Figure 9. Oil Nozzle Position

CAUTION

W7868

(NOT TO SCALE)

To change the low pressure oil nozzle position:

1. Shut off the manual oil valve at the burner. The burner must not be firing and the atomizing

air fan must be shut off.

2. If heated heavy oil is being used, allow the oil in the pipe to cool to avoid burns. Drain

residual fuel into an appropriate container.

3. Note the present orientation of the oil nozzle in the burner. Determine if the oil nozzle must

be retracted into or extended out of the primary air tube (see Figure 9).

4. Remove the bolts securing the backplate to the burner, and disconnect the pilot air pipe.

5. Loosen the jam nut on the backplate of the burner oil insert assembly.

6. Rotate the backplate to effect the required retraction or extension of the oil atomizer nozzle.

One full rotation of the backplate will move the atomizer approximately 0.1" (2.5mm).

7. Once the proper positioning of the atomizer is completed:

a. Tighten the jam nut.

b. Attach the burner oil insert assembly to the oil manifold, using the union provided.

c. Open the manual oil valve and check for leaks using accepted practices.

Page 21

MS-9

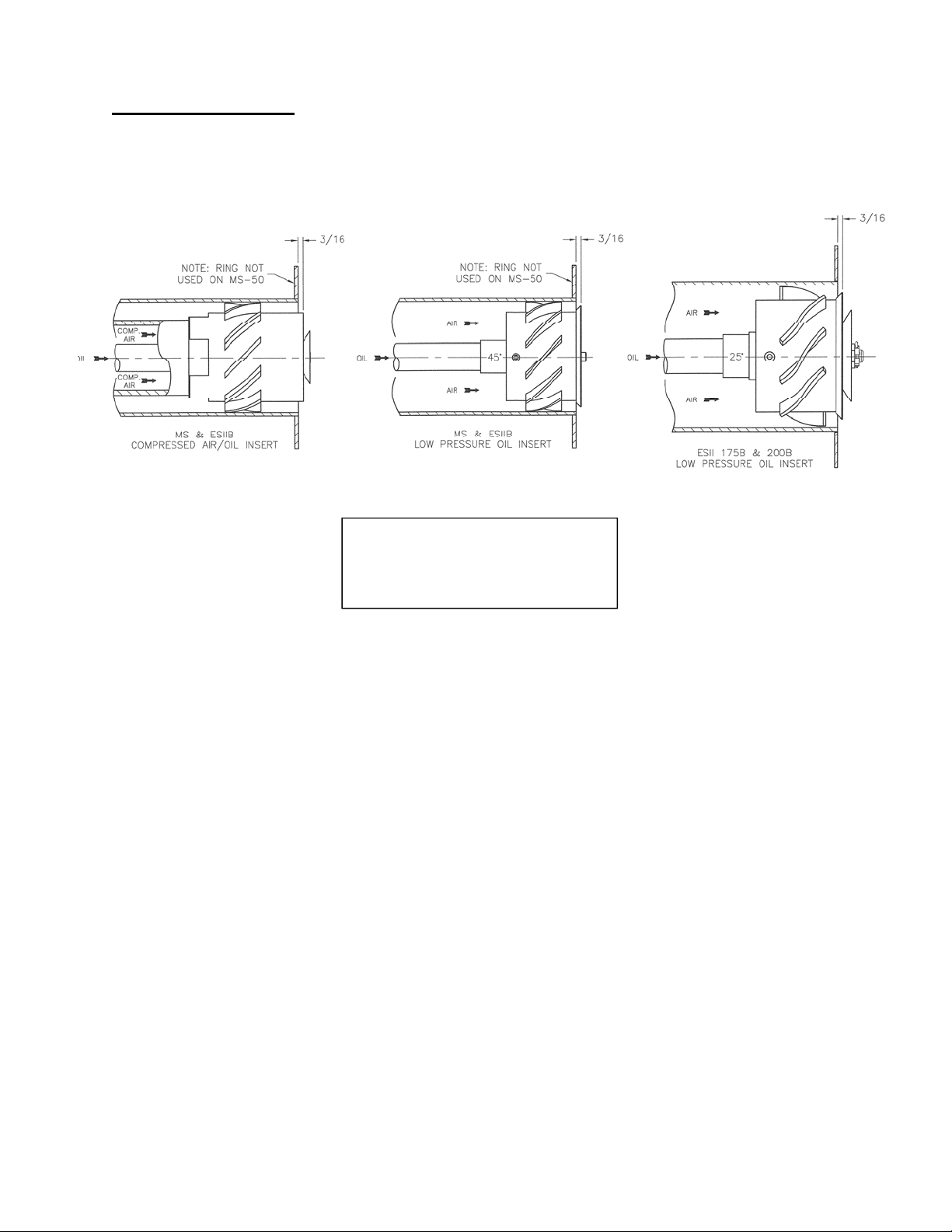

O. COMPRESSED AIR/OIL ATOMIZER

The Hauck high pressure oil nozzle is designed to finely atomize No. 2 fuel oil and clean

preheated No. 4, No. 5 and No. 6 fuel oil. Oil viscosity should be 90 SSU (1.8 x 10

-5 m2

/sec) or

less. Preheat fuel oil and heat trace piping using No. 4, No. 5 and No. 6 fuel oil to achieve 90

SSU oil at the burner (see Compressed Air/Oil Adjustment).

Care should be taken to insure that the air and oil supplied to the burner are free of dirt particles

and water. Purge oil and air lines before connecting them to the compressed air/oil insert. The

nozzle should be inspected and cleaned before the start of each session and possibly more

depending on the cleanliness of the air and fuel.

COMPRESSED AIR PIPING

1. The compressed air supply line must be of adequate size (see Table 10) and be a dedicated

line from the compressor to the burner compressed air inlet. For longer runs than those listed

in the table, increase the hose by one pipe size. Before attaching lines, purge the hose to

remove any dirt that could clog and damage the oil atomizer.

MegaStar

Model No.

TM

Min. Hose

Size

Max. Hose

Length

75-100 3/4 NPT (DN20) 70 ft (21m)

125-150 1 NPT (DN25) 160 ft (49m)

Table 10. Flexible Air Hose Size Requirements

2. Compressed air requirements are listed in Table 11. Compressed air must be supplied to

the inlet of the compressed air manifold at a minimum of 90 psig (620 kPa). The

compressed air regulator modulates the compressed air flow as oil flow is modulated to

reduce compressed air consumption at lower firing rates.

The compressed air low supply pressure switch and low

atomizing pressure switch must both be interlocked with

the burner’s oil safety shutoff valves.

The compressed air solenoid valve is normally wired in

parallel with the burner’s safety shutoff valves.

Reference the control panel drawings for wire and/or

terminal numbers.

NOTE

Page 22

MS-9

MegaStar

Model No.

75/100

Air Flow

TM

Oil Flow

Oil Pressure

To Burner

Nozzle

Compressed

(gpm) (lpm) (psig) (kPa) (scfm) (nm3/min) (psig) (kPa)

12 45.4 60 414 60 1.6 55 379

9 34.1 50 345 52 1.4 44 303

Compressed

Air Pressure

To Burner

Nozzle

6 22.7 38 262 48 1.3 32 221

1.25 4.7 24 165 42 1.1 17 117

125/150

18 68.1 60 414 90 2.4 50 345

10 37.9 36 248 85 2.3 30 207

5 18.9 23 159 82 2.2 20 138

3 11.4 20 138 80 2.1 19 131

Table 11. Compressed Air and Oil Requirements

3. When firing the burner with the compressed air atomizer, the threaded pipe plug must be

removed from the primary air tube. If using the low pressure oil or liquid propane nozzles,

the pipe plug must be installed in the primary air tube. When firing natural gas the pipe

plug can be installed or removed. The pipe plug is accessible through the main fan

housing access door (see Figure 11).

COMPRESSED AIR/OIL ADJUSTMENT

1. Air and fuel flows and pressures can be observed at the burner using the compressed air

and fuel flow meters and corresponding pressure gauges (see Figure 10). For compressed

air data in addition to Table 11, see individual MegaStar

TM

capacity and performance sheets.

2. Compressed air supply pressure to the inlet of the compressed air manifold must be 90 psig

(620 kPa) or greater. The supply pressure is measured via the gauge on the inlet to the

compressed air flow meter (see Figure 10). The compressed air low supply pressure switch

is preset at 60 psig (414 kPa). Set point adjustment may be required depending on the

burner and compressed air piping specifics.

3. For the compressed air manifold with regulator to function properly, the impulse line and

upper chamber of the pressure reducing regulator must be loaded with oil by opening the

vent valve on the regulator until oil vents then closing the vent valve.

4. Final compressed air flow and pressure adjustment is made via the compressed air trim

valve (see Figure 10). With the burner at high fire, adjust the trim valve until the compressed

air burner inlet pressure gauge, located downstream of the trim valve, reads approximately

60 psig (414 kPa). The compressed air low atomizing air switch is preset at 5 psig

(34.5 kPa). Set point adjustment may be required depending on the burner and compressed

air piping specifics.

5. Compressed air flow can be read directly from the compressed air flow meter

(see Figure 10). Refer to Figure 12 for detailed instructions on how to head the compressed

air flow meter. Verify that both the compressed air flow and burner inlet pressure, from step

4, meet or exceed the values given in Table 11 and/or the additional burner capacity and

performance data sheets.

Page 23

MS-9

For all heavy fuel oil applications, i.e., any oil requiring heating for

use, oil piping must be heat traced (electric or steam) and

insulated. Self-regulating heat tracing is recommended to

maintain the desired temperature of a given fuel oil to achieve 90

SSU (1.8 x 10

-5 m2

/sec) or less at the burner. Electrical heat tracing

with a nominal rating of 12W/ft (39W/m) covered with a nominal 2"

(50mm) fiberglass type insulation is sufficient for most applications.

IMPORTANT

Y7041

(NOT TO SCALE)

Figure 10. Compressed Air Manifold Detail

Page 24

MS-9

W7084

(NOT TO SCALE)

Figure 11. Primary Air Tube Pipe Plug Location

COMPRESSED AIR FLOW METER

The compressed air flow meter is offered with a standard multi-pressure flow scale.

The multi-pressure flow scale has a vertically graduated scale, calibrated for air in standard

cubic feet per minute (scfm) at 1.0 s.g. (70°F at 100 psig), or liters per second (lps) at 1.0 s.g.

(21°C at 6.9 bar). The multi-pressure scale design allows for use at supply pressures from 40 130 psig in 10 psig increments (3.0 - 9.0 bar in 1 bar increments) .

To determine the compressed air flow rate, refer to Figure 12 and proceed as follows:

1. Read the inlet pressure on the pressure gauge of the compressed air flow meter.

2. Select the appropriate inlet pressure (psig) vertical line, or interpolated value closest to the

gauge reading, and follow the line upward until it intersects the brightly colored horizontal

indicator bar.

3. From the intersecting point on the horizontal indicator bar, follow the slope as shown on

the diagonal lines to the 100 psig inlet pressure vertical line and interpolate the scfm or

lps flow rate (Note for the example shown in Figure 12, with an inlet pressure of 60 psig,

the compressed air flow rate is approximately 40 scfm).

Page 25

MS-9

Figure 12. Compressed Air Flow Meter and Scale

To change the compressed air/oil nozzle position.

1. Ensure that the burner is not firing, then close the manual oil valve and the manual

compressed air ball valve at the burner. The burner must not be firing

2. If heated heavy oil is being used, allow the oil in the pipe to cool to avoid burns. Drain

residual fuel into an appropriate container.

3. Note the present orientation of the air/oil nozzle in the burner. Determine if the air/oil

nozzle must be retracted into or extended out of the primary air tube (see Figure 9).

4. Loosen the two set screws on the backplate lock collar of the air/oil insert assembly.

5. Slide the insert assembly to effect the required retraction or extension of the air/oil nozzle.

6. Once the proper positioning of the air/oil nozzle is completed:

a. Tighten the two setscrews in the backplate lock collar.

b. Attach the air/oil insert assembly to the oil manifold, using the union provided.

c. Open the manual oil valve. Check for leaks using accepted leak check practices.

Page 26

MS-9

P. LIQUID PROPANE (LP) FUEL PIPING SYSTEM

WARNING

Adjustment of this equipment and its components by unqualified personnel can

result in fire, explosion, severe personal injury, or even death.

LP is highly flammable and heavier than air. It will accumulate near the ground in

the area of a leak and will dissipate relatively slowly. LP or Butane in its liquid state

can cause freezing and severe injury.

Hauck does not recommend installation of a line-reducing regulator in the LP

supply line. If the regulator diaphragm were to total system pressure would be

applied to the burner and could result in damage to equipment, including the

baghouse, and result in serious injury to personnel.

Hauck recommends the use of LP manifolds that meet NFPA guidelines. NFPA

requires two safety shutoff valves piped in series in the burner's main LP line. A

low/high pressure LP switch must be interlocked with the burner's safety shutoff

valves. Hauck's LP manifolds have been designed to ensure compliance to NFPA

requirements. All piping must be installed in compliance with applicable piping

codes and regulations. Equipment must meet the ratings for service as indicated in

NFPA 58.

NOTE

1. LP or butane is supplied to the MegaStar™ burner in a liquid form and is vaporized as the

fuel exits the burner nozzles.

2. Hauck recommends using a flexible connection to connect the LP line to the burner. A

flexible connection will reduce vibration stress on the LP connection. Refer to Table 12 for

recommended flex connection. Follow Figure 13 for the suggested piping layout.

MegaStar™ Model No. 50 75-100 125-150

Flexible LP Hose Part No. 45754 45755 47533

Size 3/4" NPT (DN15) 1" (DN25) 1¼" (DN32)

Table 12. Recommended LP Flexible Hose Size

3. Before attaching LP fuel lines, purge the lines with compressed air. Then, leak test piping

with compressed air.

4. Connect the main LP line at the appropriate connection on the burner skid. The capacity of

the LP fuel system should be 1.5 times the rated capacity of the burner.

5. If Hauck has supplied the LP pump set for this application, consult the pump installation

instructions for information on the unit.

If the burner is being converted from natural gas or oil to LP firing, the diverter ring

located on the end of the primary air tube assembly must be removed (consult

Hauck for details). Also, the LP nozzle must be removed prior to converting the

burner to natural gas firing to avoid damage to the LP nozzle.

NOTE

Page 27

MS-9

Figure 13. Typical Schematic of LP Piping

NOTE

The LP piping system shown in Figure 13 is designed for optimum

performance at ambient air temperatures above 40

ambient temperatures below 40

Hauck strongly recommends that a bypass flow control valve and a

backpressure regulator be installed in all LP systems and piped as shown in

Figure 13.

o

F, consult Hauck for recommendations.

CAUTION

o

F (5°C). For operation in

6. After completing piping, check all LP lines and connections for leaks following accepted

standards and practices. Do not operate the system until all leaks are repaired.

X7869

(NOT TO SCALE)

Page 28

MS-9

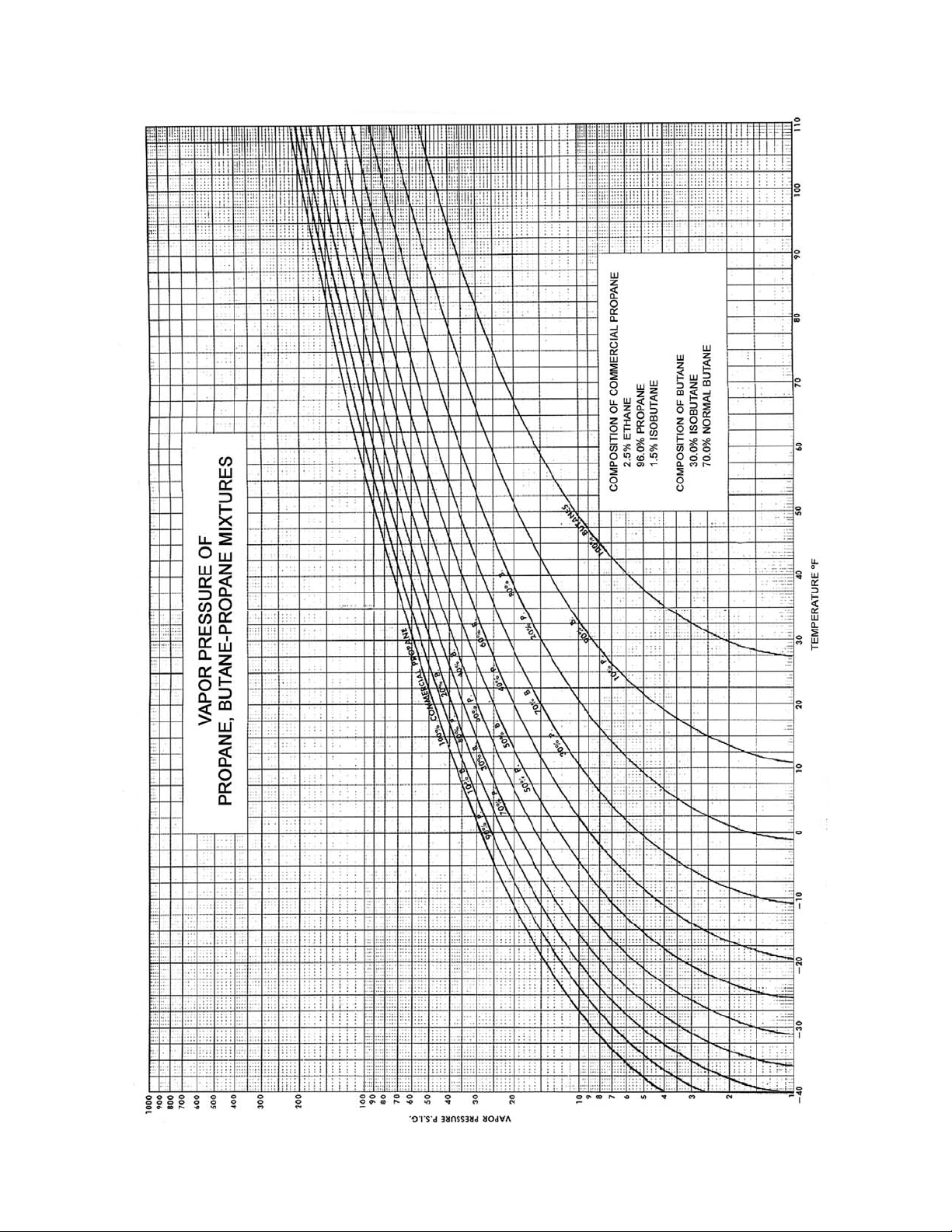

7. Adjustment of LP supply pressure: (see Table 13 for recommended settings).

a. Install an amp probe on the LP pump power supply line.

b. Close the ball valve between the back pressure regulator and the tank to temporarily

take the regulator out of the system (see Figure 13).

c. The bypass flow control valve is used as a system safety. Normally set at 50 psig

(345 kPa) above the maximum expected tank pressure, it operates only in the case of

a back pressure regulator failure.

d. Adjust the bypass flow control valve to the following initial settings:

100% Commercial Propane 235 psig (16.20 bar)

50/50 Propane/Butane 170 psig (11.70 bar)

100% Butane 95 psig (6.55 bar)

e. The back pressure regulator functions as the primary control in setting the LP supply

pressure to the burner. To adjust the back pressure regulator, open the ball valve

between of the back pressure regulator and the tank, and adjust the regulator to an

initial setting of 25 psig (172 kPa) below the flow control valve setting.

f. Adjust the back pressure regulator to the following initial settings:

100% Butane 70 psig (4.80 bar)

If pump motor nameplate amperage is exceeded, reduce

pressure in Step 7.d to below nameplate amp rating.

Frost or icing is an indication of an LP leak. It is

possible for a leak to occur without such evidence.

Although the LP supply is initially in a liquid state, as it

is vaporized it becomes heavier than air and

accumulates near the ground and dissipates relatively

slowly, becoming highly flammable. Extreme care

should be exercised with LP fuels and systems.

Do not exceed the minimum LP pump motor nameplate

amp load at any time while making adjustments.

100% Commercial Propane 210 psig (14.50 bar)

50/50 Propane/Butane 145 psig (10.00 bar)

WARNING

CAUTION

NOTE

Page 29

MS-9

g. The low/high LP pressure switch is factory set at a low set point of 165 psig (1140 kPa)

and a high set point of 230 psig (15.9 bar). The low pressure switch setting should be

approximately 15 psig (1.03 bar) below the back pressure regulator setting.

h. Check with your LP supplier for the exact maximum expected tank pressure for your fuel.

8. The burner LP flow control (metering) valve is preset based on flow required from low to

high fire. The low fire LP setting can be changed by loosening the coupling connecting the

LP valve to the control motor, adjusting the LP valve pointer, and re-tightening the coupling.

The high fire LP flow can be changed via the burner control system, or if necessary , by

increasing or decreasing LP pressure. See the individual burner performance sheets for LP

fuel flow data and settings. If the burner LP fuel control valve continually freezes at low fire,

increases LP flow slightly until freezing stops. If the burner LP nozzle continually freezes it

usually indicates that water is in the fuel. Contact your LP fuel supplier about the addition of

methanol to your LP fuel tank.

Any adjustment to the LP fuel flow settings should be

made as a minor incremental change and verified that it

has not resulted in any detrimental effect to plant

operation prior to making another adjustment.

CAUTION

LP fuel flow settings per the individual burner

performance sheets are for initial set-up only.

Final settings may have to be readjusted for

required operation.

NOTE

9. Different size nozzle holes are required on propane, butane, or mixtures of both to assure

optimum vaporization and combustion. If using a butane or propane / butane mixture, be

sure to specify the fuel when ordering and consult Hauck for specific nozzle hole sizes.

10. The MegaStar

TM

utilizes a multi-port LP nozzle assembly positioned around the primary air

tube. Atomizing air supplied from an auxiliary blower assists in mixing and vaporizing the

propane. The nozzle assembly incorporates a series of holes and nozzles to control the LP

flow. Check for plugged nozzle holes by removing the nozzle from the burner and running

water through it to make sure all the holes are clear. Clean any blocked holes and return

the nozzle to its original position.

Max. Tank Temp.

(°F) (°C) (psig) (bar) (psig) (bar) (psig) (bar)

70 21 175 12.10 125 860 75 520

80 27 190 13.10 140 965 80 550

90 32 215 14.80 160 1,100 85 585

100 38 230 15.90 170 1,170 95 655

100% Propane

50% Propane

50% Butane

100% Butane

Table 13. Recommended Burner Supply Fuel Pressures

Page 30

MS-9

Figure 14. Vapor Pressures of Propane, Butane and Butane-Propane Mixtures

Page 31

MS-9

Q. LIQUID PROPANE (LP) NOZZLE

To install the liquid propane (LP) nozzle, it is necessary to work on both the front and rear of the

burner. All necessary safety procedures should be followed to ensure that work can be

performed on both ends of the burner. The LP nozzle will appear different depending on the

operating capacity of the burner, see figure 15 for details. The following procedure should be

followed when installing the LP nozzle.

1. Check the primary tube for a choke ring (Figure 16). If the choke ring is present, it must be

removed to accept the LP nozzle.

2. Remove the access door from the rear of the burner air housing. Verify that a 2" NPT pipe

plug is installed in the primary air tube. (see Figure 17)

3. Loosen the lock nut and insert backplate from the LP insert.

4. From the front end of the burner, insert the nozzle and feed piping from the primary tube.

5. When properly installed, LP nozzle rests against the secondary air tube (Figure 16). NOTE:

On the ESII175B and ESII200B, the primary tube will contact a stop in the nozzle.

6. Align the nozzle as shown in Figure 16. Tighten setscrews on the nozzle and reinstall the

insert backplate and lock nut.

W9048

(NOT TO SCALE)

Figure 15. LP Nozzle Orientation

Page 32

MS-9

W9048

(NOT TO SCALE)

Figure 16. Burner Front End

W9048

(NOT TO SCALE)

Figure 17. LP Insert

Page 33

MS-9

R. BURNER PILOT SYSTEM

The MegaStar™ incorporates a gas pilot with induced air (see Figure 18). The pilot is detected

by the main burner UV scanner which is factory mounted and wired. The pilot is properly

installed as delivered and should not need to be moved or adjusted. Note, UV scanner is

shipped loose.

1. Before connecting to the pilot assembly gas line, the gas line should be purged to remove

any dirt. Pipe the pilot gas supply line to the inlet of the pilot gas shutoff valve and check for

leaks. Size the pilot gas supply line to avoid excessive pressure drops. For pilot gas

supply lines up to 25 ft (7.6m), use 1/2 NPT (DN 15) or larger piping.

2.

Constant gas pressures ranging from 15 psig (1.03 bar) minimum to 25 psig (1.72 bar)

maximum must be available at the inlet of the Hauck gas pilot manifold. Pilot capacity

should not exceed 150,000 Btu/hr (44kW).

3. The spark wire gap is factory set at 1/8" (3mm). This gap can be changed by carefully

removing the pilot internals. Bend the spark wire to adjust, reinsert, and check the gap.

For field adjustment, a U.S. 5¢ coin with 0.08" (2mm) thickness can be used as a

gauge for adjusting the spark gap.

W9003

(NOT TO SCALE)

Figure 18. Pilot Manifold Detail

4. Complete the initial pilot adjustment of the air shutter as follows (see Figure 18):

a. Loosen, but do not remove, the locking thumbscrew.

b. Adjust the air shutter to approximately 1/4" (6.4mm) gap opening.

c. Securely tighten the locking thumbscrew.

d. Slowly open the gas flow valve and light the pilot by means of electric ignition.

The pilot ignition transformer can cause an electric shock - use care around

the ignition cable. When test firing the pilot, leave pilot gas on briefly. If pilot

does not light quickly, shut it off and repurge before attempting to relight.

CAUTION

Page 34

MS-9

S. PRIMARY AIR

Primary air is used for improved mixing at low fire on LP fuel, and for the optional low pressure

atomization of oil fuel. Hauck offers a TBA blower for primary air supply. The primary air blower

is supplied with an outlet flange to mate to the air connection on the burner. Piping between the

blower and the burner is not supplied with the burner. Once installed, verify that no air leaks

exist between the blower and the burner. If leaks exist, burner efficiency will be reduced.

T. BURNER SETUP

Adjustment of this equipment by unqualified personnel

can result in fire, explosion, severe personal injury, or

even death.

WARNING

These settings are for initial setup only. Final settings will have

to be readjusted for required operating conditions.

NOTE

Use of individual control motors allows the fuel valves to be characterized via the BCS6000

control panel to maintain a tighter air/fuel ratio over the entire burner operating range. Starting

points for fuel control valves are shown in Figure 19 and in the individual burner capacity and

performance data sheets. Final settings of the fuel valves can then be set at multiple control

points using the BCS6000 control panel.

Nominal Settings (see Figure 19)

1. All control motors have a travel of 90°.

2. The low fire starting frequency for the combustion air blower is 16Hz. Always be sure that

the combustion air blower is operating at 16Hz prior to pilot and main flame ignition. During

operation, the blower frequency will need to modulate between 16 and 60Hz as required to

maintain process temperature.

3. Natural Gas Valve. Low fire is adjusted at the main gas valve. Adjust using the gas

metering orifice (see Orifice Meter Capacity Chart in Figure 4). The natural gas valve has a

nominal travel from the off position (low fire) to 9 (high fire) on the valve position indicator

dial plate.

4. Oil Metering Valve . The valve has a nominal travel from position 2 to 11 (see capacity and

performance data sheets).

Page 35

MS-9

5. Propane Metering Valve. Low fire is adjusted at the main LP fuel valve. Adjust while

watching the LP fuel flow meter. If freezing occurs, open the low fire setting ¼ of a position

at a time until the freezing stops. The valve travel varies for a given burner model

(see individual burner capacity and performance data sheets).

X7870

(NOT TO SCALE)

Figure 19. Individual Control Motor Settings

U. OPERATION

Adjustment of this equipment by unqualified personnel can result in fire,

explosion, severe personal injury, or even death.

WARNING

1. The MegaStarTM uses individual control motors directly coupled for each fuel control valve.

The optional remote rack mounted fuel manifold includes a separate control motor for the

fuel control valves, which is electronically linked to the air control. Air control is performed

with a VFD, modulating the output frequency between 16 Hz and 60 Hz to achieve a precise

air flow.

Page 36

MS-9

2. The combustion air must cycle to 60 Hz for purging the system before light off, the safety

limits must be satisfied, and the purge air pressure switch must be made for the purge to

begin. The plant exhaust fan must be running with its damper open sufficiently for the

proper purge time. The minimum purge time is the time required for four volumes of air to

flow through the entire combustion and exhaust system (including the baghouse and flue

stack). For most applications, the combustion air blower will modulate from 16Hz at low fire

to 60Hz at high fire.

3. Set the low gas pressure switch to an initial setting of 0.5 psig (3.4 kPa).

4. Set the high gas pressure switch to an initial setting of 5 psig (34.5 kPa).

5. The fuel valve must be adjusted for proper flow control. See individual burner performance

sheets for fuel flows. Adjustment can be electronically performed with bias points

characterizing the valve position, or it can be set manually so that the closed position

provides the correct flow rate for low fire.

6. Before light off, the combustion air blower must be running at 16Hz; the contacts in the

combustion air switch must be set to close at 1" wc (25 mm wc). The low fire fuel limit

switches, located on the fuel manifold, must be set to have closed contacts when the fuel

valve is at low fire. Do not attempt to ignite the burner unless it is at low fire.

V. ADJUSTMENTS

1. In order to drive each control motor, consult burner control panel instructions.

2. The spin vane adjustment affects the flame shape and combustion intensity. Spin set at 0°

will produce a long narrow flame; a spin setting of 50° will produce a short wide flame (see

individual burner capacity and performance data sheets). For most applications, the spin

should be set in the mid range (30° - 45° on indicator). For a very short flame, in a large

diameter combustion zone, the spin can be set on maximum (50° on indicator). Caution

is advised as overheating of the combustion flights or drum could occur when using

maximum spin. When adjusting the spin to less than 30° for a long flame, check the exhaust

gas to make sure the flame is not too long that it extends into the veiling zone of the dryer

(this can lead to incomplete combustion resulting in high CO and unburned hydrocarbon

emissions in the flue gas).

The MegaStarTM Burner flame is very intense. It is designed to burn quickly and

completely in the recommended combustion space. Flame adjustments on new

installations should be started with a narrow flame (30°) spin setting. Drum

temperatures should be checked using a hand held non-contact infra-red

thermometer particularly in the combustion zone area. The flame shape can then

be widened while observing drum temperature in the combustion zone.

WARNING

3. During the adjustment process take exhaust gas measurements to verify that complete

combustion is taking place (see Application Sheet GJ73 for general information on

conducting exhaust gas analysis).

Page 37

MS-9

W. MAINTENANCE

The Hauck MegaStarTM burner has minimal internal moving parts and is relatively maintenance

free. However, there are a few items that should be periodically checked.

1. Check the fuel control valves for proper operation.

2. For burners fired on oil:

Dirt can clog the atomizing air nozzle, as well as cause problems firing the burner. If the

nozzle is dirty, fuel oil will not atomize properly and will result in lower combustion efficiency.

Twice a year (or more frequently when firing heavy fuel oil, waste oil or in dusty conditions),

remove and clean the burner oil insert tube and nozzle assembly as described below:

a. Shut off the oil flow to the burner.

b. Note the relative location of the oil atomization nozzle with respect to the primary air

tube.

c. Remove the bolts that secure the atomizing air backplate and remove the backplate

and its attached fuel tube and atomizing oil nozzle.

d. Disassemble the nozzle. Clean all the components of oil and other foreign material

that may be plugging the nozzle holes. If used on heavy fuel oil, remove the nozzle

and soak it in a solvent to loosen the oil deposits. Scrape the nozzle body and holes

(if necessary) using wooden tools or a plastic bristle brush only, being careful

not to damage machined parts.

e. Reassemble the oil nozzle, reattach the nozzle to primary air tube, and then attach the

burner backplate to the burner body.

f. Check to ensure that the atomizing oil nozzle is at the proper position inside the

burner (see Section N).

3. Periodically check all safety equipment, such as pressure switches, solenoid valves, and

safety shutoff valves to ensure they are not clogged with dirt, or in any way inoperative.

4. Check and clean UV scanner lens as conditions dictate to keep it clean of dirt and dust.

If the fan motor or impeller are removed or replaced, the

fan vibration should be checked upon reassembly. If

vibration levels are excessive, the fan should be trim

balanced to minimize motor bearing wear.

NOTE

5. A yearly check of the fan (impeller/motor) vibration, measured in the vertical direction at the

motor bearings, is recommended. Consult Hauck for acceptable vibration levels.

6. MegaStar

TM

fan impellers are equipped with wear resistant impeller blades. However, every

effort should be made to minimize dust entering into the fan impeller. Excessive dust may

cause premature wearing of impeller blades and burner parts in addition to unbalance of the

fan.

7. Should it be necessary to remove the fan impeller from the motor shaft, it is important to

replace the fan impeller in the proper position. See Figure 20 for installation instructions.

If the fan wheel is not installed properly, air capacity

of the main fan will be reduced, diminishing burner

capacity and efficiency.

IMPORTANT

Page 38

MS-9

8. Periodically check air/fuel ratio to ensure that the burner is operating at peak efficiency.

Exhaust gas analysis can be performed with most commercially available gas analyzers.

Y7871

(NOT TO SCALE)

Figure 20. Proper Impeller Position On Motor Shaft

X. RECOMMENDED SPARE PARTS

ITEM QTY. PART NO. DESCRIPTION

1 1 20627 Control Motor, Air, High Torque

1A 1 62960 Control Motor, Fuel, Medium Torque

2 1 20579 UV Scanner

3 2 84447812 Air Pressure Switch, Combustion Air & Purge Air,

1 - 20" wc (25-508mm wc) (LP & Low Pressure Oil Only)

4 1 84447832 Air Pressure Switch, Primary Air, 12-60"wc (405-1520mm wc)

5 1 61020 Air Pressure Switch, Compressed Air, 30 psig (207 kPa)

Table 14. Recommended Spare Parts

Page 39

MS-9

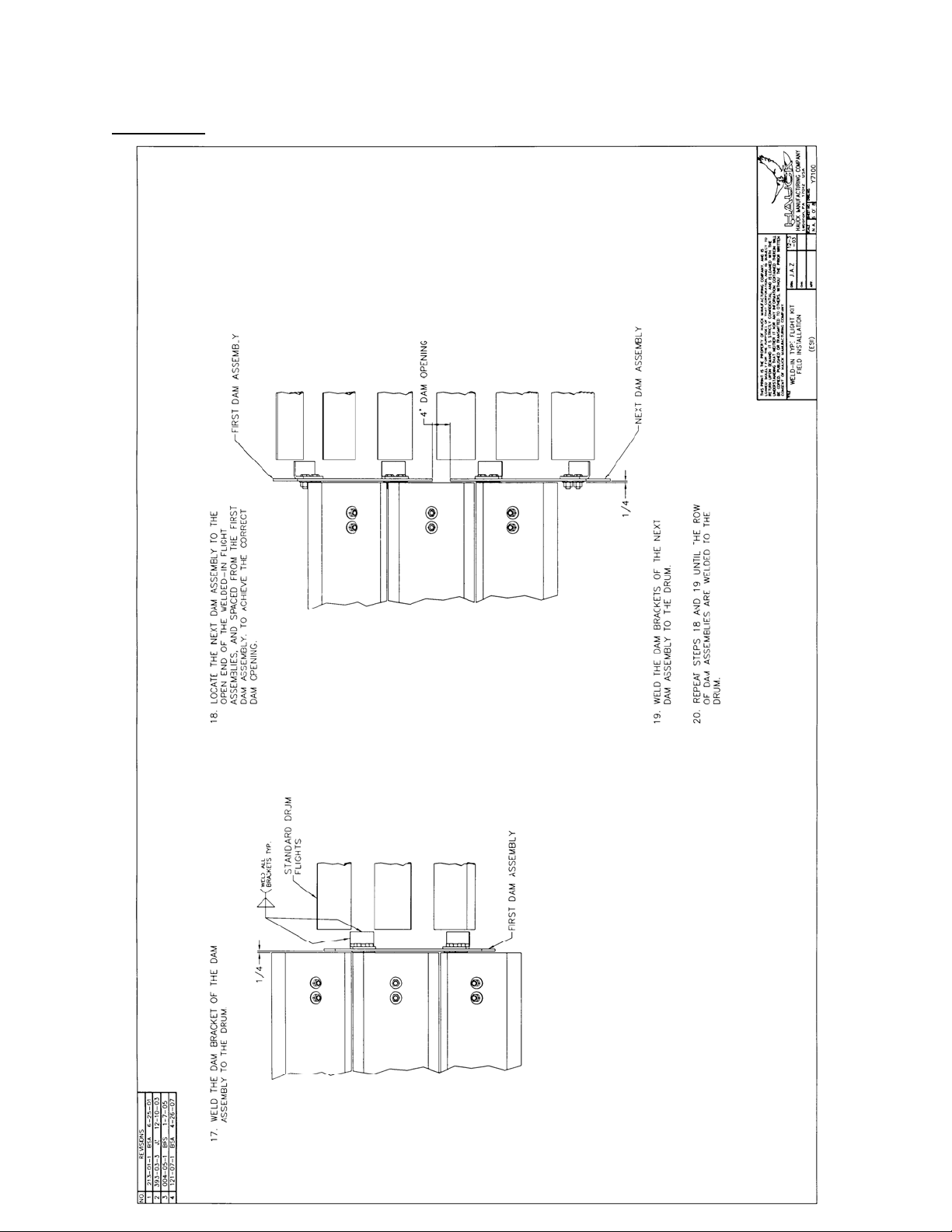

APPENDIX:

Page 40

MS-9

APPENDIX:

Page 41

MS-9

APPENDIX:

Page 42

MS-9

APPENDIX:

Page 43

MS-9

APPENDIX:

Page 44

MS-9

APPENDIX:

Page 45

MS-9

APPENDIX:

Page 46

MS-9

APPENDIX:

DRYER DRUM GAS ANALYSIS

HAUCK MANUFACTURING CO.,

FOR NATURAL GAS, OIL AND LP

Gas analyses are used to indicate the air/fuel ratio and to indicate the degree of completeness

of combustion. If the mixing is poor, an excess of air must be supplied so that every particle of

fuel will contact some air and burn. Unburned fuel is simply wasted since it does not contribute

heat to the process.

A critical step in every dryer drum gas analysis is the placement of the sample tube. The applicability of the readings depends directly on the location from which the sample is drawn. To give

you an idea of the recommended placement, we have included a drawing in this section. Refer

to “Typical Sample Tube Installation for Dryer Drum Gas Analysis”.

The procedures used to make an accurate gas analysis vary not only with the method employed

but also with the manufacturer of the equipment. In most instances good readings require that

the manufacturers instructions be adhered to rigidly.

Conditions to perform a good analysis.

1. Use a reliable gas analyzer.

2. Sample pipe must be installed in the dryer drum to eliminate reading stray O

RAP, or overheated AC.

3. Sample should be taken with average tonnage, moisture and firing rates.

4. Allow at least 10 to 15 minutes running time at production rates before taking readings.

5. Sample tubing from the sample pipe to the analyzer should be as short as possible. Tubing

should be approximately 1/4 inch (6.4 mm) I.D. rubber, plastic, or silicone.

6. Gases should be sampled until instrument settles out, normally a few minutes depending on

sample line size, length, and pump volume.

12/04 www.hauckburner.com Fax: 717-273-9882

P.O. Box 90 Lebanon, PA 17042-0090 717-272-3051

APPLICATION SHEET

, overheated

2

GJ73FE

Page 2

GJ73FE

Interpretation of Gas Readings.

EXAMPLE

Assuming a drum gas analysis is taken at production rates.

Readings Taken: O

- 4%

2

CO - 2000 PPM

Combustibles - 2%

Problem: 4% O2 - is too low

CO - is too high

Combustibles are too high

Solution: Gradually reduce fuel flow or increase air flow while watching O

combustibles. Typically the following will occur – O

will increase, CO will

2

, CO, and

2

decrease, and combustibles will decrease. Reduce fuel until minimal amount

of combustibles are present. Then reduce fuel by a small amount for a safety

margin.

NOTE: Typically some CO and combustibles will always be present.

Variables Affecting the Combustion Process.

1. Poor atomization of fuel: Atomizer contamination with particulate. Air passages clogged.

2. Poor oil: Oil laden with particulate and unburnables.

3. Switching fuels: Light to heavy oils, LP to butane.

4. Flame shape.

5. Stray air: Poor drum seals, larger than necessary feed openings, draft to high.

6. Inadequate combustion zone.

7. Material veiling thru flame: Interrupts burning, creating high CO and high combustibles.

8. Overheating RAP or AC.

9. Contaminated material.

Page 3

GJ73FE

BATCH PLANT

TYPICAL SAMPLE TUBE INSTALLATION FOR DRYER DRUM GAS ANALYSIS

W7406

(NOT TO SCALE)

Page 4

GJ73FE

W7407

(NOT TO SCALE)

DRUM MIX PLANT

TYPICAL SAMPLE TUBE INSTALLATION FOR DRYER DRUM GAS ANALYSIS

APPLICATION SHEET

APPLICATION OF ECO-STARIITM OR MEGASTAR

TM

BURNERS WITHOUT COMBUST ION CHAMBERS ON

ROTARY AGGREGATE DRYERS

The dryer combustion zone must be sized to allow full development of the Eco-StarII

TM

MegaStar

meet a variety of combustion zone sizes.

Combustion Volume

When applying an Eco-StarII

have the correct volume to burn, but also must be free from any material falling into or

through the flame. If material veils or showers through the flame, the fire cools and result s in

incomplete combustion. Cooling the flame from material impingment is commonly called

burner flame. The burner main air spin adjustment provides flame shaping to

TM

or MegaStarTM to a rotary dryer, the flame must not only

TM

or

flame quenching. Quenching will result in several undesirable outcomes. In situations where

quenching exists, fuel will not be fully burned. When fuel is not fully burned, efficiency is

reduced and emissions of Total Hydrocarbon (THC) and Carbon Monoxide (CO) are

significantly increased. Furthermore, on oil fired applications, material contamination can

occur if material falls through the oil flame. In short, a combustion zone that has material veil

can result in elevated operating costs, increased pollutant emissions and result in scrapped

material. Solutions to problems of combustion zone size and material veiling will be

addressed in this application sheet.

To prevent veiling, combustion zone flights are required. Welded-in flights are reco mmended

for aggregate dryers. The recommended combustion flights are designed to be low profile for

prevention of flight overheating and they provide full radiation shielding to keep the drum

temperature to a minimum. Typically, the combustion zone flights are installed in two sets. In

long combustion zones, however, additional sets might be needed to keep the individual

flight length down to a manageable length (6 ft or less). Hauck does not recommend carrying

material. The dam installed in front of each set of combustion zone flights have a 4 inch

opening between the dam sections. These openings allow a port ion of material to go under

the flights to help cool the drum. Flights are available from Hauck to optimize performance of

TM

the Eco-StarII

Hauck weld-in type flights, see Y7100.

HAUCK MANUFACTURING CO., 100 North Harris Street Cleona, PA 17042 717-272-3051

2/14 www.hauckburner.com Fax: 717-273-9882

or MegaStarTM on a rotary dryer; for detailed installation instructions of

GJ75FJ

Page

2

GJ75FJ

On most drums using the recommended combustion flighting, the hottest section of the drum

is at the first set of material drying veiling flights. Due to the veiling flights being higher than

the combustion flights, little radiation protection exists for that section of the dryer.

Temperatures in this area can vary depending on drum diameters and amount of burner spin

used. Typically the temperature in this section will be around 500°F and has been succe ssful

installed on parallel flow and counter-flow applications. If the application has an overheating

problem, a dam or radiation plate can be installed in this area to help reduce tempe ratures.

Drum temperatures in the combustion zone are usually less 500°F to 750°F. Considering

TM

that the Eco-StarII

or MegaStarTM efficiently operates with a slight amount of excess air

and produces a 3000°F flame, the recommended combustion flighting works well.

Combustion Zone Sizing

The following example demonstrates how to calculate the necessary combustion zone

length. (Hauck’s e-Solutions for Combustion® Asphalt Heat Balance program is also

available).

1. Determine the maximum Btu/hr from the burner capacity sheet necessary; assume

burner capacity of 100,000,000 Btu/hr for this example.

2. Take the Btu/hr and divide it by the combustion zone intensity that is desired. (In a

normal case, use 250,000 Btu/ft

100,000,000 Btu/hr ÷ 250,000 Btu/ft

3

·hr)

3

• hr = 400 ft3 of combustion space required.

3. Determine the effective combustion zone inside diameter(ID). Use the drum diameter in

inches minus two times the height of the combustion flights.

If the drum is 96" in diameter and the flight height is 6", the effective drum inside

diameter is:

96" - (2 x 6") = 84" effective combustion zone ID.

4. Use the effective combustion zone ID to calculate the amount of cubic feet per foot of

drum length.

(Effective Combustion Zone ID÷2)

2

x 0.02181

In The Example:

(84"÷2)

2

X 0.02181 = 38.5 ft3 combustion volume / ft drum length.

Page

3

GJ75FJ

5. To determine the drum length required in feet, divide the combustion volume required

(see step 2) by the cubic feet per foot of drum (Step 4).

400 ft

3

÷ 38.5 ft3 / ft drum length = 10.4ft combustion flighting required.

For most applications this method produces good results, however for unusual

configurations or firing rates the flame lengths for the burners should be checked to ensure

that the planned combustion length and diameter is within the burner’s capability. (see

attached flame length tables).

Combustion Zone Produces Flame Intensity

The Eco-StarII

defined as Btu/hr ·ft

TM

or MegaStarTM is capable of high flame intensities. Flame intensity is

3

of combustion space. This is determined by finding the Btu/hr firing rate

that is used and dividing it by the cubic feet of combustion space available. A normal

3

maximum flame zone intensity is 250,000 to 300,000 Btu/ft

3

250,000 Btu/ft

on oil firing. Propane fired burners require 150,000 to 200,000 Btu/ft3. This

on natural gas and 175,000 to

intensity can be higher under ideal conditions, or lower if pollution requirements necessitate

very low CO and THC levels. Ideal conditions mean that the burner chosen will run near

its maximum firing capability. Running the burner near its maximum capacity will

allow for higher efficiency, promote optimum mixing and result in lowest emissions.

Due to the variety of rotary drying applications, the proper number to use for sizing the

combustion zone is based somewhat on experience. It is a good idea to consider normal

available flame shapes for the size burner that is desired as well.

When sizing a burner and combustion zone for stringent emission regulation applications,

allow extra space for the flame to fully combust. Applications that require low CO and THC

benefit from larger combustion zones. In situations where (flue gas recirculation) is added to

reduce NOx, a larger combustion zone is also helpful. Combustion intensities in these cases

will be lower. Do not be concerned when removing several more feet of veiling flighting to

complete the combustion flighting as the new combustion flights will allow extra material

heating and drying from conductive heat transfer. Veiling flights can be added to make up

the difference in the balance of the drum (Consult Hauck).

Page

GJ75FJ

For example, consider an ESII-100 firing natural gas at 100 MMbtu/hr in an 8 ft diameter

3

drum. First, use 250,000 Btu/ft

as the combustion intensity and then check to see if the

flame fits into the available combustion zone. This is a 9 ft long x 5 ft diameter flame @ 30°

spin in an 8 ft. diameter dryer which appears reasonable. Consideration must be made for