TABLE OF CONTENTS

Subject Page

A. General Information……………………………………………………………………... 2

B. Receiving and Inspection………………………………………………………………. 2

C. Capacities………………...……………………………………………………………… 3

D. Dimensions………………………………………………………………………………. 6

E. Installation……………………………………………………………………………….. 6

F. Operation………………………………………………………………………………… 7

G. Maintenance……………………………………………………………………………... 7

These instructions are intended to serve as guidelines covering the installation, operation, and maintenance of Hauck equipment. While

every attempt has been made to ensure completeness, unforeseen or unspecified applications, details, and variations may preclude

covering every possible contingency. WARNING: TO PREVENT THE POSSIBILITY OF SERIOUS BODILY INJURY, DO NOT USE OR

OPERATE ANY EQUIPMENT OR COMPONENT WITH ANY PARTS REMOVED OR ANY PARTS NOT APPROVED BY THE

MANUFACTURER. Should further information be required or desired or should particular problems arise which are not covered

sufficiently for the purchaser's purpose, contact Hauck Mfg. Co.

HAUCK MANUFACTURING CO., 100 North Harris Street Cleona, PA 17042 717-272-3051

4/14 www.hauckburner.com Fax: 717-273-9882

GAS LIMITING ORIFICE VALVES

WARNING

These instructions are intended for use only by

experienced, qualified combustion start-up personnel.

Adjustment of this equipment and its components, by

unqualified personnel, can result in fire, explosion,

severe personal injury, or even death.

LVG SERIES

INSTRUCTIONS

LVG-9

Page 2

WARNING

This equipment is potentially dangerous with the possibility of serious personal injury

and property damage. Hauck Manufacturing Company recommends the use of flame

supervisory equipment and fuel safety shutoff valves. Furthermore, Hauck urges rigid

adherence to National Fire Protection Association (NFPA) standards and insurance

underwriter’s requirements. Operation and regular preventative maintenance of this

equipment should be performed only by properly trained and qualified personnel.

Annual review and upgrading of safety equipment is recommended.

A. GENERAL INFORMATION

The Hauck LVG Series Limiting Orifice Gas Valves are designed for use with each burner in a

multiple furnace application. They allow fine gas flow adjustment of individual burners to

achieve the desired air/gas ratio at each burner. The standard LVG series valves can be used

as straight through type valves, and are designed for use with any commercial fuel gas.

B. RECEIVING AND INSPECTION

Upon receipt, check each item on the bill of lading and/or invoice to determine that all

equipment has been received. A careful examination of all parts should be made to ascertain if

there has been any damage in shipment.

LVG-9

Page 3

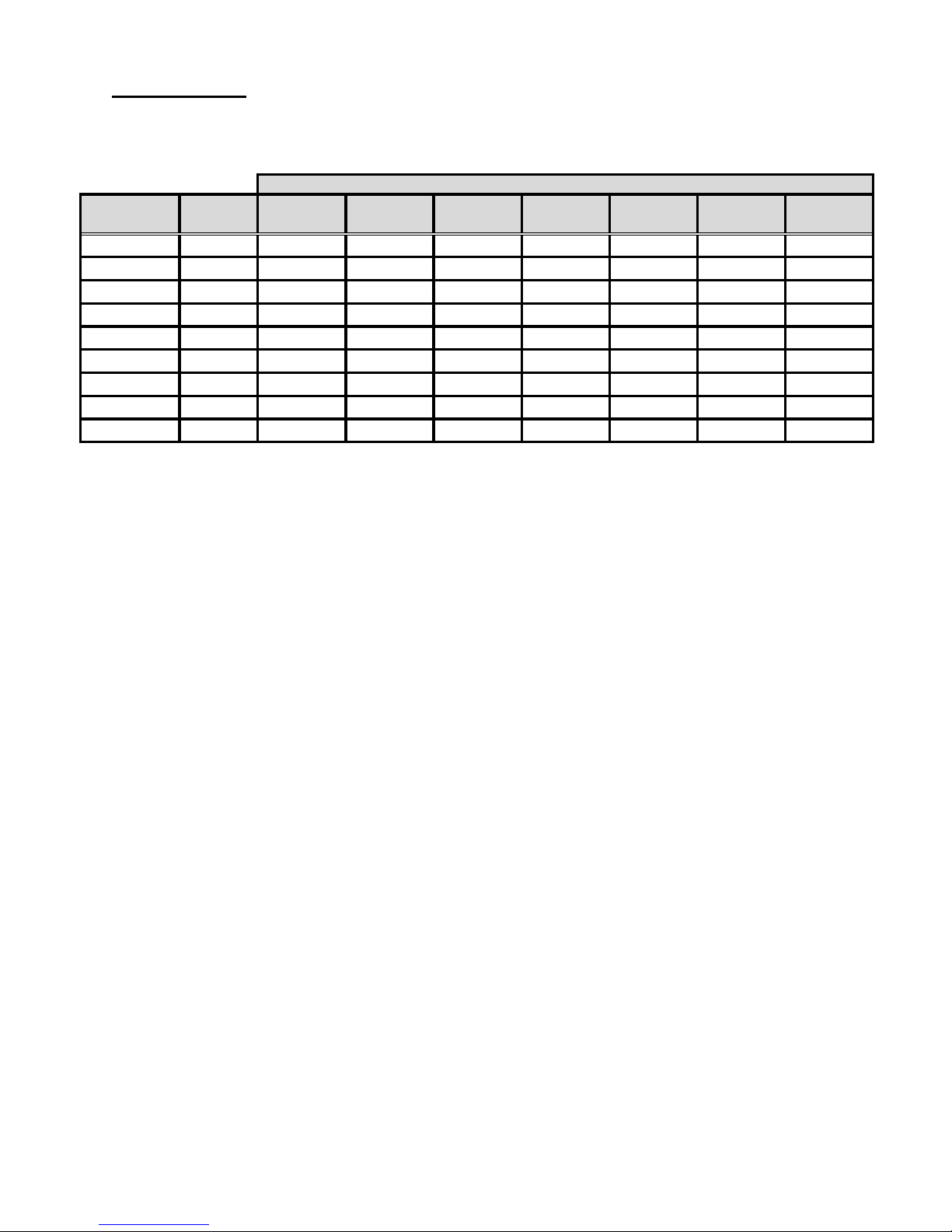

C. CAPACITIES

LVG-9

NATURAL GAS

Full Open Valve Capacity

PRESSURE DROP

Model No.

LVG 505E 1/2 NPT 275 410 575 757 1,055 1,290 1,470

LVG 507E 3/4 NPT 405 590 815 1,070 1,520 1,855 2,120

LVG 510D 1 NPT 635 870 1,230 1,625 2,245 2,750 3,155

LVG 512D 1-1/4 NPT 1,070 1,520 2,160 2,840 4,020 4,890 5,630

LVG 515D 1-1/2 NPT 1,500 2,140 3,000 3,930 5,560 6,740 7,680

LVG 520D 2 NPT 2,560 3,520 5,010 6,565 9,080 11,120 12,700

LVG 525A 2-1/2 NPT 3,985 5,630 7,970 10,480 14,830 18,160 20,960

LVG 530A 3 NPT 5,215 7,830 14,330 13,720 19,420 23,770 27,440

LVG 540A 4"FLG 9,370 13,240 18,740 24,640 34,880 42,700 49,270

Pipe 1"wc 2"wc 4"wc 6.9"wc 13.8"wc 20.8"wc 27.7"wc

Size 2.5 mbar 5 mbar 10 mbar 17.2 mbar 34.3 mbar 51.8 mbar 69 mbar

Notes

1. Capacities based on natural gas at 0.60 s.g. and 60°F (or 0°C).

2. Pressure drop measured across full open valve.

3. Maximum inlet pressure is 15 psig (1034 mbar)

4. For natural gas leakage rat es with valve fully closed, consult Hauck .

C. CAPACITIES (Continued)

LVG 505E (1/2")

Per centage o f Maximu m

Flow vs No. of Turns Open

100

80

60

40

20

0

Percentage of Max. Flow

01234567

No. of Turns Open

Percentage of Maximum Flow vs No. of

100

80

LVG 510D (1")

Turns Open

60

40

20

0

Per centage o f Max. F l o w

012345678910

No. of Turns Open

Percentage of Maximum Flow vs No. of

100

LVG 515D (1 1/2")

Turns Open

80

60

40

20

0

Percentage of Max. Flow

0123456789101112131415

No. of Tu r n s Open

LVG 507E (3/4")

Percentage of Maximum Flow vs No. of

Turns Open

100

80

60

40

20

0

Percentage of Max. Flow

Percentage of Max. Flow

Percentage of Max. Flow

012345678

No. o f Turns Op en

LVG 512D (1 1/4")

Percentage of Maximum Flow vs No. of

Turns Open

100

80

60

40

20

0

0123456789101112

No. of Turns Open

LV G 520D (2")

Percentage of Maximum Flow vs No. of

Turns Open

100

80

60

40

20

0

0123456789101112131415

No. of Turns Ope n

Page 4

LVG-9

C. CAPACITIES (Continued)

Percentage of Maximum Flow vs No. of Turns Open

100

90

80

70

60

50

40

30

20

10

0

Percentage of Max. Flow

0 2 4 6 8 10 12 14 16 18 20 22 24

Percentage of Maximum Flow vs No. of Turns Open

100

90

80

70

60

50

40

30

20

10

Percentage of Max. Flow

0

0 2 4 6 8 10 12 14 16 18 20 22 24

Percentage of Maximum Flow vs No. of Turns Open

100

90

80

70

60

50

40

30

20

10

Percentage of Max. Flow

0

0 4 8 1216202428323640

LVG 525A (2 1/2")

No. of Turns Open

LVG 530A (3")

No. of Turns Open

LVG 540A (4")

No. of Turns Open

Page 5

LVG-9

Page 6

D. DIMENSIONS

See appropriate Dimension sheet for detailed dimensional information.

LVG-9

E. INSTALLATION

The LVG valves are designed as straight through valves and feature an arrow indicating the

intended direction of flow.

NOTE

Tighten all connections to ANSI/ASME B1.20.1 specifications.

Install the LVG in the gas line as close to the burner as possible, downstream of a shutoff valve,

gas orifice meter and gas controlling valve, and in an area that allows easy access to the

valve’s adjusting mechanism.

X7026

(NOT TO SCALE)

Page 7

F. OPERATION

The LVG series valves can be used with any clean commercial fuel gas.

For flow adjustment, remove the hex screw cap from the valve. Using a flat-head screwdriver

(1/4" allen wrench on LVG 525 – 540 sizes), adjust the piston assembly until the desired flow

rate is achieved. Counterclockwise rotation increases gas flow.

G. MAINTENANCE

All LVG series valves are designed for maintenance free operation. Under normal usage, no

service should be necessary. For the LVG 505 - 520 size valves, the entire piston cartridge may

be removed for inspection or maintenance of the valve orifice. Remove the cartridge by

unscrewing the brass hex connection. Replace the cartridge when complete.

Replace the hex screw cap when adjustment is complete to seal the valve.

IMPORTANT

LVG-9

Loading...

Loading...