Hauck IPG, IPG 412, IPG 411, IPG 413 Instructions Manual

INSTRUCTIONS

IPG GAS PILOT BURNERS

TABLE OF CONTENTS

Subject

A. General Information ……………………………………………………….…..….……. 2

B. Receiving and Inspection ………………………………………….…….…...…….….. 2

C. Capacities ………….……………………………………………………………………. 3

D. Dimensions …………….………………………………………………………………... 6

E. Installation ……………………………………………………………………………….. 6

F. Ignition……………………………………………………………………………………. 6

G. Operation…………………………………………………………………………………. 9

H. Shutoff Valve Leak Testing…………………………………………………………….. 9

I. Maintenance……………………………………………………………………………… 9

These instructions are intended to serve as guidelines covering the installation, operation, and maintenance of Hauck equipment. While

every attempt has been made to ensure completeness, unforeseen or unspecified applications, details, and variations may preclude

covering every possible contingency. WARNING: TO PREVENT THE POSSIBILITY OF SERIOUS BODILY INJURY, DO NOT USE OR

OPERATE ANY EQUIPMENT OR COMPONENT WITH ANY PARTS REMOVED OR ANY PARTS NOT APPROVED BY THE

MANUFACTURER. Should further information be required or desired or should particular problems arise which are not covered

sufficiently for the purchaser's purpose, contact Hauck Mfg. Co.

HAUCK MANUFACTURING CO.,

9/12 www.hauckburner.com Fax: 717-273-9882

These instructions are intended for use only by experienced, qualified

combustion start-up personnel. Adjustment of this equipment and its

components by unqualified personnel can result in fire, explosion, severe

personal injury, or even death.

P.O. Box 90 Lebanon, PA 17042-0090 717-272-3051

WARNING

Page

IPG-9

Page 2

IPG-9

WARNING

This equipment is potentially dangerous with the possibility of serious personal injury

and property damage. Hauck Manufacturing Company recommends the use of flame

supervisory equipment and fuel safety shutoff valves. Furthermore, Hauck urges rigid

adherence to National Fire Protection Association (NFPA) standards and insurance

underwriter’s requirements. Operation and regular preventative maintenance of this

equipment should be performed only by properly trained and qualified personnel.

Annual review and upgrading of safety equipment is recommended.

A. GENERAL INFORMATION

The Hauck Series IPG Gas Pilot provides a means of lighting the flame of Hauck burners and

many other industrial gas or oil burners. IPG pilots are engineered for exceptional flame stability

and long life, even under the most severe and adverse operating conditions. IPG pilots are

designed for electric spark ignition. The standard IPG Gas Pilots are suitable for firing into

neutral, negative or positive pressure applications.

The back-loaded feature offers the capability to compensate the pilot air/fuel ratio for variations

in furnace or burner pressure.

B. RECEIVING AND INSPECTION

Upon receipt, check each item on the bill of lading and/or invoice to determine that all

equipment has been received. A careful examination of all parts should be made to ascertain if

there has been any damage in shipment.

If the installation is delayed and the equipment is stored outside,

provide adequate protection as dictated by climate and period of

exposure. Special care should be given to all motors and bearings, if

applicable, to protect them from rain or excessive moisture.

IMPORTANT

Page 3

IPG-9

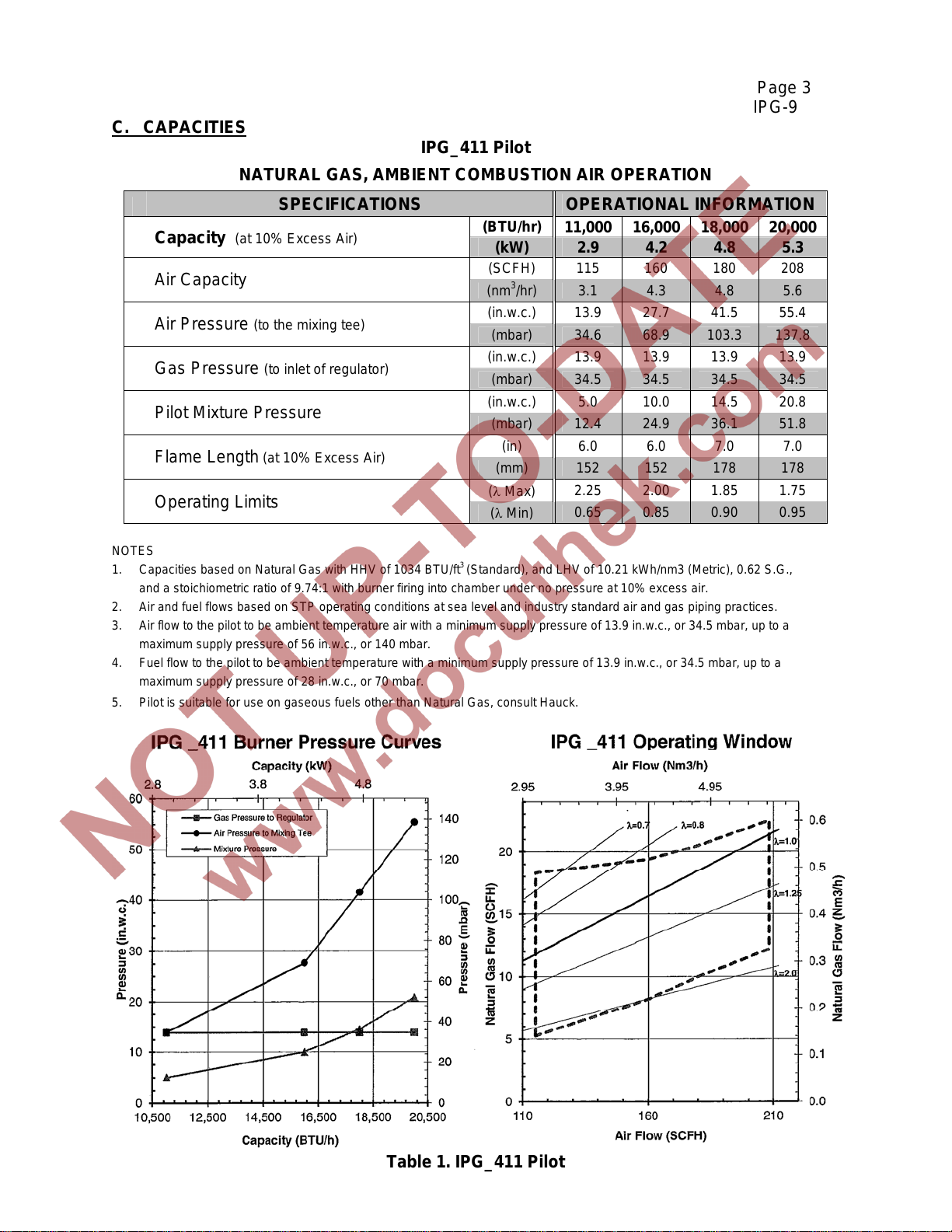

C. CAPACITIES

IPG_411 Pilot

NATURAL GAS, AMBIENT COMBUSTION AIR OPERATION

Capacity

Air Capacity

Air Pressure (to the mixing tee)

Gas Pressure (to inlet of regulator)

Pilot Mixture Pressure

Flame Length (at 10% Excess Air)

Operating Limits

(at 10% Excess Air)

SPECIFICATIONS OPERATIONAL INFORMATION

(BTU/hr)

(kW) 2.9 4.2 4.8 5.3

(SCFH) 115 160 180 208

(nm3/hr) 3.1 4.3 4.8 5.6

(in.w.c.) 13.9 27.7 41.5 55.4

(mbar) 34.6 68.9 103.3 137.8

(in.w.c.) 13.9 13.9 13.9 13.9

(mbar) 34.5 34.5 34.5 34.5

(in.w.c.) 5.0 10.0 14.5 20.8

(mbar) 12.4 24.9 36.1 51.8

(in) 6.0 6.0 7.0 7.0

(mm) 152 152 178 178

( Max)

( Min)

11,000 16,000 18,000 20,000

2.25 2.00 1.85 1.75

0.65 0.85 0.90 0.95

NOTES

1. Capacities based on Natural Gas with HHV of 1034 BTU/ft

and a stoichiometric ratio of 9.74:1 with burner firing into chamber under no pressure at 10% excess air.

2. Air and fuel flows based on STP operating conditions at sea level and industry standard air and gas piping practices.

3. Air flow to the pilot to be ambient temperature air with a minimum supply pressure of 13.9 in.w.c., or 34.5 mbar, up to a

maximum supply pressure of 56 in.w.c., or 140 mbar.

4. Fuel flow to the pilot to be ambient temperature with a minimum supply pressure of 13.9 in.w.c., or 34.5 mbar, up to a

maximum supply pressure of 28 in.w.c., or 70 mbar.

5. Pilot is suitable for use on gaseous fuels other than Natural Gas, consult Hauck.

3

(Standard), and LHV of 10.21 kWh/nm3 (Metric), 0.62 S.G.,

Table 1. IPG_411 Pilot

Loading...

Loading...