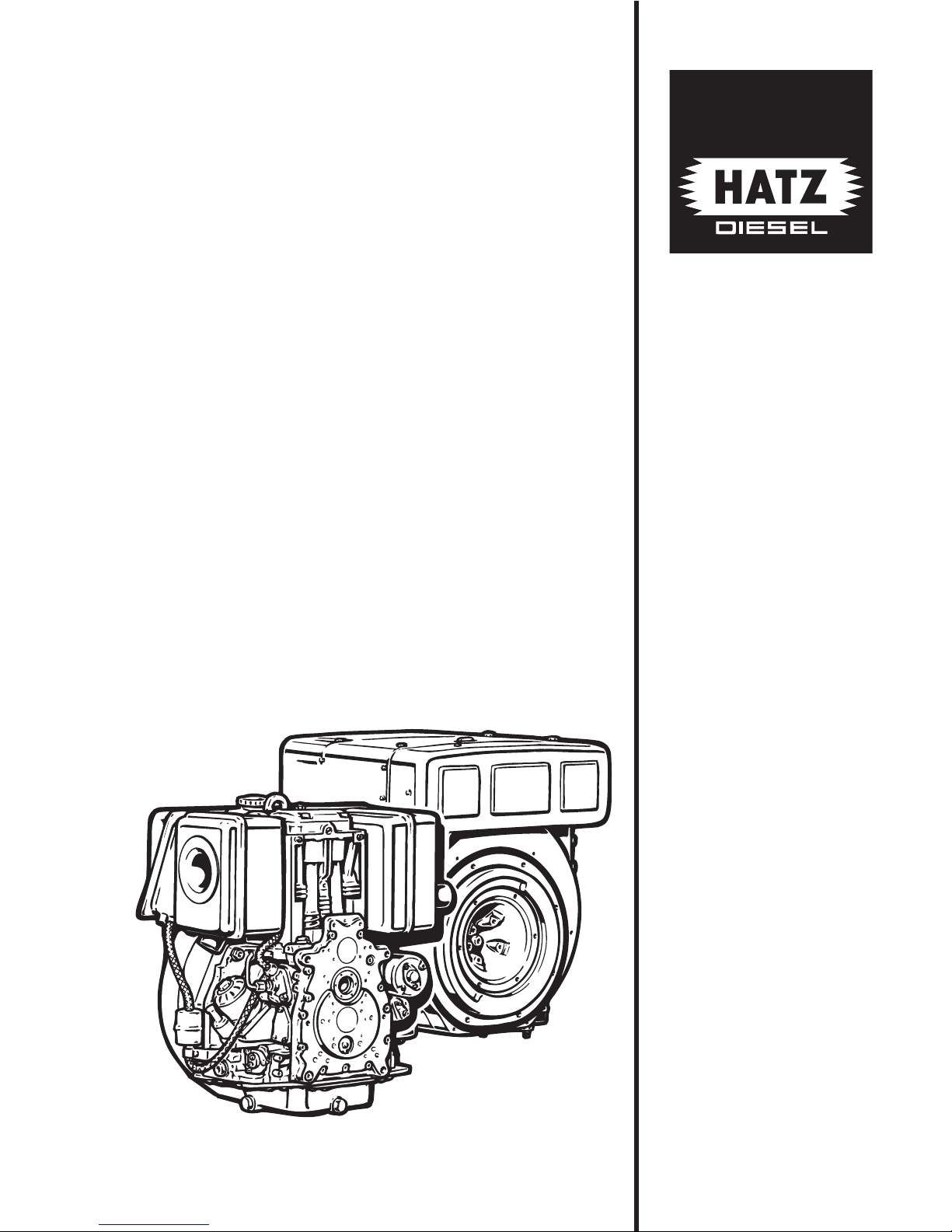

Page 1

Workshop manual

438 202 01 - Printed in Germany

1 D . .

Page 2

Page 3

Foreword

1. General

Engine illustrations

Technical data

Type plate data

Lubrication oil circuit

Special tools and

workshop equipments

Jointing material / Sealing and

bonding agents

2. Additional equipments

A 01.00 Fuel

A 01.10 Fuel tank

A 01.40 Fuel feed pumps

A 02:00 Combustion air

A 02.10 Oil bath air filters

A 02.11 Dry type air filters

A 02.13 Service indicators;

vacuum gauges

A 02.20 Pre-cleaners; cyclons

A 03.00 Exhausts

A 03.12 Exhaust-silencers,

Protection guard

A 04.00 Start mechanical

A 04.10 Starting handles

without supports

A 04.11 Starting handle supports

A 04.12 Cranking claws

A 04.30 Rope starts

A 05.00 Start electrical

A 05.20 Starter motors

A 05.40 Alternator / Magnet segments

A 05.41 Alternator / Coils

A 05.80 Ring gears

A 07.00 Lubrication oil

A 07.20 Lub.-oil filters, strainers

A 07.30 Oil sumps

A 09.00 Speed controls

A 09.60 Low idle speed stabilization

A 11.00 Remote engine controls

A 11.10 Stop devices

A 11.30 Auto. Shut-off device

A 15.00 Housings, flanges,

adaptors

A 15.20 Adaptor housings

Contents

Page 4

3. Basic engine

M–Disassembly cross reference scheme

M 01.00 Crankcase

M 01.10 Crankcase, nozzle

and bearings

M 01.11 Plugs

M 01.20 Crankshaft-thrustplate

and cam followers

M 01.30 Oil sump and suction sieve

M 01.31 Oil sump 1 D 50

M 01.40 Base plate and

oil pressure relief valve

M 01.50 Cyl.-head screw sealants

M 02.00 Crankshaft

M 02.10 Wear and grinding dimensions

M 02.20 Crankshaft gearwheel and

stubshafts

M 02.30 Crankshaft / Wear sleeve

M 03.00 Bearing flange

M 03.10 Bearing flange 1D 90 V/W

M 04.00 Camshaft and balancer unit

M 05.00 Piston with connecting rod

M 05.10 Piston and piston rings

M 05.20 Connecting rod

M 06.00 Cylinder

M 07.00 Cylinder head

M 07.10 Rockers and decompression

device

M 07.20 Bumping clearance

M 07.30 Cyl.-head and oil supply pipe

M 07.40 Valves, valve guides and

valve seats

M 08.00 Cover for cylinder head

M 09.00 Pushrods / Protection tubes

M 10.00 Oil pump / Governor

M 11.00 Timing cover

M 12.00 Extra fuel device

M 14.00 Fuel-injection equipment

M 14.10 Fuel pressure pipe

M 14.20 Injector

M 14.30 Injection pump

M 14.40 Roller tappet

M 17.00 Flywheel

M 26.00 Cowling / Air duct

M 31.00 Breather system

M 32.00 Speed control

M 35.00 Capsule

4. Data sheets

Injection equipment adjustment data

Governor equipment

General adjustment and testing data

Screw tightening torques

Designations in circuit diagrams

HATZ wiring designations

Electrical circuit diagrams

Circuit diagram for measuring

currents and voltages

Generator output characteristic

Troubleshooting – electrical system

Contents

Page 5

Foreword

This Workshop Manual covers the latest technical developments according to

month/year indicated on each page. It has been written in such a way, that it contains all

dismantling and assembly instructions in accordance with the table of contents, including all required data etc., so as to permit a trained mechanic to carry out correct and

professional repairs.

We have not included information such as cleaning parts, replacing of "O" Rings,

gaskets, oil seals etc. since it is assumed, of course, that the mechanic will be aware of

the necessity of carrying out such work.

Use only the tools prescribed or absolutely identical tools when carrying out work of

whatever nature.

It has been assumed that a standard set of workshop tools is available.

Please refer to the instruction book for maintenance work, operating materials and trouble shooting information.

Use only GENUINE HATZ PARTS for repairs!

Only these parts guarantee perfect dimensional accuracy and quality.

For the rest, please observe the general legal regulations and the regulations of the responsible professional associations.

Discrepancies may occur between the described features and actual features owing to

special equipment, and it has not been possible to allow for such discrepancies either in

the Workshop Manual or in the spare parts list.

Should you have any difficulties, please contact your nearest HATZ-Service agent.

Page 6

Page 7

1

1D . . / 03.06

1. General

Page 8

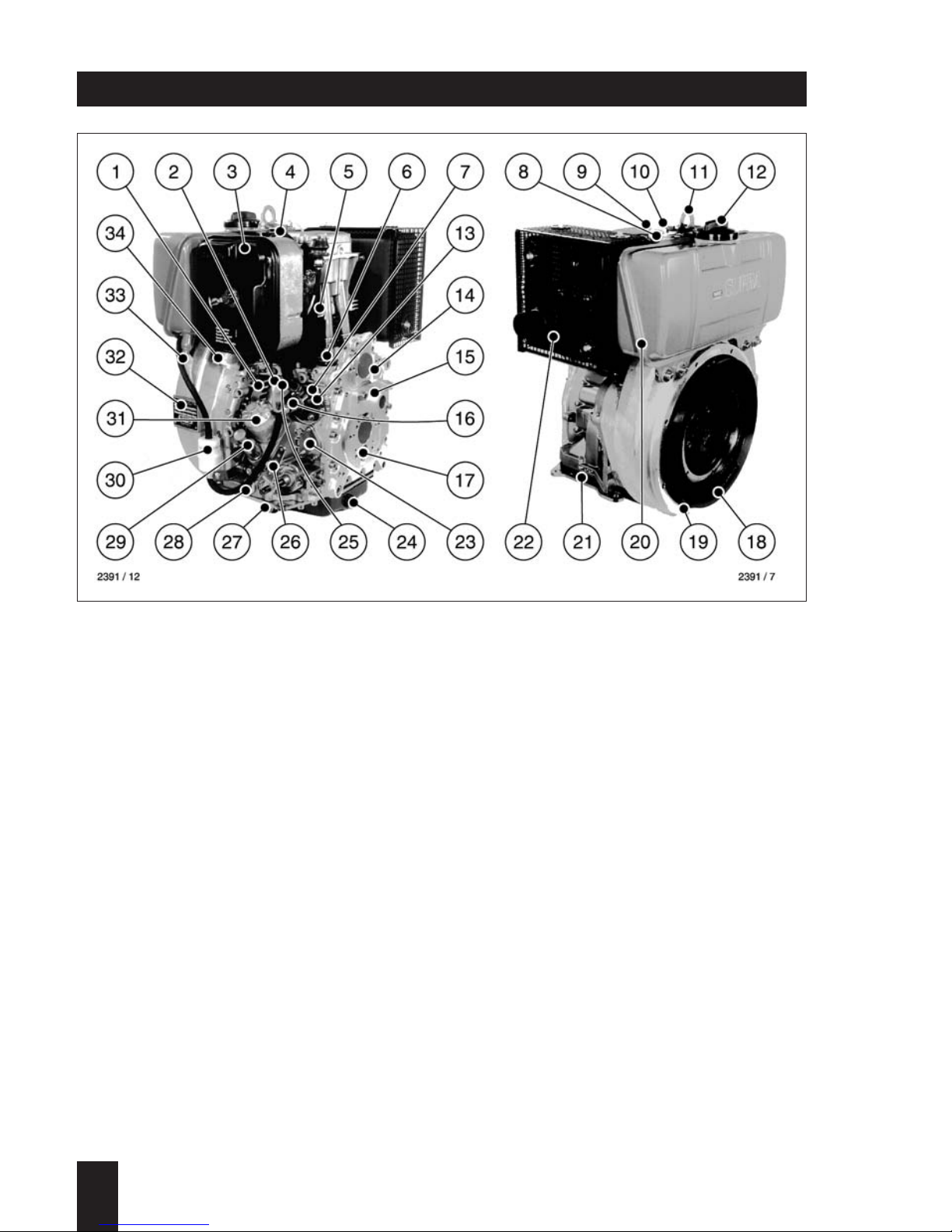

1 Cooling air inlet

2 Oil pressure switch

3 Dry type air cleaner

4 Decompression lever

5 Cooling air outlet

6 Extra fuel device

7 Injection pump

8 Injector

9 Cylinder head cover

10 Cold start-oil priming device

11 Lifting bracket, max. 120 kg / 265 lb

12 Fuel filler cap

13 Stop lever

14 Timing cover

15 Guiding shell for starting handle

16 Fuel pressure pipe

17 Governor

1

1D . . / 03.06

18 Flywheel

19 Engine flange

20 Fuel tank

21 Engine base plate

22 Exhaust silencer

23 Fuel feed pump (mounting pos.)

24 Oil drain plug, governor side

25 Injection pump bleeder valve

26 Speed control lever

27 Oil drain plug, control side

28 Oil pressure relief valve

29 Oil filling hole and dipstick

30 Fuel filter

31 Oil filter (optional)

32 Type plate

33 Fuel tank drain plug

34 Combustion air intake

Engine illustrations

Engine 1D30, 1D31, 1D40, 1D41, 1D50, 1D60, 1D80, 1D81, 1D90 S/Z/T/U

Page 9

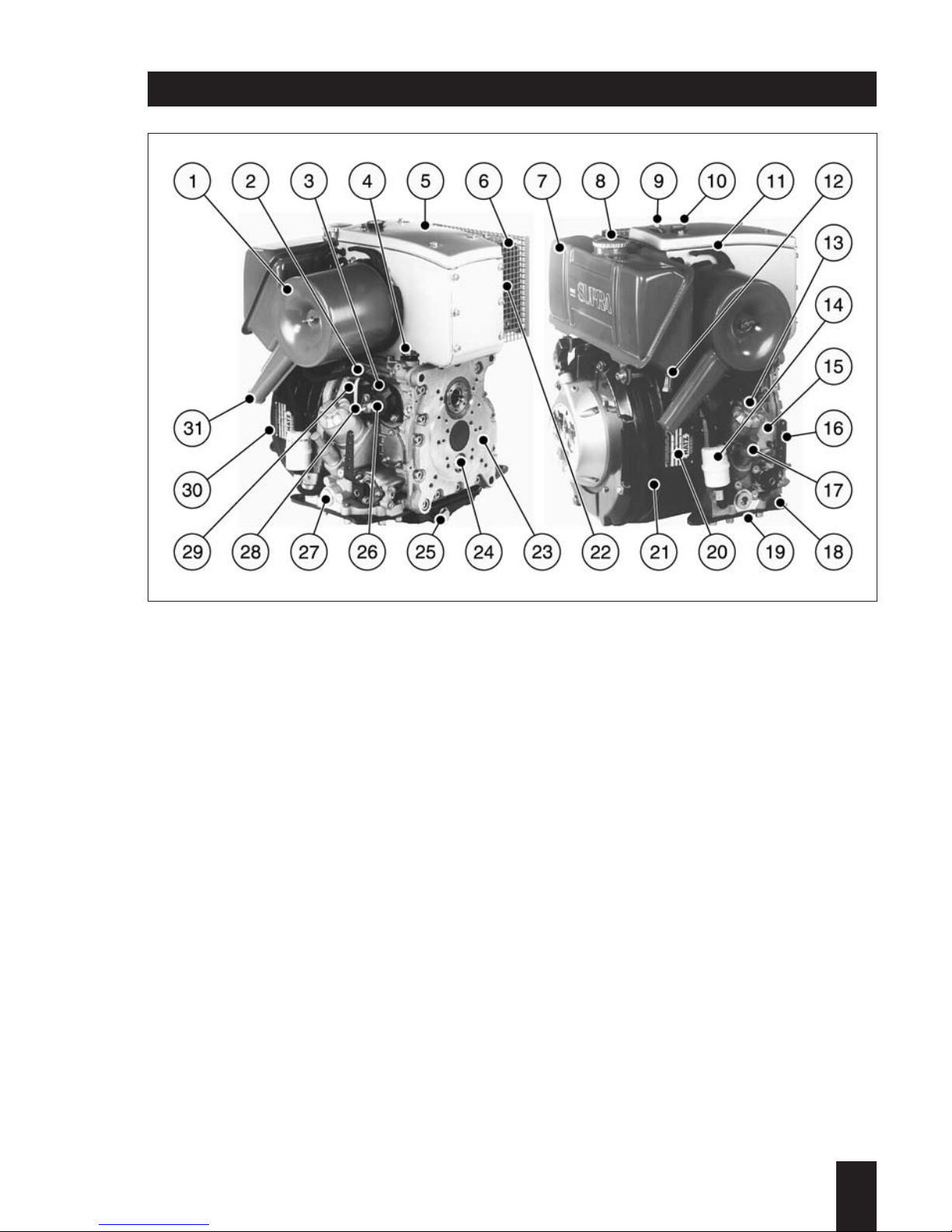

16 Speed control lever

17 Oil filling hole and dipstick

18 Engine base plate

19 Oil drain plug, control side

20 Type plate

21 Engine flange

22 Cooling air outlet

23 Timing cover

24 Governor

25 Oil drain plug, governor side

26 Injection pump

27 Oil pressure relief valve

28 Fuel pressure pipe

29 Cooling air inlet

30 Flywheel

31 Combustion air intake

1

1D . . / 03.06

1 Air filter

2 Oil pressure switch

3 Injection pump bleeder valve

4 Extra fuel device

5 Air cowling cover

6 Exhaust silencer

7 Fuel tank

8 Fuel filler cap

9 Lifting bracket, max. 120 kg / 265 lb

10 Cold start-oil priming device

11 Decompression lever

12 Fuel tank drain plug

13 Oil filter (optional)

14 Fuel filter

15 Fuel feed pump (mounting pos.)

Engine illustrations

Noise-optimized version

Engine A1D35, A1D40, A1D41 S/Z/T/U

Page 10

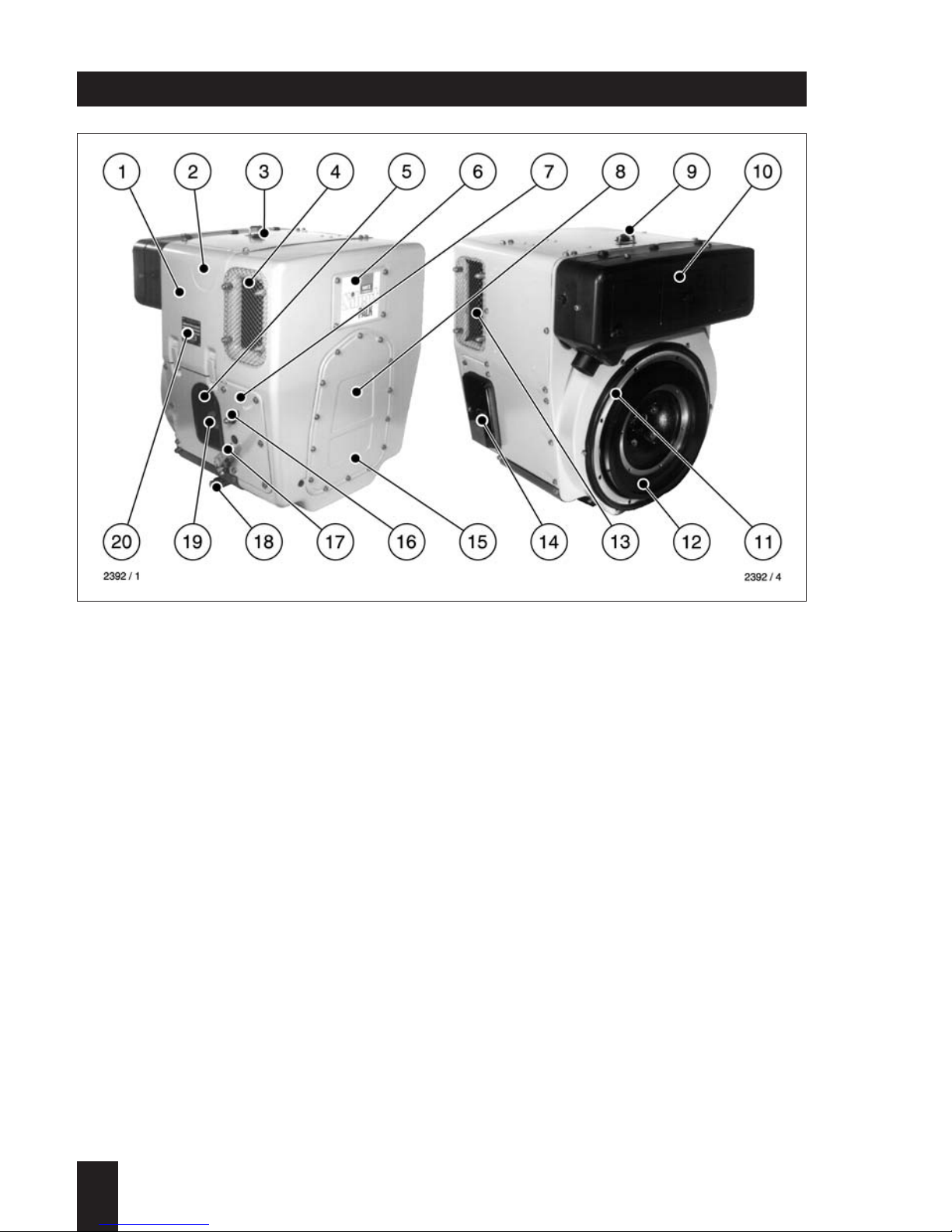

1 Capsule

2 Decompression lever

3 Cold start-oil priming device

4 Combustion and cooling air intake

5 Oil filter

6 Cleaning opening

7 Side panels

8 Access for starting handle

9 Lifting bracket, max. 120 kg / 265 lb

10 Exhaust silencer, enclosed

11 Engine flange

1

1D . . / 03.06

12 Flywheel

13 Cooling air outlet

14 Battery connections and central plug

for electrical system

15 Access to timing cover

16 Stop lever

17 Speed control lever

18 Oil drain plug

19 Oil filling hole and dipstick

20 Type plate

Engine illustrations

Fully encapsulated version

Engine 1D30C, 1D31C, 1D40C, 1D41C, 1D60C, 1D80C, 1D81C

Page 11

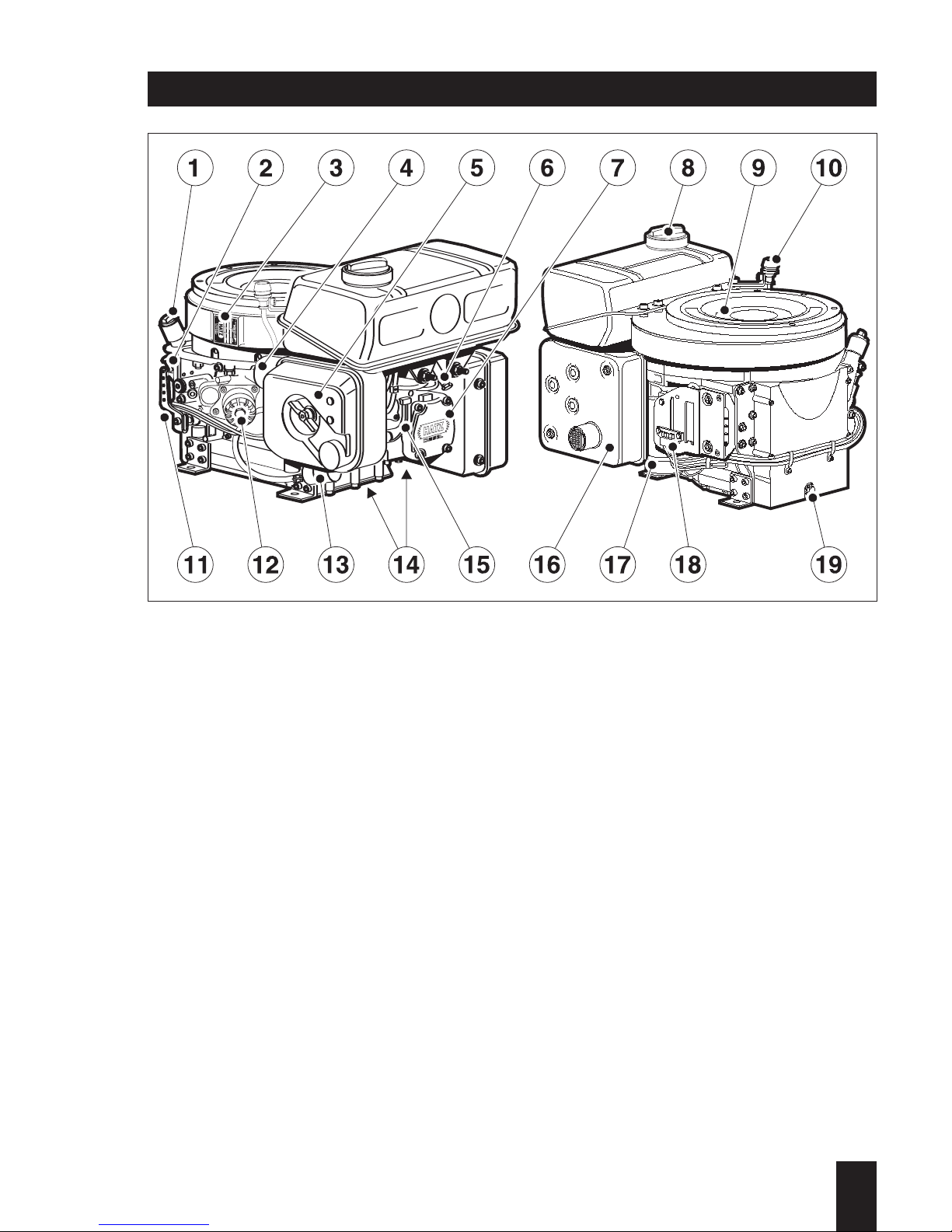

1 oil filler cap

2 dipstick

3 type plate

4 combustion air intake

5 dry type airfilter

6 fuel tank drain plug

7 cylinder head cover

8 fuel filler cap

9 cooling air inlet

10 mechanical maintenance indicator

11 speed control lever

12 oil filter

13 fuel filter

14 cooling air outle

15 decompression levert

16 exhaust silencer

17 electric starter

18 central plug f. electrical equipment

19 oil drain plug

Engine illustrations

Engine 1D90 V/W

1

1D . . / 03.06

Page 12

1

1D . . / 03.06

Type 1D30.. 1D40.. A1D35..

1D31.. A1D40..

Engine models S, Z, T, U, C S, Z, T, U, S, Z, T, U

Mode of operation Air-cooled four-stroke diesel engine

Combustion method Direct-injection

Number of cylinders 1 1 1

Bore / stroke mm 86/65 86/65 86/65

Cubic capacity cm

3

377 377 377

Compression ratio 1D30: 20.5:1 20.5:1 20.5:1

1D31: 21.0:1 22.0:1*

Direction of rotation 1D . . S / Z / C counter-clockwise

looking at the flywheel 1D . . T / U clockwise

Cooling air required

at 3000 min

-1

m3/min 6.0 6.0 6.0

Combustion air required

at 3000 min-1 m3/min 0.56 0.56 0.56

Oil capacity without oil filter approx. 1.1 1.1 1.1

with oil filter ltr. 1.2 1.2 1.2

Difference between approx. 0.4 0.4 0.4

„max“ and „min“ markings ltr.

Oil consumption Approx. 1% of fuel combustion at full load

Max. permissible inclination approx. 30° approx. 30° approx. 30°

in each direction during operation

Net weight

Engine models S, Z, T, U approx. 68 68 74

Engine models C kg 89 89 –

Model S: non-encapsulated, normal system of balancing, counter-clockwise rotation

Z: non-encapsulated, add. system of balancing, counter-clockwise rotation

T: non-encapsulated, normal system of balancing, clockwise rotation

U: non-encapsulated, add. system of balancing, clockwise rotation

C: SILENT PACK, add. system of balancing, counter-clockwise rotation

*Engines in connection with compaction units

Technical data

Page 13

1

1D . . / 03.06

Type 1D41.. 1D50.. 1D60..

A1D41..

Engine models S, Z, T, U, C S, Z S, Z, T, U, C

Mode of operation Air-cooled four-stroke diesel engine

Combustion method Direct-injection

Number of cylinders 1 1 1

Bore / stroke mm 90/65 97/70 88/85

Cubic capacity cm

3

413 517 517

Compression ratio 20.0:1 20.0:1 20.5:1

Direction of rotation 1D . . S / Z / C counter-clockwise

looking at the flywheel 1D . . T / U clockwise

Cooling air required

at 3000 min-1 m3/min 6.0 6.0 10.5

Combustion air required

at 3000 min-1 m3/min 0.62 0.78 0.78

Oil capacity without oil filter approx. 1.1 1.4 1.8

with oil filter ltr. 1.2 1.5 1.9

Difference between approx.

„max“ and „min“ markings ltr. 0.4 0.5 0.9

Oil consumption Approx. 1% of fuel combustion at full load

Max. permissible inclination

in each direction during operation approx. 30° approx. 30° approx. 30°

Net weight

Engine models S, Z, T, U approx. 68* 76 91

Engine models C kg 89 – 114

Model S: non-encapsulated,normal system of balancing,counter-clockwise rotation

Z: non-encapsulated, add. system of balancing, counter-clockwise rotation

T: non-encapsulated, normal system of balancing,clockwise rotation

U: non-encapsulated,add. system of balancing, clockwise rotation

C: SILENT PACK, add. system of balancing, counter-clockwise rotation

*A1D41: 74 kg

Technical data

Page 14

1

1D . . / 03.06

Technical data

Type 1D80.. 1D90.

1D81..

Engine models S, Z, T, U, C S, Z, V, W

Mode of operation Air-cooled four-stroke diesel engine

Combustion method Direct-injection

Number of cylinders 1 1

Bore / stroke mm 100/85 104/85

Cubic capacity cm

3

667 722

Compression ratio 20.5:1 20.5:1

Direction of rotation 1D . . S / Z / C / V / W counter-clockwise

looking at the flywheel 1D . . T / U clockwise

Cooling air required

at 3000 min-1 m3/min 10.5 10.5

Combustion air required

at 3000 min-1 m3/min 1.0 1.1

Oil capacity without oil filter approx. 1.8 1.8

with oil filter ltr. 1.9 1.9

Difference between approx.

„max“ and „min“ markings ltr. 0.9 0.9

Oil consumption Approx. 1% of fuel combustion at full load

Max. permissible inclination

in each direction during operation approx. 30° approx. 30°

Net weight

Engine models S/Z/T/U/V/W approx. 91 92

Engine models C 121 –

Model S: non-encapsulated, normal system of balancing, counter-clockwise rotation

Z: non-encapsulated, add. system of balancing, counter-clockwise rotation

T: non-encapsulated, normal system of balancing, clockwise rotation

U: non-encapsulated, add. system of balancing, clockwise rotation

C: SILENT PACK, add. system of balancing, counter-clockwise rotation

V: vertical crankshaft, non-encapsulated, normal system of balancing,

counter-clockwise rotation

W: vertical crankshaft, non-encapsulated, add. system of balancing,

counter-clockwise rotation

Page 15

1

1D . . / 03.06

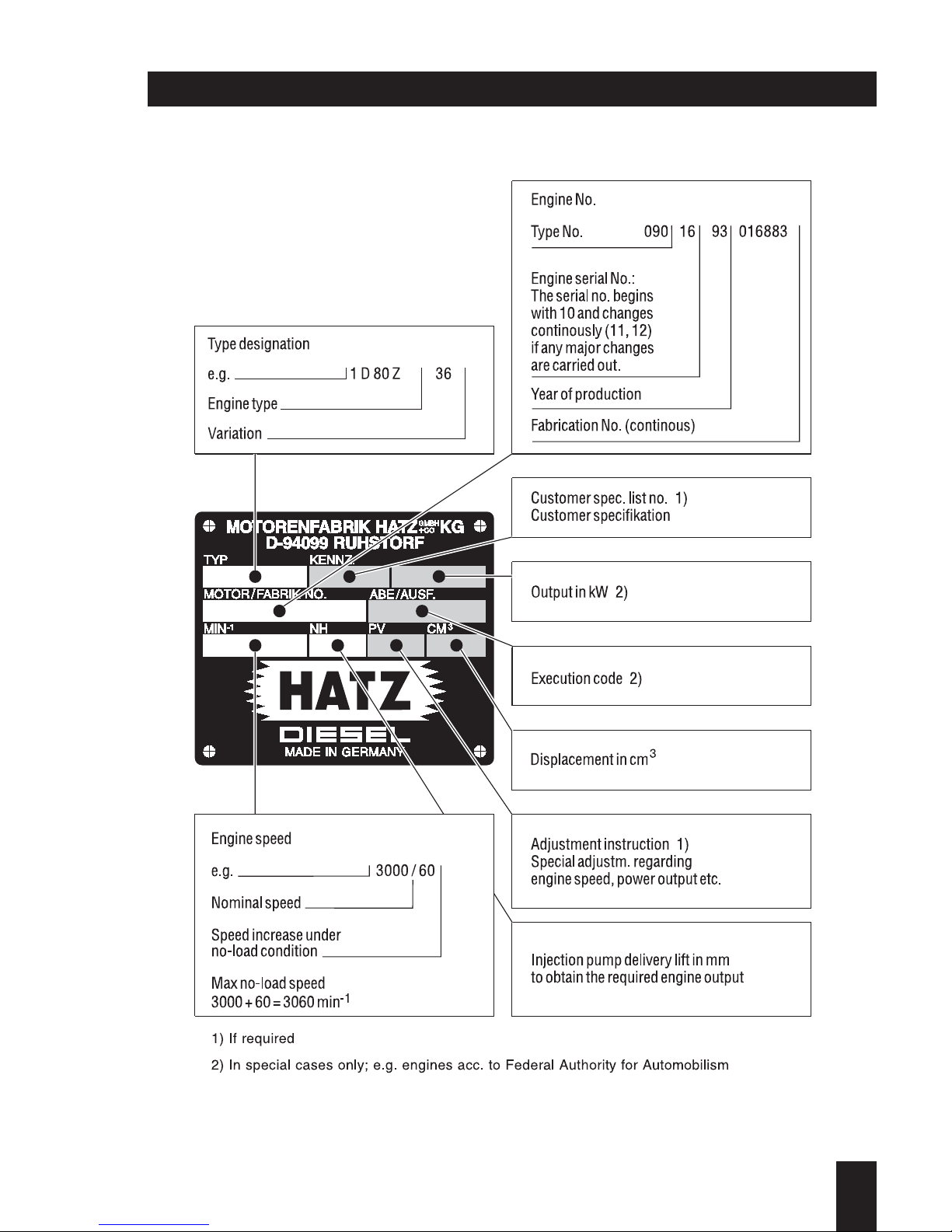

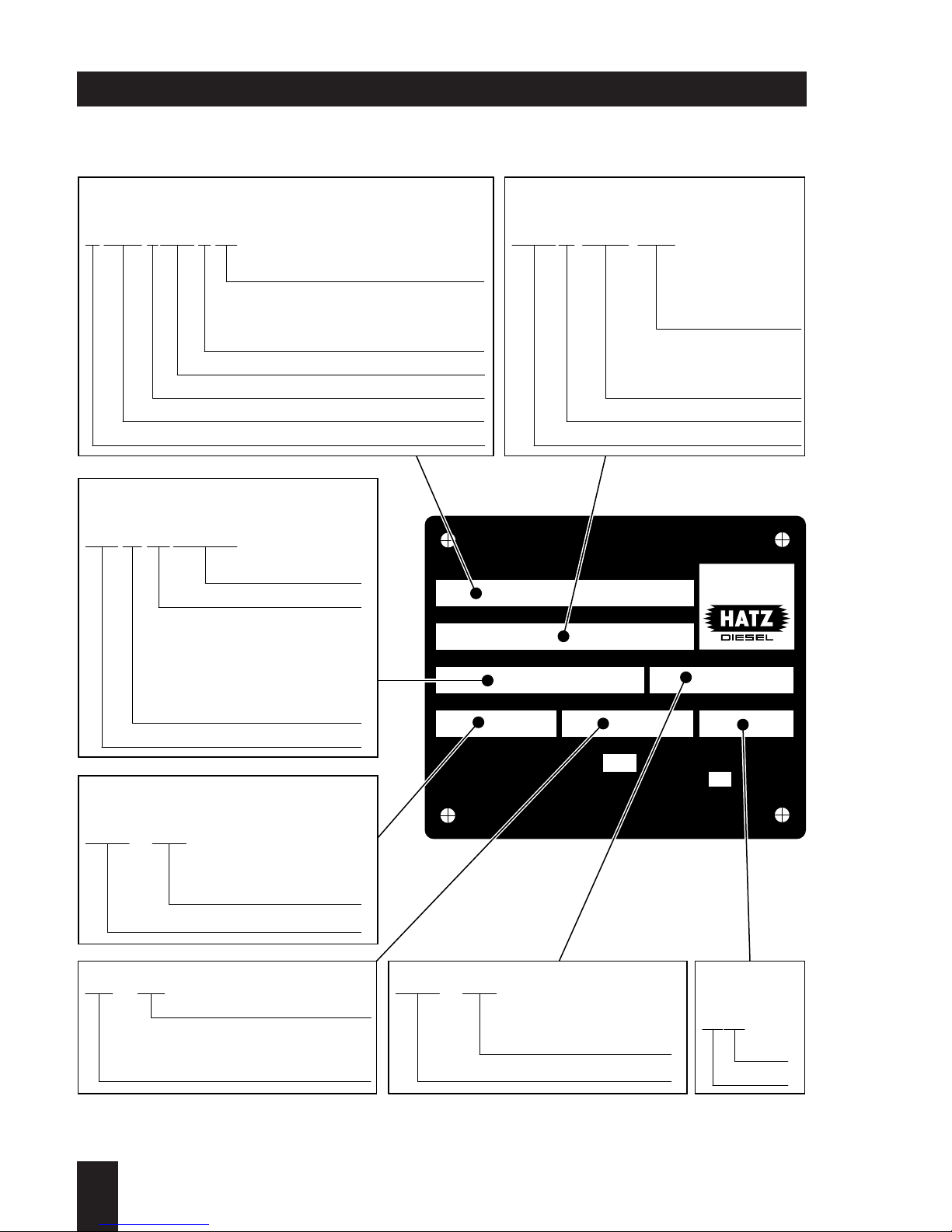

Type plate data

Page 16

EPA / Carb type plate data

ENG.FAM.

TYPE / SPEC. / FDT

MIN

SERIAL NO.

NH / kW

-1

MOTORENFABRIK HATZ KG·D-94099 RUHSTORF

CM3 / PV

BUILD DATE

IMPORTANT ENGINE INFORMATION

This engine conforms to MY U.S. EPA regulations large

nonroad compression-ignition engines and MY California

regulation for off-road compression-ignition engines.

Refer to owner's manual

for maintenance specifications and adjustments.

VARIABLE SPEED

GMBH

CO

+

Made in Germany

0.98 10.4 0667 189A

0504

1D81 Z 216B 13.04 HZX L.667 V 83

2950 290

073 23 04 083019

Rated power in kW

Injection pump delivery lift

in mm to obtain the required

power output

Special adjustment

instruction

Displacement in cm

3

Year

Month

Variation

Customer specification

(only for special

equipment)

Engine type

Static timing

(begin of fuel

delivery)

V = variable speed application

C = constant speed application

A = V + C as well

Displacement (in cm

3

or liters)

Diesel engine (Benzin/gasoline = S)

Manufactorer HZX = HATZ

Manuf. year (X = 1999, Y = 2000, 1 = 2001,...)

Type code

Speed increase under

no-load condition

Nominal speed

Engine serial No.:

The serial No. beginns

with 10 and changes

continously if any major

changes are carried out

Year of production

Type No.

Fabrication No.

Manuf. year

Type / Spec./ FDTEngine family

Engine speed

Engine number

1

1D . . / 03.06

Page 17

1

1D . . / 03.06

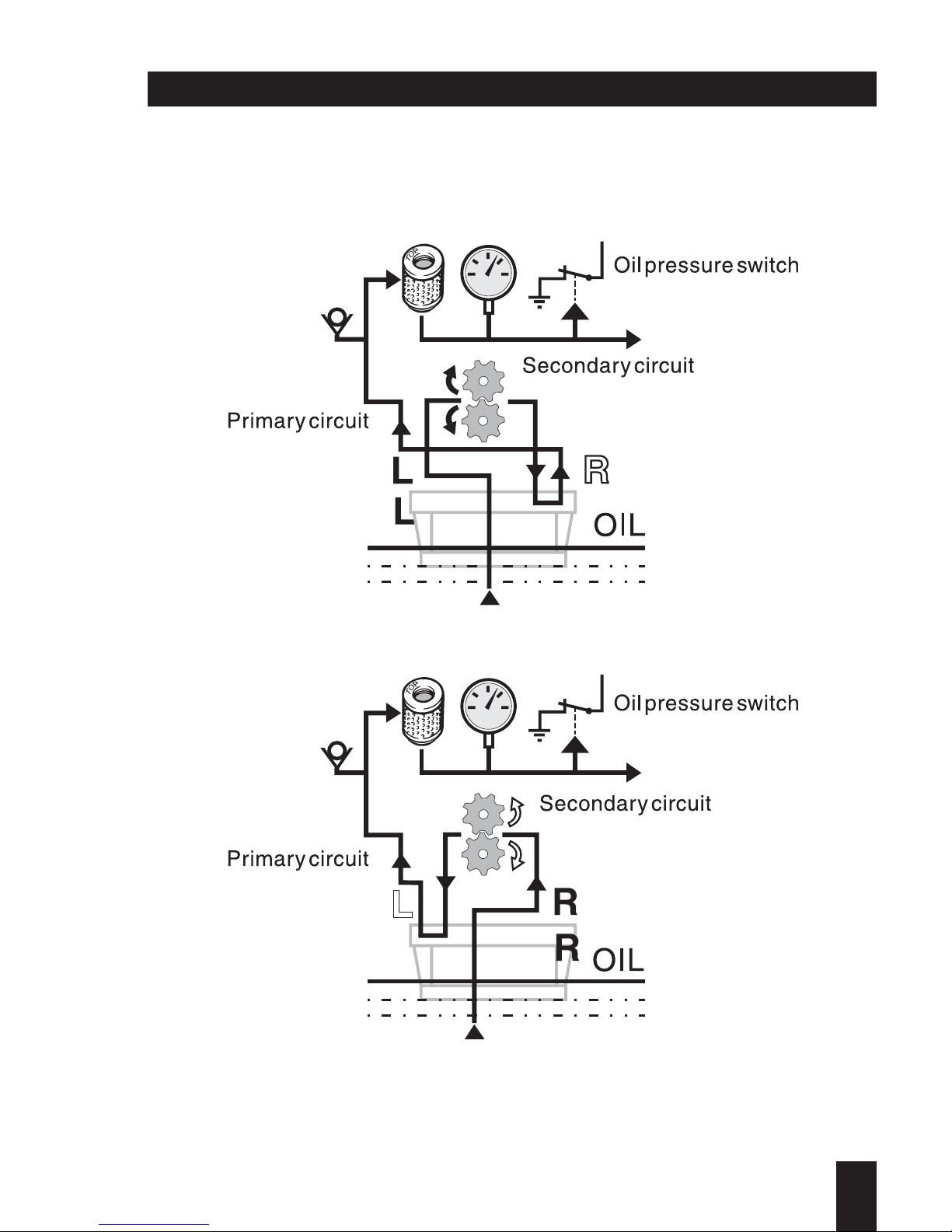

Lubrication oil circuit

Page 18

1

1D . . / 03.06

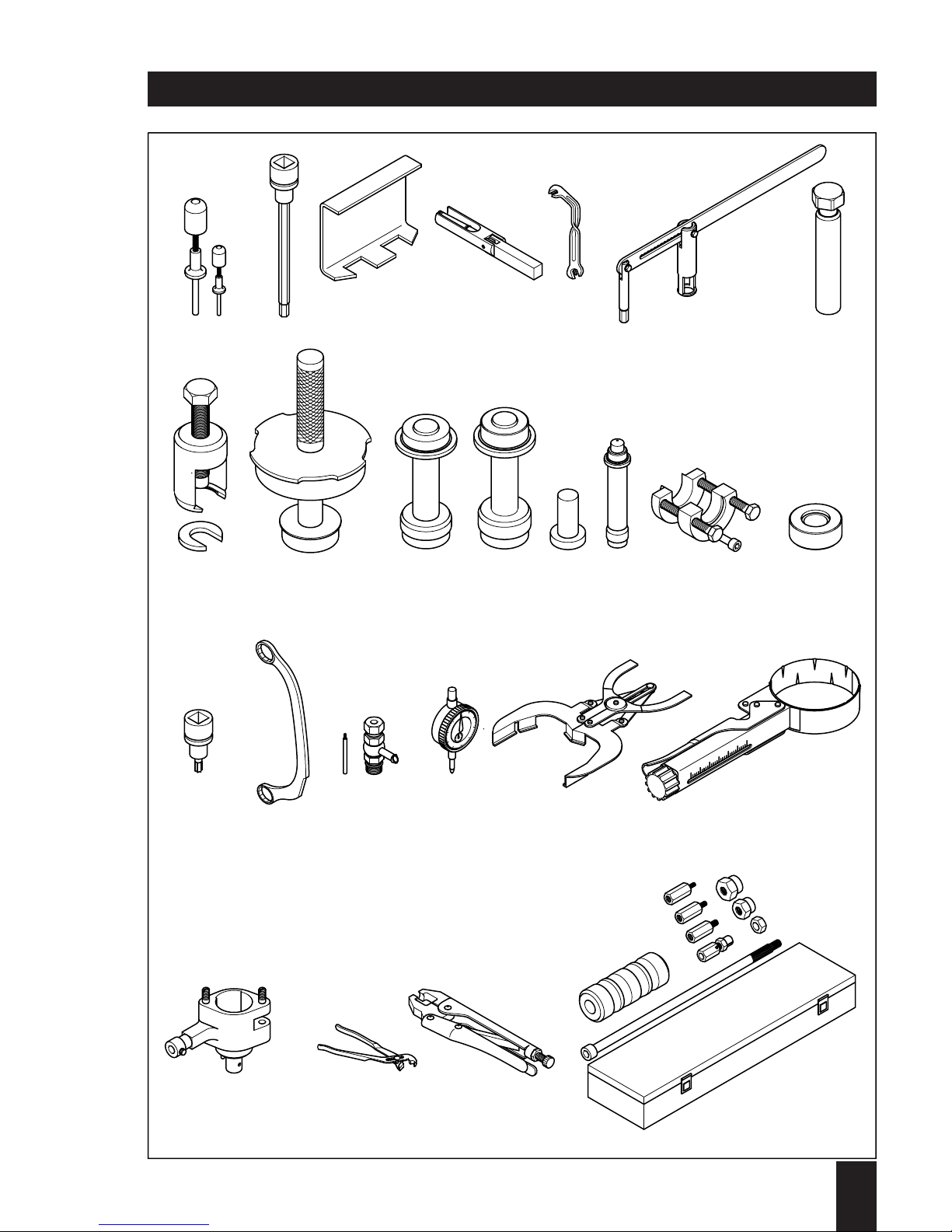

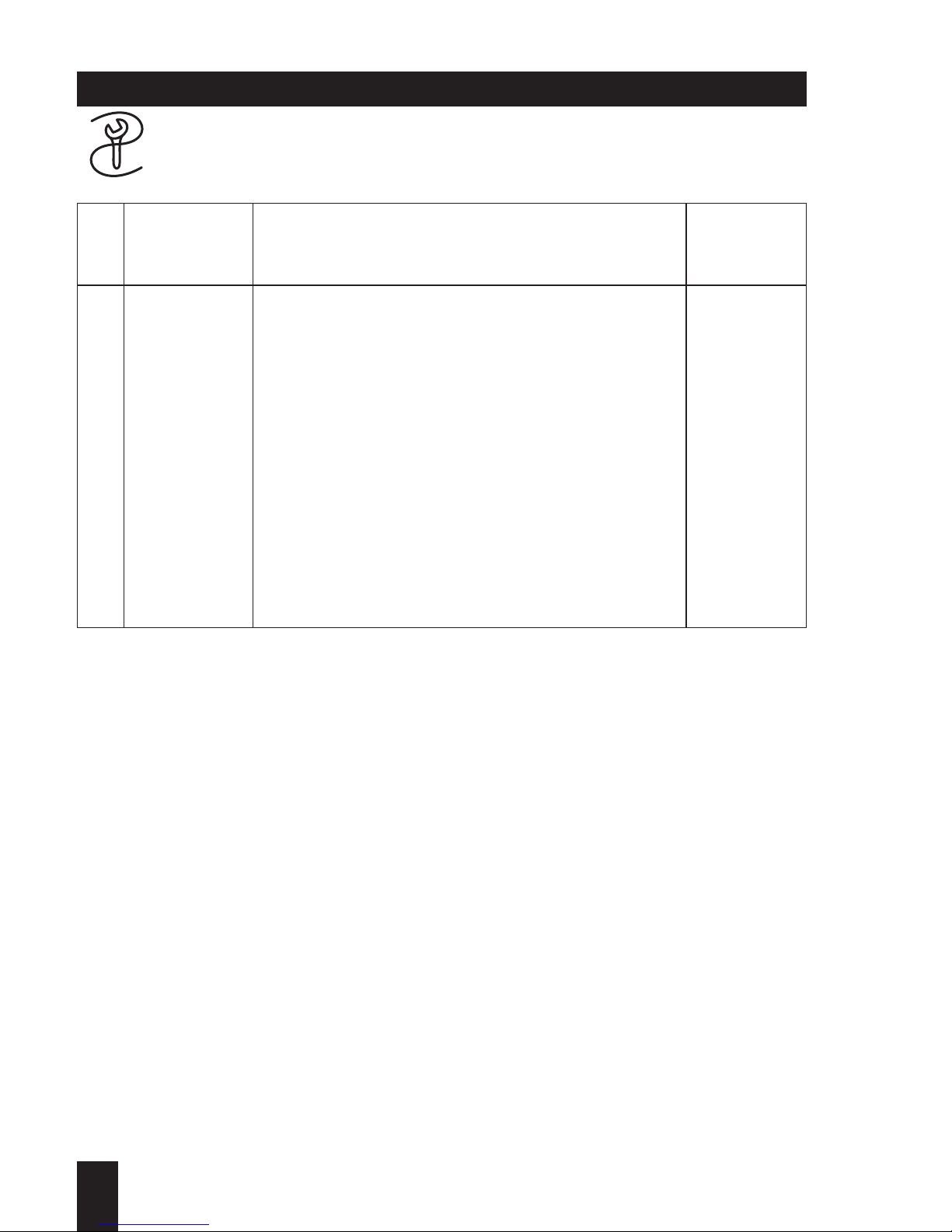

Special tools and workshop equipments

Engine series 1 D . . (SUPRA)

Bezeichnung

Verwendung

bei Typen

30-50 60-90

1

2

3

3

4

5

6

7

8

9

9

10

11

11

12

13

14

15

16

17

18

18

19

20

21

22

23

24

25

644 345 90

630 815 00

629 301 00

629 102 00

627 501 00

632 579 00

629 223 01

631 392 00

603 823 91

629 016 02

629 298 02

627 496 02

627 398 02

629 299 02

629 284 00

627 494 00

634 147 00

627 495 02

627 500 00

631 133 01

665 030 91

625 401 90

612 087 00

612 090 01

626 383 00

639 477 00

636 421 00

640 564 00

626 753 91

Clip tool for lead plugs

Allen socket 6 mm lg 1/2"

Clamp for pushrod tube

Clamp for pushrod tube

Retainer for governor spring

Adjustment wrench

Valve lifter

Mandrel for valve stem seal cap

Multi-purpose extractor

Punch for main bearing gov.-side

Punch for main bearing gov.-side

Punch for outer camshaft bushing

Punch for main bearing flywheel side

Punch for main bearing flywheel side

Heating insert for gear/stubshaft

Drift punch for camshaft bushing

Comb. extractor f. gear + stubshaft

Assembly device for oil pump shaft

Torx-socket TX 30 – 1/2"

Ring spanner 18 x 19 for starter

Spill device for injection pump M18x1.5

Spill device for injection pump M20x1.5

Dial gauge – 1/100 mm

Piston ring pliers

Piston ring clamp.device ∅ 70-100 mm

Measuring device for injection pump

Pliers for EPA - radial (tamper-resistant)

Pliers for EPA - axial (tamper-resistant)

Impact hammer with fittings

xx

xx

x–

–x

xx

xx

xx

xx

xx

–x

x–

xx

–x

x–

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

Ident-Nr.Nr.

Page 19

1

1D . . / 03.06

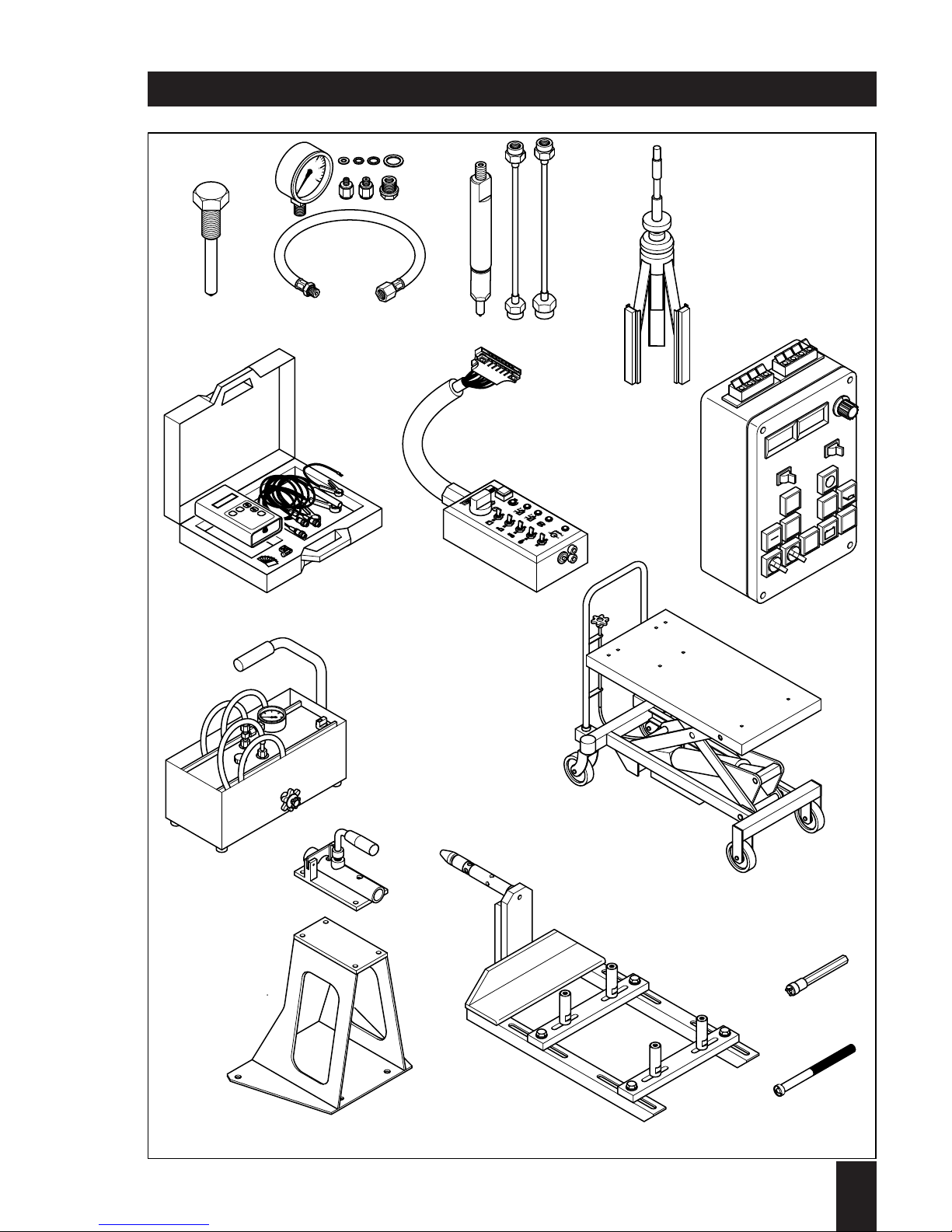

Special tools and workshop equipments

2

345 6 7

8 9 10 11 12 13 14 15

16 17

1

9

1

8

18 19 20 21

22 23 24 25

1

Page 20

Engine series 1 D . . (SUPRA)

Special tools and workshop equipments

1

1D . . / 03.06

Nr.

Bezeichnung

Verwendung

bei Typen

30-50 60-90

26

27

28

29

30

31

32

33

34

35

36

37

38

39

633 013 00

620 926 92

630 094 90

634 142 00

624 838 92

641 610 90

633 178 00

632 913 00

624 863 02

625 682 01

625 751 90

631 300 00

644 991 01

645 020 00

Forcing screw for centrif.-clutch

Oil pressure gauge 0... 6 bar

Test nozzle 400 bar / 5800 psi

Honing tool

Rev.-counter for fuel press.-pipe

Testbox for instrument box

Components testbox

High-pressure supply pump

Hydraulic lift trolley

Revolvable fixing - basic part

Console for revolvable fixing

Revolvable fixing - adaptor engine side

Socket wrench for lock nut

Punch for tab washer

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

Ident-Nr.

Page 21

1

1D . . / 03.06

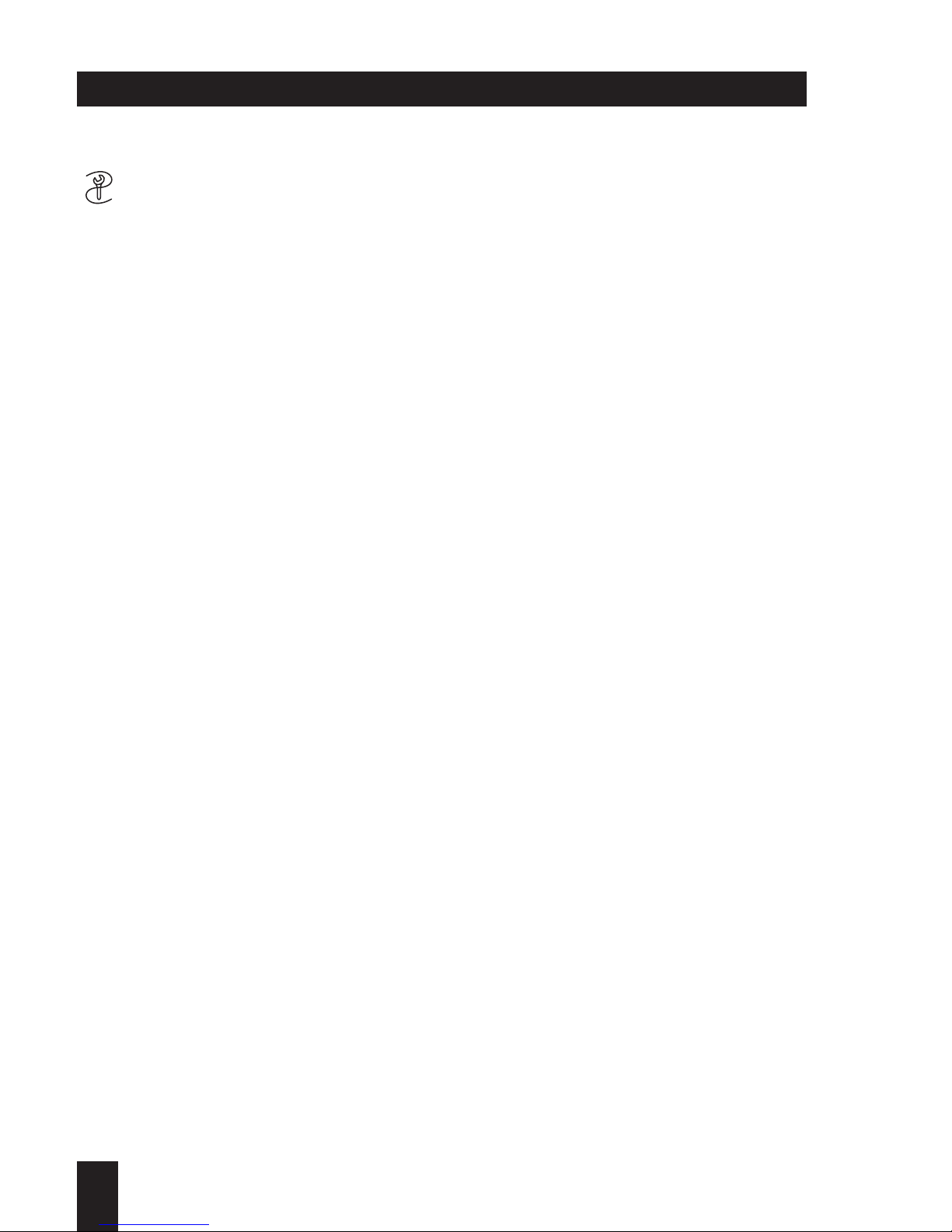

Special tools and workshop equipments

26

27

1

2

3

5

6

4

0

28

29

31

30

#

*

ON

15

86

87a

50

87

STAR

- +

32

34

33

10

20

30

40

max. 750 kg

35

36

37

39

38

Page 22

1

1D . . / 03.06

Jointing material / Sealing and bonding agents

Sealing and bonding agents are available from HATZ for use in maintenance and/or repair works.

All items listed below may be ordered as individual spare parts.

Refer to appropriate spare parts list for ordering.

Application of sealing and bonding agents:

The letter coding in the drawings indicates which agents should be applied when fitting

the part refered to.

See the following list for decoding the material; this list is the same as already being

used with all other service literature including spare parts list.

A = 502 230 01 Loctite Activator 500 ml

B = 502 231 00 Loctite 573 50 ml

C = 502 232 00 Loctite 601 50 ml

D = 502 233 00 Loctite 221 50 ml

E = 502 234 00 Loctite 648 10 ml

F = 502 238 00 Technicoll 8058 750 g

+ 502 239 00 Technicoll 8367 750 g

G = 502 565 01 Loctite IS 407 20 g

H = 502 825 01 Silicon sealer 30 ml

J = 502 830 02 Anti-Seize compound 1000 g

K = 503 426 00 High-temp. lub.-grease 100 g

L = 502 566 00 Silicon sealer 100 g

M = 504 851 00 Polishing paste K 240 80 ml

Page 23

2

1D . . / 03.06

2. Additional equipment

Page 24

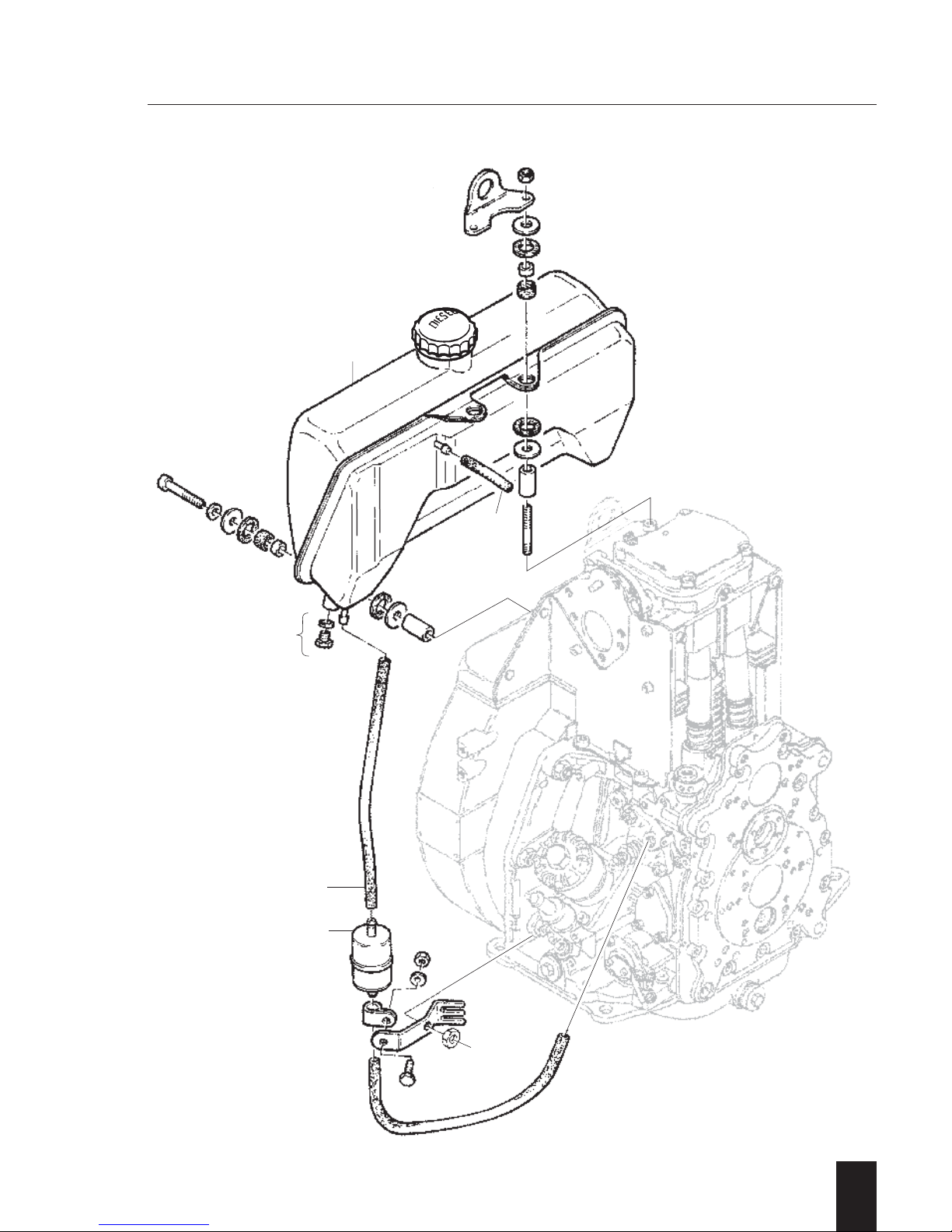

A 01.10 Fuel tank

–

Preparations: –

Dismantling:

– Loosen drain plug 1 and drain off fuel or

close off fuel supply pipe 2.

– Remove (pull off) fuel hoses 2...3 from

fuel filter and fuel tank.

– Unscrew respectively remove all retaining

components in question, including fuel

tank 4.

– Remove fuel filter 5 with retaining compo-

nents if necessary.

Inspection / repair:

– Visual inspection.

– Check fuel tank for cracks and/or any

other damage.

– Check all rubber parts for ageing etc.

Maintenance according to instruction book!

Assembly:

– Re-assemble and re-connect fuel tank 4

and fuel filter 5 as well as fuel hoses 2...3.

Tighten all retaining items uniformly to

obtain a stress free assembly of the fuel

tank.

– Remove clamp tool and/or tighten drain

plug 1.

2

1D . . / 03.06

A 01.00 Fuel

Page 25

A 01.00

A 01.10

2

1D . . / 03.06

4

3

2

5

1

Page 26

2

1D . . / 03.06

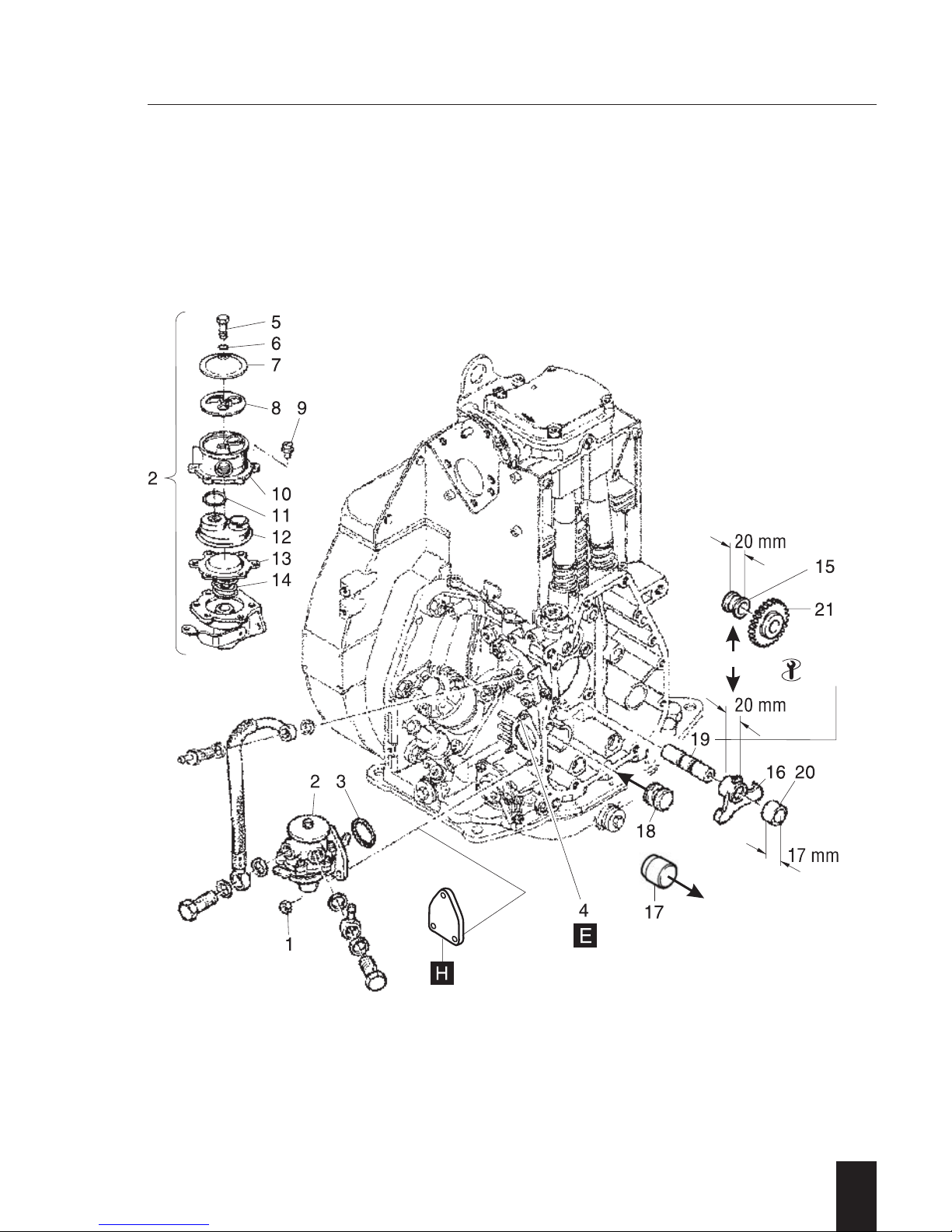

A 01.40 Fuel feed pumps

- 25 -

I. Fuel feed pump

General:

When connecting the fuel feed pump take

care for arrangement of suction and supply

hose.

Preparations:

– Disconnect fuel supply from fuel feed and

injection pump.

Dismantling:

– Remove in numerical sequence 1 ... 3.

NOTE:

When removing the upper nut, make sure

that the stud 4 does not turn in the crankcase as it serves as the anchor pin for the

governor lever retainer spring. If turning of

the stud cannot be avoided, remove the

spring from the pin. The front cover must be

removed to remove the spring.

Ref.: Chapt. M 11.00

Inspection / repair:

– Visual inspection.

For further repair proceed as follows:

– Remove in numerical sequence 5 ... 14.

Required only if irregularities such as poor

suction / pumping action i.e. contaminated

strainer or leaks have been noted.

– Check and replace all parts in question.

Assembly:

– Pre-assemble in reverse sequence 14...5.

– Assemble in reverse sequence 3 ... 1.

– Ensure actuating lever 16 is in bottom

position and „O“-Ring 3 remains in its

groove when assembling.

– After installation and a short test run,

check the fuel system for leaks.

II. Fuel feed pump drive

General:

Models Z/U/C

Bushing 15 is replaced by the actuating

lever 16.

Models S/T

Plug 17 is replaced by the plug 18 with

ring groove.

Preparations:

– Remove fuel feed pump.

– Remove timing cover.

Ref.: Chapt. M 11.00

Dismantling:

– Remove part 20/21 and lever 16.

– Remove shaft 19.

For removal use tool - 25 -

Plug 18 remains in crankcase.

Inspection / repair:

– Visual inspection.

– Check parts for wear and/or any other

damage.

Assembly:

– Assemble in reverse sequence .

– Press in shaft 19 to a protrusion of 52 ±

0,5 mm.

Extractor thread must face front!Models

Z/U/C

Ensure all gear timing marks match!

– Finish assembling.

A 01.00 Fuel

Page 27

2

1D . . / 03.06

A 01.00

A 01.40

25

Page 28

2

1D . . / 03.06

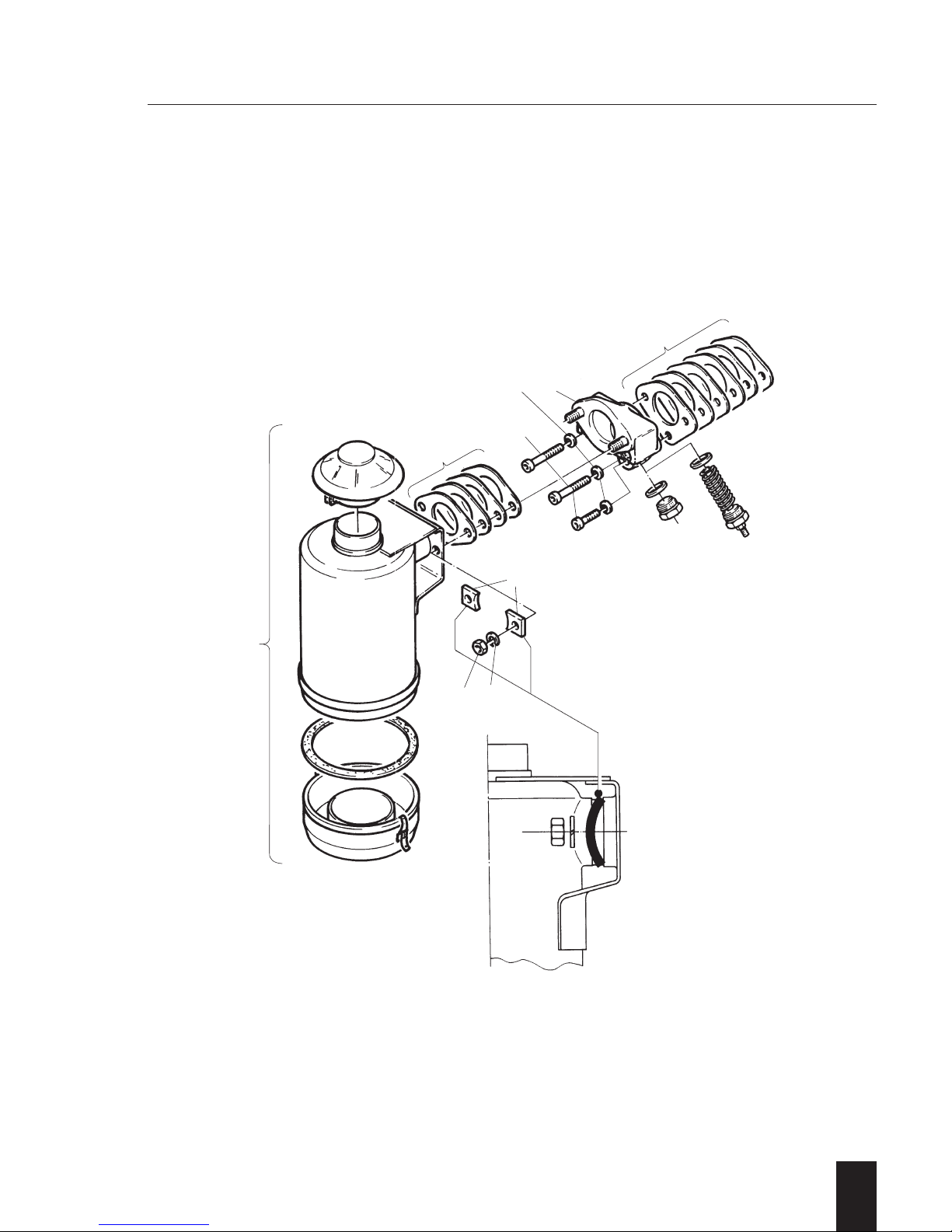

A 02.10 Oil bath air filters

–

General:

The oil bath air filter is fitted by means of an

intermediate flange which adapts from the

triangle-type flange at cylinder head to the

twin-screw flange of oil bath air filter. This

flange also holds the glow plug in case a

pre-heating system is fitted.

Preparations: –

Dismantling:

– Disconnect cable connection from glow

plug if fitted.

– Remove in numerical sequence 1...9.

Studs and Hex.-head screw plug or glow

plug may remain.

Don't tip oil bath air filter !

Inspection / repair:

– Visual inspection.

– Check air filter body for cracks and/or any

other damage.

Maintenance according to instruction book!

NOTE:

Never „repair“ an oil bath air filter by

welding/soldering etc.

It causes total damage to the part and may

lead to engine failure!

Assembly:

– Assemble in reverse sequence 9...1.

Ensure the correct amount of gaskets

are used and parts seal properly to

avoid infiltrated air.

When fixing the oil bath air filter take

care for correct position of kidneyshaped washers 3, convex side faces

retaining nuts 1.

– Reconnect cable connection to glow

plug if so fitted.

A 02.00 Combustion air

Page 29

2

1D . . / 03.06

A 02.00

A 02.10

78

6

3

12

4

9

5

Page 30

A 02.11 Dry type air filters

–

Version A 02.11.1

Fixation of filter element and cover by flat

washers and Hex.-nuts.

Preparations: –

Dismantling:

– Remove in numerical sequence 1...10.

Inspection/repair:

– Visual inspection.

– Check filter element 6 and sealing strip

around cover 3.

Maintenance according to instruction book!

Assembly:

– Assemble in reverse sequence 10...1.

Torque to specification!

NOTE:

Mind total length of bushing 4 and washer 5

respectively length of bushing 4 without

washer.

Take care for correct position of insulating

flange in between, correct amount of

gaskets and proper sealing of all parts to

avoid infiltrated air.

Conversion:

Possible to current standard in case all parts

in question become replaced.

2

1D . . / 03.06

Version A 02.11.2

Fixation of filter element separately by

retaining plate, flat washers and Hex.-nuts.

Preparations: –

Dismantling:

– Disconnect cable connection from

heater flange if so fitted.

– Remove in numerical sequence 1...12.

– If necessary dismantle cover retaining

screw to replace sealing sleeve (rubber)

between screw cap and cover.

Inspection / repair:

– Visual inspection.

– Check filter element 6 and sealing strip

around cover 1.

Maintenance according to instruction book!

Assembly:

– Assemble in reverse sequence 12...1.

Torque to specification!

NOTE:

Take care for correct position of insulating

flange in between, correct amount of

gaskets and proper sealing of all parts to

avoid infiltrated air.

– Reconnect cable connection to heater

flange if so fitted.

Conversion:

Possible to current standard in case all

parts in question become replaced.

A 02.00 Combustion air

Page 31

2

1D . . / 03.06

A 02.00

A 02.11

45

4

44

5

78

76.5

78

23 Nm

17 lb ft

23 Nm

17 lb ft

67.5 mm

64.7 mm

1D30 - 1D40

1D60 - 1D80

A 02.11.1

A 02.11.2

3

6

78

9

10

5

12

2

3

6

789

11

12

10

1

Page 32

A 02.11 Dry type air filters

–

Version A 02.11.3

Fixation of filter element by front cover

assembly.

Preparations: –

Dismantling:

– Disconnect cable connection from heater

flange if so fitted.

– Remove in numerical sequence 1...11.

– If necessary dismantle cover retaining

assembly to replace sealing sleeve (rubber) between centering and front cover.

Inspection / repair:

– Visual inspection.

– Check filter element 2 and sealing strip

around cover 1.

Maintenance according to instruction book!

Assembly:

– Assemble in reverse sequence 11...1.

Take care for correct position of insulating

flange in between, correct amount of

gaskets and proper sealing of all parts to

avoid infiltrated air.

– Reconnect cable connection to heater

flange if so fitted.

2

1D . . / 03.06

Version A 02.11.4 (A 1 D...)

Fixation of filter element separately by retaining plate, flat washers and Hex.-nuts.

Preparations: –

Dismantling

– Disconnect cable connection from hea-

ter flange if so fitted.

– Remove in numerical sequence 1...15.

Inspection / repair:

– Visual inspection.

– Check filter element 8, „O“-Ring around

retaining cover 11 and insulation plate 12.

Maintenance according to instruction book!

Assembly:

– Assemble in reverse sequence 15...1.

Take care for correct position of insulating flanges in between, correct amount

of gaskets and proper sealing of all

parts to avoid infiltrated air.

– Reconnect cable connection to heater

flange if so fitted.

A 02.00 Combustion air

Page 33

2

1D . . / 03.06

A 02.11.3

A 02.11.4

B

2

6

64.7

134

67

528

9

10

11

3

45

7

8910

11

12

13

15

14

A 02.00

A 02.11

Page 34

2

1D . . / 03.06

–

Preparations: –

Dismantling:

– Remove in numerical sequence 1...2.

– Remove in numerical sequence 3...6.

Ensure not to lose flap valve 6!

– Remove in numerical sequence 7...10.

Hose pulled off from banjo hose nipple

during removal.

Hose nipple connection 16 may remain.

1 D 60 - 80 - 81 only:

– Snip cable strap 11.

– Remove in numerical sequence

10/12...15.

Parts may remain as a unit.

Inspection / repair:

– Visual inspection.

– Check maintenance indicator by sucking

and releasing at the end of hose or adapter for indication.

Sucking = indicator „CLOSED“

(green section ring not visible)

Release = indicator „OPEN“

(green section ring visible).

–Check all rubber parts for material

ageing etc.

–Check all parts in question for proper fit.

Maintenance according to instruction book!

Assembly:

– Assemble in reverse sequence 15...10.

1 D 60 - 80 - 81 only!

– Cable strap remains loose.

– Connect hose 10 to hose nipple

connection and assemble parts 9...7.

– Put flap valve 6 onto pin location of

retaining bracket 5.

– Assemble in reverse sequence 5...3.

Ensure flap valve remains in position

during assembly!

– Check function of flap valve in connec-

tion with maintenance indicator as follows:

– Press indicator cap.

Cap has to remain for a short term in

„CLOSED“ position.

Green section ring not visible!

NOTE:

A minimum time of 3 s between

„CLOSED“ and „OPEN“ has to be

obtained.

– Lift flap valve.

Cap has to come to „OPEN“ position.

Green section ring visible!

Ensure the indicator reacts as described.

If not, check seating position in housing

or replace flap valve.

– Assemble in reverse sequence 2...1.

1 D 60 - 80 - 81 only:

– Tighten cable strap.

A 02.00 Combustion air

A 02.13 Service indicators; vacuum gauges

Page 35

2

1D . . / 03.06

A 02.00

A02.13

Page 36

2

1D . . / 03.06

A 02.20 Pre-cleaners; cyclons

–

Version A 02.20.1

Cyclon fitted at bottom side inlet port.

Front inlet port and through holes plugged.

Preparations: –

Dismantling:

– Loosen hose clip and remove cyclon 1.

Inspection / repair:

– Visual inspection.

– Check closing plugs for tightness.

Maintenance according to instruction book!

Don't use oily cleansers.

Assembly:

Place cyclon 1 and tighten hose clip.

Version A 02.20.2

Cyclon fitted to front side inlet port.

Bottom inlet port closed.

Preparations: –

Dismantling:

– Remove front cover 1 including cyclon

system.Closing cap at bottom side

remains.

– Remove in numerical sequence 2...5.

Inspection / repair:

– Visual inspection.

– Check rubber elbow for material ageing,

replace if necessary.

Maintenance according to instruction book!

Don't use oily cleansers.

Assembly:

– Assemble in reverse sequence 5...1.

A 02.00 Combustion air

Page 37

2

1D . . / 03.06

A 02.20.1 A 02.20.2

1

45 1

32

A 02.00

A 02.20

Page 38

2

1D . . / 03.06

- 2 -

Version A 03.12.1

Exhaust silencer fitted in connection with

studs, flat washers and hex.-nuts.

Version A 03.12.2

Fixation by Allen screws.

Preparations:

– Remove protection guard if so fitted.

Dismantling:

Version A 03.12.1

– Remove in numerical sequence 1...5.

Bushings 4 are fitted only in connection

with an exhaust silencer with recessed

bores to prevent the silencer getting loose.

Version A 03.12.2

– Remove in numerical sequence 1...3.

For removal use tool - 2 -

Inspection / repair:

– Visual inspection.

– Check exhaust silencer for possible cracks

and/or any other damage.

Assembly:

– Assemble in reverse sequence.

Apply lubricant as specified!

Torque to specification!

Ensure gasket-kit is fitted in correct sequence i.e. the creased gaskets face towards

exhaust silencer.

– Assemble protection guard if so fitted.

Conversion:

Possible to current standard.

Protection guard

General:

The fixation of the guard has been modified to avoid breaks around the fixation

due to excessive vibrations.

Preparations:–

Dismantling:

– Remove in numerical sequence 1...3/4.

Inspection / repair:

– Visual inspection.

– Check guard around fixation for breakage.

Assembly:

– Assemble in reverse sequence 4/3...1.

Use anti-seize compound as specified.

Ensure the concave side of the curved

washers 4 face towards guard 3.

A 03.00 Exhausts

A 03.12. Exhaust-silencers, high performance / Protection guard

Page 39

2

1D . . / 03.06

A 03.12.1

A 12.30.1

A 03.12.2

A 12.30.2

53

21

43 21

23 Nm

17 lb ft

5

3

1

2

1

2

4

33

4

1

2

4

4

3

2

A 03.00

A 03.12

Page 40

2

1D . . / 03.06

–

Version A 04.10.1

Standard starting handle:

Replaceable at any time by a safety starting

handle if required or specified.

ATTENTION !

Take care, a worn shaft or broken handle

can cause serious injuries.

Preparations: –

Dismantling: –

Inspection / repair:

– Visual inspection.

– Check shaft 1 and handle 2 for wear

and/or any other damage.Handle 2 can be

replaced by removing and replacing snap

ring 3.

In case shaft 1 is worn replace complete

starting handle.

A 04.00 Start mechanical / pneumatic

A 04.10 Starting handles without supports

Page 41

2

1D . . / 03.06

A 04.10.1

A 04.10.2

47

8

15

14 13

12

11

10

9

6

5

16

1521

3

A

1

23

A 04.00

A 04.10

Page 42

2

1D . . / 03.06

–

Version A 04.10.2

Anti-kick-back starting handle, specified as

type A for 1 D.. S/Z/C engines.

ATTENTION !

Take care, a worn shaft or broken handle

can cause serious injuries.

Preparations: –

Dismantling:

– Remove in numerical sequence 1...3.

– Remove Allen screws 4 and cover 5.

Remove cover carefully to avoid plate

spring 11 jumping out.

Risk of injury !

– Remove in numerical sequence 6...10.

– Hold leg spring 13 firmly down to avoid

release of spring tension.

– Pull plate spring 11 off its pin location and

out of the hook shaped part of the leg

spring 13.

– Release spring tension of leg spring using

a screw driver or similar tool.

Risk of injury!

– Remove in numerical sequence 12...13.

Housing 14 remains with all fixed parts.

Inspection / repair:

– Visual inspection.

If cover 5 and housing 14 are worn or

damaged, use a new starting handle.

Bearing bushings 15 and oil seal 16 can

be replaced.

– Check handle 7 for wear and/or damage

concerning teeth and/or handle.

Take care not to damage teeth when a

new end plug 8 becomes fitted.

End plug has to be existent !

– Check conditions of bushing and plate

spring on lever 9.

– Check condition of plate spring 11 and

leg spring 13.

– Check starting handle shaft 3 for wear

and/or any other damage.

Replace worn shaft and hardware if

necessary.

Assembly:

– Assemble in reverse sequence 13...12.

Apply locking agent as specified!

Ensure leg spring is not squeezed,

straight end catches groove in location

pin.

– Force leg spring 13 against spring ten-

sion until hook shaped part catches end

position at inside of through hole eye.

– Hold leg spring 13 firmly down to avoid

release of spring tension.

– Place plate spring 11 into hook shaped

part of leg spring 13 respectively onto

location pin.

Rolled end of plate spring faces centre

of housing.

– Put lever 9 onto location bolt.

– Place handle 7 / 8 onto handle shaft.

Check handle-teeth, lever and plate

springs for free moving.

– Apply approx. 50g/1.8 oz. of grease as

specified into cavity of housing 14

respectively over all mechanical parts.

– Place gasket 6 and cover 5 carefully

over handle 7 onto housing 14.

– Place and tighten Allen screws 4 cross-

wise and uniformly.

– Assemble in reverse sequence 3...1.

– Check complete unit for proper function.

A 04.00 Start mechanical / pneumatic

A 04.10 Starting handles without supports

Page 43

2

1D . . / 03.06

A 04.10.1

A 04.10.2

47

8

15

14 13

12

11

10

9

6

5

16

1521

3

A

1

23

A 04.00

A 04.10

Page 44

2

1D . . / 03.06

–

General:

Version A 04.11.1

Part without replaceable bushing.

Version A 04.11.2

Part with replaceable bushing.

ATTENTION !

Take care, a worn guiding shell can cause

serious injuries.

Preparations: –

Dismantling:

– Remove in numerical sequence 1...3/4.

NOTE:

Engines working under extremly dusty conditions should be equipped with a protection

plate 4 which avoids access of dust to the

contact area of camshaft seal ring.

Inspection / repair:

– Visual inspection.

– Check bore for wear and/or any other

damage.

Version A 04.11.1

– In case bore is worn (oval) replace

guiding shell.

Version A 04.11.2

– In case bore/bushing is worn (oval)

replace guiding bushing 5.

Assembly:

– Assemble in reverse sequence 4/3...1.

Apply locking agent as specified!

Use starting handle to align guiding shell

before tightening Allen screws.

- 25 -

General:

Version A 04.12.1

Part is bonded into camshaft.

Version A 04.12.2

Parts fitted loose in camshaft.

ATTENTION !

Take care, a worn or damaged cranking

claw can cause serious injuries.

Preparations:

– Remove guiding support if so fitted.

Dismantling:

Version A 04.12.1

– Weld (spots and arc-welding only) M8

nut onto crank jaw.

For removal of crank jaw use tool - 25 -

Protect area around camshaft to avoid

any damage.

Version A 04.12.2

– Remove parts (pull) by hand in numerical

sequence 1...3.

Inspection / repair:

– Visual inspection.

Replace crank jaw in case of wear.

Assembly:

Version A 04.12.1

– Apply high strenght locking agent

around location pin and insert (push)

crank claw firmly in.

Version A 04.12.2

– Bring location groove in camshaft to

TOP-position.

– Put location pin 3 onto crank jaw 2.

– Insert parts together into bore

– Place and tighten Allen screw 1.

Apply locking agent as specified!

– Assemble guiding support if so fitted.

A 04.00 Start mechanical / pneumatic

A 04.11 Starting handle supports A 04.12 Cranking claws

Page 45

2

1D . . / 03.06

4321

421

321

25

A 04.11.1

A 04.11.2

A 04.12.1

A 04.12.2

3

5

A 04.00

A 04.11

A 04.12

Page 46

A 04.30 Rope starts

–

General:

Recoil starters available respectively fitted

as additional equipment in connections with

engines as follows:

Preparations: –

Dismantling:

– Remove in numerical sequence 1...2 from

respective engine flange.

– Pull knot / rope 3 with snipe nosed pliers

from handle 4 and untie.

– Allow rope pulley 5 to retract slowly until

recoil spring 6 is unwound.

Rope guide 13 and closing screw 14 may

remain.

– Remove in numerical sequence 7...12.

Brake spring 10 may remain.

– Remove rope pulley 5 carefully from recoil

spring 6 respectively housing.

NOTE:

To prevent the recoil spring from uncoiling,

rotate rope pulley back and forth to disengage inner spring eye and carefully lift out of

housing.

Recoil spring needs not to be removed from

housing, unless it is broken.

To remove recoil spring 6 take housing in

both hands, open side down and hit housing

on work bench or other flat surface.

Spring will drop out.

– Remove rope 3 from rope pulley 5.

2

1D . . / 03.06

Inspection / repair:

– Visual inspection.

– Check all parts in question, inclusive

driving elements 15 for wear and / or

any other damage.

Assembly:

It is of utmost importance to follow the

details as specified to obtain the correct

assembly as far as engine models in connection with direction of rotation is concerned.

With unwound recoil spring out of housing:

– Wind recoil spring 6 into housing.

With new recoil spring - prewound:

– Place recoil spring in housing and push

down into housing. Remove retaining

wire.

NOTE:

The outer spring eye must be properly

hooked around the retaining tab.

The clearance required between inner

spring eye and rope pulley shaft has to be

obtained as specified.

If necessary, rebend spring eye.

Apply high-temp. lub.-grease as specified

over all mechanical parts during assembly.

– Slide rope 3 through hole in rope pulley

5 and wind rope around pulley accor-

ding to engine model.

– Fit rope pulley together with rope 3 and

carefully rotate it back and forth until it

engages in the inner spring eye of the

recoil spring 6.

– Fit long end of torsion spring 12 into

hole of rope pulley 5 as specified

according to engine model, pushing it

over pawl guide.

A 04.00 Start mechanical / pneumatic

Engine types 1 D 30 - 31 - 35 - 40 - 41

models position

direction

of rotation

execution

of housing

S/Z

Flywheel

side

counter

clockwise

closed

T/U clockwise open

Page 47

2

1D . . / 03.06

4mm

4mm

13

1

14

4

3

5

12 11

10 9

87

6

2

2

15

13 1

4

3

65

12 11

10 9

8

7

S/Z

T/U

A 04.00

A 04.30

Page 48

A 04.30 Rope starts

– Slip pawl 11 according to engine model

over pawl guide.

Short end of torsion spring 11 must fit into

groove of pawl.

– Push down brake disk 9 with brake

spring 10 as specified according to engine

model onto rope pulley shaft.

– Place and tighten retaining items 8...7.

Apply locking agent as specified !

– Rotate rope pulley 5 as specified 3 - 4

turns against the recoil spring tension and

hold firm.

– Slide rope 3 through the rope guide 13 in

the housing respectively through handle 4

and tie knot.

Slowly return handle.

– Check recoil starter for proper function.

If the recoil starter has been properly

assembled, the pawl must move outward

when rope is pulled.

2

1D . . / 03.06

A 04.00 Start mechanical / pneumatic

Page 49

2

1D . . / 03.06

4mm

4mm

13

1

14

4

3

5

12 11

10 9

87

6

2

2

15

13 1

4

3

65

12 11

10 9

8

7

S/Z

T/U

A 04.00

A 04.30

Page 50

General:

The execution of electrical equipment

depends on voltage (12 V or 24 V) as well

as the direction of rotation.

Different ring gears, starter motors, coils

and magnet segments are applied.

2

1D . . / 03.06

A 05.00 Start electrical

Page 51

Page 52

2

1D . . / 03.06

A 05.20 Starter motors

- 17 -

General:

Starter motors are different in construction

as well as voltage and direction of rotation is

concerned.

It is of utmost importance not to combine

parts from different construction or version.

Preparations:

– Disconnect battery in sequence - / +

– Disconnect cable connections as necessary,

respectively remove retaining plate with

voltage regulator depending on kind of

equipment.

Dismantling:

– Remove in numerical sequence 1...6.

Studs 7 may remain.

For removal use tool - 17 -

Inspection / repairs:

– Visual inspection.

– Check bushing and pinion for wear and/or

any other damage.

– Check pinion for free movement on shaft.

NOTE:

Repairs or adjustments in connection with

the starter motor should be carried out by a

HATZ-Distributor or any other authorized

workshop.

Assembly:

– Assemble in reverse sequence 6...1.

– Reassemble respectively reconnect elec-

trical system as dismantled before.

– Reconnect battery in sequence +/-

– Check (start) electrical system for proper

function.

A 05.00 Start electrical

Page 53

2

1D . . / 03.06

17

21

4

53

76

A 05.00

A 05.20

Page 54

2

1D . . / 03.06

–

General:

It is recommended to always check the

alternator for degree of function before any

disassembly.

Ref.: Section 4

Preparations:

– Remove flywheel (M 17.00).

Version A 05.40.1

The magnet segments are located on the

flywheel by means of centering/roll pins.

Version A 05.40.2

The magnet segments are located on the

flywheel by means of a machined location

ring groove.

Version A 05.40.3

The magnet segments are substituted by a

magnet ring.

Dismantling:

– Remove in numerical sequence

Inspection / repair:

– Check magnet segments for wear or any

other damage.

Assembly:

– Assemble in reverse sequence

Torque to specification!

A 05.00 Start electrical

A 05.40 Alternator / Magnet segments

Page 55

2

1D . . / 03.06

A 05.40.3

A 05.40.1 A 05.40.2

2.8 Nm

2.1 lb ft

1

2

3

4

2

1

1

2

A 05.00

A 05.40

Page 56

2

1D . . / 03.06

A 05.41 Alternator / Coils

–

Version A 05.41.1

Open coils fixed to the crankcase.

Fixation and adjustment of air gap is done

by spacers.

Preparations:

– Remove flywheel and housing.

Dismantling:

– Disconnect electrical system.

– Remove in numerical sequence 1...5.

Inspection / repair:

– Visual inspection.

– Check coils for wear and/or any other

damage.

Assembly:

– Assemble in reverse sequence 4...1.

Without spacers 5 and retaining nuts 1

loose.

Adjustment:

– Assemble flywheel.

NOTE:

Flywheel tight, not torqued.

– Push flywheel towards governor side or

even better put engine onto flywheel to

eliminate the end float.

– Measure gap between coils and magnet

segments.

Use feeler gauge.

– Keep spacers as required next to the

corresponding coil to obtain air gap as

specified.

– Remove flywheel.

– Place spacers as required between

crankcase and corresponding coils.

– Tighten Hex.-nuts uniformly.

– Finish assembling.

A 05.00 Start electrical

Page 57

2

1D . . / 03.06

A 05.41.1

45

321

min 0.7 mm

5

A 05.00

A 05.41

Page 58

2

1D . . / 03.06

A 05.41 Alternator / Coils

–

Version A 05.41.2 (1D 60-80)

Coils fitted to support and fixed on bottom

side of crankcase.

Fixation and adjustment of air gap by

moving the complete unit in longitudinal

slots.

Preparations:

– Remove flywheel and housing.

Dismantling:

– Disconnect electrical system.

– Remove in numerical sequence 1...4.

If necessary separate coils and support.

Inspection / repair:

– Visual inspection.

– Check coils for wear and/or any other

damage.

Assembly:

– Assemble in reverse sequence 4...1.

NOTE:

Push unit 3 as far as possible in direction to

crankcase and tighten Hex.-nuts 1 tempora-

rily.

Adjustment:

– Assemble flywheel.

– Put engine onto flywheel to eliminate the

end float.

– Place feeler gauges between coils and

flywheel-magnet segments to obtain air

gap as specified.

– Release retaining nuts 1.

Allow complete unit 3 to drop down onto

feeler gauges.

– Tighten Hex.-nuts uniformly.

– Finish assembling.

A 05.00 Start electrical

Page 59

2

1D . . / 03.06

A 05.41.2

min 0.7 mm

4

2

1

3

A 05.00

A 05.41

Page 60

2

1D . . / 03.06

A 05.41 Alternator / Coils

–

Version A 05.41.3

Coil encapsulated and fitted to crankcase.

Fixation and adjustment of air gap by

moving the coil in longitudinal slots.

Preparations:

– Remove flywheel.

1 D 30 - 31 - 35 - 40 - 41 - 50 only !

– Remove protection guard 1.

Dismantling:

– Disconnect electrical system.

– Remove in numerical sequence 2...4.

Inspection / repair:

– Visual inspection.

– Check coil for wear and/or any other

damage.

Assembly:

– Assemble in reverse sequence 4...2.

– Push coil 4 as far as possible in direction

to crankcase and tighten Allen screws

temporarily.

Adjustment:

– Assemble flywheel.

1 D 30 - 31 - 35 - 40 - 41 - 50 only !

– Push flywheel towards crankcase.

Ensure flywheel remains in position !

– Remove grub screw or plug 5.

– Place feeler gauge between coil and

flywheel-magnet segments to obtain air

gap as specified.

– Release Allen screws 2.

– Push coil towards flywheel against

feeler gauge.

Ensure flywheel remains in position !

– Tighten Allen screws uniformly.

– Reassemble protection guard 1 and

grub screw or plug 5.

– Reconnect electrical system.

Alternator 12 V “high output” 350 W

(1D60 ... 90):

On this alternator the gap between the

coil and the magnet ring must be adjusted

to 1.2 mm . Otherwise the max current of

25 A will be exceeded and the voltage

regulator switch could be damaged.

A 05.00 Start electrical

Page 61

2

1D . . / 03.06

A 05.00

A 05.41

Page 62

2

1D . . / 03.06

A 05.80 Ring gears

–

General:

Ring gears are different in pitch as well as

direction of rotation is concerned.

It is of utmost importance not to combine

parts with incorrect pitch or rotation.

Preparations:

– Remove flywheel (M 17.00).

Inspection / repair:

– Check part for broken teeth and/or other

damage.

Burrs can be filed down to a certain

extent.

Dismantling:

– Check condition of ring gear before removal.

In case ring gear has to be removed proceed as follows:

– Heat starter ring gear rapidly (gas torch)

and detach ring from flywheel.

Another way is to drill and chisel the ring

gear open.

Assembly:

– Heat ring gear properly around its diame-

ter and shrink fit ring gear onto flywheel.

NOTE:

Take care for correct position of chamfered

side facing towards starter motor and proper

seat on flywheel.

– Finish assembling.

A 05.00 Start electrical

Page 63

2

1D . . / 03.06

°C

°F

300

150

S/Z/C

T/U

1

A 05.00

A 05.80

Page 64

2

1D . . / 03.06

A 07.20 Lub.-oil filters, strainers

–

General:

Retro-fit of lub.-oil filter is possible at any

time and requires removing of closing cover

only.

Version A 07.20.1

Version A 07.20.2

Preperations: –

Dismantling:

– Remove in numerical sequence 1...6.

Version A 07.20.2:

Spring in filter housing 5 remains.

Inspection / repair:

– Visual inspection.

– Check oil filter element 2 and rectangular

rings 6.

Maintenance according to instruction book.

Assembly:

– Assemble in reverse sequence 6...1.

Apply High-temp. lub. -grease as speci-

fied!

– Ensure rectangular ring 6 at bottom side

remains in position during assembly.

– Place and tighten Allen screws crosswise

and uniformly.

A 07.00 Lubrication oil

Page 65

2

1D . . / 03.06

A 07.20.1

A 07.20.2

1

1

34

34

625

6

6

5

62

A 07.00

A 07.20

Page 66

2

1D . . / 03.06

A 07.30 Oil sumps

–

General:

Additional oil sump may be used to obtain

higher oil change intervals.

Depending on the oil quantity as required

– different oil pans

– suctions strainers and adaptors

– spacer rings for the oil pan

– dipsticks of different length may be fitted.

Take care not to interchange these components by mistake during a repair and / or

conversion job.

Assembly:

Ref.: Chapt. M 01.30

In addition two of spring washers and elastic

washers are fitted between suction sieve

and oil intake tube.

Apply sealing agent as specified !

A 07.00 Lubrication oil

Page 67

2

1D . . / 03.06

60 25 58 204

60 + 60 25 118 285

40 25 58 204

40+40

25 98 225

1D30-31-35-40-41

1D60-80-81

2.8 l

4.4 l

3.2 l

4.5 l

mm mm mm mm

mm mm mm mm

A 07.00

A 07.30

Page 68

2

1D . . / 03.06

A 09.60 Low idle speed stabilization

- 5 - 30 -

General:

Several engine applications require a very

precise speed governing also in the range of

low idle, for example engines with hydraulic

pumps in cold condition.

For this case the low idle speed stabilization

is available.

Function:

– The main governor spring is approx. 1 mm

shorter than the standard one so that it is

deactivated at engine speeds below

1000 rpm.

– Governor lever 1 is working over the full

speed range.

– The retainer spring 2 is connected to an

adjustable lever 3 and works as governor

spring at the speed range below 1000 rpm.

– The stabilization spring 4 is fitted to stabi-

lize the overreaction of the governor lever

when the speed control lever is turned

back into „low“ position.

It can be adjusted by the eccentric disk 5.

– The standard stop screw 6 is turned back

a few threads to ensure it is out of function.

Basic adjustment:

– Turn screw II so that eccentric disc 5 is

facing towards timing cover.

Flat surface at outer end of screw II is now

parallel with timing cover.

– Turn screw III into a position that the

stabilization spring 4 is slightly tuching

the eccentric disc 5.

This is the final position.

Lock screw III by tightening the counter

nut.

– Turn screw II approx. 180° counter clock-

wise (Stabilization spring 4 now is forced

as far as possible towards crankcase).

– Turn screw I so that lever 3 is facing

vertical downwards (pin 7 is also in a

vertical position).

Fine tuning:

(with engine running)

– Connect rev. counter - 30 -

– Set low idle speed to approx. 600 rpm.

If engine speed drops too far and

engine stops, than turn screw I in direction „+“ (counter clockwise).

If such low speed can not be obtained

turn screw I in direction „-“ (clockwise)

or turn screw 6 back for some threads.

– Turn screw I slightly in counter clockwi-

se direction until the aspired speed is

reached and lock screw with counter nut.

– Turn screw II clockwise (use tool - 5 - )

until the stabilizing spring is just

touching the governor lever. This is indicated by an additional rise of the

engine speed (max. 5 rpm).

Lock screw by tightening the counter nut.

– Finally seal all adjustment screws with

sealing wax.

A 09.00 Speed controls

Page 69

2

1D . . / 03.06

I

II

III

I

II

III

I

II

III

7

5

3

2

1

4

6

29.5

30.5

5

A 09.00

A 09.60

Page 70

2

1D . . / 03.06

A 11.10 Stop devices

–

Version A 11.10.1

Stop lever S/Z/T/U

Preparations: –

Dismantling:

– Remove in numerical sequence 1...4.

– Remove timing cover (M 11.00).

– Remove lever 5.

Bushing 6 may remain

Inspection / repair:

– Check lever 5 and bushing 6 for wear or

any other damage.

Assembly:

– Press bushing 6 firmly in (if necessary).

Apply high strength locking agent as

specified !

– Bring bushing 6 to a position to have the

lever 5 just in the centre of the respective

contact face of the governor lever.

– Assemble in reverse sequence 5...1.

NOTE:

Hold stop lever 3 against tightening force of

Hex.-nut 1 to avoid excessive stress on

governor lever.

– Finish assembling.

Version A 11.10.2

Stop lever C.

Preparations: –

Dismantling:

– Remove in numerical sequence 1...10.

For further repair remove capsule parts

as required to have access to standard

engine respectively to bush 11 and lever 12.

Inspection / Repair:

– Check lever 5 and bushing 6 for wear or

any other damage.

Assembly:

– Assemble in reverse sequence.

NOTE:

Hold lever 9 against tightening force of

shaft 8 to avoid excessive stress on governor lever.

Hold lever 3 against tightening force of

Hex.-nut 1 to avoid excessive stress on

linkage and/or governor lever.

A 11.00 Remote engine controls

Page 71

2

1D . . / 03.06

A 11.10.1

A 11.10.2

5

12

12346

123

6

5

7

5

11

10

9

8

4

=

=

A 11.00

A 11.10

Page 72

A 11.30 Auto. Shut-off device

–

General:

In order to avoid serious engine damage

due to insufficient lubrication (e.g. excess

tilting of engine), the mechanical shut-off

device was developed.

Function:

If the oil-pressure is too low, the fuel feed

and fuel return is shut off by a valve.

- Opening pressure on cold engine 0.4

bar

- Shut-off reaction pressure approximately

1.0 bar at 3000 rpm

- Idle speed of 800 rpm admissible up to

oil level "min".

- Once fuel system has run totally dry,

relief lever must be activated for approx.

15 seconds for bleeding after tank filling.

In case of (repair) work at the shut-off

device, the correct connection of fuel

pipes (flow direction) must be assured.

1 = inlet from fuel filter (tank)

2 = inlet to injection pump

3 = return from injection pump

4 = return to tank

2

1D . . / 03.06

A 11.00 Remote engine controls

Page 73

2

1D . . / 03.06

Run:

Feed Return

Relief

lever

Relief

lever

A 11.00

A 11.30

Page 74

2

1D . . / 03.06

A 15.20 Adaptor housings

–

Preparations:

– Remove starter motor if so fitted.

Dismantling:

– Remove in numerical sequence 1...7

depending on kind of application.

Parting sheet 9 may remain.

NOTE:

Removal of parting sheet requires dismantling of flywheel 8.

Inspection / repair:

– Visual inspection.

– Check housing for cracks or any other

damage.

Assembly:

– Assemble in reverse sequence 9...1.

– Assemble starter motor if so fitted.

A 15.00 Housings - flanges - adaptors

Page 75

2

1D . . / 03.06

1

3

954

54654

78

21

A 15.00

A 15.20

Page 76

Page 77

3

1D . . / 03.06

3. Basic engine

Page 78

Page 79

3

1D . . / 03.06

M - Basic engine

M-Disassembly cross reference scheme

Page 80

- 9 - 13

Preparations:

Ref.: M-Disassembly cross reference

scheme.

Oil spray nozzle

– Install and screw nozzle 3 firmly in place

so oil spray will be directed down directly

on the camshaft.

Apply high strength locking agent E.

Clock-wise engines (version T/U) are

equipped with an additional oil spray nozzle in the timing cover. It points to the middle of the camshaft bearing bore (view to

inside of timing cover).

Main bearing

Dismantling:

– Check main bearing before removal.

– Remove main bearing 1 by pushing it in-

ward toward crankcase.

For removal use tool - 9 -

Inspection / repair:

– Visual inspection.

Inspection should be carried out before

removal !

All dimensions measured in fitted conditionat 20±10° C / 68±18° F.

3

1D . . / 03.06

Assembly:

– Apply locking agent E to bearing 1 and

press firmly in place. For assembly use

tool - 9 -

Ensure lubrication passages align.

Position in crankcase as specified !

1 D 60 - 80 - 81 - 90:

Slotted lubrication passage has to align

with the main gallery at the bottom side of

crankcase. Check the small lubrication

bore on top for free passage.

Camshaft bearing

Dismantling:

– Check condition of bearing bushing before

removal.

– Remove bearing bushing 2 by pushing it

inward toward crankcase.

For removal use tool - 13 -

1 D 60 - 80 - 81 - 90:

– Push bearing approximately half way

into the crankcase.

Be careful not to damage bore or

crankcase.

– Destroy bearing bushing to remove.

Assembly:

– Install and press bearing bushing 2 firm-

ly in place.

For assembly use tool - 13 -

Make sure lubrication passages align.

Position in crankcase as specified !

M 01.00 Crankcase

M 01.10 Crankcase, nozzle and bearings

Page 81

3

1D . . / 03.06

M 01.00

M 01.10

Page 82

M 01.11 Plugs

Variant I

up to series no.:

1 D 30.15 A 1 D 35.13

1 D 31.13 A 1 D 40.12

1 D 40.16 A 1 D 41.11

1 D 41.13

1 D 60.22 1 D 81.15

1 D 80.21 1 D 90.10

In case no fuel feed pump is fitted plug 1

without ring groove has to be fitted on

both sides. In case a fuel feed pump is

fitted plug 2 with ring groove has to be

used on the operator side instead of plug

1 to guarantee lubrication of rocker arm.

Assembly:

– Push in plugs (chamfer 2 x 45° timing

cover direction) firmly until flush with

crankcase inside wall

3

1D . . / 03.06

Variant II

from series no. on:

1 D 30.16 1 D 40.17

1 D 31.14 1 D 41.14

1 D 60.23 1 D 81.16

1 D 80.22 1 D 90.11

1 D 90 V/W.10

(modified lubrication oil duct)

In case no fuel feed pump is fitted plug 2

with ring groove has to be fitted on ex-

haust side. Plug 1 without ring groove has

to be fitted on operation side.

In case fuel feed pump is fitted plug 2 has

to be used on both sides with ring groove.

1 D 90 V:

On both sides, plug 2 with ring groove has

to be fitted.

In addition, the axle with nozzle 4 and

bushes 5 and 6 are mounted.

Axle 4 is fitted in such a way that the spray

nozzle points to the middle of the

camshaft bearing bore.

Additionally, in both cases plug 3 (with

extractor thread towards timing cover) has

to be fitted in the bore for intermediate

axle.

M 01.00 Crankcase

For versions without add. counter balance the bores for the balancer shafts are closed

with plugs to obtain full oil pressure.

Page 83

3

1D . . / 03.06

1

2

1

Variante II

Variante I

2

2

3

2

1

2

4

5

6

M 01.00

M 01.11

Page 84

3

1D . . / 03.06

- 25 -

Cam followers

General:

Models S/Z/C = anti-clockwise rotation

Cam followers symmetrically arranged.

Models T/U = clockwise rotation

Cam followers asymmetrically arranged.

Besides the normal cam follower 3 for the

inlet valve a separate cam follower 5 for

the exhaust valve is fitted onto the cam follower bracket 6.

The cam follower bracket as well as the

thrust plate are fitted together to the

crankcase by Allen screws.

1 D 30 - 31 - 35 - 40 - 41 only !

A spacer plate 7 is fitted in addition between the cam follower bracket 6 and the

thrust plate 9.

Preparations:

Ref.: M-Disassembly cross reference

scheme.

Dismantling:

– Remove in numerical sequence 1...4/5.

For removal of part 2 use tool - 25 -

Inspection / repair:

– Check all parts in question for wear

and/or any other damage.

Assembly:

– Assemble in reverse sequence 5/4...1.

Apply locking agent as specified !

Torque to specification !

M 01.00 Crankcase

M 01.20 Crankshaft-thrustplate and cam followers

Page 85

3

1D . . / 03.06

M 01.00

M 01.20

9 8

I

M 8

0.10 - 0.40 mm

3

3

2

2

1

25

25

25

25

3

2

1

9 7 6

8

8 5

2

1

10

10

M9

M8

M8

M6

M6

10.9

10.9

8.8

10.9

8.8

40

35

24

14

11

30

26

18

10

8

8

1

Nm

lb ft

Pos.

T / U

S / Z / C

3.5 mm

10

9 8

9 8

0.9 mm

II

M 8

1.05 mm

1.20 mm

10

M 9

III

M 6

4

4

4

1D90 V/W:

0.05 - 0.10 mm

Page 86

- 25 -

Crankshaft thrustplate

General:

It is of utmost importance to observe the

specified torque settings in connection

with the different type tensile strength of

the respective retaining screws.

Version I

Fixation by two each retaining screws

M 6 - M 8 without spacer shims.

Version II

Fixation by retaining screws M 8.

A = Point of support recessed in crank-

case, spacer shims 10 = 3.5 mm.

B = Point of support bossed in crankcase,

spacer shims 10 = 0.9 mm.

Version III as from 1992 onwards

Fixation by retaining screws M 9.

Spacer shims 10 = 1.05 mm and 1.20 mm

to obtain correct crankshaft end float.

1D 90 V/W:

These engines have been mounted without governor sided thrust plate. The crankshaft end float is adjusted at the bearing

flange. See M 03.10.

Preparations:

Ref.: M-Disassembly cross reference

scheme.

3

1D . . / 03.06

Dismantling:

Models S/Z/C

– Remove in numerical sequence 8...10.

Models T/U

– Remove in numerical sequence 1...10.

Inspection / repair:

– Check parts for wear, deformation and/or

any other damage.

Assembly:

– Assemble in reverse sequence.

Lub. oil pockets on thrust plate face toward crankshaft.

Apply locking agent as specified !

Torque to specification !

M 01.00 Crankcase

M 01.20 Crankshaft-thrustplate and cam followers

Page 87

3

1D . . / 03.06

M 01.00

M 01.20

9 8

I

M 8

0.10 - 0.40 mm

3

3

2

2

1

25

25

25

25

3

2

1

9 7 6

8

8 5

2

1

10

10

M9

M8

M8

M6

M6

10.9

10.9

8.8

10.9

8.8

40

35

24

14

11

30

26

18

10

8

8

1

Nm

lb ft

Pos.

T / U

S / Z / C

3.5 mm

10

9 8

9 8

0.9 mm

II

M 8

1.05 mm

1.20 mm

10

M 9

III

M 6

4

4

4

1D90 V/W:

0.05 - 0.10 mm

Page 88

–

Preparations:

Ref.: M-Disassembly cross reference

scheme.

Oil sump

Dismantling:

– Remove in numerical sequence 1...2.

– Remove oil sump 3 using a plastic ham-

mer.

Inspection / repair:

– Check oil sump for possible cracks, de-

formations, flatness of sealing surface

and any other damage.

Assembly:

– Assemble in reverse sequence 3...1.

Apply sealant and locking agent as

specified.

1 D 30 - 31 - 35 - 40 - 41 only!

Always use flat washers in addition to the

lock washers for the retaining screws in

pos. A to avoid the retaining screw from

interferring with the crankcase which will

force the base plate from its position.

3

1D . . / 03.06

Suction sieve:

The strainer housing 6 can be used both

for anti-clockwise and clockwise engines.

Only the assembly position is different.

- At anti-clockwise engines, the stamped L

on the base plate and molded L on

strainer housing have to be placed together.

- This is also applicable for clockwise engines (letter R accordingly).

The strainer housings of types 1D 30-31-

35-40-41-50 and types 1D 60-80-81-90

differ in their height b (see chart).

Apply loctite D for mounting screws 4.

M 01.00 Crankcase

M 01.30 Oil sump and suction sieve

Page 89

3

1D . . / 03.06

M 01.00

M 01.30

/ Z /

/

D30-31-35-40-41-501D60-80-81-

90

mm

)

4

5

Page 90

M 01.31 Oil sump 1D 50

–

General:

An aluminium oil sump with add. cowling is

fitted into engines 1D50.

Furthermore, a folding plate 3 is mounted

to the bottom plate.

Assembly:

– Seal oil sump 1 with sealing medium H.

– Pay attention to correct positioning of

fastening screws!

Note:

A = M 8 x 40

shim ring 8 x 14 x 1

B = M 8 x 30

shim ring 8 x 14 x 1

C = M 8 x 30 Z3

D = M 6 x 25

flat washer 6,4

E = M 6 x 16

flat washer 6,4

– Fit screws with screw retention D in

position D and E.

– Fixation of cowling 2 with screws 3.

3

1D . . / 03.06

M 01.00 Crankcase

Page 91

3

1D . . / 03.06

M 01.00

M 01.31

2

3

B

B

A

C

H

C

C

E

D

1

D

D

3

Page 92

–

Preparations:

Ref.: M-Disassembly cross reference

scheme.

Base plate

Inspection / repair:

– Check base plate for flatness, cracks or

any other damage.

Assembly:

– Apply sealing agent B onto crank case

(see drawing)

– Assemble in reverse sequence 5...1.

Ensure both seal rings remain in position

during assembly.

– Install and tighten Allen screws cross-

wise and uniformly.

Torque to specification !

1 D 90 V:

Instead of bottom plate 3 a rear panel 9 is

installed

– Pay attention to correct positioning of

fastening screws!

Note:

a = M 8 x 25 Z4

b = M 8 x 45

spring washer A 8

c = M 8 x 40

spring washer A 8

d = M 8 x 25

joint washer A 8 x 14

– Fit screws with screw retention D in

position d.

3

1D . . / 03.06

Oil pressure relief valve

Dismantling:

– Remove in numerical sequence 6...8.

Inspection / repair:

– Check relief valve for contamination

and/or any other damage.

NOTE:

The relief valve must be replaced as a

complete unit.

No repairs are possible !

Assembly:

– Assemble in reverse sequence 8...6.

Torque to specification !

M 01.00 Crankcase

M 01.40 Base plate and oil pressure relief valve

Crankcase - Sandcasting

Sealing surface machined

Crankcase - Press.- diecasting

Sealing surface unmachined

70 Nm

52 lb ft

100 Nm

74 lb ft

Page 93

3

1D . . / 03.06

7

6

8

3

4

5

1

2

23 Nm

17 lb ft

D

9

a

b

c

d

a

a

1D90V/W:

B

M 01.00

M 01.40

Page 94

M 01.50 Cyl.-head screw sealants

–

General:

Sealing caps are used between the

crankcase and cyl.-head screws to prevent

water and contaminants from entering and

causing corrosion.

Replace seal caps whenever head bolts

are removed.

NOTE:

Determine the correct position and seal

type for the specific engine type.

3

1D . . / 03.06

M 01.00 Crankcase

Page 95

3

1D . . / 03.06

M 01.00

M 01.50

50459800

50458400

04084500

50392000

04150300

1D30-31-

1D50

35-40-41

1D30-31-35

40-41-50

1D60-80-

81-90

1D60-80-

81-90

04219300

04219200

S

2.7-3.1

2.3-2.6

1.9-2.2

S [mm]

2.5

3.0

3.5

Page 96

M 02.00

M 02.10

a* Ø 55.01 - 55.05 55.15 54.51 - 54.55 54.65

b Ø 54.97 - 54.99 54.90 54.47 - 54.49 54.40

a - b 0.02 - 0.08 0.25 0.02 - 0.08 0.25

c* Ø 55.05 - 55.09 55.20 54.55 - 54.59 54.70

c - b 0.06 - 0.12 0.30 0.06 - 0.12 0.30

d Ø 51.97 - 51.99 51.90 51.47 - 51.49 51.40

e* Ø 52.02 - 52.06 52.15 51.52 - 51.56 51.65

e - d 0.03 - 0.09 0.25 0.03 - 0.09 0.25

f Ø 55.00 - 55.02 55.05 – –

g Ø 28.00 - 28.01 28.03 – –

h* Ø 25.03 - 25.04 25.10 – –

I 25.00 - 25.05 25.20 – –

k Ø 51.98 - 52.00 51.80 – –

l Ø 31.98 - 32.00 31.95 (31.85 on oil seal running surface)