Page 1

www.HATZ-DIESEL.com

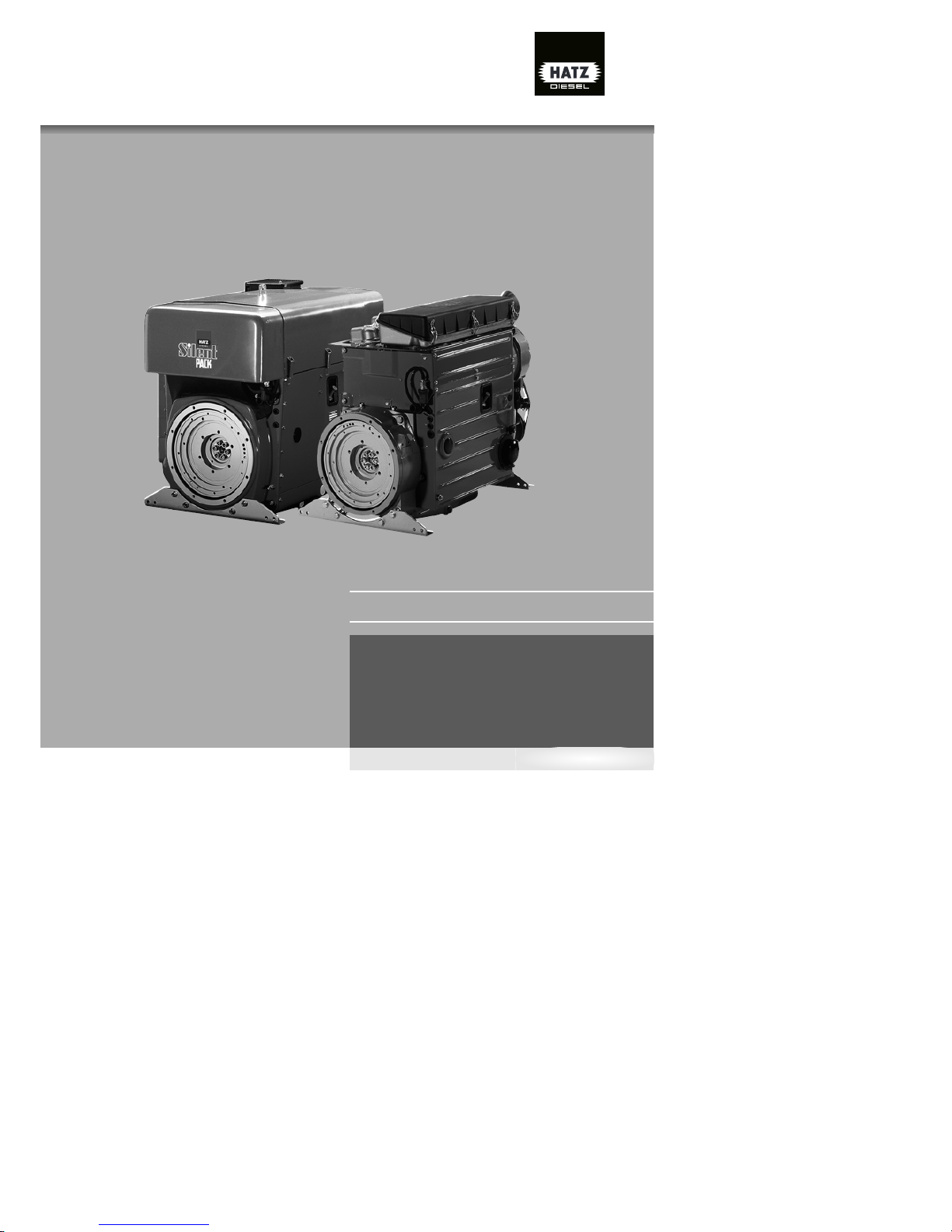

Hat z Diesel

CREATI NGPOWER SOLUTIONS.

OPERATOR’ S MANUAL

Diesel engine

2- 4L41C | 2- 4M41 | 2-4M41Z | 4L42C | 4M42

Page 2

Page 3

Table of contents

1 Notic es ............................................................................................................. 5

2 General inform ation ........................................................................................ 6

3 Safety ............................................................................................................... 7

3.1 General information .......................................................................................... 7

3.1.1 Intended use and foreseeable misuse .............................................................. 7

3.1.2 Machine user or machine manufacturer obligations ......................................... 8

3.1.3 Representation of safety notes ......................................................................... 9

3.1.4 Meaning of safety symbols ............................................................................... 10

3.2 Safety notes ...................................................................................................... 11

3.2.1 Operational safety ............................................................................................. 11

3.2.2 Machine-specific safety instructions for operation ............................................ 14

3.2.3 Machine-specific safety instructions for maintenance work .............................. 16

3.2.4 Electrical equipment .......................................................................................... 18

3.3 Labels ............................................................................................................... 19

4 Technical data ................................................................................................. 22

4.1 Engine ............................................................................................................... 22

4.2 Fuel ................................................................................................................... 23

4.3 Engine oil .......................................................................................................... 24

5 Engin e design ................................................................................................. 25

6 Transp ort, ass embly and co mmission ing .................................................... 31

6.1 Transport ........................................................................................................... 31

6.2 Assembly instructions ....................................................................................... 31

6.3 Preparations for commissioning ........................................................................ 32

7 Operati on and u se .......................................................................................... 33

7.1 Safety notes ...................................................................................................... 33

7.2 Performing tests ................................................................................................ 33

7.3 Start preparation ............................................................................................... 34

7.3.1 Pumping fuel with the manual lever .................................................................. 34

7.3.2 Pumping fuel with the manual fuel pump .......................................................... 35

7.4 Setting the speed control .................................................................................. 37

7.5 Starting the engine ............................................................................................ 37

7.5.1 Starting the engine with crankhandle ................................................................ 38

7.5.2 Starting the engine with an electric starter ........................................................ 44

7.6 Switching off the engine .................................................................................... 47

7.6.1 Switching off the engine (mechanical) .............................................................. 48

7.6.2 Switching off the engine (electrical) .................................................................. 49

7.7 Refueling ........................................................................................................... 50

7.8 Checking the water separator ........................................................................... 51

7.9 Checking the oil level and adding oil if necessary ............................................ 53

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Table of contents

HATZ

Operator's Manual 3

Page 4

8 Mainten ance .................................................................................................... 55

8.1 General maintenance instructions .................................................................... 55

8.2 Maintenance work ............................................................................................. 56

8.2.1 Maintenance notice label .................................................................................. 56

8.2.2 Maintenance plan .............................................................................................. 58

8.2.3 Checking the intake area of the combustion air ................................................ 60

8.2.4 Checking the cooling air area ........................................................................... 63

8.2.5 Change the engine oil ....................................................................................... 64

8.2.6 Cleaning the cooling fan, cooling fins and oil cooler ......................................... 66

8.2.7 Checking the screw connections ...................................................................... 70

8.2.8 Cleaning the screen insert in the exhaust pipe (additional equipment) ............ 70

8.2.9 Changing the fuel prefilter ................................................................................. 72

8.2.10 Maintaining the dry air filter ............................................................................... 74

8.2.11 Checking and cleaning the air filter cartridge .................................................... 76

8.2.12 Check and set the tappet clearance ................................................................. 78

8.2.13 Changing the oil filter ........................................................................................ 82

8.2.14 Change the fuel filter ......................................................................................... 83

8.2.15 Checking that the air filter maintenance indicator is working properly .............. 87

8.2.16 Renewing the poly v belt and checking the function of the switch-off unit ........ 89

9 Faults ............................................................................................................... 93

9.1 Troubleshooting ................................................................................................ 93

9.2 Emergency start ................................................................................................ 99

10 Storag e and dis posal ...................................................................................... 102

10.1 Storing the machine .......................................................................................... 102

10.2 Disposing of the machine .................................................................................. 102

11 Instal lation decl aration ................................................................................... 103

Table of contents 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

4 Operator's Manual

HATZ

Page 5

1 Notices

Contact data

© 2012

Motorenfabrik HATZ

Ernst-Hatz-Straße 16

94099 Ruhstorf

Germany

Tel. +49 (0)8531 319-0

Fax +49 (0)8531 319-418

marketing@hatz-diesel.de

www.hatz-diesel.com

All rights reserved!

Copyright

The copyright for this Operator's Manual rests entirely with Motorenfabrik

HATZ, Ruhstorf.

This Operator's Manual may only be copied or distributed if written approval

has been received. This also applies to the copying or distribution of excerpts of the Operator's Manual. The same conditions apply to distribution of

the Operator's Manual to third parties in digital form.

Original Operator's Manual

This Operator's Manual was translated into multiple languages.

The German version is the ori ginal Op erator' s Manual. All other language

versions are trans lation s of the or iginal Operat or's Manual.

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Notices

HATZ

Operator's Manual 5

Page 6

2 General information

Information on the document

This Operator's Manual was created with due care. It is exclusively intended

to offer a technical description of the machine and to provide instructions on

commissioning, operating and maintaining the machine. When operating the

machine, the applicable standards and legal regulations as well as any inhouse regulations apply.

Before commissioning, during operation and before maintenance work is begun on the machine, read the Operator's Manual carefully and keep it close

by for ready access.

Machine

This Operator's Manual describes the following machine.

Machine name HATZ diesel engine

Type number 2-4L41C 2-4M41 2-4M41Z 4M42 4L42C

Custom er ser vice

Have service work performed by qualified technicians only. We recommend

that you work with one of the more than 500 HATZ service station s.Trained

specialists there will repair your machine with Hatz ori ginal s pare part s and

with HATZ tools . The global HATZ service network is at your disposal to advise you and supply you with spare parts. For the address of the Hatz service stat ion nearest you, please see the directory enclosed or visit the internet at: www.hatz-diesel.com

Problems may occur if unsuitable spare parts are installed. We cannot accept responsibility for damage and secondary damage that result from this.

We therefore recommend the use of Hatz or igi nal spar e parts. These parts

are manufactured according to strict Hatz specifications and achieve maximum operational reliability through their perfect fit and functionality. The order number can be found in the enclosed spare parts list or on the internet

at: www.hatz-diesel.com

Exclusion of liability

The manufacturer cannot be held responsible for personal injury, damage to

property, or damage to the machine itself caused by improper use, foreseeable misuse, or failure to follow or adequately follow the safety measures and

procedures described in this Operator's Manual. This also applies to

changes made to the machine and use of unsuitable spare parts.

Modifications, which serve the technical improvements, are reserved.

General information 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

6 Operator's Manual

HATZ

Page 7

3 Safety

3.1 General information

Introduction

This chapter contains the information you need to work safely with this machine.

To prevent accidents and damage to the machine, it is imperative that these

safety instructions be followed.

Read this chapter carefully before beginning work.

3.1.1 Intended use and foreseeable misuse

Intend ed use

The machine described in this Operator's Manual fulfills the following functions:

▪ Diesel engine intended for installation in a machine or for assembly with

other machines to form a machine. See the chapter 11 Installation declaration, page 103.

This engine is intended exclusively for the purpose specified and tested by

the manufacturer of the machine into which the engine is installed.

Any other use is not intended and therefore not permitted. Violations compromise the safety of the personnel working with the machine. Responsibility

is not accepted by Motorenfabrik HATZ for damage resulting from this situation.

The operational safety of the machine is only guaranteed if it is used as intended.

Use according to the intended purpose also includes observance of the instructions in this Operator's Manual.

Foreseeable misuse

The following is considered to be foreseeable misuse:

▪ Any use that varies from or extends beyond the uses specified above.

▪ Failure to comply with the instructions in this Operator's Manual.

▪ Failure to comply with the safety instructions.

▪ Failure to immediately eliminate malfunctions that impact safety before

continuing work with the machine (working with the machine when it is not

in perfect condition, either functionally or in terms of safety).

▪ Failure to perform the necessary inspection and maintenance work.

▪ Any unauthorized modification of or removal of safety equipment.

▪ Use of spare parts and accessories that are unsuitable or have not been

approved by HATZ.

▪ Operation in flammable or hazardous environments.

▪ Operation in closed-off or poorly ventilated rooms.

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Safety

HATZ

Operator's Manual 7

Page 8

▪ Installation of the machine in moving equipment (e.g. vehicles, trailers) or

in closed rooms without additional measures to handle supply air, extract

air, and exhaust gas.

▪ Improper operation at variance with DIN 6271 and DIN ISO 8528 (climate,

load, safety).

Residual ris ks

Residual risks result during daily use and in association with maintenance

work.

These residual risks will be pointed out in chapter 3.2.2 Machine-specific

safety instructions for operation, page 14 and in chapter 3.2.3 Machinespecific safety instructions for maintenance work, page 16 as well as in the

further contents of the manual, directly in front of the descriptions or operating instructions concerned.

3.1.2 Machine user or machine manufacturer obligations

Machine manufacturer obligations

If you have an engine that is not yet installed in a machine, it is imperative

that you follow the Assembly Ins truction s fo r HATZ Diesel Engines before installing the engine. These assembly instructions contain important information on how to safely install the engine and are available at your nearest HATZ servic e stat ion .

It is prohibited to start the engine before it is fully installed.

In addition, please note that it is prohibited to start up the machine before it

has been determined that the machine into which this engine is installed fulfills all safety-related requirements and legal regulations.

User obligations

The user is obligated to only operate the machine while it is in perfect condition. The user must check the condition of the machine before using it and

ensure that any defects are eliminated before it is taken into service. Running the machine while identified defects exist is not permitted. The user

must also ensure that the information contained in the Operator's Manual

has been read and understood.

Obligations of the operating and maintenance personnel

Personnel assigned with operating and maintaining the machine must have

read and understood the Operator's Manual or must be able to demonstrate

the necessary qualifications for working with this equipment, acquired in

training/instructional courses. No one may work with the machine without the

necessary qualifications, even if for just a brief period.

All work performed on the machine must be in compliance with the information provided in the Operator's Manual.

Safety 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

8 Operator's Manual

HATZ

Page 9

Storing the Operator's Manual

This Operator's Manual is an integral component of the machine (also when

being sold). It must be stored in the direct vicinity of the machine and be accessible to personnel at all times.

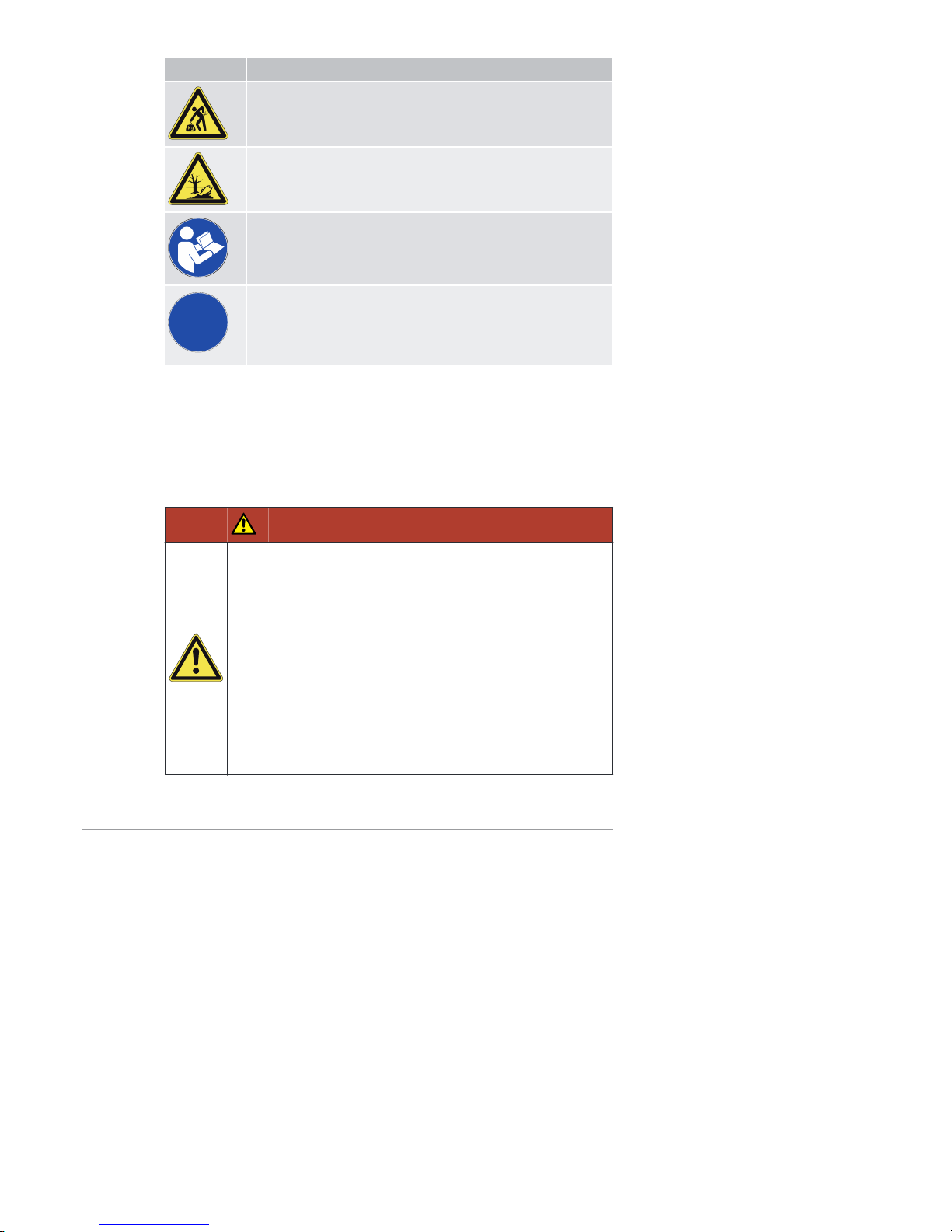

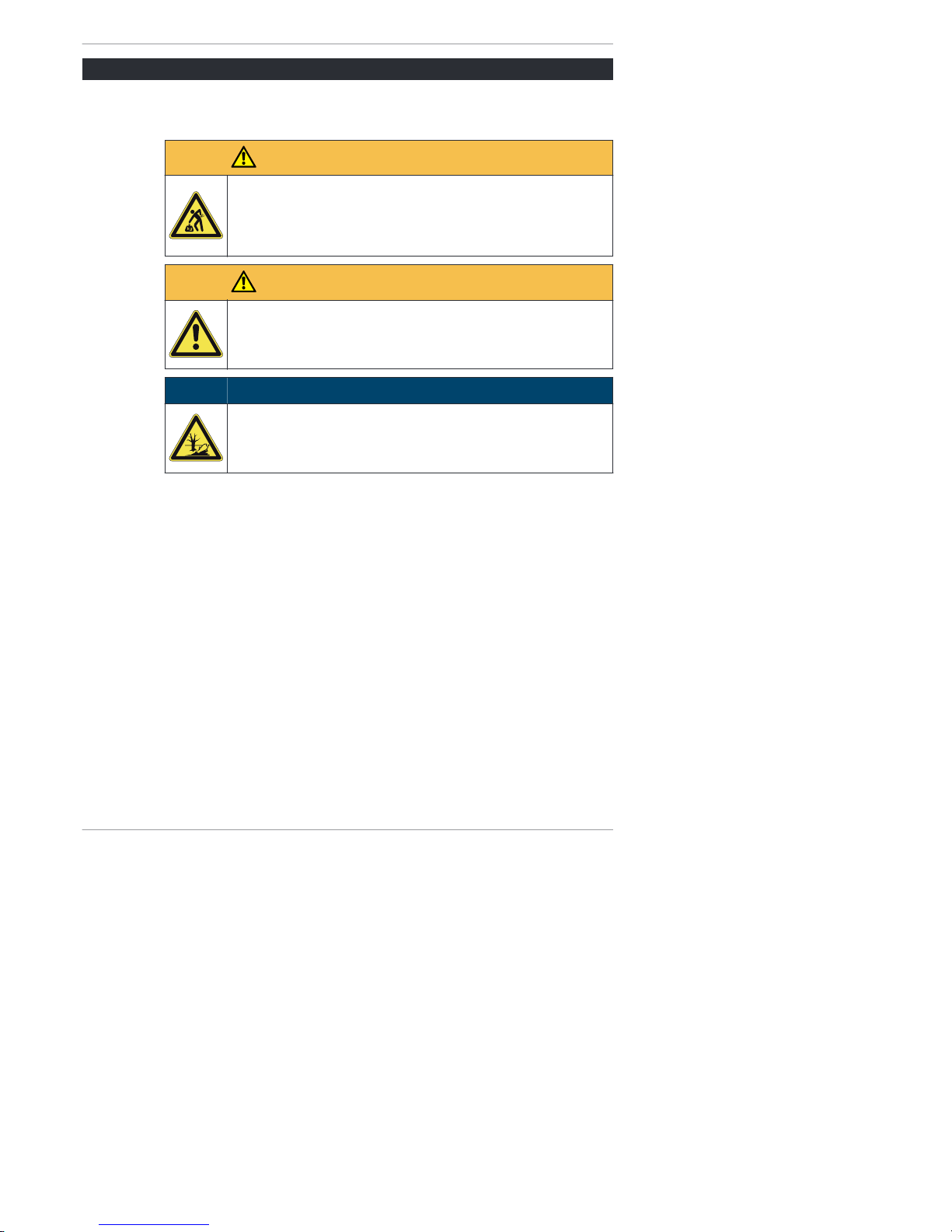

3.1.3 Representation of safety notes

Overvi ew

This machine has been designed and built according to state-of-the-art technology and the recognized safety standards. Despite these precautions,

risks exist when operating the machine and during maintenance work.

These risks are identified in this manual by means of safety notes.

The safety notes precede the related description or operating step.

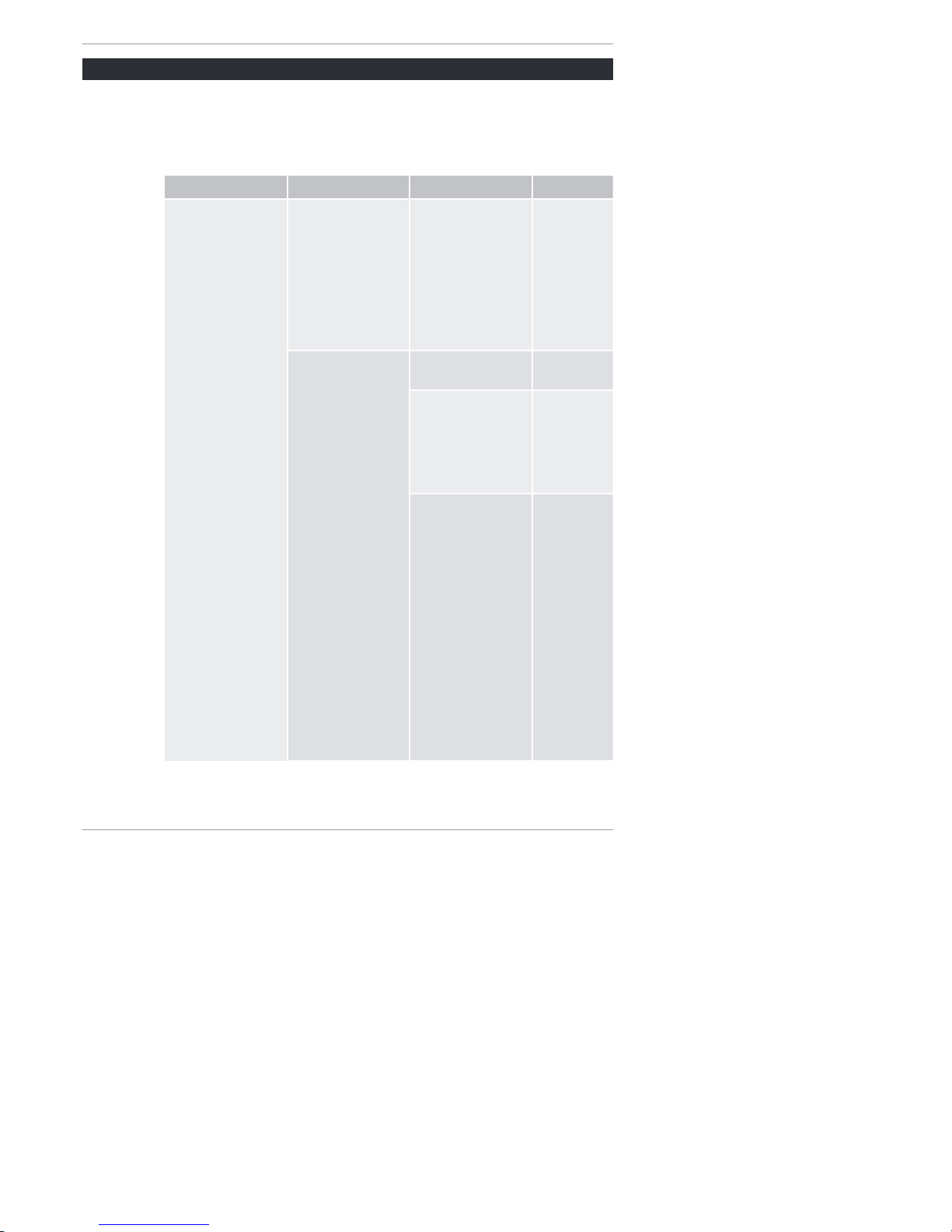

Structure of the safety notes

The safety notes consist of:

▪ Warning symbol

▪ Signal word

▪ Description of danger

▪ Possible consequences

▪ Preventative measures

General danger symbol

The general danger symbol is used to identify the danger of personal injury.

Signal words

Signal words identify the magnitude of the risk and the seriousness of the

possible injuries:

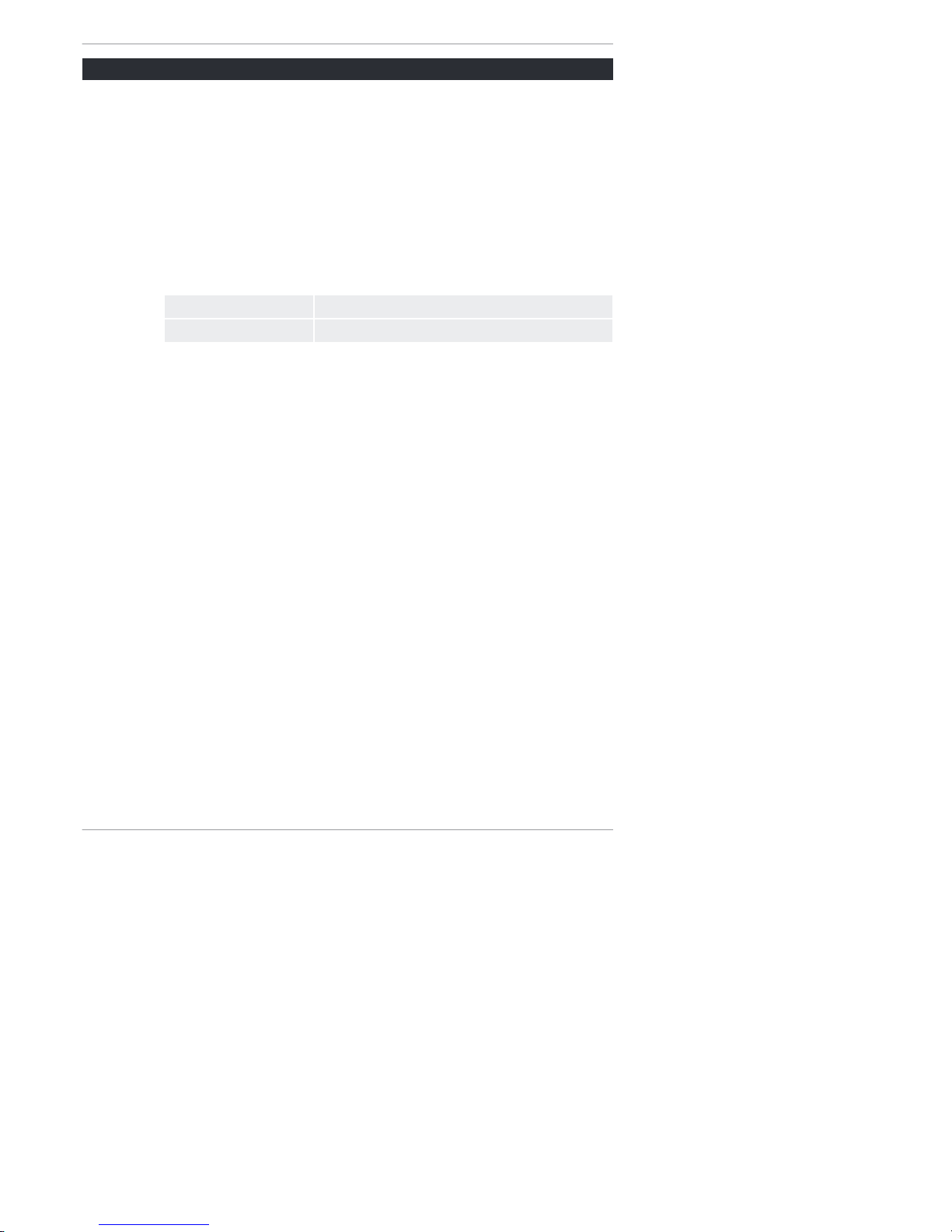

Danger symbol/

signal word

Meaning

DANGER

This signal word is used to indicate imminently

dangerous situations which, if not avoided, will

lead to serious injury or death.

WARNING

This signal word is used to indicate potentially

dangerous situations which, if not avoided, may

lead to serious injury or death.

CAUTION

This signal word is used to indicate potentially

dangerous situations which, if not avoided, may

lead to minor or moderate injury.

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Safety

HATZ

Operator's Manual 9

Page 10

Danger symbol/

signal word

Meaning

CAUTION

This signal word, without a danger symbol, is

used to indicate the risk of property damage.

NOTICE

This signal word indicates additional useful information, such as operating tips and cross references.

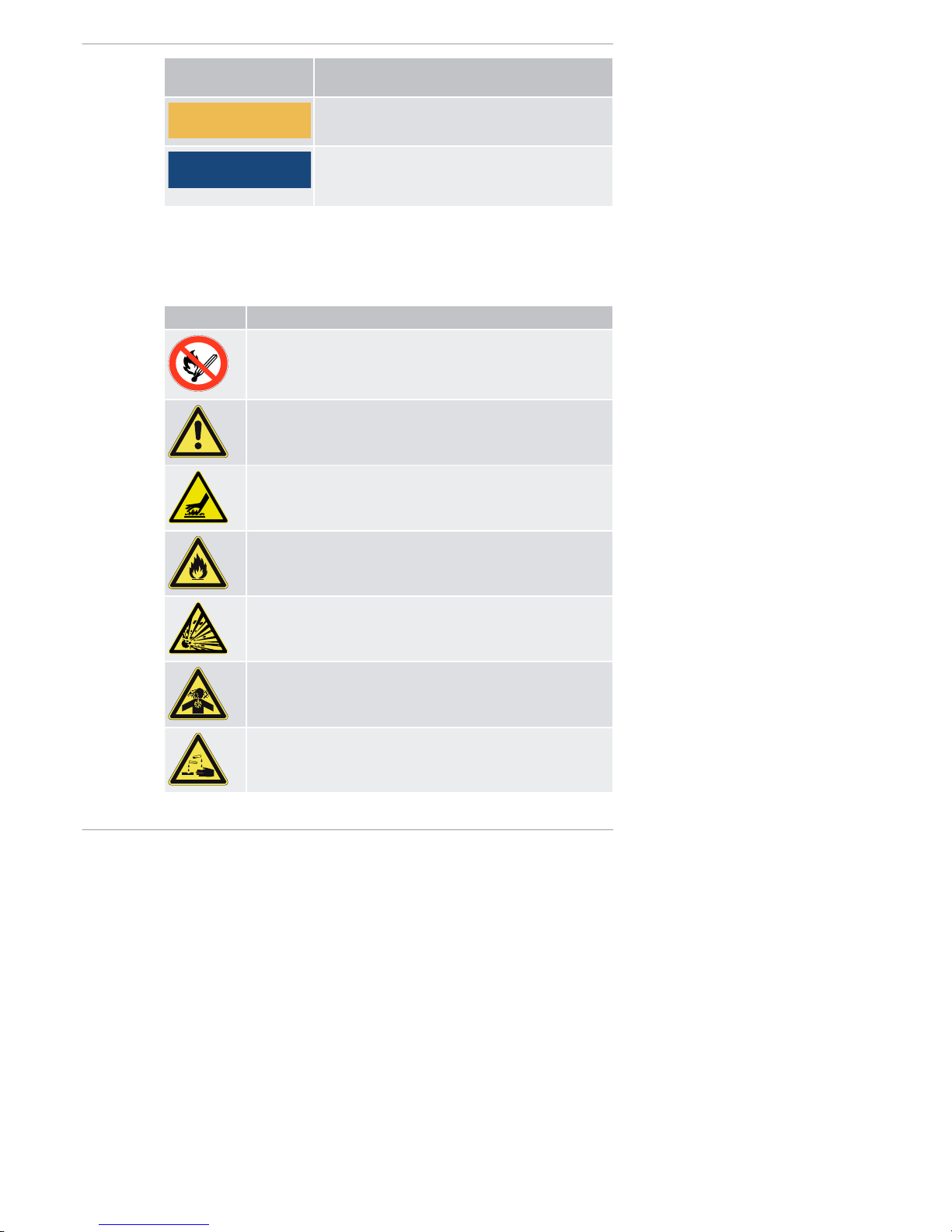

3.1.4 Meaning of safety symbols

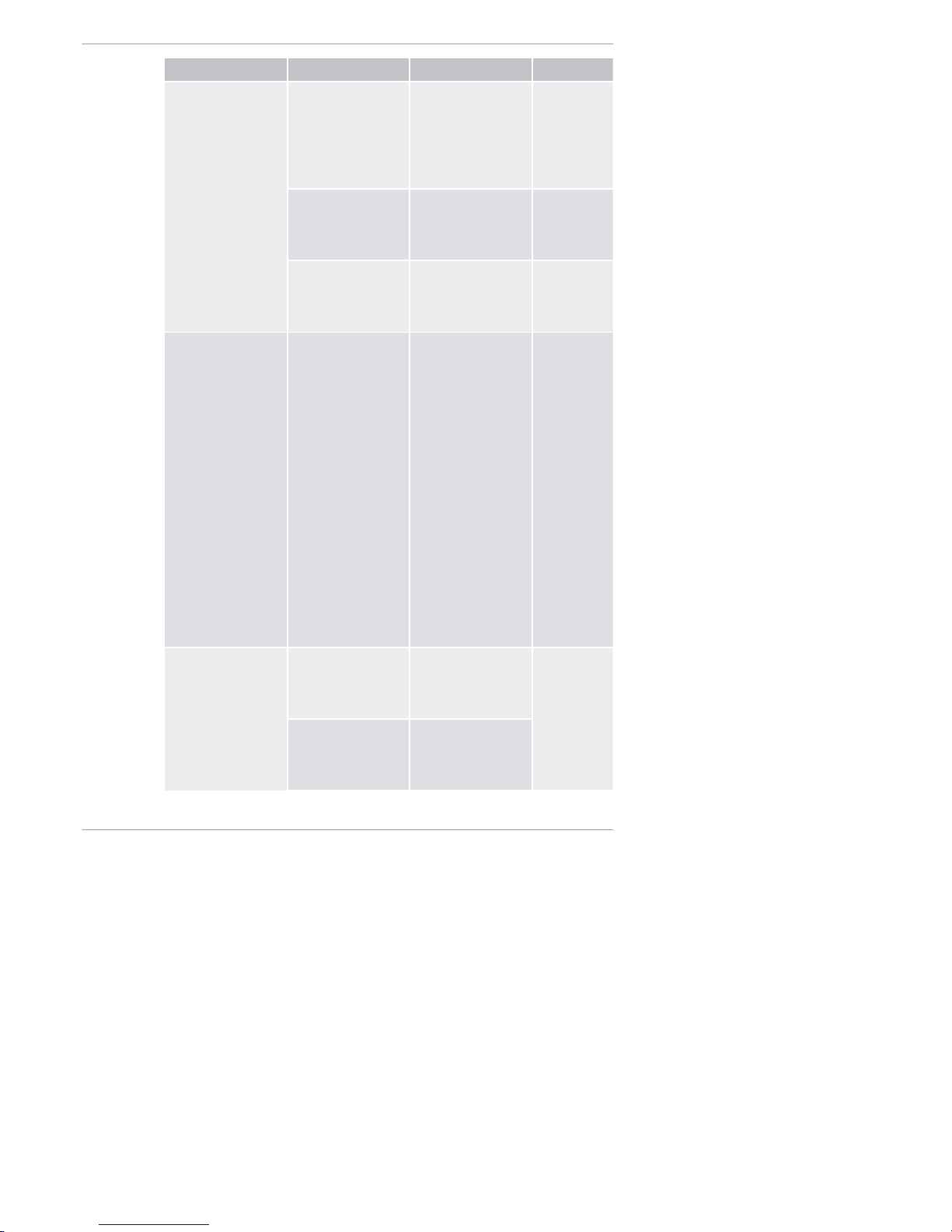

Explanation of symbols

The following table describes the meanings of the safety symbols used in

this Operator's Manual.

Symbol Meani ng

Smoking, fire and open flames are prohibited.

Warning of personal injury!

Warning of hot surfaces!

Warning of flammable substances!

Warning of explosive substances!

Warning of toxic engine exhaust!

Warning of corrosive substances!

Safety 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

10 Operator's Manual

HATZ

Page 11

Symbol Meani ng

Warning of heavy loads!

Warning of environmental damage!

Comply with the Operator's Manual or additional documentation from other manufacturers or the user.

i

Additional information that is useful to the reader.

3.2 Safety notes

3.2.1 Operational safety

Introduction

This chapter contains all of the important safety instructions for personal protection and for safe and reliable operation. Additional, task-related safety instructions can be found at the beginning of each chapter.

DANGER

Danger to life, danger of injury, or danger of property damage due to failure to comply with the Operator's Manual and

the safety instructions contained therein.

▪ As the user of the machine, you must ensure that all people

working on the machine are familiar with the contents of this

Operator's Manual.

▪ Before working on the machine, read this Operator's Manual

carefully, paying special attention to the safety notes.

▪ Fulfill all required safety conditions before working on the

machine.

▪ Follow all general safety instructions as well as the specific

task-related safety instructions contained in the individual

chapters.

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Safety

HATZ

Operator's Manual 11

Page 12

Using the machine

▪ Only operate the machine for the purposes described in the chapter 3.1.1

Intended use and foreseeable misuse, page 7.

Compliance with other regulations

▪ Adhere to the applicable accident prevention regulations of the trade asso-

ciations.

▪ Comply with the regulations concerning the minimum safety and health re-

quirements for the use of work equipment by workers at work.

▪ In addition, local safety, accident prevention and environmental regula-

tions also apply when operating the machine.

Operating personnel

▪ The machine may only be operated by qualified personnel. The personnel

must have read and understood this Operator's Manual or must be able to

demonstrate the necessary qualifications for working with this equipment,

acquired in training/instructional courses.

▪ The operating personnel must not be under the influence of drugs, medi-

cation or alcohol.

Personal protective equipment

During operation and maintenance of the machine, personal protective

equipment must be available and must be used if necessary. The required

personal protective equipment is specified in the description of the operating

steps.

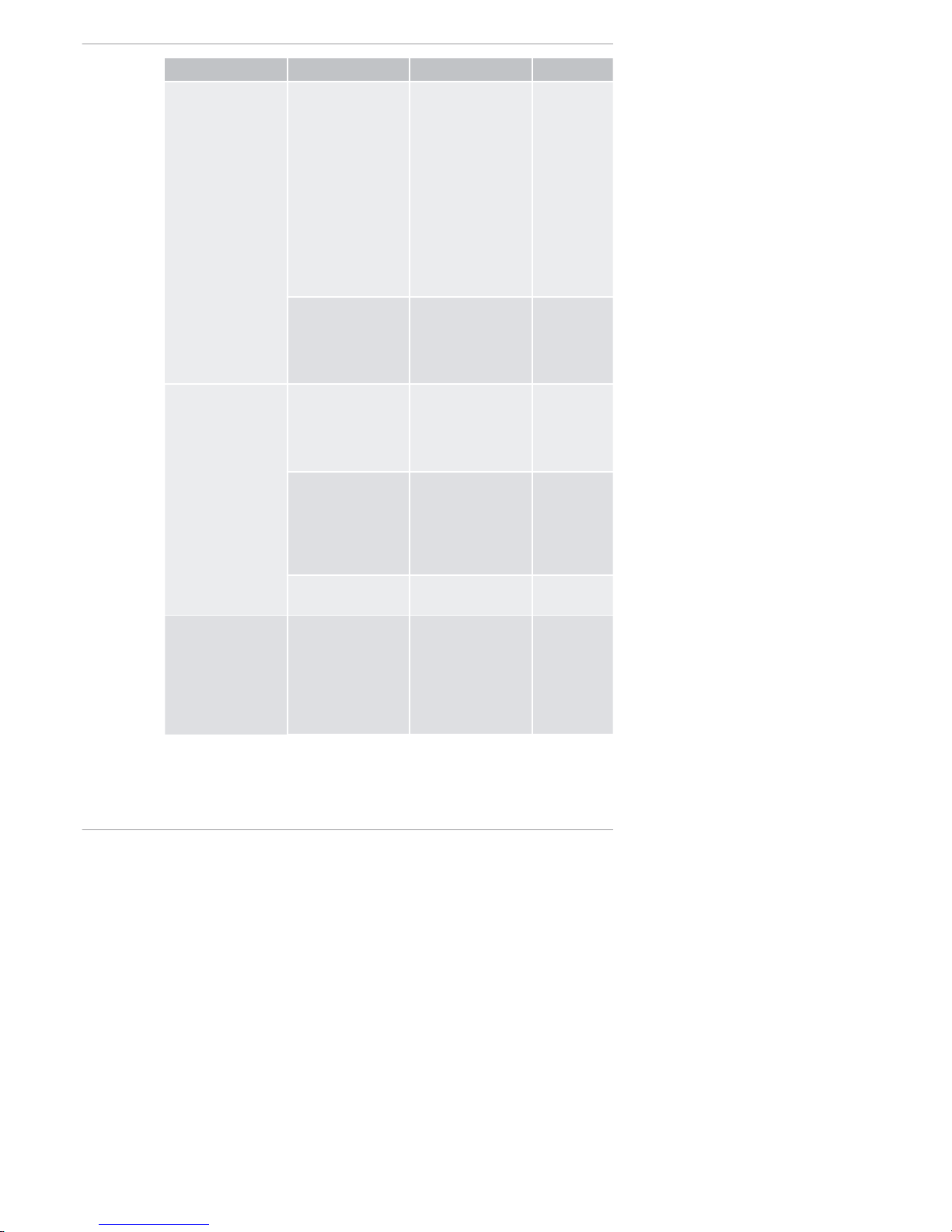

Personal protective

equipment

Pictogram Function

Safety shoes Safety shoes offer protection

against:

▪ Slipping

▪ Falling objects

Hearing protection Hearing protection offers protec-

tion against ear injuries due to

excessive and constant noise.

Safety gloves Safety gloves protect the hands

against injury, e.g. from battery

acid.

Safety 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

12 Operator's Manual

HATZ

Page 13

Personal protective

equipment

Pictogram Function

Safety goggles

(with side protection)

Safety goggles protect the eyes

from flying objects (e.g. dust

particles, spraying liquids,

spraying acid).

Working clothes Wear close-fitting clothing. How-

ever, it must not restrict the

wearer's freedom of movement.

Warning labels and information signs on the machine

The warning and notice labels on the machine must be followed (see the

chapter 3.3 Labels, page 19).

The warning and notice labels must be kept legible and must be replaced if

necessary. For this purpose, contact your nearest HATZ service s tati on.

Maintenance work

Maintenance work that goes beyond the scope described in this manual

must only be performed by qualified technicians (see the chapter 2 General

information, page 6).

Independent maintenance work and constructional changes to the machine,

especially to the safety equipment, are not permitted.

Safety equipment

Safety equipment must not be modified and must not be rendered ineffective

during normal operation.

General safety instructions

DANGER

Danger to life and danger of injury due to failure to follow

the warnings on the machine and in the Operator's Manual.

▪ Heed the warnings on the machine and in the Operator's

Manual.

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Safety

HATZ

Operator's Manual 13

Page 14

WARNING

Danger of injury and danger of incorrect operation due to

inadequate personnel qualifications.

▪ The personnel must have read and understood this Opera-

tor's Manual or must be able to demonstrate the necessary

qualifications for working with this equipment, acquired in

training/instructional courses.

▪ Only qualified personnel is permitted to operate and main-

tain this machine.

▪ Failure to comply will cause the warranty to be void.

WARNING

Danger of injury from the failure to follow the operating instructions and from performing unauthorized tasks on the

machine.

▪ Follow all instructions.

▪ Do not perform activities that are not authorized. Contact

properly trained personnel if necessary.

CAUTION

Danger of injury from overloading the body.

Lifting the machine to transport it or to move it to another location can lead to injuries (of the back, for example).

▪ Only lift the machine with a hoist (see the chapter 6.1 Trans-

port, page 31).

3.2.2 Machine-specific safety i nstructions for operation

Introduction

The machine can pose residual risks during operation. To eliminate these

risks, all persons working on the machine must follow the general and machine-specific safety instructions.

If you have an engine that is not yet installed in a machine, it is imperative

that you follow the Assembly Ins truction s fo r HATZ Diesel Engines before installing the engine.

These assembly instructions contain important information on safe installation.

If the engine is installed in a machine or assembled with other machines to

form a machine, it is prohibited to start the engine before it has been determined that the newly created machine fulfills all safety-related requirements

and applicable legal regulations.

Safety 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

14 Operator's Manual

HATZ

Page 15

Safe operat ion

▪ Before switching on the machine, ensure that no one can be injured when

the machine is started up.

▪ During machine operation, ensure that unauthorized persons do not have

access to the area in which the machine has an impact.

▪ Parts of the exhaust gas system and the surface of the engine become hot

during operation. Risk of injury from touching hot parts! Let the engine cool

before maintenance.

▪ Do not refuel during operation.

Faults

▪ Immediately eliminate faults that compromise safety.

▪ Switch off the machine and do not take into service again until all faults

have been eliminated.

Safety instructions for operation

DANGER

Danger to life from inhaling exhaust gases.

Toxic engine exhaust gases can lead to loss of consciousness

and even death in closed-off and poorly ventilated rooms.

▪ Never operate the machine in closed-off or poorly ventilated

rooms.

▪ Do not breathe in the exhaust gases.

DANGER

Fire hazard from fuel.

Leaked or spilled fuel can ignite on hot engine parts and cause

serious burn injuries.

▪ Only refuel when the engine is switched off.

▪ Never refuel in the vicinity of open flames or sparks that can

cause ignition.

▪ Do not smoke.

▪ Do not spill fuel.

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Safety

HATZ

Operator's Manual 15

Page 16

CAUTION

Danger of injury from defective crankhandle.

A damaged or broken handle bar can cause injuries. A worn

cranking shaft can slip out of the starting mechanism when starting and also cause injuries.

▪ Check the crankhandle for a broken handle bar, worn crank-

ing shaft, etc.; replace if necessary.

3.2.3 Machine-specific safety instructions for maintenance work

Introduction

The machine can pose residual risks during maintenance. To eliminate

these risks, all persons working on the machine must follow the general and

machine-specific safety instructions.

Maintenance intervals

▪ Strictly adhere to the maintenance intervals.

▪ Check the safety equipment regularly to ensure it is in good condition and

functioning properly.

▪ Check connections, cables and fasteners regularly to ensure they are in

good condition.

Maintenance work

Maintenance work that goes beyond the scope described in this manual

must only be performed by qualified technicians. We recommend that you

work with one of the more than 500 HATZ service s tation s.

Replacing parts

▪ When replacing defective components, we recommend that you use gen-

uine HA TZ origi nal spar e parts (see the chapter 2 General information,

page 6).

▪ When disposing of parts that can no longer be used, do so in accordance

with local environmental regulations or send them to a recycling center.

Measures following maintenance and troubleshooting

▪ Securely reconnect loose electrical connections; check that the electrical

components and equipment are functioning properly.

▪ Check the entire machine for foreign bodies; remove any foreign bodies.

Safety 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

16 Operator's Manual

HATZ

Page 17

Safety instructions for maintenance work

DANGER

Danger of explosion from flammable cleaning agents.

Cleaning with benzene is an explosion hazard. It is highly flammable, can become electrostatically charged and can generate

an explosive gas-air mixture.

▪ Use halogen-free, cold cleaners with a high flashpoint for

cleaning.

WARNING

Danger of injury from compressed air and dust particles.

Eye injuries may occur when cleaning with compressed air.

▪ Wear safety goggles.

CAUTION

Danger of injury if maintenance instructions are not followed.

▪ Only perform maintenance when the engine is switched off.

▪ For engines with an electric starter:

Disconnect the negative battery terminal.

Protect the starting key against unauthorized access.

CAUTION

Danger of burns.

There is a danger of burns when working on a hot engine.

▪ Let the engine cool before maintenance.

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Safety

HATZ

Operator's Manual 17

Page 18

3.2.4 Electrical equipment

Safety notes

DANGER

Danger to life, danger of injury or danger of property damage due to incorrect use of batteries.

▪ Do not place tools on the battery.

▪ Before performing work on the electrical equipment, always

disconnect the negative terminal of the battery.

▪ Never swap the positive (+) and negative (–) battery termi-

nals.

▪ When installing the battery, first connect the positiv e cable

and then the negat ive c able.

▪ When removing the battery, first disconnect the n egative

cable and then the pos itive cable.

▪ It is imperative that you prevent short circuits and mass con-

tact of current-carrying cables.

▪ If faults occur, check the cable connections for good con-

tact.

DANGER

Danger of explosion from flammable substances.

There is a danger of explosion from flammable gases.

▪ Keep batteries away from open flames and incendiary

sparks.

▪ Do not smoke when working with batteries.

CAUTION

Danger of chemical burns

Chemical burns can occur when using batteries for the electrical

operation.

▪ Protect your eyes, skin, and clothing from corrosive battery

acid.

▪ Immediately rinse areas affected by splashed acid with clear

water and consult a physician if necessary.

Safety 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

18 Operator's Manual

HATZ

Page 19

NOTICE

▪ The necessary wiring diagrams are included with the ma-

chine if it is equipped with electrical equipment. Additional

wiring diagrams can be requested when needed.

▪ We cannot be held liable for electrical equipment that is not

designed according to HATZ wiring diagrams.

▪ Promptly replace faulty indicator lamps.

▪ Do not pull out the starting key during operation.

▪ Do not disconnect the battery while the machine is running. Resulting volt-

age peaks could destroy the electronic components.

▪ When performing a manual emergency start, leave the (possibly depleted)

battery connected.

▪ When cleaning, do no spray the electrical equipment components with a

water jet or high pressure cleaner.

▪ When performing welding work on the machine, disconnect the battery

and place the ground clamp of the welding equipment as close as possible

to the welding area. Disconnect the plug-in connection to the voltage regulator.

3.3 Labels

Overvi ew

The following labels are found on the machine:

▪ Engine type plate

▪ Warning labels and information signs on the engine

▪ Warning labels and information signs on the crankhandle

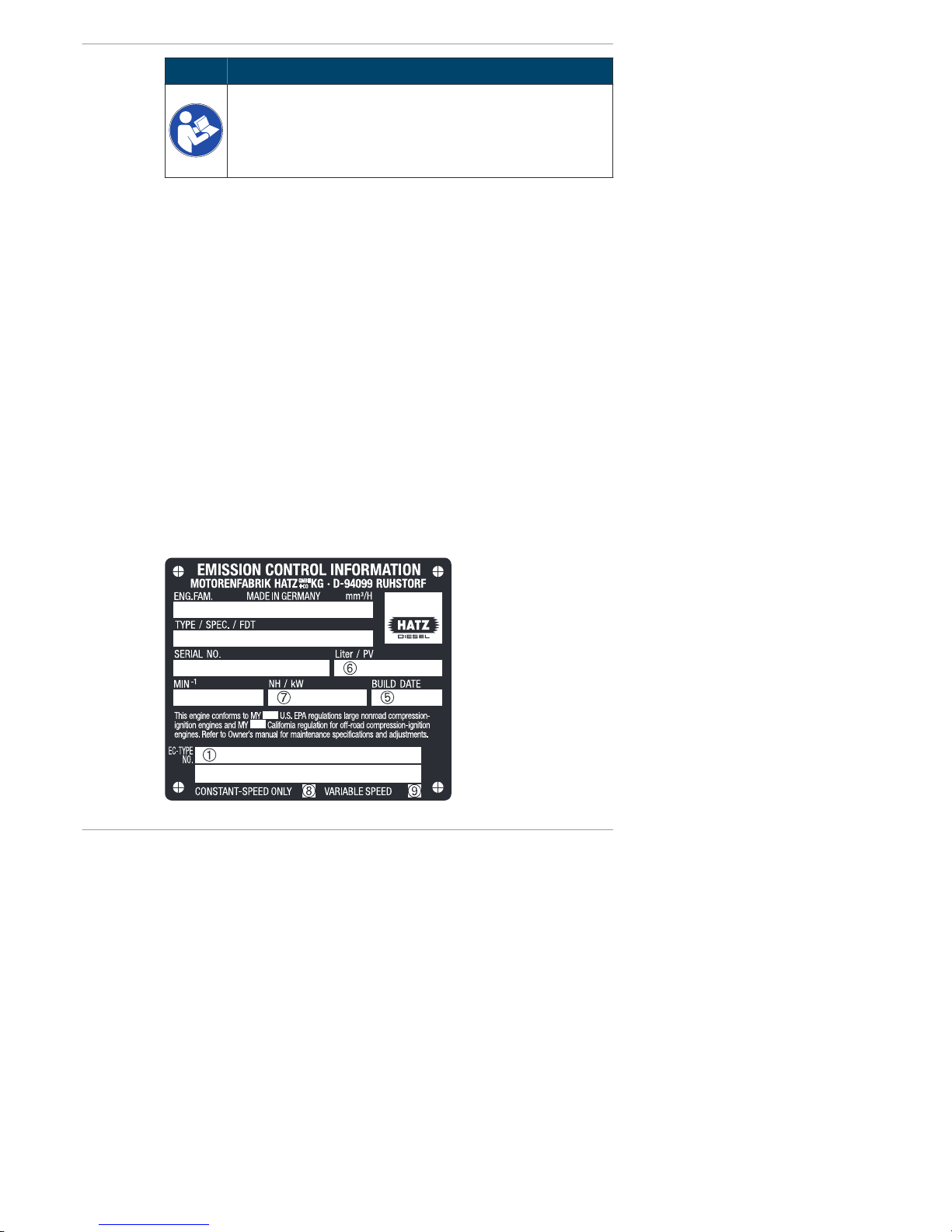

Engine type plate

➀

➁

➂

➃

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Safety

HATZ

Operator's Manual 19

Page 20

The engine type plate is located on the crankcase or sound protection hood

and contains the following engine information:

1 Number of the engine family or the EU approval (for engines with ex-

haust certificate only)

2 Engine type, customer specification and setting of pumping start (°

crankshaft before top dead center)

3 Engine serial number

4 Max. engine speed (rpm)

5 Model year

6 Displacement (liters) and inspection requirement for special settings

7 Injection pump effective stroke (mm) and engine capacity (kW)

8 “Constant speed only” (for engines with EPA/CARB exhaust certificate

only)

9 “Variable speed” (for engines with EPA/CARB exhaust certificate only)

The following data must always be specified for requests and spare part orders

2 Engine type and customer specification

3 Engine serial number

4 Max. engine speed (rpm)

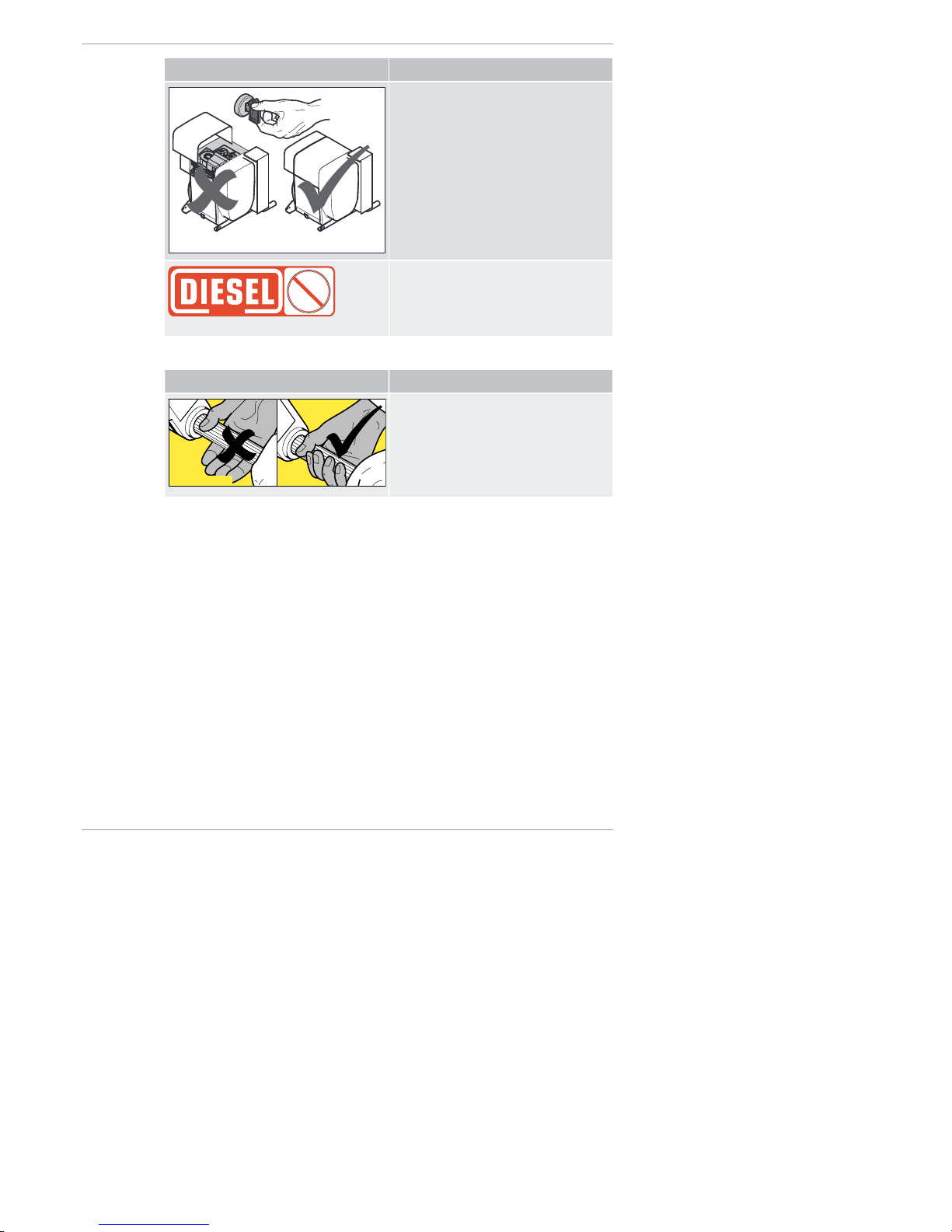

Warning labels and information signs on the engine

Label Meani ng

max

OIL

Maintenance instructions (see the

chapter 8.1 General maintenance instructions, page 55)

Safety 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

20 Operator's Manual

HATZ

Page 21

Label Meani ng

0000 036 144

CAUTION!

Damage from inadequate engine

cooling.

▪ Only run the engine when all cov-

ers are installed.

BIO

DIESEL

052 356 02

Refuel with diesel fuel only. Specification, see the chapter 4.2 Fuel,

page 23

Do not use bio diesel.

Warning labels and information signs on the crankhandle

Label Meani ng

0000 038 928 01

Hold the handle bar so that it cannot

twist, and quickly turn the crank so

that continuous traction between the

engine and crank is ensured, see

the chapter 7.5.1 Starting the engine

with crankhandle, page 38.

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Safety

HATZ

Operator's Manual 21

Page 22

4 Technical data

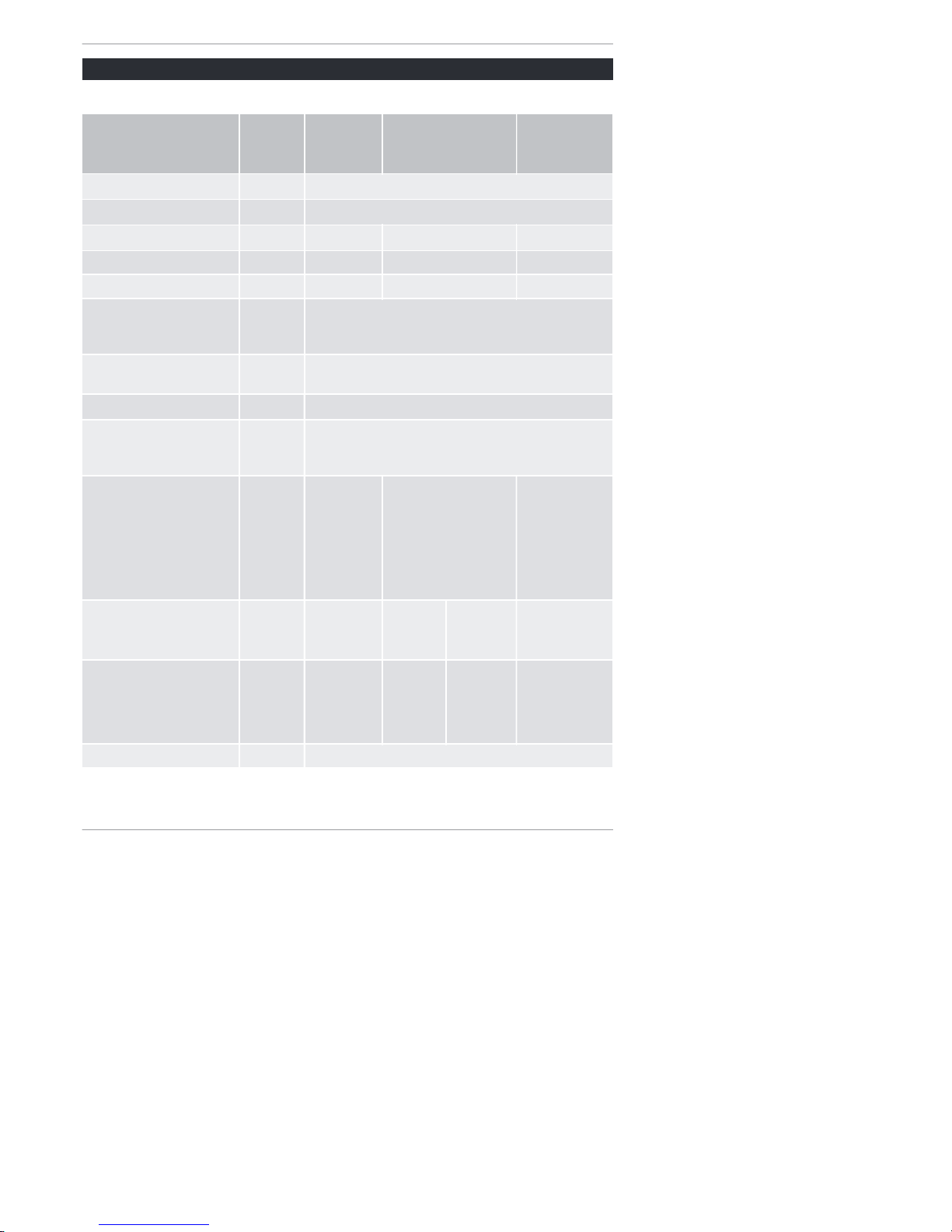

4.1 Engine

Type 2L41C

2M41.

3L41C

3M41.

4L41C /

4L42C

4M41. / 4M42

Type

Air-cooled four stroke diesel engine

Combustion system

Direct injection

Number of cylinders

2 3 4

Bore/stroke mm 102 / 105 102 / 105 102 / 105

Displacement cm

3

1716 2574 3432

Engine oil pressure at oil

temperature of 100 ±

20 °C

Min. 0.6 bar at 850 rpm

Engine oil consumption

(after running-in period)

Max. 1% of fuel consumption, pertaining to full load

Sense of rotation

When viewing flywheel: left

Tappet clearance at 10–

30 °C

inlet/outlet

mm 0.10

Net weight

.M41

.M41Z

4M42

.L41C

4L42C

Approx.

kg

258

263

303

308

315

363

373

388

378

433

438

Max. perm. inclination

during continuous operation in direction

With /

without

oil sump

With

oil sump

Without

oil sump

Only with

oil sump

Operating side

Exhaust air side

Timing cover side

Flywheel side

30°

1)

30°

1)

30°

1)

30°

1)

30°

1)

30°

1)

25°

1)

22°

1)

25°

1)

30°

1)

25°

1)

25°

1)

25°

1)

30°

1)

15°

1)

18°

1)

Battery capacity Min/max 12 V – 88/143 Ah/24 V – 55/110 Ah

1)

Exceeding these limit values causes engine damage.

Technical data 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

22 Operator's Manual

HATZ

Page 23

Engine oil capacities and dipstick equipment

Typ e Oil su mp Engine oil capacity

2)

liters

Mark on the dip-

stick

2L41C

2M41Z

With

Without

7.5

4.5

C

A

2M41 With

Without

8.5

5.5

C

A

3L41C

3M41Z

With

Without

10.5

8.0

D

A

3M41 With

Without

11.0

8.5

D

A

4L41C

4L42C

4M41Z

With

Without

13.0

–

D

–

4M41

4M42

With

Without

14.0

–

D

–

2)

These values are approximations only. The max. mark on the dipstick is

decisive in any case (see the chapter 7.9 Checking the oil level and adding

oil if necessary, page 53).

4.2 Fuel

Fuel typ e

All types of diesel fuel that meet the minimum requirements of the following

specifications are suitable:

▪ EN 590 or

▪ BS 2869 A1 / A2 or

▪ ASTM D 975- 1D / 2D

CAUTION

Danger of engine damage from low quality fuel.

The use of fuel that does not meet the specifications can lead to

engine damage.

▪ The use of fuel that does not meet specifications requires

approval by Motorenfabrik HATZ (main plant).

Winter fuel

When outside temperatures drop below 0 °C, use winter fuel or mix in petroleum in advance:

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Technical data

HATZ

Operator's Manual 23

Page 24

Lowest ambi ent temperature at start [°C]

Percentage of petroleum [%] for

Summer f uel Winter fuel

0 to -10

-10 to -15

-15 to -20

-20 to -30

20

30

50

‑

‑

‑

20

50

4.3 Engine oil

Oil quality

All oil brands that meet at least one of the following specifications are suitable:

▪ ACEA – B2 / E2 or better

▪ API – CD / CE / CF / CF-4 / CG-4 or better

If engine oils of a low quality standard are used, the oil change interval must

be reduced from 250 to 150 or from 500 to 250 operating hours depending

on the engine specification.

Oil viscosity

-40

-30

-20

-10

0

10

20

30

4050104

86

68

50

32

14

-4

-22

-40

OIL: S AE...

°C°F

5W/30

5W/40

10W

/4

0

10W

/30

15W

/4

0

30

4

0

122

10 W

Choose the recommended viscosity based on the type of start (recoil, crank

handle or electric) and on the engine temperature at which the engine will be

operated.

CAUTION

Engine damage from unsuitable engine oil.

Unsuitable engine oil considerably reduces engine service life.

Only use engine oil that fulfills the specifications stipulated

above.

Technical data 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

24 Operator's Manual

HATZ

Page 25

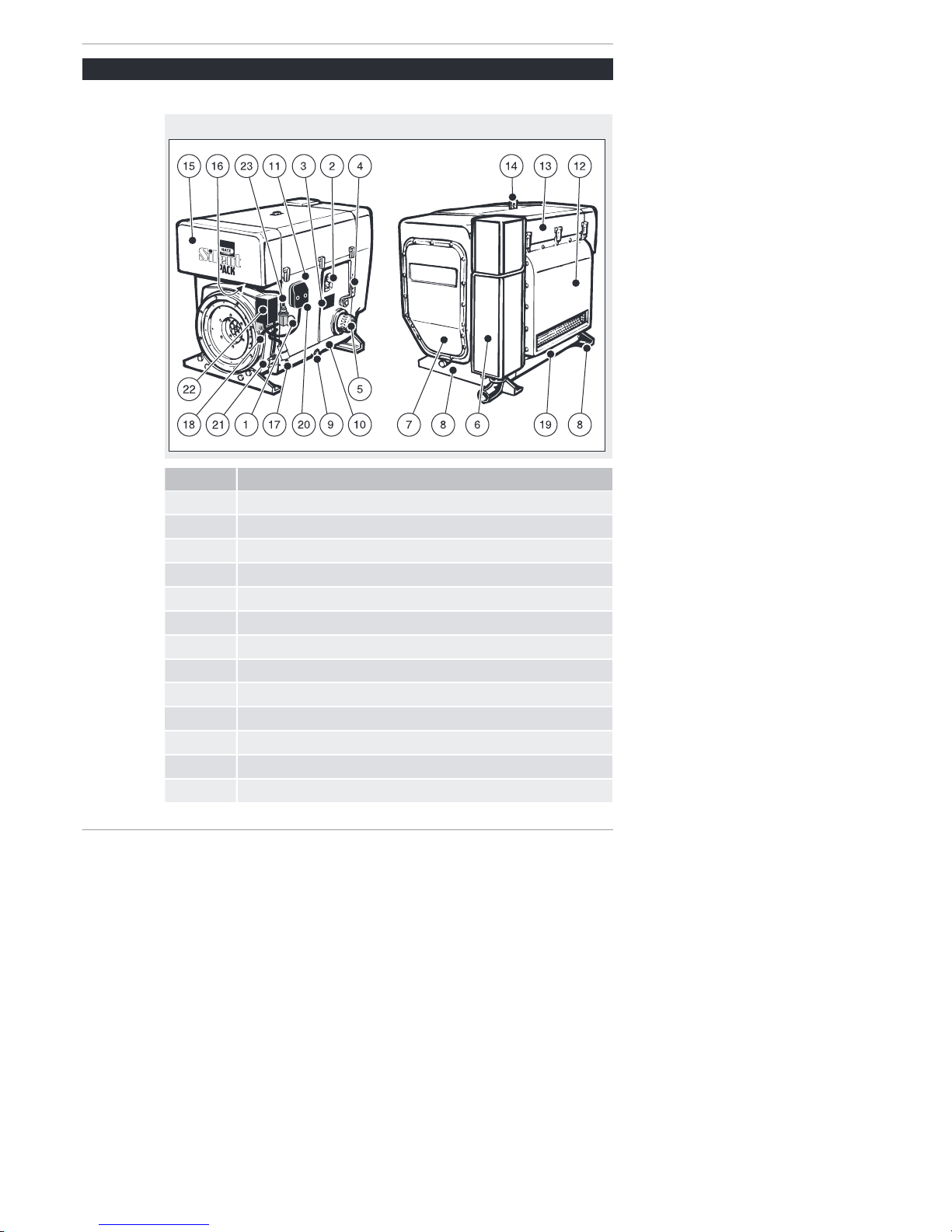

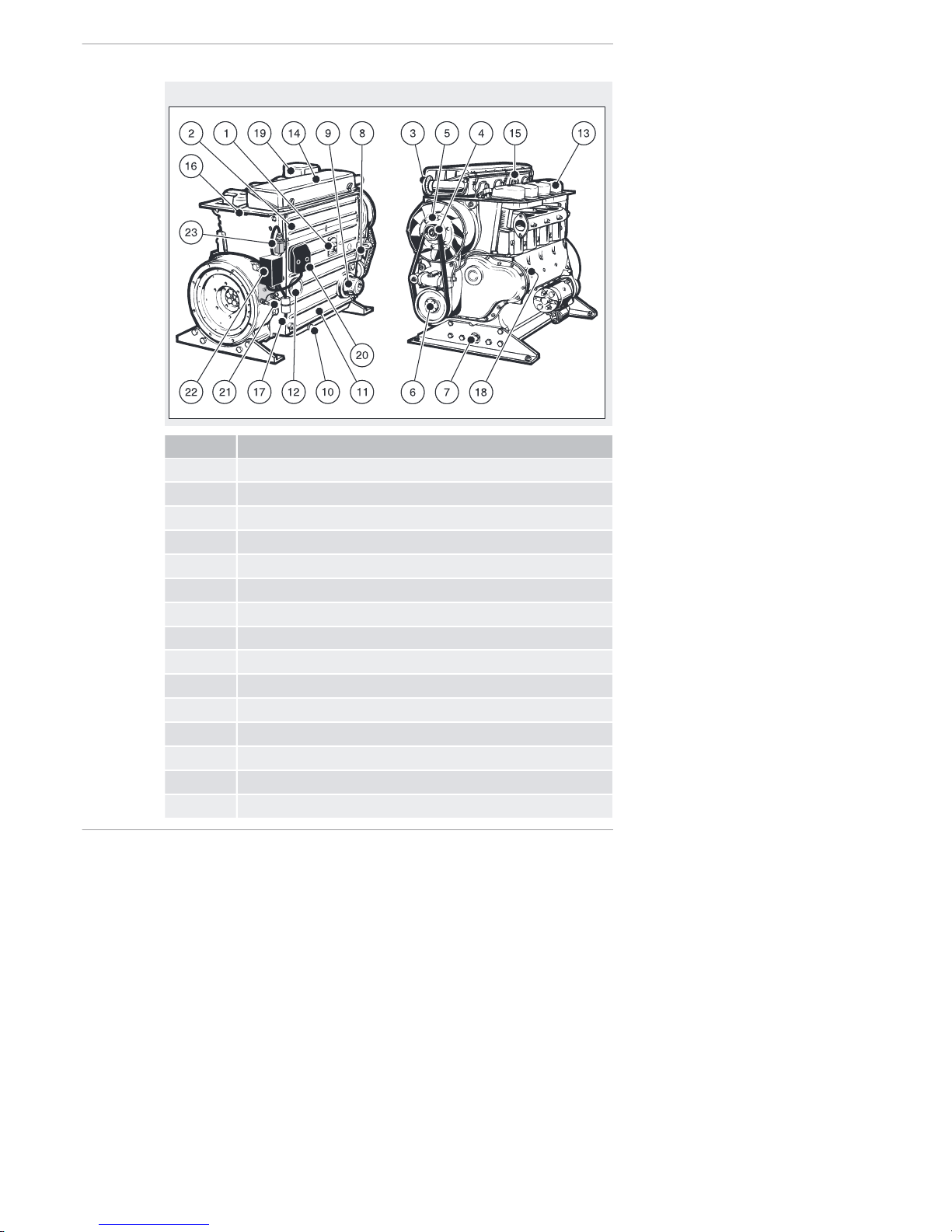

5 Engine design

Engine 2-4L 41C

Encapsulated model "Silent Pack"

Pos. Desig nati on

1 Access cap for fuel feed pump

2 Oil filling opening and dipstick

3 Type plate

4 Speed control lever

5 Oil filter

6 Exhaust silencer (encapsulated)

7 Cover for air guide housing (access to cooling fan belt)

8 Engine brackets

9 Oil drain screw

10 Cover plate on operating side

11 Side wall

12 Exhaust air duct

13 Capsule hood

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Engine design

HATZ

Operator's Manual 25

Page 26

Pos. Desig nati on

14 Retractable lifting eye, max. load 5000 N

15 Capsule intake shaft

16 Intake opening for combustion air

17 Fuel feed line with fuel prefilter

18 Fuel return line

19 Cover plate on exhaust side

20 Central connector for electrical equipment

21 Battery connections

22 Powerbox

23 Electrical maintenance switch for air filter

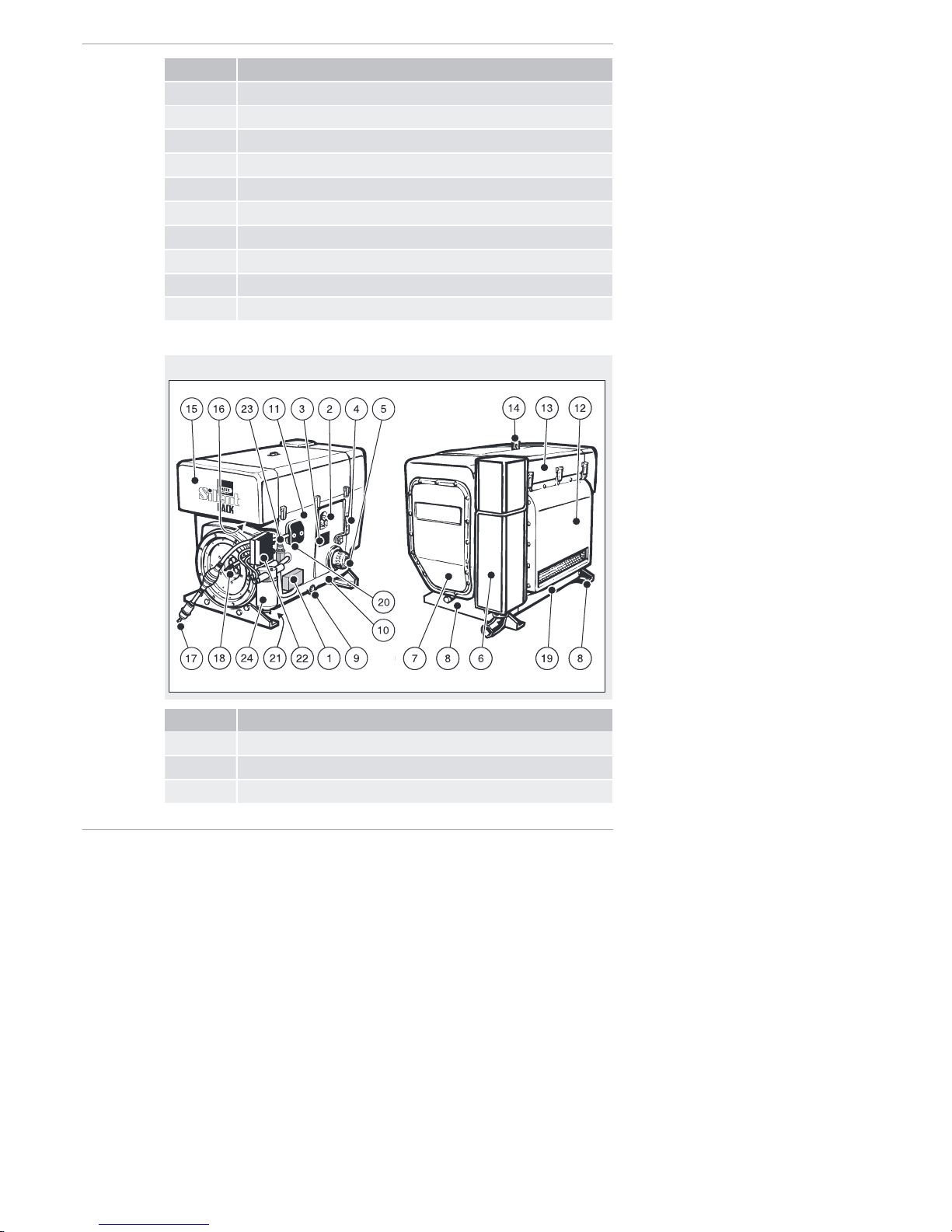

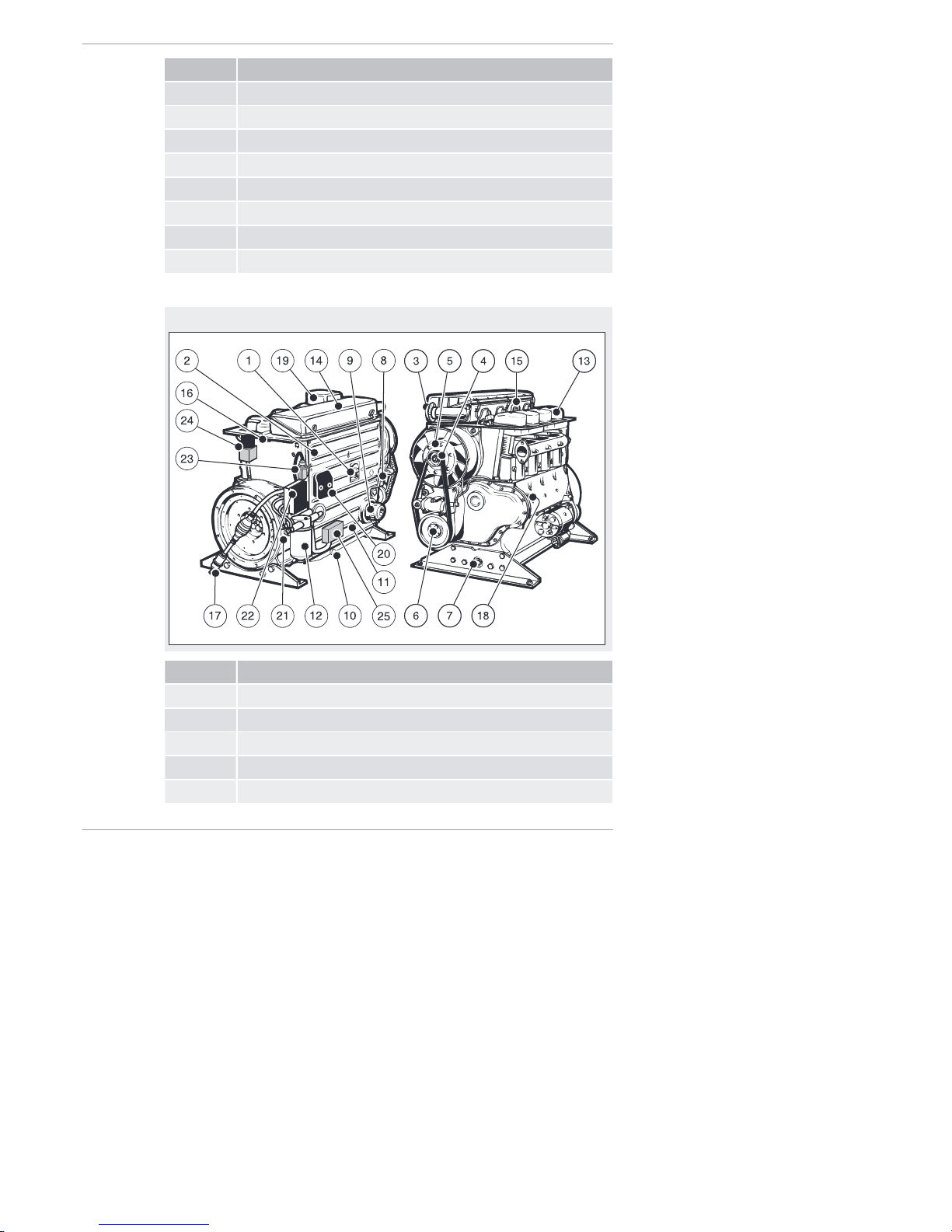

Engin e 4L42C

Encapsulated model "Silent Pack"

Pos. Desig nati on

1 Electronic control unit

2 Oil filling opening and dipstick

3 Type plate

Engine design 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

26 Operator's Manual

HATZ

Page 27

Pos. Desig nati on

4 Speed control lever

5 Oil filter

6 Exhaust silencer (encapsulated)

7 Cover for air guide housing (access to cooling fan belt)

8 Engine brackets

9 Oil drain screw

10 Cover plate on operating side

11 Side wall

12 Exhaust air duct

13 Capsule hood

14 Retractable lifting eye, max. load 5000 N

15 Capsule intake shaft

16 Intake opening for combustion air

17 Fuel feed line with fuel prefilter and manual fuel pump

18 Fuel return line

19 Cover plate on exhaust side

20 Central connector for electrical equipment

21 Battery connections

22 Powerbox

23 Electrical maintenance switch for air filter

24 Fuel filter

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Engine design

HATZ

Operator's Manual 27

Page 28

Engine 2-4M41, 2-4M41Z

Standard model

Pos. Desig nati on

1 Oil filling opening and dipstick

2 Side trim panel

3 Intake opening for combustion air

4 Cooling fan belt

5 Cooling fan with installed three phase alternator

6 1/2-inch square socket for turning the engine

7 Oil drain screw

8 Speed control lever

9 Oil filter

10 Oil drain screw (on oil sump)

11 Cooling air guide for oil cooler

12 Access cap for fuel feed pump

13 Cylinder head cover

14 Air filter housing cover

15 Lifting eye, max. load 5000 N

Engine design 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

28 Operator's Manual

HATZ

Page 29

Pos. Desig nati on

16 Fuel return line

17 Fuel feed line with fuel prefilter

18 Type plate

19 Silencer

20 Central connector for electrical equipment

21 Battery connections

22 Powerbox

23 Electrical maintenance switch for air filter

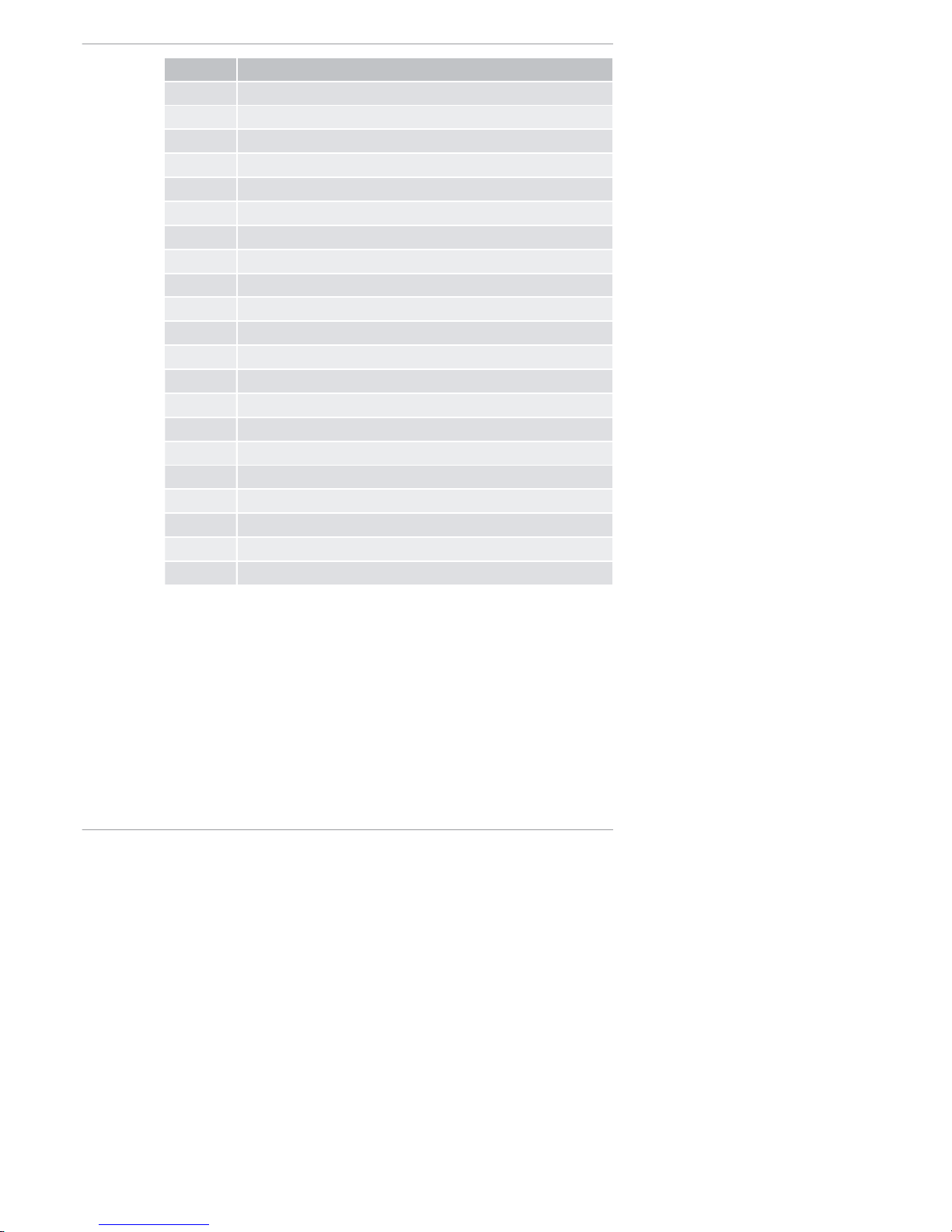

Engine 4M42

Standard model

Pos. Desig nati on

1 Oil filling opening and dipstick

2 Side trim panel

3 Intake opening for combustion air

4 Cooling fan belt

5 Cooling fan with installed three phase alternator

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Engine design

HATZ

Operator's Manual 29

Page 30

Pos. Desig nati on

6 1/2-inch square socket for turning the engine

7 Oil drain screw

8 Speed control lever

9 Oil filter

10 Oil drain screw (on oil sump)

11 Cooling air guide for oil cooler

12 Fuel filter

13 Cylinder head cover

14 Air filter housing cover

15 Lifting eye, max. load 5000 N

16 Fuel return line

17 Fuel feed line with fuel prefilter and manual fuel pump

18 Type plate

19 Silencer

20 Central connector for electrical equipment

21 Battery connections

22 Powerbox

23 Electrical maintenance switch for air filter

24 Exhaust gas return valve (EGR)

25 Electronic control unit

Engine design 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

30 Operator's Manual

HATZ

Page 31

6 Transport, assembly and commissioning

6.1 Transport

Safety notes

CAUTION

Danger of injury from overloading the body.

Lifting the machine to transport it or to move it to another location can lead to injuries (of the back, for example).

▪ Only lift the machine with a hoist.

CAUTION

Only use lifting lugs for transporting the engine.

Do not use for lifting the entire machine.

NOTICE

Danger of environmental damage from leaking fluid.

If the machine is tilted, engine oil and diesel fuel can run out.

▪ Only transport the machine in an upright position.

Transport conditions

▪ Only lift the engine by the standard fitted lifting lugs.

▪ When transporting the machine, follow the safety instructions.

▪ When transporting, follow the applicable safety and accident prevention

regulations of the trade associations.

▪ After delivery, check the machine for completeness and transport damage.

▪ Only transport the machine when it is switched off and has cooled down.

▪ If you have questions on transporting the machine, please contact your

nearest HATZ ser vic e station. For contact data, see the chapter 1 "Notices", page 5 or www.hatz-diesel.c om.

6.2 Assembly instructions

Assembly notes

HATZ diesel engines are efficient, robust and long-lived. Therefore, they are

usually installed in machines that are used for commercial purposes.

The machine manufacturer must follow the applicable regulations regarding

machine safety – the engine is a part of a machine.

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Transport, assembly and commissioning

HATZ

Operator's Manual 31

Page 32

Depending on the use and installation of the engine, it may be necessary for

the machine manufacturer and machine user to install safety equipment to

prevent inappropriate use. Note the following:

▪ Parts of the exhaust gas system and the engine surface become hot dur-

ing operation and should not be touched until they cool down after the engine is switched off.

▪ Incorrect cable connections and incorrect operation of the electrical equip-

ment can lead to sparking and must be avoided.

▪ After the engine is installed in the machine, rotating parts must be protect-

ed against contact.

HATZ safety equipment is available for the belt drive of the cooling fan and

alternator.

▪ Comply with all notice and warning labels on the engine and keep them in

a legible condition. If a label should become detached or be difficult to

read, it must be replaced promptly. For this purpose, contact your nearest

HATZ service station.

▪ Any improper modification of the engine results in a loss of liability cover-

age for resulting damage.

Only regular maintenance, as specified in this Operator's Manual, will maintain the operating readiness of the engine.

The assembly instructions contain important information on how to safely assemble the engine. They are available from any Hatz serv ice station .

If you have any questions, please contact your nearest HATZ serv ice station before commissioning the engine.

6.3 Preparations for commissioning

▪ Check the delivered parts for completeness, damage and other noticeable

issues.

▪ Ensure that the setup location is adequately ventilated.

DANGER

Danger to life from inhaling exhaust gases.

Toxic engine exhaust gases can lead to loss of consciousness

and even death in closed-off and poorly ventilated rooms.

▪ Never operate the machine in closed-off or poorly ventilated

rooms.

▪ Do not breathe in the exhaust gases.

Transport, assembly and commissioning 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

32 Operator's Manual

HATZ

Page 33

7 Operation and use

7.1 Safety notes

NOTICE

Comply with the safety chapter!

Follow the basic safety instructions in the chapter 3 Safety,

page 7.

WARNING

Danger of injury from damage and defects on the machine.

▪ Do not take the machine into service if damage has been lo-

calized and identified.

▪ Replace faulty components.

WARNING

Danger of injury from the failure to follow the operating instructions and from performing unauthorized tasks on the

machine.

▪ Define the responsibilities of the personnel taking the ma-

chine into service.

▪ Replace faulty machine parts immediately.

▪ Check the installation conditions when the machine is first

taken into service and after the machine has been inactive

for a lengthy period.

CAUTION

Danger of engine damage from low load operation.

Operating the engine at no load or at very low load for an extended period can impair the running characteristics of the engine.

▪ Make sure that the engine load is at least 15 %.

▪ Before switching off the engine following low load operation,

briefly operate it at a considerably higher load.

7.2 Performing tests

Before starting

Before starting the engine, several tests need to be performed to ensure the

machine is working properly.

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Operation and use

HATZ

Operator's Manual 33

Page 34

Procedure

Step Test

1 The machine is standing securely and on a level surface.

2 The installation location is adequately ventilated.

3 There is a sufficient amount of fuel in the fuel tank (see the chap-

ter 4.2 Fuel, page 23).

4 There is a sufficient amount of engine oil in the engine housing

(see the chapter 4.3 Engine oil, page 24).

5 For hand start:

▪ Crankhandle in functional condition.

▪ Sliding area between crankhandle and guide sleeve lightly

greased.

6 No persons are located in the danger zone of the engine or ma-

chine.

7 All safety equipment is in place.

7.3 Start preparation

Procedure

Step Activity

1 Before the first start and with an empty fuel system:

▪ Pump the fuel with the manual lever (see the chapter 7.3.1

Pumping fuel with the manual lever, page 34)

or

▪ Pump the fuel with the manual fuel pump (see the chapter

7.3.2 Pumping fuel with the manual fuel pump, page 35)

7.3.1 Pumping fuel with the manual lever

Requiremen ts

Pre-pumping of fuel with the manual lever of the fuel feed pump is necessary

in the following situations:

▪ Engine shuts down due to empty fuel tank

▪ at first filling of the fuel tank

▪ after changing the fuel filter

Operation and use 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

34 Operator's Manual

HATZ

Page 35

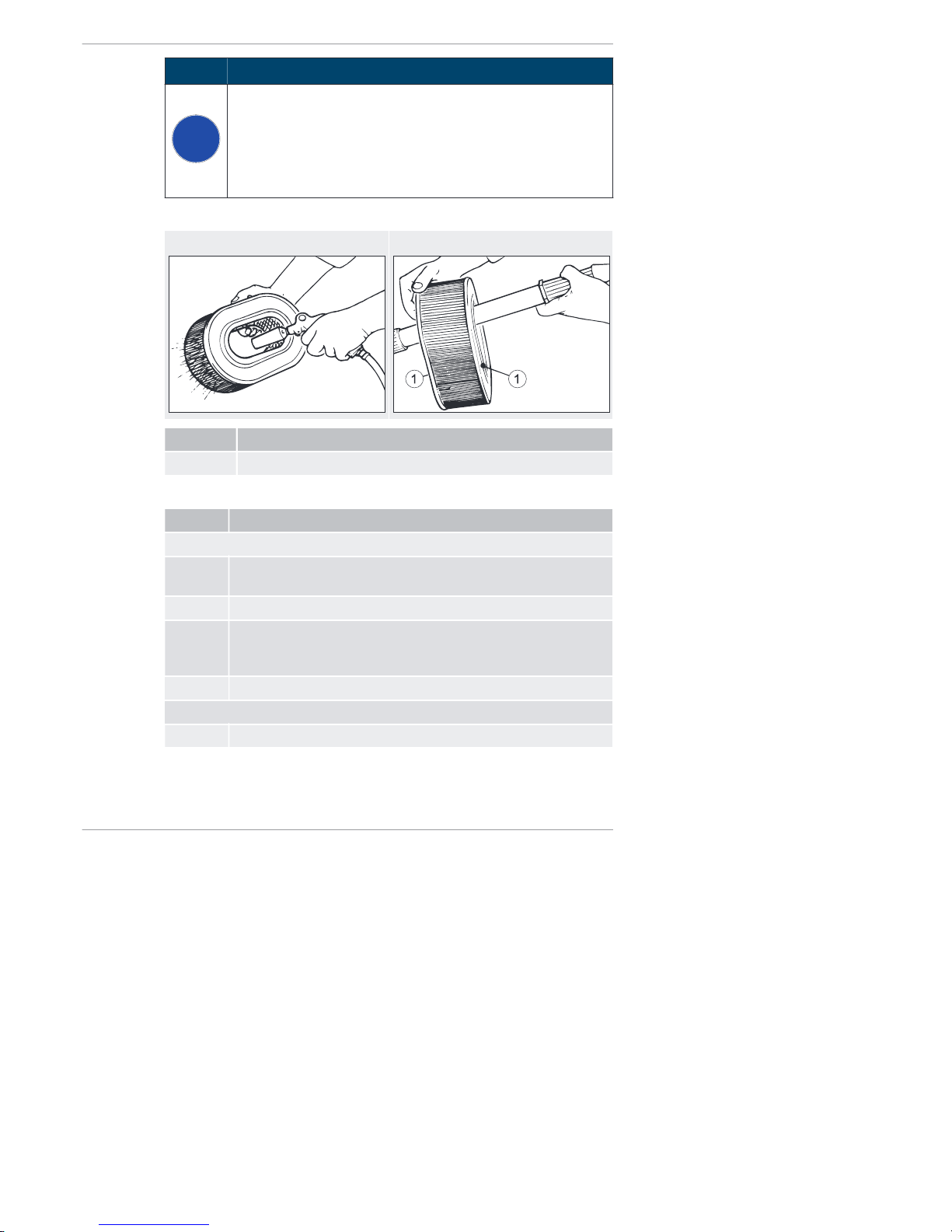

Overvi ew

Pos. Designation

1 Manual lever (fuel feed pump)

2 Return line

Procedure

Step Activity

1 Fill with fuel if necessary.

2 Remove the access cap for the fuel feed pump.

3 Actuate the manual lever (1) on the fuel feed pump until the fuel

audibly flows back into the fuel tank through the return line (2).

4 Install the access cap again.

7.3.2 Pumping fuel with the manual fuel pump

Requiremen ts

Pre-pumping of fuel with the manual fuel pump is necessary in the following

situations:

▪ Engine shuts down due to empty fuel tank

▪ at first filling of the fuel tank

▪ after changing the fuel filter

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Operation and use

HATZ

Operator's Manual 35

Page 36

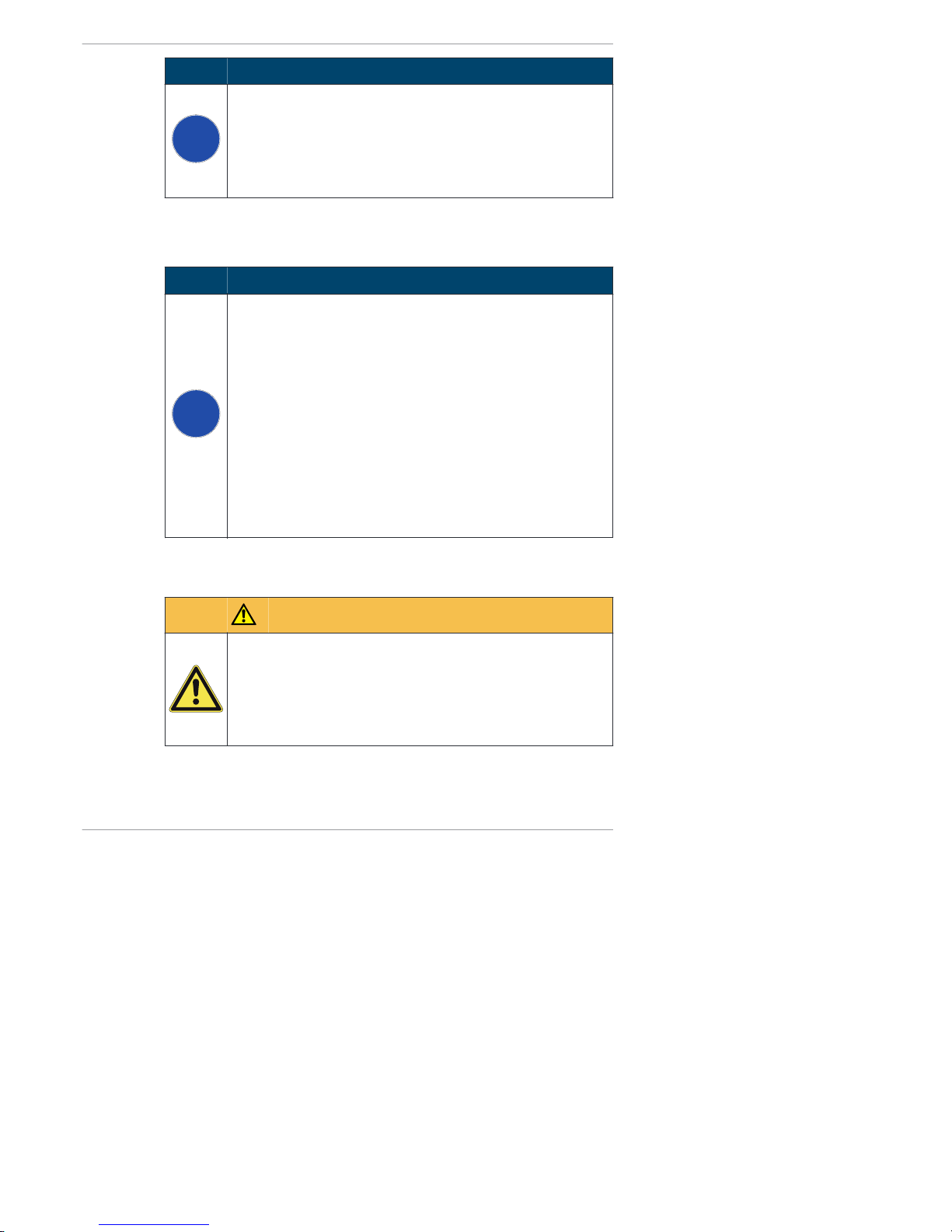

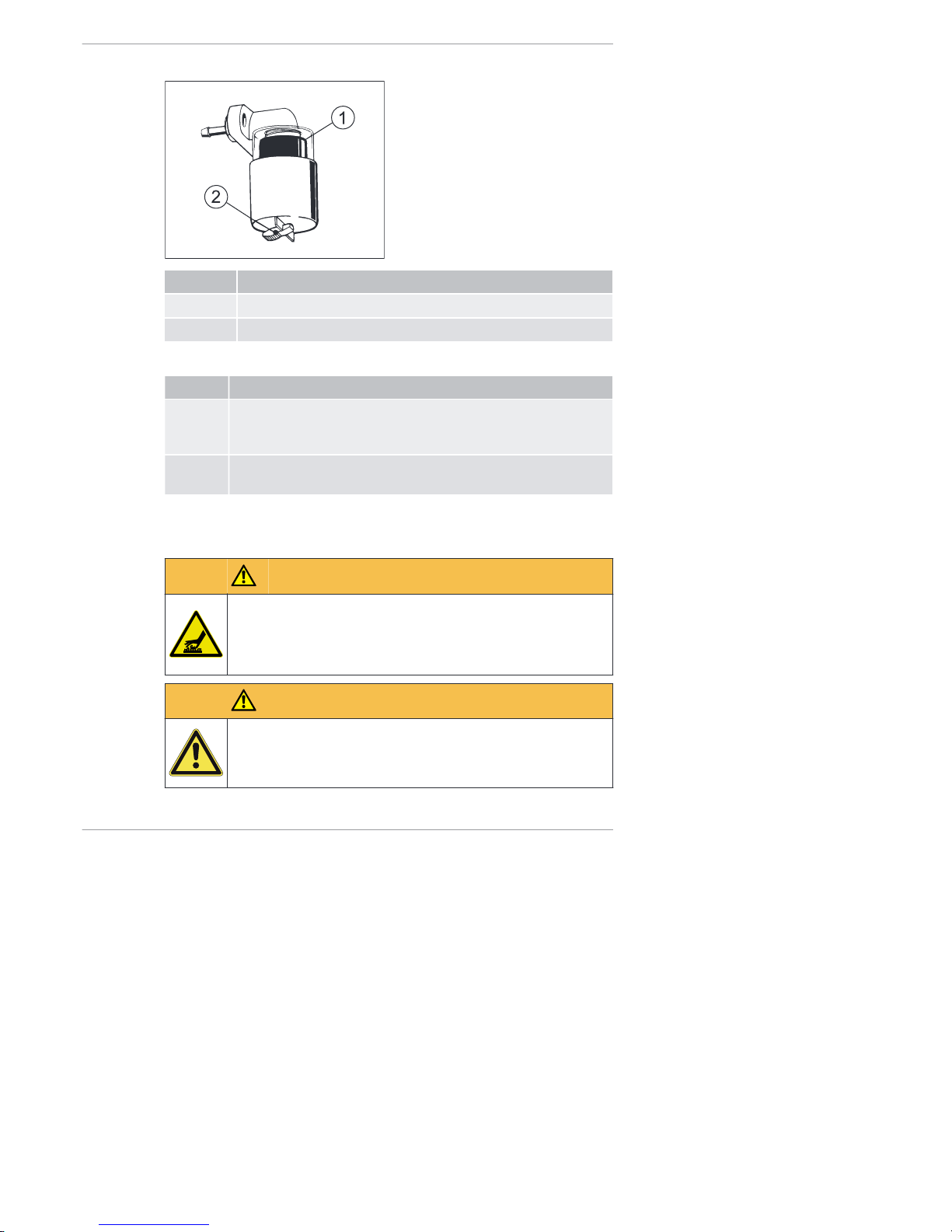

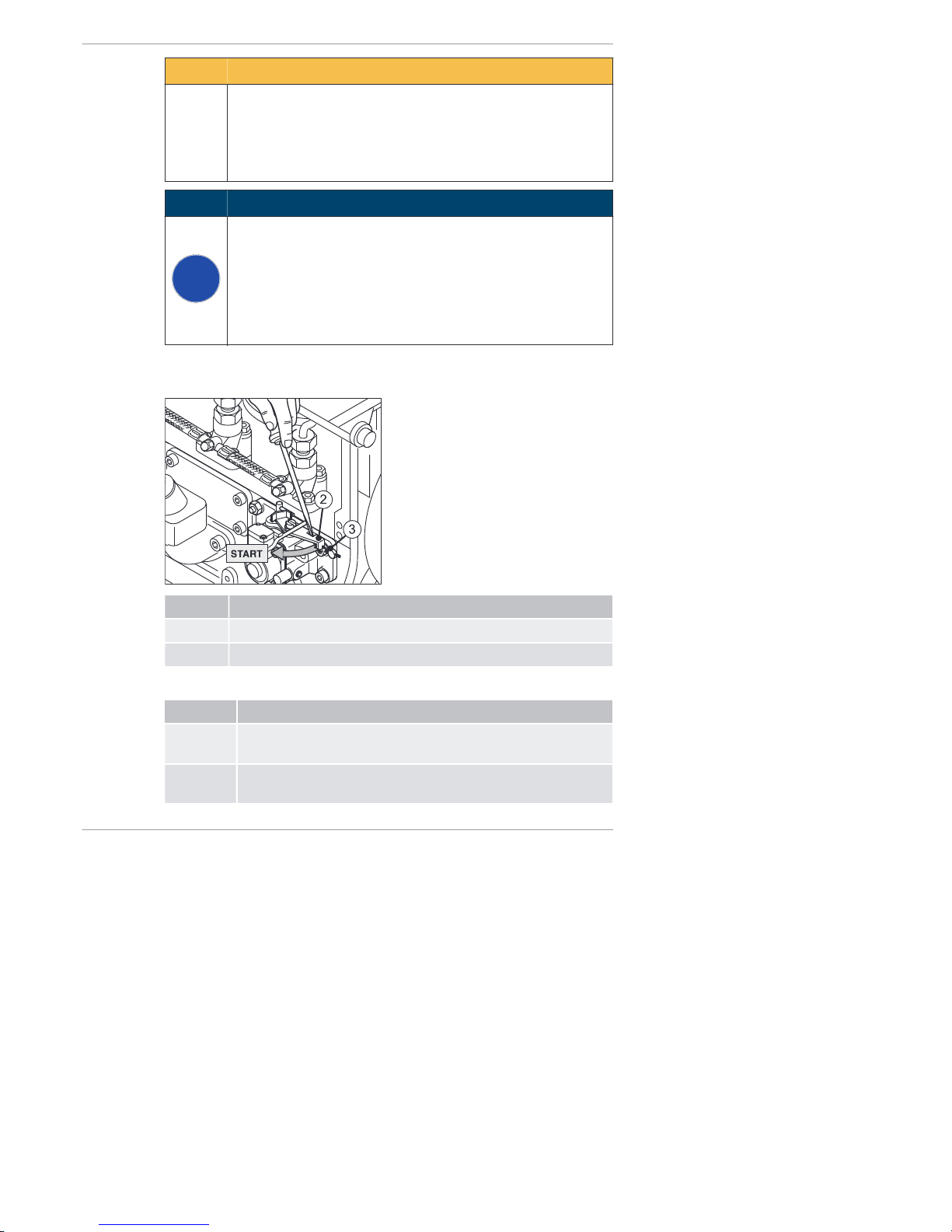

Model with manual fuel pump

Only for 4L42C and 4M42

2

3

Pos. Designation

1 Bleed screw

2 Filter

3 Rubber ball

Procedure

Step Activity

1 If there is air in the fuel system:

Fill with fuel if necessary.

2 Place a suitable container under the filter (2) to collect emerging

fuel.

3 Open the bleed screw (1) by approx. one turn.

4 Squeeze and release the rubber ball (3) repeatedly until fuel

emerges from the bleed screw (1).

5 Close the bleed screw (1) and then activate the rubber ball tw o

more times.

Operation and use 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

36 Operator's Manual

HATZ

Page 37

7.4 Setting the speed control

Overview

½

Procedure

Step Activity

1 Depending on the situation, place the speed control lev-

er in either the "1/2" or "Start" position.

NOTICE

i

A lower speed setting will cause less exhaust smoke when starting.

7.5 Starting the engine

Starting options

The standard equipment of the engine is an electric start mechanism. A

hand starter can be installed as an option.

If possible, separate the engine from the machine being driven by uncoupling it. Always switch the machine into idle mode.

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Operation and use

HATZ

Operator's Manual 37

Page 38

Safety notes

DANGER

Danger to life from inhaling exhaust gases.

Toxic engine exhaust gases can lead to loss of consciousness

and even death in closed-off and poorly ventilated rooms.

▪ Never operate the machine in closed-off or poorly ventilated

rooms.

▪ Do not breathe in the exhaust gases.

CAUTION

Danger of injury from defective crankhandle.

A damaged or broken handle bar can cause injuries. A worn

cranking shaft can slip out of the starting mechanism when starting and also cause injuries.

▪ Check the crankhandle for a broken handle bar, worn crank-

ing shaft, etc.; replace if necessary.

CAUTION

Danger of injury and danger of engine damage from the use

of starting fluid.

▪ Danger of injury during hand starting because the use of

starting fluid can result in uncontrolled ignitions.

▪ Engine damage from uncontrolled ignitions.

▪ Never use starting fluid.

7.5.1 Starting the engine with crankhandle

This chapter contains the following sections:

▪ Prep aration s for crank ing th e engine:

Adjust the continuous decompression.

▪ Cran k the engine:

Crank the engine without compression (approx. 10–20 crank turns).

This lowers the resistance to rotation.

▪ Prep aration s for start ing th e engine:

Adjust the automatic decompression.

▪ Star t the engine:

Cranking starts the cylinders one after the other and the decompression

is automatically canceled.

Operation and use 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

38 Operator's Manual

HATZ

Page 39

Turni ng over the engi ne:

Safety note

CAUTION

Danger of engine damage from decompression while the

engine is running.

▪ Do not operate the decompression lever while the engine is

running.

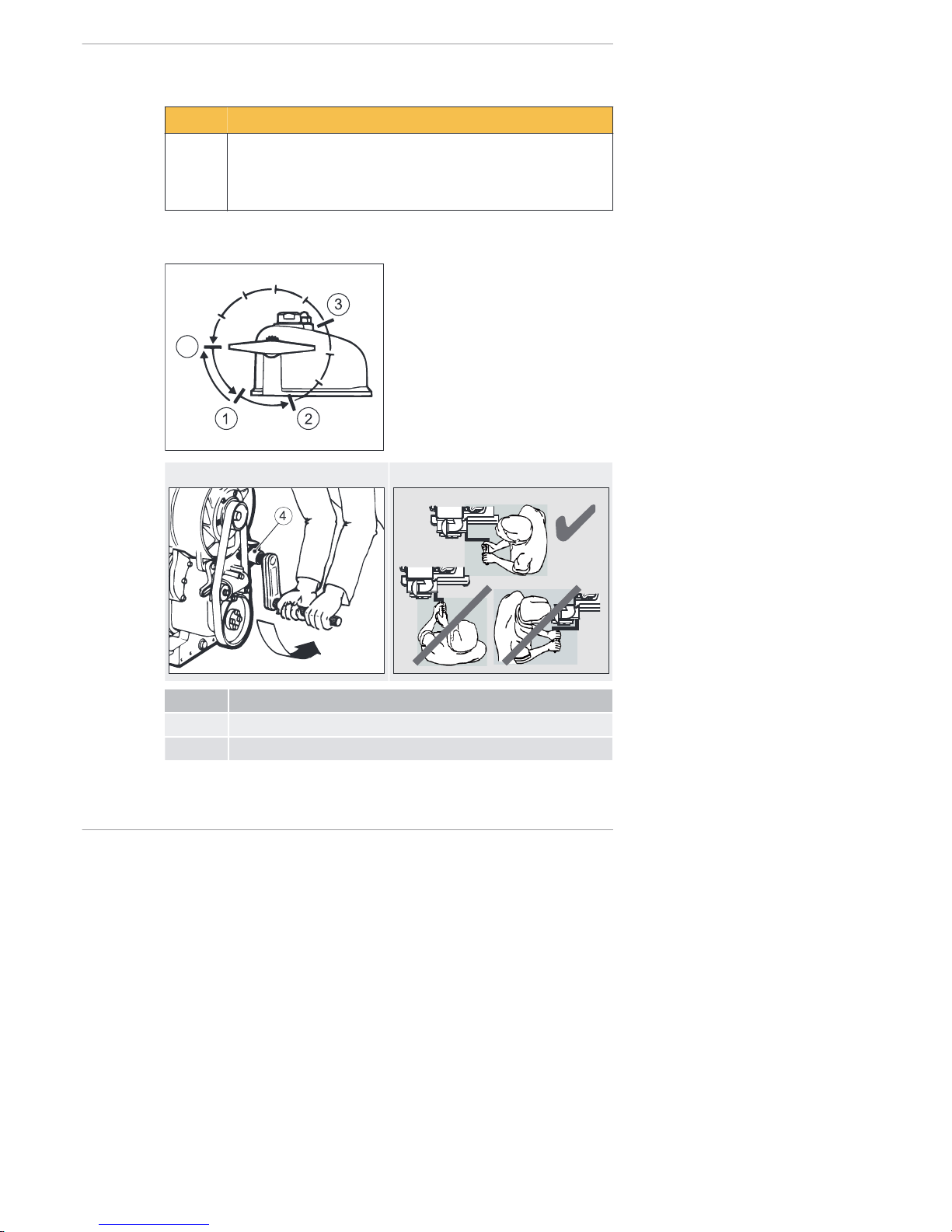

Overvi ew

Decompression lever

0

Attach the crankhandle Position of operator

Pos. Designation

0 - 3 Positions of the decompression lever

4 Guide sleeve

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Operation and use

HATZ

Operator's Manual 39

Page 40

Preparat ion

Step Activity

1 Carry out start preparations (see the chapter 7.3 Start prepara-

tion, page 34).

2 Move the speed control lever into position "Start" (see the chap-

ter 7.4 Setting the speed control, page 37).

3 Move all decompression levers to position "1".

▪ 1 lever for two cylinder engine

▪ 3 levers for three cylinder engine

▪ 4 levers for four cylinder engine

NOTICE

i

Only operate the decompression lever while the engine is at a

standstill and observe the sense of rotation

▪ Only turn the decompression lever in the direction of the ar-

row.

▪ Exception: The lever can be turned directly back from posi-

tion "1" to "0".

▪ Position "1" is the continuous decompression setting.

Procedure

Step Activity

1 Insert the crankhandle into the guide sleeve (4).

2 Assume the correct position.

3 Grasp the handle bar with both hands.

4 Crank the engine until the crank resistance becomes markedly

less.

Operation and use 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

40 Operator's Manual

HATZ

Page 41

Starting the engine

Safety note

CAUTION

Danger of injury from recoiling of the engine.

▪ Use a crankhandle with a recoil damper.

▪ Hold the handle bar so that it cannot twist and quickly turn

the crank so that continuous traction between the engine

and crank is ensured.

▪ If recoil occurs due to cautious turning where the engine

starts in the opposite sense of rotation under certain circumstances (smoke from the air filter), release the crankhandle

immediately and stop the engine.

▪ To repeat the starting process, wait until the engine has

stopped; only then recommence start preparations.

CAUTION

Danger of injury if the crankhandle recoils or turns with the

engine.

▪ The use of crankhandles without recoil damping is not per-

missible within the European Union.

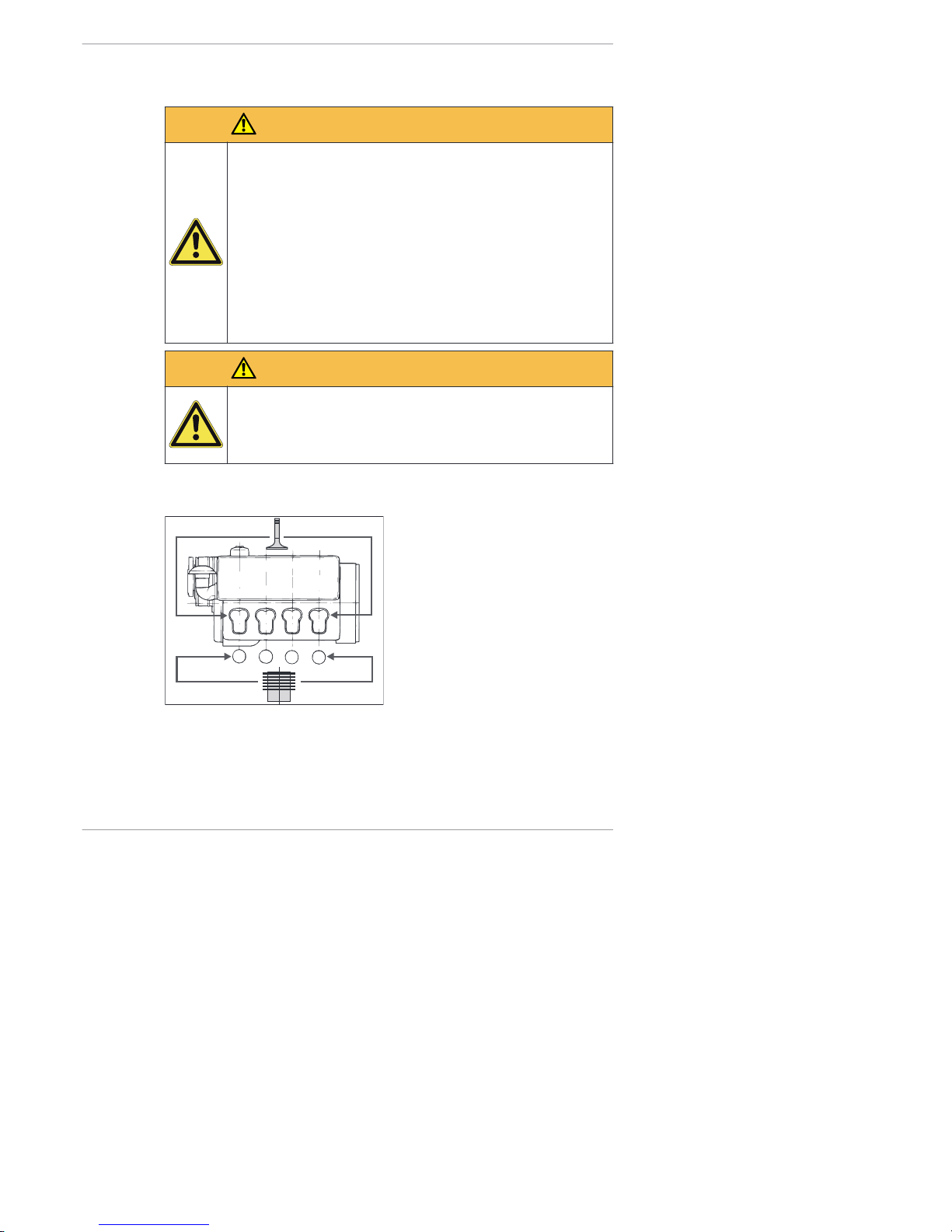

Overvi ew

Numbering of the valves and cylinders from the fan side

1

2

3

4

12 345678

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Operation and use

HATZ

Operator's Manual 41

Page 42

Crankhandle Attach the crankhandle

Pos. Designation

1 Handle bar

2 Crank arm

3 Drive dog

4 Guide sleeve

Preparat ion

The decompression lever must be set depending on the number of cylinders

of the engines 2-4M41..

0

Operation and use 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

42 Operator's Manual

HATZ

Page 43

Step Activity

1 Setting the decompression lever:

▪ Two cylinder engine 2M41.

Turn the lever to position "2".

▪ Thr ee cyli nder engi ne 3M41.

Turn the levers of the 1st and 3rd cylinders to position "2".

Turn the lever of the 2nd cylinder to position "3".

▪ Four cylinder engine 4M41.

Turn the levers of the 1st, 3rd and 4th cylinders to position

"2".

Turn the lever of the 2nd cylinder to position "3".

Starting the engine with a recoil-dampened crankhandle

Step Activity

1 Assume the correct position.

2 Grasp the handle bar with both hands.

3 First turn the crankhandle slowly until the drive dog and the en-

gagement mechanism of the crankhandle engage.

4 Turn the crankhandle forcefully with increasing speed. When the

decompression lever engages in the "0" position (compression),

the highest possible speed must be reached.

5 As soon as the engine starts, pull the crankhandle out of the

guide sleeve.

NOTICE

i

If recoil occurs during the starting process, the crank arm/drive

dog linkage releases via the handle bar due to the short reverse

rotation.

Starting with a crankhandle without recoil damping

Only applies to engines 2-4M41.

Step Activity

1 Assume the correct position.

2 Grasp the handle bar (1) with both hands.

3 Slowly turn the crankhandle until the drive dog (3) engages.

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Operation and use

HATZ

Operator's Manual 43

Page 44

Step Activity

4 Turn the crankhandle forcefully with increasing speed. When the

decompression lever engages in the "0" position (compression),

the highest possible speed must be reached.

5 As soon as the engine starts, pull the crankhandle out of the

guide sleeve (4).

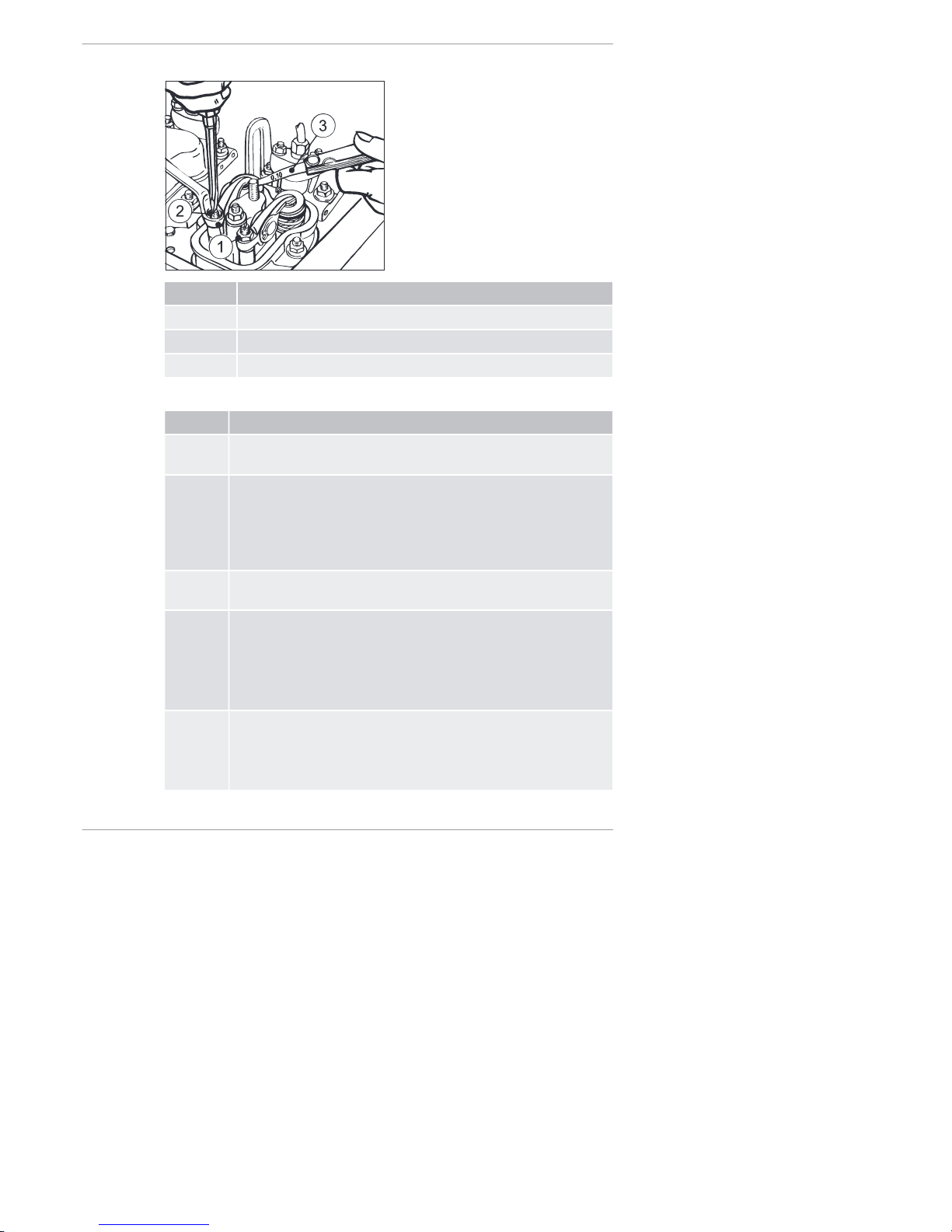

7.5.2 Starting the engine with an electric starter

Standard model

Pos. Designation

1 Operating display

2 Charge control

3 Oil pressure display

4 Engine temperature display (option)

5 Air filter maintenance display

6 Pre glow display (option)

Ignition lock

0 Off

I Operation

II Starting

Operation and use 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

44 Operator's Manual

HATZ

Page 45

Procedure

NOTICE

i

▪ Start for max. 30 seconds. If the engine is still not running

after that, turn the starting key back to position "0" and eliminate the cause (see the chapter 9.1 Troubleshooting,

page 93).

▪ Turn the starting key to position "0" every time you want to

start the engine.

▪ The anti repeat device in the ignition lock makes it impossi-

ble for the starter to engage while the engine is running and

become damaged.

NOTICE

i

The starter protection module prevents the starter from engaging while the engine is running and becoming damaged.

▪ The starter protection module is required when the user

cannot detect at the ignition lock if the engine is still running

or is already at a standstill.

▪ In models equipped with a starter protection module, the

starting key must be kept in the 0 position for at least 8 seconds before another start is possible after the engine is

switched off.

Step Activity

1 Check the speed control (see the chapter 7.4 Setting the speed

control, page 37).

2 Insert the starting key all the way and turn to position "I".

Depending on the model, the following indicators light up:

▪ Charge control (2)

▪ Oil pressure display (3)

▪ Pre glow display (6) at temperatures below 0°C

NOTES:

▪ If the optional engine temperature display (4) lights up, the

cylinder head temperature is impermissibly high. Do not start

the engine; eliminate the cause.

▪ The air filter maintenance indicator (5) only lights up during

operation if the air filter needs to be cleaned or changed.

▪ When the optional pre glow display (6) goes out, continue with

step 3.

3 Turn the starting key to position "II".

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Operation and use

HATZ

Operator's Manual 45

Page 46

Step Activity

4 As soon as the engine is running, release the starting key.

▪ The starting key springs back to position "I" and remains in

this position during operation.

▪ The charge control (2) and oil pressure display (3) go out.

▪ The operating display (1) lights up.

NOTICE

i

▪ In case of irregularities, switch off the engine immediately.

▪ Identify the fault and eliminate it.

▪ For details of troubleshooting, see the chapter 9.1 Trouble-

shooting, page 93.

Model with exhaust gas return valve

The engines 4L42C and 4M42 are equipped with an exhaust gas return

valve (EGR). The indicators change as follows:

Pos. Designation

5 Indicator EGR

Blink codes

The indicator (5) only flashes during operation if a problem arises in connection with the exhaust gas return system. This includes a dirty air filter. This

can be identified by the following flash code of the indicator (5):

▪ 7 times short flash (approx. 0.5 seconds) and 1 long flash (approx. 1.5

seconds).

▪ The flash code indicates that the air filter must be cleaned or changed

(see the chapter 8.2.11 Checking and cleaning the air filter cartridge,

page 76).

▪ If a different flash code appears, please contact the nearest Hat z servi ce.

Operation and use 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

46 Operator's Manual

HATZ

Page 47

NOTICE

i

If the electronics indicate a problem continuously for more than

15 minutes without interruption (flash code - display lamp (5)),

the engine switches off automatically.

▪ If the problem persists, the engine can be started but only

for another 15 minutes.

▪ If necessary, contact your nearest HATZ serv ice station .

Electrical automatic shutoff (additional equipment)

The identifying feature of the electrical automatic shutoff is brief flashing of

all indicators after the starting key is turned to position "I".

NOTICE

i

▪ If the engine stops again immediately after starting, or stops

independently during operation, this is an indication that a

monitoring element of the automatic shutoff has been activated.

▪ Remedy the fault before further starting attempts (see the

chapter 9.1 Troubleshooting, page 93).

▪ Despite the automatic shutoff, check the oil level every 8-15

operating hours (see the chapter 7.9 Checking the oil level

and adding oil if necessary, page 53).

▪ If the engine switches off due to an electrical fault signal or

due to insufficient oil pressure with the aid of the automatic

switch-off, an emergency start can be attempted by the

user. The user must bear responsibility for any resulting

damage (see the chapter 9.2 Emergency start, page 99).

7.6 Switching off the engine

Methods of switching off the engine

CAUTION

Danger of injury from unauthorized access.

There is a danger of injury if unauthorized persons handle the

machine.

▪ Protect the crankhandle and starting key against unauthor-

ized access upon breaks in operation or after completing

work.

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Operation and use

HATZ

Operator's Manual 47

Page 48

CAUTION

Danger of engine damage.

▪ Never stop the engine on the decompression lever.

The engine can be switched off in different ways depending on how it is

equipped:

▪ Speed control lever (mechanical)

▪ Starting key (electrical)

7.6.1 Switching off the engine (mechanical)

Overview

Procedure

Step Activity

1 Move the speed controller lever to the "STOP" position.

The engine switches off.

2 Additional step for engines with a starter:

▪ Turn the starting key to position "0".

All indicator lamps go out.

NOTICE

i

Engines with an automatic switch-off can also be switched off by

turning the starting key back to position "0".

Operation and use 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

48 Operator's Manual

HATZ

Page 49

7.6.2 Switching off the engine (electrical)

Overview

Pos. Designation

0 Off

I Operation

Procedure

NOTICE

i

Danger of full battery discharge.

▪ When the machine is switched off, always turn the starting

key to position "0" or else the battery may become fully discharged.

Step Activity

1 Turn the starting key to position "0".

The engine switches off.

All indicator lamps go out.

2 Remove the starting key.

Automatic electrical switch-off with fault storage

This is identified by brief flashing of all indicators after the starting key is

turned to position "I".

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Operation and use

HATZ

Operator's Manual 49

Page 50

NOTICE

i

If the engine stops again immediately after starting, or stops independently during operation, this is an indication that a monitoring element of the automatic shutoff has been activated.

Procedure

Step Activity

1 Check the indicators (2-4).

After the engine comes to a standstill, the fault will continue to

be displayed by the indicator for approx. another 2 minutes.

2 Then the electrical equipment switches off automatically.

3 Set the starting key to position "0".

4 Turn the starting key back to position "I".

The fault display lights up again.

Remedy the fault before making further starting attempts (see

the chapter 9.1 Troubleshooting, page 93).

The indicator goes out at the next start.

7.7 Refueling

This diesel engine is intended for installation in a machine or for assembly

with other machines to form a machine and does not have its own fuel tank.

Follow the instructions from the manufacturer and comply with the following

safety information.

Safety notes

DANGER

Fire hazard from fuel.

Leaked or spilled fuel can ignite on hot engine parts and cause

serious burn injuries.

▪ Only refuel when the engine is switched off.

▪ Never refuel in the vicinity of open flames or sparks that can

cause ignition.

▪ Do not smoke.

▪ Do not spill fuel.

Operation and use 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

50 Operator's Manual

HATZ

Page 51

CAUTION

Danger of environmental damage from spilled fuel.

Do not overfill the fuel tank and do not spill fuel.

▪ Collect emerging fuel and dispose of it in an environmentally

compatible manner.

CAUTION

Engine damage from using low quality fuel.

The use of fuel that does not meet the specifications can lead to

engine damage.

▪ Only use the fuel specified in the chapter 4.2 Fuel, page 23.

▪ The use of fuel that does not meet specifications requires

approval by Motorenfabrik HATZ (main plant).

7.8 Checking the water separator

Only for engines 4L42C and 4M42

Safety notes

CAUTION

Danger of environmental damage from spilled fuel.

When water is drained from the water separator, a small amount

of fuel is drained as well.

▪ Catch the emerging water-fuel mixture and dispose of it in

an environmentally compatible manner.

NOTICE

i

The interval for checking the water separator depends entirely

on the proportion of water in the fuel and on the care exercised

during refueling; the water separator should be checked at least

once a week.

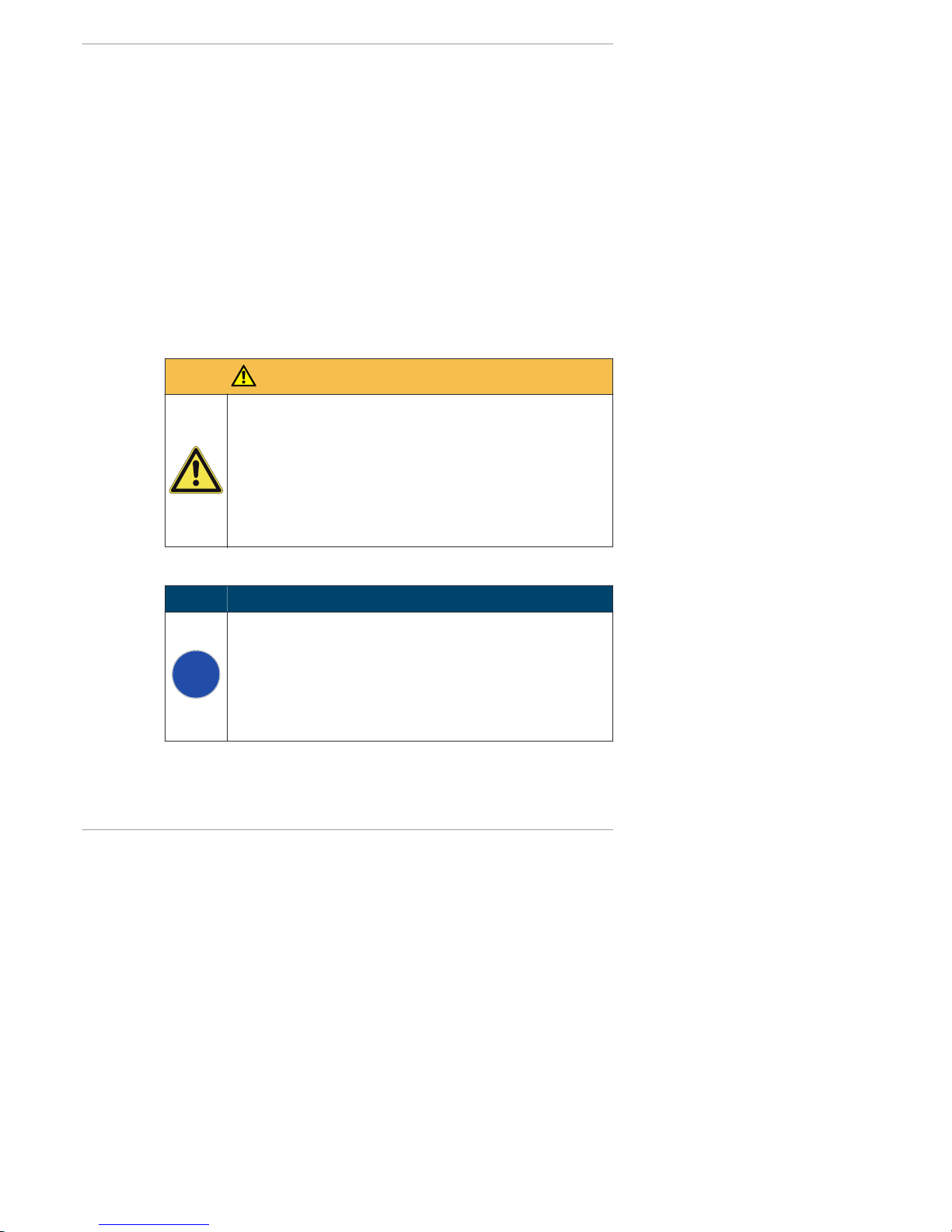

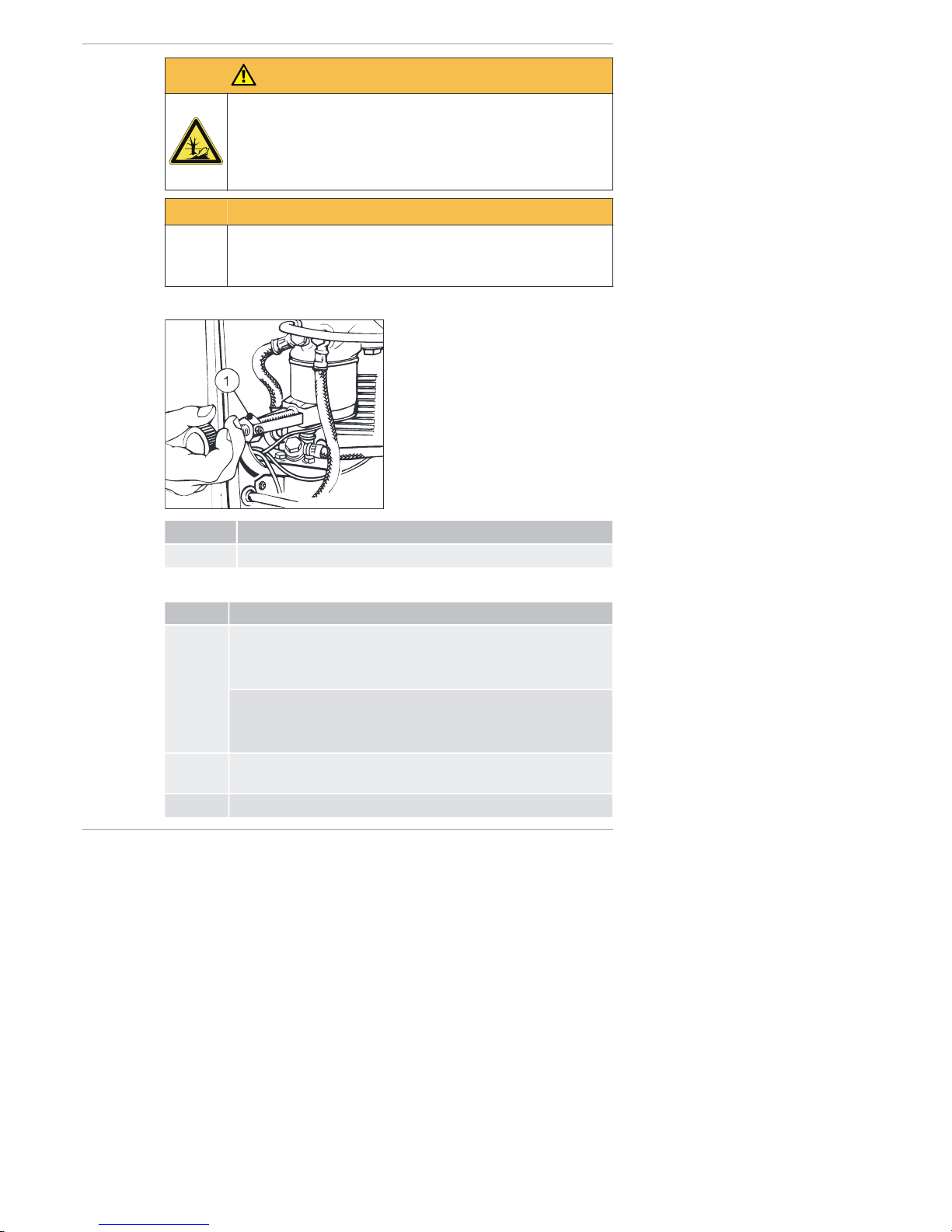

Overvi ew

Water in the fuel collects at the lowest point of the fuel filter in the water separator.

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Operation and use

HATZ

Operator's Manual 51

Page 52

Pos. Desi gnat ion

1 Drain plug

2 Bleed screw

Procedure

Step Activity

1 Place a suitable container under the drain plug (1).

NOTE: In inaccessible locations, an extension hose can be

mounted on the drain screw (1).

2 Open the drain screw (1) and drain the water into the container.

3 If not enough liquid escapes, undo additional screw (2).

4 As soon as fuel escapes, close the drain plug (1) and screw (2).

NOTE: First water escapes then fuel. This can be seen by a

clear separator.

5 Dispose of the water-fuel mixture in an environmentally compati-

ble manner.

NOTICE

i

Note - If starting difficulties occur:

Bleed the injection system with the aid of the manual fuel pump

(see the chapter 7.3.2 Pumping fuel with the manual fuel pump,

page 35).

Operation and use 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

52 Operator's Manual

HATZ

Page 53

7.9 Checking the oil level and adding oil if necessary

Safety notes

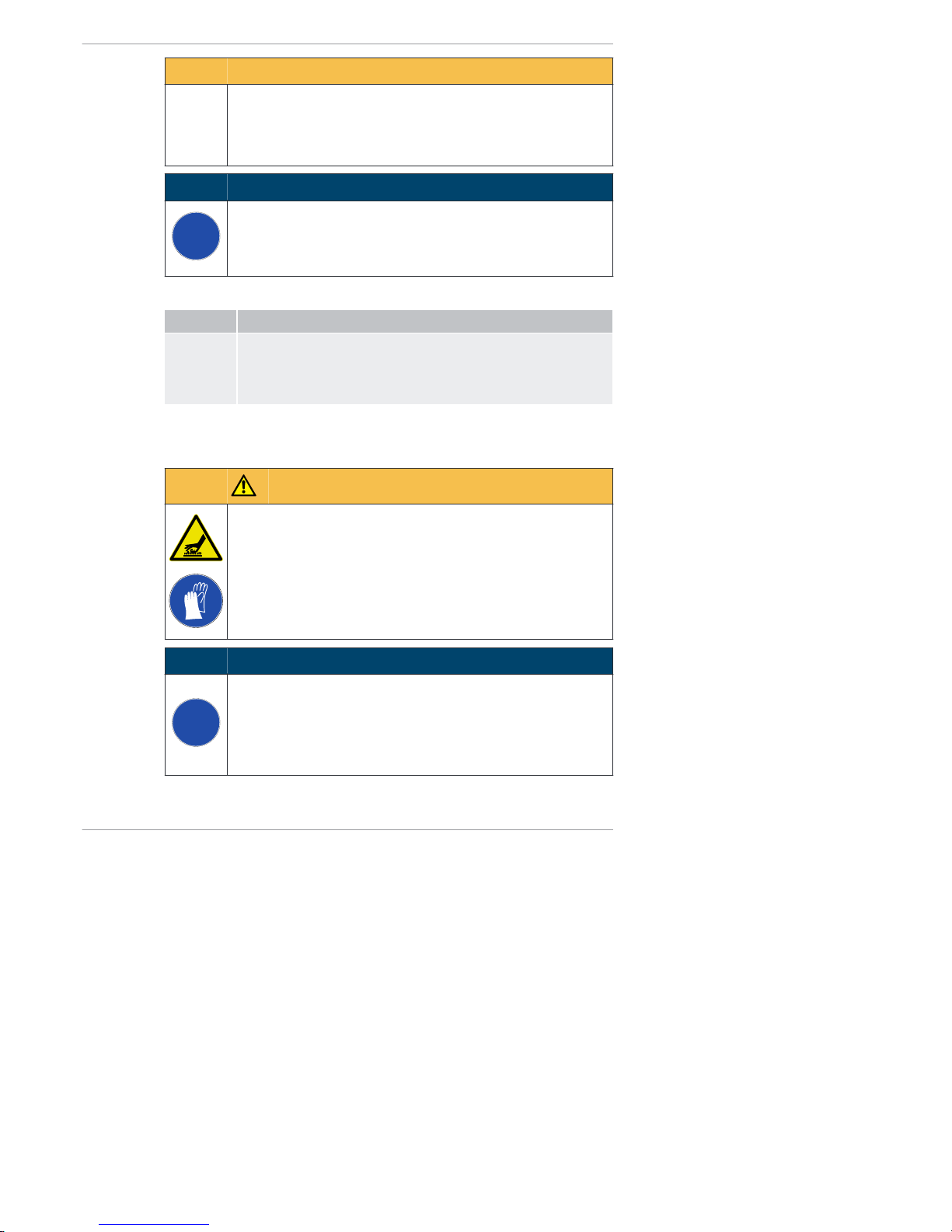

CAUTION

Danger of burns.

There is a danger of burns when working on a hot engine.

▪ Wear safety gloves.

CAUTION

Danger of later engine damage.

▪ Operating the engine with an oil level below the min. mark

or above the max. mark can lead to engine damage.

▪ When checking the oil level, the machine must be horizontal

and the engine must have been switched off for a few minutes.

Overview — Checking oil level/adding oil

Pos. Designation

1 Dipstick

2 Code letter on the dipstick

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Operation and use

HATZ

Operator's Manual 53

Page 54

Procedure — Checking oil level/adding oil

Step Activity

1 Switch off the engine and wait several minutes for the engine oil

to collect in the crank housing. The machine must be horizontal.

2 Remove contamination on the engine in the area of the dipstick

(1).

3 Pull out the dipstick and clean it.

4 Reinsert the dipstick.

5 Pull out the dipstick and check the oil level.

6 If the oil level is close to the min. mark, add engine oil to the

max. mark.

For specifications and viscosity see chapter 4.3 Engine oil,

page 24.

7 Reinsert the dipstick.

Operation and use 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

54 Operator's Manual

HATZ

Page 55

8 Maintenance

8.1 General maintenance instructions

Safety notes

WARNING

Danger of injury from the failure to follow the operating instructions and from performing unauthorized tasks on the

machine.

▪ Follow all instructions.

▪ Do not perform activities for which no qualification is availa-

ble. Contact properly trained personnel if necessary.

NOTICE

Comply with the safety chapter!

Follow the basic safety instructions in the chapter 3 Safety,

page 7.

▪ Maintenance tasks may only be performed by trained personnel.

▪ Accident prevention measures must be in accordance with the local acci-

dent prevention regulations.

▪ Perform setting and maintenance work at the specified intervals.

▪ Replace faulty machine parts as soon as possible.

▪ Always use personal protective equipment.

▪ Only use fully functional tools.

▪ Problems may occur if unsuitable spare parts are installed. We cannot ac-

cept responsibility for damage and secondary damage that result from

this. We therefore recommend the use of Hatz o rig inal spare p arts .

▪ Closely adhere to the maintenance conditions prescribed in this Operator's

Manual.

▪ Only make changes on the machine in agreement with the manufacturer.

▪ Only perform maintenance when the engine is switched off.

▪ Adhere to legal regulations when handling and disposing of used oil, fil-

ters, coolants, and cleaning agents.

▪ Protect the starting key against unauthorized access.

▪ Disconnect the negative battery terminal before carrying out maintenance

work.

▪ After completing maintenance work, check that all tools, bolts, aids and

other objects are removed from the machine and that all safety equipment

has been replaced.

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Maintenance

HATZ

Operator's Manual 55

Page 56

▪ Before starting, ensure that no persons are located in the danger zone of

the engine or machine.

Performance of maintenance work

The entire machine is designed to be maintenance friendly. Parts that require maintenance are easily accessible.

▪ Perform maintenance work faithfully at the specified intervals to prevent

premature wear of the machine.

▪ Follow the notice and warning labels on the machine.

▪ Always retighten screw connections loosened during maintenance work.

▪ After the necessary maintenance and repair work is completed, perform a

function test (test run).

▪ For maintenance work that is not listed and described in the maintenance

documentation, please contact your nearest HATZ servic e stat ion .

8.2 Maintenance work

Safety note

CAUTION

Danger of injury if the maintenance instructions are not followed.

▪ Only perform maintenance while the engine is switched off.

▪ Protect the starting key against unauthorized access.

▪ For engines with a starter: disconnect the negative battery

terminal.

▪ After the maintenance work is completed, ensure that all

tools have been removed from the machine.

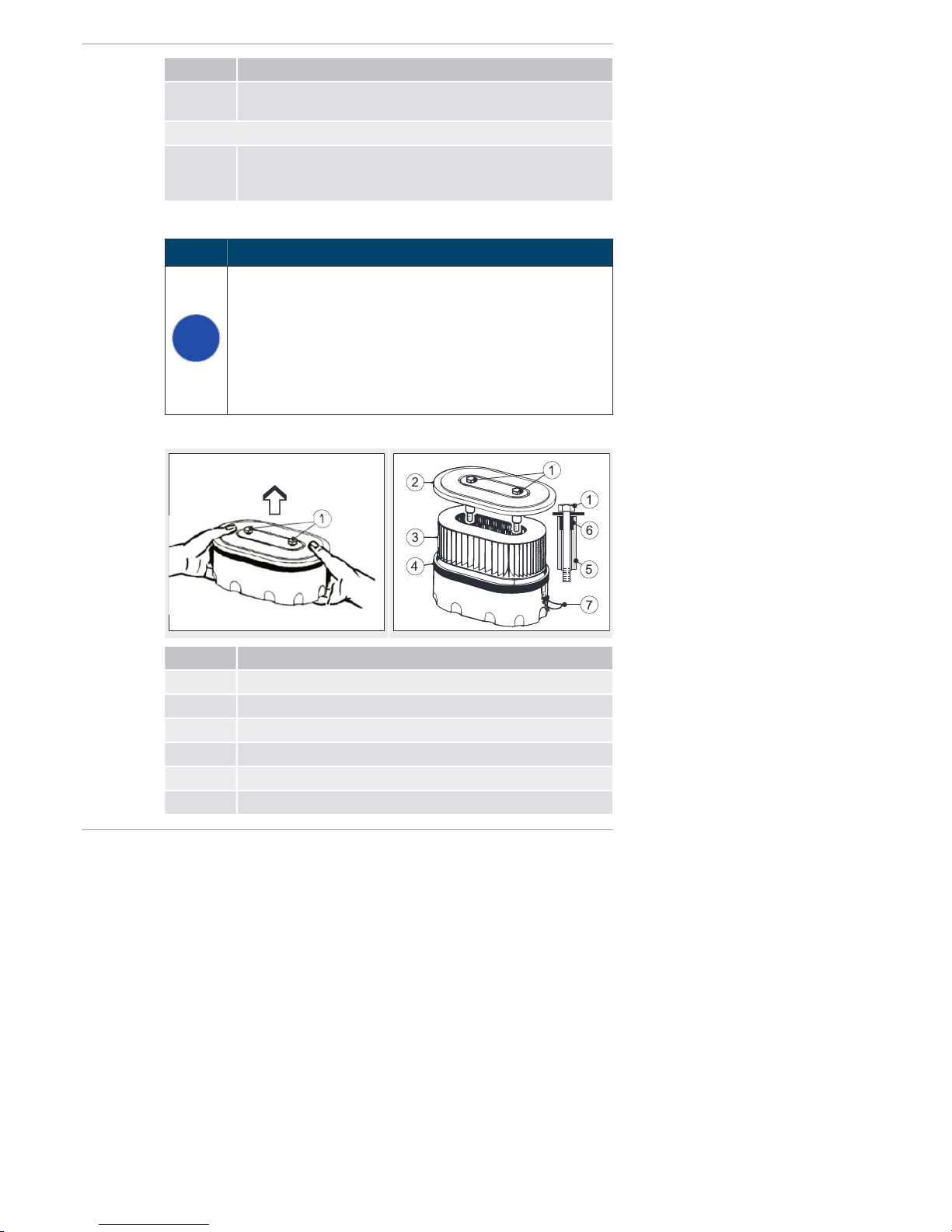

8.2.1 Maintenance notice label

NOTICE

i

Depending on the engine type, one of the maintenance plans

shown below is supplied with the engine.

▪ It should be mounted on the engine or machine in a clearly

visible location.

▪ The maintenance intervals specified on the maintenance

plan must be adhered to (see the chapter 8.2.2 Maintenance plan, page 58).

Maintenance 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

56 Operator's Manual

HATZ

Page 57

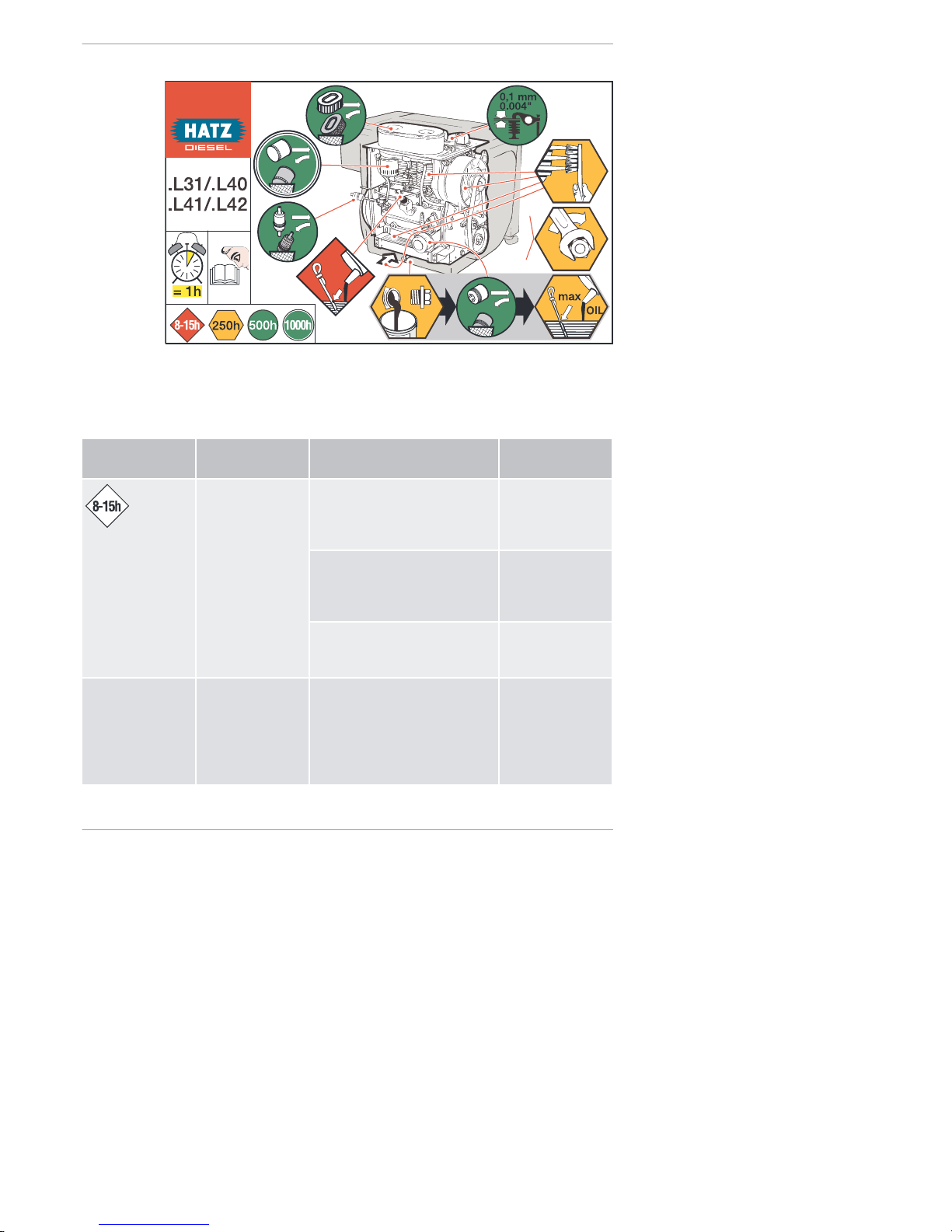

2M41. Without oil sump

2M31

2M40

2M41

500h

250h

= 1h

max

OIL

0,1 mm

0.004"

max

2M41. Wit h oi l sump; 3-4M41. an d 4M42 in general

.M31/.M40

.M41/.M42

500h

250h

= 1h

max

OIL

0,1 mm

0.004"

max

2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42 Maintenance

HATZ

Operator's Manual 57

Page 58

2-4L41C; 4L42C

max

OIL

8.2.2 Maintenance plan

The degree of contamination of the fuel, the care with which refueling is performed and the soiling on the inside of the fuel tank are decisive in determining the change interval of the fuel prefilter and the fuel filter.

Symbol Maintenance in-

terval

Maintenance activity/check Chapter

Every 8–15 operating hours or every day before

starting

Check the oil level. 7.9 Checking the

oil level and adding oil if necessary, page 53

Check the intake area of the

combustion air.

8.2.3 Checking

the intake area of

the combustion

air, page 60

Check the cooling air area. 8.2.4 Checking

the cooling air

area, page 63

Visual check of the condition

of the crankhandle (handle

bar, crank arm, drive dog)

If necessary, lightly grease

gliding area between crankhandle and guide sleeve.

−

Maintenance 2-4L41C, 2-4M41, 2-4M41Z, 4L42C, 4M42

58 Operator's Manual

HATZ

Page 59

Symbol Maintenance in-

terval

Maintenance activity/check Chapter

250h

Every 250 operating hours

Change the engine oil (2M41.

wi tho ut oil sump, 2-4L41C

and 4L42C in general).

8.2.5 Change the

engine oil,

page 64