Page 1

4H50TIC

www.HATZ-DIESEL.com

Hatz Diesel

CREATING POWER SOLUTIONS.

OPERATOR’S MANUAL

Diesel engine

00000000 443366 000044 0000 -- 0077..22001144 -- 00..11

Printed in Germany

EN

Motorenfabrik Hatz GmbH & Co. KG

Ernst-Hatz-Str. 16

94099 Ruhstorf a.d. Rott

Deutschland

Tel. +49 8531 319-0

Fax +49 8531 319-418

marketing@hatz-diesel.de

www.hatz-diesel.com

CREATING POWER SOLUTIONS.

Page 2

4H50TIC Table of contents

Table of contents

1 Notices ............................................................................................................. 5

2 General information ........................................................................................ 6

3 Safety ............................................................................................................... 7

3.1 General information .......................................................................................... 7

3.1.1 Intended use and foreseeable misuse .............................................................. 7

3.1.2 Machine user or machine manufacturer obligations ......................................... 8

3.1.3 Representation of safety notes ......................................................................... 9

3.1.4 Meaning of safety symbols ............................................................................... 10

3.2 Safety notes ...................................................................................................... 11

3.2.1 Operational safety ............................................................................................. 11

3.2.2 Machine-specific safety instructions for operation ............................................ 14

3.2.3 Machine-specific safety instructions for maintenance work .............................. 15

3.2.4 Electrical equipment .......................................................................................... 18

3.3 Labels ............................................................................................................... 19

4 Technical data ................................................................................................. 20

4.1 Engine information and filling quantities ........................................................... 20

4.2 Engine type plate .............................................................................................. 21

4.3 Engine oil .......................................................................................................... 22

4.4 Coolant .............................................................................................................. 23

4.5 Fuel ................................................................................................................... 26

5 Engine design ................................................................................................. 28

5.1 Overview ........................................................................................................... 28

6 Transport, assembly and commissioning .................................................... 31

6.1 Transport - Engine with 2 lifting eyes ................................................................ 31

6.2 Assembly instructions ....................................................................................... 32

6.3 Preparations for commissioning ........................................................................ 33

6.4 Filling engine oil ................................................................................................ 33

6.5 Filling the cooling system .................................................................................. 35

7 Operation and use .......................................................................................... 38

7.1 Safety notes ...................................................................................................... 38

7.2 Performing tests ................................................................................................ 38

7.3 Starting the engine ............................................................................................ 39

7.4 Starting the engine for the first time/after a filter change .................................. 42

7.5 Switching off the engine .................................................................................... 45

7.6 Checking the oil level and adding oil if necessary ............................................ 47

7.7 Refueling ........................................................................................................... 49

8 Maintenance .................................................................................................... 51

8.1 General maintenance instructions .................................................................... 51

8.2 Maintenance work ............................................................................................. 52

HATZ

Operator's Manual 3

Page 3

Table of contents 4H50TIC

8.2.1 Maintenance plan .............................................................................................. 52

8.2.2 Checking the intake area of the combustion air ................................................ 54

8.2.3 Checking the radiator fins for dirt accumulation ................................................ 55

8.2.4 Checking the cooling system ............................................................................ 57

8.2.5 Changing the engine oil and oil filter ................................................................. 59

8.2.6 Cleaning the radiator fins .................................................................................. 64

8.2.7 Tensioning the poly v belt ................................................................................. 67

8.2.8 Replacing the poly v belts ................................................................................. 69

8.2.9 Changing the oil separator of the crankcase ventilation ................................... 71

8.2.10 Checking the screw connections ...................................................................... 72

8.2.11 Draining the water separator ............................................................................. 73

8.2.12 Changing the fuel prefilter ................................................................................. 74

8.2.13 Changing the fuel fine filter ............................................................................... 77

8.2.14 Servicing the air filter (optional) ........................................................................ 80

8.2.15 Changing coolant .............................................................................................. 82

9 Faults ............................................................................................................... 86

9.1 Fault table ......................................................................................................... 86

10 Storage and disposal ...................................................................................... 95

10.1 Storing the machine .......................................................................................... 95

10.2 Disposing of the machine .................................................................................. 95

11 Installation declaration ................................................................................... 97

4 Operator's Manual

HATZ

Page 4

4H50TIC Notices

1 Notices

Contact data

© 2014

Motorenfabrik HATZ

Ernst-Hatz-Straße 16

94099 Ruhstorf

Germany

Tel. +49 (0)8531 319-0

Fax +49 (0)8531 319-418

marketing@hatz-diesel.de

www.hatz-diesel.com

All rights reserved!

Copyright

The copyright for this Operator's Manual rests entirely with Motorenfabrik

HATZ, Ruhstorf.

This Operator's Manual may only be copied or distributed if written approval

has been received. This also applies to the copying or distribution of excerpts of the Operator's Manual. The same conditions apply to distribution of

the Operator's Manual to third parties in digital form.

Original Operator's Manual

This Operator's Manual was translated into multiple languages.

The German version is the original Operator's Manual. All other language

versions are translations of the original Operator's Manual.

HATZ

Operator's Manual 5

Page 5

General information 4H50TIC

2 General information

Information on the document

This Operator's Manual was created with due care. It is exclusively intended

to offer a technical description of the machine and to provide instructions on

commissioning, operating and maintaining the machine. When operating the

machine, the applicable standards and legal regulations as well as any inhouse regulations apply.

Before commissioning, during operation and before maintenance work is begun on the machine, read the Operator's Manual carefully and keep it close

by for ready access.

Machine

This Operator's Manual describes the following machine.

Machine name HATZ diesel engine

Type number 4H50TIC

Customer service

Have service work performed by qualified technicians only. We recommend

that you work with one of the more than 500 HATZ service stations.Trained

specialists there will repair your machine with Hatz original spare parts and

with HATZ tools. The global HATZ service network is at your disposal to advise you and supply you with spare parts. For the address of the Hatz serv-

ice station nearest you, please see the directory enclosed or visit the internet at: www.hatz-diesel.com

Problems may occur if unsuitable spare parts are installed. We cannot accept responsibility for damage and secondary damage that result from this.

We therefore recommend the use of Hatz original spare parts. These parts

are manufactured according to strict Hatz specifications and achieve maximum operational reliability through their perfect fit and functionality. The order number can be found in the enclosed spare parts list or on the internet

at: www.hatz-diesel.com

Exclusion of liability

The manufacturer cannot be held responsible for personal injury, damage to

property, or damage to the machine itself caused by improper use, foreseeable misuse, or failure to follow or adequately follow the safety measures and

procedures described in this Operator's Manual. This also applies to

changes made to the machine and use of unsuitable spare parts.

Modifications, which serve the technical improvements, are reserved.

6 Operator's Manual

HATZ

Page 6

4H50TIC Safety

3 Safety

3.1 General information

Introduction

This chapter contains the information you need to work safely with this machine.

To prevent accidents and damage to the machine, it is imperative that these

safety instructions are followed.

Read this chapter carefully before beginning work.

3.1.1 Intended use and foreseeable misuse

Intended use

The machine described in this Operator's Manual fulfills the following functions:

▪ Diesel engine intended for installation in a machine or for assembly with

other machines to form a machine. See chapter 11 Installation declaration,

page 97.

This engine is intended exclusively for the purpose specified and tested by

the manufacturer of the machine into which the engine is installed.

Any other use is not intended and therefore not permitted. Violations compromise the safety of the personnel working with the machine. Responsibility

is not accepted by Motorenfabrik HATZ for damage resulting from this situation.

The operational safety of the machine is only guaranteed if it is used as intended.

Use according to the intended purpose also includes observance of the instructions in this Operator's Manual.

HATZ

Foreseeable misuse

The following is considered to be foreseeable misuse:

▪ Any use that varies from or extends beyond the uses specified above.

▪ Failure to comply with the instructions in this Operator's Manual.

▪ Failure to comply with the safety instructions.

▪ Failure to immediately eliminate malfunctions that impact safety before

continuing work with the machine (working with the machine when it is not

in perfect condition, either functionally or in terms of safety).

▪ Failure to perform the necessary inspection and maintenance work.

▪ Any unauthorized modification of or removal of safety equipment.

▪ Use of spare parts and accessories that are unsuitable or have not been

approved by HATZ.

▪ Operation in flammable or hazardous environments.

▪ Operation in closed-off or poorly ventilated rooms.

Operator's Manual 7

Page 7

Safety 4H50TIC

▪ Installation of the machine in moving equipment (e.g. vehicles, trailers) or

in closed rooms without additional measures to handle supply air, extract

air, and exhaust gas.

▪ Improper operation at variance with DIN 6271 and DIN ISO 8528 (climate,

load, safety).

Residual risks

Residual risks result during daily use and in association with maintenance

work.

These residual risks will be pointed out in chapter 3.2.2 Machine-specific

safety instructions for operation, page 14 and in chapter 3.2.3 Machinespecific safety instructions for maintenance work, page 15 as well as in the

further contents of the manual, directly in front of the descriptions or operating instructions concerned.

3.1.2 Machine user or machine manufacturer obligations

Machine manufacturer obligations

If you have an engine that is not yet installed in a machine, it is imperative

that you follow the Assembly Instructions for HATZ Diesel Engines before installing the engine. These assembly instructions contain important information on how to safely install the engine and are available at your nearest HATZ service station.

It is prohibited to start the engine before it is fully installed.

In addition, please note that it is prohibited to start up the machine before it

has been determined that the machine into which this engine is installed fulfills all safety-related requirements and legal regulations.

User obligations

The user is obligated to only operate the machine while it is in perfect condition. The user must check the condition of the machine before using it and

ensure that any defects are eliminated before it is taken into service. Running the machine while identified defects exist is not permitted. The user

must also ensure that the information contained in the Operator's Manual

has been read and understood.

Obligations of the operating and maintenance personnel

Personnel assigned with operating and maintaining the machine must have

read and understood the Operator's Manual or must possess the qualifications necessary for working with this equipment, acquired in training/instructional courses. No one may work with the machine without the necessary

qualifications, even if for just a brief period.

The operating personnel must not be under the influence of drugs, medication or alcohol.

All work performed on the machine must be in compliance with the information provided in the Operator's Manual.

8 Operator's Manual

HATZ

Page 8

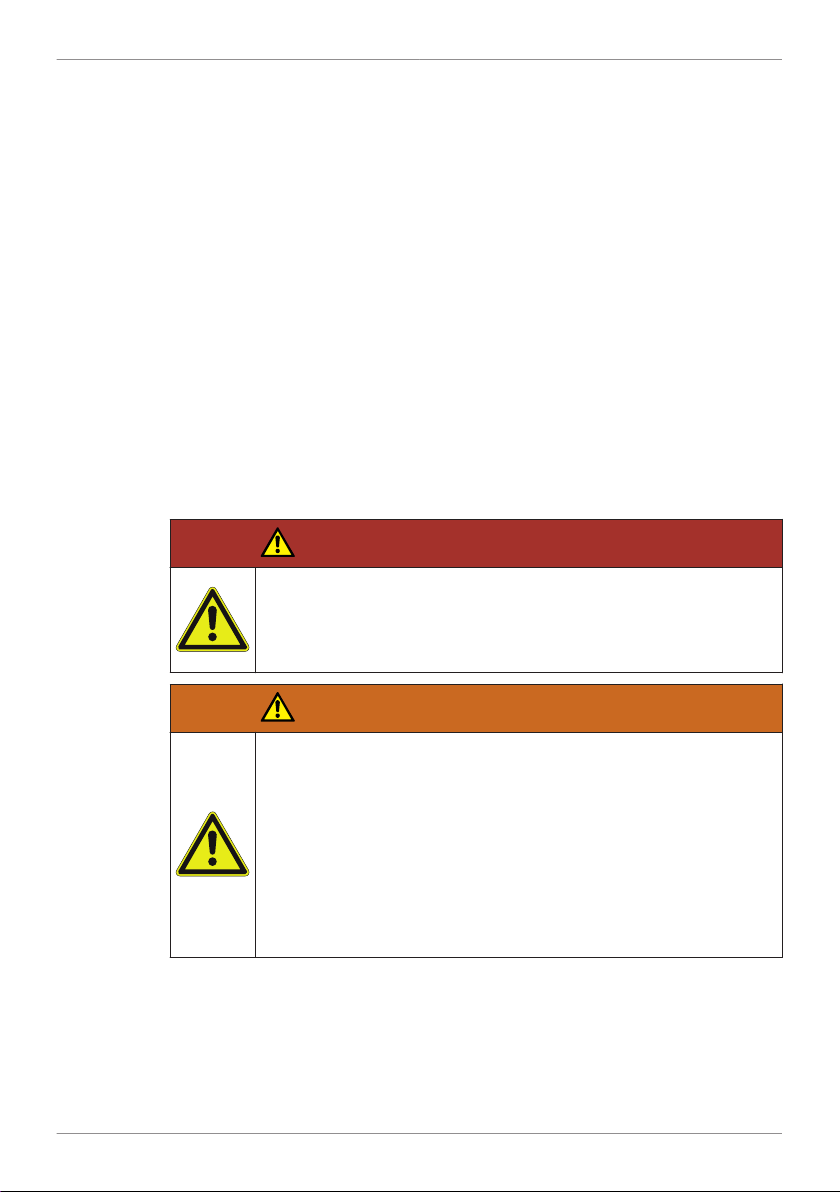

DANGER

WARNING

CAUTION

4H50TIC Safety

Storing the Operator's Manual

This Operator's Manual is an integral component of the machine (also when

being sold). It must be stored in the direct vicinity of the machine and be accessible to personnel at all times.

3.1.3 Representation of safety notes

Overview

This machine has been designed and built according to state-of-the-art technology and the recognized safety standards. Despite these precautions,

risks exist when operating the machine and during maintenance work.

These risks are identified in this manual by means of safety notes.

The safety notes precede the related description or operating step.

Structure of the safety notes

The safety notes consist of:

▪ Warning symbol

▪ Signal word

▪ Description of danger

▪ Possible consequences

▪ Preventative measures

General danger symbol

HATZ

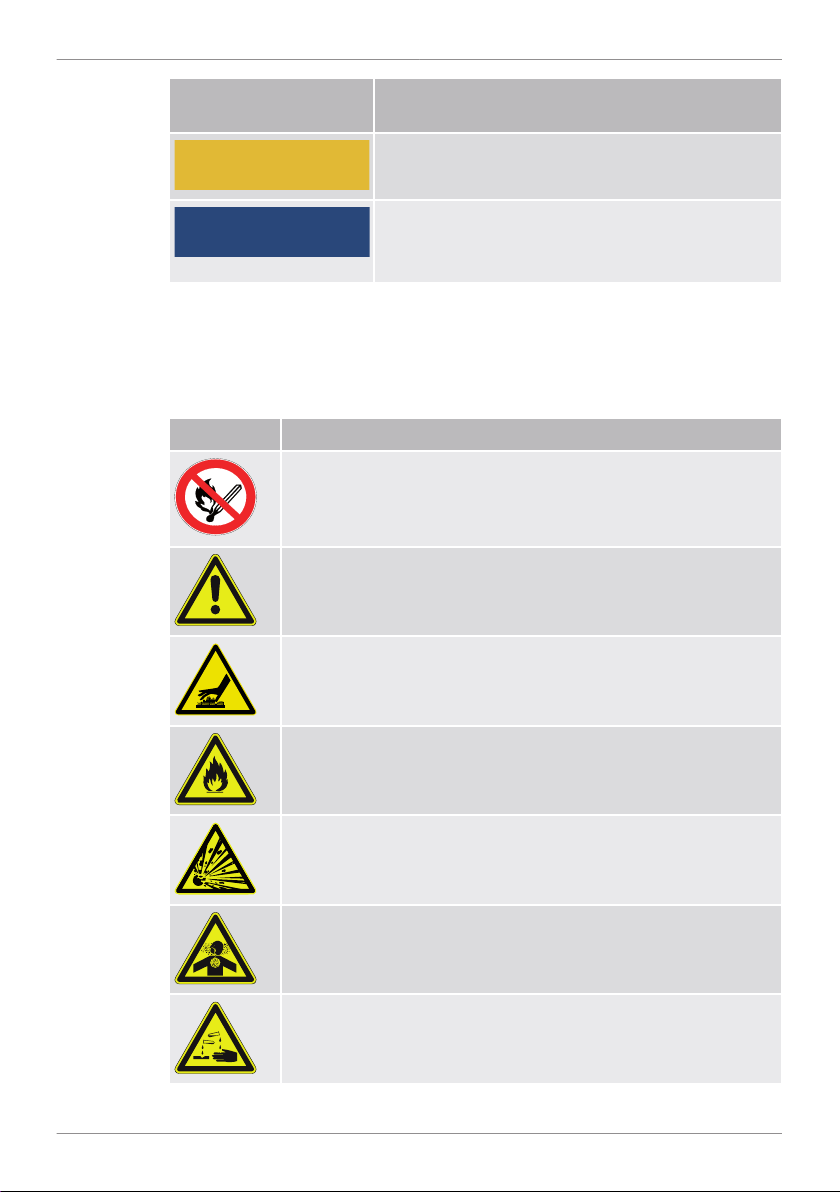

Signal words

The general danger symbol is used to identify the danger of personal injury.

Signal words identify the magnitude of the risk and the seriousness of the

possible injuries:

Danger symbol/

Meaning

signal word

This signal word is used to indicate imminently

dangerous situations which, if not avoided, will

lead to serious injury or death.

This signal word is used to indicate potentially

dangerous situations which, if not avoided, may

lead to serious injury or death.

This signal word is used to indicate potentially

dangerous situations which, if not avoided, may

lead to minor or moderate injury.

Operator's Manual 9

Page 9

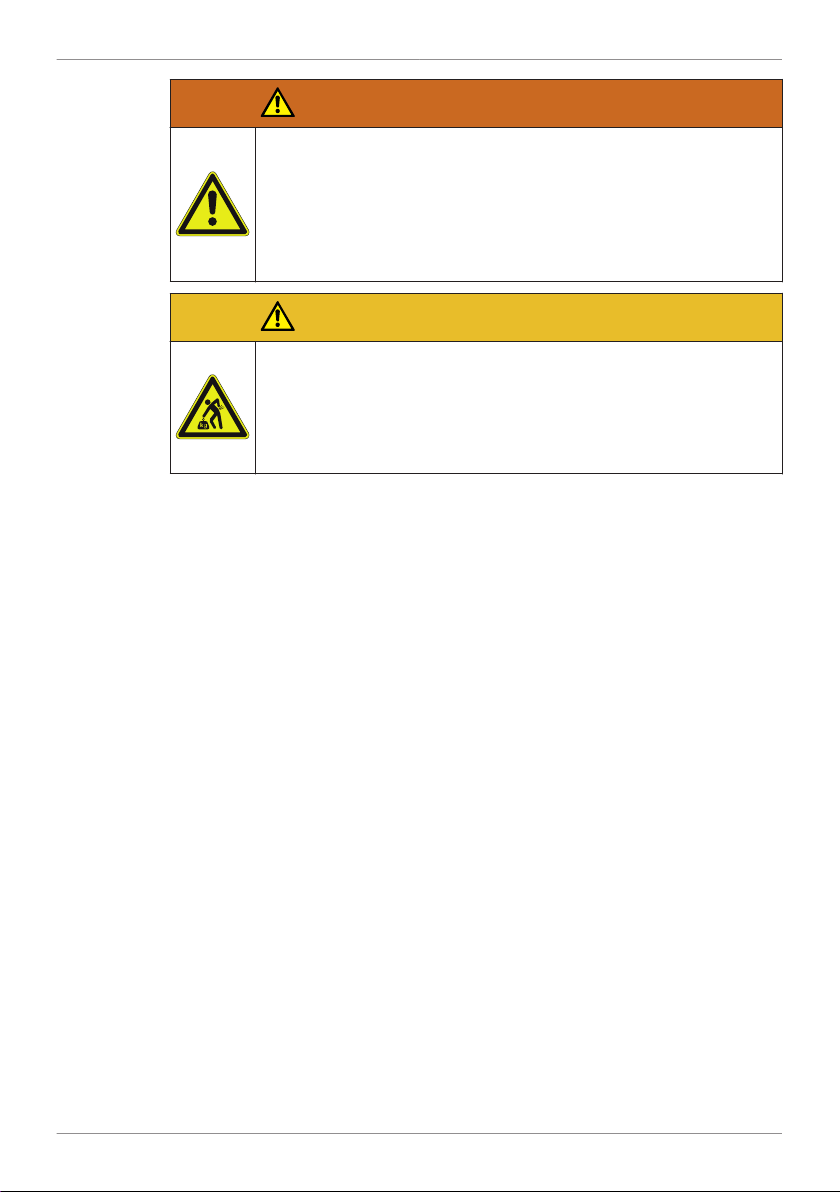

CAUTION

NOTICE

Safety 4H50TIC

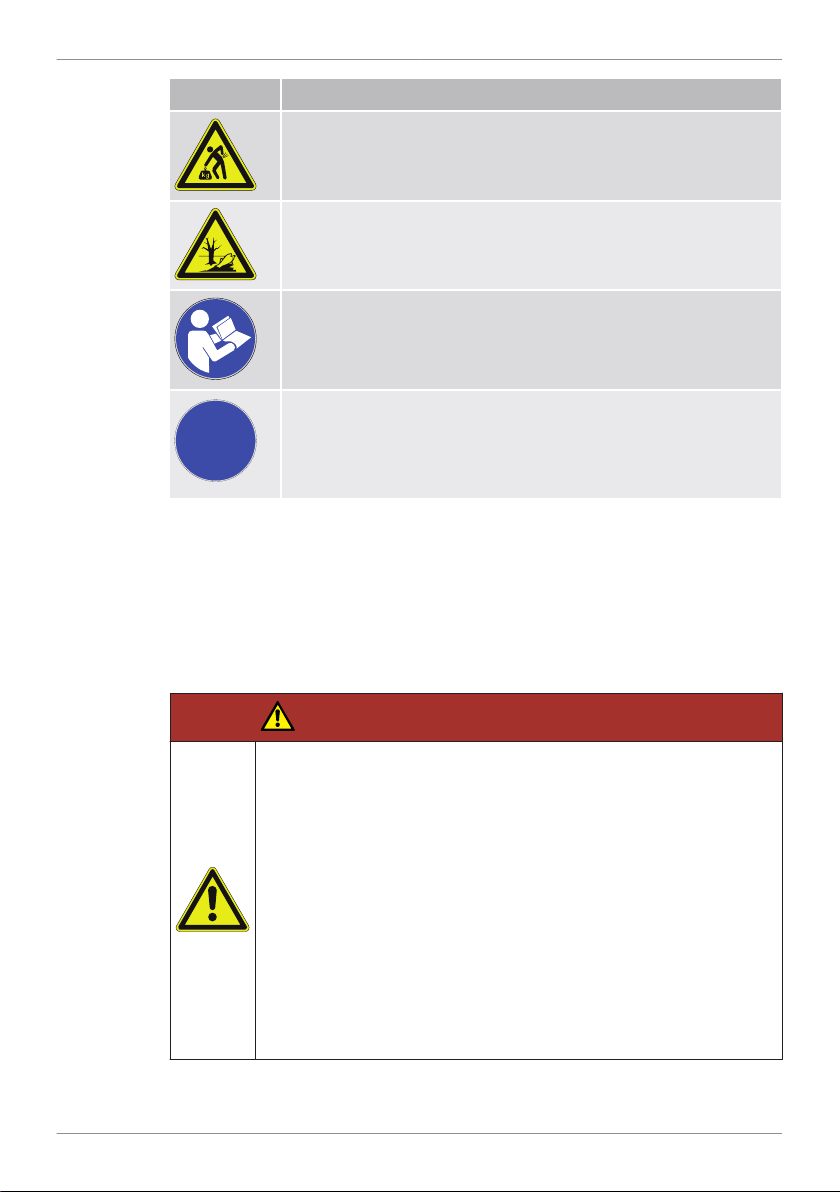

Danger symbol/

signal word

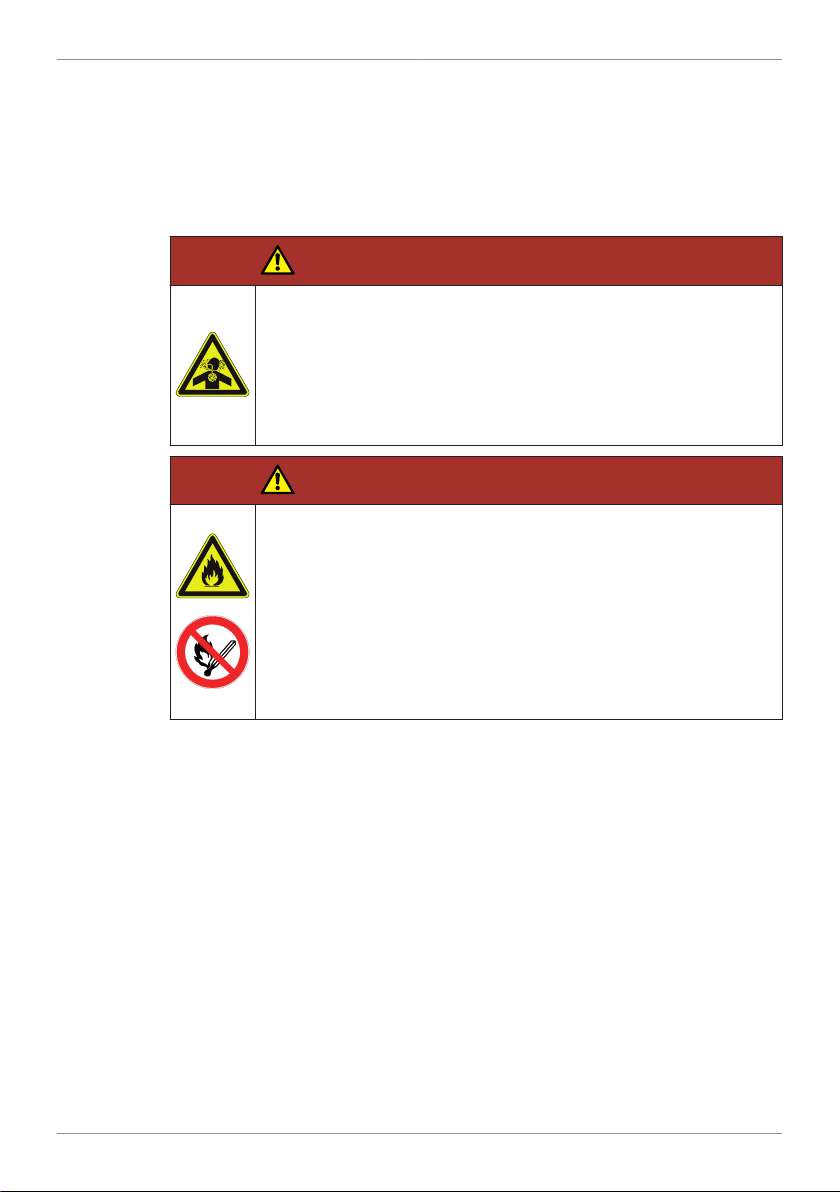

3.1.4 Meaning of safety symbols

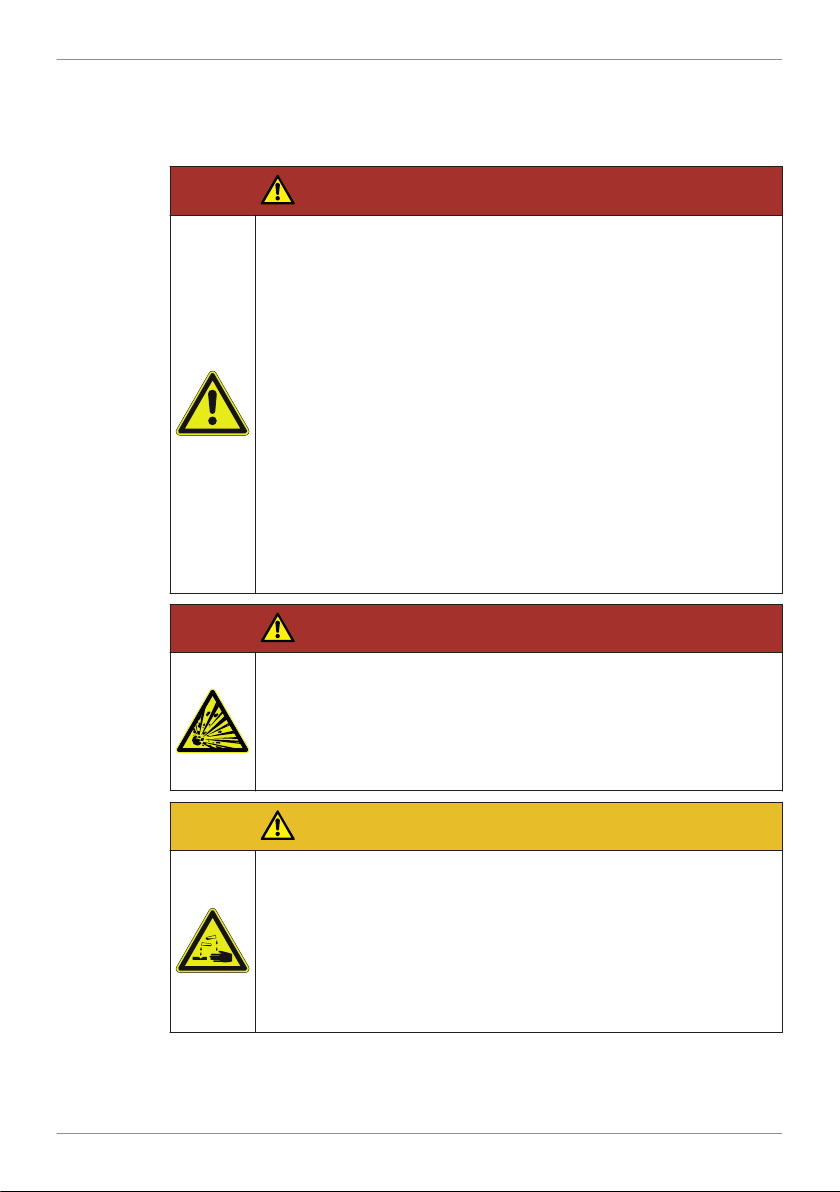

Explanation of symbols

The following table describes the meanings of the safety symbols used in

this Operator's Manual.

Symbol Meaning

Smoking, fire and open flames are prohibited.

Warning of personal injury!

Warning of hot surfaces!

Meaning

This signal word, without a danger symbol, is

used to indicate the risk of property damage.

This signal word indicates additional useful information, such as operating tips and cross references.

Warning of flammable substances!

Warning of explosive substances!

Warning of toxic engine exhaust!

Warning of corrosive substances!

10 Operator's Manual

HATZ

Page 10

i

4H50TIC Safety

Symbol Meaning

Warning of heavy loads!

Warning of environmental damage!

Comply with the Operator's Manual or additional documentation from other manufacturers or the user.

Additional information that is useful to the reader.

3.2 Safety notes

3.2.1 Operational safety

HATZ

Introduction

This chapter contains all of the important safety instructions for personal protection and for safe and reliable operation. Additional, task-related safety instructions can be found at the beginning of each chapter.

DANGER

Danger to life, danger of injury, or danger of property damage due to failure to comply with the Operator's Manual and

the safety instructions contained therein.

▪ As the user of the machine, you must ensure that all people

working on the machine are familiar with the contents of this

Operator's Manual.

▪ Before working on the machine, read this Operator's Manual

carefully, paying special attention to the safety notes.

▪ Fulfill all required safety conditions before working on the

machine.

▪ Follow all general safety instructions as well as the specific

task-related safety instructions contained in the individual

chapters.

Operator's Manual 11

Page 11

Safety 4H50TIC

Using the machine

▪ Only operate the machine for the purposes described in the chapter 3.1.1

Intended use and foreseeable misuse, page 7.

Compliance with other regulations

▪ Adhere to the applicable accident prevention regulations of the trade asso-

ciations.

▪ Comply with the regulations concerning the minimum safety and health re-

quirements for the use of work equipment by workers at work.

▪ In addition, local safety, accident prevention and environmental regula-

tions also apply when operating the machine.

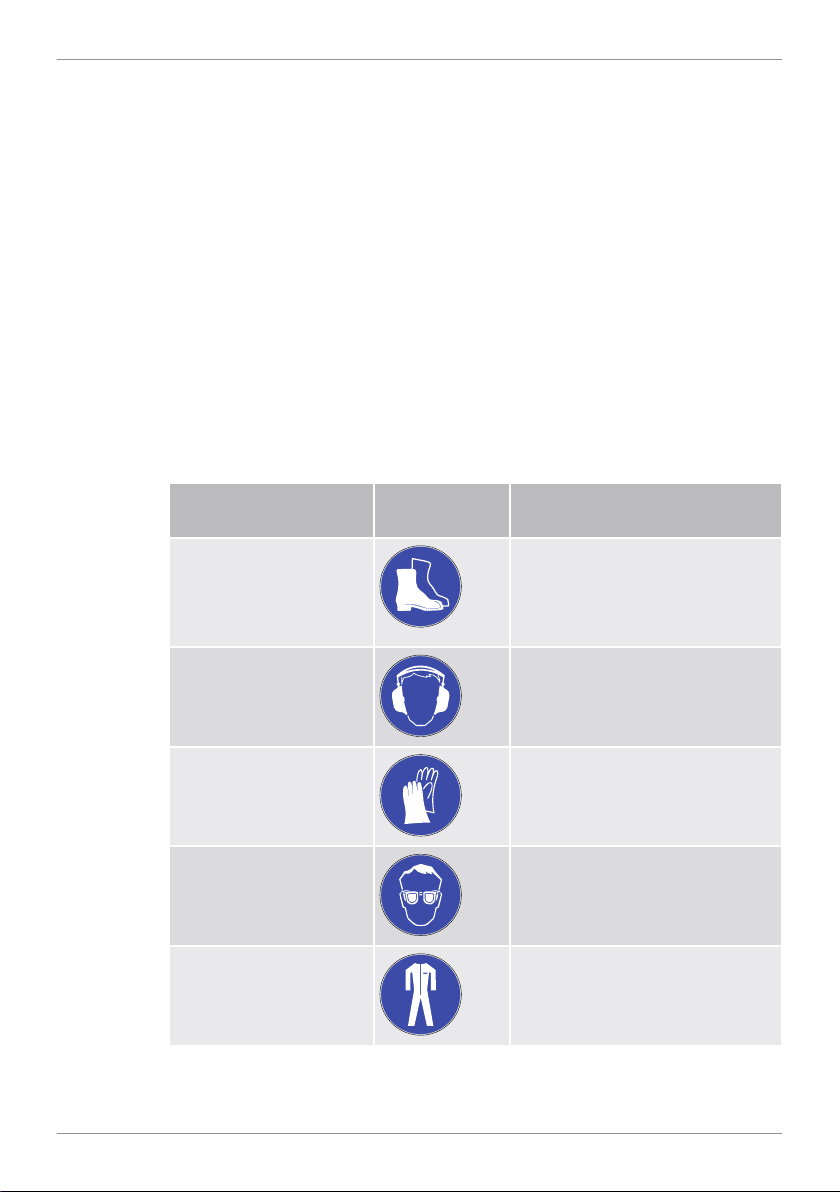

Personal protective equipment

During operation and maintenance of the machine, personal protective

equipment must be available and must be used if necessary. The required

personal protective equipment is specified in the description of the operating

steps.

Personal protective

Pictogram Function

equipment

Safety shoes Safety shoes offer protection

against:

▪ Slipping

▪ Falling objects

Hearing protection Hearing protection offers protec-

tion against ear injuries due to

excessive and constant noise.

Safety gloves Safety gloves protect the hands

Safety goggles

(with side protection)

Working clothes Wear close-fitting clothing. How-

12 Operator's Manual

against injury, e.g. from battery

acid.

Safety goggles protect the eyes

from flying objects (e.g. dust

particles, spraying liquids,

spraying acid).

ever, it must not restrict the

wearer's freedom of movement.

HATZ

Page 12

4H50TIC Safety

Warning labels and information signs on the machine

The warning labels and information signs on the machine must be followed

(see the chapter "Labels" 3.3 Labels, page 19).

The warning labels and information signs must be kept legible and must be

replaced if necessary. For this purpose, contact your nearest HATZ service

station.

Maintenance work

Maintenance work that goes beyond the scope described in this manual

must only be performed by qualified technicians (see the chapter 2 General

information, page 6).

Independent maintenance work and constructional changes to the machine,

especially to the safety equipment, are not permitted.

Safety equipment

Safety equipment must not be modified and must not be rendered ineffective

during normal operation.

General safety instructions

DANGER

Danger to life and danger of injury due to failure to follow

the warnings on the machine and in the Operator's Manual.

▪ Heed the warnings on the machine and in the Operator's

Manual.

HATZ

WARNING

Danger of injury and danger of incorrect operation due to

inadequate personnel qualifications.

▪ The personnel must have read and understood this Opera-

tor's Manual or must possess the qualifications necessary

for working with this equipment, acquired in training/instructional courses.

▪ Only qualified personnel are permitted to operate and main-

tain this machine.

▪ Failure to comply will cause the warranty to become void.

Operator's Manual 13

Page 13

Safety 4H50TIC

WARNING

Danger of injury from the failure to follow the operating instructions and from performing unauthorized tasks on the

machine.

▪ Follow all instructions.

▪ Do not perform activities for which no qualification is availa-

ble. Contact properly trained personnel if necessary.

CAUTION

Danger of injury from overloading the body.

Lifting the machine to transport it or to move it to another location can lead to injuries (of the back, for example).

▪ Only lift the machine with a hoist (see the chapter 6.1 Trans-

port - Engine with 2 lifting eyes, page 31).

3.2.2 Machine-specific safety instructions for operation

Introduction

The machine can pose residual risks during operation. To eliminate these

risks, all persons working on the machine must follow the general and machine-specific safety instructions.

If you have an engine that is not yet installed in a machine, it is imperative

that you follow the Assembly Instructions for HATZ Diesel Engines before installing the engine.

These assembly instructions contain important information on safe installation.

If the engine is installed in a machine or assembled with other machines to

form a machine, it is prohibited to start the engine before it has been determined that the newly created machine fulfills all safety-related requirements

and applicable legal regulations.

Safe operation

▪ Before switching on the machine, ensure that no one can be injured when

the machine is started up.

▪ During machine operation, ensure that unauthorized persons do not have

access to the area in which the machine has an impact.

▪ Parts of the exhaust gas system and the surface of the engine become hot

during operation. Risk of injury from touching hot parts! Let the engine cool

before maintenance.

▪ Do not refuel during operation.

14 Operator's Manual

HATZ

Page 14

4H50TIC Safety

Faults

▪ Immediately eliminate faults that compromise safety.

▪ Switch off the machine and do not take into service again until all faults

have been eliminated.

Safety instructions for operation

DANGER

Danger to life from inhaling exhaust gases.

Toxic engine exhaust gases can lead to loss of consciousness

and even death in closed-off and poorly ventilated rooms.

▪ Never operate the machine in closed-off or poorly ventilated

rooms.

▪ Do not breathe in the exhaust gases.

DANGER

Fire hazard from fuel.

Leaked or spilled fuel can ignite on hot engine parts and cause

serious burn injuries.

▪ Only refuel when the engine is switched off.

▪ Never refuel in the vicinity of open flames or sparks that can

cause ignition.

▪ Do not smoke.

▪ Do not spill fuel.

3.2.3 Machine-specific safety instructions for maintenance work

HATZ

Introduction

The machine can pose residual risks during maintenance. To eliminate

these risks, all persons working on the machine must follow the general and

machine-specific safety instructions.

Maintenance intervals

▪ Strictly adhere to the maintenance intervals.

▪ Check the safety equipment regularly to ensure it is in good condition and

functioning properly.

▪ Check connections, cables and fasteners regularly to ensure they are in

good condition.

Operator's Manual 15

Page 15

Safety 4H50TIC

Maintenance work

Maintenance work that goes beyond the scope described in this manual

must only be performed by qualified technicians. We recommend that you

work with one of the more than 500 HATZ service stations.

Replacing parts

▪ When replacing defective components, we recommend that you use gen-

uine HATZ original spare parts (see the chapter 2 General information,

page 6).

▪ When disposing of parts that can no longer be used, do so in accordance

with local environmental regulations or send them to a recycling center.

Measures following maintenance and troubleshooting

▪ Securely reconnect loose electrical connections; check that the electrical

components and equipment are functioning properly.

▪ Check the entire machine for foreign bodies; remove any foreign bodies.

Safety instructions for maintenance work

DANGER

Danger of explosion from flammable cleaning agents.

Cleaning with benzene is an explosion hazard. It is highly flammable, can become electrostatically charged and can generate

an explosive gas-air mixture.

▪ Use halogen-free, cold cleaners with a high flashpoint for

cleaning.

DANGER

Fire hazard from spontaneous combustion.

Cleaning materials soaked with cold cleaner may produce heat

together with atmospheric oxygen and combust spontaneously.

▪ Collect cleaning materials soaked with cold cleaner only in

fire-proof, tightly sealed containers.

▪ Do not dispose of cold cleaner residues and used cleaning

materials with domestic waste, rather only in accordance

with manufacturer instructions.

▪ Comply with the instructions for preventing fire on the safety

data sheet for the cold cleaner.

16 Operator's Manual

HATZ

Page 16

4H50TIC Safety

WARNING

Danger of injury from compressed air and dust particles.

Eye injuries may occur when cleaning with compressed air.

▪ Wear safety goggles.

CAUTION

Danger of injury if maintenance instructions are not followed.

▪ Only perform maintenance when the engine is switched off.

▪ For engines with an electric starter:

Disconnect the negative battery terminal.

Protect the starting key against unauthorized access.

CAUTION

Danger of burns.

There is a danger of burns when working on a hot engine.

▪ Let the engine cool before maintenance.

HATZ

Operator's Manual 17

Page 17

Safety 4H50TIC

3.2.4 Electrical equipment

DANGER

Danger to life, danger of injury or danger of property damage due to incorrect use of batteries.

▪ Do not place tools on the battery.

▪ Before performing work on the electrical equipment, always

disconnect the negative terminal of the battery.

▪ Never swap the positive (+) and negative (–) battery termi-

nals.

▪ When installing the battery, first connect the positive cable

and then the negative cable.

▪ When removing the battery, first disconnect the negative

cable and then the positive cable.

▪ It is imperative that you prevent short circuits and mass con-

tact of current-carrying cables.

▪ If faults occur, check the cable connections for good con-

tact.

Safety notes

DANGER

Danger of explosion from flammable substances.

There is a danger of explosion from flammable gases.

▪ Keep batteries away from open flames and incendiary

sparks.

▪ Do not smoke when working with batteries.

CAUTION

Danger of chemical burns

Chemical burns can occur when using batteries for the electrical

operation.

▪ Protect your eyes, skin, and clothing from corrosive battery

acid.

▪ Immediately rinse areas affected by splashed acid with clear

water and consult a physician if necessary.

18 Operator's Manual

HATZ

Page 18

BIO

DIESEL

052 356 02

0000 053 657 02

4H50TIC Safety

3.3 Labels

Warning labels and information signs on the engine

NOTICE

▪ The necessary wiring diagrams are included with the ma-

chine if it is equipped with electrical equipment. Additional

wiring diagrams can be requested when needed.

▪ We cannot be held liable for electrical equipment that is not

designed according to HATZ wiring diagrams.

▪ Promptly replace faulty indicator lamps.

▪ Do not pull out the starting key during operation.

▪ Do not disconnect the battery while the machine is running. Resulting volt-

age peaks could destroy the electronic components.

▪ When cleaning, do no spray the electrical equipment components with a

water jet or high pressure cleaner.

▪ When performing welding work on the machine, disconnect the battery

and place the ground clamp of the welding equipment as close as possible

to the welding area. Disconnect the plug-in connection to the voltage regulator.

Label Meaning

Refuel with diesel fuel only. For the

specification, see the chapter 4.5

Fuel, page 26

Do not use bio diesel.

The engine may only be operated

with fuel that is "EXTREMELY LOW

IN SULFUR OR SULFUR-FREE".

The fuel label is located close to the

fuel cap. If there is no fuel tank installed on the engine, the label must

be applied permanently close to the

fuel filler opening.

HATZ

Operator's Manual 19

Page 19

Technical data 4H50TIC

4 Technical data

4.1 Engine information and filling quantities

Type 4H50TIC

Type

Combustion system

Injection system Bosch common rail

Number of cylinders

Bore/stroke mm 84 / 88

Displacement cm

3

Engine oil capacity Approx.

ltr.

Difference between the

"max." and "min."

marks

Approx.

ltr.

Engine oil consumption

(after running-in period)

Max. 0.5 % of fuel consumption, pertaining to full load

Engine oil pressure 2.5 bar to 4.5 bar

Coolant quantity Approx.

ltr.

Sense of rotation

Tappet clearance Automatic valve lash adjustment with hydraulic

Max. perm. inclination

30° 2) (with HATZ standard radiator)

during continuous operation in every direction

Weight (without operating

Approx.kg226 (with HATZ standard radiator and catalytic

fluids)

Battery capacity Max. 12 V – 110 Ah / 450 A according to DIN

Liquid-cooled four stroke diesel engine

Direct injection, turbocharger with charge air cool-

ing, cooled exhaust-gas recirculation

4

1,952

1)

7.0

1)

1.0

12.5 (HATZ standard radiator with external expansion tank)

13.2 (HATZ OpenPowerUnit radiator with integrat-

ed expansion tank)

When viewing flywheel: left

valve tappets

20° 2) (with HATZ OpenPowerUnit radiator)

converter)

260 (with HATZ OpenPowerUnit radiator and cata-

lytic converter)

24 V – 66 Ah / 300 A according to DIN

20 Operator's Manual

HATZ

Page 20

120R-xxxxxx*xx

24R-xxxxxx

EMISSION CONTROL INFORMATION

MOTORENFABRIK HATZ KG ¬ D-94099 RUHSTORF

GMBH

+CO

Model: 4H50TIC – 162J

S/N: 1361014000001 Build: 03/2014

Power: 36.4kW @ 1800 RPM Constant

Displ: 1.95L

Eng.Fam: FHZXL1.95C50

Emission Control System: DDI, DOC, EGR, ECM, TC, CAC

Power Category: 19≤kW<37

ULTRA LOW SULFUR DIESEL FUEL ONLY.

THIS ENGINE COMPLIES WITH U.S. EPA AND CALIFORNIA REGULATIONS

FOR THE MY2015 YEAR NONROAD DIESEL ENGINES.

Use in Constant-Speed Applications only.

EU-Type: e1*97/68KA*2012/46*0801*00 (IIIA)

www.hatz-diesel.com

187_44_C_3B

120R xxxxxx*xx

24R xxxxxx

E

1

8

9

4H50TIC Technical data

1)

These values are approximations only. The max. mark on the dipstick is

decisive in any case (see the chapter 7.6 Checking the oil level and adding

oil if necessary, page 47).

2)

Exceeding these limit values can cause engine damage.

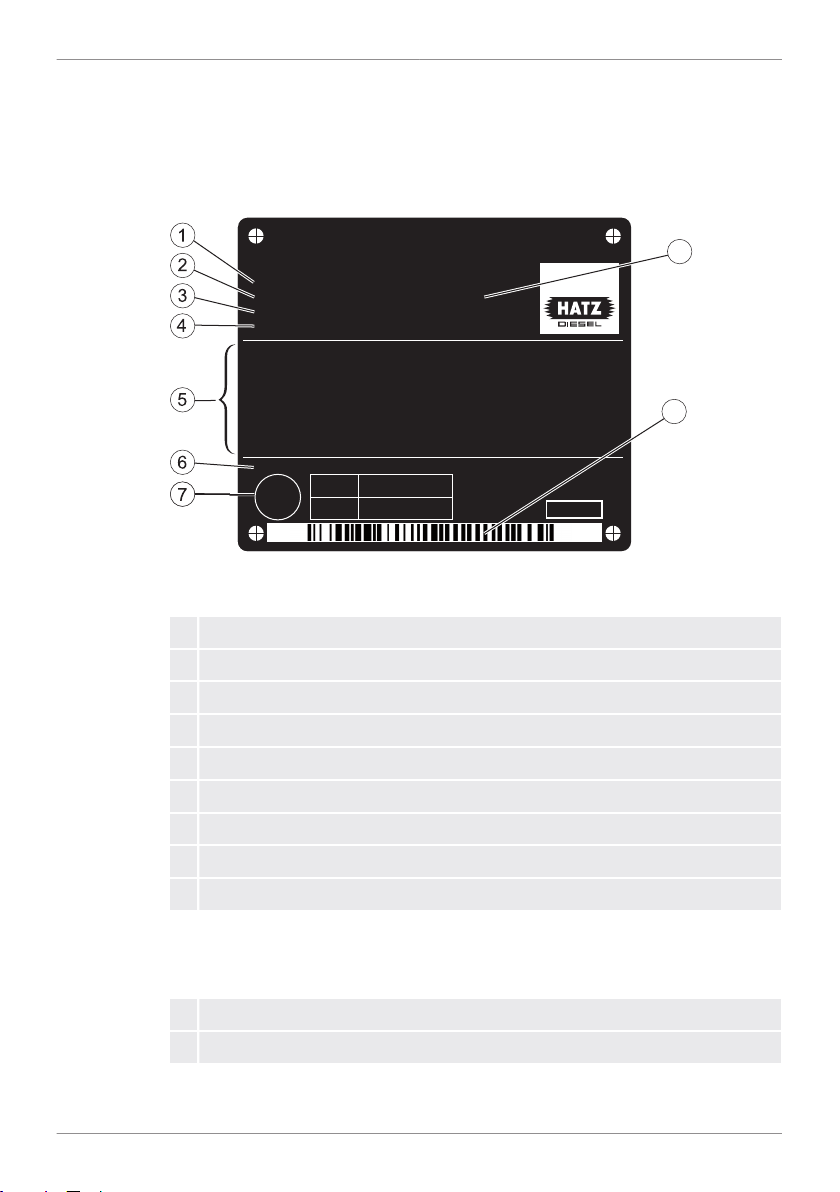

4.2 Engine type plate

The engine type plate is located on the crankcase and contains the following

engine information:

1 Model designation of the engine

2 Engine serial number

3 Serial rating (kW) at nominal speed (rpm)

4 Displacement (liters)

5 Information for US emission certification (EPA/CARB)

6 EU type approval

7 EU country of origin (Germany)

HATZ

8 Model year (month/year)

9 Bar code (engine serial number)

The following data must always be specified for requests and spare part orders

1 Model designation

2 Engine serial number

Operator's Manual 21

Page 21

Technical data 4H50TIC

4.3 Engine oil

Oil quality

All brand name oils that satisfy at least the following specification are suitable:

Engines with catalytic converter or with catalytic converter and particulate filter

▪ ACEA E6 "Low SAPS" (preferred)

▪ ACEA E9

▪ ACEA C3 / C4 (HTHS ≥ 3.5 mPas)

▪ API CJ-4

CAUTION

Damage to the catalytic converter and/or particulate filter

from using unsuitable engine oil.

Unsuitable engine oil diminishes the functionality and service life

of the catalytic converter and/or particulate filter.

Only use engine oil that fulfills the specifications stipulated

above. In principle, engine oils with low ash (low SAPS) are recommended.

Engines without catalytic converter and without particulate filter

▪ ACEA E6, E7 or E9

▪ ACEA C1, C2, C3 or C4

▪ API CJ-4 or CI-4

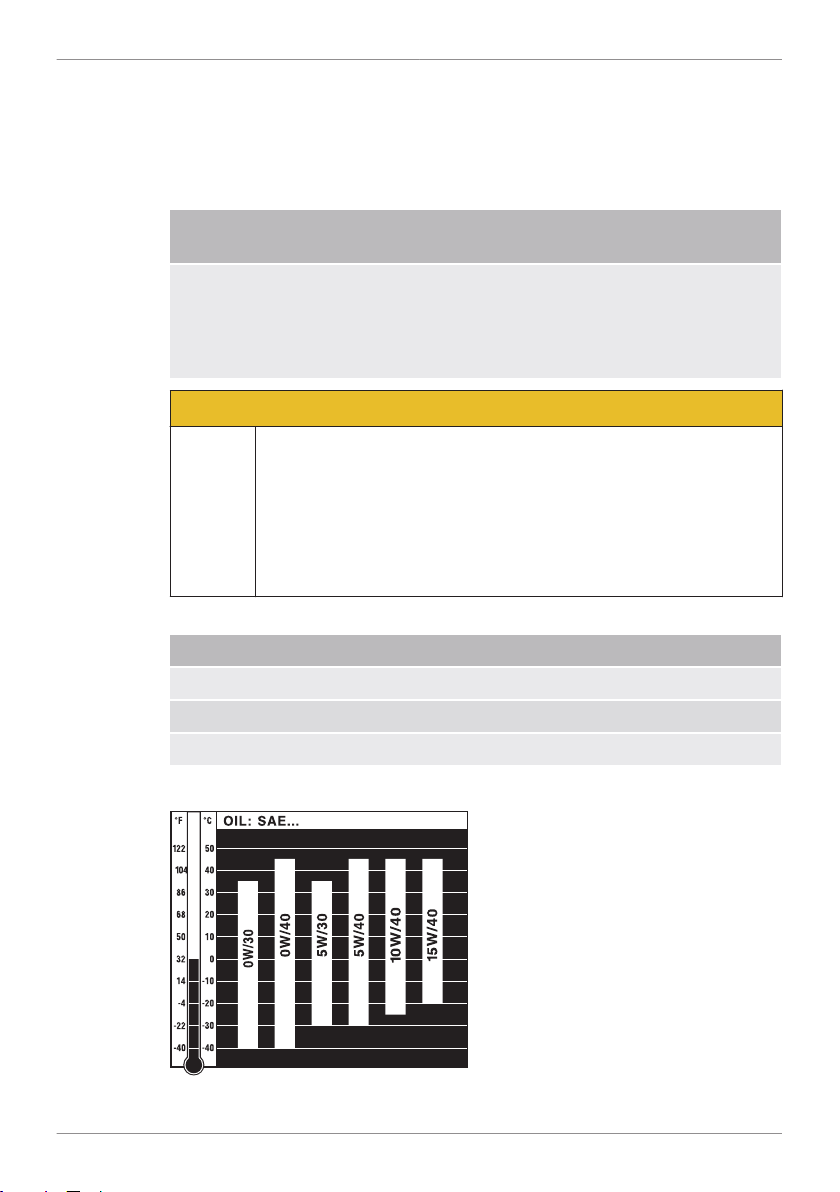

Oil viscosity

22 Operator's Manual

HATZ

Page 22

4H50TIC Technical data

Select the recommended viscosity depending on the ambient temperature in

which the engine will be operated.

4.4 Coolant

Introduction

Liquid-cooled engines require a coolant specified by HATZ for engine cooling.

Coolant is prepared in accordance with manufacturer's instructions, please

comply with the information on the packaging label.

Radiator protection fluids give effective protection against corrosion and

freezing. Additionally, the coolant boiling point is significantly raised and deposits of lime in the cooling system are reduced.

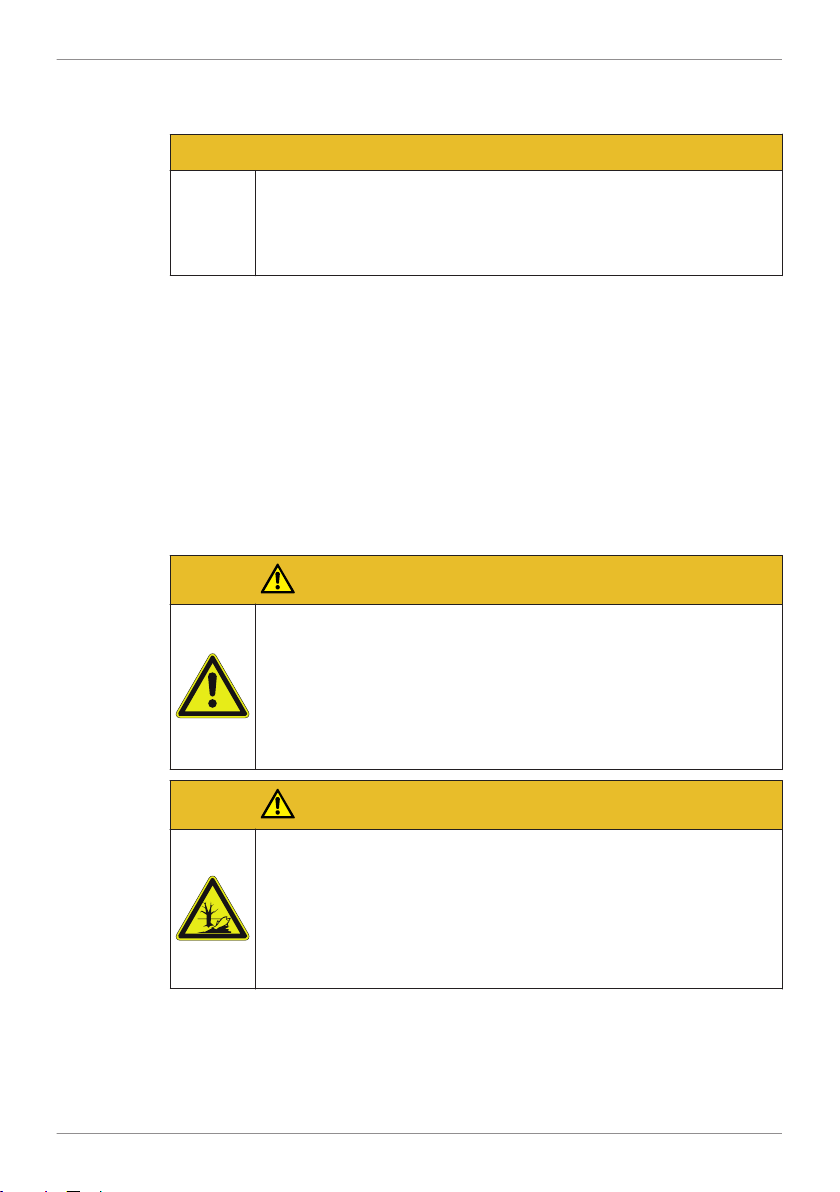

Safety notes

CAUTION

Engine damage from unsuitable engine oil.

Unsuitable engine oil considerably reduces engine service life.

Only use engine oil that fulfills the specifications stipulated

above.

CAUTION

Danger of damage to health

Radiator protection fluids are harmful to health.

▪ Avoid contact to eyes and skin.

▪ Store only in the sealed original container and in a place in-

accessible for unauthorized persons.

▪ Comply with manufacturer's instructions.

HATZ

CAUTION

Danger of environmental damage from spilled coolant.

Coolant is water-polluting.

▪ Do no allow it to enter the ground water, water bodies, or

sewage system.

▪ Collect coolant and dispose of it in an environmentally com-

patible manner.

Operator's Manual 23

Page 23

Technical data 4H50TIC

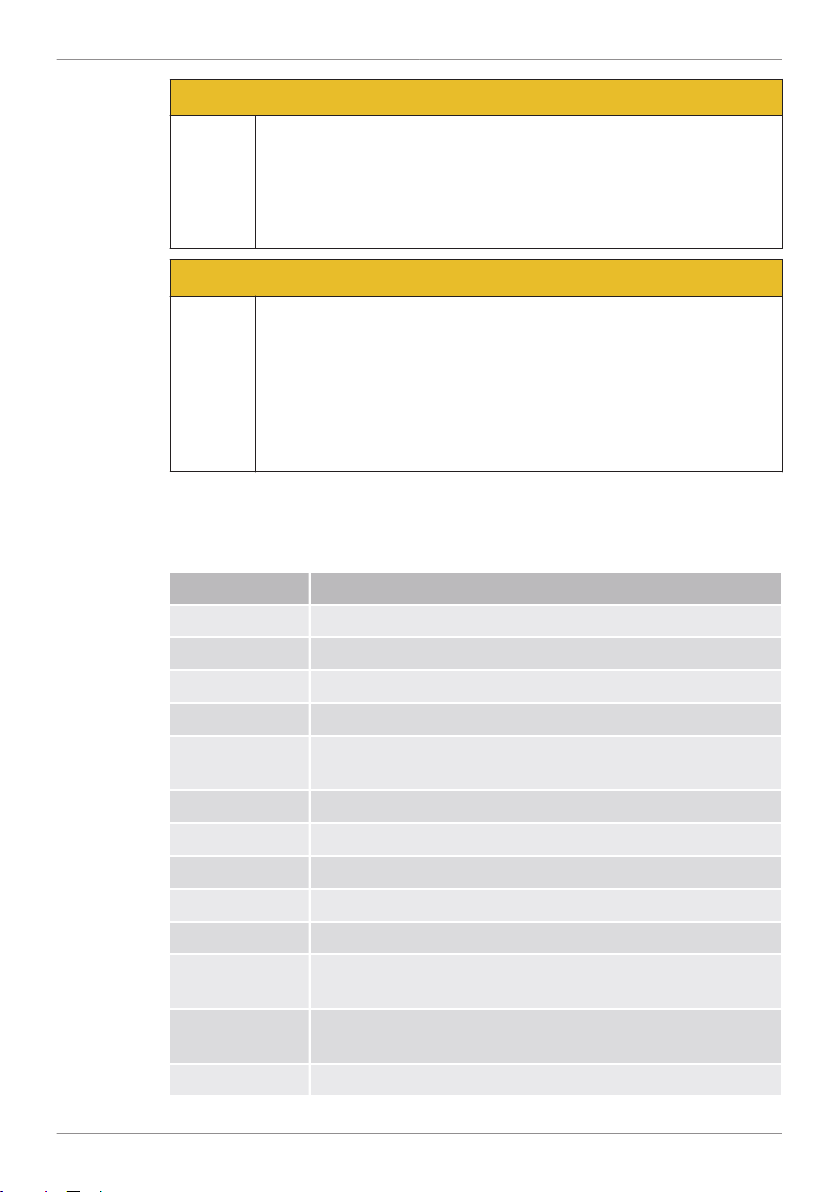

CAUTION

Danger of engine damage from radiator protection fluid.

Use of a radiator protection fluid not approved by HATZ may

cause engine damage.

▪ If you have any questions, please contact your nearest

HATZ service station before commissioning the engine.

CAUTION

Danger of engine damage by mixing radiator protection fluids from different manufacturers.

The effectiveness may be degraded when different radiator protection fluids are mixed. The consequence may be damage to

the water pump, radiator, hoses, and gaskets.

▪ Before changing the product, flush the entire cooling system

(see the chapter 8.2.15 Changing coolant, page 82).

Approved radiator protection fluids

The following radiator protection fluids are approved by HATZ:

Manufacturer Product name

ARAL Aral Antifreeze Silikatfrei (silicate-free)

Arteco Havoline XLC (OF02), Havoline XLC+B

Auto-Teile-Ring Cartechnic Antifreeze CT 12 plus

BASF Glysantin® G30®, Glysantin® G40®

Belgin Madeni

LUBEX ANTIFREEZE G-12 PLUS

Yaglar Tic

BP BP Procool

Bucher MOTOREX COOLANT M4.0

BVG Blume Mofin Antifreeze M40 Extra

Castrol Radicool SF, Radicool Si OAT

CCI LLC C521, LLC L415

CHEMIA-

Glidex Extra Premium

BOMAR

Chevron Caltex Extended Life Coolant, Havoline XLC Concentrate,

Ursa ELC NF Concentrate

CLASSIC CLASSIC KOLDA UE G30, CLASSIC KOLDA UE G40

24 Operator's Manual

HATZ

Page 24

i

4H50TIC Technical data

Manufacturer Product name

Eurolub Radiator protection fluid D-30, PROCAR radiator protec-

tion fluid silicate-free, radiator protection fluid D-40 SUPER

Exxon Mobil Delvac ELC Coolant

Fuchs MAINTAIN FRICOFIN G 12 PLUS, MAINTAIN FRICOFIN

LL, MAINTAIN FRICOFIN DP

GazpromneftLubricants

Krafft K-140 Energy - Plus

Kuttenkeuler Kuttenkeuler Antifreeze K 12 Plus

LUKOIL OMV coolant SF, OMV coolant SOT

Mitan Alpine C40, Alpine C12+

MOL-LUB EVOX Premium Concentrate

Müller Mineralöle

Neste Markkinointi

OAO Technoform

Old World Industries

Petrol Ofisi

Anonim Sirketi

Tedex Tedex Antifreeze OT LL

Total Total Glacelf Auto Supra

Valvoline Zerex G 30, Zerex G 40-91

G-ENERGY ANTIFREEZE SNF

Startol Top G 12 Plus

Neste Superjäähdytinneste XLC

Cool Stream Premium

Final Charge Global Coolant

PO EXTENDED LIFE coolant

HATZ

NOTICE

Prior approval from HATZ is needed when none of these radiator protection fluids is available or an own-product radiator protection fluid is to be used.

Operator's Manual 25

Page 25

i

Technical data 4H50TIC

Preparation of the coolant

▪ The radiator protection fluid must be prepared according to manufacturer's

instructions before pouring it into the cooling circuit. Comply with the information on the packaging label.

▪ If the radiator protection fluid has to be mixed with water, use only clean

water that is not too hard. Tap water with as low as possible content of

salt, minerals, and suspended matter is ideal. Distilled water is equally ideal.

The coolant mixture ratio is not to be below or exceed the following concentration:

Radiator protection

CAUTION

Danger of engine damage from incorrect radiator protection

fluid concentration.

A too low radiator protection fluid concentration increases the

risk of corrosion and also the risk of the cooling system freezing.

A radiator protection fluid proportion of over 50 vol% degrades

the cooling action and also the protection against frost is reduced. Therefore, serious engine damage may result from exceeding or dropping below the radiator protection fluid concentration.

Water Frost-resistant to ap-

fluid

min. 40 vol% 60 vol% -27 °C

max. 50 vol% 50 vol% -38 °C

prox.

NOTICE

As the corrosion and antifreeze concentration reduces with time,

carry out an annual check with a commercially available antifreeze tester. If the concentration is too low, change the coolant

independent of the service interval (see the chapter 8.2.15

Changing coolant, page 82).

4.5 Fuel

26 Operator's Manual

Fuel type

All types of diesel fuel that meet the minimum requirements of the following

specifications are suitable:

▪ Europe: EN 590

▪ UK: BS2869 A1/A2

▪ USA: ASTM D 975-09a 1-D or 2-D (engines without catalytic converter

and without particulate filter)

ASTM D 975-09a 1-D S15 or 2-D S15

HATZ

Page 26

4H50TIC Technical data

▪ Japan: JIS K 2204 (with a maximum HFRR value of 520 µm)

CAUTION

Danger of engine damage from low quality fuel.

The use of fuel that does not meet the specifications can lead to

engine damage.

▪ Only use fuel that is very low in sulfur or that contains no

sulfur at all.

▪ The use of fuel that does not meet specifications requires

approval by Motorenfabrik HATZ (main plant).

HATZ

Operator's Manual 27

Page 27

4

32

5

5

6

7

8

9

10

11

12

13

14

15

16

17

1

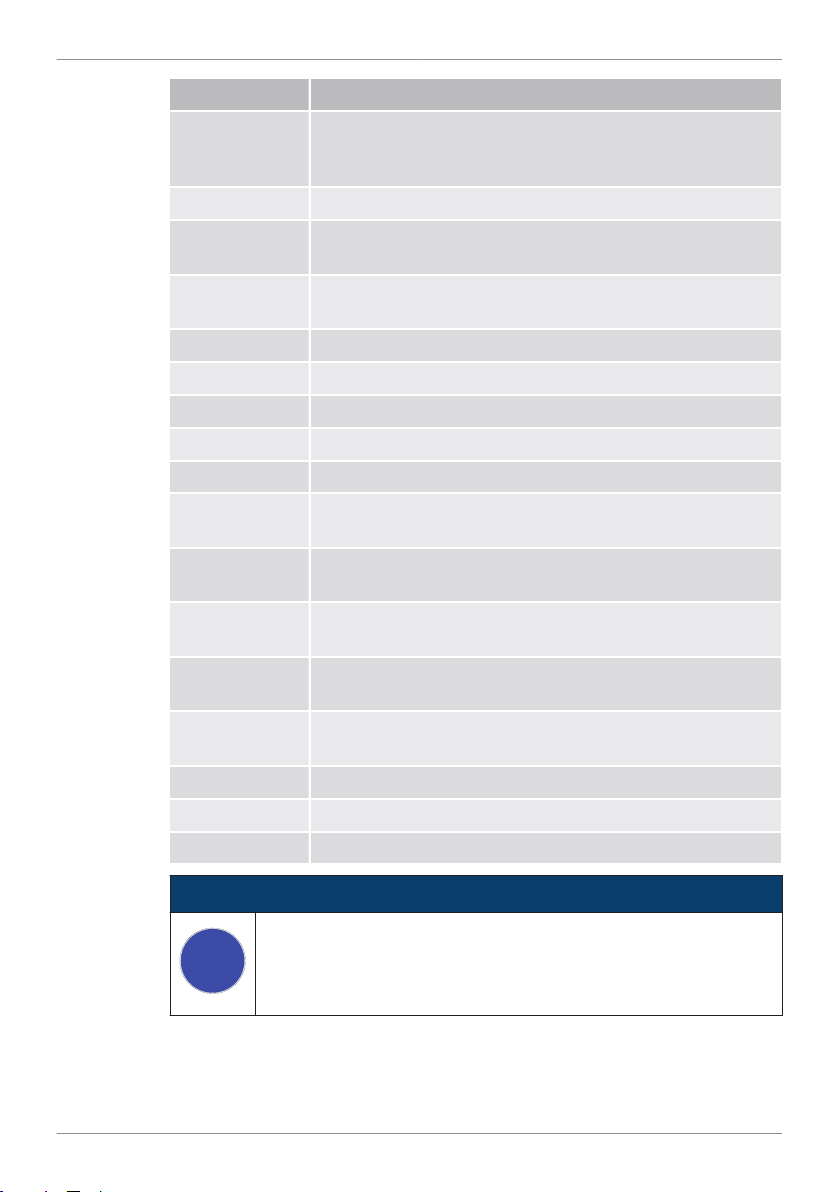

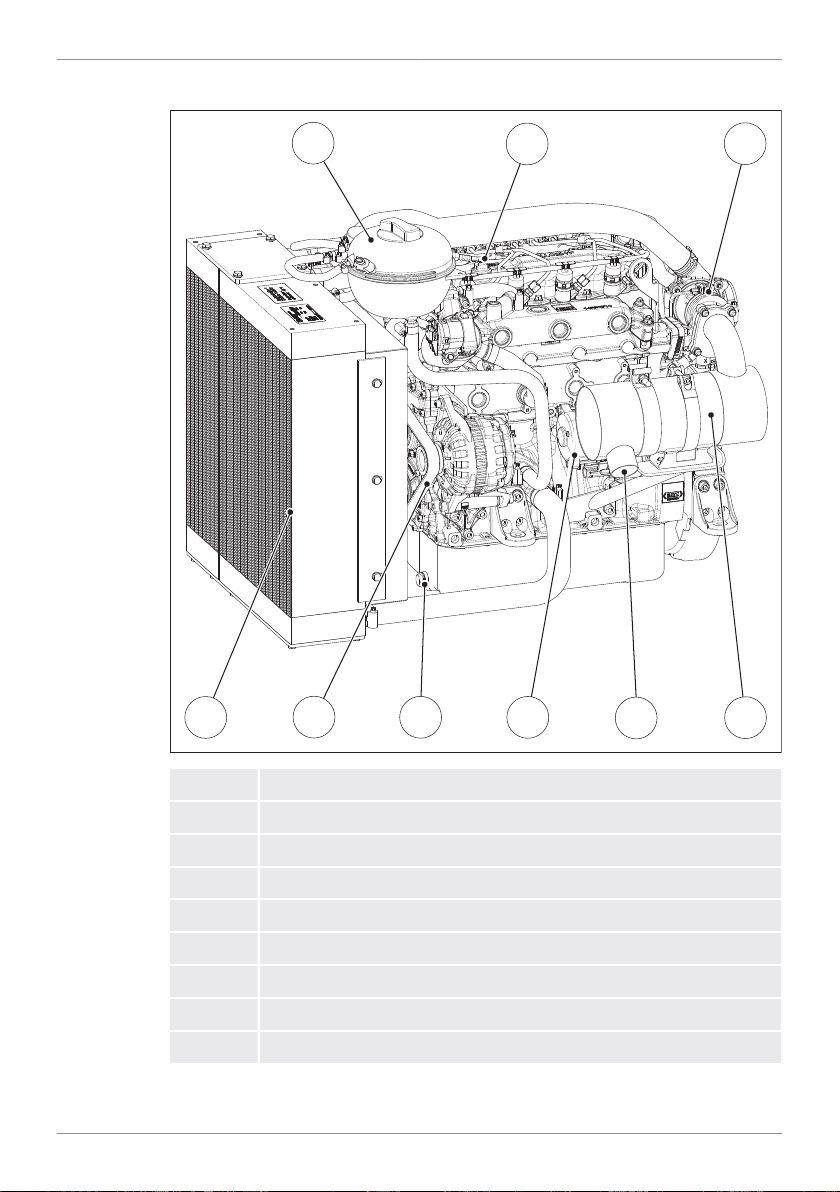

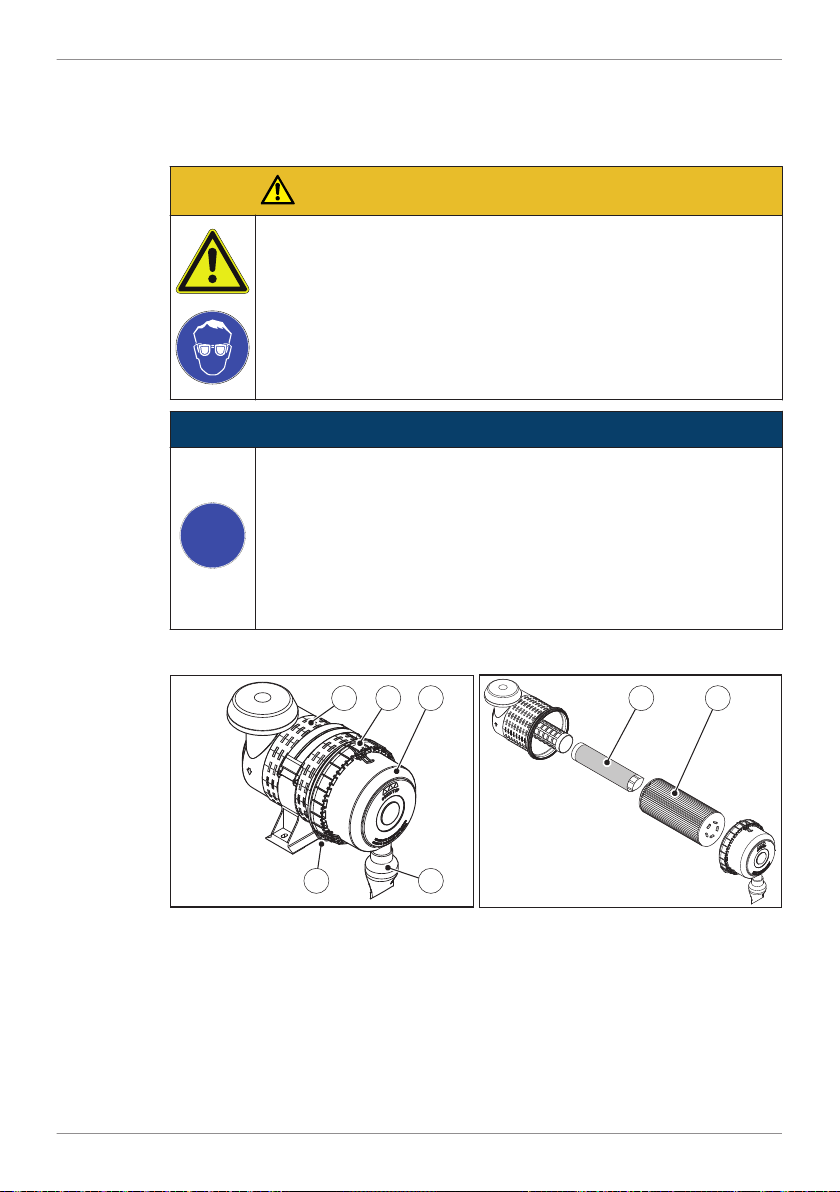

Engine design 4H50TIC

5 Engine design

5.1 Overview

Intake side

28 Operator's Manual

HATZ

Page 28

4H50TIC Engine design

1 Intake opening for combustion air

2 Rain cap

3 Air filter (optional)

4 Dust discharge valve

5 Lifting eyes

6 Fan

7 Oil filter

8 Fuel fine filter

9 Side oil drain screw

10 Starter (low mounting position)

11 Electric fuel pump

12 Drain plug on fuel prefilter

13 Fuel prefilter

14 Engine type plate

15 Dipstick

16 Oil filler plug, bottom

17 Crankcase ventilation

HATZ

Operator's Manual 29

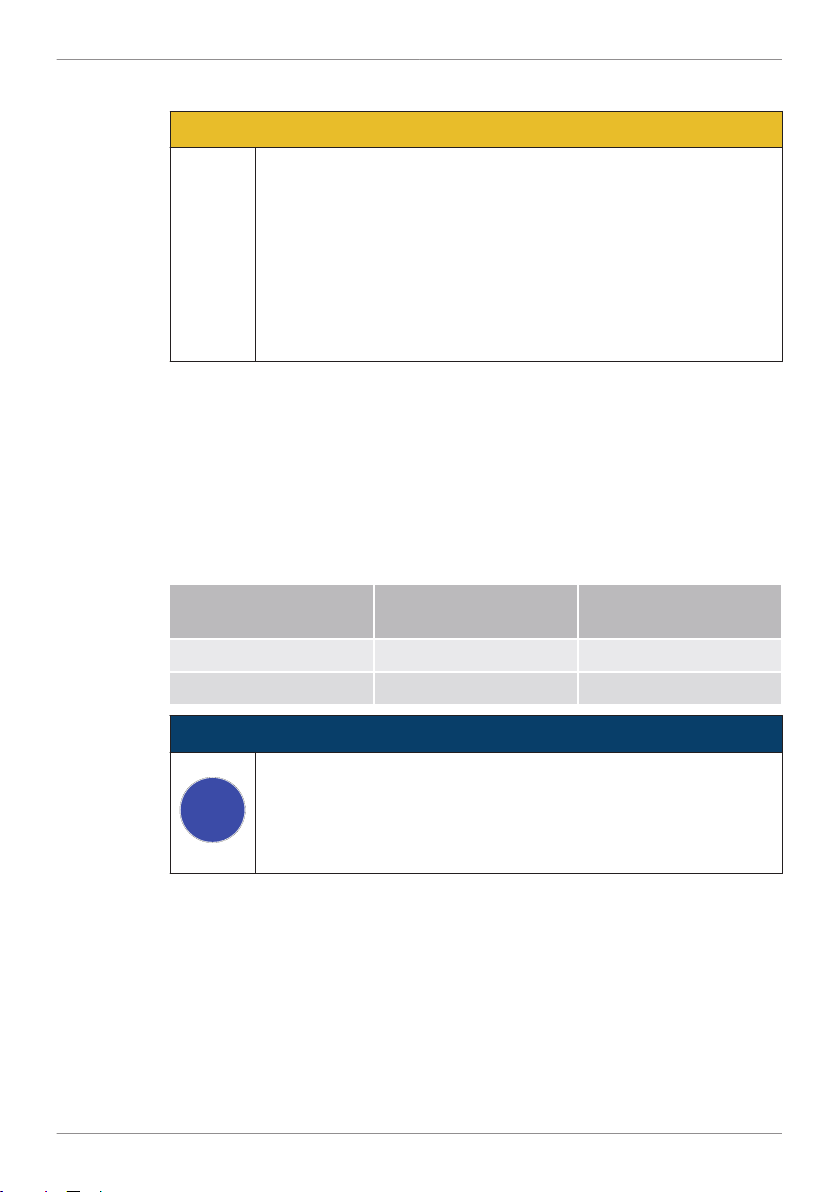

Page 29

1

2

3

4

5

6

7

8

9

Engine design 4H50TIC

Exhaust side

1 Expansion tank for coolant

2 Oil filler plug, top

3 Turbocharger

4 Oxidation catalytic converter

5 Exhaust outlet

6 Starter (high mounting position)

7 Oil drain screw, front

8 Poly v belt

9 Cooler

30 Operator's Manual

HATZ

Page 30

4H50TIC Transport, assembly and commissioning

6 Transport, assembly and commissioning

6.1 Transport - Engine with 2 lifting eyes

WARNING

Danger of injury from improper lifting and transport.

Danger of crushing from falling or tipping of the engine.

▪ Only use the lifting eye already mounted on the machine for

lifting.

▪ Only use a suitable hoist with a sufficient carrying capacity.

▪ Do not remain under suspended loads.

Safety notes

CAUTION

Only use lifting lugs for transporting the engine.

Do not use for lifting the entire machine.

CAUTION

Danger of injury from overloading the body.

Lifting the machine to transport it or to move it to another location can lead to injuries (of the back, for example).

▪ Only lift the machine with a hoist.

HATZ

NOTICE

Danger of environmental damage from leaking fluid.

If the machine is tilted, engine oil and fuel can run out.

▪ Only transport the machine in an upright position.

Operator's Manual 31

Page 31

Transport, assembly and commissioning 4H50TIC

Lifting points

1 Lifting point

Transport conditions

▪ Two lifting eyes (1) are used on engines with a HATZ standard radiator.

Ensure that the load on the lifting eyes is always vertical.

▪ The lifting eyes deform when they are overloaded. If this happens, the lift-

ing eyes must be replaced and if necessary additional lifting points must

be used.

▪ When transporting the machine, follow the safety instructions.

▪ When transporting, follow the applicable safety and accident prevention

regulations of the trade associations.

▪ After delivery, check the machine for completeness and transport damage.

▪ Only transport the machine when it is switched off and has cooled down.

▪ If you have questions on transporting the machine, please contact your

nearest HATZ service station. For contact data, see the chapter 1 Im-

pressum, page 5 or www.hatz-diesel.com.

6.2 Assembly instructions

32 Operator's Manual

Assembly notes

HATZ diesel engines are efficient, robust and long-lived. Therefore, they are

usually installed in machines that are used for commercial purposes.

The machine manufacturer must follow the applicable regulations regarding

machine safety – the engine is a part of a machine.

Depending on the use and installation of the engine, it may be necessary for

the machine manufacturer and machine user to install safety equipment to

prevent inappropriate use. Note the following:

HATZ

Page 32

4H50TIC Transport, assembly and commissioning

▪ Parts of the exhaust gas system and the engine surface become hot dur-

ing operation and should not be touched until they cool down after the engine is switched off.

▪ Incorrect cable connections and incorrect operation of the electrical equip-

ment can lead to sparking and must be avoided.

▪ After the engine is installed in the machine, rotating parts must be protect-

ed against contact.

HATZ safety equipment is available for the belt drive of the cooling fan and

alternator.

▪ Comply with all notice and warning labels on the engine and keep them in

a legible condition. If a label should become detached or be difficult to

read, it must be replaced promptly. For this purpose, contact your nearest

HATZ service station.

▪ Any improper modification of the engine results in a loss of liability cover-

age for resulting damage.

Only regular maintenance, as specified in this Operator's Manual, will maintain the operating readiness of the engine.

The assembly instructions contain important information on how to safely assemble the engine. They are available from any Hatz service station.

If you have any questions, please contact your nearest HATZ service sta-

tion before commissioning the engine.

6.3 Preparations for commissioning

▪ Check the delivered parts for completeness, damage, and other noticeable

issues.

▪ Ensure that the setup location is adequately ventilated.

Danger to life from inhaling exhaust gases.

Toxic engine exhaust gases can lead to loss of consciousness

and even death in closed-off and poorly ventilated rooms.

6.4 Filling engine oil

HATZ

Engines are normally delivered without an engine oil filling.

DANGER

▪ Never operate the machine in closed-off or poorly ventilated

rooms.

▪ Do not breathe in the exhaust gases.

Operator's Manual 33

Page 33

Transport, assembly and commissioning 4H50TIC

CAUTION

Danger of later engine damage.

▪ Operating the engine with an oil level below the min. mark

Safety note

or above the max. mark can lead to engine damage.

▪ When checking the oil level, the engine must be horizontal

and have been switched off for a few minutes.

Overview

1 Dipstick

2 Oil filler plug, top

3 Oil refilling container

4 Oil filler plug, bottom

Procedure

Step Activity

1 Pull out the dipstick (1) and clean it.

34 Operator's Manual

HATZ

Page 34

4H50TIC Transport, assembly and commissioning

Step Activity

2 Depending on accessibility, unscrew oil filler plug (2) or (4).

3 Fill engine oil. For the specification, viscosity and filling quantity,

see the chapter 4.3 Engine oil, page 22.

4 Reinsert the dipstick.

5 Pull out the dipstick and check the oil level.

6 If required, top up engine oil to the max. mark.

7 Reinsert the dipstick.

8 Screw in the oil filler plug.

6.5 Filling the cooling system

CAUTION

Danger of burns.

There is a danger of burns when working on a hot cooling system. The cooling system is pressurized.

▪ Let the engine cool.

▪ Wear safety gloves.

Safety notes

CAUTION

Danger of later engine damage.

▪ Operating the engine with a coolant level below the MIN.

mark can lead to engine damage.

▪ When checking the coolant level, the engine must be hori-

zontal and be switched off.

HATZ

Operator's Manual 35

Page 35

MAX

MIN

MAX

MIN

12

43

Transport, assembly and commissioning 4H50TIC

Overview

1 Expansion tank for coolant

2 Sealing cap

3 MAX - Maximum coolant level

4 MIN - Minimum coolant level

Procedure

Step Activity

1 Open the sealing cap (2).

2 For the HATZ standard radiator: Top up coolant to the MAX

mark on the expansion tank.

For the HATZ OpenPowerUnit radiator: Top up coolant to the

edge of the pipe cut-out.

Preparation of the coolant, see the chapter 4.4 Coolant,

page 23.

3 Tighten the sealing cap (2) by hand all the way.

4 Start the engine (see the chapter 7 Operation and use,

page 38).

5 Warm up the engine until the coolant has reached a tempera-

ture of approx. 85°C. Above this temperature the coolant is

pumped through the entire cooling system and forces out remaining air bubbles.

6 Switch off the engine and let it cool down completely (see the

chapter 7 Operation and use, page 38).

7 Check the coolant level again. The coolant must be seen be-

tween the MIN and MAX mark; for a warm engine the level can

also be slightly above the MAX mark.

36 Operator's Manual

HATZ

Page 36

4H50TIC Transport, assembly and commissioning

Step Activity

8 Check the cooling system for leaks, retighten the hose clips if

necessary (see the chapter 8.2.4 Checking the cooling system,

page 57).

HATZ

Operator's Manual 37

Page 37

Operation and use 4H50TIC

7 Operation and use

7.1 Safety notes

NOTICE

Comply with the safety chapter!

Follow the basic safety instructions in the chapter 3 Safety,

page 7.

WARNING

Danger of injury from damage and defects on the machine.

▪ Do not take the machine into service if damage has been lo-

calized and identified.

▪ Replace faulty components.

WARNING

Danger of injury from the failure to follow the operating instructions and from performing unauthorized tasks on the

machine.

▪ Define the responsibilities of the personnel taking the ma-

chine into service.

▪ Replace faulty machine parts immediately.

▪ Check the installation conditions when the machine is first

taken into service and after the machine has been inactive

for a lengthy period.

CAUTION

Danger of engine damage from low load operation.

Operating the engine at no load or at very low load for an extended period can impair the running characteristics of the engine.

▪ Make sure that the engine load is at least 15 %.

▪ Before switching off the engine following low load operation,

briefly operate it at a considerably higher load.

7.2 Performing tests

38 Operator's Manual

Before starting

Before starting the engine, several tests need to be performed to ensure the

machine is working properly.

HATZ

Page 38

4H50TIC Operation and use

Procedure

Step Test

1 The machine is standing securely and on a level surface.

2 The installation location is adequately ventilated.

3 There is a sufficient amount of fuel in the fuel tank (see the chap-

ter 7.7 Refueling, page 49).

4 There is a sufficient amount of engine oil in the engine housing

(see the chapter 7.6 Checking the oil level and adding oil if nec-

essary, page 47).

5 There is a sufficient amount of coolant in the expansion tank

(see the chapter 8.2.4 Checking the cooling system, page 57).

6 Radiator and radiator hoses are free from leaks (see the chapter

8.2.4 Checking the cooling system, page 57).

7 No persons are located in the danger zone of the engine or ma-

chine.

8 All safety equipment is in place.

7.3 Starting the engine

Safety notes

DANGER

HATZ

Danger to life from inhaling exhaust gases.

Toxic engine exhaust gases can lead to loss of consciousness

and even death in closed-off and poorly ventilated rooms.

▪ Never operate the machine in closed-off or poorly ventilated

rooms.

▪ Do not breathe in the exhaust gases.

CAUTION

Danger of engine damage from the use of starting fluid.

▪ The use of engine damage from the use of starting fluid can

lead to uncontrolled ignition.

▪ Engine damage from uncontrolled ignitions.

▪ Never use starting fluid.

Operator's Manual 39

Page 39

4

II

I

6

7

8

9

10

11

5

0

1

3

2

Operation and use 4H50TIC

NOTICE

See also starting instructions in the documentation for the complete machine.

Overview — HATZ instrument boxes

Pos. Designation

1 Error diagnosis display

2 Service interval indicator

3 Button for error interrogation

4 Protective cap

5 Starting key

6 Pre glow display

7 Air filter service required

8 Engine temperature display

9 Oil pressure display

10 Charge control

40 Operator's Manual

11 Operating display

Ignition lock

0 Off

I Operation

II Starting

HATZ

Page 40

i

i

4H50TIC Operation and use

Procedure

Step Activity

1 Remove the protective cap (4) from the ignition lock.

2 Insert the starting key all the way and turn to position "I".

3 Turn the starting key to position "II".

4 As soon as the engine is running, release the starting key.

NOTICE

▪ After approx. 20 seconds the start procedure cuts off auto-

matically to protect the starter. If the engine is still not running after that, turn the starting key back to position "0" and

eliminate the cause (see the chapter 9.1 Fault table,

page 86).

▪ Turn the starting key to position "0" every time you want to

start the engine.

▪ The anti repeat device in the ignition lock makes it impossi-

ble for the starter to engage while the engine is running and

become damaged.

Depending on the model, the following indicators light up:

▪ Charge control (10)

▪ Oil pressure display (9)

▪ Pre glow display (6)

NOTE: If the optional engine temperature display (8) lights up,

the coolant temperature is impermissibly high. Do not start the

engine; eliminate the cause.

When the optional pre glow display (6) goes out, continue with

step 3.

▪ The starting key springs back to position "I" and remains in

this position during operation.

▪ The charge control (10) and oil pressure display (9) go out.

▪ The operating display (11) lights up.

HATZ

NOTICE

▪ In case of irregularities, switch off the engine immediately.

▪ Identify the fault and eliminate it.

▪ For details of troubleshooting, see the chapter 9.1 Fault ta-

ble, page 86.

Operator's Manual 41

Page 41

4

II

I

6

7

8

9

10

11

5

0

1

3

2

Operation and use 4H50TIC

7.4 Starting the engine for the first time/after a filter change

DANGER

Danger to life from inhaling exhaust gases.

Toxic engine exhaust gases can lead to loss of consciousness

and even death in closed-off and poorly ventilated rooms.

▪ Never operate the machine in closed-off or poorly ventilated

rooms.

▪ Do not breathe in the exhaust gases.

Safety notes

CAUTION

Danger of engine damage from the use of starting fluid.

▪ The use of engine damage from the use of starting fluid can

lead to uncontrolled ignition.

▪ Engine damage from uncontrolled ignitions.

▪ Never use starting fluid.

NOTICE

See also starting instructions in the documentation for the complete machine.

Overview — HATZ instrument boxes

42 Operator's Manual

HATZ

Page 42

i

4H50TIC Operation and use

Pos. Designation

1 Error diagnosis display

2 Service interval indicator

3 Button for error interrogation

4 Protective cap

5 Starting key

6 Pre glow display

7 Air filter service required

8 Engine temperature display

9 Oil pressure display

10 Charge control

11 Operating display

Ignition lock

0 Off

I Operation

II Starting

HATZ

Procedure

Step Activity

1 Remove the protective cap (4) from the ignition lock.

NOTICE

▪ After approx. 20 seconds the start procedure cuts off auto-

matically to protect the starter. If the engine is still not running after that, turn the starting key back to position "0" and

eliminate the cause (see the chapter 9.1 Fault table,

page 86).

▪ Turn the starting key to position "0" every time you want to

start the engine.

▪ The anti repeat device in the ignition lock makes it impossi-

ble for the starter to engage while the engine is running and

become damaged.

Operator's Manual 43

Page 43

i

Operation and use 4H50TIC

Step Activity

2 Insert the starting key all the way and turn to position "I".

Depending on the model, the following indicators light up:

▪ Charge control (10)

▪ Oil pressure display (9)

▪ Pre glow display (6)

NOTE: If the optional engine temperature display (8) lights up,

the coolant temperature is impermissibly high. Do not start the

engine; eliminate the cause.

When the optional pre glow display (6) goes out, continue with

step 3.

3 Leave the starting key at position "I" until you hear the fuel feed

pump switches off (approx. 30 seconds).

4 Turn the starting key to position "II". The start procedure takes

longer than normal as air is still in the fuel system.

5 As soon as the engine is running, release the starting key.

▪ The starting key springs back to position "I" and remains in

this position during operation.

▪ The charge control (10) and oil pressure display (9) go out.

▪ The operating display (11) lights up.

NOTE: There is air in the fuel system when starting the engine

for the first time/after a filter change. The engine therefore starts

in the emergency program (reduced power and speed).

6 Run the engine for approx. 2 minutes in the emergency program

to make sure there is no more air in the fuel system.

7 Switch off the engine and leave it switched off for at least 2 mi-

nutes. At the next start the engine again runs in the normal program.

44 Operator's Manual

NOTICE

▪ In case of irregularities, switch off the engine immediately.

▪ Identify the fault and eliminate it.

▪ For details of troubleshooting, see the chapter 9.1 Fault ta-

ble, page 86.

HATZ

Page 44

i

4H50TIC Operation and use

7.5 Switching off the engine

Safety notes

CAUTION

Danger of injury from unauthorized access.

There is a danger of injury if unauthorized persons handle the

machine.

▪ Protect the starting key against unauthorized access during

breaks in operation or after completing work.

CAUTION

Protect the ignition lock against dirt and moisture.

▪ With the starting key pulled out, seal the ignition lock with

the protective cap.

NOTICE

Danger of overheating and full battery discharge.

▪ To prevent damage due to overheating, cool down the en-

gine before switching it off by running it for approx. 5 minutes at a reduced speed and load.

▪ When the machine is switched off, always turn the starting

key to position "0" or else the battery may become fully discharged.

HATZ

NOTICE

See also instructions in the documentation for the complete machine.

Operator's Manual 45

Page 45

2

I

0

2

1

Operation and use 4H50TIC

Overview — HATZ instrument boxes

Pos. Designation

1 Starting key

2 Protective cap

Ignition lock

0 Off

I Operation

Procedure

Step Activity

1 Turn the starting key (1) to position "0".

The engine switches off.

All indicator lamps go out.

2 Remove the starting key.

3 Seal the ignition lock with the protective cap (2).

46 Operator's Manual

HATZ

Page 46

4H50TIC Operation and use

7.6 Checking the oil level and adding oil if necessary

CAUTION

Danger of burns.

There is a danger of burns when working on a hot engine.

▪ Wear safety gloves.

Safety notes

CAUTION

Danger of later engine damage.

▪ Operating the engine with an oil level below the min. mark

or above the max. mark can lead to engine damage.

▪ When checking the oil level, the engine must be horizontal

and have been switched off for a few minutes.

HATZ

Operator's Manual 47

Page 47

Operation and use 4H50TIC

Overview

1 Dipstick

2 Oil filler plug, top

3 Oil refilling container

4 Oil filler plug, bottom

Procedure — Checking oil level/adding oil

Step Activity

1 Switch off the engine and wait several minutes for the engine oil

to collect in the crank housing. Engine must be level.

2 Remove contamination on the engine in the area of the dipstick

(1).

3 Pull out the dipstick and clean it.

4 Reinsert the dipstick.

5 Pull out the dipstick and check the oil level.

48 Operator's Manual

HATZ

Page 48

i

4H50TIC Operation and use

Step Activity

6 If the oil level is close to the min. mark, add engine oil to the

max. mark.

For the specification and viscosity, see the chapter 4.3 Engine

oil, page 22.

7 Reinsert the dipstick.

7.7 Refueling

This diesel engine is intended for installation in a machine or for assembly

with other machines to form a machine and does not have its own fuel tank.

Follow the instructions from the manufacturer and comply with the following

safety information.

Safety notes

NOTICE

If possible, never run the fuel tank empty, otherwise air can enter the fuel system and the engine switches to the emergency

program. There is also the risk that damage is caused in the fuel

high-pressure section.

If the fuel tank is nevertheless run empty, the procedure described under "7.4 Starting the engine for the first time/after a filter

change, page 42" must be adhered to.

DANGER

Fire hazard from fuel.

Leaked or spilled fuel can ignite on hot engine parts and cause

serious burn injuries.

▪ Only refuel when the engine is switched off.

▪ Never refuel in the vicinity of open flames or sparks that can

cause ignition.

▪ Do not smoke.

▪ Do not spill fuel.

CAUTION

Danger of environmental damage from spilled fuel.

Do not overfill the fuel tank and do not spill fuel.

▪ Collect emerging fuel and dispose of it in an environmentally

compatible manner.

HATZ

Operator's Manual 49

Page 49

Operation and use 4H50TIC

CAUTION

Engine damage from using low quality fuel.

The use of fuel that does not meet the specifications can lead to

engine damage.

▪ Only use the fuel specified in the chapter 4.5 Fuel, page 26.

▪ The use of fuel that does not meet specifications requires

approval by Motorenfabrik HATZ (main plant).

50 Operator's Manual

HATZ

Page 50

4H50TIC Maintenance

8 Maintenance

8.1 General maintenance instructions

HATZ

Safety notes

WARNING

Danger of injury from the failure to follow the operating instructions and from performing unauthorized tasks on the

machine.

▪ Follow all instructions.

▪ Do not perform activities for which no qualification is availa-

ble. Contact properly trained personnel if necessary.

NOTICE

Comply with the safety chapter!

Follow the basic safety instructions in the chapter 3 Safety,

page 7.

▪ Maintenance tasks may only be performed by trained personnel.

▪ Accident prevention measures must be in accordance with the local acci-

dent prevention regulations.

▪ Perform setting and maintenance work at the specified intervals.

▪ Replace faulty machine parts as soon as possible.

▪ Always use personal protective equipment.

▪ Only use fully functional tools.

▪ Problems may occur if unsuitable spare parts are installed. We cannot ac-

cept responsibility for damage and secondary damage that result from

this. We therefore recommend the use of Hatz original spare parts.

▪ Closely adhere to the maintenance conditions prescribed in this Operator's

Manual.

▪ Only make changes on the machine in agreement with the manufacturer.

▪ Only perform maintenance when the engine is switched off.

▪ Adhere to legal regulations when handling and disposing of used oil, fil-

ters, coolants, and cleaning agents.

▪ Protect the starting key against unauthorized access.

▪ Disconnect the negative battery terminal before carrying out maintenance

work.

▪ After completing maintenance work, check that all tools, bolts, aids and

other objects are removed from the machine and that all safety equipment

has been replaced.

Operator's Manual 51

Page 51

Maintenance 4H50TIC

▪ Before starting, ensure that no persons are located in the danger zone of

the engine or machine.

Performance of maintenance work

The entire machine is designed to be maintenance friendly. Parts that require maintenance are easily accessible.

▪ Perform maintenance work faithfully at the specified intervals to prevent

premature wear of the machine.

▪ Follow the notice and warning labels on the machine.

▪ Always retighten screw connections loosened during maintenance work.

▪ After the necessary maintenance and repair work is completed, perform a

function test (test run).

▪ For maintenance work that is not listed and described in the maintenance

documentation, please contact your nearest HATZ service station.

8.2 Maintenance work

Safety note

Danger of injury if maintenance instructions are not followed.

▪ Only perform maintenance when the engine is switched off.

▪ Protect the starting key against unauthorized access.

▪ Disconnect the negative terminal of the battery.

▪ After the maintenance work is completed, ensure that all

CAUTION

tools have been removed from the machine.

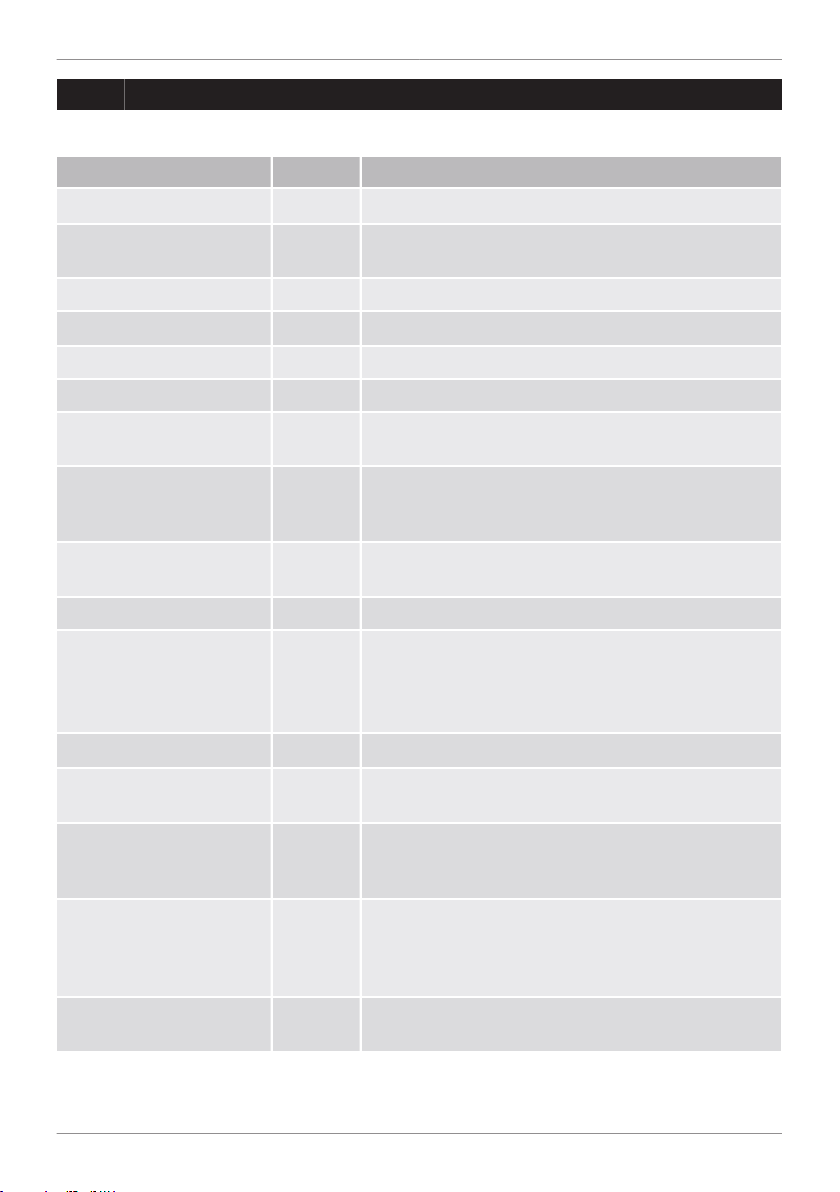

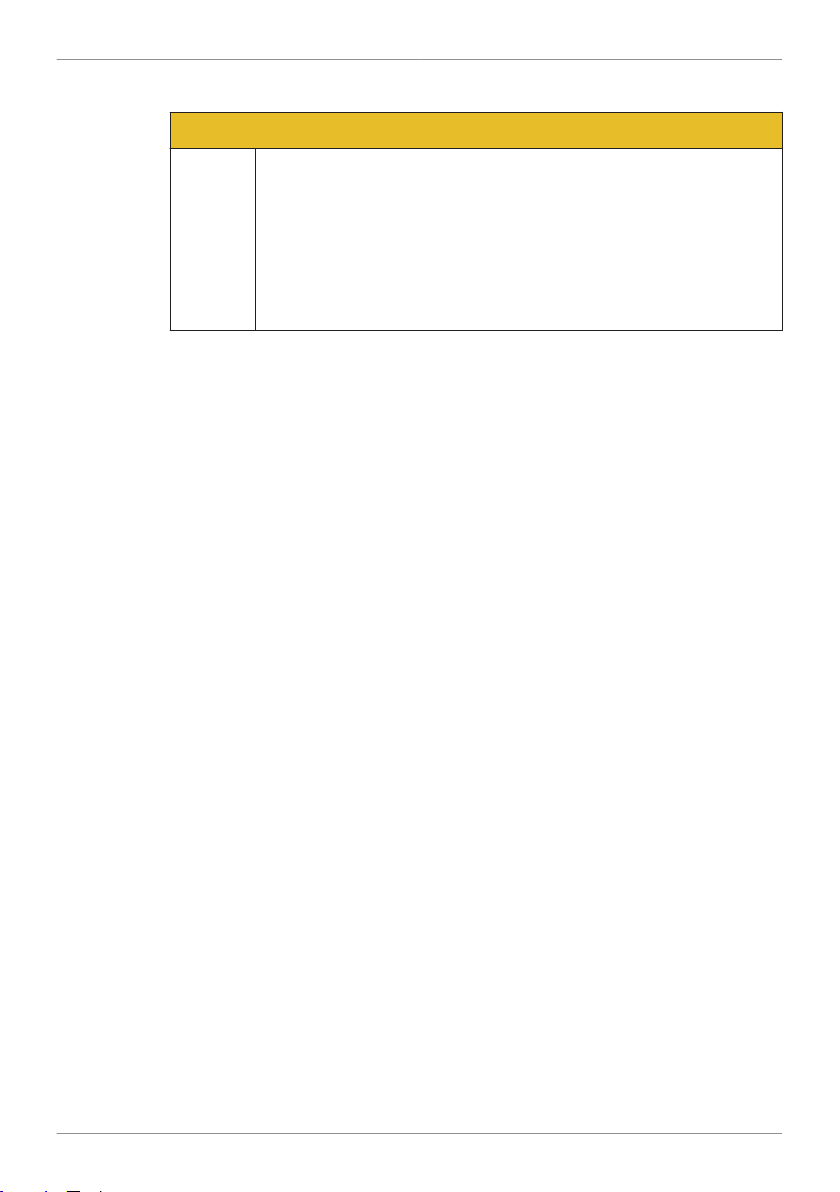

8.2.1 Maintenance plan

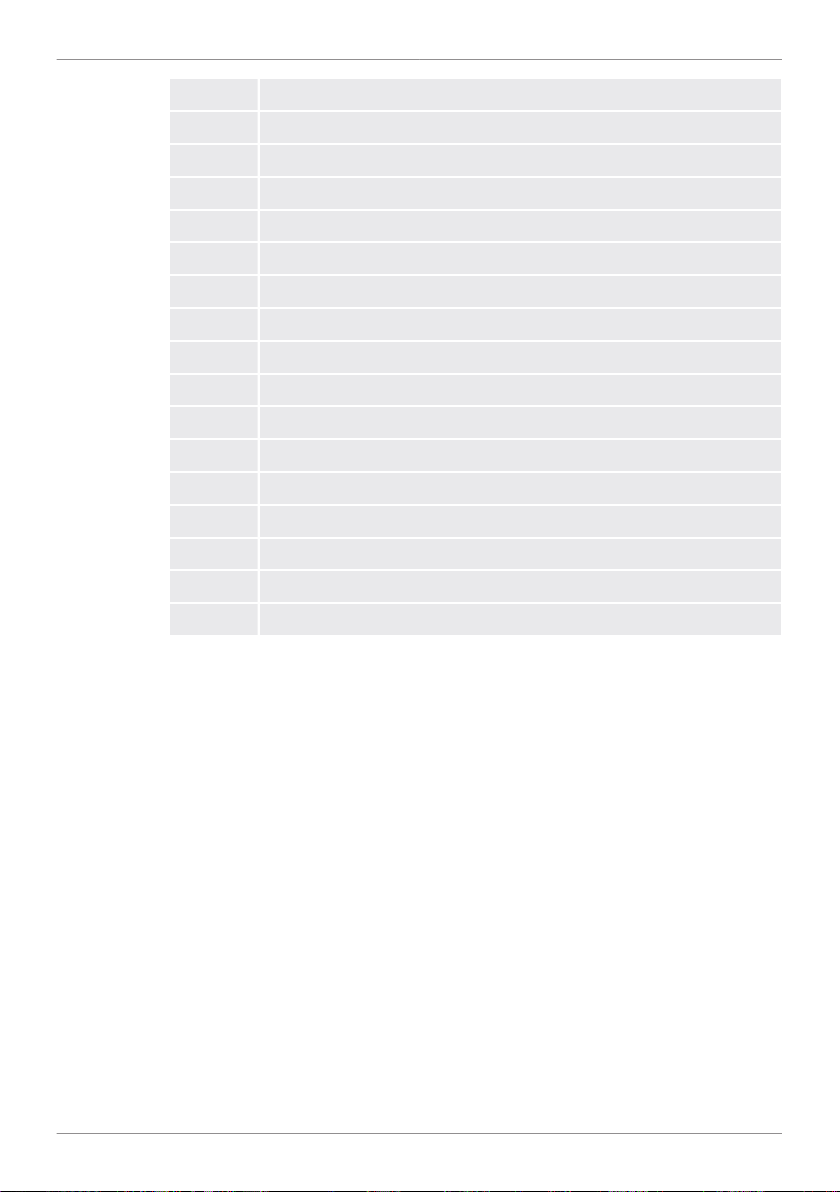

Symbol Maintenance in-

terval

Every 8-15 operating hours or every day before

starting

52 Operator's Manual

Maintenance activity/Check Chapter

Check the oil level. 7.6 Checking the

Check the intake area of the

combustion air.

oil level and add-

ing oil if necessa-

ry, page 47

8.2.2 Checking

the intake area of

the combustion

air, page 54

HATZ

Page 52

500h

4H50TIC Maintenance

Symbol Maintenance in-

Maintenance activity/Check Chapter

terval

Check the radiator fins for dirt

accumulation.

Checking the cooling system 8.2.4 Checking

Every 500 operating hours or every

Change the engine oil and oil

1)

filter

2 years

Change the fuel prefilter

Change the fuel fine filter

Check the poly v belt

Change the oil separator of the

crankcase ventilation

1)

1)

Check the screw connections1)8.2.10 Checking

Clean the radiator fins

Every 500 operat-

Change the air filter cartridges 8.2.14 Servicing

1)

ing hours or when

indicated, at least

every 2 years

When indicated Drain the water separator

8.2.3 Checking

the radiator fins

for dirt accumula-

tion, page 55

the cooling sys-

tem, page 57

8.2.5 Changing

the engine oil and

oil filter,

page 59

1)

8.2.12 Changing

the fuel prefilter,

page 74

1)

8.2.13 Changing

the fuel fine filter,

page 77

8.2.7 Tensioning

the poly v belt,

page 67

8.2.9 Changing

the oil separator

of the crankcase

ventilation,

page 71

the screw con-

nections,

page 72

8.2.6 Cleaning

the radiator fins,

page 64

the air filter (optional), page 80

1)

8.2.11 Draining

the water separa-

tor, page 73

HATZ

Operator's Manual 53

Page 53

i

Maintenance 4H50TIC

Symbol Maintenance in-

terval

If necessary, ev-

ery 3000 operating hours at the

latest

Every 4000 oper-

ating hours

1)

Service according to service interval or after 2 years depending on which

criteria is first.

In new and generally overhauled engines, after 50 operating hours:

▪ Change the engine oil and oil filter. See the chapter 8.2.5 Changing the

engine oil and oil filter, page 59.

▪ Check the screw connections (do not retighten the screws for attaching

the cylinder head). See the chapter 8.2.10 Checking the screw connec-

tions, page 72.

Maintenance activity/Check Chapter

Replacing the poly v belts 8.2.8 Replacing

Clean the entire EGR section

(EGR precooler, EGR valve,

EGR main cooler as well as

EGR mixing nozzle)

(To be carried out by a trained

specialist)

8.2.2 Checking the intake area of the combustion air

Safety notes

CAUTION

the poly v belts,

page 69

Danger of burns.

There is a danger of burns when working on a hot engine.

▪ Let the engine cool.

▪ Wear safety gloves.

54 Operator's Manual

NOTICE

In case of heavy contamination, shorten the maintenance intervals accordingly (see the chapter 8.2.1 Maintenance plan,

page 52).

HATZ

Page 54

4H50TIC Maintenance

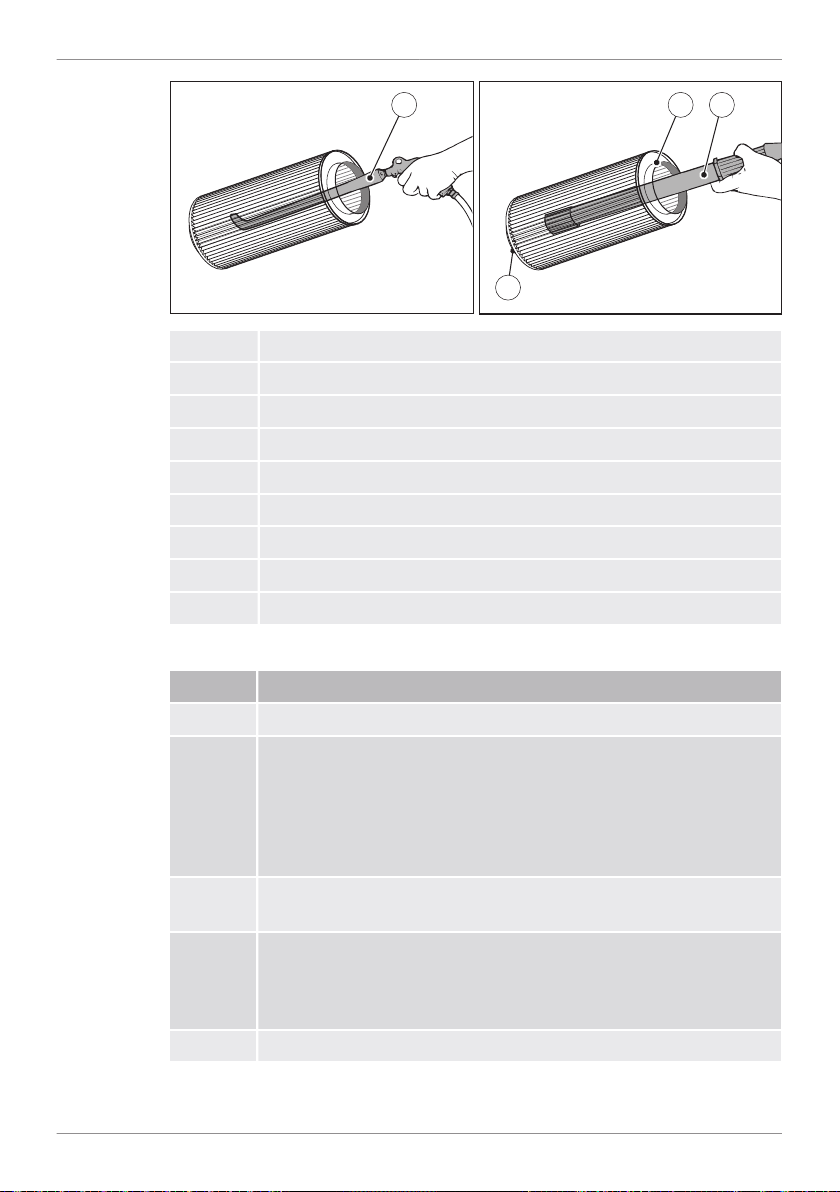

Overview (HATZ air filter)

1 Intake opening for combustion air

2 Dust discharge valve

Procedure

Step Activity

1 Check the intake opening (1) for coarse contamination such as

leaves, heavy dust deposits, etc., and clean if necessary.

2 Check that the dust discharge valve (2) is clear. Remove dust

seals by pressing them together.

8.2.3 Checking the radiator fins for dirt accumulation

HATZ

Safety notes

CAUTION

Danger of burns.

There is a danger of burns when working on a hot engine.

▪ Let the engine cool.

▪ Wear safety gloves.

Operator's Manual 55

Page 55

i

Maintenance 4H50TIC

Overview

CAUTION

Danger of injury.

When working with compressed air, foreign bodies may fly into

your eyes.

▪ Wear safety goggles.

▪ Never direct the compressed air jet toward people or toward

yourself.

CAUTION

Danger of engine damage from overheating.

The engine temperature display (option) lights up as soon as the

engine becomes impermissibly hot.

▪ Switch off the engine immediately and eliminate the cause.

NOTICE

In case of heavy contamination, shorten the maintenance intervals accordingly (see the chapter 8.2.1 Maintenance plan,

page 52).

1 Radiator fins

56 Operator's Manual

HATZ

Page 56

4H50TIC Maintenance

Step Activity

1 Check the radiator fins (1) for coarse contamination such as

leaves, heavy dust deposits, etc., and clean if necessary (see

the chapter 8.2.6 Cleaning the radiator fins, page 64).

8.2.4 Checking the cooling system

Procedure

Safety notes

CAUTION

Danger of scalding and risk of environmental damage due

to hot coolant.

▪ Excessive coolant is blown off from the sealing cap on the

expansion tank. After topping up the cooling system never

move parts of your body or face close to the sealing cap.

▪ Never top up coolant above the MAX - mark on the expan-

sion tank.

▪ Never stop escaping coolant with your bare hands.

CAUTION

Danger of burns.

There is a danger of burns when working on a hot engine.

▪ Let the engine cool before maintenance.

HATZ

CAUTION

Danger of burns.

There is a danger of burns when working on a hot cooling system. The cooling system is pressurized.

▪ Let the engine cool.

▪ Wear safety gloves.

Operator's Manual 57

Page 57

MAX

MIN

MAX

MIN

12

43

Maintenance 4H50TIC

CAUTION

Danger of later engine damage.

▪ Operating the engine with a coolant level below the MIN.

mark can lead to engine damage.

▪ When checking the coolant level, the engine must be hori-

zontal and be switched off.

Overview

1 Expansion tank for coolant

2 Sealing cap

3 MAX - Maximum coolant level

4 MIN - Minimum coolant level

Step Activity

1 The coolant must be between the MIN and MAX marks on a

switched-off and cooled-down engine. For a warm engine, the

level can also be slightly above the MAX mark.

Procedure for topping up coolant

Procedure for checking the coolant level

Step Activity

1 Open the sealing cap (2).

2 Top up prepared coolant to the MAX mark on the expansion

tank. Preparation of the coolant, see the chapter 4.4 Coolant,

page 23.

3 Tighten the sealing cap (2) by hand all the way.

58 Operator's Manual

HATZ

Page 58

4H50TIC Maintenance

Checking the cooling system for leaks

Coolants losses are mostly caused by leaks in the cooling system.

On a non-leaking cooling system, losses only occur when the coolant boils

and this then causes coolant to be pressed out of the cooling system at the

sealing cap on the expansion tank. The cause of this can be contamination

in the area of the radiator fins (see the chapter 8.2.3 Checking the radiator

fins for dirt accumulation, page 55).

Overview

1 Hose clip

Procedure

Step Activity

1 Check the cooling system for leaks and rectify the cause imme-

diately - in case of doubt consult HATZ Service for advice.

2 When hose connections are loose, retighten the hose clips (1).

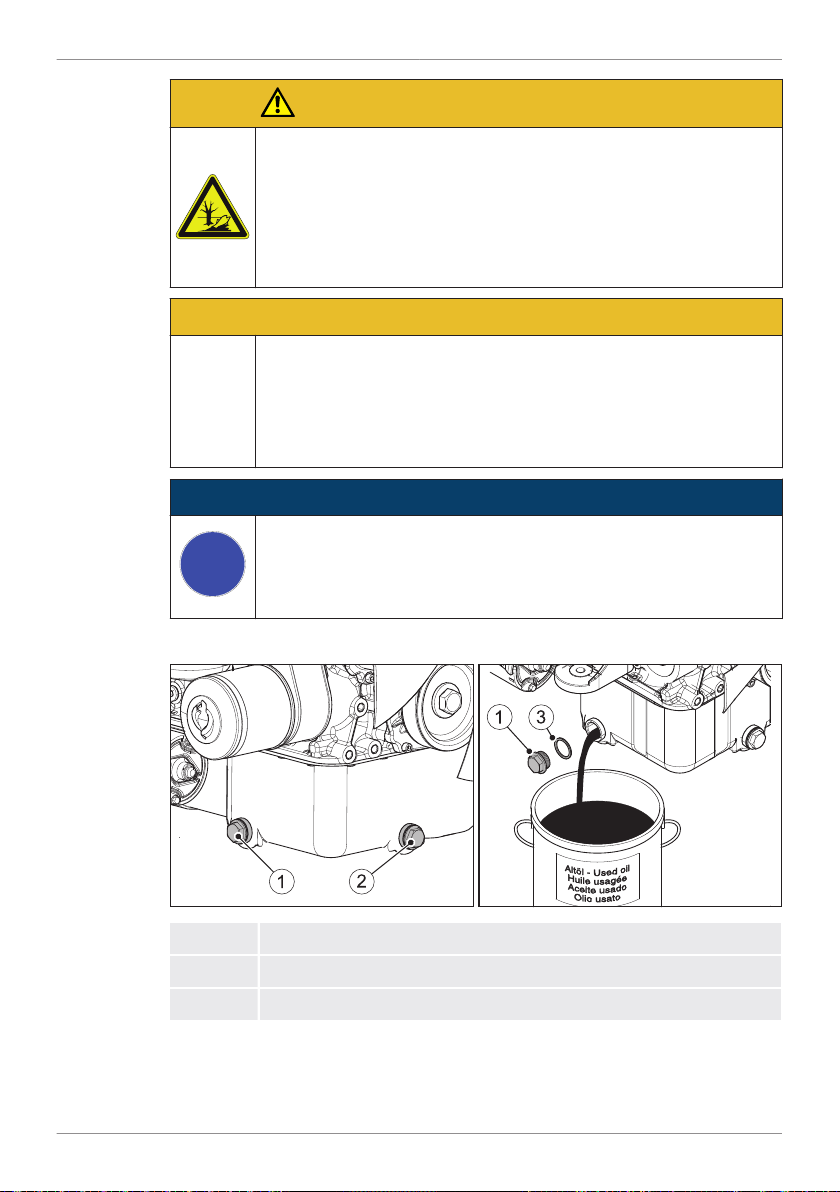

8.2.5 Changing the engine oil and oil filter

HATZ

Safety notes

CAUTION

Danger of burns.

When working on the engine there is a danger of burns from hot

oil.

▪ Wear personal protective equipment (gloves).

Operator's Manual 59

Page 59

i

Maintenance 4H50TIC

Overview of draining engine oil

CAUTION

Danger of environmental damage from spilled used oil.

Used oil is water-polluting.