Hatz Diesel 2L41C, 2M41Z, 2M41 Operator's Manual

2L41C | 2M41 | 2M41Z

www.HATZ-DIESEL.com

Hatz Diesel

CREATING POWER SOLUTIONS.

OPERATOR’S MANUAL

Diesel engine

IINNCCLLUUDDEESS SSUUPPPPLLEEMMEENNTTAALL IINNFFOORRMMAATTIIOONN TTOO

TTHHEE OOWWNNEERR’’SS MMAANNUUAALL FFOORR MMOODDEELL YYEEAARR 22001166

EEPPAA CCEERRTTIIFFIIEEDD NNOONNRROOAADD CCOOMMP

PRREESSSSIIOONN--

IIGGNNIITTIIOONN EENNGGIINNEESS..

IINNCCLLUUDDEESS SSUUPPPPLLEEMMEENNTTAALL IINNFFOORRMMAATTIIOONN FFOORR

TTHHEE UUSSEE OOFF EEPPAA CCEERRTTIIFFIIEEDD EENNGGIINNEESS WWI

ITTHHIINN

CCAALLIIFFOORRNNIIAA..

2L41C, 2M41, 2M41Z Table of contents

Table of contents

1 Notices .................................................................................................................5

2 General information ............................................................................................ 6

3 Safety ................................................................................................................... 7

3.1 General information............................................................................................... 7

3.1.1 Intended use and foreseeable misuse .................................................................. 7

3.1.2 Machine user or machine manufacturer obligations ............................................. 8

3.1.3 Representation of safety notes ............................................................................. 9

3.1.4 Meaning of safety symbols.................................................................................. 10

3.2 Safety notes ........................................................................................................ 11

3.2.1 Operational safety ............................................................................................... 11

3.2.2 Machine-specific safety instructions for operation .............................................. 14

3.2.3 Machine-specific safety instructions for maintenance work ................................ 16

3.2.4 Electrical equipment............................................................................................ 18

3.3 Labels.................................................................................................................. 20

4 Technical data ................................................................................................... 21

4.1 Engine information and filling quantities.............................................................. 21

4.2 Engine type plate ................................................................................................ 22

4.3 Fuel .....................................................................................................................23

4.4 Engine oil ............................................................................................................ 24

5 Engine design.................................................................................................... 26

6 Transport, assembly and commissioning ...................................................... 29

6.1 Transport............................................................................................................. 29

6.2 Installation notes ................................................................................................. 30

6.3 Preparations for commissioning.......................................................................... 31

7 Operation and use............................................................................................. 32

7.1 Safety notes ........................................................................................................ 32

7.2 Performing tests .................................................................................................. 32

7.3 Start preparation ................................................................................................. 33

7.3.1 Pumping fuel with the manual lever .................................................................... 33

7.4 Setting the speed control .................................................................................... 35

7.5 Starting the engine .............................................................................................. 35

7.5.1 Starting the engine with crankhandle .................................................................. 36

7.5.2 Starting the engine with a starter ........................................................................ 41

7.6 Switching off the engine ...................................................................................... 44

7.6.1 Switching off the engine (mechanical) ................................................................ 44

7.6.2 Switching off the engine (electrical) .................................................................... 45

7.7 Refueling ............................................................................................................. 46

7.8 Checking the oil level and adding oil if necessary............................................... 47

8 Maintenance ...................................................................................................... 50

HATZ

3Operator’s Manual

Table of contents 2L41C, 2M41, 2M41Z

8.1 General maintenance instructions....................................................................... 50

8.2 Maintenance work ............................................................................................... 51

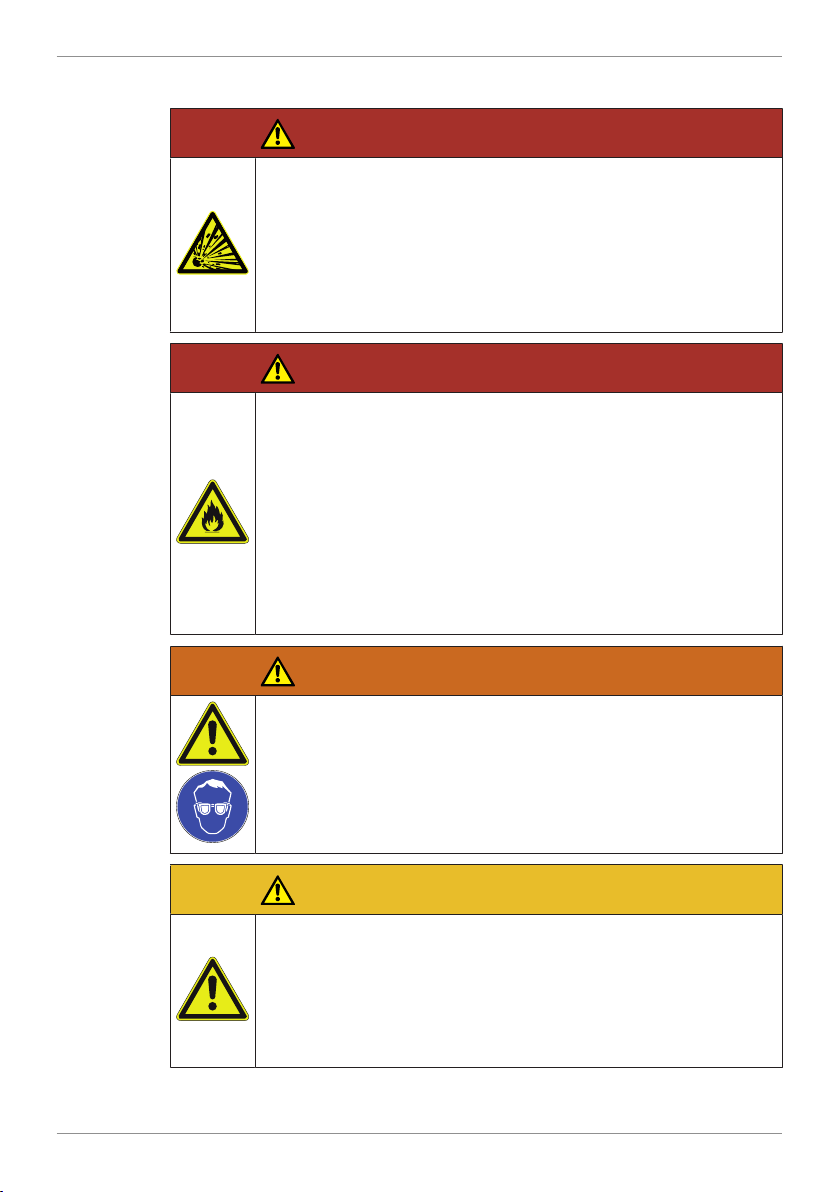

8.2.1 Maintenance notice label .................................................................................... 51

8.2.2 Maintenance plan................................................................................................ 53

8.2.3 Checking the intake area of the combustion air .................................................. 55

8.2.4 Checking the cooling air area.............................................................................. 58

8.2.5 Change the engine oil ......................................................................................... 59

8.2.6 Cleaning the cooling fan, cooling fins and oil cooler ........................................... 61

8.2.7 Checking the screw connections......................................................................... 64

8.2.8 Cleaning the screen insert in the exhaust pipe (additional equipment)............... 64

8.2.9 Changing the fuel prefilter ................................................................................... 66

8.2.10 Maintaining the dry air filter ................................................................................. 68

8.2.11 Checking and cleaning the air filter cartridge ...................................................... 70

8.2.12 Check and set the tappet clearance.................................................................... 72

8.2.13 Changing the oil filter .......................................................................................... 75

8.2.14 Changing the fuel filter ........................................................................................ 76

8.2.15 Checking that the air filter maintenance indicator is working properly ................ 78

8.2.16 Renewing the poly v belt and checking the function of the switch-off unit .......... 80

9 Faults.................................................................................................................. 84

9.1 Troubleshooting .................................................................................................. 84

9.2 Emergency start .................................................................................................. 89

10 Storage and disposal........................................................................................ 92

10.1 Storing the machine ............................................................................................ 92

10.2 Disposing of the machine.................................................................................... 93

11 Installation declaration ..................................................................................... 94

12 EPA CERTIFIED ENGINES................................................................................ 95

13 EPA CERTIFIED ENGINES WITHIN CALIFORNIA......................................... 105

4

Operator’s Manual

HATZ

2L41C, 2M41, 2M41Z Notices

1 Notices

Contact data

© 2015

Motorenfabrik HATZ

Ernst-Hatz-Straße 16

94099 Ruhstorf

Germany

Tel. +49 (0)8531 319-0

Fax +49 (0)8531 319-418

marketing@hatz-diesel.de

www.hatz-diesel.com

All rights reserved!

Copyright

The copyright for this Operator's Manual rests entirely with Motorenfabrik

HATZ, Ruhstorf.

This Operator's Manual may only be copied or distributed if written approval

has been received. This also applies to the copying or distribution of excerpts of the Operator's Manual. The same conditions apply to distribution of

the Operator's Manual to third parties in digital form.

Original Operator's Manual

This Operator's Manual was translated into multiple languages.

The German version is the original Operator's Manual. All other language

versions are translations of the original Operator's Manual.

HATZ

5Operator’s Manual

General information 2L41C, 2M41, 2M41Z

2 General information

Information on the document

This Operator's Manual was created with due care. It is exclusively intended

to offer a technical description of the machine and to provide instructions on

commissioning, operating and maintaining the machine. When operating the

machine, the applicable standards and legal regulations as well as any inhouse regulations apply.

Before commissioning, during operation and before maintenance work is begun on the machine, read the Operator's Manual carefully and keep it close

by for ready access.

Machine

This Operator's Manual describes the following machine.

Machine name HATZ diesel engine

Type number 2L41C, 2M41, 2M41Z

Customer service

Have service work performed by qualified technicians only. We recommend

that you work with one of the over 500 HATZ service stations. Trained specialists there will repair your machine with Hatz original spare parts and

with HATZ tools. The global HATZ service network is at your disposal to advise you and supply you with spare parts. For the address of the Hatz ser-

vice station nearest you, please see the directory included or visit the internet at: www.hatz-diesel.com

Problems may occur if unsuitable spare parts have been installed. We cannot accept responsibility for damage and secondary damage that result from

this.

We therefore recommend the use of genuine Hatz original spare parts.

These parts are manufactured according to strict Hatz specifications and

achieve maximum operational reliability through their perfect fit and functionality. The order number can be found in the enclosed spare parts list or on

the internet at: www.hatz-diesel.com

Exclusion of liability

The manufacturer cannot be held responsible for personal injury, damage to

property, or damage to the machine itself caused by improper use, foreseeable misuse, or failure to follow or adequately follow the safety measures

and procedures described in this Operators Manual. This also applies to

changes made to the machine and the use of unsuitable spare parts.

Modifications, which serve technical improvement, are reserved.

6

Operator’s Manual

HATZ

2L41C, 2M41, 2M41Z Safety

3 Safety

3.1 General information

Introduction

This chapter contains the information you need to work safely with this machine.

To prevent accidents and damage to the machine, it is imperative that these

safety instructions be followed.

Read this chapter carefully before beginning work.

3.1.1 Intended use and foreseeable misuse

Intended use

The machine described in this Operator's Manual fulfills the following functions:

▪ Diesel engine intended for installation in a machine or for assembly with

other machines to form a machine. See the chapter 11 Installation decla-

ration, page 94.

This engine is intended exclusively for the purpose specified and tested by

the manufacturer of the machine into which the engine is installed.

Any other use is not intended and therefore not permitted. Violations compromise the safety of the personnel working with the machine. Responsibility

is not accepted by Motorenfabrik HATZ for damage resulting from this situation.

The operational safety of the machine is only guaranteed if it is used as intended.

The intended use also includes observance of the instructions in this Operator's Manual to preserve the environment, including in the appendix for the

model year 2016 as per EPA Nonroad Diesel Engines.

HATZ

Foreseeable misuse

The following is considered to be foreseeable misuse:

▪ Any use that varies from or extends beyond the uses specified above.

▪ Failure to comply with the instructions in this Operator's Manual.

▪ Failure to comply with the safety instructions.

▪ Failure to immediately eliminate malfunctions that impact safety before

continuing work with the machine (working with the machine when it is not

in perfect condition, either functionally or in terms of safety).

▪ Failure to perform the necessary inspection and maintenance work.

▪ Any unauthorized modification of or removal of safety equipment.

▪ Use of spare parts and accessories that are unsuitable or have not been

approved by HATZ.

7Operator’s Manual

Safety 2L41C, 2M41, 2M41Z

▪ Operation in flammable or hazardous environments.

▪ Operation in closed-off or poorly ventilated rooms.

▪ Installation of the machine in moving equipment (e.g. vehicles, trailers) or

in closed rooms without additional measures to handle supply air, extract

air, and exhaust gas.

▪ Improper operation at variance with DIN 6271 and DIN ISO 8528 (climate,

load, safety).

Residual risks

Residual risks result during daily use and in association with maintenance

work.

These residual risks will be pointed out in chapter 3.2.2 Machine-specific

safety instructions for operation, page 14 and in chapter 3.2.3 Machinespecific safety instructions for maintenance work, page 16 as well as in the

further contents of the manual, directly in front of the descriptions or operating instructions concerned.

3.1.2 Machine user or machine manufacturer obligations

Machine manufacturer obligations

If you have an engine that is not yet installed in a machine, it is imperative

that you follow the Assembly Instructions for HATZ Diesel Engines before installing the engine. These assembly instructions contain important information on how to safely install the engine and are available at your nearest HATZ service station.

It is prohibited to start the engine before it is fully installed.

In addition, please note that it is prohibited to start up the machine before it

has been determined that the machine into which this engine is installed fulfills all safety-related requirements and legal regulations.

User obligations

The user is obliged to operate the machine when it is in perfect condition

only. The user must check the condition of the machine before use and ensure that any defects are eliminated before it is taken into service. Running

the machine while identified defects exist is not permitted. The user must

also ensure that all persons who work on the machine are familiar with the

contents of this Operators Manual.

Obligations of the operating and maintenance personnel

Personnel assigned with operating and maintaining the machine must have

read and understood the Operator's Manual or must possess the qualifications necessary for working with this equipment, acquired in training/instructional courses. No one may work with the machine without the necessary

qualifications, even if for just a brief period.

The operating personnel must not be under the influence of drugs, medication or alcohol.

8

Operator’s Manual

HATZ

2L41C, 2M41, 2M41Z Safety

All work performed on the machine must be in compliance with the information provided in the Operator's Manual.

Storing the Operator's Manual

This Operator's Manual is an integral component of the machine (also when

being sold). It must be stored in the direct vicinity of the machine and be accessible to personnel at all times.

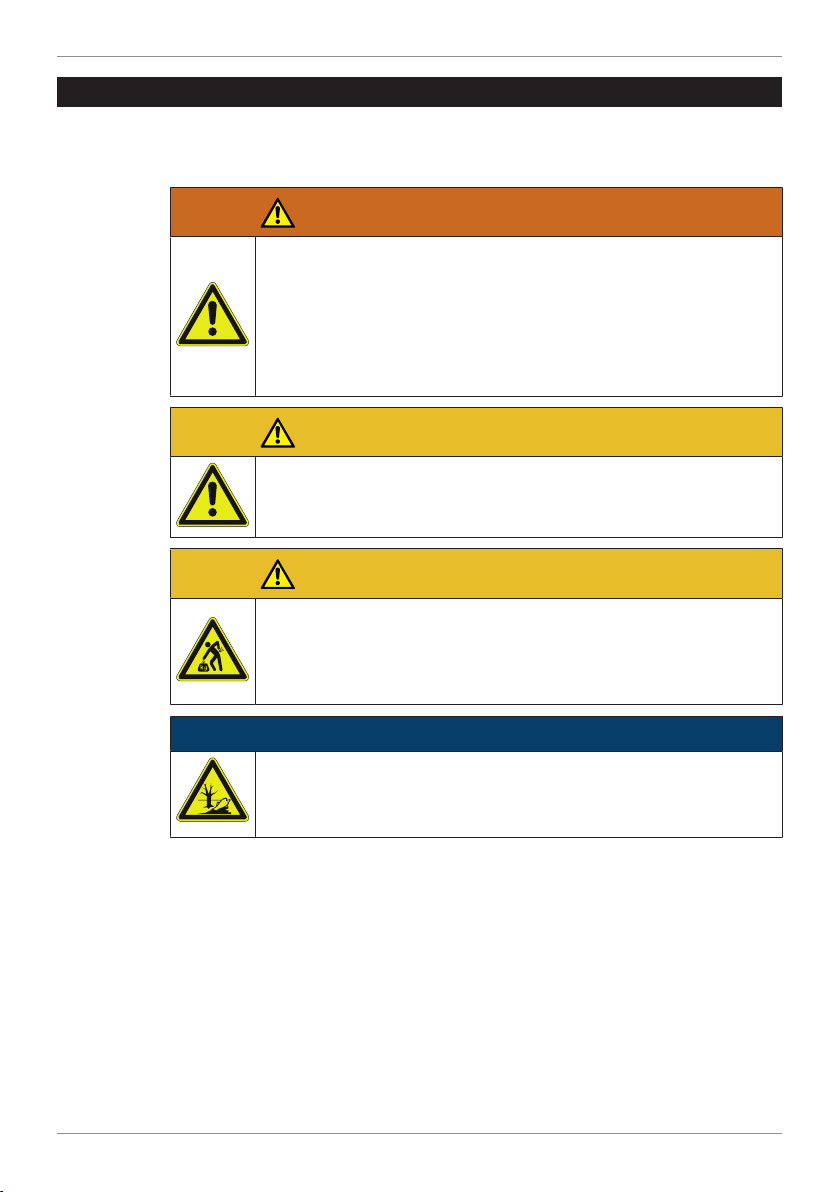

3.1.3 Representation of safety notes

Overview

This machine has been designed and built according to state-of-the-art technology and the recognized safety standards. Despite these precautions,

risks exist when operating the machine and during maintenance work.

These risks are identified in this manual by means of safety notes.

The safety notes precede the related description or operating step.

Structure of the safety notes

The safety notes consist of:

▪ Danger symbol

▪ signal word

▪ Description of danger

▪ Possible consequences

▪ Preventative measures

HATZ

General danger symbol

The general danger symbol is used to identify the danger of personal injury.

9Operator’s Manual

Safety 2L41C, 2M41, 2M41Z

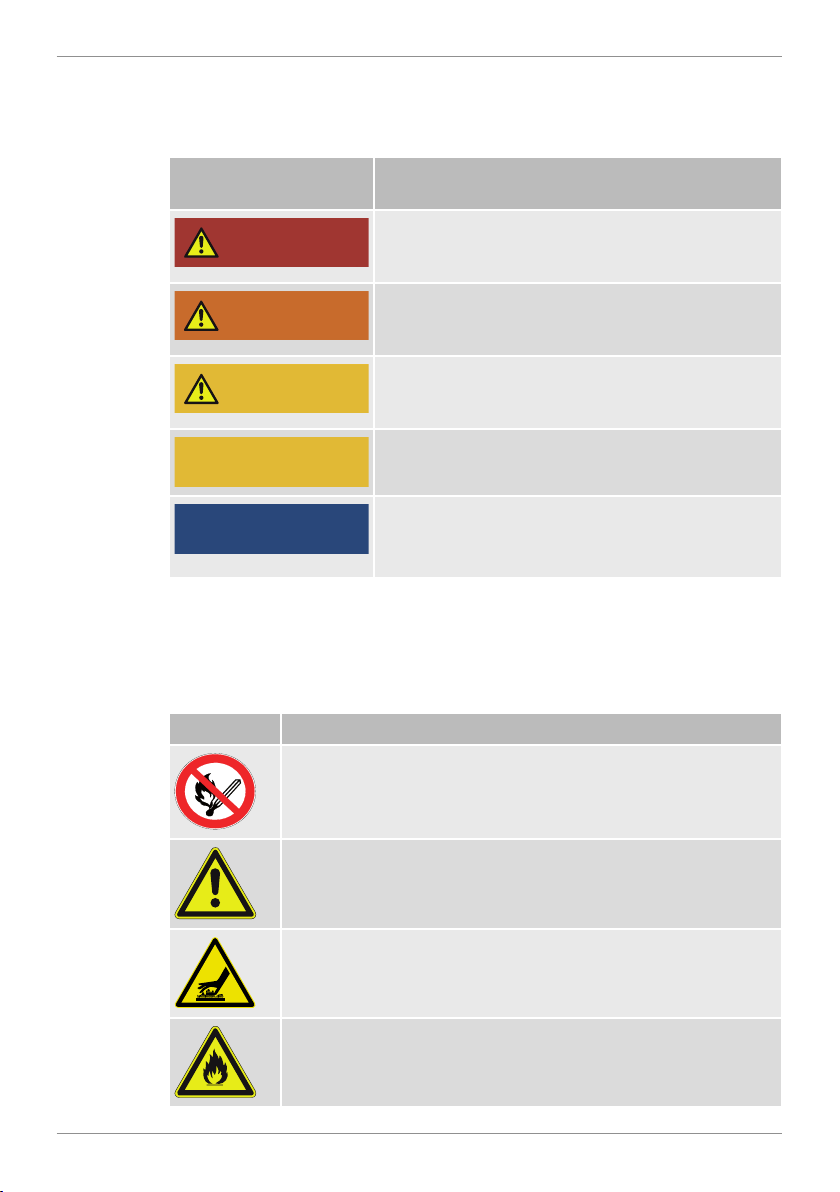

DANGER

WARNING

CAUTION

CAUTION

NOTICE

Signal words

Signal words identify the magnitude of the risk and the seriousness of the

possible injuries:

Danger symbol/

signal word

3.1.4 Meaning of safety symbols

Explanation of symbols

The following table describes the meanings of the safety symbols used in

this Operator's Manual.

Symbol Meaning

Smoking, fire, and open flames are prohibited!

Meaning

This signal word is used to indicate imminently

dangerous situations which, if not avoided, will

lead to serious injury or death.

This signal word is used to indicate potentially

dangerous situations which, if not avoided, may

lead to serious injury or death.

This signal word is used to indicate potentially

dangerous situations which, if not avoided, may

lead to minor or moderate injury.

This signal word, without a danger symbol, is

used to indicate the risk of property damage.

This signal word indicates additional useful information, such as operating tips and cross references.

10

Warning of personal injury!

Warning of hot surfaces!

Warning of flammable substances!

Operator’s Manual

HATZ

2L41C, 2M41, 2M41Z Safety

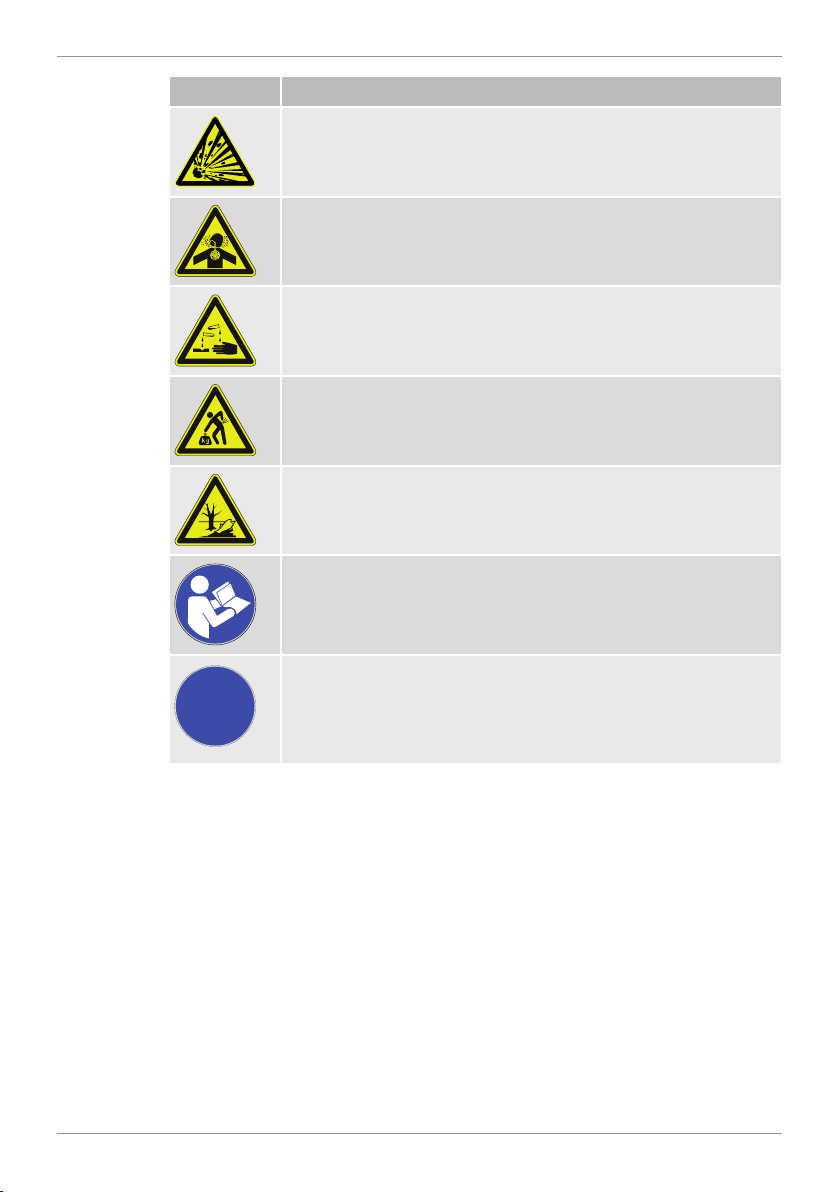

i

Symbol Meaning

Warning of explosive substances!

Warning of toxic engine exhaust!

Warning of corrosive substances!

Warning of heavy loads!

Warning of environmental damage!

Comply with the Operator's Manual or additional documentation from other manufacturers or the user!

3.2 Safety notes

3.2.1 Operational safety

Introduction

This chapter contains all of the important safety instructions for personal protection and for safe and reliable operation. Additional, task-related safety instructions can be found at the beginning of each chapter.

HATZ

Additional information that is useful to the reader.

11Operator’s Manual

Safety 2L41C, 2M41, 2M41Z

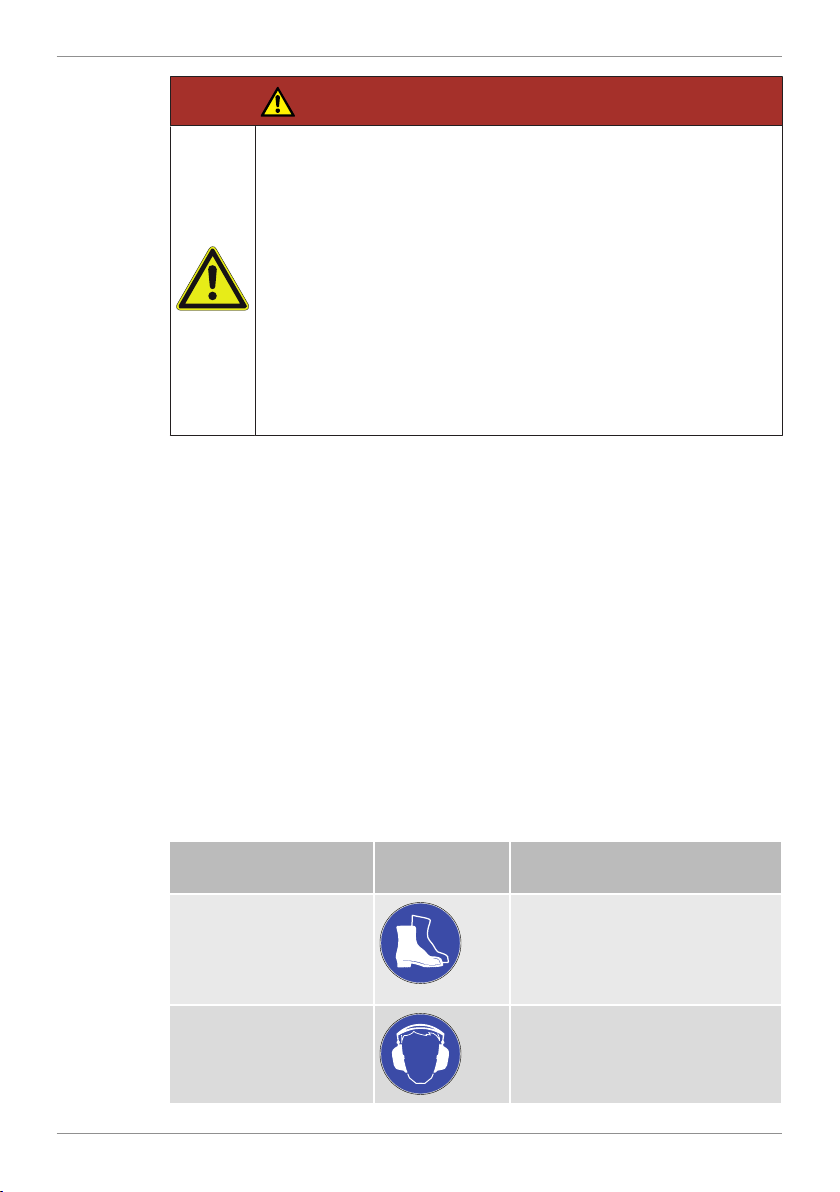

DANGER

Danger to life, danger of injury or danger of property damage due to failure to comply with the Operator's Manual and

the safety instructions contained therein.

▪ As the user of the machine, you must ensure that all people

working on the machine are familiar with the content of this

Operator's Manual.

▪ Before working on the machine, read this Operator's Manual

carefully, paying special attention to the safety notes.

▪ Fulfill all required safety conditions before working on the

machine.

▪ Follow all general safety instructions as well as the specific

task-related safety instructions contained in the individual

chapters.

Using the machine

▪ Only operate the machine for the purposes described in chapter 3.1.1 In-

tended use and foreseeable misuse, page 7.

Compliance with other regulations

▪ Adhere to the applicable accident prevention regulations of the trade asso-

ciations.

▪ Comply with the regulations concerning the minimum safety and health re-

quirements for the use of work equipment by workers at work.

▪ In addition, local safety, accident prevention and environmental regula-

tions also apply when operating the machine.

12

Personal protective equipment

During operation and maintenance of the machine, personal protective

equipment must be available and must be used if necessary. The required

personal protective equipment is specified in the descriptions of the operating steps.

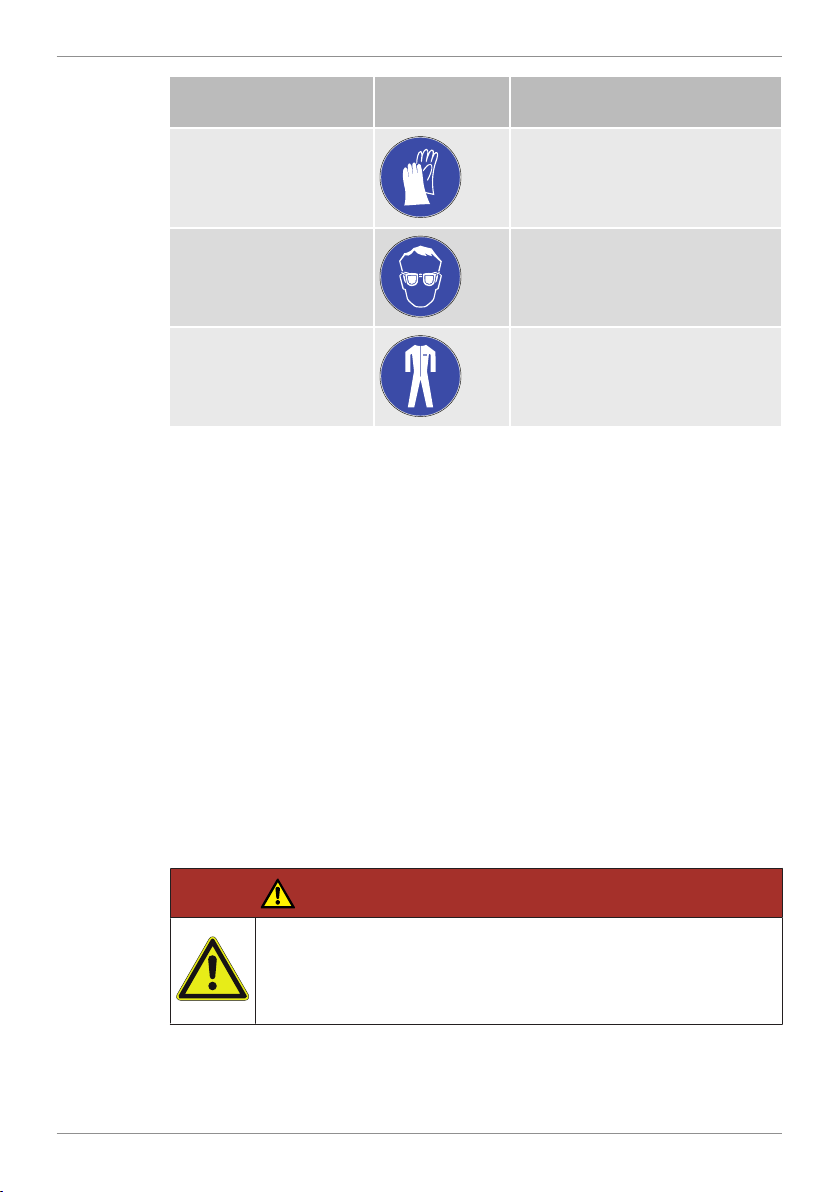

Personal protective

equipment

Safety shoes Safety shoes offer protection

Hearing protection Hearing protection offers protec-

Pictogram Function

against:

▪ Slipping

▪ Falling objects

tion against ear injuries due to

excessive and constant noise.

Operator’s Manual

HATZ

2L41C, 2M41, 2M41Z Safety

Personal protective

equipment

Safety gloves Safety gloves protect the hands

Safety goggles

(with side protection)

Working clothes Wear close-fitting clothing. How-

Warning labels and information signs on the machine

The warning labels and information signs on the machine must be followed

(see chapter "Labels" 3.3 Labels, page 20).

The warning labels and information signs must be kept legible and must be

replaced if necessary. For this purpose, contact your nearest HATZ service

station.

Maintenance work

Maintenance work that goes beyond the scope described in this manual

must only be performed by qualified technicians (see chapter 2 General in-

formation, page 6).

Independent maintenance work and constructional changes to the machine,

especially to the safety equipment, are not permitted.

Pictogram Function

against injury, e.g. from battery

acid.

Safety goggles protect the eyes

from flying objects (e.g. dust

particles, spraying liquids, spraying acid).

ever, it must not restrict the

wearer's freedom of movement.

HATZ

Safety equipment

Safety equipment must not be modified and must not be rendered ineffective

during normal operation.

General safety instructions

DANGER

Danger to life and danger of injury due to failure to follow

the warnings on the machine and in the Operator's Manual.

▪ Heed the warnings on the machine and in the Operator's

Manual.

13Operator’s Manual

Safety 2L41C, 2M41, 2M41Z

WARNING

Danger of injury and danger of incorrect operation due to

inadequate personnel qualifications.

▪ The personnel must have read and understood this Opera-

tor's Manual or must possess the qualifications necessary

for working with this equipment, acquired in training/instructional courses.

▪ Only qualified personnel is permitted to operate and main-

tain this machine.

▪ Failure to comply will cause the warranty to be void.

WARNING

Danger of injury from failure to follow the operating instructions and from performing unauthorized tasks on the machine.

▪ Follow all instructions.

▪ Do not perform activities for which no qualification is avail-

able. Contact properly trained personnel if necessary.

CAUTION

Danger of injury from overloading the body.

Lifting the machine to transport it or to move it to another location can lead to injuries (of the back, for example).

▪ Only lift the machine with a hoist (see chapter 6.1 Transport,

page 29).

3.2.2 Machine-specific safety instructions for operation

Introduction

The machine can pose residual risks during operation. To eliminate these

risks, all persons working on the machine must follow the general and machine-specific safety instructions.

If you have an engine that is not yet installed in a machine, it is imperative

that you follow the Assembly Instructions for HATZ Diesel Engines before installing the engine.

These assembly instructions contain important information on safe installation.

If the engine is installed in a machine or assembled with other machines to

form a machine, it is prohibited to start the engine before it has been determined that the newly created machine fulfills all safety-related requirements

and applicable legal regulations.

14

Operator’s Manual

HATZ

2L41C, 2M41, 2M41Z Safety

Safe operation

▪ Before switching on the machine, ensure that no one can be injured when

the machine is started up.

▪ During machine operation, ensure that unauthorized persons do not have

access to the area in which the machine has an impact.

▪ Parts of the exhaust gas system and the surface of the engine become hot

during operation. Risk of injury from touching hot parts! Let the engine cool

before maintenance.

▪ Do not refuel during operation.

Faults

▪ Immediately eliminate faults that compromise safety.

▪ Switch off the machine and do not take into service again until all faults

have been eliminated.

Safety instructions for operation

DANGER

Danger to life from inhaling exhaust gases.

Toxic engine exhaust gases can lead to loss of consciousness

and even death in closed-off and poorly ventilated rooms.

▪ Never operate the machine in closed-off or poorly ventilated

rooms.

▪ Do not breathe in the exhaust gases.

HATZ

DANGER

Fire hazard from fuel.

Leaked or spilled fuel can ignite on hot engine parts and cause

serious burn injuries.

▪ Only refuel when the engine is switched off.

▪ Never refuel in the vicinity of open flames or sparks that can

cause ignition.

▪ Do not smoke.

▪ Do not spill fuel.

15Operator’s Manual

Safety 2L41C, 2M41, 2M41Z

CAUTION

Danger of injury from defective crankhandle.

A damaged or broken handle bar can cause injuries. A worn

cranking shaft can slip out of the starting mechanism when starting and also cause injuries.

▪ Check the crankhandle for a broken handle bar, worn crank-

ing shaft, etc.; replace if necessary.

3.2.3 Machine-specific safety instructions for maintenance work

Introduction

The machine can pose residual risks during maintenance. To eliminate

these risks, all persons working on the machine must follow the general and

machine-specific safety instructions.

Maintenance intervals

▪ Strictly adhere to the maintenance intervals.

Regular maintenance according to the instructions in this Operator's Manual is essential for ensuring reliable operation and the correct engine exhaust quality.

▪ Check the safety equipment regularly to ensure it is in good condition and

functioning properly.

▪ Check connections, cables and fasteners regularly to ensure they are in

good condition.

16

Maintenance work

Maintenance work that goes beyond the scope described in this manual

must only be performed by qualified technicians. We recommend that you

work with one of the over 500 HATZ service stations.

Replacing parts

▪ When replacing defective components, we recommend that you use gen-

uine HATZ original spare parts (see chapter 2 General information, page

6).

▪ When disposing of parts that can no longer be used, do so in accordance

with local environmental regulations or send them to a recycling center.

Measures following maintenance and troubleshooting

▪ Securely reconnect loose electrical connections; check that the electrical

components and equipment are functioning properly.

▪ Check the entire machine for foreign bodies; remove any foreign bodies.

Operator’s Manual

HATZ

2L41C, 2M41, 2M41Z Safety

Safety instructions for maintenance work

DANGER

Danger of explosion from flammable cleaning agents.

Cleaning with benzene is an explosion hazard. It is highly

flammable, can become electrostatically charged, and can generate an explosive gas/air mixture.

▪ Use halogen-free, cold cleaners with a high flashpoint for

cleaning.

▪ Comply with manufacturer's instructions.

DANGER

Fire hazard from spontaneous combustion.

Cleaning materials soaked with cold cleaner may produce heat

together with atmospheric oxygen and combust spontaneously.

▪ Collect cleaning materials soaked with cold cleaner only in

fire-proof, tightly sealed containers.

▪ Do not dispose of cold cleaner residues and used cleaning

materials with domestic waste, rather only in accordance

with manufacturer instructions.

▪ Comply with the instructions for preventing fire on the safety

data sheet for the cold cleaner.

HATZ

WARNING

Danger of injury from compressed air and dust particles.

Eye injuries may occur when cleaning with compressed air.

▪ Wear safety goggles.

CAUTION

Danger of injury if maintenance instructions are not followed.

▪ Only perform maintenance when the engine is switched off.

▪ For engines with an electric starter:

Disconnect the negative battery terminal.

Protect the starting key against unauthorized access.

17Operator’s Manual

Safety 2L41C, 2M41, 2M41Z

CAUTION

Danger of burns.

There is a danger of burns when working on a hot engine.

▪ Let the engine cool before maintenance.

3.2.4 Electrical equipment

Safety notes

DANGER

Danger to life, danger of injury or danger of property damage due to incorrect use of batteries.

▪ Do not place tools on the battery.

▪ Before performing work on the electrical equipment, always

disconnect the negative battery terminal.

▪ Never swap the positive (+) and negative (–) battery termi-

nals.

▪ When installing the battery, first connect the positive cable

and then the negative cable.

▪ When removing the battery, first disconnect the negative

cable and then the positive cable.

▪ It is imperative that you prevent short circuits and mass con-

tact of current-carrying cables.

▪ If faults occur, check the cable connections for good con-

tact.

18

DANGER

Danger of explosion from flammable substances.

There is a danger of explosion from flammable gases.

▪ Keep batteries away from open flames and incendiary

sparks.

▪ Do not smoke when working with batteries.

Operator’s Manual

HATZ

2L41C, 2M41, 2M41Z Safety

CAUTION

Danger of chemical burns

Chemical burns can occur when using batteries for the electrical

operation.

▪ Protect your eyes, skin, and clothing from corrosive battery

acid.

▪ Immediately rinse areas affected by splashed acid with clear

water and consult a physician if necessary.

NOTICE

▪ The necessary wiring diagrams are included with the ma-

chine if it is equipped with electrical equipment. Additional

wiring diagrams can be requested when needed.

▪ We cannot be held liable for electrical equipment that is not

designed according to HATZ wiring diagrams.

▪ Promptly replace faulty indicator lamps.

▪ Do not pull out the starting key during operation.

▪ Do not disconnect the battery while the machine is running. Resulting volt-

age peaks could destroy the electronic components.

▪ When performing a manual emergency start, leave the (possibly depleted)

battery connected.

▪ When cleaning, do no spray the electrical equipment components with a

water jet or high pressure cleaner.

▪ When performing welding work on the machine, disconnect the battery

and place the ground clamp of the welding equipment as close as possible

to the welding area. Disconnect the plug-in connection to the voltage regulator.

HATZ

19Operator’s Manual

Safety 2L41C, 2M41, 2M41Z

max

OIL

0000 036 144

BIO

DIESEL

052 356 02

0000 053 657 02

0000 038 928 01

3.3 Labels

Warning labels and information signs on the engine

Label Meaning

Maintenance instructions (see the

chapter 8.1 General maintenance in-

structions, page 50)

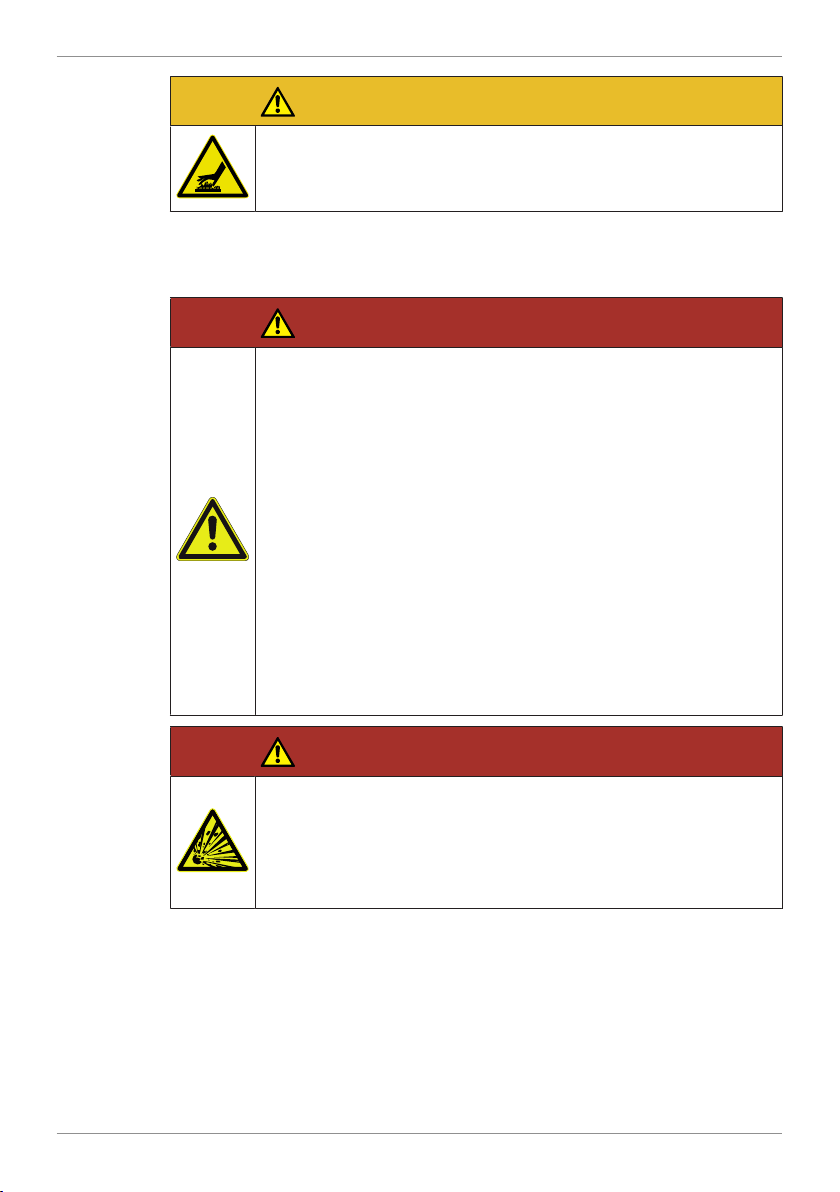

CAUTION!

Damage from inadequate engine

cooling.

▪ Only run the engine when all cov-

ers are installed.

20

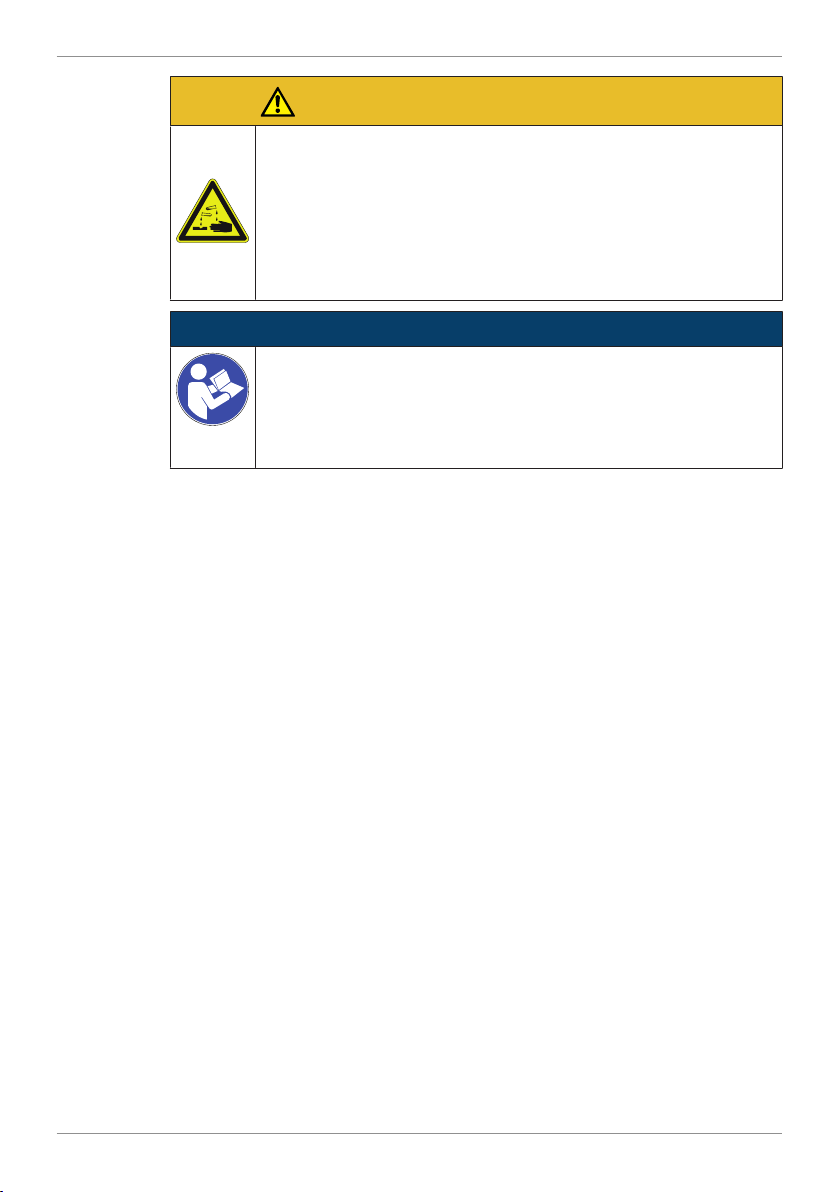

Refuel with diesel fuel only. Specification, see the chapter 4.3 Fuel,

page 23

Do not use bio diesel.

The engine may only be operated

with fuel that is "EXTREMELY LOW

IN SULFUR".

The fuel label is located close to the

fuel cap. If there is no fuel tank installed on the engine, the label must

be applied permanently close to the

fuel filler opening.

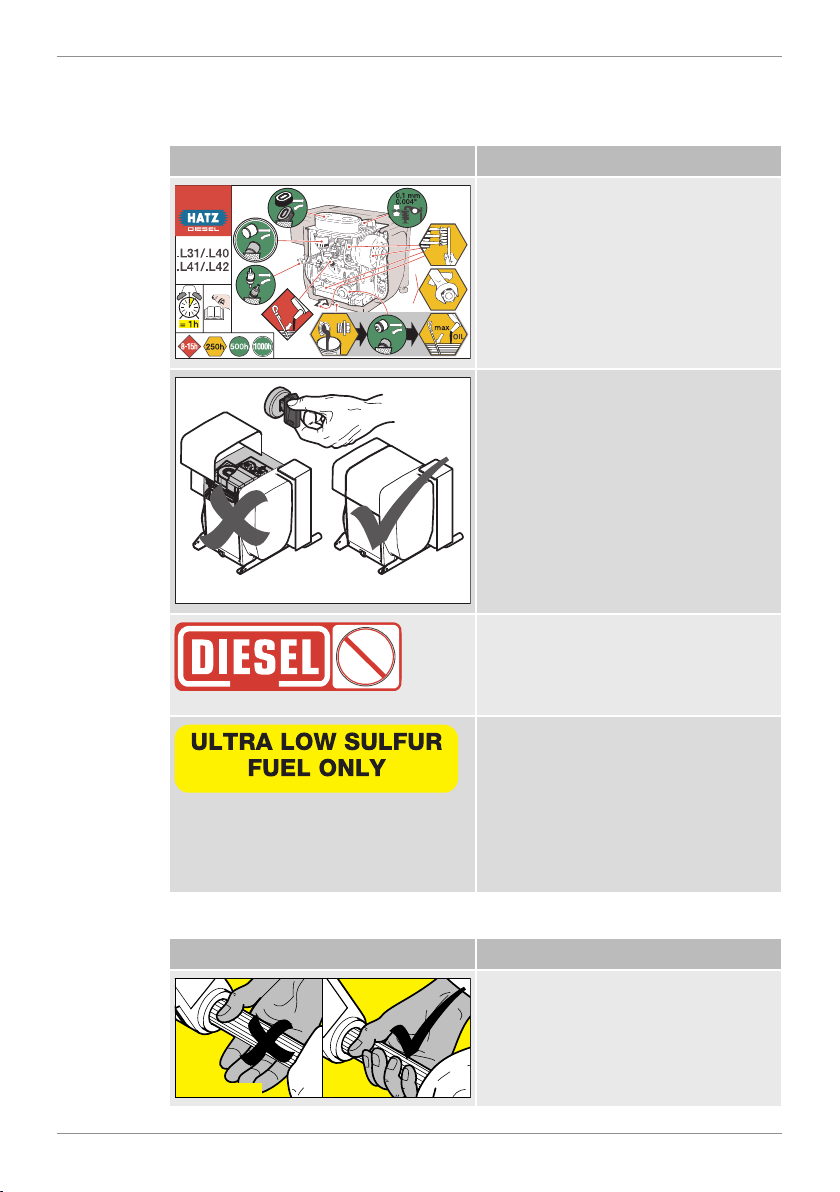

Warning labels and information signs on the crankhandle

Label Meaning

Hold the handle bar so that it cannot

twist and quickly turn the crank so

that continuous traction between the

engine and crank is ensured, see

chapter 7.5.1 Starting the engine

with crankhandle, page 36.

Operator’s Manual

HATZ

2L41C, 2M41, 2M41Z Technical data

4 Technical data

4.1 Engine information and filling quantities

Type 2L41C, 2M41, 2M41Z

Type Air-cooled four stroke diesel engine

Combustion system Direct injection

Number of cylinders 2

Bore/stroke mm 102 / 105

Displacement cm

Engine oil pressure at oil

temperature of 100 ±

20°C

Engine oil consumption

(after running-in period)

Sense of rotation When viewing flywheel: left

Tappet clearance at 10–

30°C

inlet/outlet

Net weight

2M41

2M41Z

2L41C

Max. perm. inclination

during continuous operation in direction

Operating side

Exhaust air side

Timing cover side

Flywheel side

Battery capacity Min/max 12V – 88/143Ah/24V – 55/110Ah

1)

Exceeding these limit values causes engine damage.

3

1716

Min. 0.6bar at 850rpm

Max. 1% of fuel consumption, pertaining to full load

mm 0.10

258

Approx.

kg

263

303

With and without

oil sump

1)

30°

1)

30°

1)

30°

1)

30°

HATZ

21Operator’s Manual

Technical data 2L41C, 2M41, 2M41Z

VARIABLE SPEED. ULTRA LOW SULFUR FUEL ONLY.

Power Category:

EMISSION CONTROL SYSTEM INFORM.:

Engine oil capacities and dipstick equipment

Type Oil sump Engine oil capacity

2L41C

2M41Z

2M41 With

2)

These values are approximations only. The max. mark on the dipstick is

decisive in any case (see the chapter 7.8 Checking the oil level and adding

oil if necessary, page 47).

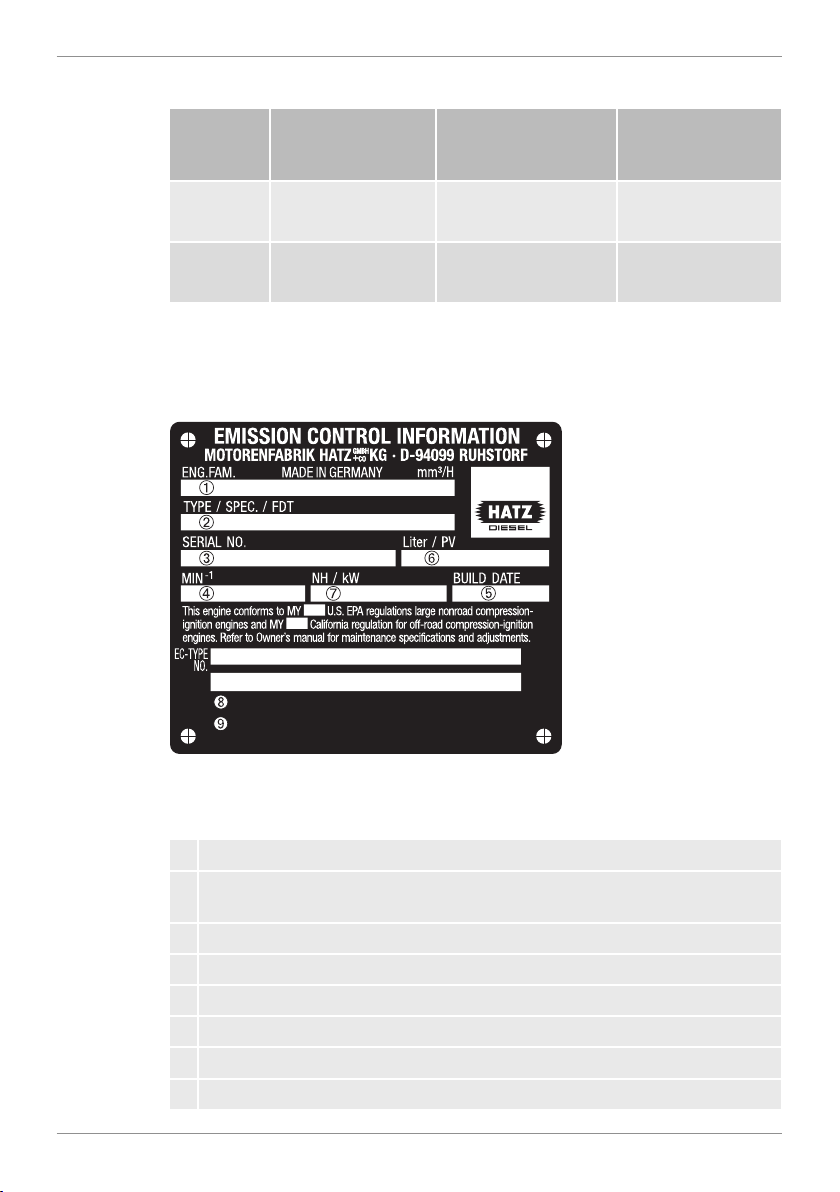

4.2 Engine type plate

With

Without

Without

2)

liters

7.5

4.5

8.5

5.5

Mark on the dip-

stick

C

A

C

A

The layout of the EPA/CARB type plate depends on the engine application

and is affixed to the crankcase or noise reduction capsule.

It contains the following information:

1 EPA/CARB engine family number

2 Engine type, customer specification and setting of pumping start (°

crankshaft before top dead center)

3 Engine serial number

4 Max. engine speed (rpm)

5 Model year

6 Displacement (liters) and inspection requirement for special settings

7 Injection pump effective stroke (mm) and engine capacity

8 Information on exhaust control system

22

Operator’s Manual

HATZ

2L41C, 2M41, 2M41Z Technical data

9 “variable speed" or "constant speed only" (if necessary)

The type plate also defines the applicable emissions-related performance

class of the engine.

The figure shows an EPA/CARB type plate.

A text that refers to the exhaust legislation and corresponds to the engine

type is printed on the type plate (EPA or EPA and CARB).

Every engine is equipped with an additional unattached type plate. When the

engine is built into a machine and the original type plate is not readily visible,

the second unattached type plate must be affixed to the application in a position that is clearly visible for an average person.

The following data must always be specified for requests and spare part orders

2 Engine type/specification (only for special equipment)

3 Engine serial number

4 Max. engine speed (rpm)

Always install the engine appropriate for the intended application to fulfill the

EPA and CARB exhaust requirements.

4.3 Fuel

Fuel type

All types of diesel fuel that meet the minimum requirements of the following

specifications are suitable:

▪ EN 590 or

▪ BS 2869 A1 / A2 or

▪ ASTM D 975- 1D / 2D

HATZ

CAUTION

Danger of engine damage from low quality fuel.

The use of fuel that does not meet the specifications can lead to

engine damage.

▪ Only use fuel that is very low in sulfur or that contains no

sulfur at all.

▪ The use of fuel that does not meet specifications requires

approval by Motorenfabrik HATZ (main plant).

23Operator’s Manual

Technical data 2L41C, 2M41, 2M41Z

-40

-30

-20

-10

0

10

20

30

40

50

104

86

68

50

32

14

-4

-22

-40

OIL : SAE ...

°C°F

5W/ 30

5W/ 40

10

W/

4

0

10W/ 3

0

15W

/

40

30

40

122

10

W

Winter fuel

When outside temperatures drop below 0°C, use winter fuel or mix in petroleum in advance:

Lowest ambient temperature at start [°C]

4.4 Engine oil

Oil quality

All brand name oils that satisfy at least the following specification are suitable:

▪ ACEA – B3 / E4 or better

▪ API – CF / CH-4 or better

If engine oils of a low quality standard are used, the oil change interval must

be reduced from 250 to 150 or from 500 to 250 operating hours depending

on the engine specification.

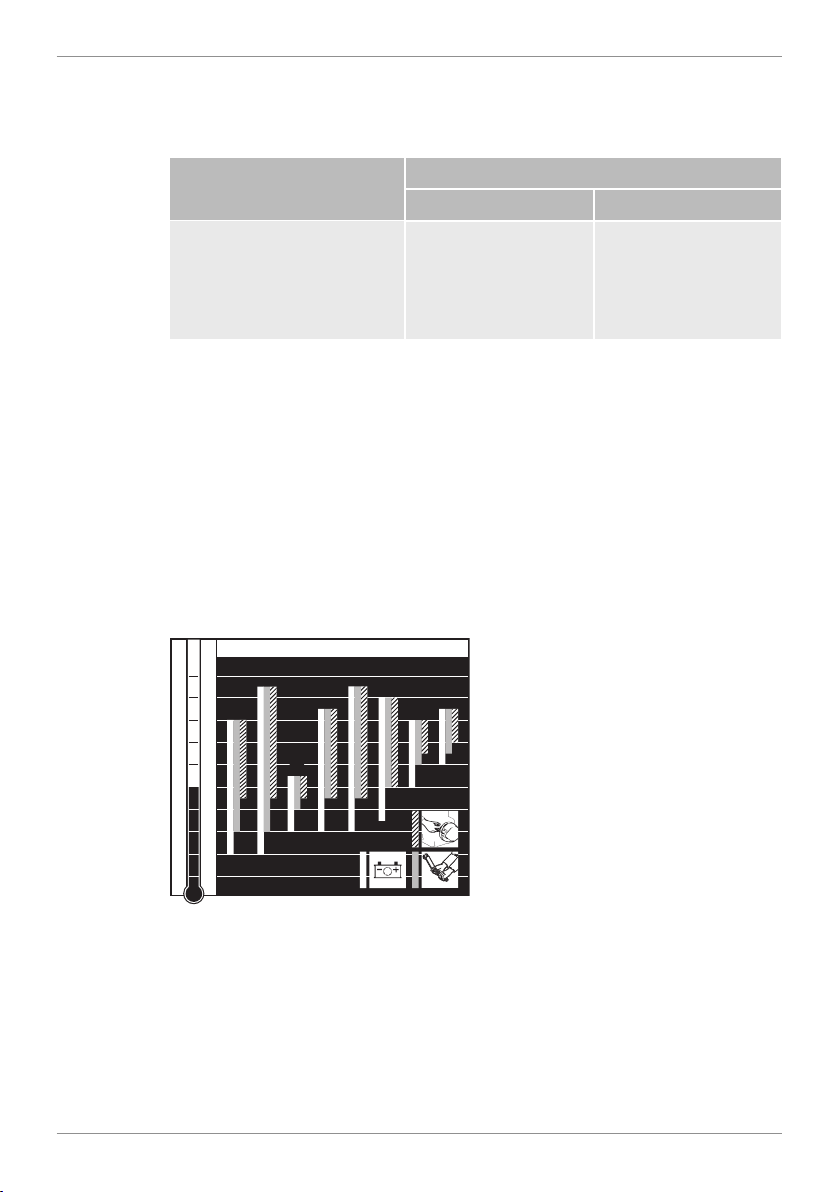

Oil viscosity

0 to -10

-10 to -15

-15 to -20

-20 to -30

Percentage of petroleum [%]for

Summer fuel Winter fuel

20

30

50

‑

‑

‑

20

50

24

Choose the recommended viscosity based on the type of start (recoil,

crankhandle or electric) and on the engine temperature at which the engine

will be operated.

Operator’s Manual

HATZ

2L41C, 2M41, 2M41Z Technical data

CAUTION

Engine damage from unsuitable engine oil.

Unsuitable engine oil considerably reduces engine service life.

Only use engine oil that fulfills the specifications stipulated

above.

HATZ

25Operator’s Manual

Engine design 2L41C, 2M41, 2M41Z

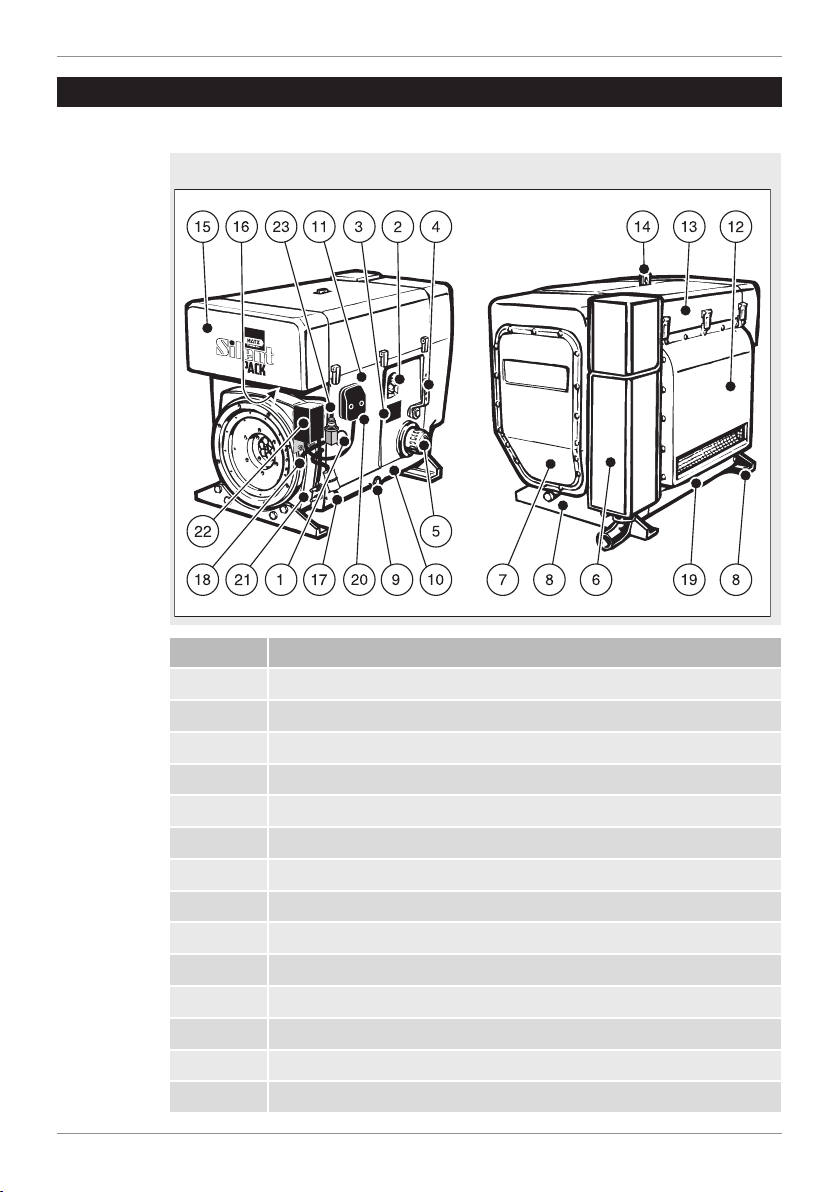

5 Engine design

Engine 2L41C

Encapsulated model "Silent Pack"

26

Pos. Designation

1 Access cap for fuel feed pump

2 Oil filling opening and dipstick

3 Type plate

4 Speed control lever

5 Oil filter

6 Exhaust silencer (encapsulated)

7 Cover for air guide housing (access to cooling fan belt)

8 Engine brackets

9 Oil drain screw

10 Cover plate on operating side

11 Side wall

12 Exhaust air duct

13 Capsule hood

14 Retractable lifting eye, max. load 5000 N

Operator’s Manual

HATZ

2L41C, 2M41, 2M41Z Engine design

Pos. Designation

15 Capsule intake shaft

16 Intake opening for combustion air

17 Fuel feed line with fuel prefilter

18 Fuel return line

19 Cover plate on exhaust side

20 Central connector for electrical equipment

21 Battery connections

22 Powerbox

23 Electrical maintenance switch for air filter

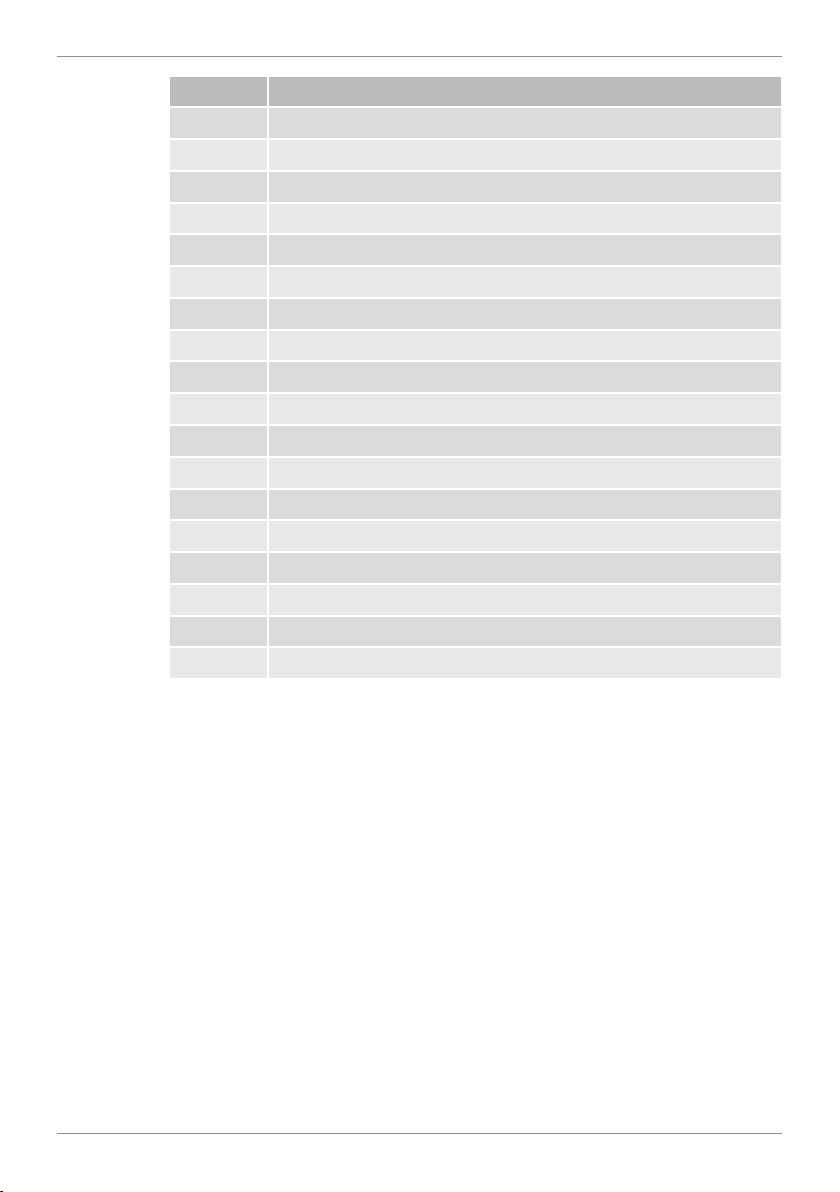

Engine 2M41, 2M41Z

Standard model

HATZ

Pos. Designation

1 Oil filling opening and dipstick

2 Side trim panel

3 Intake opening for combustion air

4 Cooling fan belt

5 Cooling fan with installed three phase alternator

27Operator’s Manual

Engine design 2L41C, 2M41, 2M41Z

Pos. Designation

6 1/2-inch square socket for turning the engine

7 Oil drain screw

8 Speed control lever

9 Oil filter

10 Oil drain screw (on oil sump)

11 Cooling air guide for oil cooler

12 Access cap for fuel feed pump

13 Cylinder head cover

14 Air filter housing cover

15 Lifting eye, max. load 5000 N

16 Fuel return line

17 Fuel feed line with fuel prefilter

18 Type plate

19 Silencer

20 Central connector for electrical equipment

21 Battery connections

22 Powerbox

23 Electrical maintenance switch for air filter

28

Operator’s Manual

HATZ

2L41C, 2M41, 2M41Z Transport, assembly and commissioning

6 Transport, assembly and commissioning

6.1 Transport

Safety notes

WARNING

Danger of injury from improper lifting and transport.

Danger of crushing from falling or tipping of the engine.

▪ Only use the lifting eye already mounted on the machine for

lifting.

▪ Only use a suitable hoist with a sufficient carrying capacity.

▪ Do not remain under suspended loads.

CAUTION

Only use the lifting eye for transporting the engine.

Do not use for lifting the entire machine.

CAUTION

Danger of injury from overloading the body.

Lifting the machine to transport it or to move it to another location can lead to injuries (of the back, for example).

▪ Only lift the machine with a hoist.

HATZ

NOTICE

Danger of environmental damage from leaking fluid.

If the machine is tilted, engine oil and fuel can run out.

▪ Only transport the machine in an upright position.

Transport conditions

▪ When transporting the machine, follow the safety instructions.

▪ When transporting, follow the applicable safety and accident prevention

regulations of the trade associations.

▪ After delivery, check the machine for completeness and transport damage.

▪ Only transport the machine when it is switched off and has cooled down.

▪ If you have questions on transporting the machine, please contact your

nearest HATZ service station. For contact data, see chapter 1 Impres-

sum, page 5 or www.hatz-diesel.com.

29Operator’s Manual

Transport, assembly and commissioning 2L41C, 2M41, 2M41Z

6.2 Installation notes

HATZ diesel engines are efficient, robust and have a long service life. Therefore, they are usually installed in machines that are used for commercial purposes.

The machine manufacturer must follow the applicable regulations regarding

machine safety – the engine is a part of a machine.

Depending on the use and installation of the engine, it may be necessary for

the machine manufacturer and machine user to install safety equipment to

prevent inappropriate use. Note the following:

▪ Parts of the exhaust gas system and the engine surface become hot dur-

ing operation and may not be touched until they cool down after the engine is switched off.

▪ Incorrect cable connections and incorrect operation of the electrical equip-

ment can lead to sparking and must be avoided.

▪ After the engine is installed in the machine, rotating parts must be pro-

tected against contact.

HATZ safety equipment is available for the belt drive of the cooling fan and

alternator.

▪ Comply with all notices and warning labels on the engine and keep them

in a legible condition. If a label should become detached or be difficult to

read, it must be replaced promptly. For this purpose, contact your nearest

HATZ service station.

▪ Any improper modification of the engine results in a loss of liability cover-

age for resulting damage.

Only regular maintenance, as specified in this Operators Manual, will maintain the operating readiness of the engine.

The assembly instructions contain important information on how to safely

assemble the engine. They are available from any Hatz service station.

If you have any questions, please contact your nearest HATZ service sta-

tion before commissioning the engine.

30

Operator’s Manual

HATZ

Loading...

Loading...