Page 1

2G40

2G40 H

33

0000 433 302 06 - ENG - 01.11 - 0.2

Printed in Germany

Translation of the

ORIGINAL INSTRUCTION BOOK

Page 2

A new HATZ Diesel engine - working for you

This engine is intended only for the purpose determined and tested by the manufacturer of the

equipment in which it is installed. Using it in any other manner contravenes the intended purpose.

For danger and damage due to this, Motorenfabrik HATZ assumes no liability. The risk is with the

user only.

Use of this engine in the intended manner presupposes compliance with the maintenance and repair

instructions laid down for it. Noncompliance leads to engine breakdown.

Please do not fail to read this operating manual before starting the engine. This will help you to avoid

accidents, ensure that you operate the engine correctly and assist you in complying with the maintenance intervals in order to ensure long-lasting, reliable performance.

Please pass this Instruction Manual on to the next user or to the following engine owner.

Always have service work performed by qualified specialists. To this effect, we recommend that you

consult one of the 500 HATZ service stations. There, your engine is repaired by staff who constantly

undergo training and who use both original HATZ spare parts and HATZ tools. The world-wide HATZ

service network is also available to you for consultation and spare parts supply.

For the address of your nearest HATZ service station, please refer to the attached list or the internet

under: www.hatz-diesel.com

The installation of inappropriate spare parts may cause problems. We cannnot accept any liability for

damage or consequential damage resulting therefrom.

Thus, we recommend that you use original HATZ spare parts. These parts are manufactured following the strict HATZ specifications and ensure, thanks to their perfect fit and function, maximum operating reliability. For the reference number, please consult the attached spare part list or the internet

under: www.hatz-diesel.com. Please take the complete spare parts kits in Table M00 into account.

We reserve the right to make modifications in the course of technical progress.

MOTORENFABRIK HATZ GMBH & CO KG

1

Page 3

2

Page

1. Important notes on safe operation

of the engine 3

2. Description of the engine 5

3. General information 6

3.1. Technical data 6

3.2. Transport 7

3.3 Instructions for installation 7

3.4. Load on engine 7

3.5. Type plate 8

4. Operation 8

4.1. Before initial start-up 8

4.1.1. Engine oil 8

4.1.2. Oilbath air cleaner 9

4.1.3. Fuel 10

4.2. Starting the engine 11

4.2.1. Preparations for starting 11

4.2.2. Electric starter 11

4.3. Stopping the engine 13

5. Maintenance 14

5.1. Maintenace summary 14

5.2. Maintenance every 8 – 15

hours of operation 16

5.2.1. Check engine oil level 16

5.2.2. Check combustion air intake area 16

5.2.3. Check the cooling air system 17

Page

5.3. Maintenance every 250

hours of operation 18

5.3.1. Maintenance work on oilbath

air cleaner 18

5.3.2. Engine oil change and

oil filter renewal 18

5.3.3. Check and adjust vlave clearances 20

5.3.4. Clean the cooling air system 21

5.3.5. Check threaded connections 22

5.4. Maintenance every 500

hours of operation 22

5.4.1. Renew the fuel filter 22

5.4.2. Dry-type air cleaner maintenance 23

6. Functional test 24

6.1. Air filter maintenance indicators 24

7. Malfunctions – Causes – Remedies 25

8. Work on the electrical system 29

9 . Protective treatment 29

Declaration for Incorporation 30

Contents

This symbol identifies important safety precautions.

Please comply with these most carefully in order to avoid any risk of injury to persons or

damage to materials.

General legal requirements and safety regulations issued by the competent authorities or

industrial accident insurers must also be complied with.

Page 4

1. Important notes on safe operation of the engine

HATZ diesel engines are economical, stronly built and long-lasting. They are therefore frequently

chosen for commercially and industrially operated equipment and machinery.

Since the engine forms part of the finished equipment or machine, its manufacturer will take all the

applicable safety regulations into account.

Nevertheless, we give below certain additional comments on operating safety, and would recommend

you to note them carefully.

Depend on the manner in which the engine is installed and its intended application, the equipment

manufacturer or operator may have to attach additional safety devices and prohibit potentially

hazardous aspects of operation, for example:

– Exhaust system components as well as the surface of the engine will naturally be hot and must not

be touched while the engine is running or until it has cooled down after being stopped.

– Faulty wiring or incorrect operation of electrical equipment may lead to sparks forming, and must

be avoided as a potential fire hazard.

– Rotating parts must be shielded against accidental contact when the engine is installed in other

equipment or machinery.

Guards are available from HATZ to protect belt drives to cooling fans and generators.

– Before attempting to start the engine it is essential to have studied the starting information in the

instruction book.

– Mechanical starting devices must not be used by children or persons of insufficient physical

strength.

– Before starting the engine, ensure that all the specified protective guards are in place.

– The engine must only be operated, serviced or repaired by persons who have received the

appropriate trainig.

– Keep the ignition key out of reach of unauthorized persons.

– Do not run the engine in closed or badly ventilated rooms.

Do not breath in emissions – danger of poisoning!

– Also fuel and lubricants could contain poisonous components. Please follow the instructions of the

mineral oil producer (safety data sheets).

3

Page 5

Important notes on safe operation of the engine

– Stop the engine before performing any maintenance, cleaning- or repair work.

– Stop the engine before refuelling.

Never add fuel near a naked flame or a source of sparks.

Don't smoke. Don't spill fuel.

– Keep explosive materials as well as flammable materials away from the engine because the exhaust

gets very hot during operation.

– Wear close-fitting clothing when working on a running engine.

Please don't wear necklaces, bracelets or any other things which you could get caught with.

– Please pay attention to all advice- and warning stickers placed on the engine and keep them in legi-

ble condition. In case a label has come off or is no longer clearly legible, it must be replaced immediately. To this effect, please contact the HATZ service station in your area.

– Note that any unauthorized modification to the engine absolves its manufacturer from liability for

the consequences.

Regular servicing in accordance with the details provided in this instruction book is essential to keep

the engine operating reliably.

In case of doubt, always consult your nearest HATZ service station before starting the engine.

4

Page 6

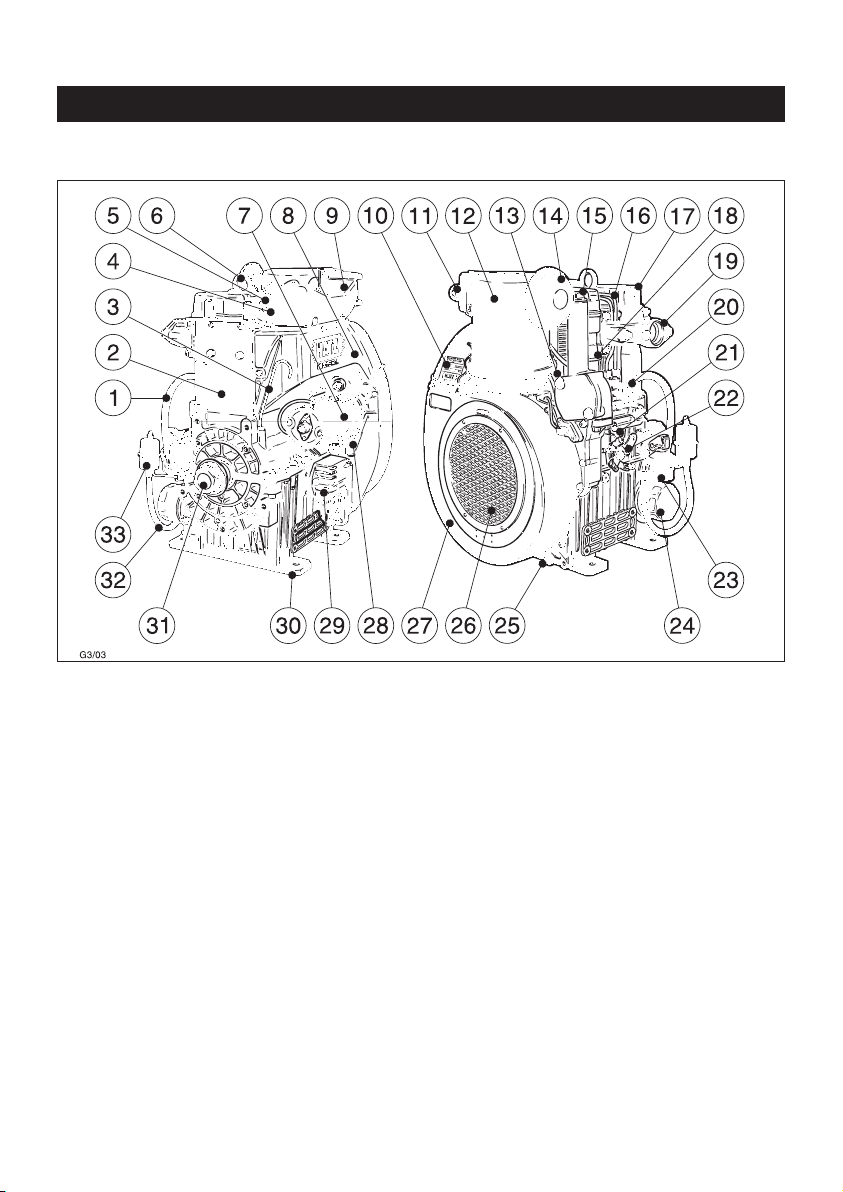

2. Description of the engine

5

Fig. 1

1 Fuel line (feed pump –

fuel-injection pump)

2 Air deflector

3 Oil dipstick

4 Fuel return line

5 Injector

6 Lifting eyebolt

7 Starter motor

8 Air guide

9 Air intake pipe

10 Type plate

11 Glow plug

(additional equipment)

12 Oilbath air cleaner

13 Oil pressure switch

14 Rainproof cap

15 Oil filler cap

16 Fuel pressure pipe

17 Cylinder head cover

18 Engine oil line

19 Exhaust manifold

20 Fuel injection pump

21 Stop lever

22 Speed control lever

23 Fuel feed pump

24 Engine oil filter

25 Oil drain plug

26 Guard

27 Air guide housing

28 Separable connector

29 Voltage regulator

30 Engine mount

31 Crankshaft, power-take-off

32 Fuel line

(fuel filter - feed pump

33 Fuel filter

Page 7

3. General remarks

3.1. Technical data

Type 2G40 / 2G40H

Design Air-cooled four-stroke diesel engine

Combustion system Direct injection

Number of cylinders 2

Bore/stroke mm 92 / 75

Displacement cm³ 997

Engine oil content 2.5 excl. sump

1)

incl. filter renewal l. approx. 3.0 incl. sump

1)

Difference between

„max“ and „min“ levels l. approx. 0.8

1)

Engine oil pressure min. 1 bar at 900 r.p.m. engine speed

Engine oil consumption

(after running-in period) approx. 1% of fuel consumption at full load

Direction of rotation,

power take-off end anti-clockwise

Valve clearances at 10 - 30 °C

Inlet/exhaust mm 0.10

Max. permissible perm. inclination Exhaust Flywheel

Angle of inclination in ° low high low high

without oil sump 30

2)

17

2)

25

2)

25

2)

with oil sump 30 2)17

2)

30

2)

25

2)

Weight (incl. fuel tank, air-cleaner, kg

exhaust silencer and electric starter) approx. 106

Battery capacity min / max 12 V - 45 / 88 Ah • 24 V - 36 / 55 Ah

1)

These values are intended as an approximate guide. The max. marking on the dipstick is the

determining factor, Fig. 6.

2)

Exceeding these limits causes engine breakdown.

6

Page 8

3.2. Transport

2

The lifting eyebolt provided as stand-

ard equipment is intended for safe

movement of the engine.

It is not intended for lifting complete machinery to which the engine is attached, and this is

strictly forbidden.

3.3. Instructions for installation

If you have an engine which is not yet installed

in a machine and still has to be installed, make

sure that the Assembly Instructions for HATZ

Diesel Engines are complied with prior to installation. These Assembly Instructions contain important information about safe assembly of the

engine and are available from your the HATZ

service center in your area.

Pending complete installation, the engine

must not be started !

Moreover, we would like to point out that in this

case, commissioning of the machine is also prohibited until it has been verified that the machine

into which this engine is to be incorporated

complies with all the safety precautions and regulations provided by law.

Refer also to the Declaration for Incorporation

at the end of these Operating Instructions.

3

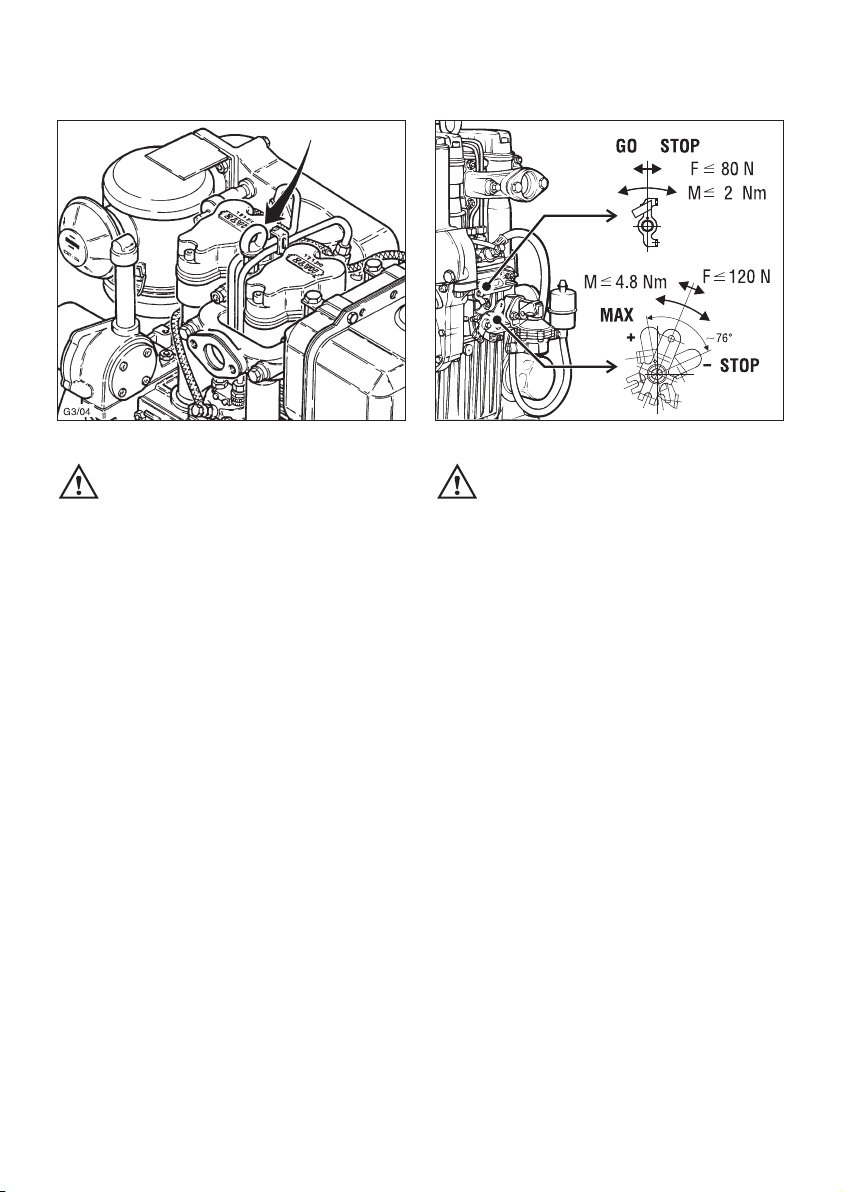

The permitted loads and elements on

the speed adjusting lever and the stop

lever should be observed as an exess can lead

to damage to the contacts and inner governor

parts.

3.4. Load on engine

Operating the engine for a lengthy period offload or at very low loads can affect its running

quality.

We therefore recommend a minimum engine

load of 15 %. If operated at such low loads, it is

best to operate the engine at a significantly higher load for a short period before switching it off.

7

Page 9

8

3.5. Type plate

4

The type plate is placed on the air guide (Fig. 1,

pos. 10) and includes the following engine information:

➀ engine type

➁ code (only for special equipment)

➂ engine number

➃ max. engine speed

For any offer as well as spare parts orders it is

necessary to mention these data (also see spare

parts list, page 1).

➀

➁

➂

➃

4. Operation

4.1. Before initial start-up

Engines are normally delivered without fuel and

oil.

4.1.1. Engine oil

Oil quality

Qualified are all trademark oils which fulfil at

least one of the following specifications:

ACEA – B2 / E2 or more significant

API – CD / CE / CF / CF-4 / CG-4 or more

significant.

If engine oil of a poorer quality is used, reduce

oil change intervals to 150 hours of operation.

Oil viscosity

5

Please select the recommended viscosity depending on the ambient temperature at which

the engine is operated.

Inappropriate engine oil may shorten the

engine’s service life significantly.

-40

-30

-20

-10

0

10

20

30

40

50

104

86

68

50

32

14

-4

-22

-40

OIL: SAE...

°C°F

5W/30

5W/40

10W/40

10W/30

15W/40

30

40

122

10 W

Page 10

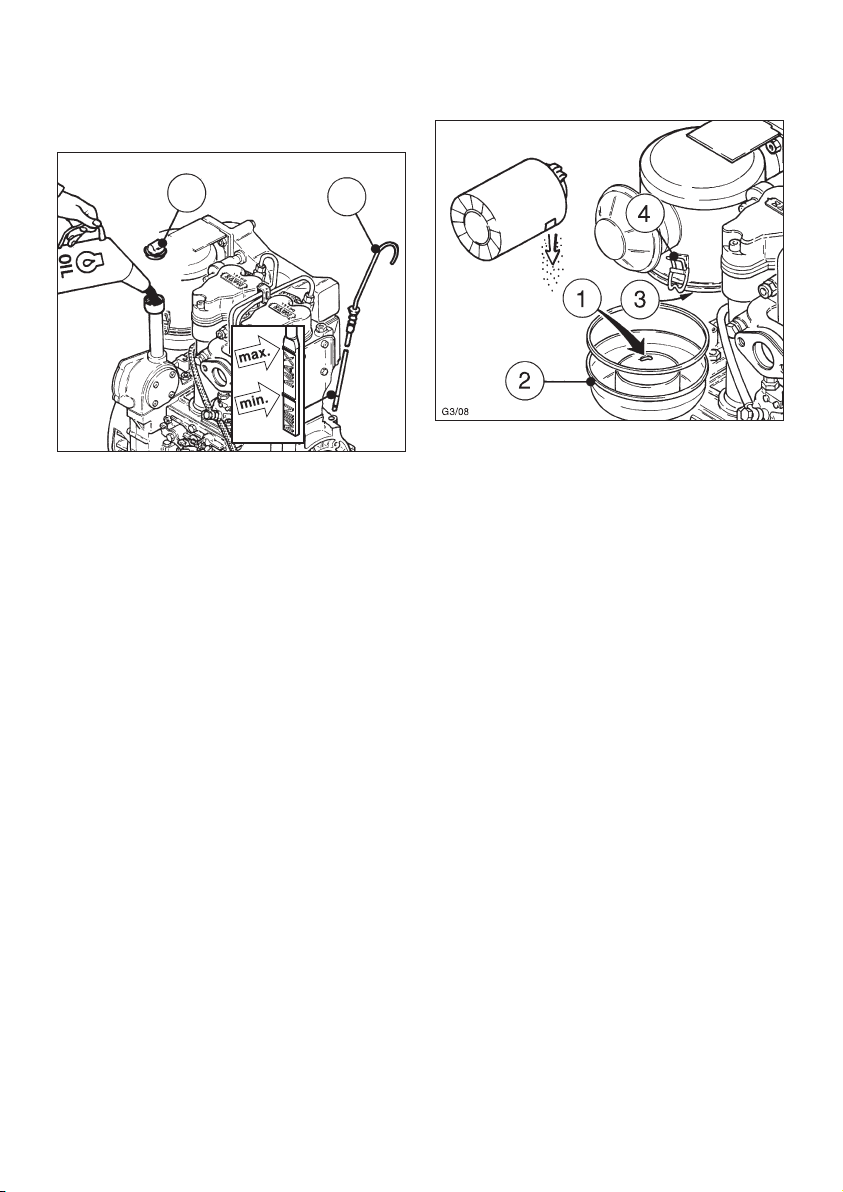

When adding oil or checking the level, the engine must be in a horizontal position.

6

– Remove oil filler screw „1“ and dipstick „2“.

– Add engine oil up to the max. mark on the

dipstick.

Lubricating oil capacity: see Chapter 3.1.

– Insert the oil filler screw and tighten it (hand-

tight only).

Attention !

If the engine is operated while the oil level is

below the min. mark or above the max. mark,

it can cause damage to the engine.

1

2

4.1.2. Oilbath air cleaner

7

If a cyclone-type dust trap is fitted, make sure

that the dust outlet is pointing in the correct

direction.

– Fill the oil tank up to mark „1“ with engine oil.

– Attach oil tank „2“, making sure that sealing

ring „3“ is correctly seated and clips „4“ are

fastened securely.

9

Page 11

4.1.3. Fuel

8

Stop the engine before refuelling.

Never add fuel near a naked flame or

a source of sparks. Don't smoke. Use only pure

fuel and clean filling equipment. Take care not

to spill fuel.

Diesel fuel complying with the minimum requirements of the following specifications may be

used:

EN 590 or

BS 2869 A1 / A2 or

ASTM D 975 - 1D/2D

Important !

The use of fuels of different specifications

requires the prior written consent of the HATZ

headquarters.

9

Before starting for the first time or if the fuel

system was run dry, prime it by operating lever

„1“ on feed pump „2“ until fuel is heard to flow

back into the fuel tank through the return line.

At temperatures below 0 °C, winter-grade fuel

should be used or paraffin added to the fuel well

in advance.

Lowest ambient

temperature when

starting, in °C

Paraffin content for:

Summer Winter

fuel fuel

0 up to –10 20 % –

–10 up to –15 30 % –

–15 up to –20 50 % 20 %

–20 up to –30 – 50 %

10

Page 12

4.2. Starting the engine

Do not run the engine in closed or

badly ventilated rooms – danger of

poisoning!

Before starting the engine, make sure that no

one is within the danger area near the engine

or the machinery it is driving, and that all the

necessary guards are installed.

4.2.1. Preparations for starting

– If possible, disengage the engine from any

driven equipment

The auxiliary equipment should always be

placed in neutral.

10

– Depending on operation conditions and re-

quirements, set speed control lever „1“ to either the 1/2 START or max. START position.

– Make sure that stop lever „2“ is in the off

position „START“.

Start

Run

Stop

Start

Stop

11

Never use starting aids in the form of

aerosols or sprays !

4.2.2. Electric starter

– For starting preparations, see Chapter 4.2.1.

12

– Insert the start key to its stop and turn it to

position I.

Battery charge telltale „2“ and oil pressure

warning light „3“ will come on.

– Turn start key to position II

11

Page 13

– As soon as the engine runs, release the start

key. It must return to position I by itself and

remain in this position during operation.

The battery charge telltale and oil pressure

warning must go out immediately after starting. Indicator light „1“ is on when the engine

is in operation.

– The engine temperature display „4“ (additional

equipment) lights up if the temperature at the

cylinder head becomes too high.

Switch off the engine and trace and eliminate the cause of the problem, chapter 7.

– The air cleaner maintenance indicator „5“

(additional equipment) only lights up during

operation if the air cleaner element needs to

be cleaned or renewed (chapter 5.4.2.).

– Always turn the start key back to position 0

before re-starting the engine. The repeat lock

in the ignition lock prevents the starter motor

from engaging and possibly being damaged

while the engine is still running.

Important !

If a starter protection module is fitted, the key

must be turned back to position 0 for at least

8 seconds if the engine fails to start, before a

second attempt of starting can be made.

Note:

Start for max. 30 seconds. If the engine does

not run after this time, turn starter key back to

position 0 and eliminate the cause, Chapter 7.

Preheating device with automatic heating

timer (additional equipment)

The preheating light „6“ lights up additionally at

temperatures below 0° Celsius (Fig. 12).

– After the light has gone out, start the engine

without delay.

Automatic shut-down function

(additional equipment)

This is characterized by a brief flashing of all

pilot lamps once the starter key has been turned

to position I (Fig. 12).

Important !

If the engine cuts out immediately after starting

or switches off by itself during operation, a monitoring element in the automatic shutdown system has tripped. The corresponding indicator

light (Fig. 12, positions 2 - 4) will come on. After

the engine has stopped, the display continues to

glow for about 2 minutes.

The electrical device then switches itself off automatically.

The display lights up again after the start key

has been turned back to position 0 and then to

position I again.

Trace and eliminate the cause of the

operating fault before trying to restart the

engine (see chapter 7).

The display light goes out when the engine is

next started.

Even with automatic shutdown monitoring the

oil level must be checked every 8 – 15 operating hours (chapter 5.2.1.).

12

Page 14

4.3. Stopping the engine

13

– Move speed control lever „1“ back to the

„STOP“ position.

– On engines with the lower idling speed out of

use, move speed control lever „1“ back, then

move stop lever „2“ towards STOP and hold it

there until the engine has come to a standstill.

– Once the engine is not running any longer,

release the stop lever. The stop lever is returned automatically to its operating position

START via a spring.

Start

Run

Stop

Start

Stop

14

– The battery charge telltale light „2“ and the oil

pressure warning light „3“ come on.

– Turn the starter key back to position „0“ and

pull it out. The telltale and warning lights must

go out.

Note:

Engines with an automatic electrical shutdown

system can also be stopped by turning the

starter key back to positon „0“.

During breaks in operation or at the

end of the work session, pull out the

starter key and keep in a safe place where it

cannot be reached by unauthorized persons.

3

2

13

Page 15

14

5. Maintenance

5.1. Maintenance summary

Maintenance interval Maintenance work required Chap.

The engine must be stopped before any maintenace work is attempted.

Comply with legal requirements when handling and disposing of old oil, filters and

cleaning materials.

Keep the engine's starting key and starting handle out of reach of unauthorized persons.

To immobilize engines with an electric starter, disconnect the negative battery terminal.

At the end of the maintnance work, check that all tools have been removed from the engine and

all safety guards, covers etc. replaced in their correct positions.

Before starting the engine, make sure that no-one is in the danger area (engine or driven

machinery).

Every 8 – 15

operating hours or

before daily starting

Check oil level.

Check area around combustion air input.

Check cooling air system.

Check that the oil level in the lower part of the

oil bath air cleaner is correct and that the oil is

not contaminated.

5.2.1.

5.2.2.

5.2.3.

4.1.2.

5.3.1.

Every 250

operating hours

Maintenance of air filter/oil bath air filter.

Replace engine oil and oil filter.

Check and adjust valve clearances.

Clean cooling air system.

Examine screw connections.

5.3.1.

5.3.2.

5.3.3.

5.3.4.

5.3.5.

Every 500

operation hours

Renew fuel filter.

Maintenance of air filter/dry-air filter

5.4.1.

5.4.2.

250

500

8-15

Page 16

The above maintenance chart is supplied with

every engine. This label should be affixed to the

engine or equipment in an easily visible position.

The maintenance chart governs the maintenance

intervals.

For new or reconditioned engines, the following

must always be carried out after the first 25

operating hours.

– Replace engine oil and oil filter, chap. 5.3.2.

– Check tappet clearance, and adjust if necess-

ary, chap. 5.3.3.

– Examine screw connections, chap. 5.3.5.

For short operating periods: replace engine oil

and oil filter after 12 months at the latest,

regardless of the number of operating hours.

15

Page 17

5.2. Maintenance work every 8 – 15

operating hours

5.2.1. Check engine oil level

When the oil level is checked, the engine must

be stopped and in a horizontal position.

– Remove any dirt in the dipstick area.

15

– For oil level inspection, remove the dipstick „2“

and wipe it dry using a lint-free, clean piece of

cloth; then insert it to its stop and pull it out

again.

– Check oil level at the dipstick; top up if

necessary as far as the „max“ mark (see

Chapter 4.1.1.).

Attention !

If the engine is operated while the oil level is

below the min. mark or above the max. mark, it

can cause damage to the engine.

5.2.2. Check combustion air intake area

Heavy contamination is an indication that increased dust accumulation necessitates a correspondingly shorter maintenance interval,

Chapter 5.3.1. and 5.4.2.

1

2

With oilbath air cleaner:

16

– Inspect air inlets „1“ (depending on version)

for severe dirt and dust deposits, and clean if

necessary.

– Make sure that dust outlet „2“ on the

cyclone-type dust trap (depending on version)

is not obstructed, and clean if necessary

(chap. 5.3.1.).

With dry-type air cleaner:

17

– Inspect air inlets „1“ and clean if necessary.

– Check that dust discharge valve „2“ is not ob-

structed; eliminate dust blockage by pressing

together as shown.

16

Page 18

17

– Check that connecting hose „3“ and hose clips

„4“ are in good condition and not leaking

(fig. 17).

18

– Run the engine up to maximum speed briefly

and check that indicator lamp „1“ (depending

on version) comes on briefly or that the red

zone is visible in maintenance indicator „3“.

1

5.2.3. Check the cooling air system

Heavy contamination is an indication that increased dust accumulation necessitates acorrespondingly shorter maintenance interval.

19

– Inspect air inlets and outlets for coarse soiling

such as leaves, dust accumulation etc., clean if

necessary (chap. 5.3.4.).

The temperature indicator „1“ – if installed – will

light up as soon as the engine becomes

too hot.

Shut down the engine immediately !

Page 19

5.3. Maintenance work every 250

operating hours

5.3.1. Maintenance work on oilbath

air cleaner

20

Trap the old oil and dispose of it in

accordance with local legislation.

– Take off the oil tank „1“.

– Remove contaminated oil and sludge from the

oil tank, and clean it out.

– Take off rain cap „2“ or cyclone-type dust trap

„3“, and clean.

– Clean right through intake pipe „4“

– Check condition of sealing ring „5“ and renew

if necessary.

– Add engine oil to the oil tank up to mark „6“

and re-assemble the oilbath air cleaner

(fig. 20, chap. 4.1.2.).

If the filter packing is severely contaminated with

dust and dirt, the upper part of the air cleaner

must also be cleaned as follows:

21

– Detach upper part of air cleaner „1“ from

engine and rinse in diesel fuel.

– Allow the diesel fuel drip off thoroughly, or

wipe it off, before re-assembling.

– Install a new filter packing if the sealing sur-

face is uneven, the body of the filter is cracked

and/or filter wool is missing.

– Install the upper part of the air cleaner, using a

new flange gasket „3“.

– Re-assemble the remaining parts of the air

cleaner and fill with oil to prepare for further

operation (chap. 4.1.2.).

5.3.2. Engine oil change and

oil filter renewal

The engine must be stopped and in a horizontal

position.

Drain the engine oil only when the engine is

warm.

Danger of scalding from hot oil !

Trap the old oil and dispose of it in

accordance with local legislation.

2

1

3

18

Page 20

22

23

– Take out drain plug „1“ and allow the oil to

drain out completely (fig. 22 without oil sump,

fig. 23 with oil sump).

– Insert oil drain plug „1“ with a new sealing

ring „2“ and tighten.

24

– Slacken off and unscrew the throwaway engine

oil filter using HATZ strap wrench „1“, Order

No. 620 307 01, or a similar tool.

25

– Use a screwdriver to lift mesh screen „1“,

which is located behind the filter element,

away from the oil pressure relief valve.

Do not damage contact face „2“.

– Clean mesh screen „1“ from the inside by

blowing through with compressed air.

Persons handling compressed air must

wear protective goggles. Never direct

the jet to animals, persons or yourself !

1

G3/28

2

19

Page 21

– After cleaning, press the mesh screen back on

to the oil pressure relief valve.

26

– Clean sealing face „1“ thoroughly.

– Never re-use the throwaway filter element.

Oil sealing ring „2“ on the new filter element

lightly.

– Screw in throwaway filter element „3“

handtight.

– Add engine oil (chap. 4.1.1.).

– Run the engine briefly to check that there

are no leaks at the oil filter; take up slack if

necessary.

– Check the oil level; add oil if necessary

(chap. 5.2.1.).

5.3.3. Check and adjust vlave clearances

– Adjust only when the engine is cold

(10 - 30 °C).

– Remove any dirt from the area where the

cover is attached to the cylinder head.

27

– Remove screws „1“ and take off cover „3“

complete with sealing rings „2“ and „4“.

Never re-use these sealing rings.

Adjusting procedure:

– Cylinder 1 is at the flywheel end; clockwise

rotation.

Cylinder 2 is at the power take-off end; anticlockwise rotation.

– Turn the engine in its normal direction of rota-

tion until the valves in cylinder 2 are in the

overlap position (exhaust valve not yet closed,

inlet valve starts to open).

– Turn the crankshaft through 180 degrees in the

normal direction of rotation, then check valve

clearances for cylinder 1 and adjust if necessary.

– Turn the crankshaft through a further 180 de-

grees; check valve clearances for cylinder 2

and adjust if necessary.

20

Page 22

Adjusting:

– Measure valve clearance with 0.10 mm feeler

gauge „5“ (fig. 27, chapt. 3.1.).

– If adjustment is necessary, slacken off hex nut

„6“, turn adjusting screw „7“ and retighten nut

„6“. It should then be possible to pull feeler

gauge „5“ through with just perceptible resistance to movement (fig. 27).

– Replace the cover in position and tighten it

down uniformly.

– Run the engine briefly to check that there are

no leaks at the cover.

5.3.4. Clean the cooling air system

28

– Take off all air guides.

If dirt deposits are dry:

– Clean all air guides and the entire cooling air

system including cylinder heads, cylinders and

flywheel blades without making them wet, and

blow them through with compressed air.

Persons handling compressed air must

wear protective goggles. Never direct

the jet to animals, persons or yourself !

If dirt deposits are damp or oily:

– Disconnect the battery.

– Apply a detergent solution (cold cleaner or

similar) to the entire system in accordance

with the manufacturer's instructions, then

spray off with a powerful water jet.

Do not splash electrical device with water jet

or pressure jet during engine cleaning.

– Establish the cause of contamination with oil

and have any leaks repaired.

Re-attach all air guides.

The engine must never be run without

the air guides.

– Run the engine immediately after re-assembly

until it is warm; this will prevent rust from

forming.

21

Page 23

5.3.5. Check threaded connections

Check the condition and tightness of all threaded

connections, pipes and lines, hose clips and

other fastenings on the engine or its mountings

which can be reached during maintenance work.

Do not tighten the cylinder head bolts.

29

The adjusting screws at the engine

governor and on the injection system

are sealed with lacquer or with lead and are

not to be tightened or adjusted.

5.4. Maintenance work every 500

hours of operation

5.4.1. Renew the fuel filter

The maintenance intervals for the fuel filter are

dependent upon the purity of the diesel oil being

used and, if necessary, may have to be reduced

to 250 hours.

When working on the fuel system, do

not expose it to naked flames; do not

smoke.

Important !

Keep the entire area clean so that no dirt

reaches the fuel. Fuel particles may damage

the injection system.

– Shut off the fuel supply.

30

– Pull fuel feed line „1“ off fuel filter „2“ at both

sides, and insert a new filter. Make sure that

the direction of fuel flow is as shown by the

arrows.

– Open up the fuel supply again and if necessary

operate the priming pump (chap. 4.1.3.).

– Run the engine briefly to check that there are

no leaks at the fuel filter and fuel lines.

22

Page 24

5.4.2. Dry-type air cleaner maintenance

It is best to clean the filter cartridge only when

the maintenance indicator displays the appropriate signal. This is only the case if the maintenance indicator functions properly (chap. 6.1.).

Apart from this, the cartridge should be renewed

after 500 hours of operation.

31

– Take off rain cap „1“ and clean it.

– Slacken off wingnut „2“ and remove cover „3“

with dust discharge valve „4“.

– Examine the cover and dust discharge valve

for distortion, aging and cracks; renew if

necessary.

– Unscrew and remove collar nut „5“.

– Carefully pull out filter element „6“.

– The cartridge may no longer be used if there is

damage to the filter „6“ or in the area of the lip

seal „7“.

– Pull guide „8“ out of filter housing „9“.

– Clean all parts except the filter element.

Make sure that dirt or other foreign matter

cannot enter the engine air intake port.

Cleaning the filter cartridge

Dry contamination

32

– Using a compressed-air pistol with a bent tube

insert, blow through the cartridge from the inside with dry compressed air, moving up and

down, until no more dust is emitted.

Important !

The pressure must not exceed max. 5 bar.

Persons handling compressed air must

wear protective goggles. Never direct

the jet to animals, persons or yourself !

Wet or oily contamination

Replace the filter cartridge.

– Assembly is carried out in reverse order.

Check the seal insert of collar nut „5“, replace

the collar nut if the seal insert is missing. Ensure

that the dust extractor valve is correctly positioned downwards (fig. 31).

– When the filter has been installed, unlock

maintenance indicator „3“ – if installed – by

pressing reset button „4“ (fig. 33).

23

Page 25

6. Functional test

6.1. Air filter maintenance indicators

(only on version with Dry-type

air cleaner)

For electrical indicator

33

– Unscrew maintenance switch „2“ then recon-

nect to the on-board electric system.

34

– Turn the ignition key to position I.

1

– Create a vacuum at the maintenance switch

with powerful suction, indicator lamp „1“ must

light up (fig. 33).

– If there is no reaction, check cable connectors

and replace filament lamp and/or maintenance

switch if necessary.

For mechanical indicator

– Unscrew maintenance indicator „3“ (fig. 33).

– Create a vacuum at the maintenance indicator

with powerful suction, the visible red area

must latch in, replace maintenance indicator if

necessary.

– Before putting into operation, unlock mainte-

nance indicator „3“ with reset button „4“

24

Page 26

7. Malfunctions – causes and remedies

Malfunctions Possible causes Remedy Chap.

25

The engine does

not start or not immediately, can

however be turned

over with the

starter motor.

At low

temperatures.

Speed adjustment lever in the

stop or idle position.

Stop lever in stop position.

No fuel at the fuel-injection

pump.

Insufficient compression:

- Wrong valve clearances

- Worn out cylinders and/or

piston rings.

Unserviceable injector jets.

Below the start-limit temperatures.

Device not disengaged.

Glow-plug equipment defective

(additional equipment).

Fuel flocculent due to inadequate cold stability.

Move the lever in START

position.

Fill up with fuel.

Check the complete fuel supply

system systematically. If no result, check:

- fuel supply line to the engine.

- fuel filter.

- function of the feed pump.

Check valve clearances, adjust if

necessary.

See workshop manual.

See workshop manual.

Operate glow-plug equipment

(additional equipment).

Disengage the engine from the

device - if possible.

See workshop manual.

Pull out the return line and

check whether clear, uncloudy

fuel comes out when operating

the feed pump.

If the fuel is flocculent, either

warm up the engine or drain off

the complete fuel supply system.

Refill with temperature-resistant

fuel mixture.

4.2.1.

4.1.3.

5.4.1.

4.1.3.

5.3.3.

4.2.2.

4.1.3.

4.1.3.

Page 27

Malfunctions Possible causes Remedy Chap.

26

At low

temperatures.

Starter motor does

not operate or engine does not turn

over.

Engine ignites, but

stops running as

soon as the starter

motor is disengaged.

In addition, if automatic electrical engine shutdown is

installed.

Starting speed too low:

- Oil too viscous.

- Battery inadequately charged.

Descrepancies in the electrical

system:

- Battery and/or other cable

connections wrongly connected.

- Loose and/or oxidized cable

connections.

- Battery defective and/or not

charged.

- Stater motor defective.

- Defective relays, monitoring

elements etc.

Speed control lever not located

far enough in the start direction.

Device not disengaged.

Fuel filter blocked.

Fuel supply interrupted.

Stop signal from monitoring element for automatic shutdown

system (optional extra):

- oil pressure lost

- cylinder head temperature

too high.

- alternator has failed.

Replace and fill up with oil.

Check the battery, if necessary

contact a service station.

Check the electical system and

its components or contact HATZ

service station !

Move the lever to START position.

Disengage the engine from the

device if possible.

Replace fuel filter.

Check the entire fuel supply

systematically.

Check oil level.

Clean cooling air system.

See workshop manual.

5.3.2.

4.1.1.

8.

8.

4.2.1.

5.4.1.

5.2.1.

5.3.4.

Page 28

Malfunctions Possible causes Remedy Chap.

27

Engine shuts down

independently during operation.

In addition, if automatic electrical engine shutdown is

installed.

Drop off in performance and speed

of the engine.

Fuel supply interrupted:

- Tank run dry

- Fuel filter blocked.

- Fuel feed pump defective.

Mechanical malfunctions.

Stop signal from monitoring

element because of:

- oil pressure too low.

- cylinder head temperature

too high.

- alternator has failed.

Malfunction signal from overvoltage and polarity reversal

protection in voltage regulator:

- Battery and/or other cable

connections incorrectly connected.

- Cable connections loose.

Fuel supply detrimentally

affected:

- Tank run dry.

- Fuel filter blocked.

- Inadequate tank ventilation.

- Line connections leaky.

- The speed control lever does

not remain in the required

position.

Fill up with fuel.

Replace fuel filter.

Check the entire fuel supply

system.

Contact a HATZ service station.

Check engine for:

Engine oil level

Cooling air passages blocked

or cooling system otherwise

affected.

See workshop manual.

Check electrical equipment and

the components thereof.

Fill up with fuel.

Replace fuel filter.

Ensure adequate ventilation of

the tank.

Check the line screw-connections for leaks.

Block the speed control.

4.1.3.

5.4.1.

4.1.3.

5.2.1.

5.3.4.

4.1.3.

5.4.1.

Page 29

28

Malfunctions Possible causes Remedy Chap.

Drop off in engine

performance and

speed, black

smoke from the

exhaust.

Engine runs very

hot, the indicator

lamp for cylinder

head temperatur

(additional equipment) comes on.

Air filter contaminated.

Incorrect valve clearances.

Injector jets unserviceable.

Too much oil in the engine.

Inadequate cooling:

- Contamination in the entire

area for the air guides.

- Insufficiently enclosed air

guides.

Clean air filter.

Adjust valve clearances.

See workshop manual.

Drain off oil to the upper mark

on the dipstick.

Clean the area of cooling air.

Check that the air guides and

shafts are complete and that

they are sealed.

5.3.1.

5.4.2.

5.3.3.

5.3.2.

5.3.4.

Page 30

8. Work on the electrical

system

Batteries generate explosive gases.

Keep them away from naked flame and

sparks which could cause them to ignite.

Do not smoke.

Protect eyes, skin and cloth against the corrosive battery acid. Pour clear water over acid

splashes immediately. In case of emergency

call doctor.

Do not place any tools on top of the battery.

Always disconnect the negative (–) pole of the

battery before working on the electric device.

– The positive (+) and negative (–) battery ter-

minals must not be accidentally interchanged.

– When installing the battery, connect the posi-

tive lead first, followed by the negative lead.

Negative pole to earth (ground) on engine

block.

– When removing the battery, disconnect the

negative lead first, followed by the positive

lead.

– In all circumstances, avoid short circuits and

shorts to earth (ground) at life cables.

– If electrical faults occur, first check for good

contact at the cable connections.

– Replace a failed indicator light without delay.

– Do not take the key out while the engine is

running.

– Never disconnect the battery while the engine

is running. Electric voltage peaks can cause

damage to electrical components.

– Do not splash electrical device with water jet

or pressure jet during engine cleaning.

– When carrying out welding work on the en-

gine or attached equipment, attach the earth

(ground) clip as near as possible to the welding point, and disconnect the battery. If an alternator is fitted, separate the plug connector

leading to the voltage regulator.

The relevant circuit diagrams are supplied with

engines which have an electrical system. Additional copies of circuit diagrams can be obtained

on request.

HATZ assumes no liability for electrical systems

which was not carried out acc. HATZ circuit diagrams.

9. Protective treatment

A new engine can normally be stored for up to

12 months in a dry place. If atmospheric humidity is high (or if exposed to sea air), protection is sufficient for about 6 months’ storage.

If the engine is to be stored for a longer period,

or laid up out of use, please consult the nearest

HATZ service point.

29

Page 31

30

Page 32

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its

constituents are known to the State

of California to cause cancer, birth

defects, and other reproductive harm.

Loading...

Loading...