Hatz Diesel 2-4L41C, 2-4M41, 4L42C, 4M42 Instruction Book

INSTRUCTION BOOK

433 416 06-USA-EPA IV-CARB

1.08 - 0.1

Printed in Germany

33

2-4L41C

2-4M41.

4L42C

4M42

INCLUDES SUPPLEMENTAL INFORMATION TO THE

OWNER’S MANUAL FOR 2008 AND LATER EPA CERTIFIED

NONROAD COMPRESSION-IGNITION ENGINES

INCLUDES SUPPLEMENTAL INFORMATION TO THE

OWNER’S MANUAL FOR 2008 AND LATER CALIFORNIA

REGULATIONS FOR HEAVY-DUTY OFF-ROAD ENGINES

A new HATZ Diesel engine - working for you

This engine is intended only for the purpose determined and tested by the manufacturer of the

equipment in which it is installed. Using it in any other manner contravenes the intended purpose.

For danger and damage due to this, Motorenfabrik HATZ assumes no liability. The risk is with the

user only. Use of this engine in the intended manner presupposes compliance with the maintenance

and repair instructions laid down for it. Noncompliance leads to engine breakdown.

Please do not fail to read this operating manual before starting the engine. This will help you to avoid

accidents, ensure that you operate the engine correctly and assist you in complying with the maintenance intervals in order to ensure long-lasting, reliable performance.

Please follow all maintenance references carefully including the schedule for 2008 and later

EPA certified nonroad compression-ignition engines and for 2008 and later CARB certified

Heavy-Duty off-road engines to prevent our environment.

Please pass this Instruction Manual on to the next user or to the following engine owner.

The worldwide HATZ Service Network is at your disposal to advise you, supply with spare parts and

undertake servicing work.

You will find the address of your nearest HATZ service station in the enclosed list.

Use only original spare parts from HATZ. Only these parts guarantee a perfect dimensional stability

and quality. The order numbers can be found in the enclosed spare parts list. Please note the spare

part kits shown in Table M00.

We reserve the right to make modifications in the course of technical progress.

MOTORENFABRIK HATZ GMBH & CO KG

1

Contents

Page

1. Important notes on safe operation of the engine 3

2. Description of engine 5

3. General information 9

3.1. Technical data

3.2. Transport

3.3 Installation instructions

3.4. Load on engine

3.5. EPA/CARB-type plates and fuel label

3.6. Emission-related installation

instructions

4. Operation 12

4.1. Before initial start-up

4.2. Starting the engine

4.3. Stopping the engine

5. Maintenance 21

5.1. Maintenance summary

5.2. Maintenance every 8 - 15 hours of operation

5.3. Maintenance every 250 hours of operation

5.4. Maintenance every 500 hours of operation

5.5. Maintenance every 1000 hours of operation

6. Operating checks and repair work 37

6.1. Checking operation of air cleaner maintenance indicator

6.2. Renewing fan drive belt, checking operation of belt monitor

7. Malfunctions – causes and remedies 41

8. Work on the electrical system 45

9. Protective treatment 45

SUPPLEMENTAL INFORMATION TO THE OWNER’S MANUAL FOR 2008 AND LATER

EPA CERTIFIED NONROAD COMPRESSION IGNITION ENGINES 47

SUPPLEMENTAL INFORMATION TO THE OWNER’S MANUAL FOR 2008

AND LATER CALIFORNIA REGULATIONS FOR HEAVY-DUTY OFF-ROAD ENGINES 65

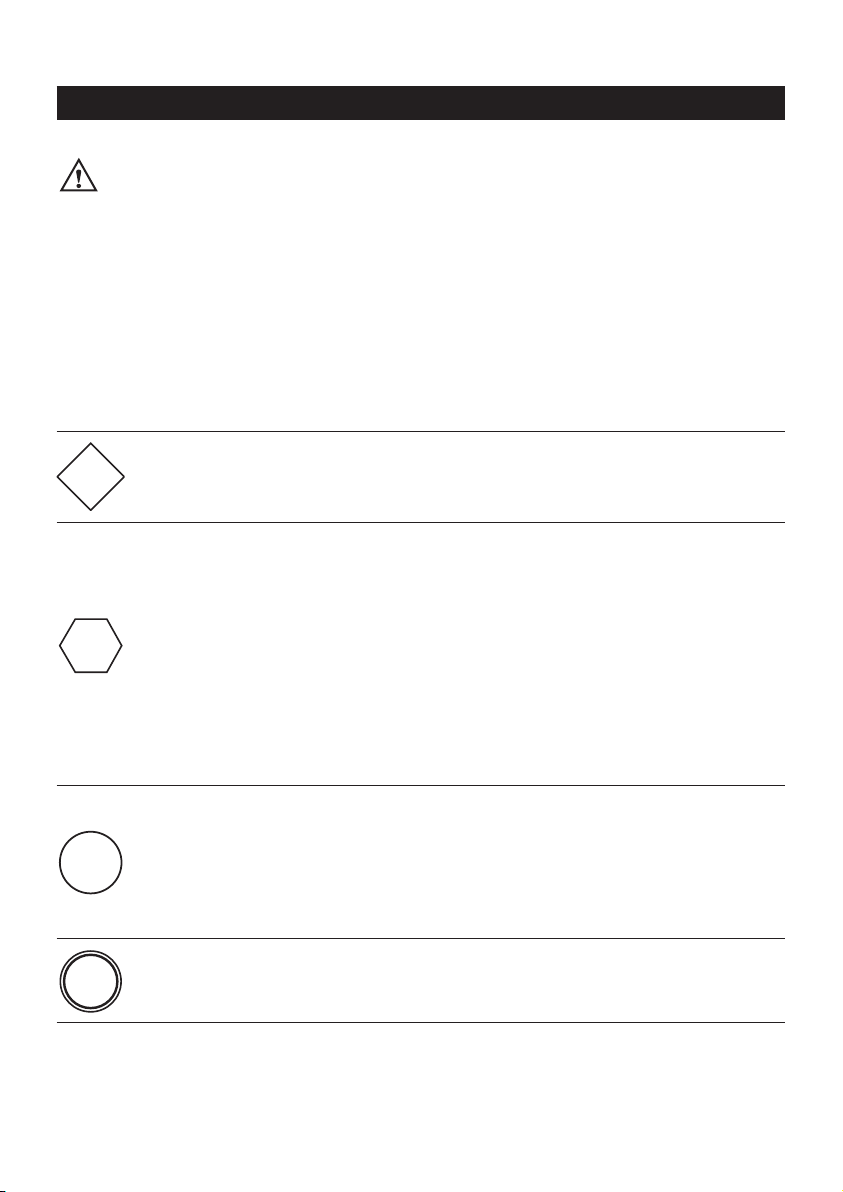

This symbol draws attention to important safety precautions.

Please comply with them most carefully in order to avoid any risk of injury to persons or

damage to materials.

General legal requirements or safety regulations issued by the competent authorities or

industrial accident insurers are also applicable.

2

1. Important notes on safe operation of the engine

HATZ diesel engines are economical, strongly built and long-lasting. They are therefore frequently

chosen for commercially and industrially operated equipment and machinery.

If the engine forms part of the finished equipment or machine, its manufacturer will take all the applicable safety regulations into account.

Nevertheless, we would like you to note certain additional comments on operating safety which

follow. Depending on the manner in which the engine is installed and its intended application, the

equipment manufacturer or operator may have to attach additional safety devices and prohibit potentially hazardous aspects of operation, for example:

– Exhaust system components as well as the surface of the engine will naturally be hot and must not

be touched while the engine is running or until it has cooled down after being stopped.

– Faulty wiring or incorrect operation of electrical equipment may lead to sparks forming, and must

be avoided as a potential fire hazard.

– Rotating parts must be shielded so that they cannot be touched accidentally when the engine is in-

stalled in other equipment or machinery.

Guards are available from HATZ to protect belt drives for cooling fans and generators.

– Before attempting to start the engine it is essential to have studied the starting information in the

Instruction Book.

– Mechanical starting devices must not be used by children or persons of insufficient physical

strength.

– In order to benefit from the advantages of the starting handle with kick-back damping, it must be

used precisely as recommended in this Instruction Book.

– Before starting the engine, ensure that all the specified protective guards are in place.

– The engine must only be operated, serviced or repaired by persons who have received the appro-

priate training.

– Keep the starting handle and the key out of reach of unauthorized persons.

– Do not run the engine in closed or badly ventilated rooms.

Do not breath in emissions – danger of poisoning!

– Also fuel and lubricants could contain poisonous components. Please follow the instructions of the

mineral oil producer.

3

Important notes on safe operation of the engine

– Stop the engine before performing any maintenance, cleaning- and repair work.

– Stop the engine before refuelling.

Never refuel near a naked flame or sparks which could start a fire. Don’t smoke. Don’t spill fuel.

– Keep explosive materials as well as flammable materials away from the engine because the exhaust

gets very hot during operation.

– Wear close-fitting clothing when working on the engine while it is running.

Please don’t wear necklaces, bracelets or any other things which you could get caught with.

– Please pay attention to all advice- and warning stickers placed on the engine and keep them in legi-

ble condition. Contact your next HATZ service station, if a sticker comes off or is illegible and ask

for a new one.

– Note that any unauthorized modifications to the engine absolve its manufacturer from liability for

the consequences.

Regular servicing in accordance with the details provided in this Instruction Book is essential to keep

the operating reliably and to ensure the exhaust quality of the engine.

In case of doubt, always consult your nearest HATZ service station before starting the engine.

4

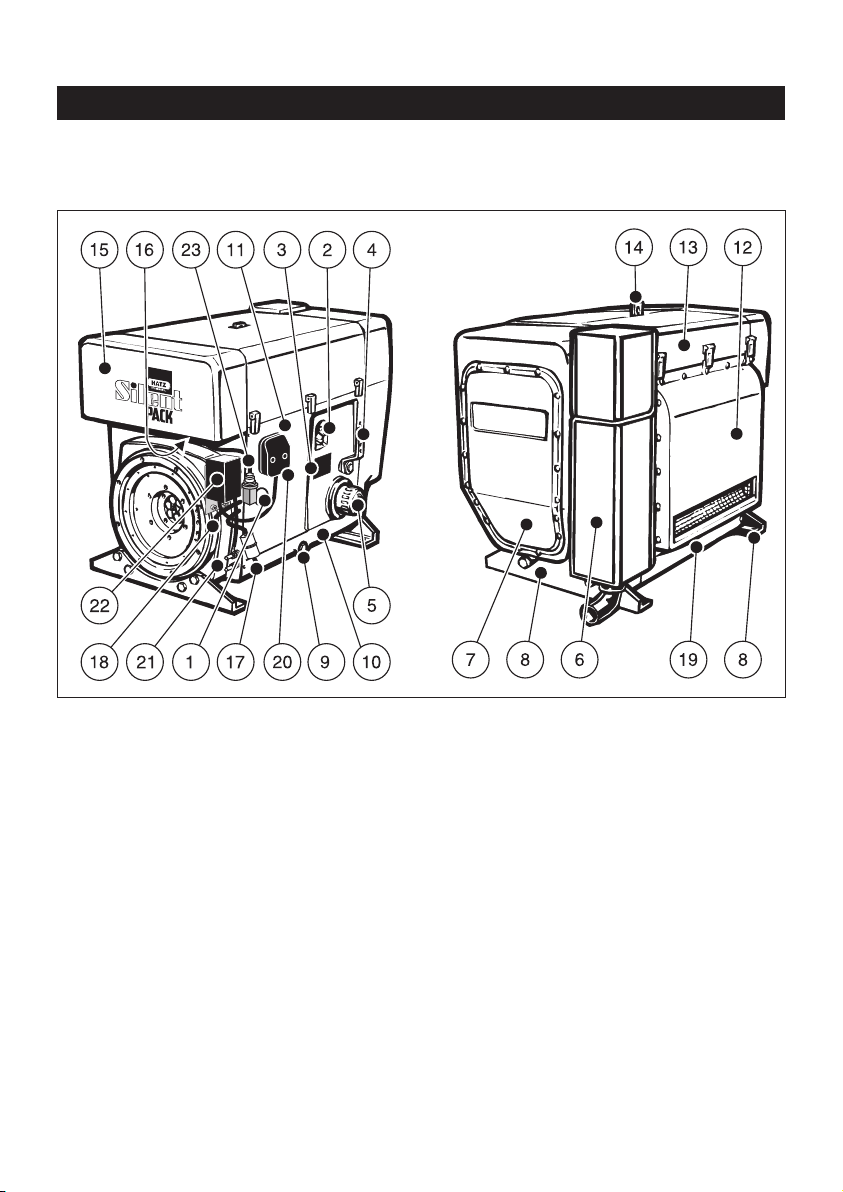

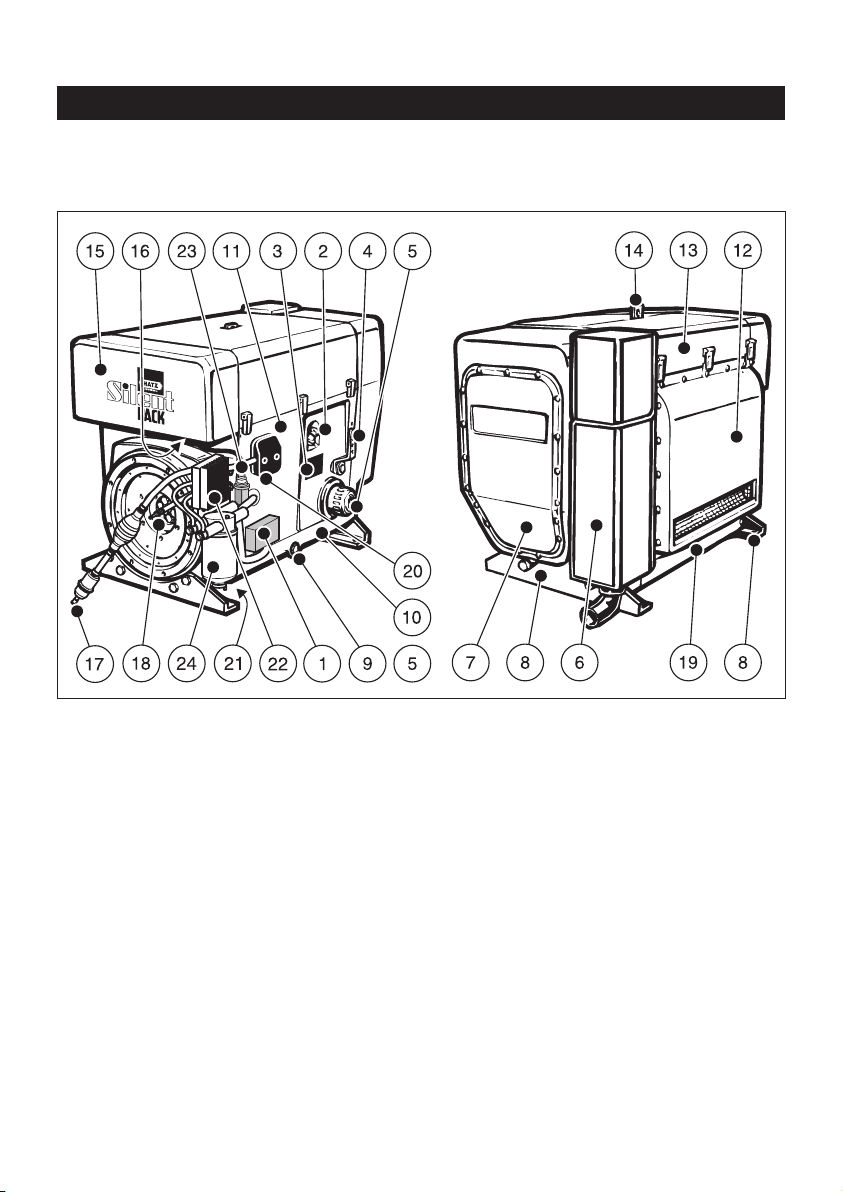

2. Description of engine

Fully encapsulated „Silent Pack“ version

Engine 2 ...4L41C

5

1

1 Access cover for fuel delivery pump

2 Oil filler pipe and dipstick

3 Type plate

4 Speed control lever

5 Replaceable-element oil filter

6 Exhaust silencer (in capsule)

7 Cover for air guide housing

(Access to fan drive belt)

8 Engine support feet

9 Oil drain plug

10 Cover plate, control side

11 Side panel

12 Air outlet duct

13 Capsule hood

14 Suspension lug (retractable),

max. load 5000 N

15 Air intake duct for capsule

16 Combustion air intake aperture

17 Fuel feed line with fuel pre-filter

18 Fuel return line

19 Cover plate, air outlet side

20 Central plug for electrical system

21 Battery connections

22 Power-Box

23 Electrical maintenance switch for

air cleaner

Description of engine

Fully encapsulated „Silent Pack“ version

Engine 4 L 42 C

6

1 Electronic control unit

2 Oil filler pipe and dipstick

3 Type plate

4 Speed control lever

5 Replaceable-element oil filter

6 Exhaust silencer (in capsule)

7 Cover for air guide housing

(Access to fan drive belt)

8 Engine support feet

9 Oil drain plug

10 Cover plate, control side

11 Side panel

12 Air outlet duct

13 Capsule hood

14 Suspension lug (retractable),

max. load 5000 N

15 Air intake duct for capsule

16 Combustion air intake aperture

17 Fuel feed line with fuel pre-filter and

manual fuel pump

18 Fuel return line

19 Cover plate, air outlet side

20 Central plug for electrical system

21 Battery connections

22 Power-Box

23 Electrical maintenance switch for

air cleaner

24 Fuel filter

2

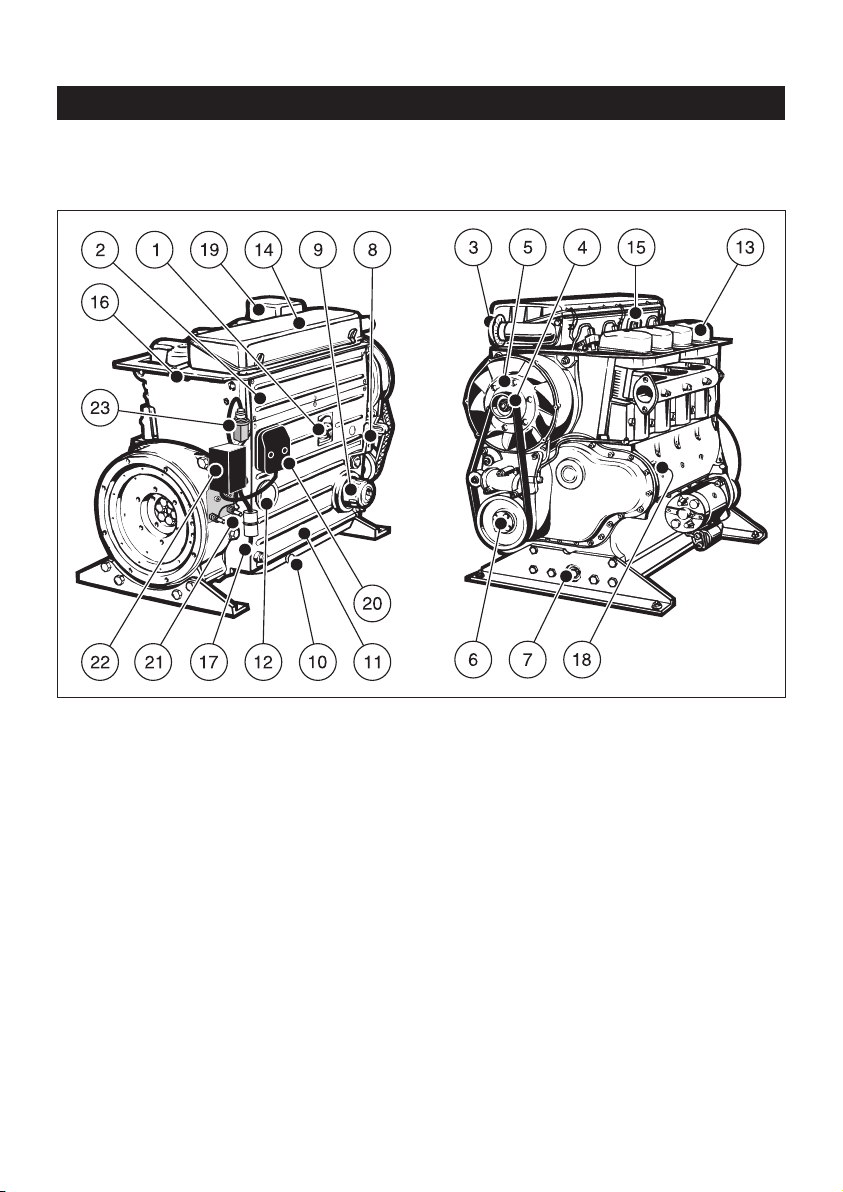

Description of engine

Standard version

Engine 2 ... 4 M 41 • 2 ... 4M41Z

7

3

1 Oil filler pipe and dipstick

2 Side panel

3 Combustion air intake aperture

4 Cooling fan drive belt

5 Cooling fan with alternator attached

6 1/2-inch intl. hex socket for turning over

engine

7 Oil drain plug

8 Speed control lever

9 Replaceable-element oil filter

10 Oil drain plug (if sump is fitted)

11 Cooling air duct for engine oil cooler

12 Access cover for fuel delivery pump

13 Cylinder head cover

14 Air cleaner cover

15 Suspension lug, max. load 5000 N

16 Fuel return line

17 Fuel feed line with fuel pre-filter

18 Type plate

19 Exhaust silencer

20 Central plug for electrical system

21 Battery connections

22 Power-Box

23 Electrical maintenance switch for

air cleaner

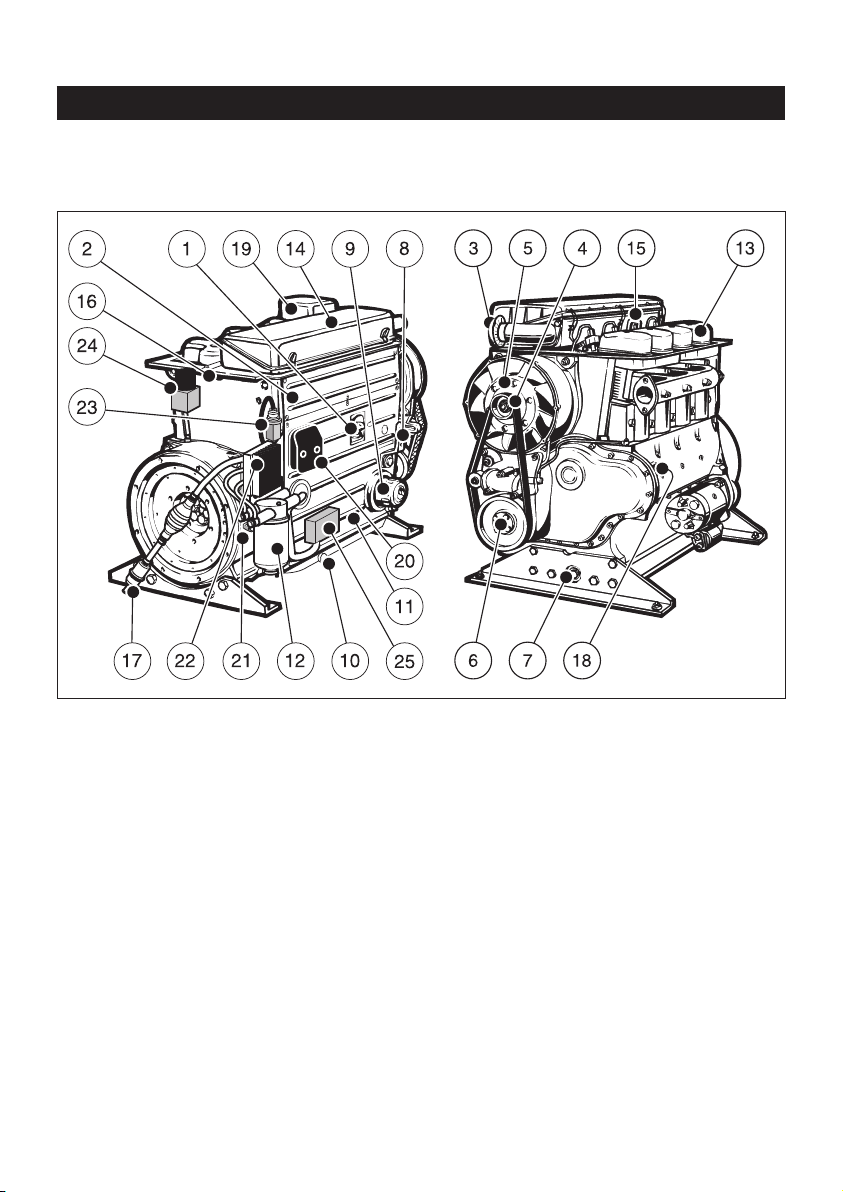

Description of engine

Standard version

Engine 4 M 42

8

4

1 Oil filler pipe and dipstick

2 Side panel

3 Combustion air intake aperture

4 Cooling fan drive belt

5 Cooling fan with alternator attached

6 1/2-inch intl. hex socket for turning over

engine

7 Oil drain plug

8 Speed control lever

9 Replaceable-element oil filter

10 Oil drain plug (if sump is fitted)

11 Cooling air duct for engine oil cooler

12 Fuel filter

13 Cylinder head cover

14 Air cleaner cover

15 Suspension lug, max. load 5000 N

16 Fuel return line

17 Fuel feed line with fuel pre-filter and

manual fuel pump

18 Type plate

19 Exhaust silencer

20 Central plug for electrical system

21 Battery connections

22 Power-Box

23 Electrical maintenance switch for

air cleaner

24 Exhaust gas return valve (EGR)

25 Electronic control unit

9

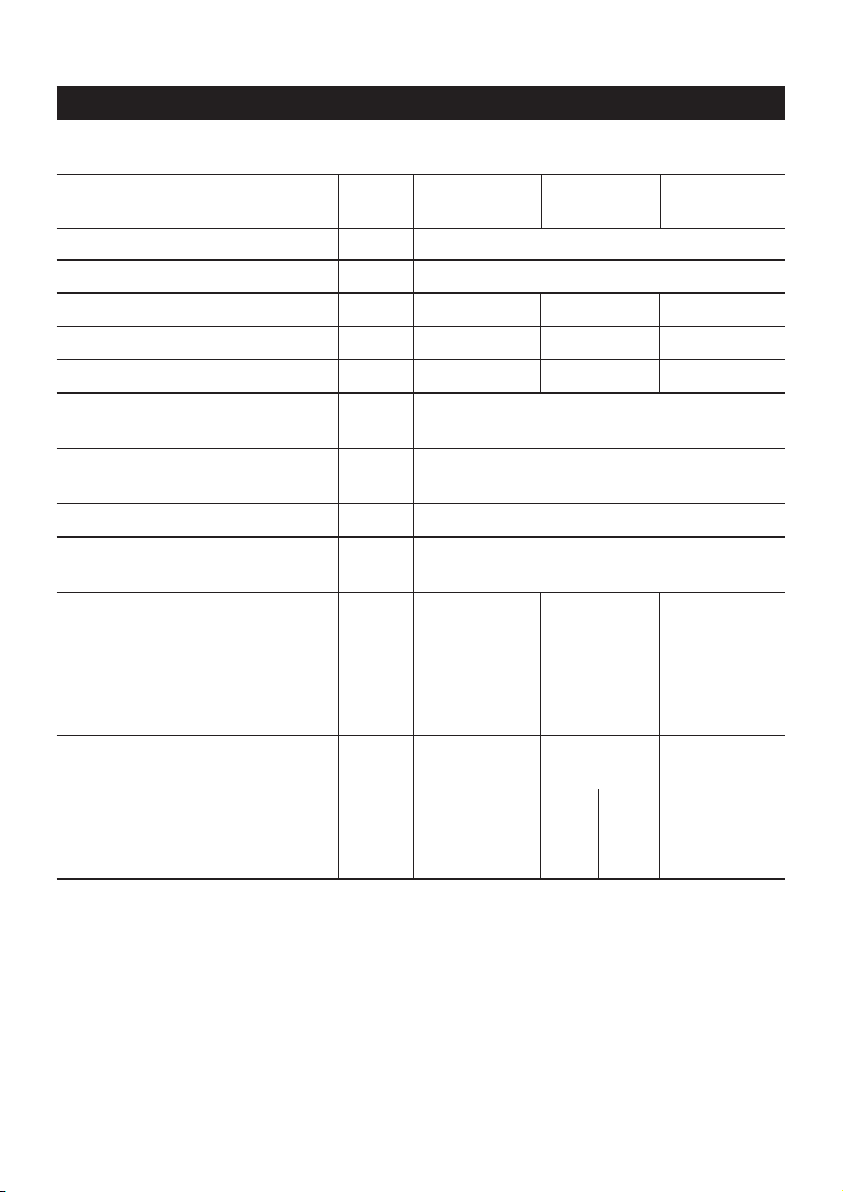

3. General information

3.1. Technical data

2L41C 3L41C 4L41C / 4L42C

2 M 41. 3 M 41. 4 M 41. / 4 M 42.

Type Air-cooled, four-stroke diesel engine

Combustion method Direct fuel injection

Number of cylinders 2 3 4

Bore/stroke mm 102 / 105 102 / 105 102 / 105

Displacement cm³ 1716 2574 3432

Engine oil pressure

Oil temperature 100 ± 20°C min. 0.6 bar at 850 r.p.m.

Consumption of lubrication max. 1 % of fuel consumption

oil after running-in period at full-load

Direction of rotation Counterclockwise, looking at flywheel

Valve clearance (at 10 - 30 °C)

Inlet/exhaust mm 0.10

Net weight

Standard version .M41 258 308 373

Version 4M42 approx. 378

Version .M41 Z kg 263 315 388

Version .L41 C 303 363 433

Version 4L42 C 438

Max. angle from vertical in any with and without with without only with

direction (in continuous operation) sump sump sump

Control side 30°

1)

30° 1)25°

1)

25°

1)

Air outlet side 30°

1)

30° 1)30°

1)

30°

1)

Timing gear side 30°

1)

25° 1)25°

1)

15°

1)

Flywheel side 30°

1)

22° 1)25°

1)

18°

1)

1)

Exceeding these limits causes engine breakdown.

3.2. Transport

A suspension lug is provided as stand-

ard equipment, so that the engine and

its auxiliaries can be lifted safely. It is not

suitable for lifting complete machines or similar to which the engine has been attached, and

this is strictly prohibited. (See Chapter 2.)

3.3. Instructions for installation

The „Manual for Selection and Installation of

Engines“ contains all the information you need if

your engine has not yet been installed on or in

the equipment it is intended to drive, or set up in

its correct operating position. You can obtain a

copy of this manual from your nearest HATZ

service station.

3.4. Load on engine

See supplemental information for EPA certified

engines, Page 47; resp. supplemental information for California regulations for off road

engines, Page 65.

3.5. EPA/CARB-type plates and

fuel label

There are two EPA/CARB- type plates applied for

the identification of the engine. The type plates

are placed on the crankcase resp. on the capsule

(chapt. 2).

They include the following emission control information (Figure 5a):

Label 1/2

5a

➀ EPA/CARB-Engine Family Number

➁ engine type / spec. (only for special

equipment) /Fuel Delivery Timing

➂ engine number

➃ max. engine rated speed

➄ build date

➅ displacement

➆ rated power

➇ “constant speed only” (if requested)

➈ “variable speed” (if requested)

Every engine is equipped with an additional

loose engine type plate. If the original type

plate on the engine is not readily visible after

the engine is installed in the equipment then

the second loose type plate must be attached

on the equipment in such a manner that it is

readily visible to an average person.

10

For any offer as well as spare parts orders it is

necessary to mention the following data (also

see spare parts list, page 1):

➁ engine type / spec.

(only for special equipment)

➂ engine number

➃ max. engine rated speed

The layout is identical for constant-speed and

variable speed application.

Attention:

If the engine was certified for constant-speed

application and shall be used so, the field "constant-speed only" is marked with “X”.

If the engine was certified for variable speed application and shall be used so, the field "variable

speed" is marked with “X”.

Always install the engine for its intended application in order to comply with EPA and CARB

emission regulation requirements.

Label 2/2

5b

The engine must be operated with “LOW SULFUR FUEL OR ULTRA LOW SULFUR FUEL

ONLY”.

The label also states the applicable emissionrelated power category of the engine.

Fuel label

5c

The fuel label is placed nearby the fuel inlet.

If there was no fuel tank mounted to the engine,

the label has to be permanently attached to the

equipment near the fuel inlet.

3.6. EMISSION-RELATED

INSTALLATION INSTRUCTIONS

See supplemental information for EPA certified

engines, Page 47; resp. supplemental information for California regulations for off road

engines, Page 65.

11

LOW SULFUR FUEL OR ULTRA

LOW SULFUR FUEL ONLY

EMISSION CONTROL INFORMATION

LOW SULFUR FUEL OR

ULTRA LOW SULFUR FUEL ONLY

❏ < 8 kW / ❏ 8-19kW / ❏ 19-37kW /

❏ 37-56 kW PM Standard: 0.3 g/kWh

Power category:

Label 2/2

4. Operation

4.1. Before first start-up

Engines are normally delivered without any fuel

or oil.

4.1.1. Engine oil

Oil quality

Qualified are all trademark oils which fulfil at

least one of the following specifications:

ACEA – B2 / E2 or more significant

API – CD / CE / CF / CF-4 / CG-4 or more

significant.

If engine oils with low quality standard are being

used, the intervals of changing the engine oil

have to be reduced from 250 to 150 resp. 500 to

250 hours of operation, see chapter 5.1.

Oil viscosity

6

Choose a suitable oil viscosity according to the

ambient temperature when the engine is started

from cold (Figure 6).

-40

-30

-20

-10

0

10

20

30

40

50

104

86

68

50

32

14

-4

-22

-40

OIL: SAE...

°C°F

5W/30

5W/40

10 W / 4 0

10 W / 3 0

15 W / 4 0

30

40

122

10 W

Engine oil quantities and dipstick markings

dipstick

Engine type Sump

Oil content marking

(liter) (Figure 7,

item 2)

2L41C, 2 M41 Z

Yes 7.5 C

No 4.5 A

2M41

Yes 8.5 C

No 5.5 A

3L41C, 3 M41 Z

Yes 10.5 D

No 8.0 A

3M41

Yes 11.0 D

No 8.5 A

4L41C, 4L42C, Yes 13.0 D

4 M 41 Z No – –

Yes 14.0 D

4 M 41, 4 M 42

No – –

Note:

The engine oil contents stated here are to be

regarded as approximate.

In all cases, the MAX marking on the dipstick

should be complied with.

12

The engine should be in a horizontal position

before adding oil or checking the oil level.

7

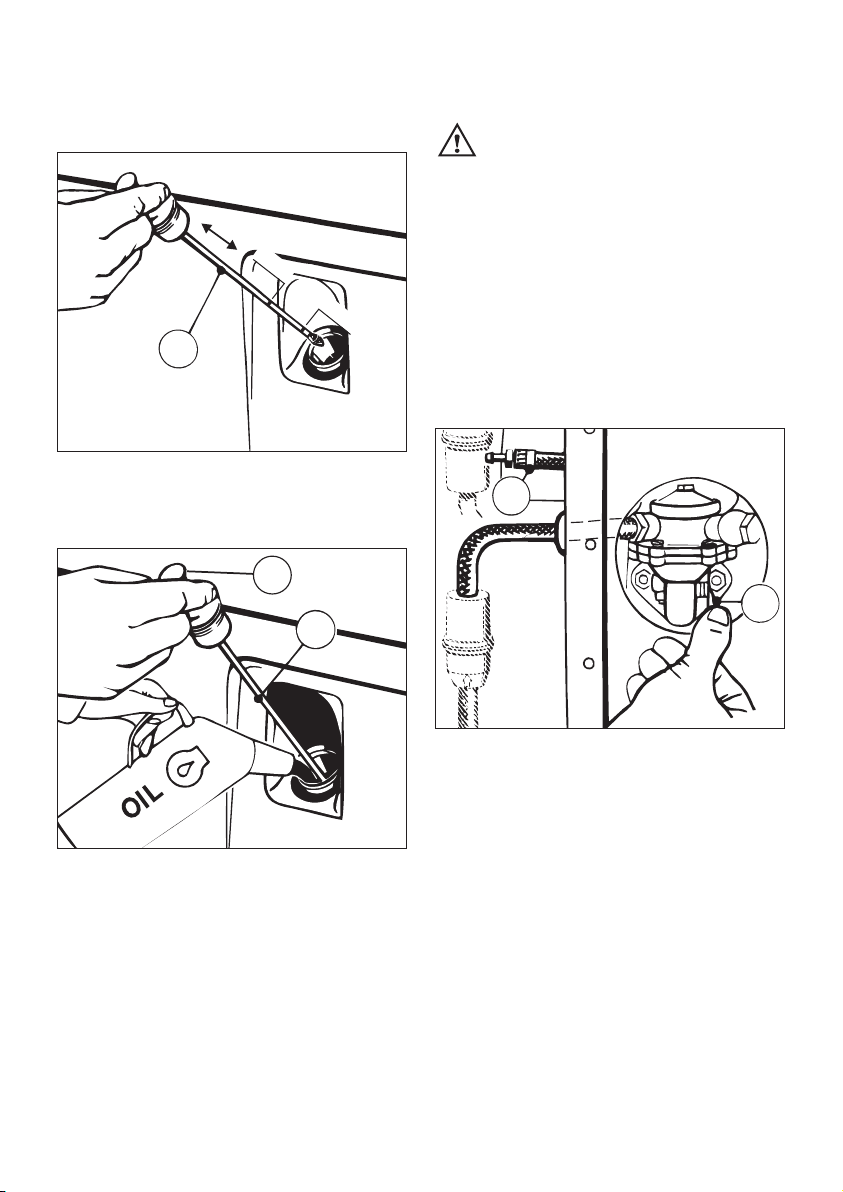

– Pull out dipstick „1“ (fig. 7).

8

– Add engine oil up to the MAX mark on dipstick

„1“ (Figures 7 and 8).

– Run the engine for a short time, then check oil

level again and correct if necessary.

1

L3/45

A

2

1327/2

L3/47

MAX

MIN

1

4.1.2. Fuel

Stop the engine before refilling the

fuel tank. Never refuel near a naked

flame or sparks which could start a fire. Don’t

smoke. Use only pure fuel and clean filling

equipment. Take care not to spill fuel.

All diesel oils sold as fuel and complying with

the following minimum specifications can be

used:

EN 590 or

BS 2869 A1 / A2 or

ASTM D 975 - 1D / 2D

9

– Before the engine is first started, or if the fuel

system was run dry, prime the fuel delivery

pump at lever „1“ until fuel is heard to flow

back through the return line „2“ to the fuel

tank.

Important !

Remember to replace the access cover for the

fuel delivery pump in the side panel of the engine enclosure after priming the pump (Chap. 2).

L3/46

2

1

13

Models with manual fuel pump

(On 4L42C and 4M42 engines only)

10

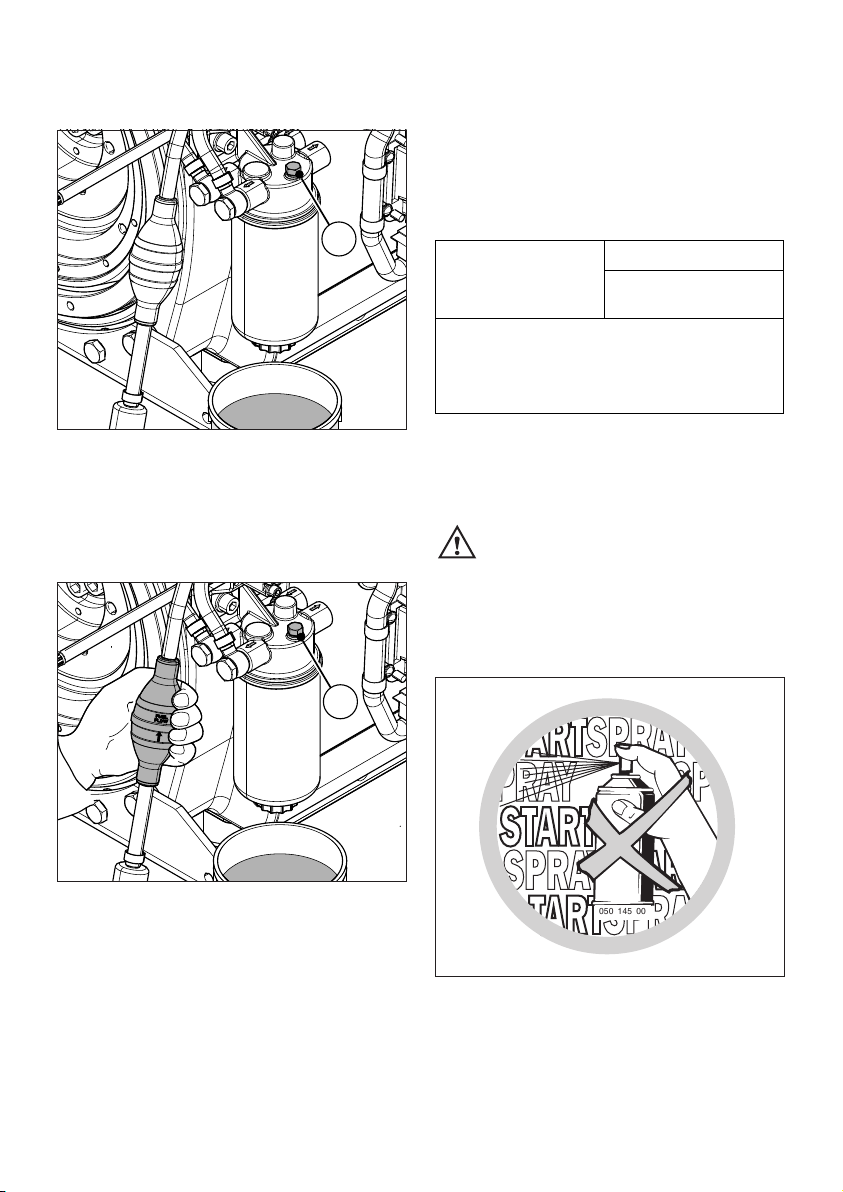

– Place a suitable vessel under the filter to trap

escaping fuel.

– Open the vent screw 1 by approx. one turn.

11

– Compress and release rubber ball repeatedly,

until fuel escapes from the vent screw 1.

– Close vent screw 1, then actuate rubber ball

another two times.

1

1

Low temperature resistance

At low temperatures, the viscosity of Diesel fuel

increases. This may result in clogging of the fuel

system. Thus, winter fuel must be used at outside temperatures below 0 °C, or petroleum

must be added in time.

4.2. Starting

Do not run the engine in closed or

badly ventilated rooms – danger of

poisoning! Before the engine is started, always

make sure that nobody is in the danger area

(moving parts on engine or machinery) and

that all safety guards are in place.

12

Never use any spray starting aids

L3/250

050 145 00

Lowest ambient

temperature when

starting, in °C

Paraffin content for:

Summer Winter

fuel fuel

0 up to –10 20 % –

–10 up to –15 30 % –

–15 up to –20 50 % 20 %

–20 up to –30 – 50 %

14

If possible, disengage the engine from any

driven equipment.

The auxiliary equipment should always be placed

in neutral.

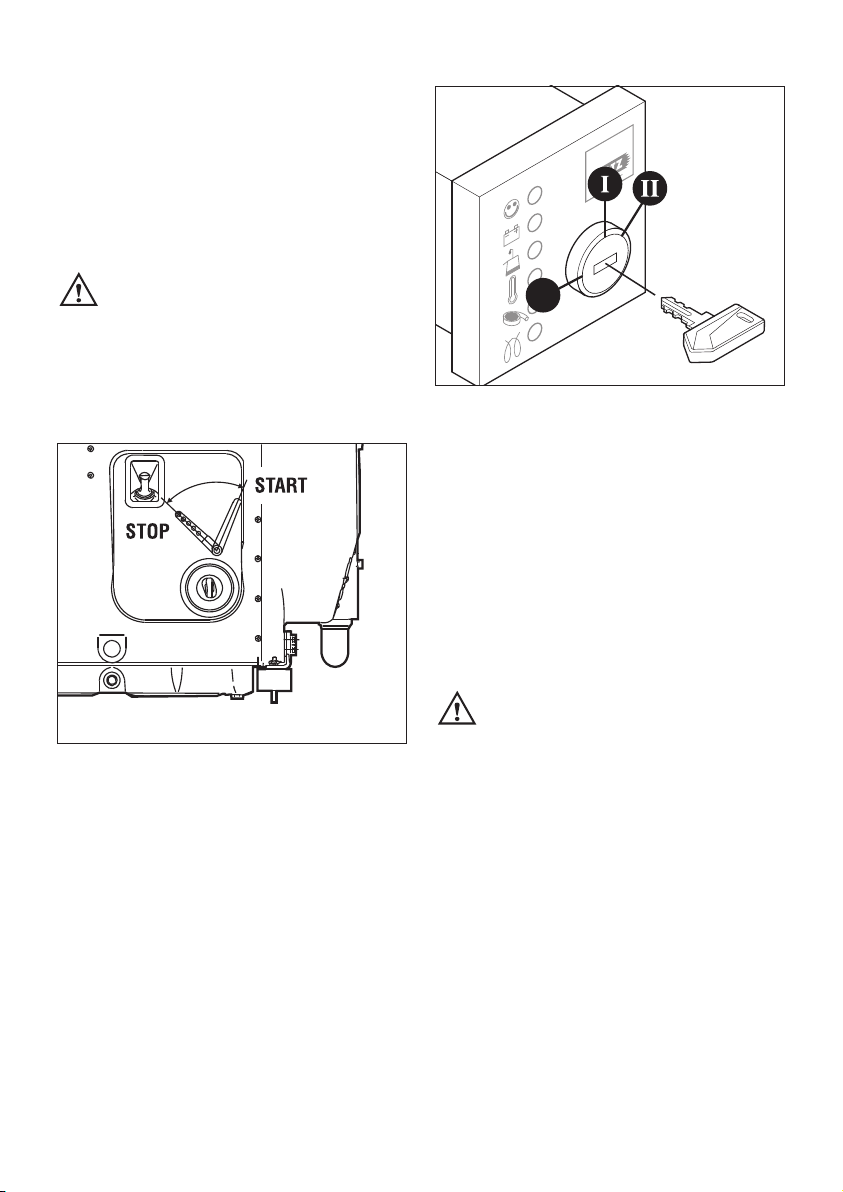

4.2.1. Starting with the electric starter

13

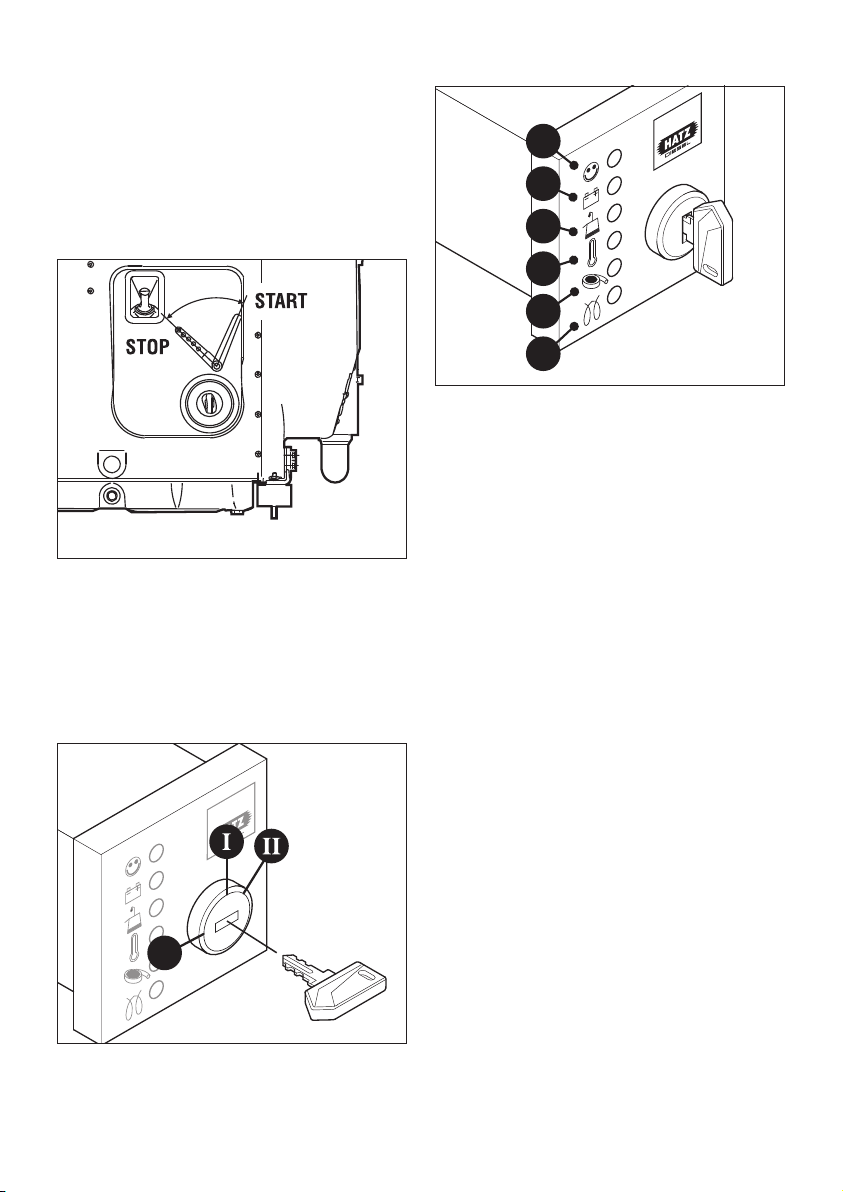

– Move the speed control lever to the 1/2 START

or max. START position, according to requirements and starting conditions.

Note that a lower speed setting will cause less

exhaust smoke when starting.

14

– Insert the key to its stop and turn it to

position I.

0

15

– Battery charge telltale „2“ and oil pressure

warning „3“ must light up.

– Turn start key to position II (Fig. 14).

– As soon as the engine runs, release the start

key. It must return to position I by itself and

remain in this position during operation.

The battery charge telltale and oil pressure

warning must go out immediately after starting. Indicator light „1“ is on when the engine is

in operation.

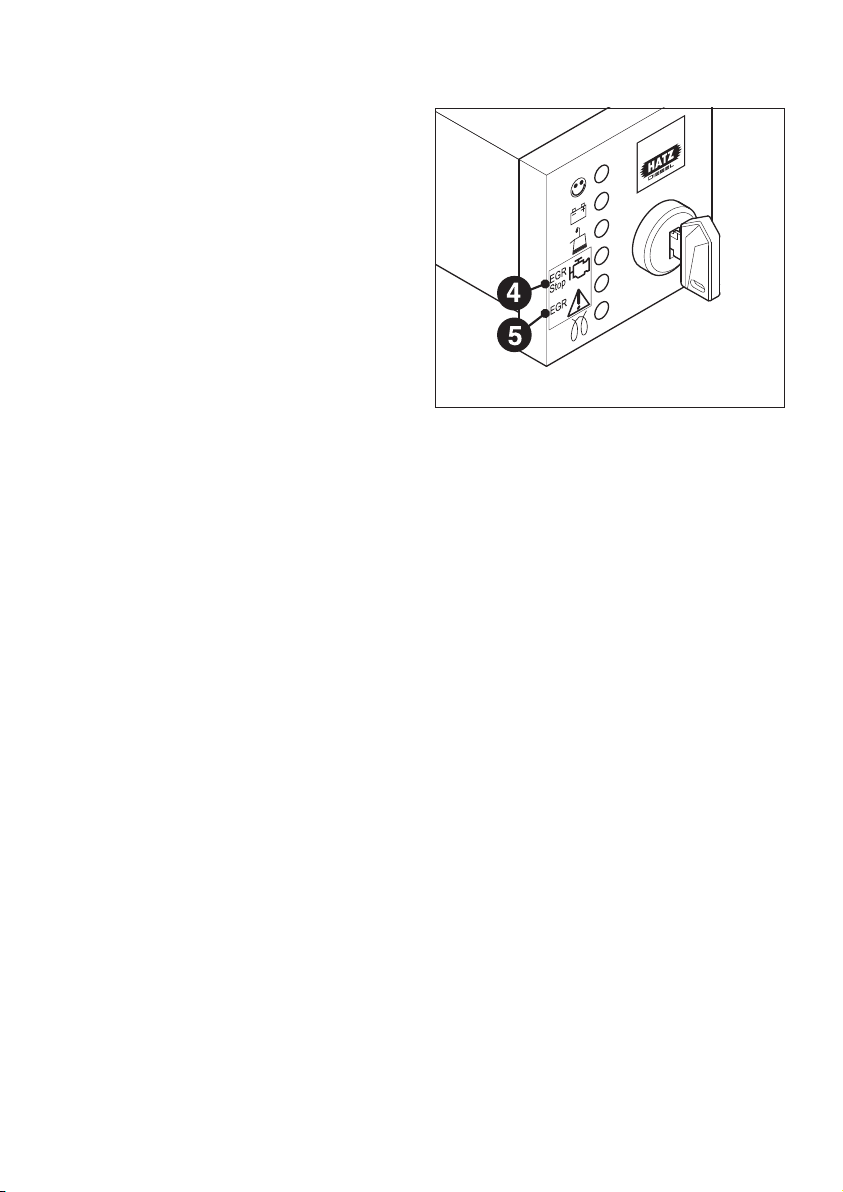

– The air cleaner maintenance indicator „5“ only

lights up during operation if the air cleaner element needs to be cleaned or renewed (Fig. 15,

see chapter 5.4.2.).

– The engine temperature display „4“ (additional

equipment) lights up if the temperature at the

cylinder head becomes too high.

Switch off the engine and trace and eliminate the cause of the problem, see chapter 7.

– Always turn the start key back to position 0

before re-starting the engine. The repeat lock

in the ignition lock prevents the starter motor

from engaging and possibly being damaged

while the engine is still running.

1

2

3

4

5

6

15

Important!

If a starter protection module is installed, the

start key has to be returned to position 0 for at

least 8 seconds after the engine has failed to

start or after switching it off before a further

attempt can be made to start the engine.

Preheating device with automatic heating

timer (additional equipment)

The preheating light „6“ lights up additionally at

temperatures below 0° Celsius (Fig. 15).

– After the light has gone out, start the engine

without delay.

Automatic shut-down function

(additional equipment)

This is characterized by a brief flashing of all

pilot lamps once the starter key has been turned

to position I, figure 15.

Important!

If the engine cuts out immediately after starting

or switches off by itself during operation, a

monitoring element in the automatic shutdown

system has tripped. The corresponding indicator

light (Fig. 15, positions 2 - 5) will come on.

After the engine has stopped, the display continues to glow for about 2 minutes.

The electrical device then switches itself off automatically. The display lights up again after the

start key has been turned back to position 0 and

then to position I again.

Trace and eliminate the cause of the operating

fault before trying to restart the engine (see

chapter 7).

The display light goes out when the engine is

next started.

Even with automatic shutdown monitoring the

oil level must be checked every 8 – 15 operating hours (Chapter 5.2.1.).

On 4L42C and 4M42 engines only

16

These engines are equipped with an exhaust gas

recirculation valve (EGR). This results in the following changes regarding the pilot lamps:

– The engine diagnosis indicator „4“ goes on as

soon as the cylinder head temperature exceeds

the admissible range.

Stop the engine and eliminate the cause as

described in Chapter 7.

– The pilot lamp „5“ flashes during operation

only if there is a problem in conjunction with

the exhaust gas recirculation system. This also

includes a contaminated air cleaner. This is indicated by the following flashing code of pilot

lamp „5“:

7 short flashes (approx. 0.5 seconds) and

1 long flash (approx. 1.5 seconds)

The flashing code indicates that the air cleaner

must be cleaned or replaced, chapter 5.4.2.

For troubleshooting regarding other flashing

codes, please contact immediately your nearest

HATZ service station.

Problems in the exhaust gas recirculation

system may impair the engine’s exhaust gas

values.

16

4.2.2. Emergency starting

If the engine has been stopped by the automatic

shutdown system because of an electrical fault

signal or inadequate oil pressure, an emergency

start can be attempted, though in this case the

manufacturer will accept no liability for consequential damage.

An emergency start could for example be unavoidable if the engine is used to power a vehicle which has come to a halt in a potentially

dangerous area (for example on a rail crossing

or road junction).

Proceed as follows:

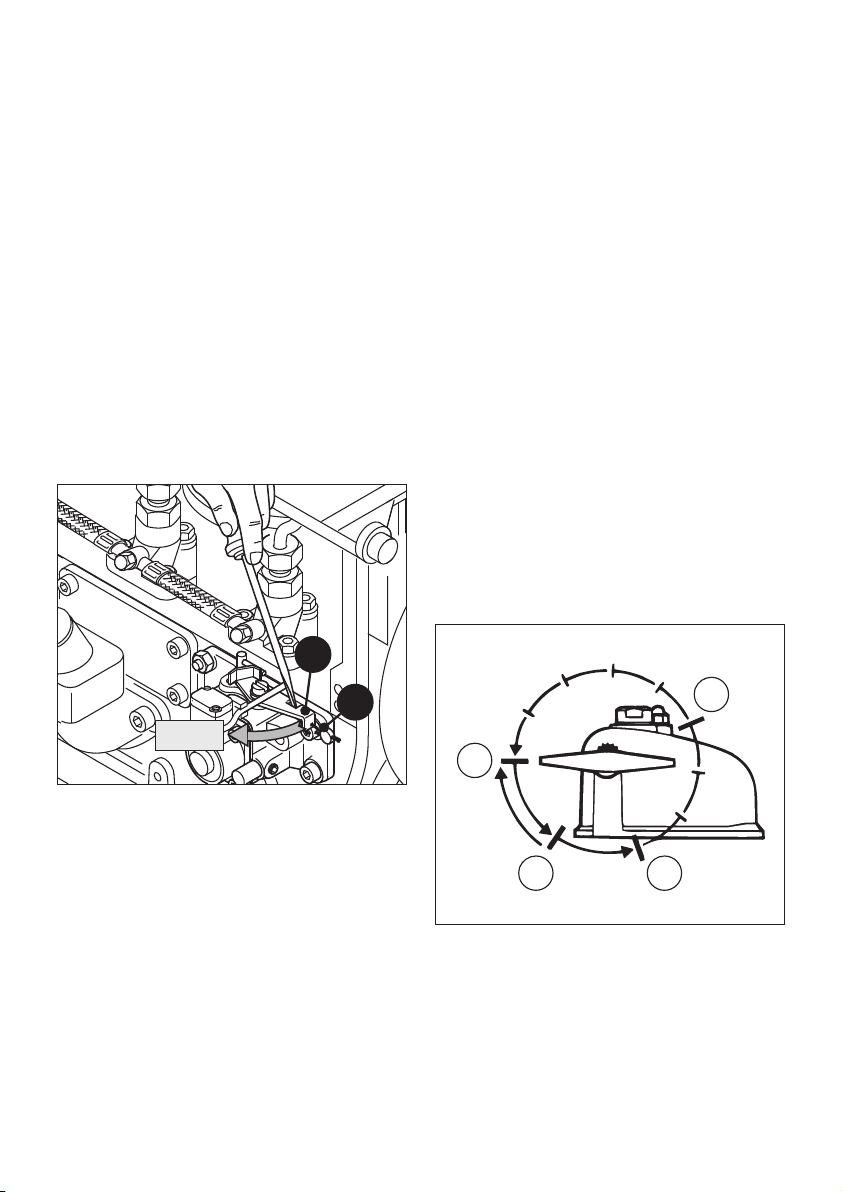

– Detach the hood of enclosure „13“ (Figures 1

and 2) or side panel „2“ (Figures 3 and 4).

17

– Place a suitable tool, for example a screw driv-

er, behind emergency start lever „2“ and pull

sharply outwards. This will break the lead seal

„3“ between the emergency start lever and the

screw on the engine block.

– As soon as the emergency start lever is in the

starting position, the engine can be started

again.

3

2

START

Important:

If the emergency start lever is used, the automatic shutdown system ceases to operate and the

warranty is invalidated. For this reason, run the

engine only in a genuine emergency and for a

very short time (a few seconds) after operating

the emergency start lever. Make sure before restarting the engine that there is sufficient oil in

the engine; if oil pressure is too low, irreparable

engine damage may occur very quickly.

Immediately after running the engine in an emergency, locate the origin of the fault signal and

rectify the fault (see Chapter 7).

If any problems arise, please contact the nearest

HATZ service point.

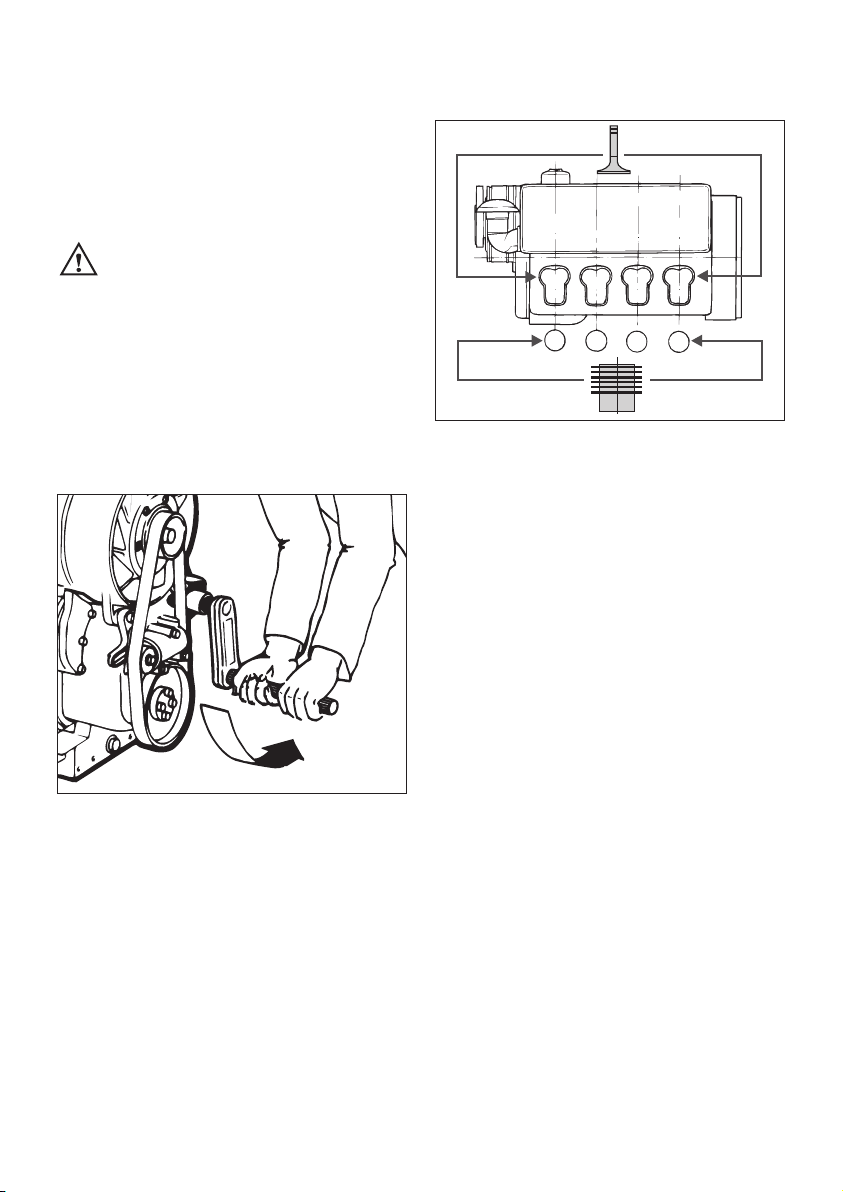

4.2.3. Starting with handle

(on 2-4 M 41 engines only)

Preparations

– Move the speed control lever to START posi-

tion (Fig. 13).

18

– Turn all decompression levers (1 on two-cylin-

der engines, 3 on three-cylinder engines, 4 on

four-cylinder engines) to position 1.

L3/1

2

1

3

0

17

Important !

Turn decompression levers only in the direction

shown by the arrow.

Exception:

the lever can be moved back directly from position „1“ to „0“.

Never operate the automatic decompression system when the engine is

running.

– Check that the starting handle is in correct

working order, without a broken tubular handle

worn engagement dogs or similar faults.

– Lightly grease the sliding-contact area between

the starting handle and the guide sleeve.

19

– Insert the starting handle, hold it with both

hands and stand in the correct position in

relation to the engine.

– Turn the engine over until it is felt to move

more freely.

2M41 two-cylinder engines

– Turn the decompression lever to position „2“

(Figure 18).

L3/2

3M41 three-cylinder engines

20

– Turn the decompression levers for cylinders 1

and 3 (counting from the fan end) to position

„2“ (Figures 18 and 20).

– Turn the decompression lever for cylinder 2 to

position „3“.

4M41 four-cylinder engines

– Turn the decompression levers for cylinders 1,

3 and 4 (counting from the fan end) to position „2“ (Figures 18 and 20).

– Turn the decompression lever for cylinder 2 to

position „3“.

Starting procedure

– Turn the starting handle with both hands at an

increasing speed.

The maximum speed of rotation must have been

reached by the time the decompression lever

has returned to position „0“.

– As soon as the engine has started, pull the

starting handle out of the guide sleeve.

1

2

3

4

12 345678

L3/246

18

– If the engine backfires during starting because

it was not turned over with sufficient force (the

engine could even start to run backwards in

certain circumstances), release the starting

handle immediately and move the speed control lever to the STOP position (Chapt. 4.3.).

The starting handle could be driven

round by the engine and cause injury.

– Wait until the engine has come to a standstill

before repeating the preparatory procedure

and making another attempt to start it.

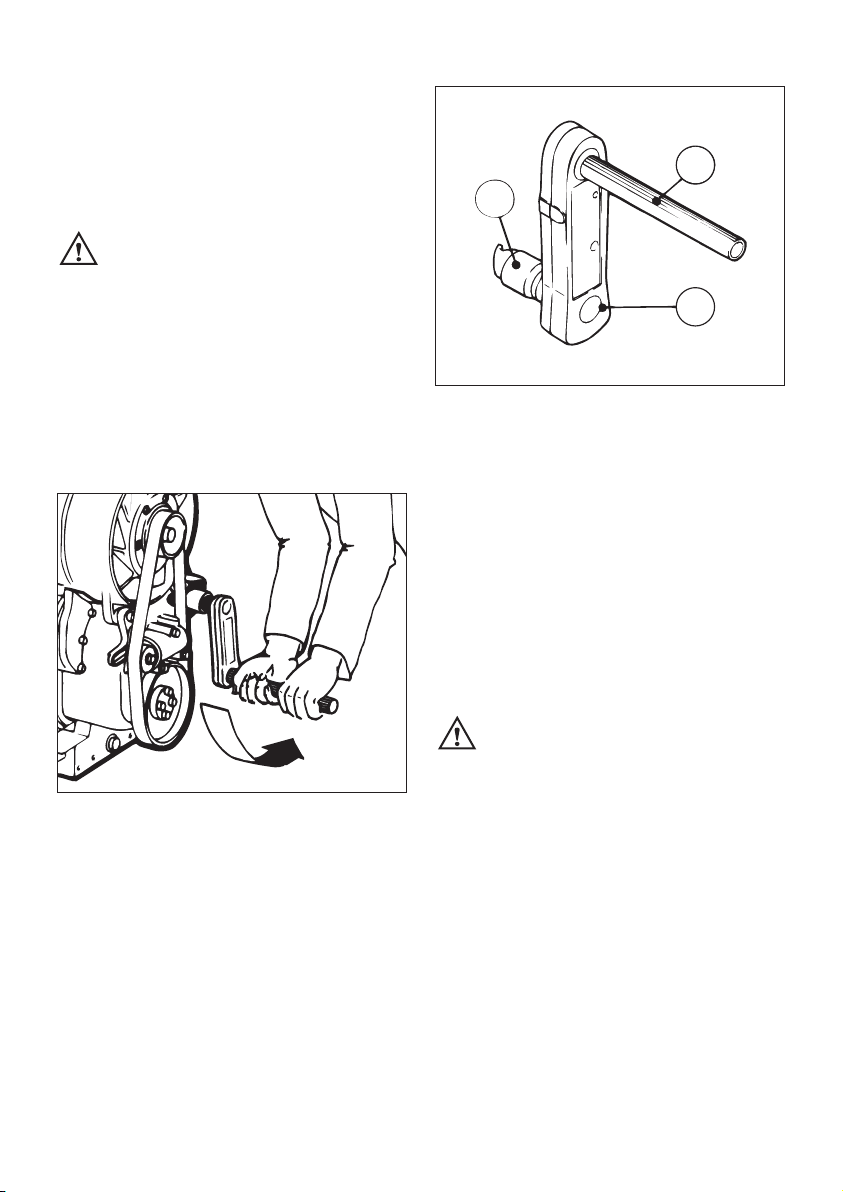

4.2.4. Starting with the handle with

kick-back damping

21

L3/2

22

– Preparations for starting the engine and the

hand starting procedure are precisely the

sameas with the standard handle.

Always hold tubular grip „1“ with both hands

(Figures 21 and 22).

– Turn the handle slowly at first, until the pawl

engages in the ratchet, then increase turning

force to build up speed. The highest speed

must have been reached by the time the decompression lever returns to position „0“.

As soon as the engine has started, pull the

starting handle out of the guide sleeve.

You must hold the tubular grip firmly

to maintain contact all the time between the starting handle and the engine.

Maintain turning force during the entire hand

starting operation.

– If backfiring should occur while hand starting

the engine too soft, the brief reversal of movement disengages the pawl between the crankshaft „2“ and the drive dog „3“ (Fig. 22).

– If backfiring occured and the engine starts

running backwards (smoke from airfilter),

release crankhandle immediately and move

speed control lever into STOP-position,

chapt. 4.3.

L3/3

1

2

3

19

– To repeat the starting attempt, wait for the en-

gine to cease rotating, reset the automatic decompression device and turn the starting

handle in the correct starting direction again.

4.3. Stopping the engine

If the engine is shut down for a short

period, or at the end of the working

day or shift, keep the key and the starting

handel in a safe place, out of reach of unauthorized persons.

Engines with electric starter

23

– Move the speed control lever to the stop posi-

tion; the engine will be shut down.

24

– Turn the starter key to the 0 position and pull

it out. The pilot lamp lights must then go out.

Note:

Engines with an automatic shut-down function

can also be switched off by turning the start key

back to position 0.

Engines with starting handle

– Move the speed control lever to the stop posi-

tion; the engine will be shut down (Picture 23).

Never stop the engine by moving the

decompression lever.

0

20

5. Maintenance

The engine must be stopped before any maintenance work is attempted.

Comply with legal requirements when handling and disposing of old oil, filters and

cleaning materials.

Keep the engine’s starting key out of reach of unauthorized persons.

Disconnect the negative battery terminal.

At the end of the maintenance work, check that all tools have been removed from the engine and

all safety guards, covers etc. replaced in their correct positions. Before starting the engine, make

sure that nobody is in the danger area (engine or driven machinery).

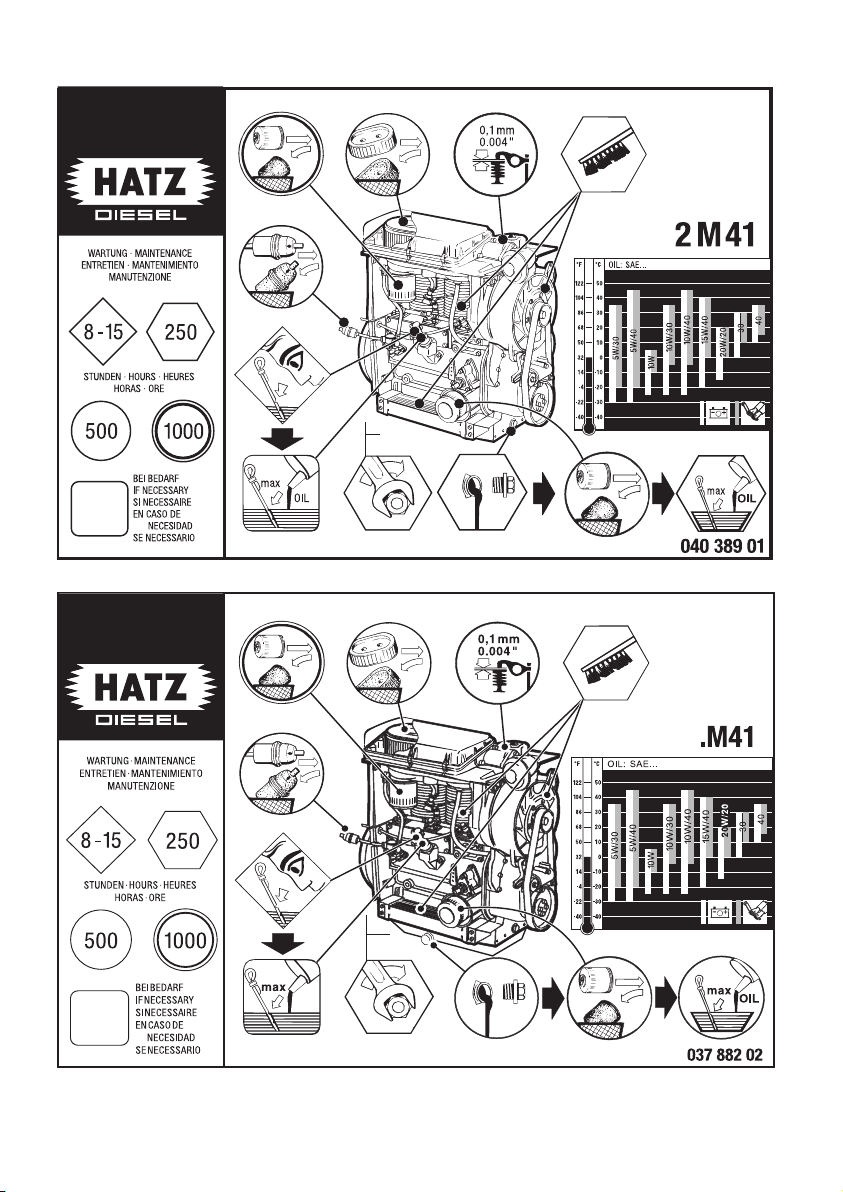

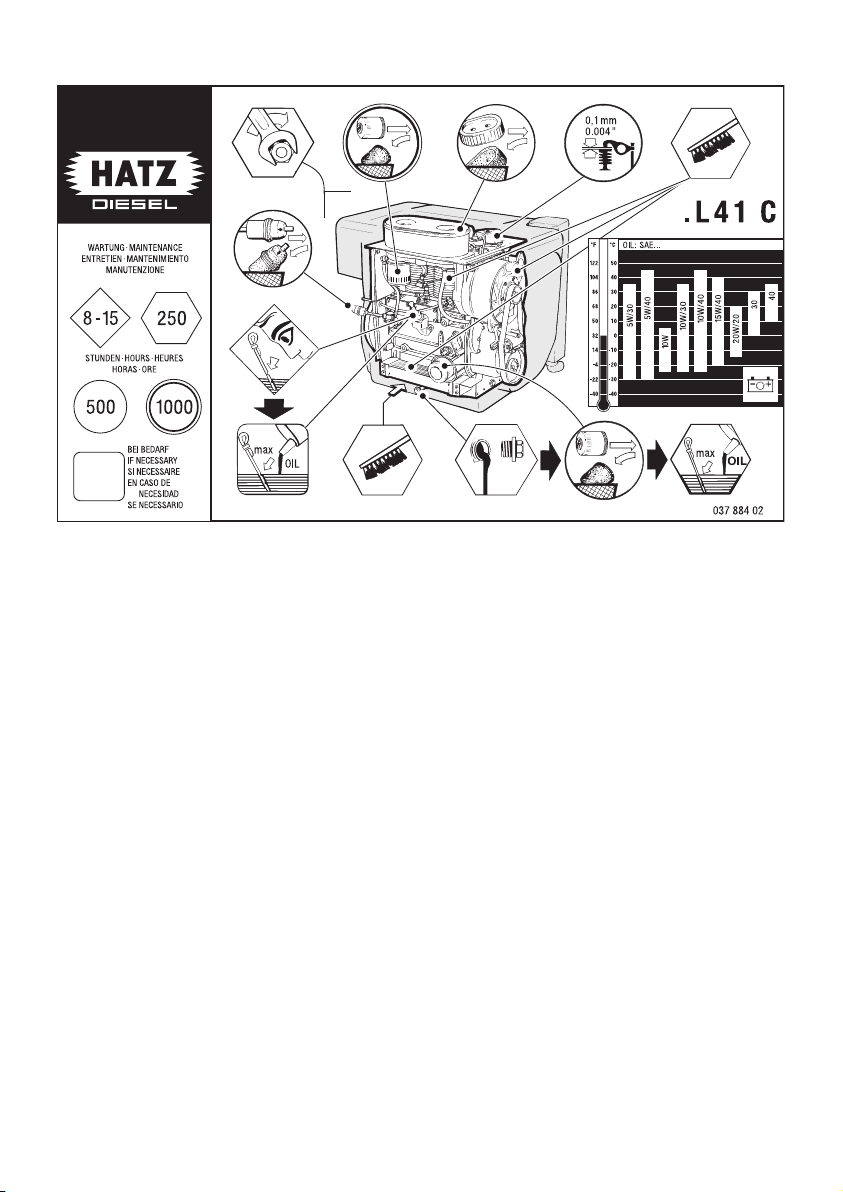

5.1. Maintenance summary

Maintenance intervals Maintenance work required Chap.

21

Every 8 – 15 hours of

operation, or before

each daily start-up

Every 250 hours

of operation

Every 500 hours

of operation

Every 1000 hours

of operation

Check oil level.

Check combustion air intake area.

Check the cooling air system

Engine oil change (2 M 41 without sump,

2...4 L 41 and 4 L 42 in general).

Clean fan, cooling fins and oil cooler.

Check tightness of threaded connections.

Cleaning of mesh insert in exhaust pipe.

Check water trap

Check for contamination of fuel pre-filter, renew if

necessary.*

Checking operation of air cleaner maintenance

indicator.

Do not tighten the cylinder head nuts.

Renew the fuel pre-filter.

Air cleaner maintenance.

Check and adjust valve clearances.

Engine oil change (2 M 41 with sump,

3...4 M 41 and 4 M 42 in general).

Renew the oilfilter.

Renew the fuel filter

5.2.1.

5.2.2.

5.2.3.

5.3.1.

5.3.2.

5.3.3.

5.3.4.

5.3.5.

5.4.1.

6.1.

5.4.1.

5.4.2.

5.4.3.

5.4.4.

5.4.5.

5.5.1.

8-15

250

500

1000

* Fuel pre-filter renewal intervals depend on the degree of fuel contamination, the care taken when

refuelling and the amount of contamination inside the fuel tank.

2 M 41 without oil pan

2 M 41 with oil pan; 3 - 4 M 41 in all cases

22

25

26

27

Depending on engine type and version, one of

the three self-adhesive maintenance charts illustrated here and on the previous page will be

supplied. It should be attached to the engine or

equipment at a point where it is clearly visible.

Comply with the maintenance intervals stated in

the maintenance summary in this chapter

The following work is essential on new or

reconditioned engines after the first 25 hours

of operation:

– Change the engine oil and renew the oil filter

element (Chapter 5.3.1. and 5.4.5.).

– Check valve clearances and adjust if neces-

sary(Chapter 5.4.3.).

– Check tightness of all screw connections

(Chapter 5.3.3.).

Do not take up slack at cylinder head bolts.

If the engine has not been operated for long

periods at a time, change the oil and renew the

filter element after a maximum of 12 months,

regardless of how many operating hours have

been recorded.

23

5.2 Maintenance every 8 – 15 hours

of operation

5.2.1. Check engine oil level

When checking the oil level, the engine should

be standing level, and must not be running.

28

– Check oil level at the dipstick. Add oil up to

the MAX mark on dipstick „1“ if necessary

(Chapter 4.1.1.).

5.2.2. Check combustion air intake area

Severe contamination is a sign that the air contains a high level of dust, and that the maintenance intervals should be shortened accordingly

(Chapter 5.4.2.).

1327/2

L3/47

MAX

MIN

1

29

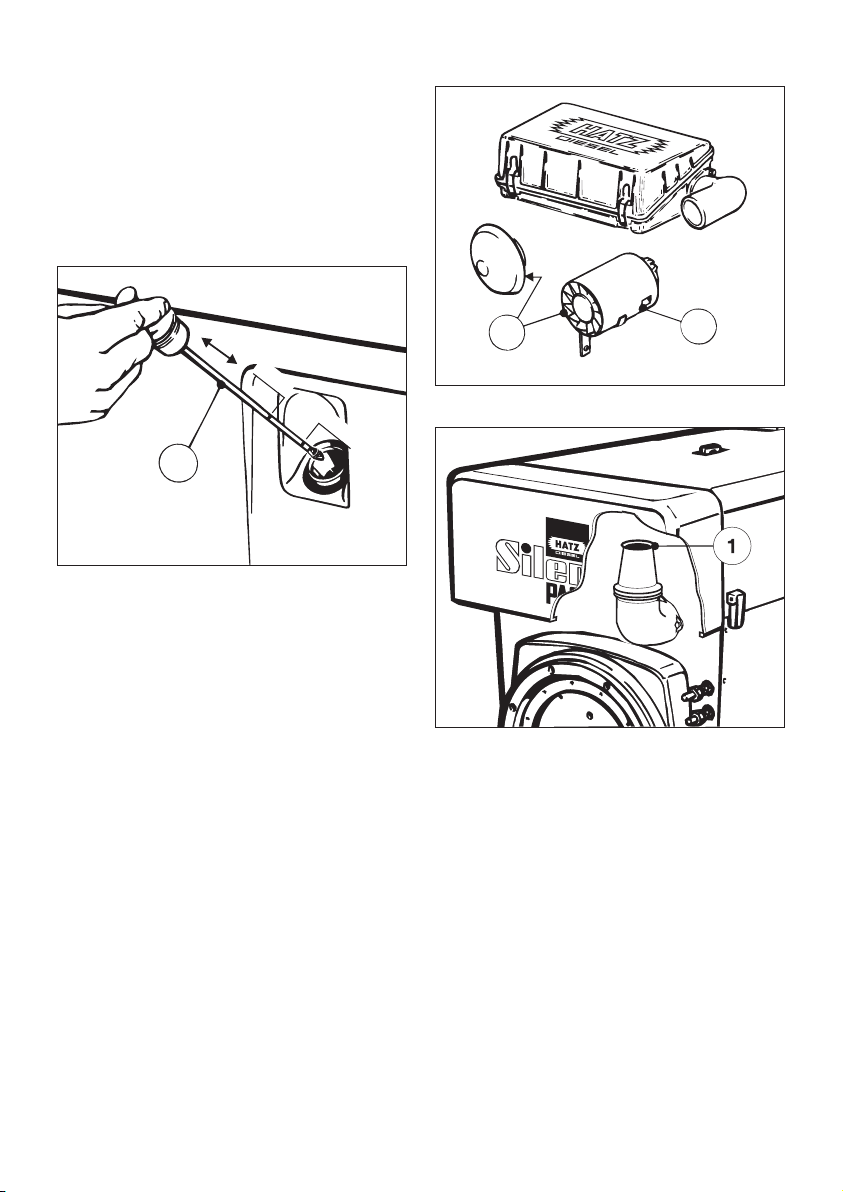

30

– Inspect intake opening „1“ on the rain protec-

tion cap or cyclone separator for severe blockage with dirt, for instance leaves, heavy dust

deposits etc., and clean if necessary.

(Figures 29 and 30).

– Check for free airflow at dust outlet hole „2“

on the underside of the housing, and clean if

necessary (Picture 29).

With oily contamination remove cyclone and

clean it.

1

2

L3/63

24

Loading...

Loading...