Hatz Diesel 2-4L30, H2-3L30, 2-4L41, 2-4L31, 2-4M31 Workshop Manual

...

Workshop manual

2-4L30.

H2-3L30.

2-4L31.

2-4L40.

2-4L41.

2-4M31.

2-4M40.

2-4M41.

438 402 00 - 1.97 - 0.4 Printed in Germany

Introduction

1. General

Illustrations of engine

Type plate data

Lubricating oil circuit

Technical data

Sealants and adhesives

Special tools and

Workshop equipment

2. Additional equipment

A 01.00 Fuel

A 01.40 Delivery pump

with hand pump

A 03.00 Exhaust

A 03.12 Detaching and attaching

enclosure for silencer

(muffler)

A 04.00 Mechanical starting

A 04.10 Crank handle

A 04.20 Automatic decompressor

A 04.70 Engine rotating device

A 04.80 Start release

A 05.00 Electric starting

A 05.40 Alternator

A 07.00 Lubricating oil

A 07.10 Lubricating oil cooler,

air cooling

A 07.11 Lubricating oil cooler,

water cooling.

A 11.00 Automatic mechanisms

A 11.70 Temperature-controlled

starting fuel volume

regulator

A 15.00 Housing

A 15.20 Connecting housing

A 30.00 Liquid cooling

A 30.20 Water pump

A 30.40 Thermostat

Contents

3. Basic engine equipment

M 01.00 Crankshaft

M 01.10 Balancing weights 2L / 3L

M 01.20 Balancing weights, 4L

M 01.30 Cleaning crankcase,

installing injector nozzles

M 02.00 Crankshaft

M 04.00 Camshaft

M 04.10 Camshaft for valve timing

M 04.20 Camshaft for injection pump

M 04.30 Governor and injection timer

M 05.00 Conrod

M 06.00 Piston and cylinder

M 06.10 Air-cooled engines

M 06.20 Water-cooled engines

M 07.00 Cylinder head

M 07.10 Air-cooled engines

M 07.20 Cylinder head repairs

(air-cooled engines)

M 07.30 Water-cooled engines

M 07.40 Cylinder head repairs

(water-cooled engines)

M 10.00 Oil pump

M 11.00 Timing case cover

M 12.00 Starting charge

M 12.10 with injection pump

PFR 1K 80

M 12.20 with injection pump

PFR 1K 90

M 12.30 with injection pump

PFR 1K 90

from serial No. L/M31.12,

M40.16, 2L40.19, 3-4L40.18

and L/M41

M 13.00 Fan

M 14.00 Fuel injection equipment

M 14.00 Injection pump, functional test

M 14.10 with injection pump

PFR 1K 80

M 14.20 with injection pump

PFR 1K 90

M 14.30 Injector

M 14.40 Injector nozzle

M 14.50 Adjusting work with

injection pump PFR 1K 80

M 14.60 Adjusting work with injection

pump PFR 1K 90

M 17.00 Flywheel

M 20.00 Engine shutdown device,

belt tensioner

M 22.00 Air cleaner

M 31.00 Crankcase breather

M 32.00 Speed control

M 32.10 with injection pump

PFR 1K 80

M 32.20 with injection pump

PFR 1K 90

M 35.00 Enclosure

4. Tables

Tightening torques

Repair data

Fuel injection equipment and

adjusting values

Governors

Lubricating oil contents and dipstick

Key to circuit diagrams

HATZ wiring identification

Circuit diagrams

Trouble-shooting table for the

electrical system

Contents

Introduction

This workshop manual is in accordance with the technical status shown on each page

(month / year). It has been compiled in such a way that a trained mechanic can perform

all repair work correctly. Instructions such as „Clean parts“ etc. have been omitted, as

they are assumed to be self-evident.

All work must be carried out only with the specified tools or with others of absolutely

equivalent quality.

It is assumed that the normal hand tools will be available, even if not called for specifically in this manual.

Please refer to the operating manual for details of routine maintenance work, operating

fluids and materials, troubleshooting etc.

Use only genuine HATZ spare parts in repair work.

Comply also with generally or locally valid legislation and with the instructions issued by

trade associations or accident insurers.

The details provided here may differ if special equipment is installed. Please appreciate

that neither the workshop manual nor the spare parts list can take all such deviations

into account. If problems occur, please contact the nearest HATZ service point.

1

L / M . . 10.98

1. General

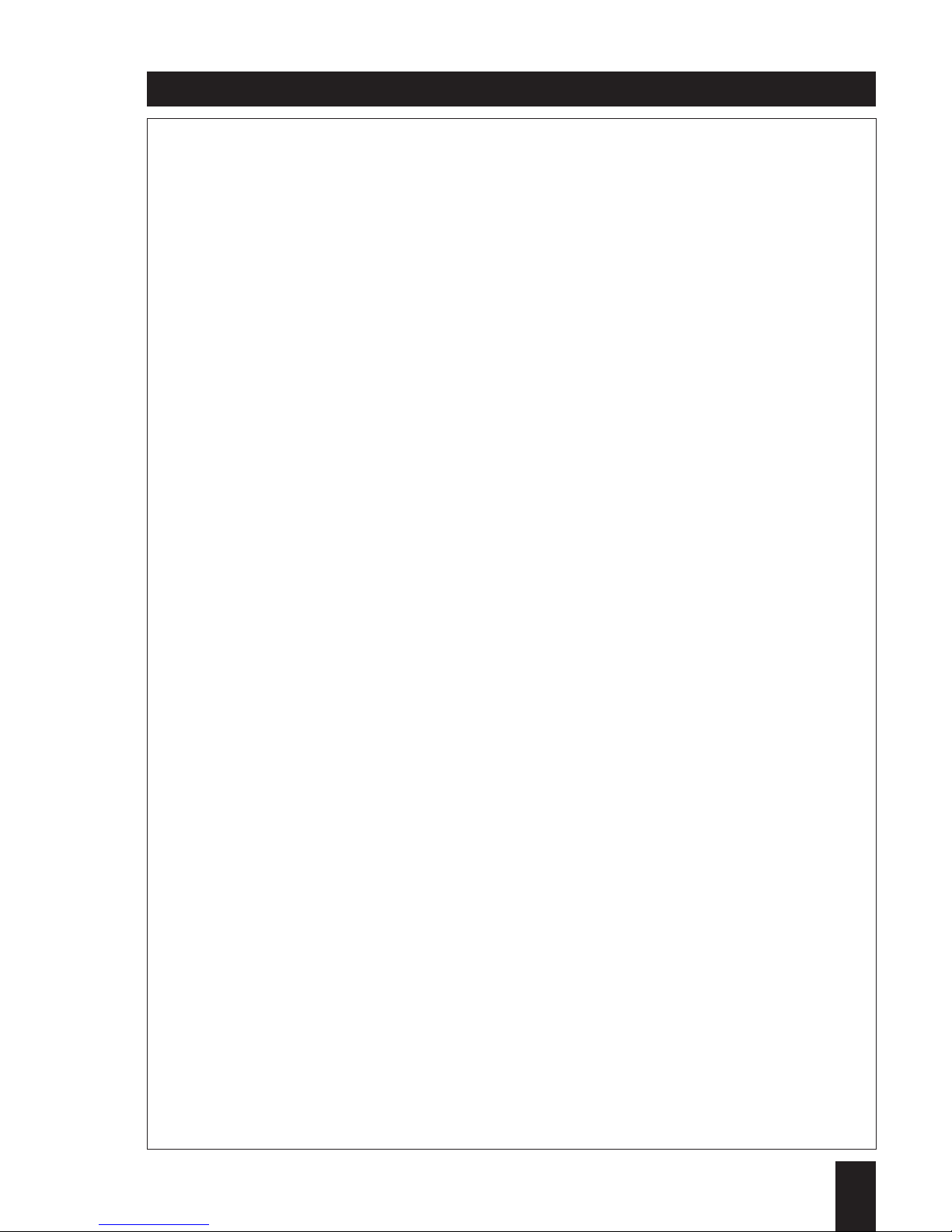

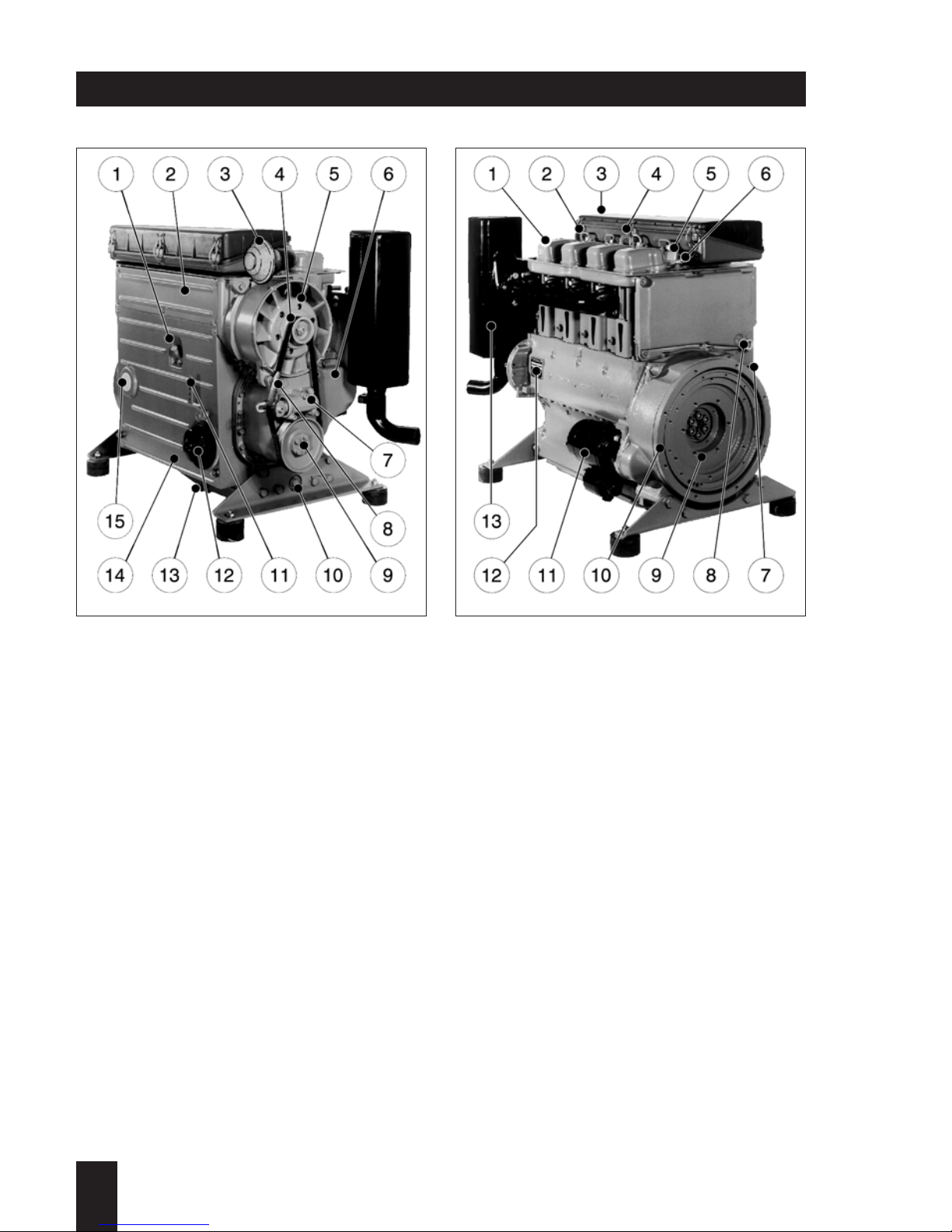

Service and flywheel side

Governor and exhaust side

1

L / M . . 10.98

Starter and flywheel side

Engines: 2 - 4 L . . S / Z

1 Lub.-oil filling and dipstick

2 Speed control lever

3 Exhaust silencer

4 Oil drain plug

5 Lub.-oil filter

6 Engine cover

7 Side panel

8 Cooling fan with built-in alternator

9 Cooling fan drive belt

10 Hydraulic belt tensioner

11 Stop device

12 Governor housing

13 Cooling air duct for lub.-oil cooler

21 Cyclone-type pre-cleaner

22 Eye hook for transport, disappearing

max. load 500 kg

23 Access to fuel feed pump

24 Starter motor

25 Fuel feed line

26 Fuel return line

27 Belt pulley with 1/2“ internal square

for cranking engine

Engine illustrations

Operating and flywheel side

Encapsulated design

1 Lub.-oil filling and dipstick

2 Speed control lever

4 Oil drain plug

5 Lub.-oil filter

6 Batter y + terminal

7 Batter y - terminal

8 Wiring harness

9 Type plate

10 Fuel feed line

11 Fuel return line

14 Cover for capsule

15 Air intake duct of capsule

16 Outgoing air duct

17 Exhaust silencer (encapsulated)

20 Cover for air duct housing

(Access to governor housing of engine)

22 Eye hook for transport, disappearing

max. load 500 kg

23 Engine brackets

24 Access to fuel feed pump

25 Engine flange

26 Side panel

27 Cover, service side

28 Cover, outgoing air side

Operating and governor side

Outgoing air and flywheel side

Engine illustrations

1

L / M . . 10.98

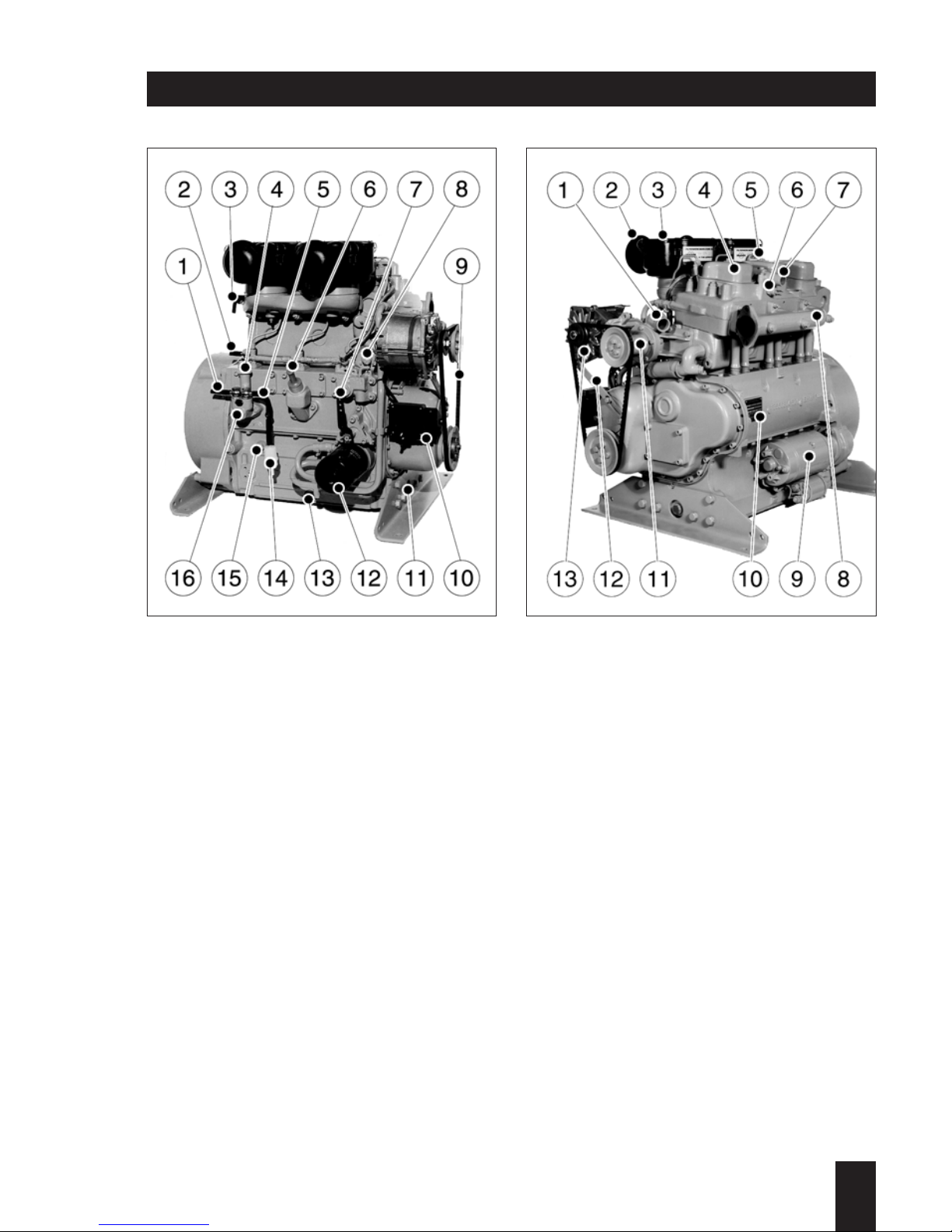

Operating side

Engine: 2 ... 4 M 31,

2 ... 4 M 40,

2 ... 4 M 41

1 Lub.-oil filling and dipstick

2 Side panel

3 Rain protection cap

4 Cooling fan drive belt

5 Cooling fan with built-in alternator

6 Governor housing

7 Hydraulic belt tensioner

8 Stop device

9 Belt pulley with 1/2“ internal square for

cranking engine

10 Oil drain plug

11 Speed control lever

12 Lub.-oil filter

13 Oil drain plug (oil sump)

14 Cooling air duct for lub.-oil cooler

15 Access to fuel feed pump

1

L / M . . 10.98

Flywheel side

Engine: 2 ... 4 M 31,

2 ... 4 M 40,

2 ... 4 M 41

1 Cylinder head cover

2 Fuel pressure pipe

3 Cover for air filter(s)

4 Eye hook for transport, max. load 500 kg

5 Injector

6 Fuel return line

7 Fuel feed line

8 Wiring harness duct

9 Flywheel

10 Engine flange

11 Starter motor

12 Type plate

13 Exhaust silencer

Engine illustrations

Operating side

Engine: H 2 L 30,

H 3 L 30

1 Fuel line (feed pump - filter)

2 Fuel line (filter - injector pumps)

3 Hose connection

(Maintenance indicator for air filter)

4 Primer pump

5 Fuel feed line

(Fuel tank - fuel feed pump)

6 Lub.-oil filling and dipstick

7 Speed control lever

8 Solenoid, engine stop

9 V-belt

10 Voltage regulator

11 Oil drain plug, governor side

12 Lub.-oil filter

13 Oil drain plug,

14 Fuel pre-filter

15 Oil pressure switch

16 Fuel feed pump (Bosch)

Governor- and exhaust side

Engine: H 2 L 30,

H 3 L 30

1 Cooling water inlet

2 Rain protection cap

3 Air filter

4 Cylinder head cover

5 Fuel pressure pipe

6 Temperature switch

7 Cooling water outlet

8 Exhaust manifold

9 Starter motor

10 Type plate

11 Centrifugal pump

12 Belt-adjustment link

13 Alternator

IMPORTANT !

The standard transport suspension enables

safe transportation of the engine including

supplementary equipments, and is designed

for a maximum load of 500 kg (1100 lbs).

It is neither suitable nor approved to lift

complete units.

Engine illustrations

1

L / M . . 10.98

1

L / M . . 10.98

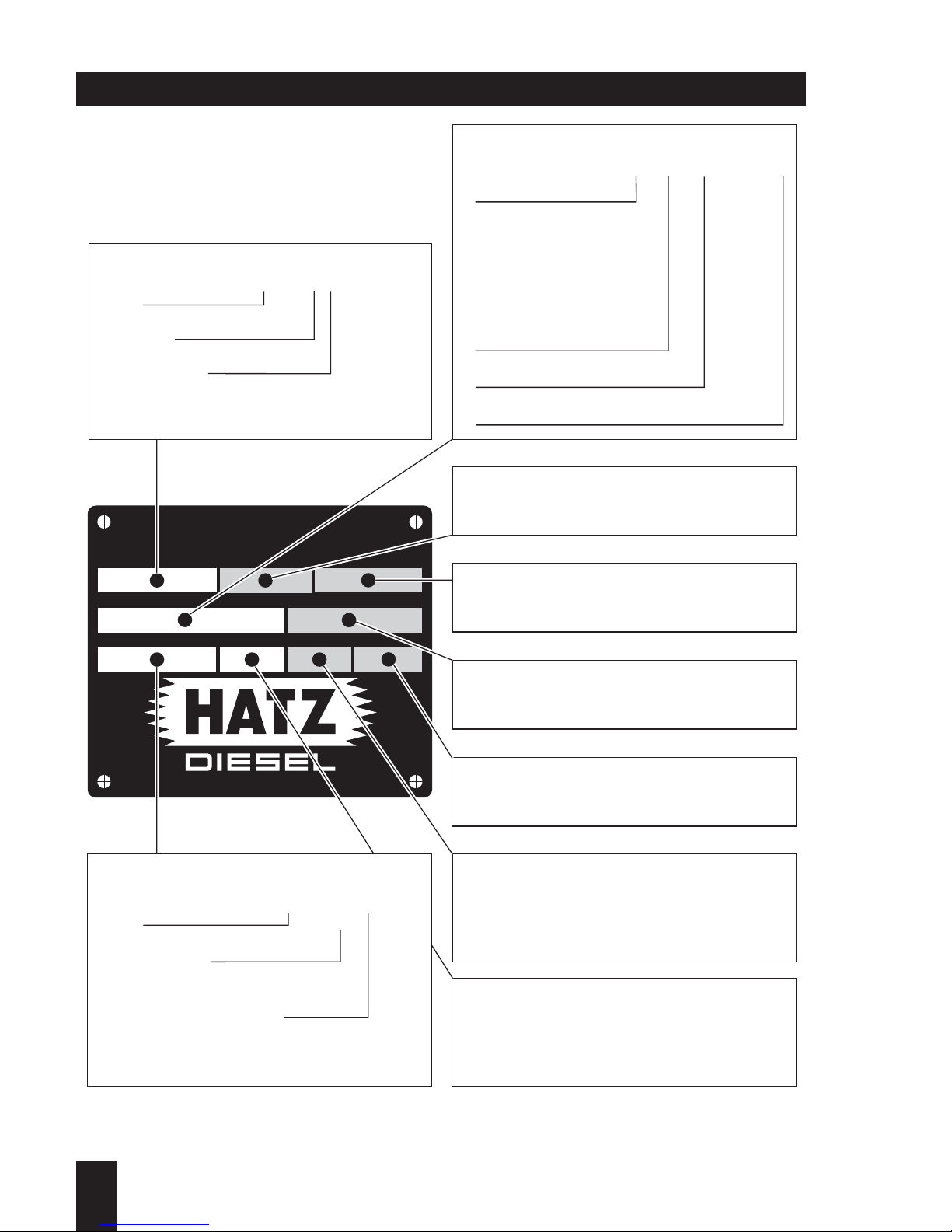

Type plate data

Complete type description

e.g.

Engine type

Engine version

2L40 C

Customer spec. list No. 1)

Customer-specification

Output in kW 2)

Execution code 2)

Adjustment instruction 1)

Special adjustm. regarding

engine speed, power output etc.

Injection pump delivery lift in mm

to obtain the required engine output.

Governor rod travel for adjusting the

correct fuel quantity in 1/100 mm

Engine number

Type-No.

064 10 81 031814

MOTORENFABRIK HATZ KG

D-94099 RUHSTORF

GMBH

CO

+

TYP KENNZ.

MOTOR / FABRIK NO.

ABE /AUSF.

MIN NH PV CM

MADE IN GERMANY

-1

3

Displacement in cm

3

3000 / 60

Engine speed

e.g.

Nominal speed

Speed increased under

no-load condition

max. no-load speed

1) If required

2) in special cases only; e.g. engines acc. to Federal Authority for Automobilism

Engine series no.:

The serial no. begins

with 10 and changes

continously (11,12) if

any major changes are

carried out.

Year of production

Fabrication-No. (continous)

3000 + 60 = 3060 min

-1

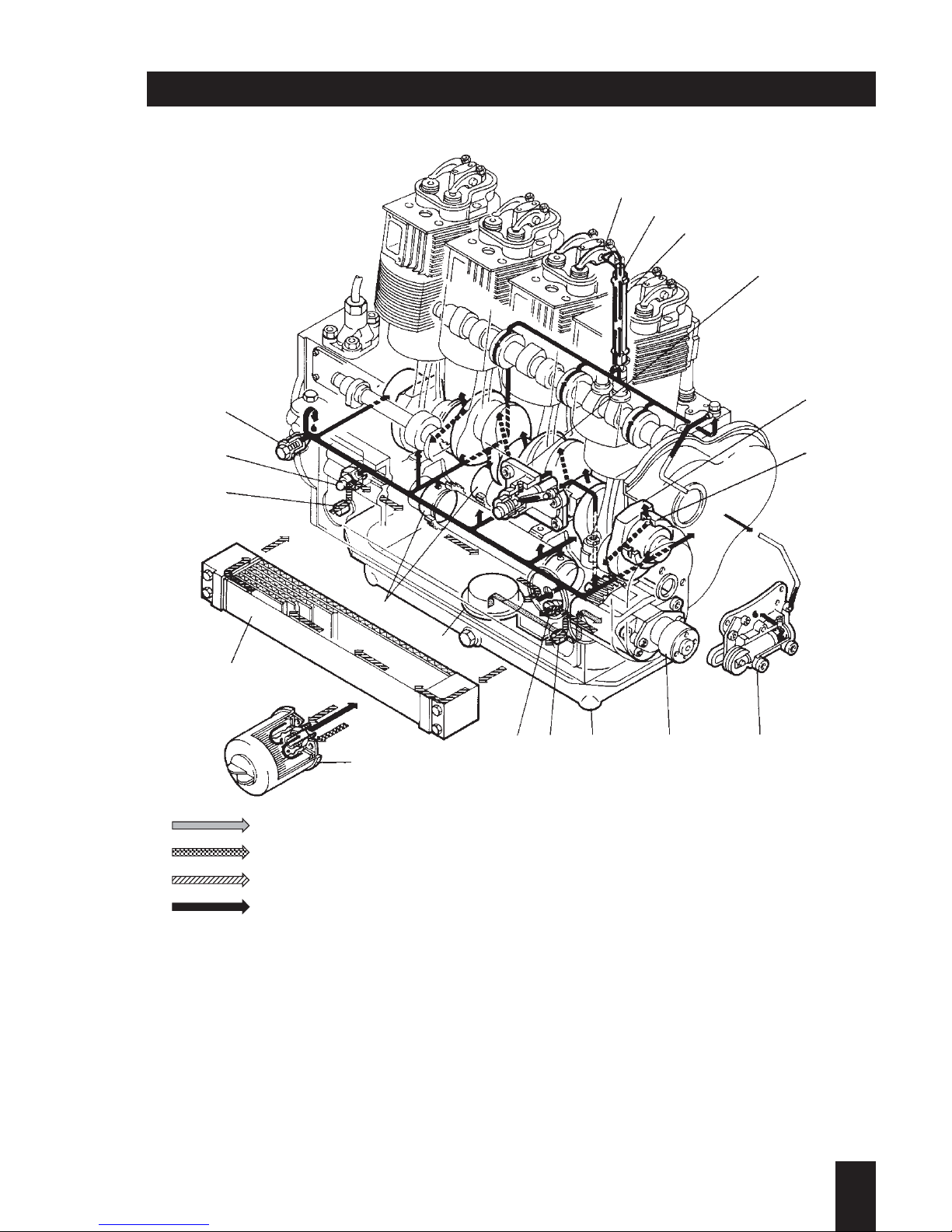

1 Rockers

2 Pushrods

3 Pushrod tubes

4 Hydr. starting charge device or

oil servo

5 Crankshaft

6 Main bearings

7 Hydraulic belt tensioner

8 Lubricating oil pump

9 Sump

10 Plug

– on engines without oil cooler

11 Threaded rod

– on engines with oil cooler

12 Oil suction strainer

13 Balancing shaft(s)

14 Lub. oil filter with bypass valve

15 Oil cooler

16 Oil pressure switch

17 Oil pressure relief valve

Lubricating oil circuit

1

L / M . . 10.98

1

2

3

4

5

6

7

8

910

11

12

13

14

15

10

16

17

Suction line

Oil pressure feed to filter on engines without oil cooler

Oil pressure feed to filter on engines with oil cooler

Oil circuit after oil cooler

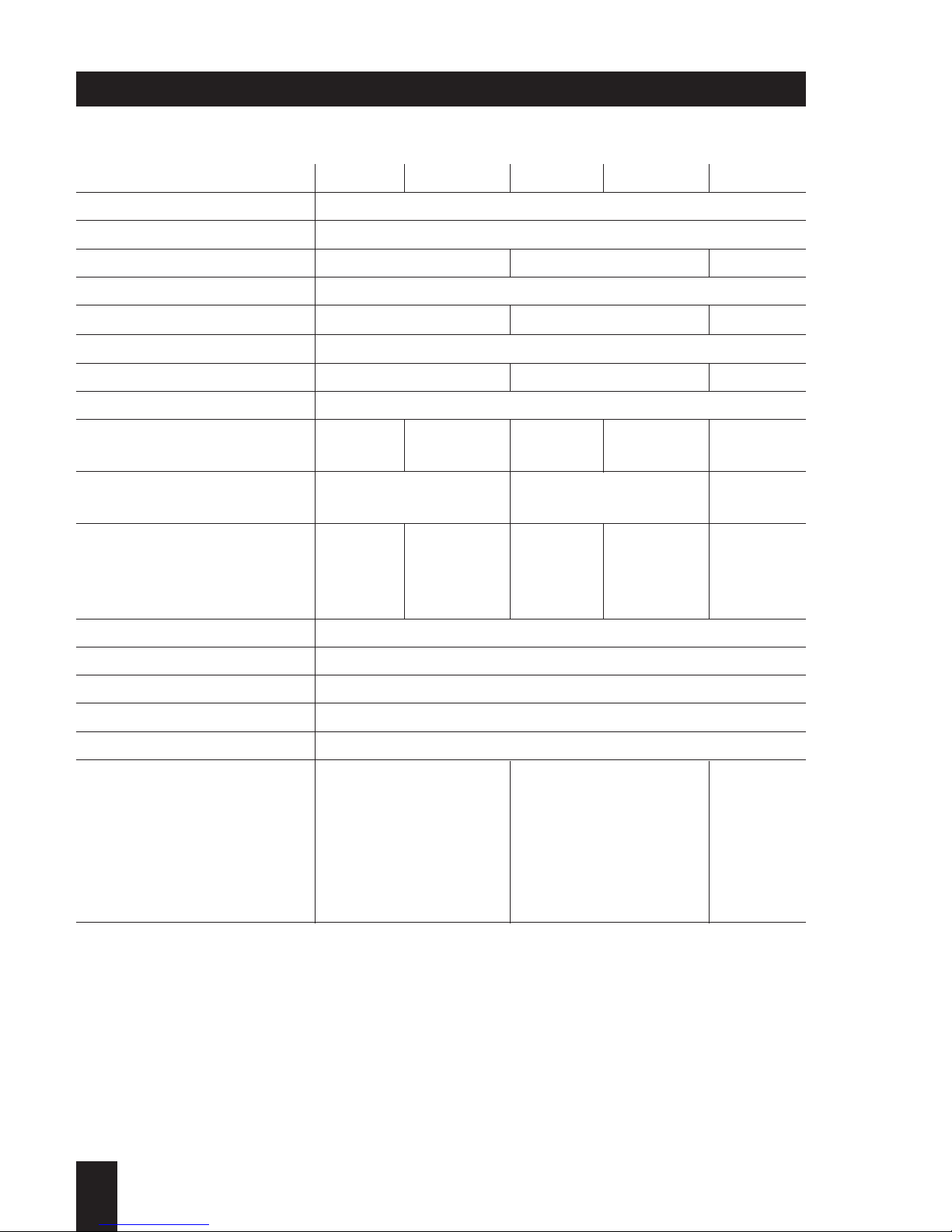

Type 2L30 H2L30 3L30 H3L30 4L30

Operating cycle 4-stroke

Combustion system Direct injection

Number of cylinders 2 3 4

Bore / stroke mm 95 / 100

Displacement cm

3

1416 2124 2832

Compression ratio 18:1

Firing order, cyl.1:timing end 2-1 1-3-2 1-3-4-2

Direction of rotation anti-clockwise (looking at flywheel)

Cooling air requirement at

n = 3000 rpm m3/min 25 - 35 - 45

Combustion air requirement

at n = 3000 rpm m3/min 2.1 3.2 4.2

Net weight approx. kg

L 30 S 223 222 255 271 291

L 30 Z 228 228 262 279 306

L 30 C / K 276 - 331 - 396/386

Lubricating oil pressure at n = 800 rpm min.: 0.9 bar

Lubricating oil consumption max.: 1 % of fuel consumption, at full load

Starter motor 12 V, 2,7 kW or 24 V, 4,0 kW

Alternator 14 V, 50 A or 28 V, 40 A*

Battery 12 V, 88 / 143 Ah or 24 V, 55 / 110 Ah

Max. continuous inclination with and without with without only with

towards oil sump oil sump oil sump

Operating side 30° 30° 25° 25°

Flywheel side 30° 22° 25° 18°

Air outlet/starter side 30° 30° 30° 30°

Governor side 30° 25° 25° 15°

* At H 2 L 30 and H 3 L 30: 14 V, 33 A or 28 V, 27 A

1

L / M . . 10.98

Technical data L 30

1

L / M . . 10.98

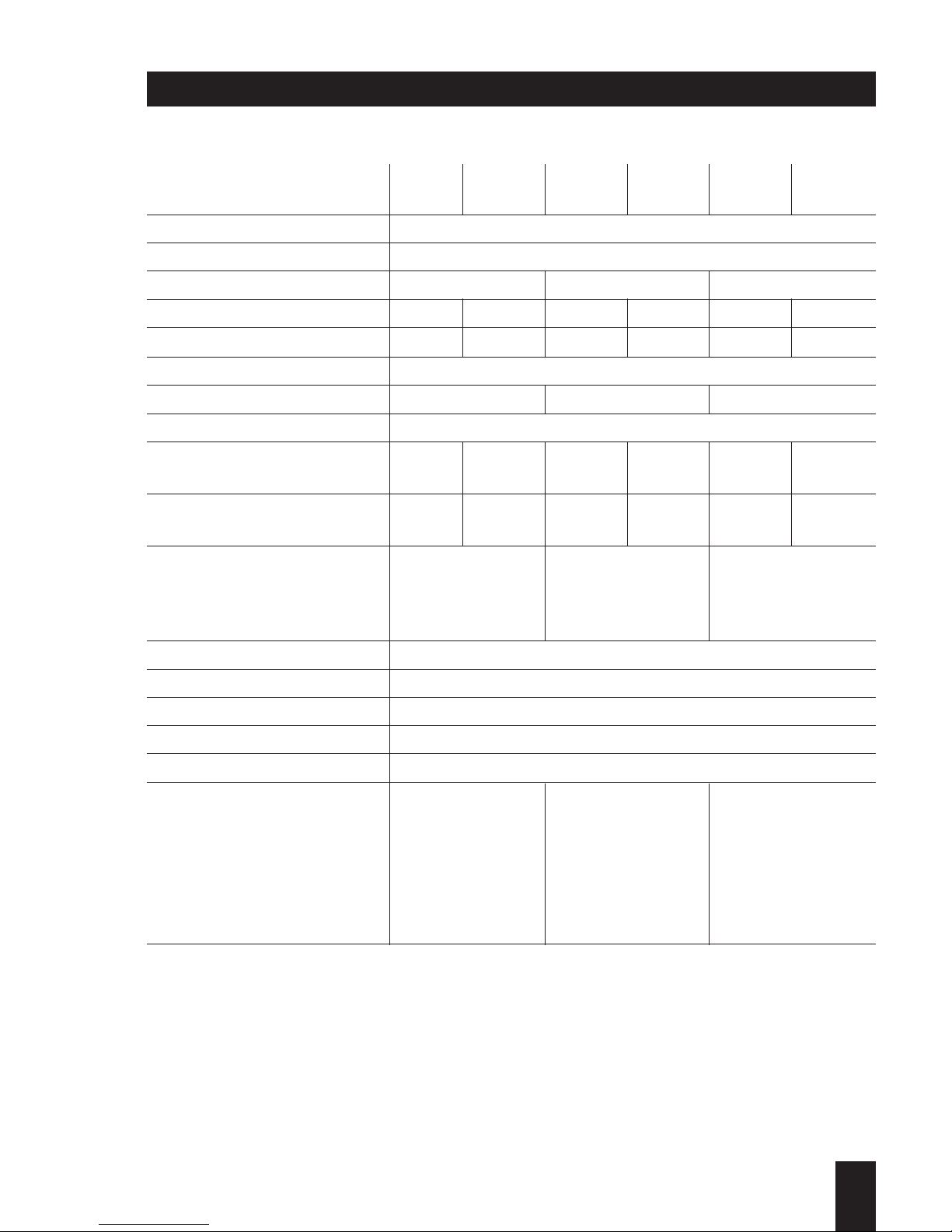

Type 2L31 2L40 3L31 3L40 4L31 4L40

2M31 2M40 3M31 3M40 4M31 4M40

Operating cycle 4-stroke

Combustion system Direct injection

Number of cylinders 2 3 4

Bore / stroke mm 102/90 102/105 102/90 102/105 102/90 102/105

Displacemen cm

3

1470 1716 2205 2574 2940 3432

Compression ratio 18:1

Firing order, cyl.1: timing end 2-1 1-3-2 1-3-4-2

Direction of rotation anti-clockwise (looking at flywheel)

Kühlluftbedarf bei

n = 3000 min-1m3/min 25 29 35 39 46 49

Combustion air requirement

at n = 3000 rpm m3/min 2.1 2.6 3.2 3.9 4.2 5.2

Net weight approx. kg

L 31 S, L 40 S, M 40 223 255 291

L 31 Z, L 40 Z, M 40 Z 228 262 306

L 31 C / K, L 40 C / K 276 331 396/386

Lubricating oil pressure at n = 800 rpm min.: 0,9 bar

Lubricating oil consumption max.: 1 % of fuel consumption, at full load

Starter motor 12 V, 2,7 kW or 24 V, 4,0 kW

Alternator 14 V, 50 A or 28 V, 40 A

Battery 12 V, 88 / 143 Ah or 24 V, 55 / 110 Ah

Max. continuous inclination with and without with without only with

towards oil sump oil sump oil sump

Operating side 30° 30° 25° 25°

Flywheel side 30° 22° 25° 18°

Air outlet/starter side 30° 30° 30° 30°

Governor side 30° 25° 25° 15°

Technical data L 31, M 31, L 40, M 40

1

L / M . . 10.98

Type 2L41 3L41 4L41

2M41 3M41 4M41

Operating cycle 4-stroke

Combustion Direct injection

Number of cylinders 2 3 4

Bore / stroke mm 102/105 102/105 102/105

Displacement cm

3

1716 2574 3432

Compression ratio 18,7:1

Firing order, cyl.1:timing end 2-1 1-3-2 1-3-4-2

Direction of rotation anti-clockwise (looking at flywheel)

Cooling air requirement at

n = 3000 rpm m3/min 29 39 49

Combustion air requirement

at n = 3000 rpm m3/min 1,9 2,9 3,9

Net weight approx. kg

M 41 S 223 255 291

M 41 Z 228 262 306

L 41 C / K 276 331 396/386

Lubricating oil pressure at n = 800 rpm min.: 0,9 bar

Lubricating oil consumption max.: 0,2 % of fuel consumption, at full load

Starter motor 12 V, 2.7 kW or 24 V, 4.0 kW

Alternator 14 V, 50 A or 28 V, 40 A

Battery 12 V, 88 / 143 Ah or 24 V, 55 / 110 Ah

Max. continuous inclination with and without with without only with

towards oil sump oil sump oil sump

Operating side 30° 30° 25° 25°

Flywheel side 30° 22° 25° 18°

Air outlet/starter side 30° 30° 30° 30°

Governor side 30° 25° 25° 15°

Technical data L 41, M 41

Sealants and adhesives

Sealants and adhesives:

Code letters in the text and drawings refer to the products stated below. The same

details appear in our spare part lists.

A = 502 230 01 Loctite Activator 500 ml

B = 502 231 00 Loctite 573 50 ml

C = 502 232 00 Loctite 601 50 ml

D = 502 233 00 Loctite 221 50 ml

E = 502 234 00 Loctite 648 10 ml

F = 502 238 00 Technicoll 8058 750 g

+ 502 239 00 Technicoll 8367 750 g

G = 502 565 01 Loctite IS 407 20 g

H = 502 825 01 Silicon 30 ml

J = 502 830 02 High-temp. paste 1000 g

K = 503 426 00 High-temp. paste 100 g

L = 502 566 00 Silicon 100 g

1

L / M . . 10.98

1

L / M . . 10.98

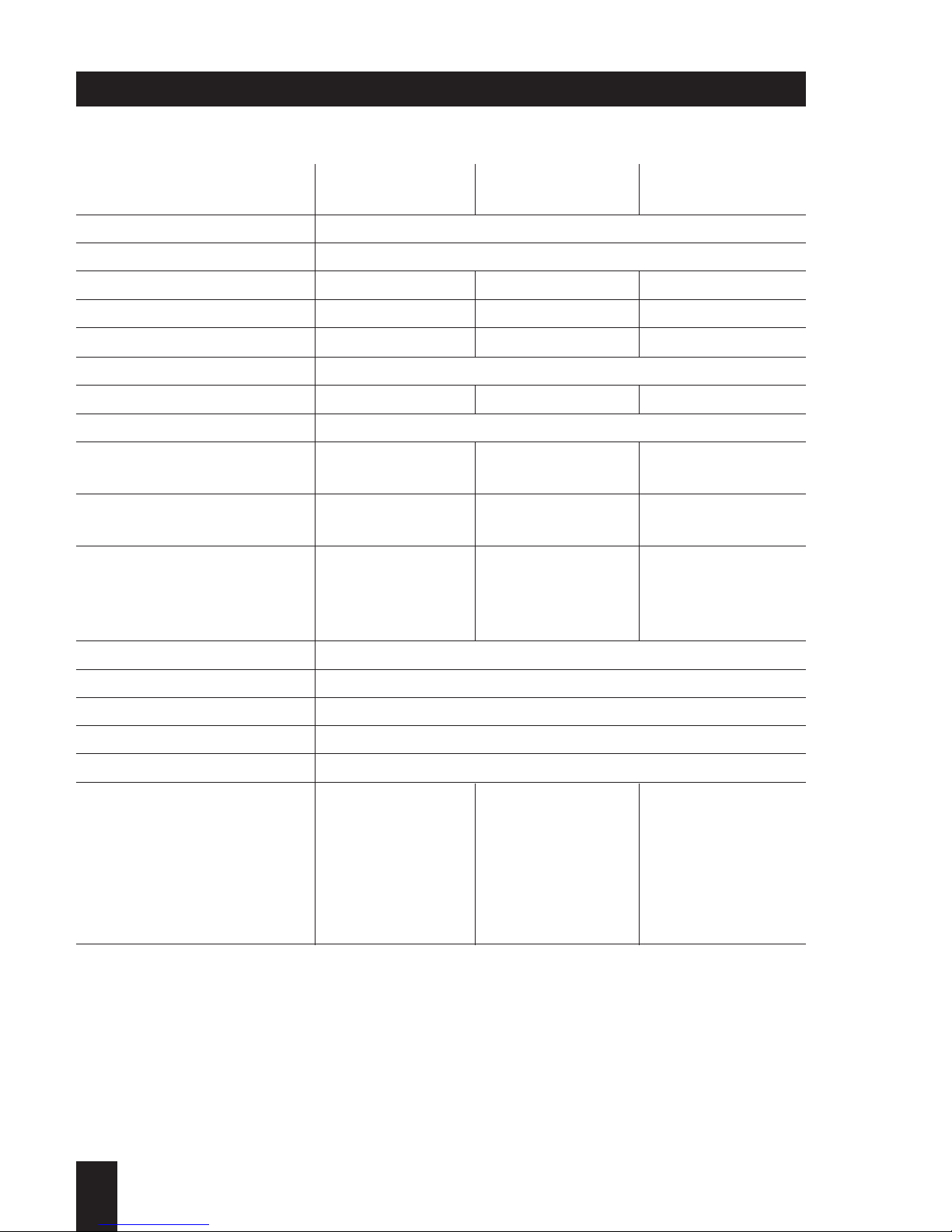

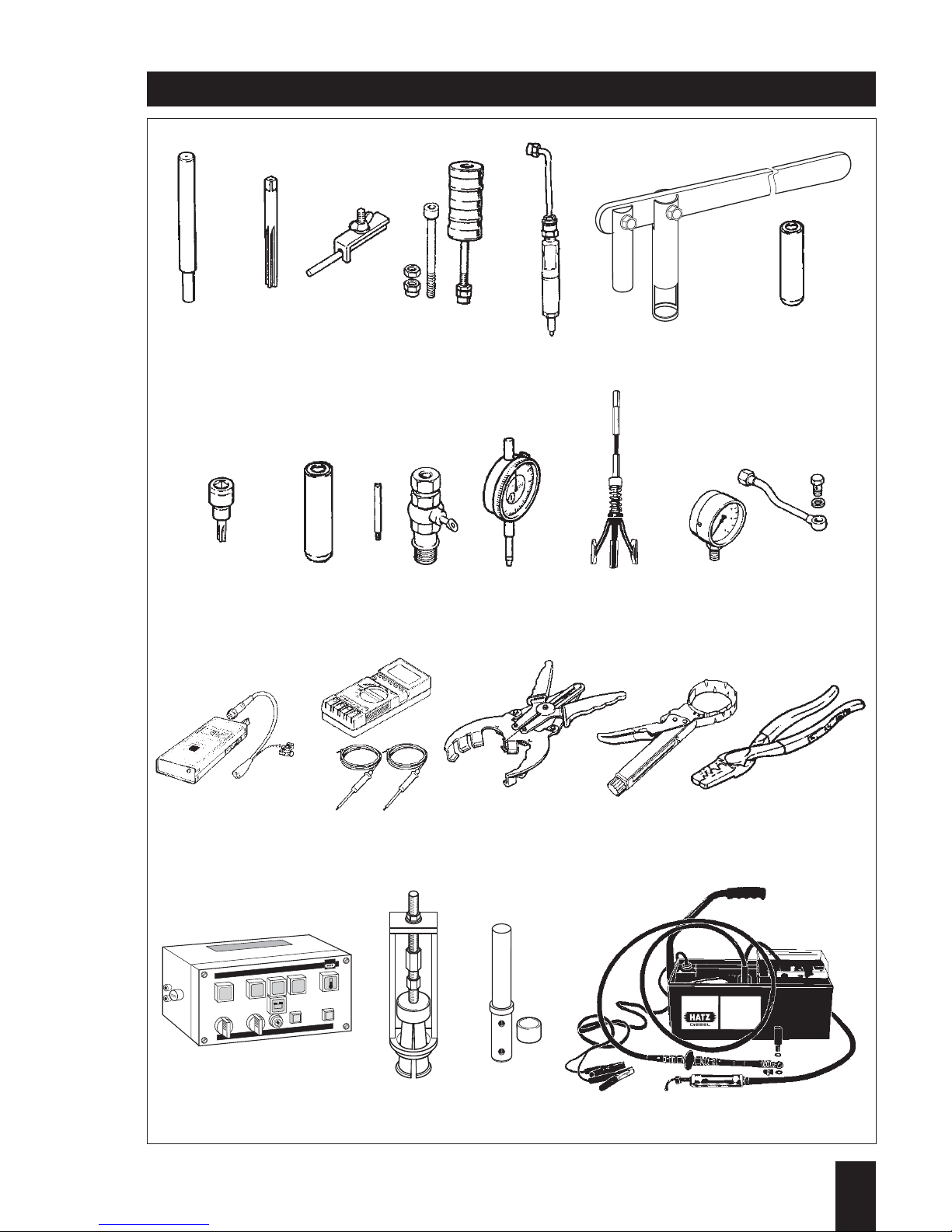

Special tools and workshop equipment

Series L / M engines

No. Ident-Nr. Code

Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

669 350 00

612 110 00

668 383 00

626 753 91

630 094 00

629 223 01

625 739 00

612 092 00

665 418 00

665 030 91

612 087 00

634 142 00

620 926 01

624 838 91

625 383 02

612 090 01

626 383 00

624 845 01

633 178 00

631 191 00

631 203 00

632 913 00

03.1.1

03.1.2

01.1.2

03.1.1

03.1.2

03.1.2

03.2.1

03.1.2

05.2.1

05.1.1

05.1.2

03.1.2

03.1.1

03.1.2

03.1.2

03.1.2

03.1.2

03.2.2

06.2.1

06.1.2

06.1.2

05.1.1

Pressing-in drift ∅ 9 mm for valve guides

Reamer 9 H 6 for valve guide

Clamp for fuel line

Impact extractor with accessories

Test nozzle 400 bar

Valve lifting tool

Pressing-in drift for valve stem seal

6 mm intl. hex. insert with centering pin

Driver sleeve for camshaft bearings

Overflow device for injection pump

Dial gauge – 1/100 mm

Honing tool

Oil pressure gauge 0 -6 6 bar with flexible tube

Rev. meter for fuel pressure pipe

Digital multimeter

Piston ring pliers

Piston ring clamping tool ∅ 70 - 100 mm

Crimping pliers up to 6 mm

2

Relay test box

Puller for belt tensioner bushings

Installation drift for belt tensioner bushings

High-pressure pump cpl.

Special tools and workshop equipment

1

L / M . . 10.98

12345 67

89101112 13

14 15 16 17 18

19 20 21 22

Injection - pump

timing set

A

B

E

C

D

R

e

l

a

is

-

F

u

n

k

t

i

o

n

s

-

u

n

d

Te

s

t

b

o

x

1

5

8

6

8

7

8

7a

5

0

–

+

Special tools and workshop equipment

Series L / M engines

Explanation of classification:

Example: 03. 1. 2

Manufacturer: 1 . . . Only available from HATZ

2 . . . Same item (or equivalent in function)

available commercialy

Necessity: 1 . . . Absolutely essential

2 . . . Useful or convenient

Type of repair: 01. . . Maintenance

02. . . Emergency repair

03. . . Repair in upper and external areas

05. . . Repair in area of driving gear

mechanism

5Q. . . General overhaul

(including all the necessary tests)

06. . . Component repairs

1

L / M . . 10.98

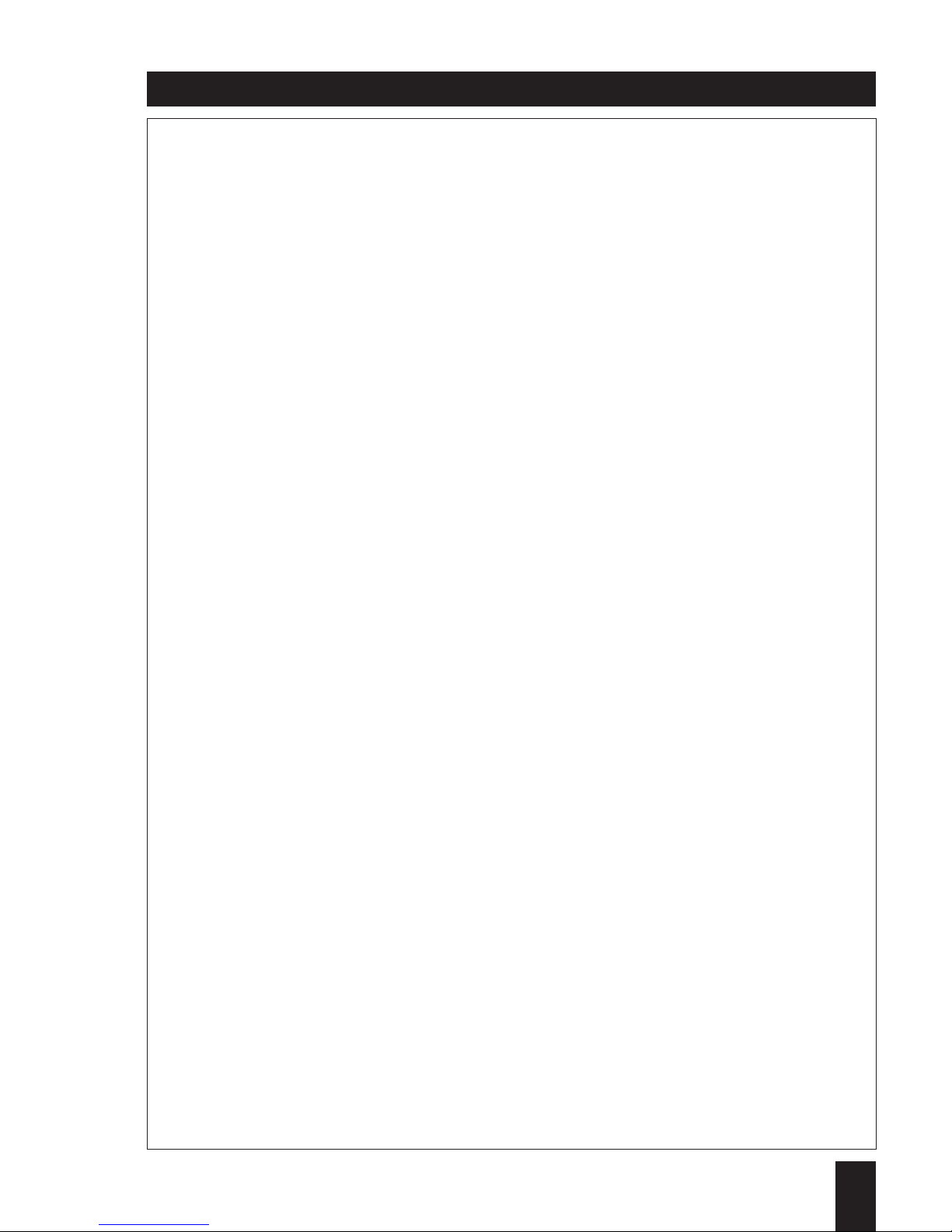

No. Ident-Nr.

Code

Item

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

624 340 01

624 346 01

624 347 00

624 348 01

624 349 00

624 350 00

606 000 00

618 140 01

618 418 00

610 390 00

620 300 00

624 393 00

621 056 00

626 211 00

604 628 00

620 307 01

620 638 01

619 746 00

630 439 00

619 852 02

619 854 02

619 855 02

624 863 02

624 864 01

629 055 00

05.1.1

05.1.1

05.1.1

05.1.1

05.1.1

05.1.1

05.1.1

03.1.1

03.1.1

03.1.1

03.1.1

05.1.1

03.1.1

03.1.1

03.1.1

01.1.2

02.1.1

05.1.1

05.2.1

5Q.1.1

5Q.1.1

5Q.1.1

03.2.1

03.2.1

02.1.2

Marking device for radial position of injection pump

Gauge for measuring governor rod travel

Gauge for adjusting start of fuel injection

Calibrating device for tool - 25 Locating pin for governor rod

Fuel injection volume adjusting tool

Wrench for starting charge adjustment

(mechanical system only)

Multipurpose puller in connection with tool - 31 Forcing-off screw for tool - 30 Forcing-off screw for centrifugal clutch

Forcing-off screw for centrifugal belt pulley

Assembly sleeve

M 10 x 1 guide pin for conrod

M 11 x 1 guide pin for conrod

Test pressure gauge for fuel injection system

Strap wrench

Locking device for tensioning roller

Holder for injection timer assembly

Gauge for oil spray nozzles

Air guide plate for 2 L / M

Air guide plate for 3 L / M

Air guide plate for 4 L / M

Elevating table, mobile

Adapter elements for - 45 Disassembly tools for cable plug

Special tools and workshop equipment

1

L / M . . 10.98

23 24 25 26 27

28 29 30 31 32 / 33 34

35/36 37 38 39

40

44

47

42

43

44

46

45

2

L / M . . 09.96

2. Additional equipment

- 3 -

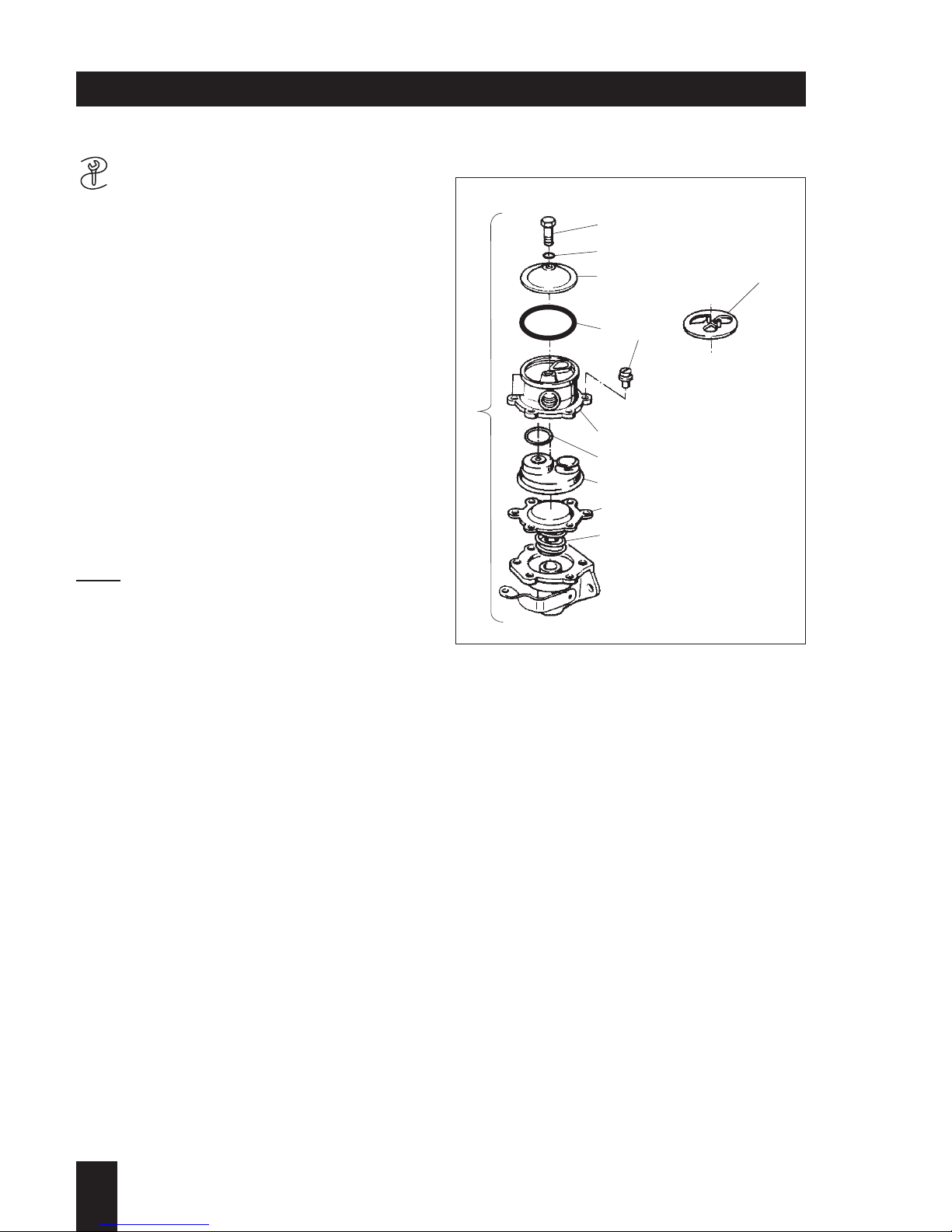

General:

– When installing the fuel delivery pump,

make sure that the delivery and suction

lines are connected correctly.

Dismantling:

– Disconnect fuel feed line with clamp - 3 -.

– Separate the fuel lines from the delivery

pump.

– Unscrew and remove nuts with spring

washers, and take off fuel delivery

pump with O-ring.

– Dismantle fuel delivery pump 1 in the

numerical order of parts illustrated

(Fig. 182).

Note:

Since September 1992 fuel strainer 12

has been replaced by O-ring 5.

Because of this, an input-side fuel filter

must always be used.

This input-side filter is supplied as a spare

part with the fuel delivery pump and also

with the repair kit for the fuel delivery

pump.

Assembling:

Assemble by following the instructions in

the reverse order as appropriate.

2

L / M . . 09.96

182

A 01.00 Fuel

A 01.40 Fuel delivery pump

2

3

4

56

7

8

9

10

11

1

12

–

Preparations:

– Remove the hood from the enclosure

and air outlet duct; see M 35.00.

Detaching:

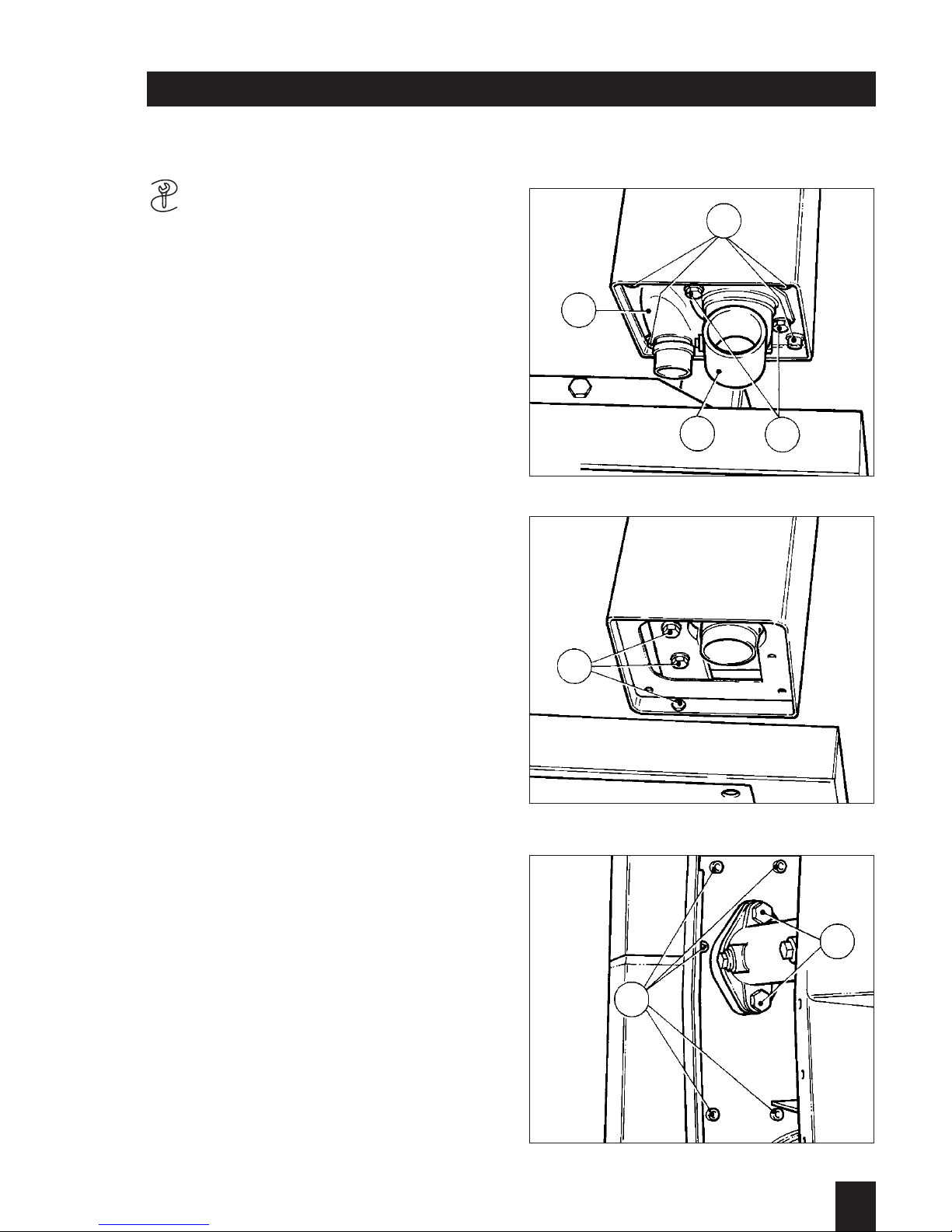

– Take out hex bolts (184/1) and detach

the connecting stub pipe with exhaust

pipe (184/2).

On more recent versions, the exhaust

pipe is secured with a clip.

– Take out the machine screws (184/3)

and remove the connecting cover

(184/4).

– Unscrew and remove the hex bolts

(185/1).

– Remove the machine screws (186/1)

and bolts (186/2).

2

L / M . . 09.96

184

185

186

A 03.00 Exhausts

A 03.12 Removing and installing the silencer (muffler)

enclosure(L 30, L 31, L 40, C/K)

L3 / 228

1

3

4

2

L3 / 229

1

L3 / 230

1

2

Lift off the enclosure with exhaust silencer

(muffler); see Fig. 187.

Note:

In some cases a spacing plate is installed

between the silencer enclosure and the

air duct housing.

– On the 2 - 3 L 40 from date of manufac-

ture 5.85 on, 4 L 40 from 1.86 on and L

31, the connecting stub pipe (189/1),

sealing washer (189/2) and plate

(189/3) are deleted.

Five sealing washers are installed

between the silencer and the exhaust

manifold.

– Pull the upper and lower sections of the

enclosure apart and lift out the silencer;

see Fig. 188.

Check the parts:

– Examine the enclosure sections and the

silencer for fractured welds or tapped

holes which are unfit for further use.

Installing:

– Install by following the removal instruc-

tions in the reverse order as

appropriate.

The silencer must be installed without

trapped stresses (a two-piece holder for

the silencer has been installed since

March 1989).

Note:

Before installing the connecting stub pipe

(189/1), check free movement of the sealing washer (189/2).

Place the sealing washer in the connecting stub pipe and install the plate (189/3).

It should be possible to move the sealing

washer radially. Next, place the sealing

washer on the silencer. Radial play must

not exceed 0.1 mm. If necessary, renew

the sealing washer.

2

L / M . . 09.96

187

188

189

L3 / 231

L3 / 232

L3 / 233

12

3

–

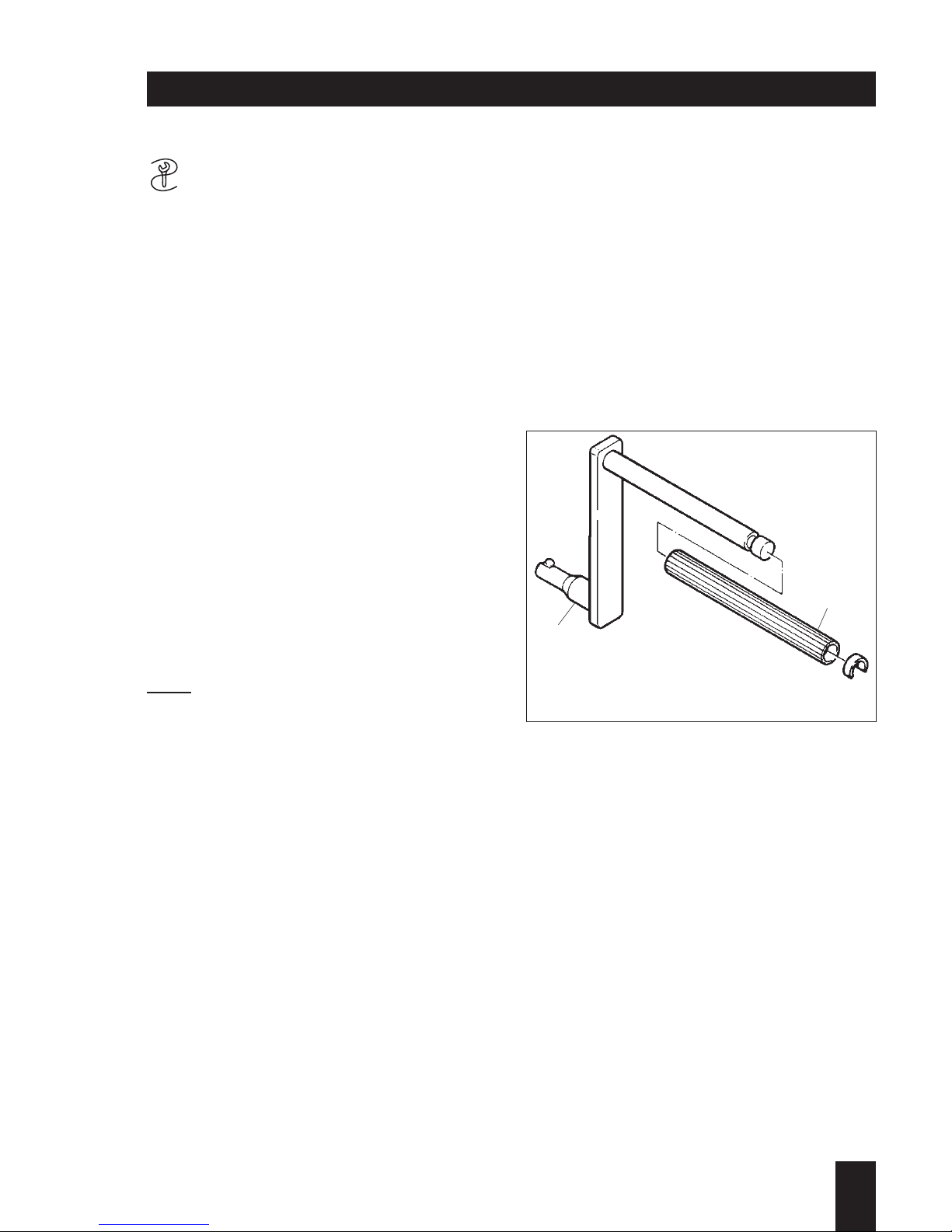

Version A 04.10.1

Standard crank handle:

This handle can be replaced at any time

by one with kick-back damping if this

becomes necessary or is required by

regulations.

Attention !

There is a risk of injury if the shaft of the

crank handle or its tubular handgrip are

worn.

Preparations: –

Demontage: –

Inspection / repair:

– Visual inspection.

– Inspect shaft 1 and tubular handgrip 2

for wear or breakage.

Note:

If the shaft of the crank handle is worn,

always renew the complete handle.

The tubular handgrip can be renewed

separately if necessary.

2

L / M . . 09.96

191

A 04.00 Start mechanical

A 04.10 Crank handle

2

1

–

Version A 04.10.2

Handle with kick-back damping:

The version for M .. engines is marked A

on its housing, and takes the place of the

standard crank handle if required.

Attention !

There is a risk of injury if the shaft of the

crank handle or its tubular handgrip are

worn.

Preparations: –

Demontage:

– Remove parts in the order 1 ... 3 as

illustrated.

– Remove machine screws 4.

– Take off cover 5 with great care, so that

leaf spring 11 cannot escape.

Risk of injury!

– Remove parts in the order 6 ... 10 as

illustrated.

– Hold torsion spring 13 in position in

order to maintain its tension.

– Pull leaf spring 11 away from its locking

pin and out of the hook eye on torsion

spring 13.

– Relieve torsion spring tension with a

screwdriver blade.

Caution - risk of injury!

– Take off parts 12 and 13.

Housing 14 remains in position with the

other parts.

2

L / M . . 09.96

192

A 04.00 Start mechanical

A 04.10 Crank handle

47

8

15

14 13

12

11

10

9

6

5

1

6

1

5

3

A

Inspection / repair:

– Visual inspection:

– Renew the complete starting handle if

there is any damage in the area of

cover 5 and/or housing 14.

– If necessary, renew pivot bushings 15

and shaft sealing ring 16.

– Examine tubular handgrip 7 for wear

and/or other damage, particularly in the

splined area.

– Install end plug 8, avoiding damage to

the splines. The end plug must installed

to prevent dirt and water from entering.

– Check condition of bushing and leaf

spring at lever 9.

– Check condition of leaf spring 11 and

torsion spring 13.

Renew in case of doubt.

– Check shaft 3 for wear and/or other

forms of damage.

– Renew O-rings and small parts.

2

L / M . . 09.96

Assembling:

– Install parts 13 and 12.

Use thread sealant D.

– Make sure that the torsion spring is not

trapped; insert its longer end into the

groove on the corresponding locating

pin.

– Preload torsion spring 13 against the

normal spring pressure until the hook

eye of the spring engages behind the

eye of the through-hole.

Caution - risk of injury!

– Hold torsion spring 13 in position to pre-

vent spring pressure from being lost.

– Push leaf spring 11 into the hook eye

on torsion spring 13 and place on

locking pin.The rolled end of the leaf

spring must face toward the center of

the housing.

– Attach lever 9.

– Push on tubular handgrip 7/8.

Check splines, lever and leaf springs for

free movement.

– Apply app. 50 grams of lubricant K to

the inside of housing 14 and over all

mechanical parts.

– Place a new gasket 6 on the housing.

– Carefully place cover 6 over tubular

handle 7.

– Insert machine screws 4 and tighten

them evenly in a crosswise pattern.

– Install shaft 3 in the order 3 ...1 as

illustrated.

– Check operation of the complete crank

handle.

–

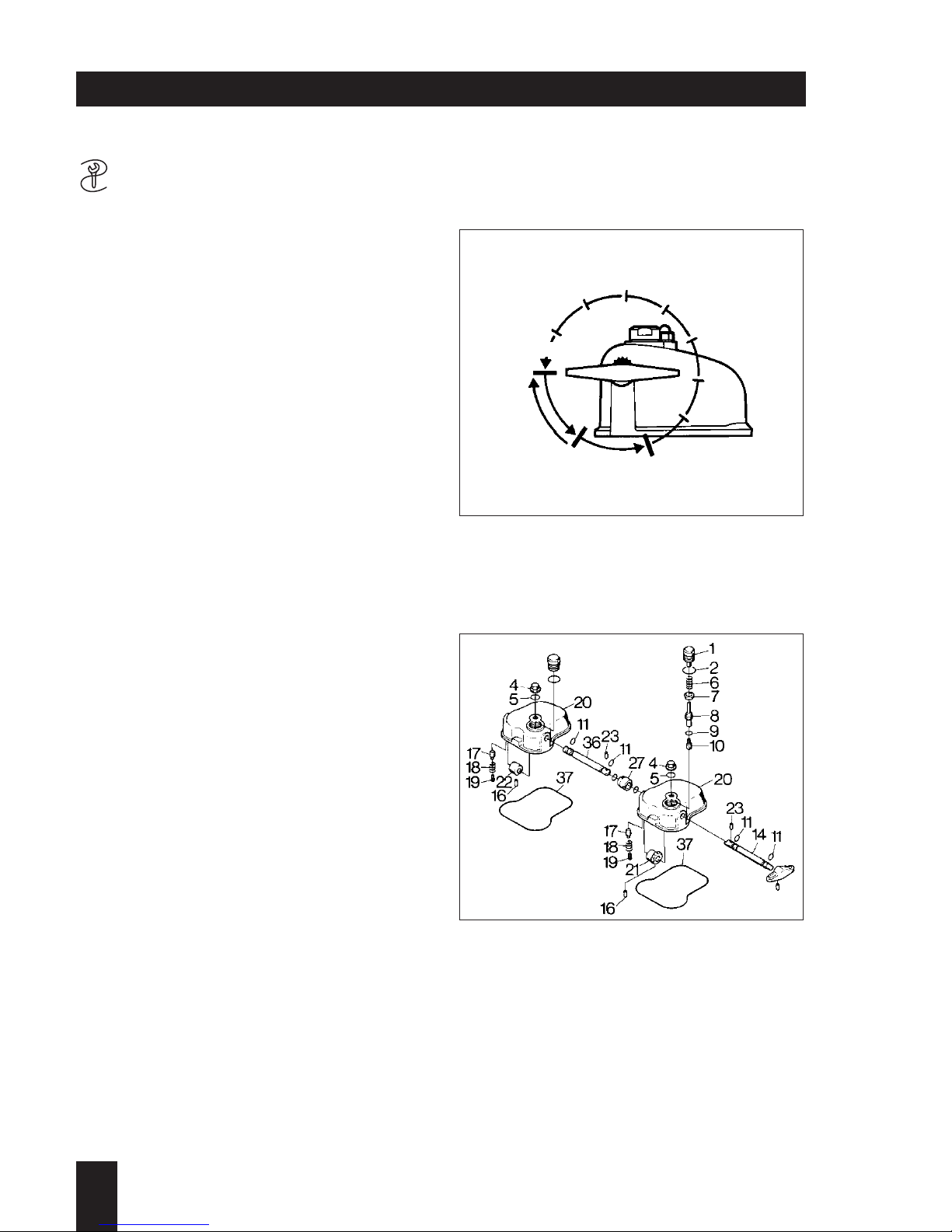

The automatic decompressor has the

following positions; Fig. 93:

0 = Operating position, with engine

running

1 = Permanent decompression, automatic

device switched off

2 = Automatic decompressor switched on,

engine compression is built up automatically after about 8 turns of the

handle.

Detaching:

– Unscrew cap nut (94/4) with sealing ring

(94/5).

– Take off cover (94/20) with gasket

(94/37).

On two-cylinder engines, shafts (94/14)

and (94/36) are connected together by

coupling sleeve (94/27) and 2 locking

collets (94/23). Camwheel (94/22) is then

used at the second cylinder (flywheel

side) instead of the gearwheel.

Dismantling the automatic decompressor:

– Unscrew and remove screw plug (94/1).

– Take out sealing ring (94/2), spring

(94/6), cap (94/7) and lifting pin with

shims and pressure pin (94/8, 9, 10).

– Unscrew threaded rod (94/19) and

remove spring (94/18) and pressure pin

(94/17).

– Using a suitable split-pin driver, drive

locking collet (94/16) about 3 mm into

gearwheel (94/21).

– Turn the gearwheel through 180° and

pull the locking collet out with pliers.

– Take out shaft (94/14) and gearwheel.

2

L / M . . 09.96

93

94

A 04.00 Start mechanical

A 04.20 Automatic decompressor (M 31, M 40, M 41)

L3 / 1

12

0

kompr.

dekompr. dekompr.autom.

L3 / 42

Loading...

Loading...