Page 1

INSTRUCTION BOOK

433 216 08-USA-EPA IV-CARB

10.07-0.1

Printed in Germany

1D 41.

1D 50.

1D 81.

1D 90.

33

INCLUDES SUPPLEMENTAL INFORMATION TO THE

OWNER’S MANUAL FOR 2008 AND LATER EPA CERTIFIED

NONROAD COMPRESSION-IGNITION ENGINES

INCLUDES SUPPLEMENTAL INFORMATION TO THE

OWNER’S MANUAL FOR 2008 AND LATER CALIFORNIA

REGULATIONS FOR HEAVY-DUTY OFF-ROAD ENGINES

Page 2

1

A new HATZ diesel engine is ready to work for you

This engine is intended only for the purpose determined and tested by the manufacturer of the

equipment in which it is installed. Using it in any other manner contravenes the intended purpose.

For danger and damage due to this, Motorenfabrik HATZ assumes no liability. The risk is with the

user only. Use of this engine in the intended manner presupposes compliance with the maintenance

and repair instructions laid down for it. Noncompliance leads to engine breakdown.

Please study this Instruction Book before you start the engine for the first time: it will help you to

avoid accidents, to operate the engine correctly, to perform maintenance work and to keep the engine

operating at full efficiency for a very long time.

Please follow all maintenance references carefully including the schedule for 2008 and later

EPA certified nonroad compression-ignition engines and for 2008 and later CARB certified

Heavy-Duty off-road engines to prevent our environment.

Please pass this Instruction Manual on to the next user or to the following engine owner.

Throughout the world, a network of HATZ service stations is at your disposal for advice, spare parts

supply and maintenance or repair work.

Please refer to the enclosed list for the address of your nearest HATZ service point.

Please use only genuine HATZ spare parts. Only these parts guarantee a perfect dimensional stability

and quality. Their order numbers are shown in the enclosed Parts List. Please note the complete

spare part kits in Table M00 of the list.

In the interests of technical progress we reserve the right to introduce modifications.

MOTORENFABRIK HATZ GMBH & CO KG

Page 3

Page

1. Important notes on safe operation

of the engine 3

2. Description of the engine 5

3. General information 7

3.1. Technical data 7

3.2. Transport 8

3.3 Instructions for installation 8

3.4. Load on engine 8

3.5. EPA/CARB-type plates 8

3.6. Emission-related installation

instructions 9

4. Operation 10

4.1. Before initial start-up 10

4.1.1. Engine oil 10

4.1.2. Oilbath air cleaner 10

4.1.3. Fuel 11

4.1.4. Mechanical oil pressure monitor 12

4.2. Starting the engine 13

4.2.1. Preparations for starting 13

4.2.2. Starting with the handle 14

4.2.3. Starting with the handle with

kick-back damping 15

4.2.4. Starting in cold weather 16

4.2.5. Electric starter 16

4.3. Stopping the engine 18

5. Maintenance 19

5.1. Maintenace summary 19

5.2. Maintenance every 8 – 15 hours

of operation 21

5.2.1. Check engine oil level 21

5.2.2. Check air intake point 21

5.2.3. Air cleaner blockage indicator 21

5.2.4. Checking cooling air zone 22

5.2.5. Checking the water trap 22

Page

5.3. Maintenance every 250 hours

of operation 23

5.3.1. Oilbath air cleaner maintenance 23

5.3.2. Changing engine oil, renewing

oil filter 24

5.3.3. Checking and adjusting

valve clearances 25

5.3.4. Clean the cooling air system 26

5.3.5. Checking threaded connections 26

5.3.6. Cleaning mesh insert in exhaust

silencer 26

5.4. Maintenance every 500 hours

of operation 27

5.4.1. Renewing fuel filter 27

5.4.2. Dry-type air cleaner maintenance 28

6. Malfunctions – Causes – Remedies 30

7. Work on the electrical system 34

8. Protective treatment 34

SUPPLEMENTAL INFORMATION TO

THE OWNER’S MANUAL FOR 2008

AND LATER EPA CERTIFIED

NONROAD COMPRESSION IGNITION

ENGINES 35

SUPPLEMENTAL INFORMATION TO

THE OWNER’S MANUAL FOR 2008

AND LATER CALIFORNIA

REGULATIONS FOR HEAVY-DUTY

OFF-ROAD ENGINES 51

2

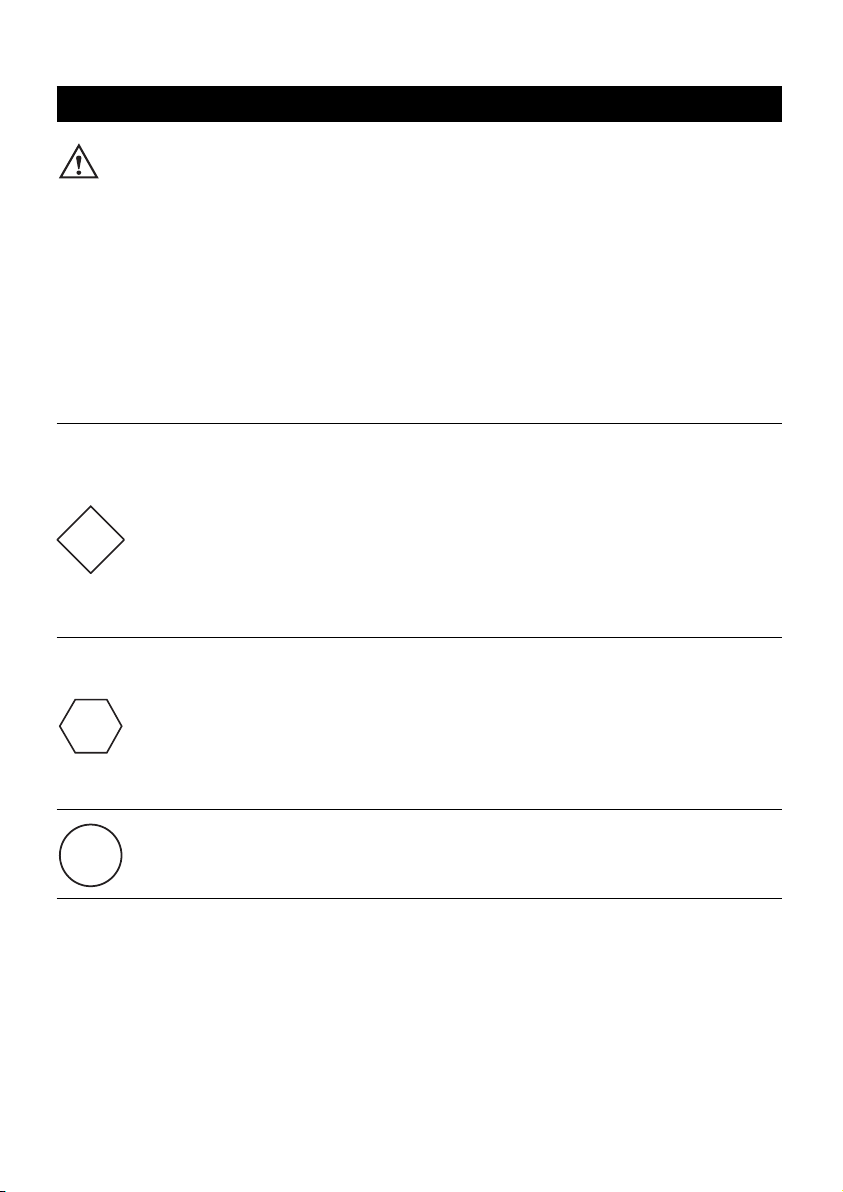

This symbol draws attention to important safety precautions.

Please comply with them most carefully in order to avoid any risk of injury to persons or

damage to materials.

General legal requirements or safety regulations issued by the competent authorities or

industrial accident insurers are also applicable.

Contents

Page 4

3

1. Important notes on safe operation of the engine

HATZ diesel engines are economical, strongly built and long-lasting. They are therefore frequently

chosen for commercially and industrially operated equipment and machinery.

Since the engine forms part of the finished equipment or machine, its manufacturer will take all the

applicable safety regulations into account.

Nevertheless, we give below certain additional comments on operating safety, and would recommend

you to note them carefully.

Depending on the manner in which the engine is installed and its intended application, the equipment

manufacturer or operator may have to attach additional safety devices and prohibit potentially hazardous aspects of operation, for example:

– Parts of the exhaust system as well as the surface of the engine are of course hot during operation

of the engine, but also when it is still cooling down after use, and must not be touched.

– Faulty wiring or incorrect operation of electrical equipment may lead to sparks forming, and must

be avoided as a potential fire hazard.

– Rotating parts must be shielded against accidental contact when the engine is installed in other

equipment or machinery.

Guards are available from HATZ to protect belt drives, cooling fans and generators.

– Before attempting to start the engine it is essential to have studied the starting information in the

Instruction Book; this is particularly important on engines started with a starting handle.

– Mechanical starting devices must not be used by children or persons of insufficient physical

strength.

– In order to benefit from the advantages of the starting handle with kick-back damping, it must be

used precisely as recommended in this Instruction Book.

– Before starting the engine, ensure that all the specified protective guards are in place.

– The engine must only be operated, serviced or repaired by persons who have received the appro-

priate training.

– Keep the starting handle and the key out of reach of unauthorized persons.

– Never run the engine in closed or badly ventilated rooms.

Do not breath in emissions - danger of poisoning!

– Also fuel and lubricants could contain poisonous components. Please follow the instructions of the

mineral oil producer.

Page 5

4

Important notes on safe operation of the engine

– Stop the engine before performing any maintenance, cleaning- and repair work.

– Stop the engine before refuelling.

Never add fuel near a naked flame or a source of sparks.

Don’t smoke. Don’t spill fuel.

– Keep explosive materials as well as flammable materials away from the engine because the exhaust

gets very hot during operation.

– Wear close-fitting clothing when working on a running engine.

Please don’t wear necklaces, bracelets or any other things which you could get caught with.

– Please pay attention to all advice- and warning stickers placed on the engine and keep them in legi-

ble condition. Contact your next HATZ service station, if a sticker comes off or is illegible and ask

for a new one.

– Note that any unauthorized modification to the engine absolves its manufacturer from liability for

the consequences.

Regular servicing in accordance with the details provided in this Instruction Book is essential to keep

the operating reliably and to ensure the exhaust quality of the engine.

In case of doubt, always consult your nearest HATZ service station before starting the engine.

Page 6

5

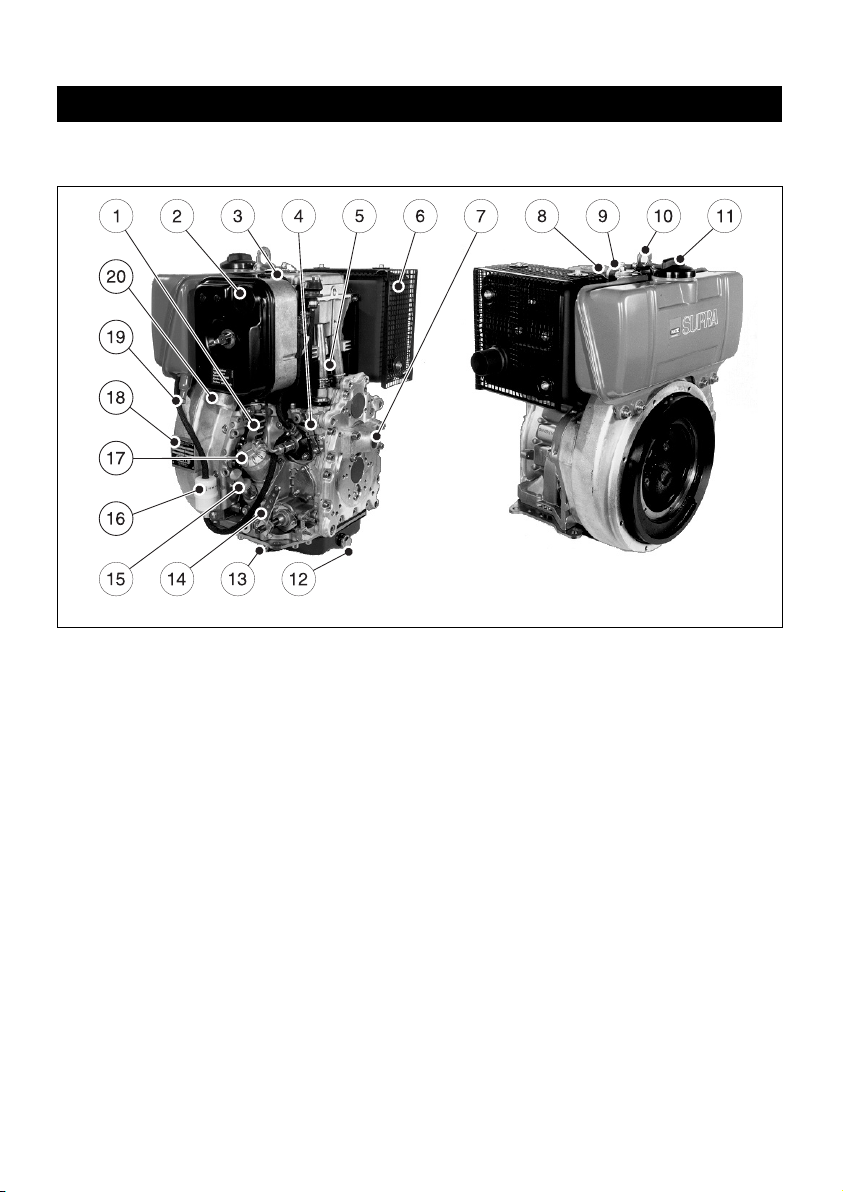

2. Description of engine

1D41 • 1D50 • 1D81 • 1D90 S / Z engines

1

2391 / 12 2391 / 7

1 Cooling air inlet

2 Dry-type air cleaner

3 Decompression lever

4 Stop lever

5 Cooling air outlet

6 Silencer (muffler)

7 Guide sleeve for starting handle

8 Cylinder head cover

9 Cold-start oil metering device

10 Suspension lug

11 Tank filler cap

12 Oil drain plug, governor housing

13 Oil drain plug, governor side

14 Speed control lever

15 Oil filler pipe and dipstick

16 Fuel filter

17 Oil filter

18 Type plate

19 Tank drain plug

20 Combustion air intake

Page 7

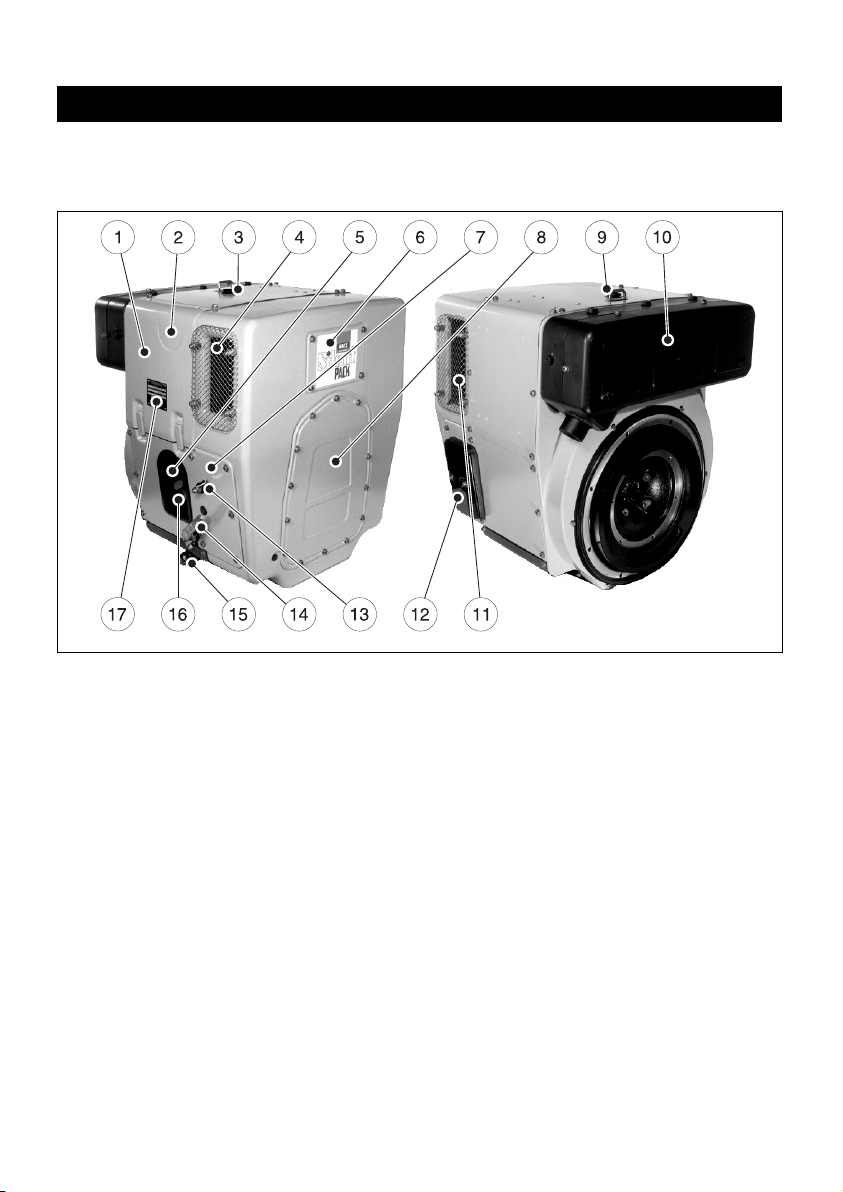

6

Description of engine

Fully-encapsulated version

1D41C • 1D81C engines

2

1 Capsule

2 Decompression lever

3 Cold-start oil metering device

4 Combustion and cooling air intake

5 Oil filter

6 Cleaning hatch

7 Side panels

8 Hold for starting handle

9 Suspension lug

10 Silencer (muffler), encapsul.

11 Cooling air outlet

12 Battery connection and central plug

for electrical system

13 Stop lever

14 Speed control lever

15 Oil drain plug

16 Oil filler and dipstick

17 Type plate

2392 / 1 2392 / 4

Page 8

7

3. General information

3.1. Technical data

Type 1D41. 1D50. 1D81. 1D90.

Engine models S, Z, C S, Z S, Z, C S, Z

Mode of operation air-cooled four-stroke diesel engine

Combustion method Direct-fuel injection

Number of cylinders 1 1 1 1

Bore / stroke mm 90 / 65 97 / 70 100 / 85 104 / 85

Displacement cm³ 413 517 667 722

Engine oil content without filter approx. L 1.1

1)

1.4

1)

1.8

1)

1.8

1)

with filter approx. L 1.2

1)

1.5

1)

1.9

1)

1.9

1)

Volume of oil between

„max“ and „min“ marks approx. L 0.4

1)

0.5

1)

0.9

1)

0.9

1)

Consumption of lubrication oil

after running-in period approx. 1 % of fuel consumption at full load

Engine oil pressure

Oil termperature 100 ± 20 °C min. 0.6 bar at 850 r.p.m.

Direction of rotation

looking at the flywheel counterclockwise

Valve clearance at 10 - 30 °C

Inlet mm 0.20 0.10 0.10 0.30

Exhaust mm 0.20 0.20 0.20 0.30

Max. angle from vertical in any

direction (continuous operation) max. 30°

2)

30°

2)

30°

2)

30°

2)

Weight (incl. fuel tank, air-cleaner,

exhaust silencer and electric starter)

Engine model S approx. kg 75 76 89 90

Engine model Z approx. kg 77 78 91 92

Engine model C approx. kg 96.5 – 121

Model S: non-encapsulated, normal system of balancing

Z: non-encapsulated, add. system of balancing

C: SILENT PACK, add. system of balancing

1)

These data are approx.-values. The max. mark on oil dipstick counts.

2)

Exceeding these limits causes engine breakdown.

Page 9

3.2. Transport

A lug is provided on top of the engine

as standard equipment, so that the engine and its auxiliaries can be lifted safely. It

is not suitable for lifting complete machines or

similar with the engine attached, and this is

strictly prohibited. (See Chapter 2.)

3.3. Instructions for installation

The „Manual for Selection and Installation of Engines“ contains all the information you need if

your engine has not yet been installed on or in

the equipment it is intended to drive, or set up

in its correct operating position. You can obtain

a copy of this manual from your nearest HATZ

service station.

3

The permitted loads and elements on

the speed adjusting lever and the stop

lever should be observed as an exess can lead

to damage to the contacts and inner governor

parts.

3.4. Load on engine

See supplemental information for EPA certified

engines, Page 35; resp. supplemental information for California regulations for off road

engines, Page 51.

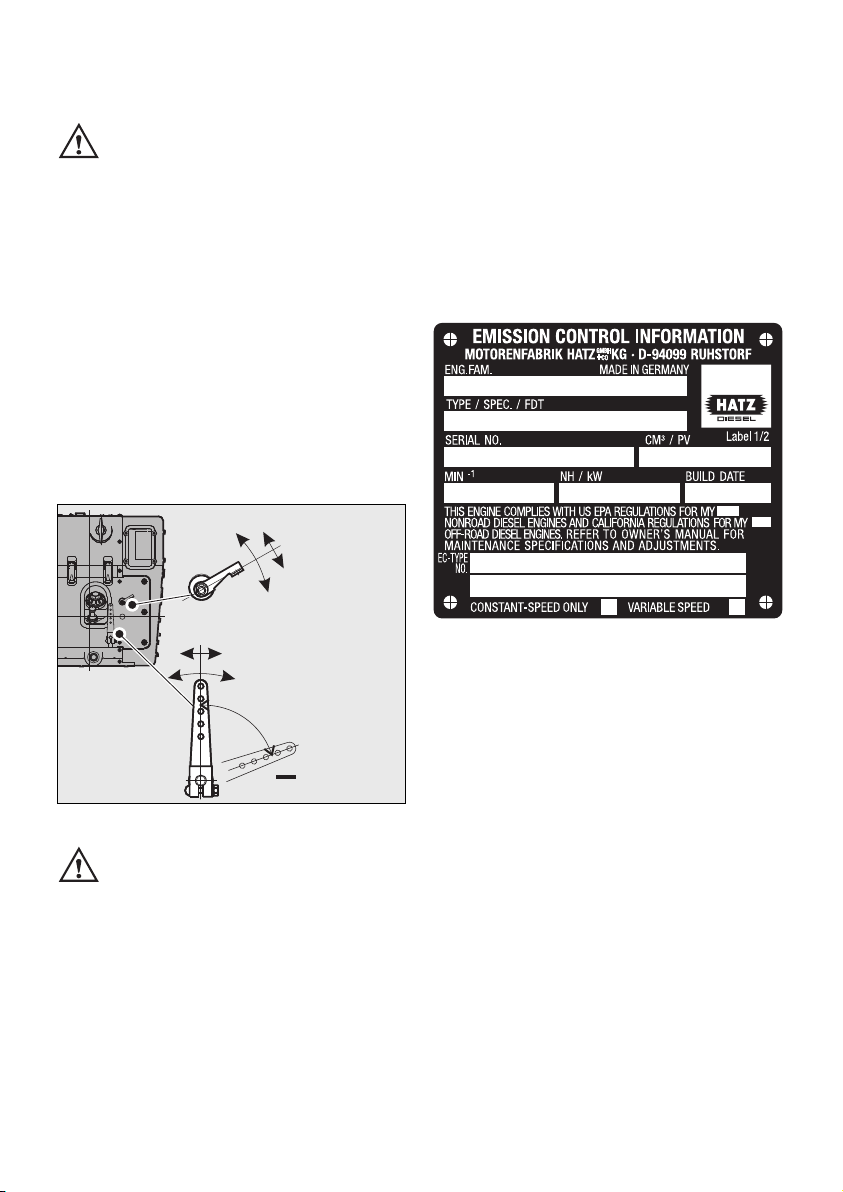

3.5. EPA/CARB-type plates and

fuel label

There are two EPA/CARB- type plates applied for

the identification of the engine. The type plates

are placed on the crankcase resp. on the capsule

(chapt. 2).

They include the following emission control information (Figure 4a):

Label 1/2

4a

➀ EPA/CARB-Engine Family Number

➁ engine type / spec. (only for special

equipment) /Fuel Delivery Timing

➂ engine number

➃ max. engine rated speed

➄ build date

➅ displacement

➆ rated power

➇ “constant speed only” (if requested)

➈ “variable speed” (if requested)

Every engine is equipped with an additional

loose engine type plate. If the original type

plate on the engine is not readily visible after

the engine is installed in the equipment then

the second loose type plate must be attached

on the equipment in such a manner that it is

readily visible to an average person.

The layout is identical for constant-speed and

variable speed application.

70°

F 120 N

M 12.6 Nm

–

–

F 10 N

M 0.35 Nm

–

–

<

<

<

<

START

STOP

+

8

➀

➁

➂

➃

➆

➇

➅

➄

➈

Page 10

For any offer as well as spare parts orders it is

necessary to mention the following data (also

see spare parts list, page 1):

➁ engine type / spec.

(only for special equipment)

➂ engine number

➃ max. engine rated speed

Attention:

If the engine was certified for constant-speed

application and shall be used so, the field "constant-speed only" is marked with “X”.

If the engine was certified for variable speed application and shall be used so, the field "variable

speed" is marked with “X”.

Always install the engine for its intended application in order to comply with EPA and CARB

emission regulation requirements.

Label 2/2

4b

The engine must be operated with “LOW SULFUR FUEL OR ULTRA LOW SULFUR FUEL

ONLY”.

The label also states the applicable emissionrelated power category of the engine.

Fuel label

4c

The fuel label is placed nearby the fuel inlet.

If there was no fuel tank mounted to the engine,

the label has to be permanently attached to the

equipment near the fuel inlet.

3.6. EMISSION-RELATED

INSTALLATION INSTRUCTIONS

See supplemental information for EPA certified

engines, Page 35; resp. supplemental information for California regulations for off road

engines, Page 51.

9

LOW SULFUR FUEL OR ULTRA

LOW SULFUR FUEL ONLY

EMISSION CONTROL INFORMATION

LOW SULFUR FUEL OR

ULTRA LOW SULFUR FUEL ONLY

❏ < 8 kW / ❏ 8-19kW / ❏ 19-37kW /

❏ 37-56 kW PM Standard: 0.3 g/kWh

Power category:

Label 2/2

Page 11

4. Operation

4.1. Before initial start-up

Engines are normally delivered without fuel and

oil.

4.1.1. Engine oil

Qualified are all trademark oils which fulfil at

least one of the following specifications:

ACEA – B2 / E2 or more significant

API – CD / CE / CF / CF-4 / CG-4 or more

significant.

If engine oil of a poorer quality is used, reduce

oil change intervals to 150 hours of operation.

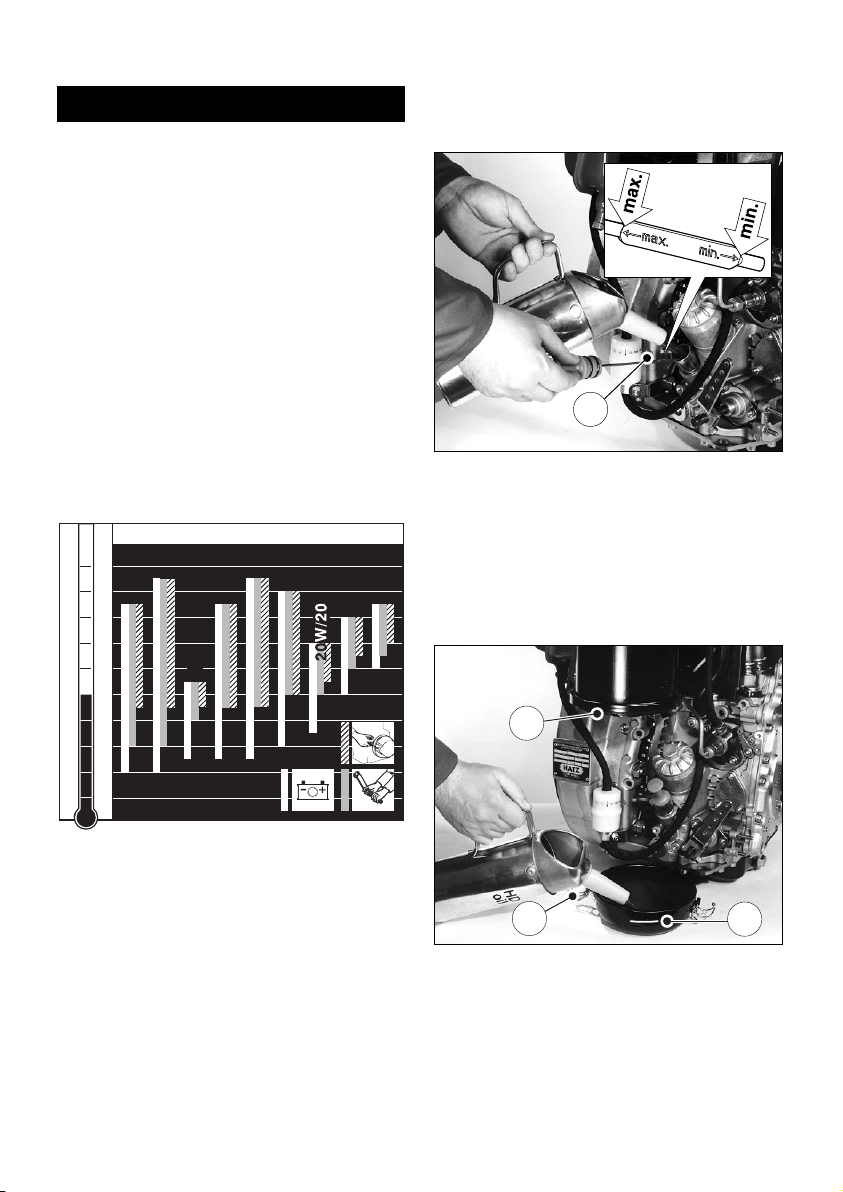

Oil viscosity

5

Choose a viscosity according to the ambient

temperatures where the engine is to be started

from cold.

The engine must be in a horizontal position before adding oil or checking the oil level.

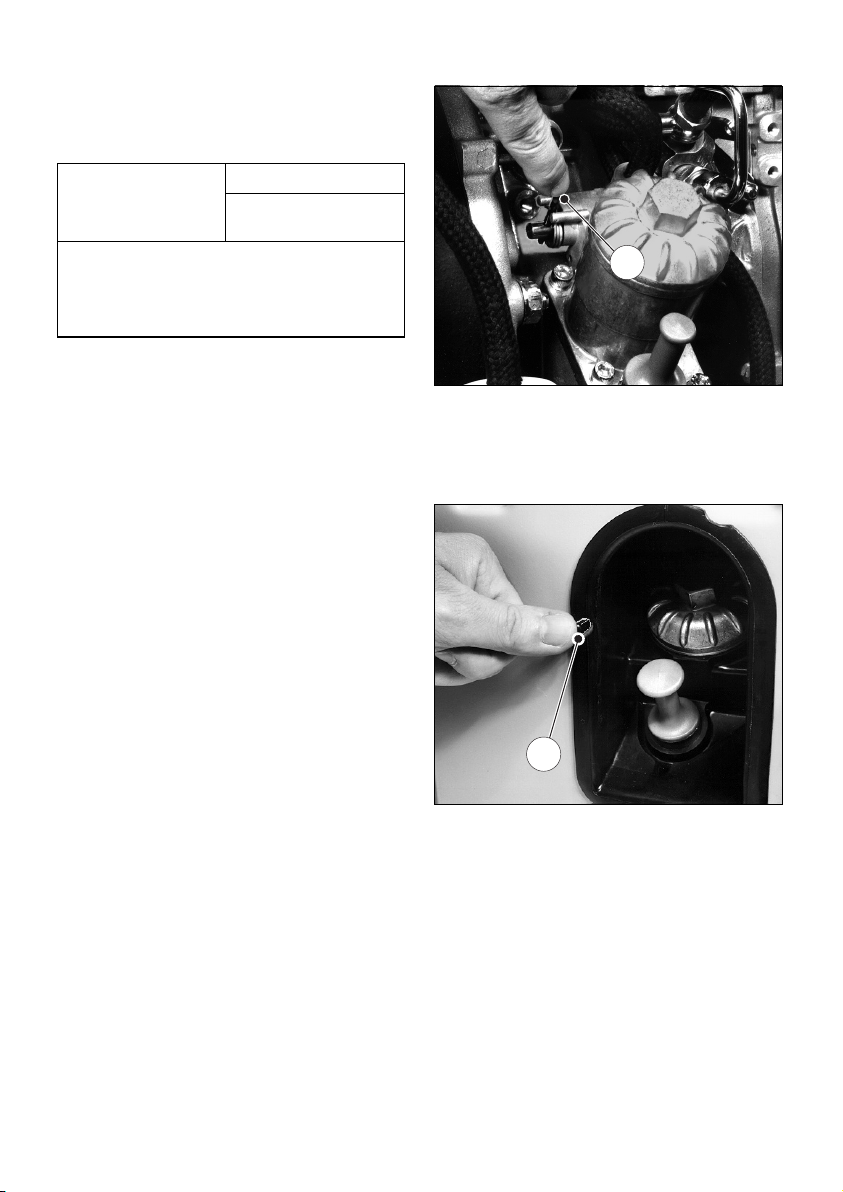

6

– Pull out dipstick „1“ and add engine oil of the

correct specification and viscosity up to the

„max“ mark on the dipstick; (Chapter 3.1.).

4.1.2. Oilbath air cleaner

7

– Take off the oil reservoir and fill it up to the

mark „1“ using engine oil.

– Attach the oil reservoir, making sure that seal-

ing ring „2“ is correctly seated and catches „3“

are tight.

2393 / 6

2

3

1

1

-40

-30

-20

-10

0

10

20

30

40

50

104

86

68

50

32

14

-4

-22

-40

OIL: SAE...

°C°F

5W/30

5W/40

10W/40

10W/30

15W/40

30

40

122

10 W

10

Page 12

4.1.3. Fuel

Only refuel when engine is stopped.

Never refuel close to open flames or

flammable sparks, don’t smoke. Use only pure

fuel and clean replenishing cups. Don’t spill

the fuel.

All diesel fuels sold as fuel and complying with

the following minimum specification can be

used:

EN 590 or

BS 2869 A1 / A2 or

ASTM D 975 - 1D / 2D

8

– Before the first start or if the fuel tank has

been run dry, completely fill the fuel tank with

diesel.

The fuel system is bled automatically if the

fuel tank is attached to the engine or located

higher than the injection pump.

9

– If the fuel tank is not mounted on top of the

engine, or is at a lower level, operate the lever

on the fuel feed pump until fuel is heard to

flow back to the tank through the return line.

10

– On fully encapsulated engines, move sleeve

„1“ to one side to gain access to the feed

pump.

After operating the feed pump, make sure that

the sleeve is replaced correctly and makes a

good seal.

1

2292 / 4

2287 / 11

2286 / 2

11

Page 13

At temperatures below 0 °C, winter-grade fuel

should be used or parafin added to the fuel well

in advance.

4.1.4. Mechanical oil pressure

monitor

(optional extra)

The mechanical oil pressure monitor should be

activated:

• when first filling, or after running the fuel tank

dry.

• if engine shut down automatically because lu-

bricating oil supply was inadequate.

• after freeing it by turning at low temperatures

(Chapter 4.2.4.)

• after replacing the fuel filter, Chapter 5.4.1.

– Add fuel, chap. 4.1.3.

– Check engine oil level, chap. 5.2.1.

11

– To activate the monitor, press lever „1“ for

approx. 15 seconds.

12

– If the engine has a full capsule, press pin „1“

for app. 15 seconds.

– If the engine has a fuel feed pump, operate its

lever for several strokes at the same time

(Figs. 9 and 10).

– Re-assemble all parts repositioned or re-

moved. Check that capsule elements make a

good seal.

2392 / 12

1

1

Lowest ambient

temperature when

starting, in °C

Paraffin content for:

Summer Winter

fuel fuel

0 up to –10 20 % –

–10 up to –15 30 % –

–15 up to –20 50 % 20 %

–20 up to –30 – 50 %

12

Page 14

13

Instructions to activate the mechanical oil pressure control are mentioned on the sticker placed

on the engine.

IMPORTANT !

Even with mechanical oil pressure monitoring

the oil level must be checked every 8 – 15

operating hours (Chapter 5.2.1.).

4.2. Starting the engine

Do not run the engine in closed or

badly ventilated rooms – danger of

poisoning ! Before the engine is started, always make sure that nobody is in the danger

area (moving parts on engine or machinery)

and that all safety guards are in place.

Check that the starting handle is in good condition: renew tubular grip if broken, worn drive pin

etc.

Lightly grease the sliding-contact area between

the starting handle and the guide sleeve.

14

Never use any spray starting aids.

4.2.1. Preparations for starting

– If possible, disengage the engine from any

driven equipment. The auxiliary equipment

should always be placed in neutral.

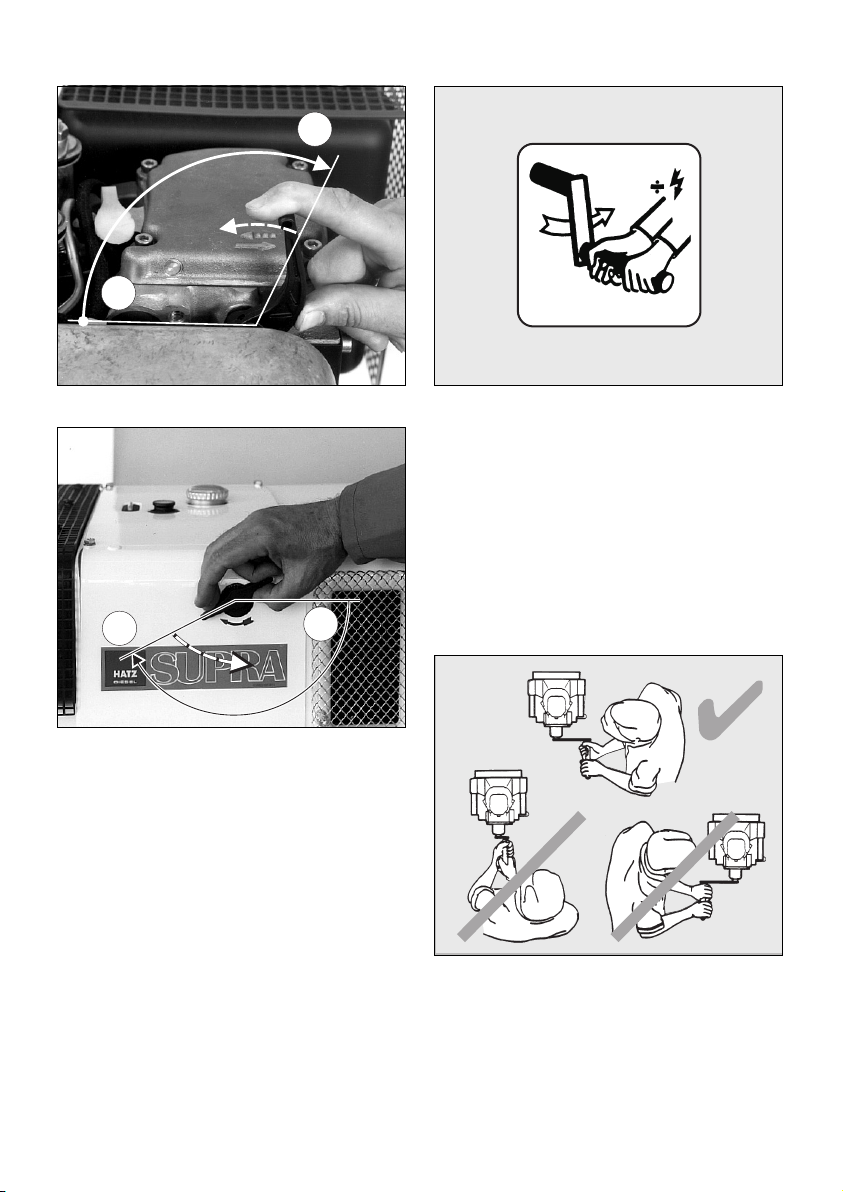

15

– Set speed control lever „1“ to a position be-

tween 1/2 START and max. START, according

to requirements. Selecting a lower engine

speed will reduce smoke when starting.

– Make sure that stop lever „2“ - if fitted - is in

the operating „START“ position.

2396 / 3

2

1

START

START

STOP

STOP

050 145 00

L3 / 250

13

Page 15

16

17

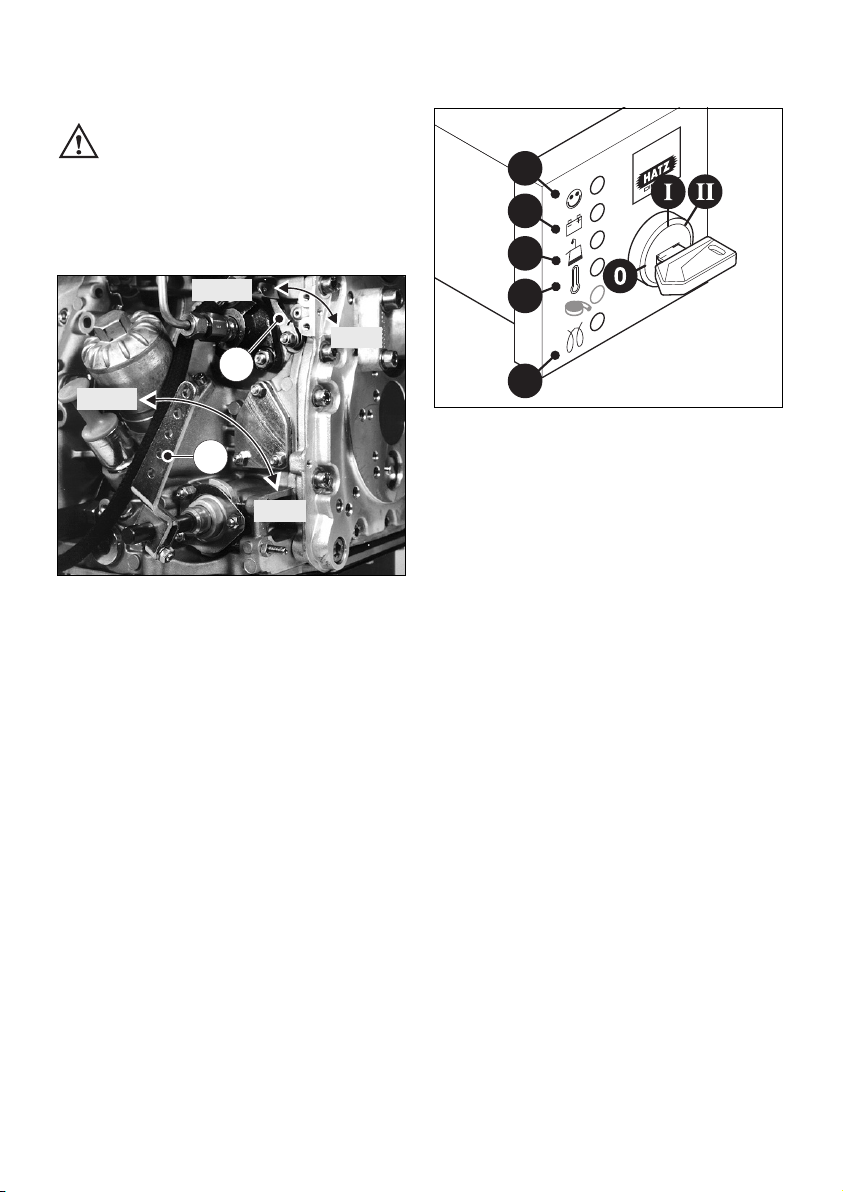

– Turn the decompression lever until stop „1“ is

reached. In this position the automatic decompression system is heard to engage and the

engine can then be started; Figs. 16 and 17.

18

After the automatic decompression device has

engaged at its limit stop, five turns of the crank

handle are needed for the engine to build up

compression and fire again.

4.2.2. Starting with the handle

For preparations to start the engine,

see Chapter 4.2.1.

19

For correct position to adopt when starting the

engine, see Fig. 19.

5x

050 252 00.874

1

0

2292 / 6

1

0

2283 / 4

14

Page 16

– Take hold of the starting handle with both

hands and turn it at increasing speed. The

maximum speed of rotation must have been

reached by the time the decompression lever

has returned to the „0“ position (compression). As soon as the engine has started, pull

the starting handle out of the guide sleeve.

– If the engine backfires because the crank han-

dle was not turned firmly enough (the engine

may even start to run backwards), release the

crank handle immediately and stop the engine

(Chapter 4.3.).

There is a risk of injury from the

rotating crank handle.

– To restart the engine, wait until it has come to

a standstill, then repeat the starting preparations.

Safety precaution

For greater protection against accidental injury

when starting with the handle, a handle with

kick-back damping can be used.

4.2.3. Starting with the handle with

kick-back damping (retrofit)

For preparations to start the engine,

see Chapter 4.2.1.

– For correct position to adopt when starting the

engine, see Fig. 19.

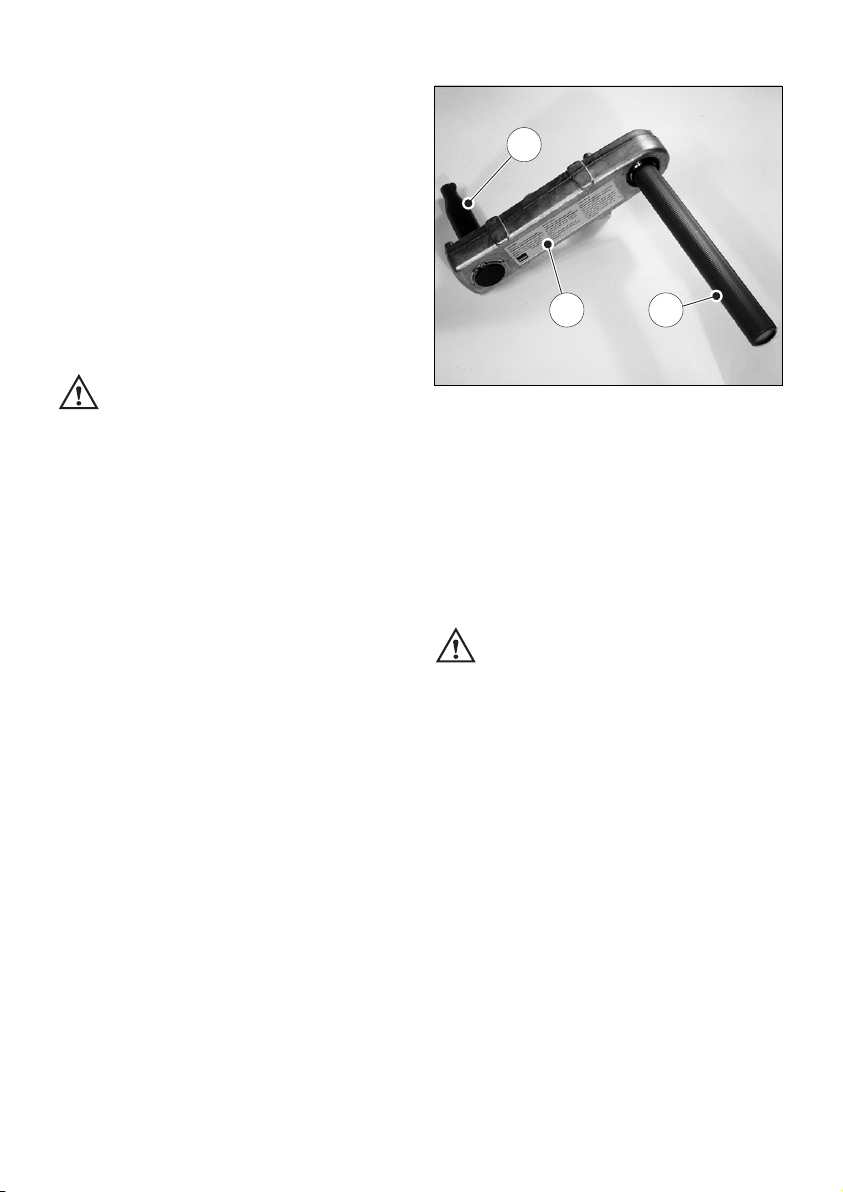

20

– Always hold tubular grip „1“ with both hands.

– Turn the handle slowly until the pawl engages

in the ratchet, then increase turning force to

build up speed. The highest speed must have

been reached when the decompression lever

returns to the „0“ position (compression). As

soon as the engine has started, pull the starting handle out of the guide sleeve.

You must hold the tubular grip firmly to

maintain contact all the time between

the starting handle and the engine. Maintain

turning force during the entire hand starting

operation.

If backfiring occurs when starting the engine because the crank handle was not turned firmly

enough, the brief reverse rotation at the handle

tube separates the link between crank lug „2“

and driving dog „3“ (Fig. 20).

– If the engine begins to run backwards after

backfiring (smoke emerges from air cleaner),

release the crank handle immediately and stop

the engine (Chapter 4.3.).

– To restart the engine, wait until it has come to

a standstill, then repeat the starting preparations.

3

2 1

2395 / 4

15

Page 17

4.2.4. Starting in cold weather

At temperatures below app. –5 °C, always turn

the engine over to ensure that it rotates freely.

– Move the speed control lever to the START

position; Fig. 15.

– Move the decompression lever to a position

not as far round as starting position „1“

(Figures 16 and 17).

– Turn the engine over with the starting handle

until it is felt to rotate more freely (10 – 20

turns of the starting handle).

– If mechanical oil pressure monitoring is

fitted, press lever „1“ or pin „1“ in for about

15 seconds (Figs. 11 and 12).

21

22

– Remove dirt from the cover of the metering

device and the surrounding area. Pull off the

cover; Figs. 21 and 22.

– Add a free-flowing lubricating oil to the

housing until the level reaches the upper rim.

Replace the cover and press it in firmly. Two

filling operations in succession are needed.

– Turn the decompression lever until

limit stop „1“ (fig. 16 and 17).

– After this, start the engine immediately.

Chap. 4.2.1. / 4.2.2. / 4.2.3.

4.2.5. Electric starter

For preparations to start, see Chapter 4.2.1.

– The decompression lever remains in pos. „0“.

Starting procedure

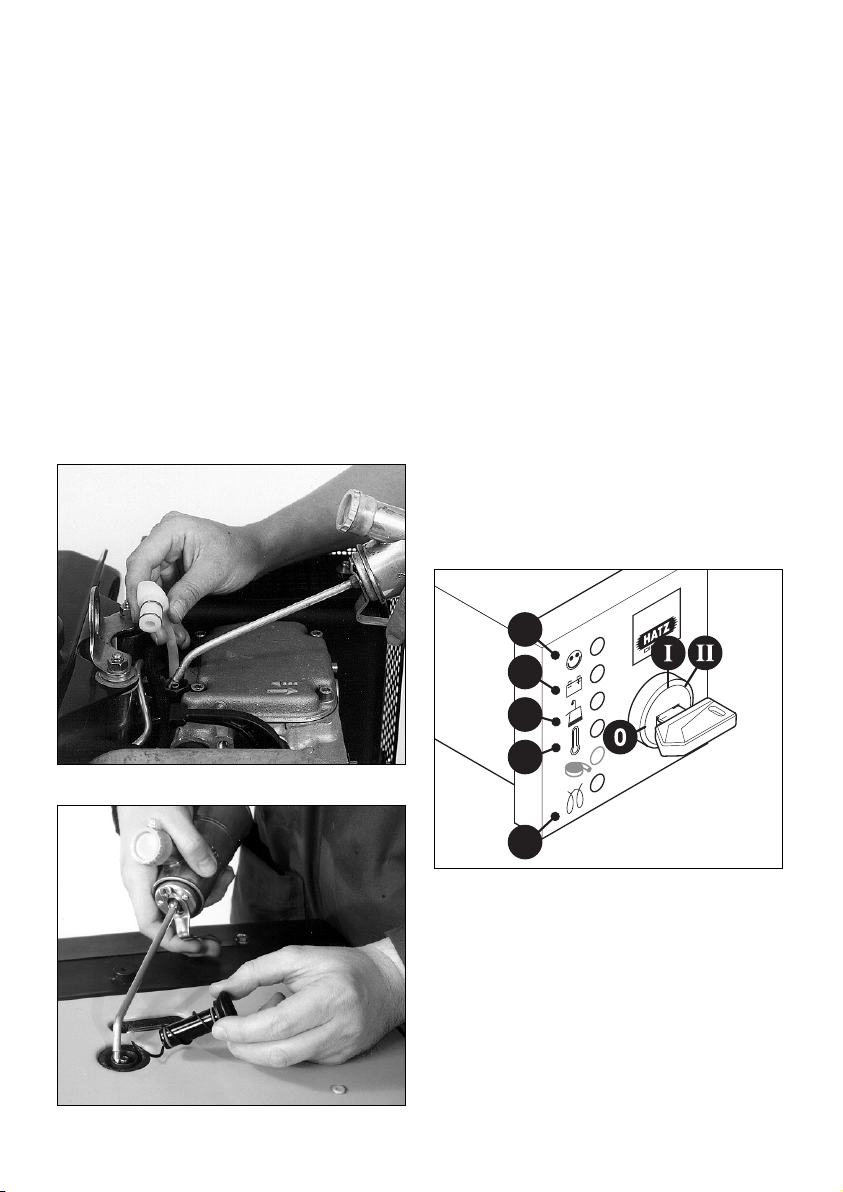

23

– Insert the key to its stop and turn it to

position I.

– Battery charge telltale „2“ and oil pressure

warning „3“ must light up.

1

2

3

4

5

2392 / 9

2283 / 8

16

Page 18

– Turn start key to position II (fig. 23).

– As soon as the engine runs, release the start

key. It must return to position I by itself and

remain in this position during operation.

The battery charge telltale and oil pressure

warning must go out immediately after starting. Indicator light „1“ is on when the engine

is in operation.

– If anything seems to be incorrect, stop the en-

gine immediately and trace and rectify the fault

(chapt. 6).

– The engine temperature display „4“ (additional

equipment) lights up if the temperature at the

cylinder head becomes too high.

Switch off the engine and trace and eliminate the cause of the problem, chap. 6.

– Always turn the start key back to position 0

before re-starting the engine. The repeat lock

in the ignition lock prevents the starter motor

from engaging and possibly being damaged

while the engine is still running.

Never operate the electric starter when

the engine is running or coasting to a

standstill. There is a risk of broken starter pinion or ring gear teeth.

Important:

If a start protection module is installed, the start

key has to be returned to position 0 for at least

8 seconds if the engine has failed to start before

a further attempt to start the engine can be

made.

Preheating device with automatic

heating timer

(additional equipment)

The preheating light „5“ lights up additionally at

temperatures below 0° Celsius (Fig. 23).

– After the light has gone out, start the engine

without delay.

Automatic electrical shutdown system

(additional equipment)

This is characterized by a brief flashing of all

pilot lamps once the starter key has been turned

to position I (Fig. 23).

Important !

If the engine cuts out immediately after starting

or switches off by itself during operation, a

monitoring element in the automatic shutdown

system has tripped. The corresponding indicator

light (Fig. 23, positions 2 - 4) will come on.

After the engine has stopped, the display continues to glow for about 12 seconds.

The electrical device then switches itself off automatically.

The display lights up again after the start key

has been turned back to position 0 and then to

position I again.

Trace and eliminate the cause of the operating

fault before trying to restart the engine

(see chapter 6).

The display light goes out when the engine is

next started.

Even with automatic shutdown monitoring the

oil level must be checked every 8 – 15 operating hours (Chapter 5.2.1.).

17

Page 19

4.3. Stopping the engine

Never stop the engine by moving the

decompression lever. During breaks

in work or at the conclusion of the working period, keep the starting handle and starting key

in a safe place, out of reach of unauthorized

persons.

24

– Move speed control lever „1“ back to the

STOP position.

– On engines with the lower engine speeds

not accessible, move speed control lever „1“

back, then move stop lever „2“ in the STOP

direction. Hold it there until the engine has

stopped.

– Release the stop lever „2“ when the engine

has stopped, making sure that the lever returns to its normal operating position.

Electrical system

25

The charge „2“ and oil pressure telltales „3“

come on.

– Turn the key to the 0 position and pull it out.

The telltale lights must then go out.

Note:

Engines with an automatic electrical shutdown

system (Chapter. 4.2.5.) can also be switched

off by turning the start key back to position 0.

1

2

3

4

5

2396 / 3

2

1

START

START

STOP

STOP

18

Page 20

19

5. Maintenance

The engine must be stopped before any maintenance work is attempted.

Comply with legal requirements when handling and disposing of old oil, filters and

cleaning materials.

Keep the engine’s starting key and starting handle out of reach of unauthorized persons.

To immobilize engines with an electric starter, disconnect the negative battery terminal.

At the end of the maintenance work, check that all tools have been removed from the engine and

all safety guards, covers etc. replaced in their correct positions.

Before starting the engine, make sure that nobody is in the danger area (engine or driven

machinery).

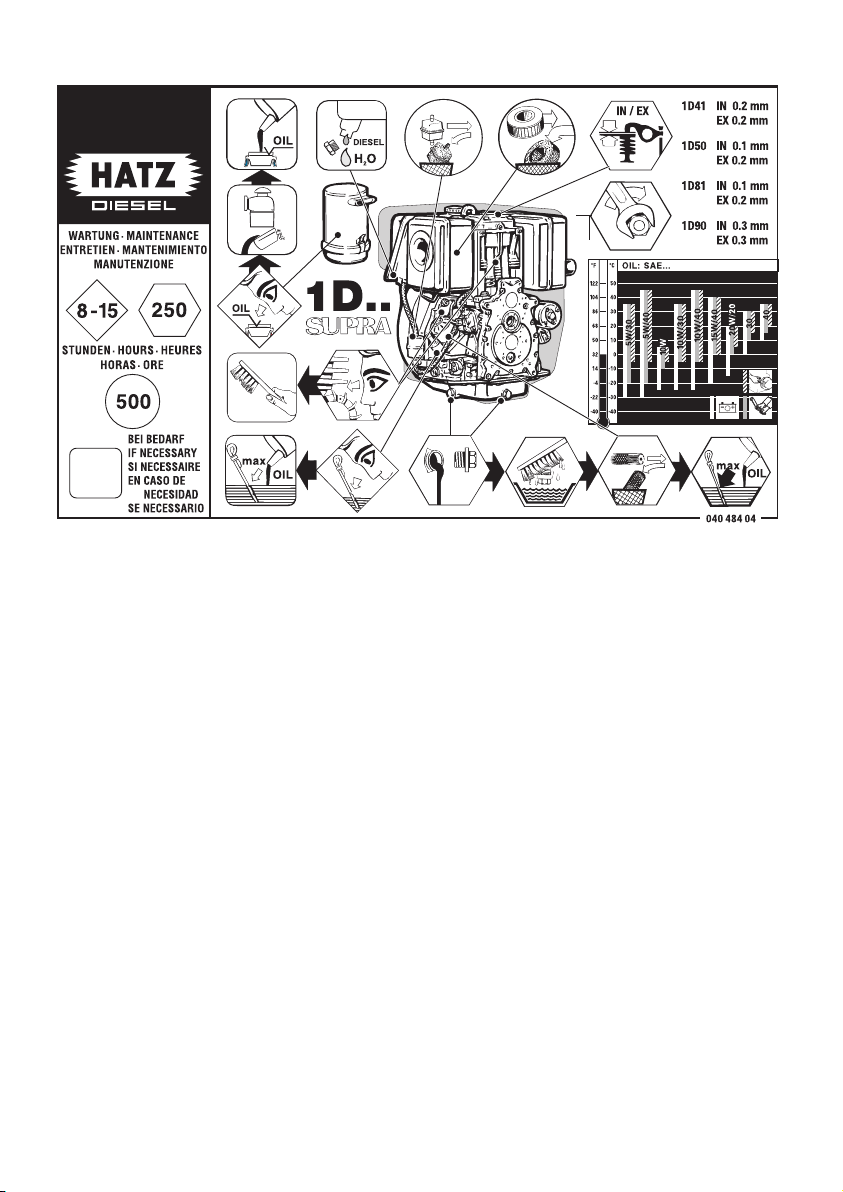

5.1. Maintenance summary

Maintenace intervals Maintenance work required Chap.

Every 8 – 15 operating

hours or before daily

starting.

Check oil level.

Check area round combustion air input.

Check the air cleaner maintenance indicator.

Check the cooling air zone.

Check the water trap.

Check the lower part of the oilbath air cleaner for

correct oil level and freedom from dirt; renew oil if

sludge has formed.

5.2.1.

5.2.2.

5.2.3.

5.2.4.

5.2.5.

4.1.2.

5.3.1.

Every 250 operating

hours

Maintenance of oil bath air filter.

Replace engine oil and oil filter.

Check and adjust tappet clearance.

Clean cooling air system.

Examine screw connections.

Cleaning mesh insert in exhaust silencer

5.3.1.

5.3.2.

5.3.3.

5.3.4.

5.3.5.

5.3.6.

Every 500 operatinghours

Replace fuel filter.

Maintenance of dry-air filter.

5.4.1.

5.4.2

8-15

500

250

Page 21

26

The above maintenance chart is supplied with

every engine. This label should be affixed to the

engine or equipment in an easily visible position.

The maintenance chart governs the maintenance

intervals.

For new or reconditioned engines, the following

must always be carried out after first 25 operat-

ing hours:

– Replace engine oil and oil filter, chap. 5.3.2.

– Check tappet clearance, and adjust if neces-

sary, chap. 5.3.3.

– Examine screw connections, chap. 5.3.5.

Do not tighten the cylinder head fastening.

For short operating periods: replace engine oil

and oil filter after 12 months at the latest, regardless of the number of operating hours.

20

Page 22

21

5.2. Maintenance every 8 – 15

hours of operation

5.2.1. Check engine oil level

When checking the oil level, the engine should

be standing level, and must not be running.

– Remove any dirt in the dipstick area.

27

– Check oil level at the dipstick; top up if neces-

sary as far as the „max“ mark

(see Chapter 4.1.1.).

5.2.2. Check air intake point

Severe contamination is a sign that there are

large amounts of dust in the atmosphere and

the air cleaner maintenance intervals should be

reduced.

– Depending on the air intake pattern, check for

severe blockage; clean if necessary

(see Chapter 2).

28

– Check that dust outlet „1“ on the centrifugal

dust trap (depending on version) is not

blocked, and clean if necessary.

5.2.3. Air cleaner blockage indicator

(optional extra)

– Run the engine at full speed shortly.

29

If the rubber bellows is pulled in and obscures

the green zone „1“, maintenance work is due on

the air cleaner; Chapt. 5.4.2. In dusty operating

conditions, check the rubber bellows several

times a day.

2391 / 10

1

2393 / 10

1

Page 23

5.2.4. Checking cooling air zone

Severe contamination is a sign that there are

large amounts of dust in the atmosphere and

that maintenance intervals should be reduced.

– Check the air inlet and outlet zones for block-

age by coarse material such as leaves, large

amounts of dust etc., and clean if necessary

(see chapters 2 and 5.3.4.).

– If a temperature warning light „4“ is provided,

it will come on if the engine overheats, fig. 25.

In this case, stop the engine immediately

(Chapter 4.3. and 5.3.4.).

5.2.5. Checking the water trap

The intervals at which you should check the

water trap depend entirely on the amount of

water in the fuel and the care taken when refuelling. The normal interval is once a week.

30

– Loosen hexagon screw „1“ with approx. 2-3

rotations.

– Trap the drops which emerge in a transparent

vessel. Since water has a greater specific

gravity than diesel fuel, the water emerges before the diesel fuel. The two substances separate at a clearly visible line.

– As soon as diesel only emerges at screw „1“,

this can be tightened again.

If an external water trap is attached, check its

water content every day, when the engine oil

level is checked. The water which has collected

is separated at a clearly visible line from the

diesel fuel above it.

31

– Open drain plug „1“ and drain the water out

into a suitable vessel.

– If the drain plug is difficult to reach, an exten-

sion hose can be attached to it.

2396 / 9

1

2396 / 7

1

22

Page 24

5.3. Maintenance every 250

hours of operation

5.3.1. Oilbath air cleaner maintenance

32

Catch waste oil and dispase acc. to

environmental regulations.

– Take off the oil reservoir „1“ and clean it.

– Remove contaminated oil and sludge from the

oil tank, and clean it out.

– Take off rain cap „2“ and clean it.

– Clean the entire length of intake pipe „3“.

– Check the inserted seal and renew if in poor

condition.

– Fill the oil reservoir up to the mark with engine

oil and re-assemble the oilbath air cleaner,

Chap. 4.1.2.

– If the filter pack is very dirty, also clean the

upper part of the air cleaner as follows:

Remove the upper part of the air cleaner from

the engine and rinse it in diesel oil.

– Before re-assembling the air cleaner, allow the

diesel fuel to drip off thoroughly, or wipe it off.

– Never attempt any repairs (welding, brazing

etc.) to the oilbath air cleaner, or it may be

rendered useless and the engine may also be

damaged.

– If the sealing face is uneven, the air cleaner

body cracked and/or the filter wool content is

incomplete, install a new air cleaner.

– Attach the upper part of the air cleaner with a

new flange gasket.

33

– Sealing package acc. picture 33 is mounted at

engines 1D41 and 1D50.

34

– Shim washers „1“ should be installed with the

convex side (outward curve) towards the nut.

– Re-assemble the complete air cleaner and fill it

with oil to make it ready for further operation.

1

2395 / 13

23

Page 25

5.3.2. Changing engine oil,

renewing oil filter

The engine must be stopped, and should stand

on a flat, level surface.

Drain the engine oil only when it is warm.

For oil drain plug, see Chapter 2.

Risk of scalding from hot oil.

Catch waste oil and dispase acc. to

environmental regulations.

– Unscrew the oil drain plug and allow all the oil

to drain out.

Fully encapsulated engines:

35

When unscrewing oil drain plug „1“, make sure

that the drain tube is not loosened. Prevent it

from turning if necessary with an open-ended

wrench of the correct size.

– Clean the oil drain plug and attach a new seal.

Insert and tighten the plug.

36

– Renew the replaceable lubricating oil filter ele-

ment.

37

– Clean sieve bottom carefully in order not to

bend the netting.

Wipe out cap screw or blow it out with compressed air.

Persons handling compressed air must

wear protective goggles.

Important !

Note the „TOP“ mark on the oil filter. Fig. 36

1

2287 / 13

2292 / 9

1

24

Page 26

– Check condition of O-ring „1“ and renew it if

necessary (Fig. 36).

– Wet the thread and the O-ring of the screw

plug with lubricant „K“ (see spare parts list).

– Add engine oil up to the „MAX“ mark on the

dipstick (see Chapter 4.1.1.)

– Run the engine for a short period, then check

the oil level again and top up if necessary.

– Check that there is no leakage past screw plug

on the oil filter housing.

5.3.3. Checking and adjusting

valve clearances

– Move the decompression lever to

position „0“; Fig. 16 and 17.

1D41 C, 1D81 C and 1D90 C engines

Take off the enclosure cover (see Chap. 2).

On engines with manual starting only, the decompression lever is also taken off when the

cover is removed.

38

– Unscrew cover „1“ and take off together with

gasket „2“. Never re-use this gasket.

– Turn the engine over in the normal direction of

rotation until compression is felt.

39

– Check valve clearances between rocker and

valve stem, using feeler gauge „1“; Fig. 39

(see Chapter 3.1.).

– If valve clearance is incorrect, slacken off hex.

nut „2“.

– Turn adjusting screw „3“ with a screwdriver

until feeler gauge „1” can just be pulled

through between the rocker and the valve

stem with slight resistance to its movement

after nut „2“ has been retightened.

– Attach the cover at the cylinder head again and

tighten down uniformly.

– Depending on version mount parts of air duct.

– Run the engine briefly and check that the

cover is not leaking.

1 2

3

2287 / 4

2393 / 15

0

1

2

25

Page 27

5.3.4. Clean the cooling air system

Before cleaning, the engine must be

stopped and allowed to cool down.

Remove parts of air duct.

Dry contamination

– Clean all air guide elements and the complete

cooling air zones on the cylinder head, cylinder and flywheel blades without making them

wet. Blow them dry with compressed air.

Persons handling compressed air must

wear protective goggles.

Moist or oily contamination

– Disconnect the battery. Clean the complete

area with a solvent, cold cleaner etc. according

to its manufacturer’s instructions, then spray

down with a powerful water jet.

Do not splash electrical device with water jet

or pressure jet during engine cleaning.

– Trace the cause of any contamination with oil

and have the leak eliminated by a HATZ

service station.

– Install the air guide elements previously re-

moved.

The engine must never be run without

the air guide elements in position.

– Immediately after re-assembly, run the engine

until warm to prevent residual moisture from

causing rust.

5.3.5. Checking threaded connections

Check the condition and tightness of all threaded

connections, wiring, hose clips and other components attached to the engine and its mountings, provided that these can be reached during

maintenance work.

Do not tighten the cylinder head bolts.

40

Adjustment screws on speed governor

and injection system are painted with

safty lacquer. Do not tighten or adjust them.

5.3.6. Cleaning mesh insert in exhaust

silencer

(additional equipment)

41

– Remove deposits from the mesh insert with a

suitable wire brush.

2396 / 3

26

Page 28

5.4. Maintenance every 500

hours of operation

5.4.1. Renewing fuel filter

Fuel filter maintenance intervals depend on the

purity of the fuel used; reduce them to 250

hours of operation if necessary.

Do not smoke or bring a naked flame

near the fuel system when working

on it.

Important !

Keep the entire area clean so that no dirt

reaches the fuel. Fuel particles may damage

the injection system.

42

– Shut off the fuel supply line upstream and

downstream of the fuel filter according to

item 1.

43

– Unscrew the fuel filter from its mount.

44

– Place a suitable vessel under the filter to trap

escaping fuel.

– Pull off fuel supply line „1“ at both ends of fuel

filter „2“ and insert the new filter.

– Always renew the fuel filter. Note the arrows

indicating the correct direction of fuel flow.

– Secure the filter to its mount.

– Open the fuel supply line or prime the pump

until the fuel flows (see Chapter 4.1.3.).

1

2

1

27

Page 29

– Activate mechanical oil pressure monitor

(optional extra), chap. 4.1.4.

– Run the engine briefly to check the fuel filter

and lines for leaks.

5.4.2. Dry-type air cleaner maintenance

It is best to clean the filter cartridge only when

the maintenance indicator displays the appropriate signal.

Apart from this, the cartridge should be renewed

after 500 hours of operation.

– On fully encapsulated engines, take off the top

cover (see Chapter 2).

On engines with manual starting only, the decompression lever is also taken off when the

cover is removed.

45

– Slacken off wing bolt „1“ and remove it with

cover „2“.

46

– Carefully pull out filter cartridge „1“.

– On the version with air cleaner maintenance

indicator, check that valve plate „4“ is clean

and in good condition.

Noise reduced model

47

– Unscrew hex. nut „1“ and take off filter hous-

ing „2“.

2392 / 15

1 2

2393 / 1

42

1

2396 / 16

1

2

28

Page 30

48

– Unscrew the hex. nuts and remove them with

filter cover „1“.

– Carefully pull out filter cartridge.

– Clean all parts except for the filtercartridge.

Do not spray into the engine’s air intake when

cleaning.

Cleaning the filter cartridge

Dry contamination

49

– Blow through the filter cartridge from the in-

side, moving the jet of dry compressed air up

and down until no further dust is expelled.

Warning: air pressure must not exceed 5 bar.

Persons handling compressed air must

wear protective goggles.

– Tilt the filter element and hold it against the

light (or shine a light through it) to trace any

cracks or other damage.

Important:

If there is even the slightest damage to paper

filter element „2“ or sealing lips „3“, the filter

element should not be re-used.

(Figs. 46 and 48)

Wet or oily contamination

– Renew the filter cartridge.

– Re-assemble in the reverse order of work.

2281 / 5

2392 / 16

2

1

3

29

Page 31

30

6. Malfunctions – Causes – Remedies

Malfunction Possible causes Remedial action Chap.

Engine will not

start or start is

delayed, although

it can be turned

over with the

starter.

Also applicable for

engines with mechanical oil pressure monitoring.

At low temperatures.

Speed control lever is in stop or

idle position.

Stop lever in stop position.

No fuel reaching injection pump.

Compression too low:

- Valve clearances incorrect

- Cylinder bore and/or piston

ring wear

Injector not operating correctly.

Oil pressure lost.

Lower starting temperature limit

exceeded.

Machinery not uncoupled.

Defective preheat system

(optional extra).

Set lever to „START“-position

Add. fuel.

Check entire fuel supply system

carefully.

If no fault is found:

- supply line to engine

- fuel filter

- Function of delivery pump

must be checked.

Check valve clearances, adjust if

necessary.

See workshop manual.

See workshop manual.

Check engine oil level.

Activate mechanical oil pressure

monitor.

Comply with cold starting

instructions.

Operate preheat system

(optional extra).

Disengage engine from machinery or equipment if possible.

See workshop manual.

4.2.

4.1.3.

4.1.4.

5.4.1.

4.1.3.

5.3.3.

5.2.1.

4.1.4

4.2.4.

4.2.5.

Page 32

31

Malfunction Possible causes Remedial action Chap.

At low

temperatures.

Starter does not

run or engine is

not turned over.

Engine fires but

stops again as

soon as starter is

switched off.

Fuel separates has inadequate

resistance to low temperatures.

Starting speed too low:

- Engine oil is too thick

- Battery charge is insufficient.

Fault in electrical system:

- Battery and/or other wiring is

wrongly connected.

- Wiring connections loose

and/or corroded.

- Battery defective and/or flat.

- Defective starter motor

- Defective relays, monitoring

elements etc.

Drive still engaged.

Fuel filter blocked.

Fuel supply interrupted.

Stop signal from monitoring

element for automatic shutdown

system (optional extra):

- oil pressure lost

- cylinder head temperature

too high.

- alternator has failed

Check whether clear (not turbid)

fuel emerges at the fuel line detached from the injection pump.

If turbid or separated - either

warm up the engine or drain the

complete fuel supply system.

Refuel with winter-grade fuel to

which paraffin has been added.

Refill with a different grade of

engine oil.

Check the battery; consult a specialist workshop if necessary.

Check electrical system incl.

indiv. components or contact a

HATZ-service station.

Uncouple engine from driven

machinery if possible.

Renew the fuel filter.

Check through the entire fuel

supply systematically.

Check oil level.

Clean cooling air system.

See workshop manual.

4.1.3.

5.3.2.

7.

7.

5.4.1.

5.2.1.

5.3.4.

Page 33

32

Malfunction Possible causes Remedial action Chap.

Engine stops by

itself during regular operation.

In addition, if automatic engine shutdown is installed.

Low engine power,

output and speed.

Fuel supply is interrupted:

- Tank run dry

- Fuel filter blocked

- Defective feed pump.

- Air in the fuel system.

Mechanical oil pressure monitor

stops the engine due to low oil

pressure.

Mechanical defects.

Stop signal from monitoring

element because of:

- oil pressure too low.

- cylinder head temperature

too high.

- alternator has failed

Fuel supply is obstructed:

- Tank run dry.

- Fuel filter blocked.

- Tank venting is inadequate

- Leaks at pipe unions.

- Air in the fuel system.

- Speed control lever does not

remain in selected position.

Add fuel.

Renew fuel filter.

Check through entire fuel supply

system.

Check fuel system for

penetration of air.

Check air vent valve.

Check engine oil level.

Activate mechanical oil pressure

monitor.

Contact a HATZ-service station.

Check engine for:

Engine oil level.

Cooling air passages blocked

or cooling system otherwise

affected.

See workshop manual.

Add fuel.

Renew fuel filter.

Ensure that tank is adequately

vented.

Check threaded pipe unions for

leaks.

Check fuel system for

penetration of air.

Check air vent valve.

Prevent speed control from

moving.

4.1.3.

4.1.4.

5.4.1.

5.2.1.

4.1.4.

4.1.3.

4.1.4.

5.4.1.

Page 34

33

Malfunction Possible causes Remedial action Chap.

Low engine power,

output and speed,

black exhaust

smoke.

Engine runs very

hot. Cylinder head

overheat, telltale

lamp (optional

extra) comes on.

Air cleaner blocked.

Incorrect valve clearances.

Malfunction at injector.

Too much oil in engine.

Inadequate cooling:

- Entire cooling air system

contaminated.

- Inadequate sealing at air guide

plates or capsule elements.

Remove dirt from air cleaner.

Adjust valve clearances.

See workshop manual.

Drain off engine oil down to

upper mark on dipstick.

Clean cooling air system.

Check that air guide plates and

enclosure elements are all present and make a tight seal.

5.3.1.

5.4.2.

5.3.3.

5.3.2.

5.3.4.

Page 35

7. Work on the electrical system

Batteries generate explosive gases.

Keep them away from naked flame

and sparks which could cause them to ignite.

Do not smoke. Protect the eyes, skin and

clothing against battery acid. Pour clear water

over acid splashes immediately. In case of

emergency call doctor.

Do not place any tools on top of the battery.

Always disconnect the negative (–) pole of the

battery before working on the electric device.

– The positive (+) and negative (–) battery ter-

minals must not be accidentally interchanged.

– When installing the battery, connect the posi-

tive lead first, followed by the negative lead.

Negative pole to earth (ground) on engine

block.

– When removing the battery, disconnect the

negative lead first, followed by the positive

lead.

– In all circumstances, avoid short circuits and

shorts to earth (ground) at live cables.

– If electrical faults occur, first check for good

contact at the cable connections.

– Replace a failed indicator light without delay.

– Do not take the key out while the engine is

running.

– Never disconnect the battery while the engine

is running. Electric voltage peaks can cause

damage to electrical components.

– In case of an emergency start in manual

mode, leave the battery (which might be discharged) connected to the engine.

– For emergency operation without battery,

make sure that the plug-and-socket connector

to the instrument box is disconnected additionally before the engine is started.

– Do not splash electrical device with water jet

or pressure jet during engine cleaning.

– When carrying out welding work on the en-

gine or attached equipment, attach the earth

(ground) clip as near as possible to the welding point, and disconnect the battery.

If an alternator is fitted, separate the plug connector leading to the voltage regulator.

The relevant circuit diagrams are supplied with

engines which have an electrical system.

Additional copies of circuit diagrams can be

obtained on request.

HATZ assumes no liability for electrical systems

which was not carried out acc. HATZ circuit diagrams.

8. Protective treatment

A new engine can normally be stored for up to

12 months in a dry place.

If atmospheric humidity is high (or if exposed

to sea air), protection is sufficient for about

6 months’ storage.

If the engine is to be stored for a longer period,

or laid up out of use, please consult the nearest

HATZ service point.

34

Page 36

SUPPLEMENTAL INFORMATION

TO THE OWNER'S MANUAL FOR 2008 AND LATER

EPA CERTIFIED

NONROAD COMPRESSION IGNITION ENGINES.

EPA EMISSION CONTROL SUPPLEMENTAL

WARRANTY STATEMENT AND

EMISSION-RELATED INSTALLATION

INSTRUCTIONS.

35

Page 37

MAINTENANCE AND WARRANTY.

SUPPLEMENTAL INFORMATION TO THE OWNERS MANUAL FOR 2008 AND

LATER EPA CERTIFIED NONROAD COMPRESSION IGNITION ENGINES.

The following supplemental information is furnished for EPA Nonroad Compression

Ignition Engines which are certified according to 40 CFR Part 89 and Part 1039.

This information contains the following specific items:

• EPA-related engine parts and engine operating conditions

• Maintenance instructions for EPA-related engine parts

• Emission control system and adjustments

• Warranty statement

• Emission-related installation instructions

ENGINE PARTS AND / OR EQUIPMENT RELATED TO EPA EXHAUST

EMISSION REGULATIONS.

Parts which are mandatory for engine operation.

The following parts as manufactured according to HATZ specifications are mandatory for

engine operation which meets EPA exhaust emission regulations.

• Fuel injection pump

• Injection nozzle

• Extra fuel device

• Crankcase breather valve assembly

• Air cleaner housing

36

Page 38

• Intake manifold

• Exhaust manifold

• Oil filler cap

• Intake and exhaust gaskets at head interfaces

• Emission Control Information Labels

Only parts manufactured by Hatz and which have passed the Hatz Quality Assurance

Program are assured of meeting EPA exhaust emission regulations.

UNUSUAL OPERATING CONDITIONS.

The engine must not be operated at a load factor less than 25 % for an extended period as

such operation will cause the fuel injector to foul. If such a condition occurs, you should

contact the nearest HATZ authorized Service Center for necessary repairs.

The engine is designed and adjusted to operate most efficiently at the following

conditions:

• Air temperature of 25° C ( 77° F)

• Atmospheric pressure of 100 kPa (14.5 psi)

• Relative humidity of 30 %

Operation of the engine at conditions other than above will affect performance and

exhaust emissions. Normally the equipment manufacturer takes this into account during

the design of the machine and your equipment will perform within specifications over a

wide range of climatic conditions. However if you must operate your equipment under

very unusual climatic conditions, please contact your nearest Hatz distributor for advice.

37

Page 39

MAINTENANCE SCHEDULE-EPA-RELATED PARTS

The following minimum intervals are being adopted for adjustment, cleaning, repair, or

replacement of following components:

At 1,500 hours, and 1,500-hours intervals thereafter:

• Fuel injector tips (cleaning only)

At 3,000 hours, and 3,000-hours intervals thereafter:

• Fuel injector

The exhaust quality of the engines can be influenced by the execution (the quality of

execution) of above described maintenance work.

Therefore, the maintenance work has to be carried out by a qualified workshop.

Hatz authorised workshops, for example, are qualified workshops.

Hatz Diesel of America will give you respective addresses, if required.

EMISSION CONTROL SYSTEM AND ADJUSTMENTS.

The emission control system for this engine is EM (Engine Modification).

No adjustments are needed or possible.

38

Page 40

EPA EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS.

Motorenfabrik Hatz GmbH & Co. KG warrants the emission control system on your

engine for the periods of time listed below provided there has been no abuse, neglect or

improper maintenance of your engine.

Your emission control system includes:

• Fuel injection pump

• Injection nozzle

• Extra fuel device

• Crankcase breather valve assembly

• Air cleaner housing

• Intake manifold

• Exhaust manifold

• Oil filler cap

• Intake and exhaust gaskets at head interfaces

• Emission Control Information Labels

Where a warrantable condition exists, Motorenfabrik Hatz will repair your engine at no

cost to you including diagnosis, parts and labor.

39

Page 41

MANUFACTURERS WARRANTY COVERAGE:

The 2008 and later EPA certified nonroad compression ignition engines are warranted for

1500 hours of operation or two years of use, whichever first occurs.

If any emission related part on your engine is defective, the part will be repaired or

replaced by Motorenfabrik Hatz.

OWNERS WARRANTY RESPONSIBILITIES:

• As the engine owner, you are responsible for the performance of the required

maintenance listed in your owner's manual. Motorenfabrik Hatz recommends that you

retain all receipts covering maintenance on your engine, but Motorenfabrik Hatz cannot

deny warranty solely for the lack of receipts or for your failure to ensure the

performance of all scheduled maintenance.

• As the engine owner, you should be aware, however, that Motorenfabrik Hatz may

deny you warranty coverage if your engine or a part has failed due to abuse, neglect,

improper maintenance or unapproved modifications.

• You are responsible for presenting your engine to a Motorenfabrik Hatz authorized

service center as soon as a problem exists. The warranty repairs should be completed in

a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you should

contact HATZ DIESEL OF AMERICA, Inc. at (262)-544-0254.

HATZ DIESEL SUPPLEMENTAL WARRANTY FOR 2008 AND LATER EPA

CERTIFIED ENGINES.

40

Page 42

PARTS WITH SUPPLEMENTAL LIMITED WARRANTY.

The following limited warranty is supplemental to the standard HATZ DIESEL LIMITED

ENGINE WARRANTY and covers 2008 and later EPA certified engines and applies to

the following exhaust emission-related components:

• Fuel injection pump

• Injection nozzle

• Extra fuel device

• Crankcase breather valve assembly

• Air cleaner housing

• Intake manifold

• Exhaust manifold

• Oil filler cap

• Intake and exhaust gaskets at head interfaces

• Emission Control Information Labels

41

Page 43

SUPPLEMENTAL LIMITED WARRANTY.

Hatz Diesel of America, Inc. hereinafter referred to as “HATZ” warrants each of the

above-listed parts when installed in a new engine sold by Hatz to be free from defects in

material and workmanship under normal use and service, only under the named warranty

coverage conditions, after the date of delivery to the original retail purchaser and Hatz

will at their option, repair or replace at Hatz's sales headquarters, or at a point designated

by Hatz, any part or parts which shall appear to the satisfaction of Hatz upon inspection at

such point, to have been defective in material or workmanship.

• Any warranted part which is scheduled for replacement as required maintenance is

warranted for the period of time up to the first scheduled replacement point for that

part.

• Any replacement part which is equivalent in performance and durability may be used in

non-warranty maintenance or repairs and will not reduce the overall engine warrranty

obligations of Hatz. However, Hatz is not responsible for failure of such replacement

parts or failure of any other parts directly caused by failure of such replacement parts.

• This warranty does not obligate Hatz to bear any transportation charges in connection

with the repair or replacement of defective parts. This warranty is transferrable to

subsequent owners, only under the named warranty coverage conditions.

• In order to obtain service under this warranty, the retail purchaser should contact Hatz

Diesel of America, Inc. at (262)-544-0254 for information and the nearest service

center. The retail purchaser will not be charged for diagnostic labor which leads to the

determination that a warranted part is defective, nor for the repair or replacement of

warranted parts if the work is performed at an authorized Hatz service center. If other

engine components are damaged due to a failure of the above-listed warranted parts

still under warranty, these other engine components will also be repaired or replaced at

no charge.

• This warranty shall not apply to any engine which shall have been installed or

operated in a manner not recommended by Hatz, nor to any engine which shall have

been repaired, altered, neglected, or used in any way which, in the opinion of Hatz,

adversely affects its performance, nor to any engine in which parts not authorized by

Hatz have been used, which parts or the use of which have damaged or caused defects

in or otherwise adversely affected the engine or its performance, nor to normal

maintenance service or replacement of normal service items.

Hatz reserves the right to modify, alter, and improve any engine or parts without incurring

any obligation to replace any engine or parts previously sold with such modified, altered,

or improved engine or parts.

42

Page 44

43

EMISSION-RELATED INSTALLATION INSTRUCTIONS

“Failing to follow these instructions when installing a certified engine in a piece of

nonroad equipment violates federal law (40CFR1068.105(b)), subject to fines or other

penalties as described in the Clean Air Act.”

“If you install the engine in a way that makes the engine's emission control information

labels hard to read during normal engine maintenance, you must place duplicate labels on

the equipment.”

EQUIPMENT-LABELLING REQUIREMENTS: FUEL LABEL (Chapter 3.5)

The fuel label has to be permanently attached to the equipment.

In case of an engine mounted fuel tank, every engine is equipped with an additional fuel

label.

Otherwise, there are two loose fuel labels available with the engine.

If the original fuel label is not readily visible after the engine is installed in the equipment

then the second loose fuel label must be attached on the equipment in such a manner that

it is readily visible to an average person.

Page 45

44

INSTRUCTIONS ON THE INSTALLATION OF THE EXHAUST SYSTEM

Following are the instructions to properly install the exhaust system and related

components consistent with the EPA emission regulation requirements.

Exhaust-silencers and protection guard

The exhaust silencer is fitted in connection with studs, flat washers and hex.-nuts.

Fixation is done by Allen screws.

1

2

4

4

1

2

4

4

3

2

3

3

1

23 Nm

17 lb ft

A) B)

C)

3

1D41 · 1D50 · 1D81 · 1D90 S / Z

Page 46

45

Preparations:

• Remove protection guard in numerical sequence 1...4 (B) if so fitted. It is mounted to

the exhaust silencer with three screws.

Dismantling:

• Remove in numerical sequence 1...3 (C).

• For opening screws 1 a special tool is required (HATZ-Ident Nr. 630 815 00).

Assembly:

• Assemble in reverse sequence.

• Apply lubricant as specified by HATZ.

• Torque to specification!

• Ensure gasket-kit is fitted in correct sequence i.e. the creased gaskets 3 face towards

exhaust silencer (A).

• Assemble protection guard if so fitted in reverse sequence 4...1 (B).

• Use anti-seize compound J as specified by HATZ.

• Ensure the concave side of the curved washers 4 face towards guard 3 (B).

Page 47

46

Encapsulated engine

Before dismantling the exhaust system the capsule has to be dismounted:

• Remove the four screws (2) of the top cover (3).

• Remove the side cover (1) by opening the two clips.

• Open the four screws (4) of the side cover (5).

• Remove the top cover (3) and the side cover (5)

• Dismantle the exhaust silencer cover (7) by opening the six screws (6).

3

2

4

5

1

7

6

1D41 C · 1D81 C

Page 48

47

Assembly:

• Assemble in reverse sequence.

• Apply lubricant as specified by HATZ.

• Torque to specification!

• Before tightening the capsule all screws have to be turned in and the different covers

have to be correctly adjusted.

Page 49

48

Sequence of dismantling the exhaust system:

• Open screws (1) and (2) and remove with shims.

• Remove big silencer with attached sealing gaskets (3).

• Open screws (4) and remove with shims.

• Remove silencer (5) with attached sealing gaskets (6).

1D41 C · 1D81 C

2

1

6

3

6

4

5

Page 50

49

Assembly:

• Assemble in reverse sequence.

• Apply lubricant as specified by HATZ.

• Torque to specification !

• Ensure gasket-kit is fitted in correct sequence i.e. the creased gaskets (6) face towards

exhaust silencer.

• Make sure that all parts are correctly placed and tightened.

SAMPLING OF EXHAUST EMISSIONS

After the engine is installed in the equipment and placed in service, the sampling of

exhaust emissions can be performed in a way that prevents diluting the exhaust sample

with ambient air as follows:

Specification 1: Adding a 20-centimeter linear extension to the exhaust pipe

Version 1

Page 51

50

Specification 2: Adding a 20-centimeter bended extension to the exhaust pipe

Version 2

Engine type Ø d (mm)

Version 1

HATZ-Ident. Nr.

Version 2

HATZ-Ident. Nr.

Clamp

HATZ-Ident. Nr.

1D41 S / Z

25 039 973 01 830 860 00 503 880 00

38 830 857 00 830 858 00 037 409 00

1D50 S / Z

25 039 973 01 830 860 00 503 880 00

38

830 857 00 830 858 00 037 409 00

1D81 S / Z

32 – 830 879 00 503 881 00

48 – 038 775 00 504 103 01

1D90 S / Z

32 – 830 879 00 503 881 00

48 – 038 775 00 504 103 01

1D41 C 33 – – –

1D81 C 48 – 038 775 00 504 103 01

Page 52

SUPPLEMENTAL INFORMATION

TO THE OWNER´S MANUAL

FOR 2008 AND LATER

CALIFORNIA REGULATIONS FOR

HEAVY-DUTY OFF-ROAD ENGINES.

CALIFORNIA EMISSION CONTROL

WARRANTY STATEMENT AND

EMISSION-RELATED INSTALLATION

INSTRUCTIONS.

51

Page 53

MAINTENANCE AND WARRANTY.

SUPPLEMENTAL INFORMATION TO THE OWNER´S MANUAL FOR 2008

AND LATER CALIFORNIA REGULATIONS FOR HEAVY-DUTY OFF-ROAD

ENGINES.

The following supplemental information is furnished for

California Heavy-Duty Off-Road Engines.

This information contains the following specific items:

• CARB-related engine parts and engine operating conditions

• Maintenance instructions for CARB-related engine parts

• Emission control system and adjustments

• Warranty statement

• Emission-related installation instructions

ENGINE PARTS AND / OR EQUIPMENT RELATED TO CARB EXHAUST

EMISSION REGULATIONS.

Parts which are mandatory for engine operation.

The following parts as manufactured according to HATZ specifications are mandatory for

engine operation which meets CARB exhaust emission regulations.

• Fuel injector

• Fuel injection pump

• Cold start device

• Intake manifold

• Exhaust manifold

• Crankcase breather valve

52

Page 54

• Oil filler Cap

• Intake and exhaust gaskets at head interfaces

• Emission Control Information Labels

Only parts manufactured by Hatz and which have passed the Hatz Quality Assurance

Program are assured of meeting CARB exhaust emission regulations.

UNUSUAL OPERATING CONDITIONS.

The engine must not be operated at a load factor less than 25 % for an extended period as

such operation will cause the fuel injector to foul. If such a condition occurs, you should

contact the nearest HATZ authorized Service Center for necessary repairs.

The engine is designed and adjusted to operate most efficiently at the following

conditions:

• Air temperature of 25° C ( 77° F)

• Atmospheric pressure of 100 kPa (14.5 psi)

• Relative humidity of 30 %

Operation of the engine at conditions other than above will affect performance and

exhaust emissions. Normally the equipment manufacturer takes this into account during

the design of the machine and your equipment will perform within specifications over a

wide range of climatic conditions. However if you must operate your equipment under

very unusual climatic conditions, please contact your nearest Hatz distributor for advice.

MAINTENANCE SCHEDULE-CARB-RELATED PARTS.

The following minimum intervals are being adopted for adjustment, cleaning, repair, or

replacement of following components:

At 1,500 hours, and 1,500 hours intervals thereafter:

• Fuel injector tips (cleaning only)

53

Page 55

At 3,000 hours, and 3000 hours intervals thereafter:

• Fuel Injectors

The exhaust quality of engines can be influenced by the execution (the quality of

execution) of above described maintenance work.

Therefore, the maintenance work has to be carried out by a qualified workshop.

Hatz authorised workshops, for example, are qualified workshops.

Hatz Diesel of America will give you respective addresses, if required.

EMISSION CONTROL SYSTEM AND ADJUSTMENTS.

The emission control system for this engine is EM (Engine Modification).

No adjustments are needed or possible.

CALIFORNIA EMISSION CONTROL SYSTEM WARRANTY STATEMENT.

YOUR WARRANTY RIGHTS AND OBLIGATIONS.

The California Air Resources Board and Motorenfabrik Hatz GmbH & Co. KG are

pleased to explain the emission control system warranty on your 2008 and later

engine. In California, new heavy-duty off-road engines must be designed, built, and

equipped to meet the State’s stringent anti-smog standards. The Motorenfabrik Hatz

GmbH & Co. KG must warrant the emission control system on your engine for the

periods of time listed below provided there has been no abuse, neglect or improper

maintenance of your engine.

Your emission control system may include parts such as the fuel-injection system and

the air induction system. Also included may be hoses, belts, connectors and other

emission-related assemblies.

Where a warrantable condition exists, the Motorenfabrik Hatz GmbH & Co. KG will

repair your heavy-duty off-road engine at no cost to you including diagnosis, parts, and

labor.

54

Page 56

MANUFACTURER’S WARRANTY COVERAGE.

The 2008 and later heavy-duty off-road engines are warranted for 1500 hours of

operation or two years of use, whichever first occurs.

If any emission-related part on your engine is defective, the part will be repaired or

replaced by Motorenfabrik Hatz GmbH & Co. KG.

OWNER’S WARRANTY RESPONSIBILITIES.

• As the heavy-duty off-road engine owner, you are responsible for the performance of

the required maintenance listed in your owner’s manual.

Motorenfabrik Hatz GmbH & Co. KG recommends that you retain all receipts covering

maintenance on your heavy-duty off-road engine, but Motorenfabrik Hatz GmbH & Co.

KG cannot deny warranty solely for the lack of receipts or for your failure to ensure the

performance of all scheduled maintenance.

• As the heavy-duty off-road engine owner, you should however be aware that

Motorenfabrik Hatz GmbH & Co. KG may deny you warranty coverage if your

heavy-duty off-road engine or a part has failed due to abuse, neglect, improper

maintenance or unapproved modifications.

• Your engine is designed to operate on low sulfur diesel fuel or ultra-low sulfur diesel

fuel only. Use of any other fuel may result in your engine no longer operating in

compliance with California’s emissions requirements.

• You are responsible for initiating the warranty process. The ARB suggests that you

present your heavy-duty off-road engine to a Motorenfabrik Hatz authorised dealer as

soon as a problem exists. The warranty repairs should be completed by the dealer as

expeditiously as possible.

If you have any questions regarding your warranty rights and responsibilities, you should

contact Hatz Diesel of America, Inc. at (262)-544-0254.

55

Page 57

HATZ DIESEL SUPPLEMENTAL WARRANTY FOR 2008 AND LATER

CALIFORNIA CERTIFIED HEAVY-DUTY OFF-ROAD ENGINES.

PARTS WITH SUPPLEMENTAL LIMITED WARRANTY.

The following limited warranty is supplemental to the standard HATZ DIESEL LIMITED

ENGINE WARRANTY and covers 2008 and later California certified Heavy-Duty offroad engines and applies to the following exhaust emission-related components:

• Fuel injector

• Fuel injection pump

• Cold start device

• Intake manifold

• Exhaust manifold

• Crankcase breather valve

• Oil filler cap

• Intake and exhaust gaskets at head interfaces

• Emission Control Information Labels

56

Page 58

SUPPLEMENTAL LIMITED WARRANTY.

Hatz Diesel of America, Inc. hereinafter referred to as "HATZ" warrants each of the

above-listed parts when installed in a new engine sold by Hatz to be free from defects in

material and workmanship under normal use and service, for a period of twenty-four (24)

months after the date of delivery to the original retail purchaser and Hatz will at their

option, repair or replace at Hatz's sales headquaters, or at a point designated by Hatz, any

part or parts which shall appear to the satisfaction of Hatz upon inspection at such point,

to have been defective in material or workmanship.

• Any warranted part which is scheduled for replacement as required maintenance is

warranted for the period of time up to the first scheduled replacement point for that

part.

• Any replacement part which is equivalent in performance and durability may be used in

non-warranty maintenance or repairs and will not reduce the overall engine warrranty

obligations of Hatz. However, Hatz is not responsible for failure of such replacement

parts or failure of any other parts directly caused by failure of such replacement parts.

• This warranty does not obligate Hatz to bear any transportation charges in connection

with the repair or replacement of defective parts. This warranty is transferrable to subsequent owners within the original twenty-four (24) months time period.

• In order to obtain service under this warranty, the retail purchaser should contact Hatz

Diesel of America, Inc. at (262)-544-0254 for information and the nearest service

center. The retail purchaser will not be charged for diagnostic labor which leads to the

determination that a warranted part is defective, nor for the repair or replacement of

warranted parts if the work is performed at an authorized Hatz service center. If other

engine components are damaged due to a failure of the above-listed warranted parts

still under warranty, these other engine components will also be repaired or replaced at

no charge.

• This warranty shall not apply to any engine which shall have been installed or operated

in a manner not recommended by Hatz, nor to any engine which shall have been

repaired, altered, neglected, or used in any way which, in the opinion of Hatz, adversely affects its performance, nor to any engine in which parts not authorized by Hatz have