Page 1

Installation and Operating Instructions

Bronze

Draining Tap

Fig.370 & Fig.371

CE Marking and the Pressure Equipment Directive 97/23/EC

This has been implemented in United Kingdom law by the Pressure Equipment Regulations

1999 (SI 1999/2001).

The regulations apply to all valves with a maximum allowable pressure greater than 0.5 bar.

Valves with a maximum allowable pressure not exceeding 0.5 bar are outside the scope of

the Directive. Valves are categorised in accordance with the maximum working pressure, size

and ascending level of hazard, which is dependent on the fluid being transported. Fluids are

classified as Group 1, dangerous fluids or Group 2, all other fluids including steam. Categories

are SEP (sound engineering practice) and for ascending levels of hazard, I, II, III or IV. All valves

designated as SEP do not bear the CE mark nor require a Declaration of Conformity.

Categories I, II, III or IV carry the CE mark and require a Declaration of Conformity (Note: all

valves up to and including 25mm (1") having a maximum allowable pressure greater than 0.5

bar are designated SEP regardless of fluid group.)

Product Life Cycle

The life of the valve is dependent on its application, frequency of use and freedom from misuse.

The system into which it is installed must also be compatible with respect to the fluid being

transported with reference to its temperature, pressure and other properties, which may cause

premature failure or non-operability.

A well designed system will take into consideration all the factors considered in the valve

design, but additionally electrolytic interaction between dissimilar metals in the valve and the

system must be examined. Before commissioning a system, it should be flushed to eliminate

debris and chemically cleaned as appropriate to eliminate contamination, all of which will

prolong the life of the valve.

Page 2

Limits of Use

Operating Pressures and Temperatures

The valve to which these installation, operation and maintenance instructions apply have been

categorised in accordance with the Pressure Equipment Directive.

The fluid to be transported is limited to Group 2 liquids i.e. non-hazardous and on no account

must these valves be used on any Group 2 gases, Group 1 liquids or Group 1 gases.

Fig.370 and Fig.371 Bronze Drain Taps in sizes up to and including 1 inch are categorised as

SEP and do not require the CE mark.

Not suitable for fatigue loading, creep conditions, fire testing, fire hazard environment, corrosive

or erosive service, transporting fluids with abrasive solids.

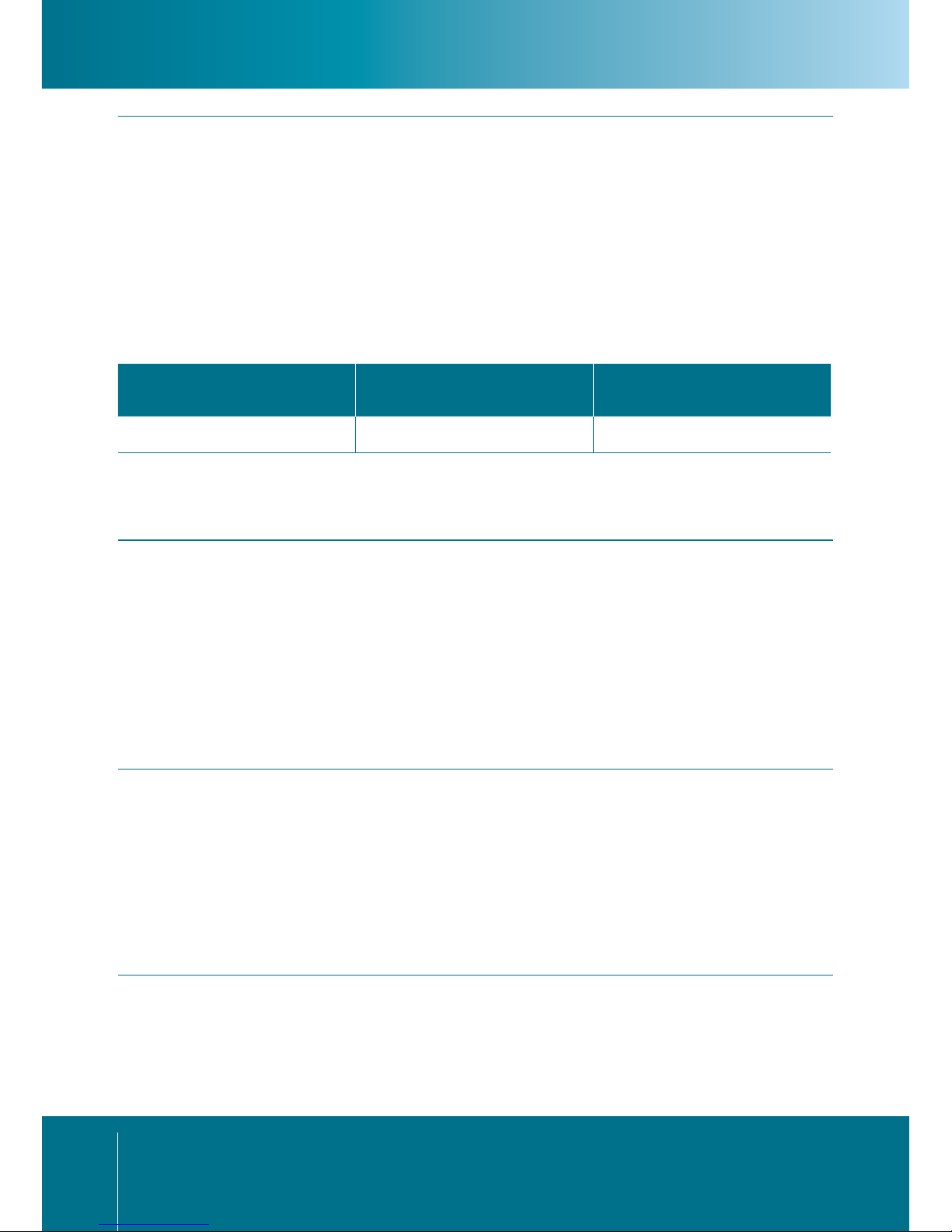

Pressure/Temperature Rating

Valves must be installed in a piping system whose normal pressure and temperature do not

exceed the above ratings.

The maximum allowable pressure in valves as specified in the standards is for non-shock

conditions. Water hammer and impact for example, should be avoided. If the limits of use

specified in these instructions are exceeded or if the valve is used on applications for which it

was not designed, a potential hazard could result.

Layout and Siting

It should be considered at the design stage where valves will be located to give access for

operation, maintenance or repair.

These drain taps may be installed in any orientation but attention should be paid to surrounding

structures, ensuring that the hose may be easily connected and that the valve operation is not

impaired.

Installation

Prior to installation, a check of the body marking must be made to ensure that the correct valve

is being installed.

PN Non-shock pressure at

temperature range

Non-shock pressure at max

temperature

16

16 bar from -10°C to 120°C 16 bar at 120°C

Hattersley Bronze Draining Tap – Fig.370 & Fig.3711

Page 3

Installation

(CONTINUED)

Valves are precision manufactured items and as such, should not be subjected to misuse such

as careless handling, allowing dirt to enter the valve through the end ports, lack of cleaning

both valve and system before operation and excessive force fitting and operation. All special

packaging material must be removed.

Immediately prior to valve installation, the pipework to which the valve is to be fastened should

be checked for cleanliness and freedom from debris.

The valve ends are threaded parallel therefore the valve must be fully tightened up to the body

shoulder. Sealing compounds appropriate to the application may be used and a sealing washer

on the body shoulder will provide additional security. The spanner must only be located on the

valve hexagon at the threaded end to avoid distortion of the valve.

After installation, the valve may be opened and closed fully to confirm satisfactory operation.

Sealing compounds may be used but excessive use of hemp type materials should be avoided,

which increases the thread interference and may cause overstressing.

Operating

Fig.370

Open the valve by anti-clockwise rotation of the stem using a suitable spanner or key until a

positive stop is felt. No further effort is necessary.

To close the valve, rotate the stem clockwise until a positive stop is felt.

Note: The operator should use suitable hand protection at extreme temperature conditions.

Fig.371

Open the valve by anti-clockwise rotation of the stem using a suitable lockshield key until a

positive stop is felt.

Key Refs: ½” valve (Fig.391 Ref 2), ¾” valve (Fig.391 Ref 3) and 1” valve (Fig.393 Ref 6).

No further effort is necessary.

To close the valve, rotate the stem clockwise until a positive stop is felt.

Note: The operator should use suitable hand protection at extreme temperature conditions.

Maintenance

The valve should be at zero pressure and ambient temperature prior to any maintenance.

Maintenance Engineers and Operators are reminded to use correct fitting tools and equipment.

A full risk assessment and methodology statement must be compiled prior to any maintenance.

The risk assessment must take into account the possibility of the limits of use being exceeded

Installation and Operating Instructions

Hattersley Bronze Draining Tap – Fig.370 & Fig.371 2

Installation and Operating Instructions

Page 4

www.cranebsu.com

H_370_371_0118

IOM_004BR0370D799_V2

Every effort has been made to ensure that the information contained

in this publication is accurate at the time of publishing. Crane Ltd

assumes no responsibility or liability for typographical errors or

omissions or for any misinterpretation of the information within the

publication and reserves the right to change without notice.

• Approved to BS EN 331: 1998

• Designed and manufactured under quality management

systems in accordance with BS EN ISO 9001:2008

FM311 ISO 9001

EPSILON TERRACE, WEST ROAD,

IPSWICH, SUFFOLK, IP3 9FJ

HOME SALES: +44 (0)1473 277410

EXPORT SALES: +44 (0)1473 277450

UK SALES ENQUIRES: uksales@hattersley.com

EXPORT SALES ENQUIRES: Mena-enquiries@hattersley.com

TECHNICAL ENQUIRES: tech-enquiries@hattersley.com

www.hattersley.com

To visit our Video Library go to:

www.youtube.com/user/CraneBSU

Maintenance

(CONTINUED)

whereby a potential hazard could result. A maintenance programme should therefore include

checks on the development of unforeseen conditions, which could lead to failure.

The Fig.370/371 valve drain taps should not normally require any maintenance. However these

drain taps can be refurbished by fitting a new elastomeric seat washer and stem seal.

Valve seal replacement

During this maintenance exercise the valve necessitates a complete system drain down.

1. Remove the drain tap from the system.

2. Position the drain tap in a suitable vice, gripping via the hexagon at the threaded end.

3. Remove the stem-retaining sleeve (lockshield) in an anti-clockwise rotation.

4. Remove the stem in an anti-clockwise rotation.

5. Slacken and remove disk seal nut and disk seal. Gripping the stem Drive Square will assist

this operation.

6. Fit a new disk seal and refit the disk seal nut and peen thread to prevent loosening.

7. Fit new ‘O’ ring seal to the stem.

8. Refit stem and disk assembly into the valve body in a clockwise rotation to the closed

position.

9. Refit the stem-retaining sleeve (lockshield) in a clockwise rotation and tighten.

10. Operate the valve to confirm suitable operation.

11. Refit the valve to the system, close valve and pressurize checking for leakage.

For the supply of genuine Hattersley spares or technical assistance contact:

Hattersley Newman Hender

Peel House, Peel Road, West Pimbo, Skelmersdale, Lancashire, WN8 9PT

T: 01695 712800 | Fax: 01695 712820 | E: uksales@hattersley.com export@hattersley.com

Loading...

Loading...