USER MANUAL

Compact Fanless Computers

HT B17 xxy-zzzz

HT B18 xxy-zzzz

xx=standard or customized

y=operating system

zzzz=configuration dependent

User Manual HT B17 / HT B18

Updated: 03 Jun 2015 Doc Id: INB100032-5 (Rev 20)

Created: 363

Approved: 6987

Please visit www.hatteland-display.com for the latest electronic version of this manual.

Hatteland Display AS, Stokkastrandvegen 87B, N-5578 Nedre Vats, Norway

Tel: (+47) 4814 2200 - mail@hatteland-display.com - www.hatteland-display.com

Copyright © 2015 Hatteland Display AS

Stokkastrandvegen 87B, N-5578 Nedre Vats, Norway.

All rights are reserved by Hatteland Display AS. This information may not, in whole or in part, be

copied, photocopied, reproduced, translated or reduced to any electronic medium or machine-

readable form without the prior written consent of Hatteland Display AS. Review also:

www.hatteland-display.com/pdf/misc/doc100703-1_permission_to_create_user_manuals.pdf

The products described, or referenced, herein are copyrighted to the respective owners.

The products may not be copied or duplicated in any way. This documentation contains proprietary

information that is not to be disclosed to persons outside the user’s company without prior written consent

of Hatteland Display AS.

The copyright notice appearing above is included to provide statutory protection in the event of

unauthorized or unintentional public disclosure.

All other product names or trademarks are properties of their respective owners !

WARNING: This is a class A product. In a domestic environment this product may cause radio interference

in which case the user may be required to take adequate measures.

Last revised 6 Jan 2015

Contents

Contents .................................................................................... 3

Contents of package ..........................................................................5

General ...................................................................................... 7

About this manual ...............................................................................8

About Hatteland Display .....................................................................8

www.hatteland-display.com ................................................................8

Contact Information ............................................................................ 8

Computers introduction ...................................................................... 9

Basic Construction - HT B17 ............................................................ 10

Basic Construction - HT B18 ............................................................ 11

Product Labels (Examples) .............................................................. 12

Serial Number Label Placement (external) ..................................12

Operating System Serial Number Label Placement .....................12

Installation ............................................................................... 13

Installation and mounting of computers ............................................14

Cables ..............................................................................................15

Conguring DC power input housing connector ...........................15

Ferrites ............................................................................................. 15

Accessible SSD (Hard Drive HDD) removal / replacement HT B18 . 16

Internal PCI Cards / Brackets dismounting and mounting HT B18 ..17

Internal SSD (Hard Drive HDD) removal / replacement HT B1x ...... 18

Physical Overview - HT B17 .............................................................19

Physical Overview - HT B18 .............................................................23

Specications ......................................................................... 27

Specications - HT B17 ....................................................................28

Specications - HT B18 ....................................................................29

3

IND100206-23

Contents

Technical Drawings ................................................................ 31

Technical Drawings - HT B17 ........................................................... 32

Technical Drawings - HT B18 ........................................................... 33

- HWCode00 ................................................................................33

- HWCode90 ................................................................................34

Technical Drawings - Accessories ........................................ 35

Technical Drawings - Mounting Bracket Kit ...................................... 36

for HT B17 and HT B18 ................................................................36

Technical Drawings - Mounting Plate/Cable Tension Relievers .......37

for HT B17 ....................................................................................37

for HT B18 HWcode00 .................................................................38

for HT B18 HWcode90 .................................................................39

Technical Drawings - Mounting Plate/Cable Tension Relievers .......40

for HT B22, HT B17, B18, B07, B08 ............................................40

Technical Drawings - Mounting Plate/Cable Tension Relievers .......41

HW00 for HT B17, B18, B07, B08 ................................................41

Technical Drawings - Mounting Plate ............................................... 42

for HT B17, B18, B07, B08 ...........................................................42

Appendixes ............................................................................. 43

SSD Selection Guide ........................................................................44

Pinout Assignments - Common Connectors .....................................48

Trouble-shooting ..............................................................................51

Declaration of Conformity .................................................................52

Return Of Goods Information ........................................................... 53

General Terms and Conditions .........................................................54

Notes ................................................................................................ 55

Revision History ...............................................................................57

4

IND100206-23

Contents of package

This product is shipped with:

Item Description Illustration

EUR TYPE F

US TYPE B

FS-CABLE EU

80099

FCE17-E2W2SS-2N0 &

L17DPPK09JSU (cover)

MEDIA STD01

1 pcs of power cable European Type F “Schuko” to IEC.

Length 1.8m

1 pcs of power cable US Type B plug to IEC.

Length 1.8m

1 pcs of DC Power Input housing with internal cable screw terminal.

Documentation and Driver DVD for factory installed components like mainboard, IDE,

network etc. For most recent drivers, please visit “www.hatteland-display.com/archive”.

Note: To use this DVD disc you will need an external USB CD/DVD drive or provide means of

getting contents copied over via USB memory stick/network to the operating system. You can

alternatively download the drivers from our website www.hatteland-display.com

Test Reports papers:

1 pcs of Product Declaration

1 pcs of Computer Checklist

1 pcs of BurnInTest Certificate

IEC

IEC

Menu browser for

Microsoft® Windows®

1 pcs of Mounting Bracket Kit suitable for Wall or Desktop mounting, consists of:

- 8 pcs M4x16 screws

- 2 pcs small brackets

- 8 pcs M4 lock nuts

HT 00245 OPT-A1 (B17) or

HT 00246 OPT-A1 (B18)

- 2 pcs mounting brackets

Package may also include: (based on accessories/options ordered)

Item Description Illustration

Recovery/Restore Kit (1 x USB Memory Stick with original installation).

For reverting back to factory/customized Operating System installations.

For more information, visit http://www.hatteland-display.com/os

HT 00300 MSOS IMAGE

HT 00228 OPT-A1

Note: Only applicable for factory delivered units with HDD/SSD hardware.

Kit contains:

1 x Mounting Plate with cable relief, RAL 9011.

6 x M3x12 (Torx DIN 965 Stainless Steel) screws

(additional screws are provided for similar computer models,

please use M4x12 for HT B17 / HT B18).

Mounting Plate / Bracket RAL 9011.

HT 00244 OPT-A1

HT 00237 OPT-A1

?

IND100207-11

Mounting bracket for PCI cards (HT B18 model only).

For computers that include 3rd party hardware; the package / accessories box may also

include additional CD / HW / Information from 3rd party supplier(s).

5

This page left intentionally blank

6

General

7

Hatteland Display AS

About this manual

The manual contains electrical, mechanical and input/output signal specications. All specications in this manual,

due to manufacturing, new revisions and approvals, are subject to change without notice. However, the last update

and revision of this manual are shown both on the frontpage and also in the “Revision History” chapter at the end of

the manual.

Furthermore, for third party datasheet and user manuals, please see dedicated Documentation and Driver DVD

delivered with the product or contact our sales/technical/helpdesk personnel for support.

About Hatteland Display

Hatteland Display is the leading technology provider of specialized display and computer products, delivering high

quality, unique and customized solutions to the international maritime, naval and industrial markets.

The company represents innovation and quality to the system integrators world wide. Effective quality assurance and

investment in sophisticated in-house manufacturing methods and facilities enable us to deliver Type Approved and Mil

tested products. Our customer oriented approach, technical knowledge and dedication to R&D, makes us a trusted

and preferred supplier of approved solutions, which are backed up by a strong service network.

www.hatteland-display.com

You will nd our website full of useful information to help you make an informed choice as to the right product for your

needs. You will nd detailed product descriptions and specications for the entire range on Displays, Computers and

Panel Computers, Military solutions as well as the range of supporting accessories. The site carries a wealth of

information regarding our product testing and approvals in addition to company contact information for our various

ofces around the world, the global service centers and the technical help desk, all ensuring the best possible

support wherever you, or your vessel, may be in the world.

Contact Information

Head ofce, Vats / Norway:

Hatteland Display AS

Stokkastrandvegen 87B

N-5578 Nedre Vats, Norway

Sales ofce, Frankfurt / Germany:

Hatteland Display GmbH

Werner Heisenberg Strasse 12,

D-63263 Neu-Isenburg, Germany

Tel: +47 4814 2200

Fax: +47 5276 5444

mail@hatteland-display.com

Sales ofce, Oslo / Norway:

Solbråveien 20

N-1383 Asker

Norway

Tel: +47 4814 2200

Fax: +47 5276 5444

Sales ofce, Vista / USA:

Hatteland Display Inc

380 South Melrose Drive,

Suite 349

Vista, CA 92081

USA

Tel: +1 760-643-4061

Fax: +1 858-408-1834

For an up-2-date list, please visit www.hatteland-display.com/locations

General

8

Tel: +49 6102 370 954

Fax: +49 6102 370 968

Sales ofce, Aix-en-Provence / France:

Hatteland Display SAS

ACTIMART, 1140 RUE AMPERE, BP 50 196

13795 AIX-EN-PROVENCE, CEDEX 3

France

Tel: +33 (0) 4 42 16 47 57

Fax: +33 (0) 4 42 16 47 00

IND100077-1

Computers

Computers introduction

Hatteland Display’s range of type-approved computers is designed to perform in

harsh environments while providing the performance and flexibility you expect.

We offer rack mount and black box/standalone computer solutions for every

need. Our computers are used by system integrators, boat builders and endusers and can be found on all vessel types, all over the world.

If you are looking for a high quality computer for navigation, monitoring or

entertainment solutions, Hatteland Display can fulfil your high expectations at a

reasonable cost.

Our computer range covers all eventualities and requirements. We offer a wide

range of processor choices, HDD and power options, and solid state technology,

neatly engineered within industry standard form factors such as 19” rack mount,

2U and 4U solutions.

We continually develop our computers portfolio to make the best use of emerging

computer technology so you can be sure that your Hatteland Display computer

offers the power needed to run modern applications, with the flexibility to be

installed wherever you want, for any marine use.

Designed to perform in harsh environments...

IND101057-2

General

9

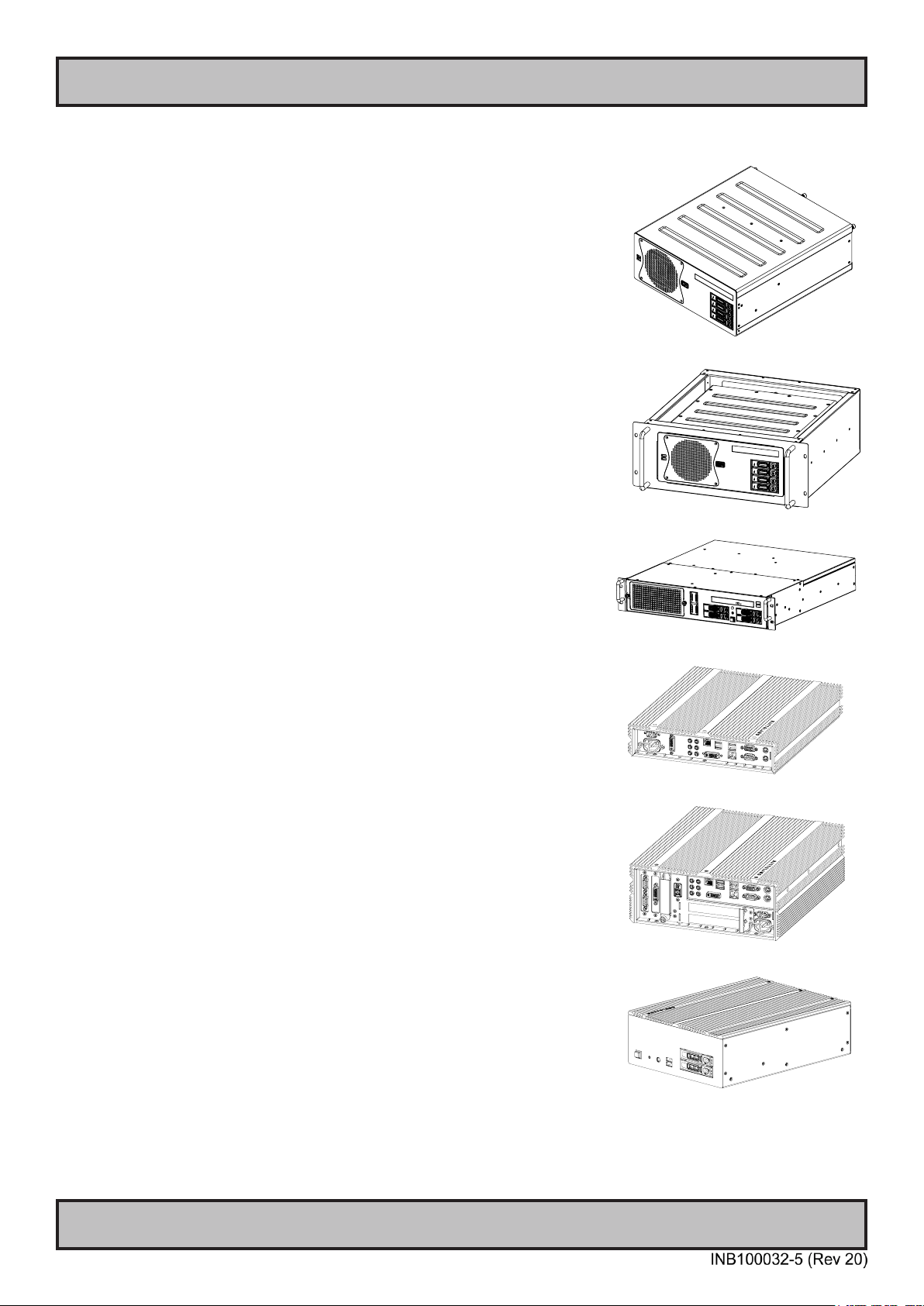

Basic Construction - HT B17

Basic Construction

Compact Fanless Computer

Chassis with

cooling design

Power Module

Connector plates

I/O Connectors

Front plate

with Serial

Number Label

Chassis Support

Mechanics

Heat Pipe Cooling

Mainboard

and CPU

SSD/HDD and Casing

Bottom chassis

plate

IND100077-102

General

Standard model, customized versions may vary

10

Basic Construction - HT B18

Basic Construction

Compact Fanless Computer

Chassis with

cooling design

Replaceable

and casing

I/O Connectors

Power Module

SSD/HDD

Connector plates

Front plate

with Serial

Number Label

Chassis Support

Mechanics

Heat Pipe Cooling

Mainboard

and CPU

Memory

IND100077-99

Power Inputs

General

PCI Card & Slots

Bottom chassis

plate

Standard model, customized versions may vary

11

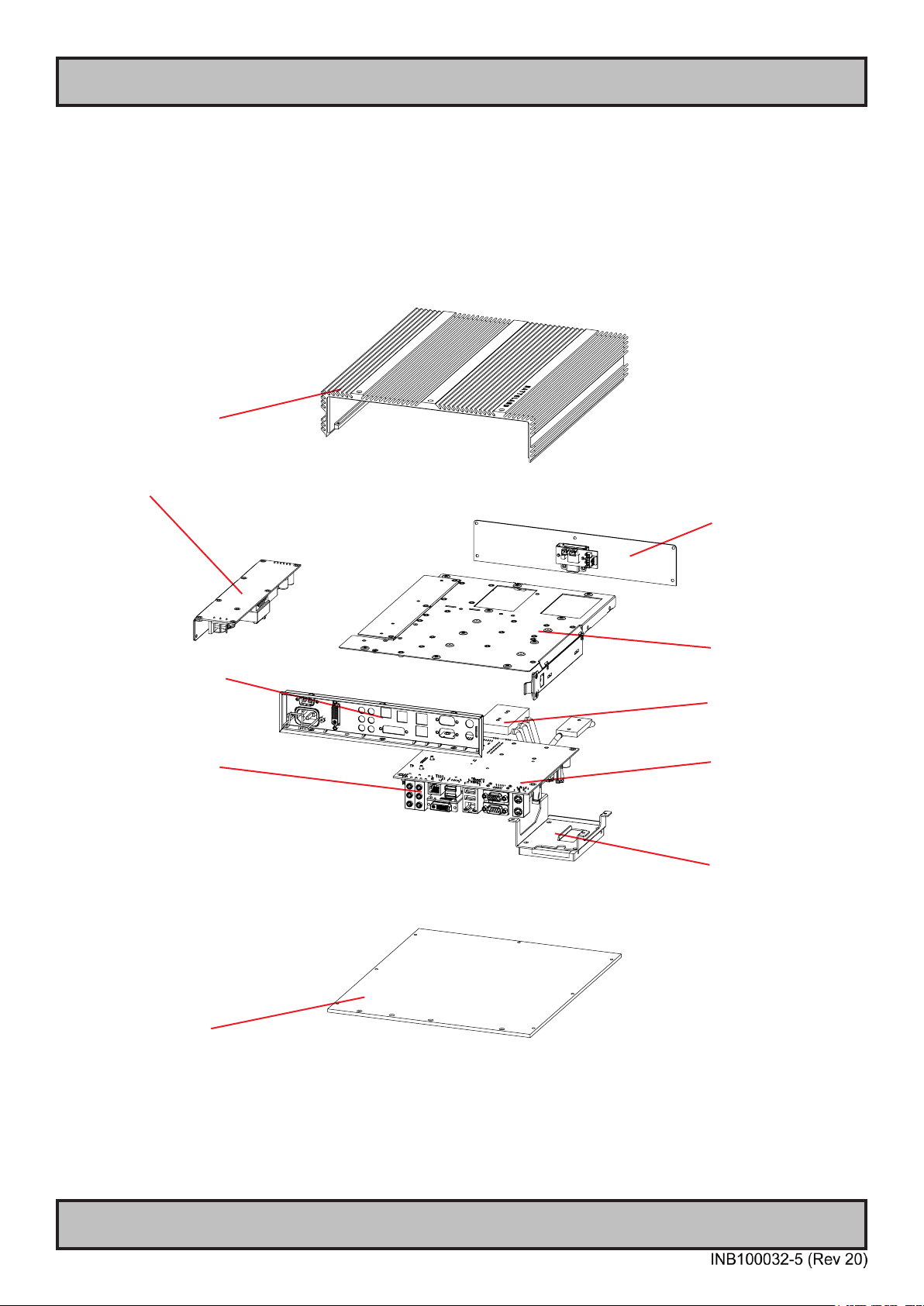

Product Labels (Examples)

Product Labels (Examples)

Serial Number Label Placement (external)

HT B17

HT B18

Serial Number Label Layout

Product Type

Input Voltages & Power Rating

Product Hardware Revision

Manufacturer & Country

Manufactured Date yyyymmdd

Barcode (TYP+SNO)

Label Size: 6cm x 2cm

Serial Number Label Nomenclature

XX XYY XXX-XYYY-YYYYYY NOMENCLATURE - X=Letters, Y=Numbers

HT B18 STD-A100-000001 Example

|| ||| ||| |||| ||||||

|| ||| ||| |||| ¤¤¤¤¤¤- Serial Number. Due to revisions, numbers may be 1 to 7 digits

|| ||| ||| |¤¤¤-------- Conguration ID (for components like memory, storage etc.)

|| ||| ||| ¤----------- Power Input ID (115&230VAC - 50/60Hz + 24VDC)

|| ||| ||¤------------ Installed Operating System ID / No Installed OS ID

|| ||| ¤¤-------------- Abbreviation for Standard (ST) or reserved customer ID

|| |¤¤----------------- Electronics / Mainboard / Technology Revision ID

|| ¤------------------- Chassis Type ID

¤¤--------------------- Manufacturer ID / Product Series ID

Operating System Serial Number Label Placement

Label Size: 7cm x 2.8cm

HT B17

General

IND100240-7

HT B18

12

Installation

13

General Installation Recommendations

Installation and mounting of computers

1. Units may be intended for various methods of installation or mounting (rack mounting, panel mounting,

bracket mounting, ceiling/wall mounting); for details, please see the relevant mechanical drawings.

2. Adequate ventilation is a necessary prerequisite for the life of the unit. The air inlet and outlet openings must

denitely be kept clear; coverings which restrict ventilation are not permissible. The product might be without

any ventilation aperatures which means pt.2 does not apply.

3. Exposure to direct sunlight can cause a considerable increase in the temperature of the unit, and might under

certain circumstances lead to overtemperature. This point should already be taken into consideration when

the bridge equipment is being planned (sun shades, distance from the windows, ventilation, etc.)

4. Space necessary for ventilation, for cable inlets, for the operating procedures and for maintenance, must be

provided.

5. To further improve the cooling of the unit we recommend installing Cooling Fans underneath blowing upwards

into the unit air inlet. This may be required in high temperature applications and also when there is reason to

expect temperature problems due to non-optimal way of mounting.

6. This Product shall be grounded to protective Earth. For AC Power cables this is done trough the ground wire

in the connector, for DC input the ground bolt shall be used. A shorter and thicker cable gives better

grounding. A 6mm² is recommended, but a 4mm² or even 2.5mm² can be used for this purpose.

7. Expose to heavy vibration and acoustic noise might under certain circumstances affect functionality and

expected lifetime. This must be considered during system assembly and installation. Mounting position must

carefully be selected to avoid any exposure of amplied vibration.

General mounting instructions

1. The useful life of the components of all Electronics Units generally decreases with increasing ambient

temperature; it is therefore advisable to install such units in air-conditioned rooms. If there are no such

facilities, these rooms must at least be dry, adequately ventilated and kept at a suitable temperature in order

to prevent the formation of condensation inside the unit.

2. With most Electronic Units, cooling takes place via the surface of the casing. The cooling must not be

impaired by partial covering of the unit or by installation of the unit in a conned cabinet.

3. In the area of the wheel house, the distance of each electronics unit from the magnetic standard compass or

the magnetic steering compass must not be less than the permitted magnetic protection distance. This

distance is measured from the centre of the magnetic system of the compass to the nearest point on the

corresponding unit concerned. The exact distance is often mentioned in the specic product specications.

4. Transportation damage, even if apparently insignicant at rst glance, must immediately be examined and be

reported to the freight carrier. The moment of setting-to-work of the equipment is too late, not only for

reporting the damage but also for the supply of replacements.

5. The classication is only valid for approved mounting brackets provided by Hatteland Display. The unit shall

be mounted stand-alone without any devices or loose parts placed at or nearby the unit. Any other type of

mounting might require test and re-classication.

IND100210-1

Installation

14

General Installation Recommendations

Cables

Use only high quality shielded signal cables. For RGB/DVI cables use only cables with separate coax for Red, Green

and Blue.

Conguring DC power input housing connector

Note: Only applicable for certain models!

For installations that require DC power input, use the provided

2-pin DC Power Input housing with internal cable screw terminal.

1: Open the housing

2: Unmount the fasteners. (FIG 1)

3: Mount power cables to screw terminal (FIG 2). Note polarity!

4: Secure the cable tightly with fasteners (FIG 3, FIG 1)

5: Close the housing

Note: Please check polarity before connecting any cables

to the screw terminal.

Ferrites

On selected products, the ferrites prevent high frequency

electrical noise (radio frequency interference) from exiting or

entering the equipment. To verify if your product require this,

please see the “Physical Overview” chapter in this manual. The

ferrites are part of the contents of the package also specied in the

“Contents Of Package” chapter early in this manual. The ferrites

must be mounted on specic cables to fully comply with the

Type Approvals!

+ -

-

FIG1

FIG 3

+

FIG 1

FIG 2

Screw terminal

+ -

FIG2

The ferrites should be mounted (clipped in place on the cable as

shown in illustration) as close as possible to the cable connector

on the rear side of the computer product. Open up the ferrite,

place the cable inside as shown in FIG1, and then gently close it

until a click can be heard (FIG2).

To computer

To computer

IND100210-1

Installation

15

General Installation Recommendations

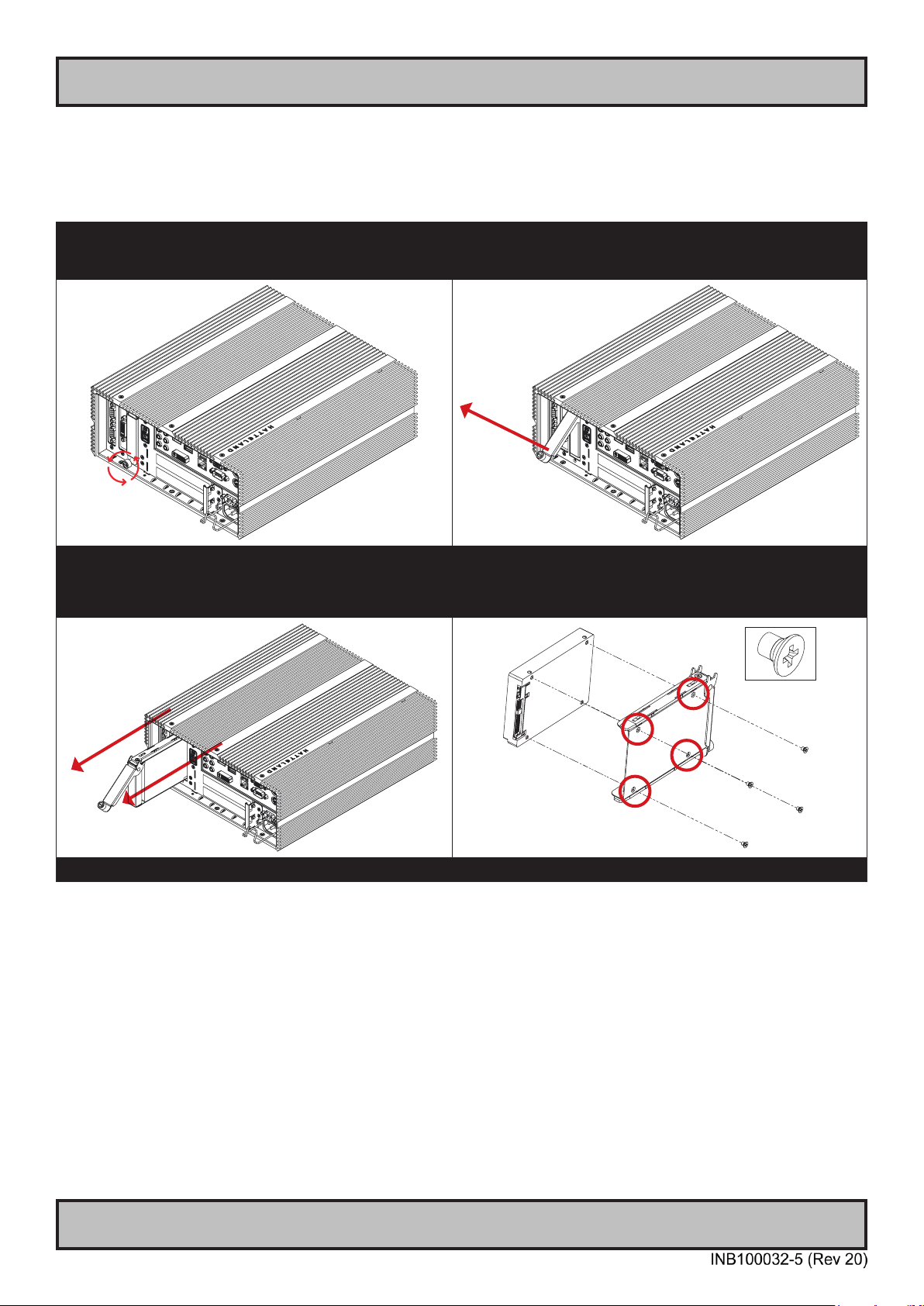

Accessible SSD (Hard Drive HDD) removal / replacement HT B18

Note: Areas of interest are marked in this section with symbols in RED color. Please power off and disconnect ALL

cables from the computer unit before proceeding!

▼ 1: Unscrew 1 pcs of knob screw anti-clockwise as

indicated with your ngers.

▼ 3: Pull out the SSD and its casing as indicated.

▼ 2: Lift the bracket upwards as indicated.

▼ 4: Unscrew 4 pcs x M3x4mm Phillips countersunk

screws as indicated and replace or remove the SSD drive

as needed.

IND100210-6

- Repeat the procedure backwards to nalize operation -

Installation

16

General Installation Recommendations

Internal PCI Cards / Brackets dismounting and mounting HT B18

Note: Areas of interest are marked in this section with symbols in RED color. Please power off and disconnect ALL

cables from the computer unit before proceeding!

▼ 1: Unscrew the bottom cover plate (10 pcs of

M3x6mm Torx countersunk screws and lift the cover

up.

▼ 3: Now remove the PCI dummy bracket(s) as needed

for the PCI card(s) you want to install. Only remove the

respective dummy bracket for the PCI card(s) you install,

otherwise dust and cooling issues might occur.

▼ 2: Unscrew 6 pcs countersunk screws and remove

both the EMC Bracket (top 2 screws) and PCI Bracket

holder (2 screws inside + 2 x M3x6mm Torx screws in

rear) as indicated.

▼ 4: Position the PCI card(s) until it stops into the

rear of the computer as arrow#1 indicates. Then, slide

the connector area of the PCI card(s) into the PCI Slot

header(s) gently until it’s fully inserted as arrow #2

shows. Use a rm grip and do not bend/force the cards.

- Repeat the procedure backwards to nalize operation -

Installation

#1

#2

17

IND100210-6

General Installation Recommendations

Internal SSD (Hard Drive HDD) removal / replacement HT B1x

Note: Areas of interest are marked in this section with symbols in RED color. Please power off and disconnect ALL

cables from the computer unit before proceeding! HT B17 used as illustration in this procedure, but it is valid for both

HT B17 and HT B18 computers.

▼ 1: Unscrew the bottom cover plate (10 pcs of

M3x6mm Torx countersunk screws and lift the cover

up.

▼ 3: Unscrew 4 pcs x M3x4mm Phillips countersunk

screws as indicated and replace or remove the SSD

drive as needed.

▼ 2: Unscrew 2 pcs x M3x4mm Phillips countersunk

screws and 2 pcs x M3 Fastener Nut as indicated. Then

lift the entire SSD Device bracket up.

▼ 4: Connect your Serial ATA cable ~20cm (not included)

to the SSD. Power Cable is already available from the

internal power module.

IND100210-6

- Repeat the procedure backwards to nalize operation -

Installation

To SSD To HT B1x Motherboard

18

Physical Overview - HT B17

Front area of computer

Reset Button, Power LED & Button

2.5” internal S-ATA SSD Hard Drive

Power LED & Button:

To turn ON the computer, press down button and release it immediately. The Power LED indication riing will illuminate

green and the operating system will automatically boot. To turn OFF the computer, press down this button and hold it

for 4 seconds. The operating system may require additionally tasks to be performed before computer shuts down and

turns off the unit.

Reset Button: (Hard Reset)

To reset the computer in case of severe software failure, press this button. This reset button is a hard reset which

means the operating system will NOT be warned. Using this reset method may damage les and / or operating system

in worst case scenarios. Precaution should be taken when using this. To perform a safe software reset, press either

the power button, or use the operating system own reset functionality if possible.

2.5” internal S-ATA SSD Hard Drive:

The B17 unit can use 1 x SSD, 2.5” as the main data storage device. The operating system and all other les will

be placed on this, normally visible as drive C: This device is normally factory installed option. The storage device is

located inside the unit and can not be accessed/replaced from the outside.

IND100133-41

19

Physical Overview - HT B17

Operation/Connection area of computer

DC Power Input DVI-D OUT (D2) USB 1,2,3,4

AC Power Input

Network #2

DVI-D OUT (D1) COM1 RS-232Audio IN/OUT Connectors

RGB/VGA OUT

Keyboard Port

HDD LED

Mouse Port

Network #1

COM1 Serial Port INPUT/OUTPUT:

Supports RS-232 using D-SUB 9P Male connectors. Fasten the cable to the connector using the provided screws on

the cable housing itself.

DVI-D OUT:

Connect your DVI cables to the DVI-D 24P Connectors (female) on the rear side of the unit. Screw the DVI cables to

the connectors and make sure you don’t bend any of the pins inside the cable connector when connecting. Note: For

1920x1200 and 1600x1200 resolutions, DVI must be set to CVT-RB (Coordinated Video Timing-Reduced Blanking)

mode manually to avoid intermittent flickering of the displayed image.

RGB OUTPUT:

Will output a signal from the computer for use with external display or monitor. Connects via a High Density D-SUB

15P Female connector. Fasten the cable to the connector using the provided screws on the cable housing itself.

Note for DVI and RGB outputs:

You can either use 2 x DVI-D outputs or 1 x DVI-D + 1 x DB15F (RGB/VGA), but not all 3 at once. It is important that

you connect display units BEFORE you boot up the computer. Once inside a booted Operating System (OS),

detection of connected or disconnected units will not be successfull as the hardware and OS driver does not allow

for realtime detection. In case of loss of signal, turn the unit off by pressing the front power button, reconnect signal

cables and power on+boot up again.

Network #1 / #2 INPUT/OUTPUT:

Supports 10/100/1000Mbps Ethernet (GBLAN). Suitable for twisted pair cables CAT.5E. Make sure the network cable

connector ”clicks” into the RJ-45 connector.

20

IND100133-41

Physical Overview - HT B17

Audio INPUT/OUTPUT:

All connectors are 3.5” Jack Stereo. AC’97 audio support. 7.1 channel. HD Audio. It can be congured via the

operating system to act as 2-channel, 4-channel, 6-channel or 8-channel. Please review 3rd party driver software/

manual to congure the channel setup.

Light Pink / Mic In Gray / Center / LFE Out

Light Green / Line Out Black / Rear Surround Out

Light Blue / Line IN Orange / Side Surround Out

USB1,2,3,4 INPUT/OUTPUT:

Supports any USB1.1 (12Mbps) or USB2.0 (480Mbps) compliant peripherals. Drivers for most USB devices are

usually included in operating system or on separate installation CD’s delivered with Third Party products. USB 1.1

devices will operate in USB 1.1 mode (12 Mbps).

PS/2 Mouse and PS/2 Keyboard INPUTS:

Connect the PS/2 mouse cable to the PS/2 5P Connector (female) marked with MS.

Connect the PS/2 keyboard cable to the PS/2 5P Connector (female) marked with KB.

HDD LED:

The Power LED Indication will illuminate green when HDD is reading/writing. When there is no HDD activity the LED

will be off.

AC Power INPUT:

The internal AC power module supports both 115VAC/60Hz and 230/50Hz power input using a standard IEC power

housing and is part of the Multipower functionality for the unit.

IND100133-41

21

Physical Overview - HT B17

Connect your DC power cable to the 2P Amphenol FCC17 D-SUB Connector (male). Secure the cable to the hex

spacers provided on the unit, and secure the other end to your power supply. The internal DC power module supports

24VDC and is part of the Multipower functionality for the unit.

GROUNDING SCREW:

Please review “General Installation Chapter”, pt. 6 for more information.

+ -

DC POWER INPUT:

Multi-power note: (For units supporting AC & DC input simultaneously)

The unit has a dual input power supply which will accept both AC and DC input. If both inputs are connected, the

unit will be powered by AC. If AC is disconnected it will automatically switch over to DC without affecting the operation

of the unit. This makes it possible to use AC power as primary power and a 24V battery as secondary power,

eliminating the need for expensive UPS systems.

IND100133-41

22

Physical Overview - HT B18

Operation/Connection area of computer

Reset Button, Power LED & Button

Replaceable 2.5 SSD

Hard Drive

COM2

RS-232

RS-422

RS-485

Network #2

DVI-D OUT (D2)

USB 1,2,3,4

Network #1

RGB/VGA OUT

COM1 RS-232

Keyboard Port

Mouse Port

HDD LED

DC Power Input

AC Power Input

Audio IN/OUT Connectors

DVI-D OUT (D1)

2 x PCI Slots

COM1,2 Serial Port INPUT/OUTPUT:

Supports RS-232 or RS-232/RS-422 or RS-485 using D-SUB 9P Male connectors. Fasten the cable to the connector

using the provided screws on the cable housing itself.

DVI-D OUT:

Connect your DVI cables to the DVI-D 24P Connectors (female) on the rear side of the unit. Screw the DVI cables to

the connectors and make sure you don’t bend any of the pins inside the cable connector when connecting. Note: For

1920x1200 and 1600x1200 resolutions, DVI must be set to CVT-RB (Coordinated Video Timing-Reduced Blanking)

mode manually to avoid intermittent flickering of the displayed image.

RGB OUTPUT:

Will output a signal from the computer for use with external display or monitor. Connects via a High Density D-SUB

15P Female connector. Fasten the cable to the connector using the

provided screws on the cable housing itself.

Note for DVI and RGB outputs:

You can either use 2 x DVI-D outputs or 1 x DVI-D + 1 x DB15F (RGB/VGA), but not all 3 at once. It is important that

you connect display units BEFORE you boot up the computer. Once inside a booted Operating System (OS),

detection of connected or disconnected units will not be successfull as the hardware and OS driver does not allow

for realtime detection. In case of loss of signal, turn the unit off by pressing the front power button, reconnect signal

cables and power on+boot up again.

23

IND100133-40

Physical Overview - HT B18

2.5” Replaceable internal S-ATA SSD Hard Drive:

The B18 unit can use 1 x SSD, 2.5” as the main data storage device. The operating system and all other les will be

placed on this, normally visible as drive C: This device is normally factory installed option. The storage device can be

easily be upgraded or replaced by loosing the fasten screw and pull the slot out.

Power LED & Button:

To turn ON the computer, press down button and release it immediately. The Power LED indication riing will illuminate

green and the operating system will automatically boot. To turn OFF the computer, press down this button and hold it

for 4 seconds. The operating system may require additionally tasks to be performed before computer shuts down and

turns off the unit.

Reset Button: (Hard Reset)

To reset the computer in case of severe software failure, press this button. This reset button is a hard reset which

means the operating system will NOT be warned. Using this reset method may damage les and / or operating system

in worst case scenarios. Precaution should be taken when using this. To perform a safe software reset, press either

the power button, or use the operating system own reset functionality if possible.

Audio INPUT/OUTPUT:

All connectors are 3.5” Jack Stereo. AC’97 audio support. 7.1 channel. HD Audio. It can be congured via the

operating system to act as 2-channel, 4-channel, 6-channel or 8-channel. Please review 3rd party driver software/

manual to congure the channel setup.

Orange / Side Surround Out Light Blue / Line IN

Black / Rear Surround Out Light Green / Line Out

Gray / Center / LFE Out Light Pink / Mic In

Network #1 / #2 INPUT/OUTPUT:

Supports 10/100/1000Mbps Ethernet (GBLAN). Suitable for twisted pair cables CAT.5E. Make sure the network cable

connector ”clicks” into the RJ-45 connector.

IND100133-40

24

Physical Overview - HT B18

USB1,2,3,4 INPUT/OUTPUT:

Supports any USB1.1 (12Mbps) or USB2.0 (480Mbps) compliant peripherals. Drivers for most USB devices are

usually included in operating system or on separate installation CD’s delivered with Third Party products. USB 1.1

devices will operate in USB 1.1 mode (12 Mbps).

PS/2 Mouse and PS/2 Keyboard INPUTS:

Connect the PS/2 mouse cable to the PS/2 5P Connector (female) marked with MS.

Connect the PS/2 keyboard cable to the PS/2 5P Connector (female) marked with KB.

HDD LED:

The Power LED Indication will illuminate green when HDD is reading/writing. When there is no HDD activity the LED

will be off.

AC Power INPUT:

The internal AC power module supports both 115VAC/60Hz and 230/50Hz power input using a standard IEC power

housing and is part of the Multipower functionality for the unit.

Connect your DC power cable to the 2P Amphenol FCC17 D-SUB Connector (male). Secure the cable to the hex

spacers provided on the unit, and secure the other end to your power supply. The internal DC power module supports

24VDC and is part of the Multipower functionality for the unit.

GROUNDING SCREW:

Please review “General Installation Chapter”, pt. 6 for more information.

+ -

DC POWER INPUT:

Multi-power note: (For units supporting AC & DC input simultaneously)

The unit has a dual input power supply which will accept both AC and DC input. If both inputs are connected, the

unit will be powered by AC. If AC is disconnected it will automatically switch over to DC without affecting the operation

of the unit. This makes it possible to use AC power as primary power and a 24V battery as secondary power,

eliminating the need for expensive UPS systems.

PCI Slot #1 & #2:

Supports 2 x PCI (Full Height & Length Prole) in two available slots. PCI cards is normally installed from factory or

returned to factory for upgrading if needed.

25

IND100133-40

This page left intentionally blank

26

Specications

27

Specications - HT B17

SPECIFICATIONS

Note: All specifi cations are subject to change without prior notice!

Please visit www.hatteland-display.com for the latest electronic version.

• 270.00 (W) x 57.95 (H) x 310.00 (D) mm

• 10.63" (W) x 2.28" (H) x 12.20" (D)

• Weight: Approx 5 kg

• Aluminium Cooling Chassis

• Power push button, power led, reset button and SSD Led

Multi-power Supply:

• 115&230VAC - 50/60Hz + 24VDC : Model HT B17 STx-Axxx (60W) (STD IEC + 1 x 2p D-SUB (male) - Amphenol FCC17)

Note: You may connect either AC power or DC power or both. In case both sources are connected, power will be sourced from the

AC input. If AC input is lost, there will be a uninterrupted switch-over to DC input.

• Power Consumption - Operating : 30W

• Operating : Temperature -15 deg. C to +55 deg. C

Humidity up to 95%

• Storage : Temperature -20 deg. C to +60 deg. C

Humidity up to 95%

Compass Safe Distance HT B17 STx-Axxx - Standard: 75cm - Steering: 45cm - MTBF (Mean Time Between Failures) = 44622 hours

HT B17 ST0-A100 with:

1 x Intel® Core™2 Duo Desktop Processor P8400 - 2.26GHz

2 x 1GB installed (Dual Channel DDR2 800/667MHz SO-DIMM 200-pin)

1 x SSD 40GB or more* 2.5" SATA

HT B17 STD-A101 with:

1 x Intel® Core™2 Duo Desktop Processor P8400 - 2.26GHz

2 x 1GB installed (Dual Channel DDR2 800/667MHz SO-DIMM 200-pin)

1 x SSD 40GB or more* 2.5" SATA

1 x Microsoft® Windows® Embedded Enterprise (XP Professional Eng w/SP2c, 32bit)

• Installed OS : None for standard version (check Accessories / Options below for OS options)

• Processor : 1 x Intel® Core™2 Duo Desktop Processor P8400 - 2.26GHz, Bus Speed 1066MHz, 3MB L2 Cache

• Memory : 2 x 1 GB installed (Dual Channel 200-pin DDR2 800MHz SO-DIMM)

• Graphics : Intel® Graphics Media Accelerator GMA 4500MHD Integrated/Daughter Board (CH7307C) 2 x DVI-D or 1 x DB15F + 1 x DVI-D

• Graphics Res. : Max 1920 x 1200 @ 60Hz (Note: For 1600x1200/1920x1200, DVI must be set to CVT-RB (Coordinated Video Timing-Reduced Blanking) mode manually).

• System Chipset : Intel® GM45 / ICH9 support Intel® Active Management Technology

• IO Chipset : Winbond W83627DHG

• BIOS : AWARD BIOS

• PCI Slots : None

• Ethernet #1 : 1 x 10/100/1000Mbps, ICH9M Intel® 82567L 1 x RJ-45

• Ethernet #2 : 1 x 10/100/1000Mbps, Intel® 82574L PCI-E Gigabit LAN Controller 1 x RJ-45

• Serial Ports : 1 x RS-232 (COM1) 1 x DB9M

• USB Ports : 4 x USB ports - Supports 2.0 & 1.1 4 x USB Type A

• Keyboard Port : Standard PS/2 mini DIN connector 1 x PS/2

• Mouse Port : Standard PS/2 mini DIN connector 1 x PS/2

• Audio : I

CH9M+AC97 Codec ALC888, 7.1, RCA Jack (Front Out,Line In,Mic,Center/LFE,Surround,Surround back 6 x JACKS

• Speaker : No

• Power Manager : ACPI

• Watchdog Timer : Reset: 1 sec.~255 min. and 1 sec. or 1 min./step

• H/W Status Mont. : Temperatures, voltages & cooling fan status. Auto throttling control if CPU overheats

These products have been tested / type approved by the following classification societies:

IEC 60945 4th (EN 60945:2002) IACS E10 ClassNK - Nippon Kaiji Kyokai DNV - Det Norske Veritas

GL - Germanischer Lloyd BV - Bureau Veritas ABS - American Bureau of Shipping LRS - Lloyd’s Register of Shipping

EU RO MR - Mutual Recognition

• HT 00244 OPT-A1 = 1 x Mounting Plate, RAL 9011

• HT 00228 OPT-A1 = 1 x Mounting Plate with cable relief, RAL 9011

• HT 00245 OPT-A1 = 1 x Mounting Bracket Kit (included with delivery)

• JH C01MF A-A = 1 x USB Cable 1m, Type A to Chassis mount receptacle

• HT 00300 MSOS = OS options -> http://www.hatteland-display.com/os

*Please see user manual/datasheet for more information

• 4GB (Dual Channel 200-pin DDR2 800MHz SO-DIMM)

T E C H N I C A L D E S C R I P T I O N

Power Specifications:

Physical Specifications:

Environmental Considerations:

Lifetime Considerations:

Even although the test conditions for bridge units provide for a maximum

operating temperature of 55°C, continuous operation of all electronic

components should, if possible, take place at ambient temperatures of only

25°C. This is a necessary prerequisite for long life and low service costs.

M E C H A N I C A L D E S C R I P T I O N

Available Models:

* Size indicated is the lowest size available/approved for current revision of data sheet. The unit will support increased disk space in future. Please contact sales for up-to-date status.

Computer Specifications: (Standard model)

External Connector Type:

A P P R O V A L S & C E R T I F I C A T E S

Available Accessories:

Capabilities / Prepared for:

• HT B17 ST0-Axxx = No OS

• HT B17 STD-Axxx = Microsoft® Windows® Embedded Enterprise (Win XP Pro Eng w/SP2c, 32bit)

• HT B17 ST3-Axxx = Microsoft® Windows® Embedded Enterprise (Win Server 2003 Eng, 32bit)

• HT B17 ST7-Axxx = Microsoft® Windows® Embedded Enterprise (Win 7 Pro Eng, 32bit)

• HT B17 ST8-Axxx = Microsoft® Windows® Embedded Enterprise (Win Server 2008 Eng, 32bit)

Models without/with OS:

For a full overview of typenumbers, please review the following link: www.hatteland-display.com/pdflink/ind100780-5.php

IND100129-120

28

Specications - HT B18

SPECIFICATIONS

Note: All specifi cations are subject to change without prior notice!

Please visit www.hatteland-display.com for the latest electronic version.

• 4GB (Dual Channel 200-pin DDR2 800MHz SO-DIMM)

• HT 00253 OPT-A1 = 4 x COM isolated, incl. cable, RS232/422/485

• HT 00252 OPT-A1 = 8 x COM isolated, incl. cable, RS232/422/485

• 1 x 1TB HDD (SATA 2.5")

• Operating : Temperature -15 deg. C to +55 deg. C

Humidity up to 95%

• Storage : Temperature -20 deg. C to +60 deg. C

Humidity up to 95%

Multi-power Supply:

• 115&230VAC - 50/60Hz + 24VDC : Model HT B18 STx-Axxx (60W) (STD IEC + 1 x 2p D-SUB (male) - Amphenol FCC17)

Note: You may connect either AC power or DC power or both. In case both sources are connected, power will be sourced from the

AC input. If AC input is lost, there will be a uninterrupted switch-over to DC input.

• Power Consumption - Operating : 30W

• Power Consumption PCI : Max Total Power Consumption (the sum of both slots) shall not exceed 15W.

• 270.00 (W) x 105.95 (H) x 310.00 (D) mm

• 10.63" (W) x 4.17" (H) x 12.20" (D)

• Weight: Approx 5 kg

• Aluminium Cooling Chassis

• Power push button, power led, reset button and SSD Led

• HT 00244 OPT-A1 = 1 x Mounting Plate, RAL 9011

• HT 00228 OPT-A1 = 1 x Mounting Plate with cable relief, RAL 9011

• HT 00237 OPT-A1 = 1 x Mounting bracket for PCI cards

• HT 00246 OPT-A1 = 1 x Mounting Bracket Kit (included with delivery)

• JH C01MF A-A = 1 x USB Cable 1m, Type A to Chassis mount receptacle

• HT 00300 MSOS = OS options -> http://www.hatteland-display.com/os

*Please see user manual/datasheet for more information

T E C H N I C A L D E S C R I P T I O N

Power Specifications:

Physical Specifications:

Environmental Considerations:

Safety Considerations:

Even although the test conditions for bridge units provide for a maximum

operating temperature of 55°C, continuous operation of all electronic

components should, if possible, take place at ambient temperatures of only

25°C. This is a necessary prerequisite for long life and low service costs.

M E C H A N I C A L D E S C R I P T I O N

Compass Safe Distance HT B18 STx-Axxx - Standard: 75cm - Steering: 45cm

Available Models:

HT B18 ST0-A100 with:

1 x Intel® Core™2 Duo Desktop Processor P8400 - 2.26GHz

2 x 1GB installed (Dual Channel DDR2 800/667MHz SO-DIMM 200-pin)

1 x Replaceable SSD 40GB or more* 2.5" SATA

HT B18 STD-A101 with:

1 x Intel® Core™2 Duo Desktop Processor P8400 - 2.26GHz

2 x 1GB installed (Dual Channel DDR2 800/667MHz SO-DIMM 200-pin)

1 x Replaceable SSD 40GB or more* 2.5" SATA

1 x Microsoft® Windows® Embedded Enterprise (XP Professional Eng w/SP2c, 32bit)

HT B18 STD-A103 with:

1 x Intel® Core™2 Duo Desktop Processor P8400 - 2.26GHz

2 x 1GB installed (Dual Channel DDR2 800/667MHz SO-DIMM 200-pin)

1 x Replaceable SSD 40GB or more* 2.5" SATA

1 x HT 00253 OPT-A1 Serial I/O Card (4 x COM ports - Supports RS-232/422/485)

1 x Microsoft® Windows® Embedded Enterprise (XP Professional Eng w/SP2c, 32bit)

Available Accessories:

* Size indicated is the lowest size available/approved for current revision of data sheet. The unit will support increased disk space in future. Please contact sales for up-to-date status.

Computer Specifications: (Standard model)

External Connector Type:

• Processor : 1 x Intel® Core™2 Duo Desktop Processor P8400 - 2.26GHz, Bus Speed 1066MHz, 3MB L2 Cache

• Memory : 2 x 1GB installed (Dual Channel 200-pin DDR2 800/667MHz SO-DIMM)

• Graphics : Intel® Graphics Media Accelerator GMA 4500MHD Integrated/Daughter Board (CH7307C) 2 x DVI-D or 1 x DB15F + 1 x DVI-D

• Graphics Res. : Max 1920 x 1200 @ 60Hz (Note: For 1600x1200/1920x1200, DVI must be set to CVT-RB (Coordinated Video Timing-Reduced Blanking) mode manually).

• System Chipset

: Intel® GM45 / ICH9 support Intel® Active Management Technology

• IO Chipset : Winbond W83627DHG

• BIOS : AWARD BIOS

• PCI Slots : 2 x PCI Rev2.3 Slot 32-bit, 3V and 5V Interface, Full Height & Half Length (Default Configuration)

Note: Please also review max power consumption in "Power Specifications" table below.

• Ethernet #1 : 1 x 10/100/1000Mbps, ICH9M Intel® 82567L 1 x RJ-45

• Ethernet #2 : 1 x 10/100/1000Mbps, Intel® 82574L PCI-E Gigabit LAN Controller 1 x RJ-45

• Serial Ports : 1 x RS-232 + 1 x RS-232/RS-422/RS-485 2 x DB9M

• USB Ports : 4 x USB ports - Supports 2.0 & 1.1 4 x USB Type A

• Keyboard Port : Standard PS/2 mini DIN connector 1 x PS/2

• Mouse Port : Standard PS/2 mini DIN connector 1 x PS/2

• Audio :

ICH9M + AC97 Codec ALC888, 7.1, RCA Jack (Front Out,Line In,Mic,Center/LFE,Surround,Surround back 6 x JACKS

• Speaker : None

• Power Manager : ACPI

• Watchdog Timer : Reset: 1 sec.~255 min. and 1 sec. or 1 min./step

• H/W Status Mont. : Temperatures, voltages & cooling fan status. Auto throttling control if CPU overheats

A P P R O V A L S & C E R T I F I C A T E S

These products have been tested / type approved by the following classification societies:

IEC 60945 4th (EN 60945:2002) IACS E10 DNV - Det Norske Veritas EN61162 ClassNK - Nippon Kaiji Kyokai

ABS - American Bureau of Shipping GL - Germanischer Lloyd BV - Bureau Veritas LRS - Lloyd’s Register of Shipping

EU RO MR - Mutual Recognition

Capabilities / Prepared for:

• HT B18 ST0-Axxx = No OS

• HT B18 STD-Axxx = Microsoft® Windows® Embedded Enterprise (Win XP Pro Eng w/SP2c, 32bit)

• HT B18 ST3-Axxx = Microsoft® Windows® Embedded Enterprise (Win Server 2003 Eng, 32bit)

• HT B18 ST7-Axxx = Microsoft® Windows® Embedded Enterprise (Win 7 Pro Eng, 32bit)

• HT B18 ST8-Axxx = Microsoft® Windows® Embedded Enterprise (Win Server 2008 Eng, 32bit)

Models without/with OS:

For a full overview of typenumbers, please review the following link: www.hatteland-display.com/pdflink/ind100780-5.php

IND100129-119

29

This page left intentionally blank

30

Technical Drawings

31

Technical Drawings - HT B17

Dimensions might be shown with or without decimals and indicated as mm [inches]. Tolerance on drawings is +/- 1mm. For accurate measurements, check relevant DWG file.

IND100132-185

32

This document is the property of Hatteland Display AS. This document and any authorized reproduction thereof, must not be used in any way against the interest of Hatteland Display AS.

Any authorized reproduction, in whole or in part, must include this legend. Hatteland Display Proprietary information. Not to be distributed to any third party without written permission.

Technical Drawings - HT B18

1/2

Dimensions might be shown with or without decimals and indicated as mm [inches]. Tolerance on drawings is +/- 1mm. For accurate measurements, check relevant DWG fi le.

Hatteland Display AS, Åmsosen, N-5578 Nedre Vats, Norway

Tel: (+47) 4814 2200 - mail@hatteland-display.com - www.hatteland-display.com

Chassis Difference

* HWcode00 manufactured from March 2010.

* HWcode90 manufactured from June 2010. Shown on datasheet

HWcode00

HWcode90

Dimensions might be shown with or without decimals and indicated as mm [inches]. Tolerance on drawings is +/- 1mm. For accurate measurements, check relevant DWG file.

- HWCode00

IND100132-182

This document is the property of Hatteland Display AS. This document and any authorized reproduction thereof, must not be used in any way against the interest of Hatteland Display AS.

Any authorized reproduction, in whole or in part, must include this legend. Hatteland Display Proprietary information. Not to be distributed to any third party without written permission.

33

Technical Drawings - HT B18

1/2

Dimensions might be shown with or without decimals and indicated as mm [inches]. Tolerance on drawings is +/- 1mm. For accurate measurements, check relevant DWG fi le.

Hatteland Display AS, Åmsosen, N-5578 Nedre Vats, Norway

Tel: (+47) 4814 2200 - mail@hatteland-display.com - www.hatteland-display.com

Chassis Difference

* HWcode00 manufactured from March 2010.

* HWcode90 manufactured from June 2010. Shown on datasheet

HWcode00

HWcode90

Dimensions might be shown with or without decimals and indicated as mm [inches]. Tolerance on drawings is +/- 1mm. For accurate measurements, check relevant DWG file.

- HWCode90

IND100132-182

This document is the property of Hatteland Display AS. This document and any authorized reproduction thereof, must not be used in any way against the interest of Hatteland Display AS.

Any authorized reproduction, in whole or in part, must include this legend. Hatteland Display Proprietary information. Not to be distributed to any third party without written permission.

34

Technical Drawings - Accessories

35

Technical Drawings - Mounting Bracket Kit

Dimensions might be shown with or without decimals and indicated as mm [inches]. Tolerance on drawings is +/- 1mm. For accurate measurements, check relevant DWG file.

for HT B17 and HT B18

IND100132-192

36

This document is the property of Hatteland Display AS. This document and any authorized reproduction thereof, must not be used in any way against the interest of Hatteland Display AS.

Any authorized reproduction, in whole or in part, must include this legend. Hatteland Display Proprietary information. Not to be distributed to any third party without written permission.

Technical Drawings - Mounting Plate/Cable Tension Relievers

Dimensions might be shown with or without decimals and indicated as mm [inches]. Tolerance on drawings is +/- 1mm. For accurate measurements, check relevant DWG file.

for HT B17

IND100132-192

37

This document is the property of Hatteland Display AS. This document and any authorized reproduction thereof, must not be used in any way against the interest of Hatteland Display AS.

Any authorized reproduction, in whole or in part, must include this legend. Hatteland Display Proprietary information. Not to be distributed to any third party without written permission.

Technical Drawings - Mounting Plate/Cable Tension Relievers

Dimensions might be shown with or without decimals and indicated as mm [inches]. Tolerance on drawings is +/- 1mm. For accurate measurements, check relevant DWG file.

for HT B18 HWcode00

IND100132-192

38

This document is the property of Hatteland Display AS. This document and any authorized reproduction thereof, must not be used in any way against the interest of Hatteland Display AS.

Any authorized reproduction, in whole or in part, must include this legend. Hatteland Display Proprietary information. Not to be distributed to any third party without written permission.

Technical Drawings - Mounting Plate/Cable Tension Relievers

Dimensions might be shown with or without decimals and indicated as mm [inches]. Tolerance on drawings is +/- 1mm. For accurate measurements, check relevant DWG file.

for HT B18 HWcode90

IND100132-192

39

This document is the property of Hatteland Display AS. This document and any authorized reproduction thereof, must not be used in any way against the interest of Hatteland Display AS.

Any authorized reproduction, in whole or in part, must include this legend. Hatteland Display Proprietary information. Not to be distributed to any third party without written permission.

Technical Drawings - Mounting Plate/Cable Tension Relievers

Dimensions might be shown with or without decimals and indicated as mm [inches]. Tolerance on drawings is +/- 1mm. For accurate measurements, check relevant DWG file.

for HT B22, HT B17, B18, B07, B08

IND100132-266

40

This document is the property of Hatteland Display AS. This document and any authorized reproduction thereof, must not be used in any way against the interest of Hatteland Display AS.

Any authorized reproduction, in whole or in part, must include this legend. Hatteland Display Proprietary information. Not to be distributed to any third party without written permission.

Technical Drawings - Mounting Plate/Cable Tension Relievers

Dimensions might be shown with or without decimals and indicated as mm [inches]. Tolerance on drawings is +/- 1mm. For accurate measurements, check relevant DWG file.

HW00 for HT B17, B18, B07, B08

IND100132-183

41

This document is the property of Hatteland Display AS. This document and any authorized reproduction thereof, must not be used in any way against the interest of Hatteland Display AS.

Any authorized reproduction, in whole or in part, must include this legend. Hatteland Display Proprietary information. Not to be distributed to any third party without written permission.

Technical Drawings - Mounting Plate

Dimensions might be shown with or without decimals and indicated as mm [inches]. Tolerance on drawings is +/- 1mm. For accurate measurements, check relevant DWG file.

for HT B17, B18, B07, B08

IND100132-183

42

This document is the property of Hatteland Display AS. This document and any authorized reproduction thereof, must not be used in any way against the interest of Hatteland Display AS.

Any authorized reproduction, in whole or in part, must include this legend. Hatteland Display Proprietary information. Not to be distributed to any third party without written permission.

Appendixes

43

SSD Selection Guide

Solid State Disk (SSD) Devices

Last revised : 4 November 2014

SSD's has many benets over conventional hard drives, but when it comes to write

endurance it is important to choose the technology to be used with care. It is of very high

importance to consider several aspects when using an SSD for a particular

application, below the most critical ones, such as:

- Nature of the application, data written to disk during a dened time period (worst case).

- Operating System (OS) and applications settings, optimized for SSD.

- SSD selection, there are several choices of price and performance.

- Expected system life, using worst case calculations.

SSD devices have limited life time. The life time of the SSD device is direct dependent of the application software.

- Selection / dimensioning of SSD device is required for each unique application.

- Selection / dimensioning of SSD device have to be done of the system house.

- Selection / dimensioning of SSD device shall be done towards data rate , size of footprint is

secondary and in most cases not the dimensioning factor.

Hatteland Displays Recommendations, MLC device

Use of OS image adapted for HDD without any modications for SSD:

> Do not use SSD.

Basic SSD conguration of OS but not considered SSD in application SW and no estimation of

amount of written data:

> Do not use SSD.

Basic SSD conguration of OS and basic consideration of SSD in application SW. Estimation based

at guess, but actual amount of written data not known:

> Select next larger device, i.e if calculation gives 80GB, select 120GB instead.

> Minimum size 80GB.

Actual data known, based at measurements at actual application, running in worst case scenario:

> Select device according to calculation.

IND100077-130

Appendix

44

SSD Selection Guide

Calculation of required size of SSD (Multi-Level Cell - MLC) device)

The table below details the write endurance of the an enterprise environment. All values are veried by Hatteland

Display during the qualication / selection process.

Write Endurance Specications

Intel® SSD 320 Series

Device Size Value in TBW (Terabytes) Device Size Value in TBW (Terabytes)

40 GB 5 80 GB 45

80 GB 10 120 GB 70

120 GB 15 160 GB 100

160 GB 15 240 GB 140

300 GB 30 300 GB 225

600 GB 60 600 GB 330

Write endurance is measured while running 100%

random 4KB (4096 bytes) writes spanning 100% of

the drive using Iometer.

Formula for calculating disk size:

z = y * x

Where y = Requested minimum lifetime (with respect to wear out, [year]).

Where x = Data rate (GB /per year).

Where z = Total amount of data written data to SSD during its whole lifetime.

JESD218 standard1 and based on JESD219 workload.

Write Endurance Specications

Current 2.5” SSD (MLC)

Step-by-Step Calculation

Step 1: Measure (preferred) or estimate data rate y, [GB /per year].

Step 2: Dene minimum expected lifetime for SSD device x [year].

Step 3: Calculate total amount of data written to the SSD during its whole lifetime, z = y * x.

Step 4: Use table, column 2, the z value shall be less or equal to the value in the table to achieve requested lifetime.

Write Endurance Specications

Intel® SSD 320 Series

Device Size Value in TBW (Terabytes) Device Size Value in TBW (Terabytes)

40 GB 5 80 GB 45

80 GB 10 120 GB 70

120 GB 15 160 GB 100

160 GB 15 240 GB 140

300 GB 30 300 GB 225

600 GB 60 600 GB 330

Step 5: Select the SSD device, column 1, which corresponds to the selected value in column 2.

Step 6. Check that the size of the selected SSD is greater than required size of the SSD, if not select the size of the

SSD that match customer requirements.

Write Endurance Specications

Current 2.5” SSD (MLC)

IND100077-130

Appendix

45

SSD Selection Guide

Example (based on Intel® SSD 320 Series)

A general assessment based on requirements to determine the most suitable SSD device. When these factors are

known or specied in detail, we can calculate and conclude which SSD device is most suitable (see bottom of page).

Question Client Answer

We need to know how much data is written to disk

(worst case) during a known time period (per second,

minute, hour etc.) and the nature of this data?

How much space is used on as xed for your

application?

How long time shall this disk work with no problems? 5 years

Example Calculation and Conclusion

Calculation / Estimation of data rate:

Step Factors Formula Result

1 Chart Data: 2GB /Week 2GB * 52 = 104 GB /Year

Log data and User Data: 10kB /Sec 10kB * 60 * 60 * 24 * 365 = 315 GB /Year

Swap Data: 100kB /Sec 100kB * 60 * 60 * 24 * 365 = 3.15 TB /Year

2 Required lifetime: 5 years

3 Calculate total amount of data

written to the SSD during its whole

lifetime:

4 Select Disk Using Table Conclusion = 300GB SSD Device shall be used.

3.57TB * 5 = 17.8 TB

Chart Data : 2GB /Week

Log/User Data: : 10kB /Sec

Swap Data : 100kB /Sec

40GB over : Chart Data Area (typical Chart size is 30GB)

1GB : Log Data and User Data area

4GB : Swap Area

Total = 3.57 TB/Year

Measure of number of write cycles (Intel® Solid-State Drive Toolbox software)

Download Software from: https://downloadcenter.intel.com/Detail_Desc.aspx?agr=Y&DwnldID=18455

Appendix

46

IND100077-130

SSD Selection Guide

Preparation

1: Install "Intel® Solid-Sate Drive Toolbox" at target system.

2: Install the unit in valid conguration, i.e. the application shall running valid use case, if possible use worst

case scenario (with respect to disk activity).

3: Before start of measurement, check and store actual SMART data.

- Start "Intel® Solid-Sate Drive toolbol".

- Refresh (button at home screen).

- Export SMART data, store current data at le (button at home screen).

Measurement

1: Check and save time for start test scenario.

2: Execute the test scenario long enough to cover all valid use cases which may affect disk activity.

(Recommended measurement period is at least 1 week without interruption).

3: When the measurement is completed...

- Check and save time for completion of the test scenario.

- Start Intel® Solid-Sate Drive toolbox.

- Refresh (button at home screen).

- Export SMART data, store current data at le (button at home screen).

Calculation

1: Calculate number of written bytes during the measurement period, use E1 or F1 parameter (stored log le).

Number of written bytes per second = (F1compleation - F1start) / (Timecompletion - Timestart)

2: Convert to bytes per year.

3: Calculate expected life time (see previous time, section "Step-by-Step Calculation").

IND100077-130

Appendix

47

Pinout Assignments - Common Connectors

Note: Not all connectors may be available on your specic product. This depends on the amount of additional hardware installed from factory,

or customized solutions. These pin assignments are for the common connectors used. Connectors are seen from users Point Of View (POV).

RJ45 10/100 LAN

Use category 5 - twisted pair cable

1 2 3 4 5 6 7 8

Pin 01 - TDP Transmit Differential Pair (Positive)

Pin 02 - TDN Transmit Differential Pair (Negative)

Pin 03 - RDP Receive Differential Pair (Positive)

Pin 04 - NC Not Connected

Pin 05 - NC Not Connected

Pin 06 - RDN Receive Differential Pair (Negative)

Pin 07 - NC Not Connected

Pin 08 - NC Not Connected

RJ45 10/100/1000 GBLAN

1 2 3 4 5 6 7 8

Pin 01 - D0P Differential Pair 0 (Positive)

Pin 02 - D0N Differential Pair 0 (Negative)

Pin 03 - D1P Differential Pair 1 (Positive)

Pin 04 - D2P Differential Pair 2 (Positive)

Pin 05 - D2N Differential Pair 2 (Negative)

Pin 06 - D1N Differential Pair 1 (Negative)

Pin 07 - D3P Differential Pair 3 (Positive)

Pin 08 - D3N Differential Pair 3 (Negative)

15P HD RGB VGA

5 4 3 2 1

10 9 8 7 6

4P USB TYPE A

Pin 2: Negative Data

Pin 1: VCC +5V

Pin 4: Ground

Pin 3: Positive Data

4P USB TYPE B

Pin 2: Negative Data

Pin 3: Positive Data

Pin 1: VCC +5V

Pin 4: Ground

5P PS/2 MOUSE

Pin 6: Not Connected

Pin 4: Vcc +5V

Pin 2: Not Connected

Pin 5: Mouse Clock

Pin 3: Ground

Pin 1: Mouse Data

5P PS/2 KEYBOARD+MOUSE Combined

Pin 6: Mouse Clock

Pin 4: Vcc +5V

Pin 2: Mouse Data

Pin 5: Keyboard Clock

Pin 3: Ground

Pin 1: Keyboard Data

2P DC Power Input on unit

Amphenol FCC17 D-SUB MALE

Pin 1: +24VDC

Pin 2: Ground

+ -

2P DC Power Input Housing

FCE17-E2W2SS-2N0

Pin 2: Ground

Pin 1: +24VDC

- +

Pin 01 Red, analog

15 14 13 12 11

Green, analog

Pin 02

Blue, analog

Pin 03

Reserved for monitor ID bit 2 (grounded)

Pin 04

Digital ground

Pin 05

Analog ground red

Pin 06

Analog ground green

Pin 07

Analog ground blue

Pin 08

+5V power supply for DDC (optional)

Pin 09

Digital ground

Pin 10

Reserved for monitor ID bit 0 (grounded)

Pin 11

DDC serial data

Pin 12

Horizontal sync or composite sync, input

Pin 13

Vertical sync, input

Pin 14

DDC serial clock

Pin 15

9P Serial COM RS-232

This connector is commonly used for:

5 4 3 2 1

Pin 01 - DCD Data Carry Detect

Pin 02 - SIN Serial In or Receive Data

Pin 03 - SOUT Serial Out or Transmit Data

Pin 04 - DTR Data Terminal Ready

Pin 05 - GND Ground

Pin 06 - DSR Data Set Ready

Pin 07 - RTS Request To Send

Pin 08 - CTS Clear To Send

Pin 09 - RI Ring Indicate

Note: The table above lists commonly-used RS-232 signals and pin

assignments, however Serial Communication for Hatteland Display

products may vary from product to product to support different

end user systems. Please check additional pin assignments section

in this manual for specic RS-232/RS-422/RS-485 pin assignments

for your exact product.

9 8 7 6

5P PS/2 KEYBOARD

Pin 6: Not Connected

Pin 4: Vcc +5V

Pin 2: Not Connected

5P S-VHS/S-VIDEO

Pin 4: C - Color (chrominance)

Pin 2: Ground (C)

RCA/BNC 1P COMP. VIDEO

Pin 1: Video Signal

Pin 5: Keyboard Clock

Pin 3: Ground

Pin 1: Keyboard Data

Pin 3: Y - Intensity (luminance)

Pin 1: Ground (Y)

Ground Shield

IND100241-2

Appendix

48

Pinout Assignments - Common Connectors

25P Parallel

13 12 11 10 9 8 7 6 5 4 3 2 1

25 24 23 22 21 20 19 18 17 16 15 14

Pin 01 - STROBE This signal indicates to the printer that data at PD7..0 are valid.

Pin 02 - DATA0 Parallel data bus from PC board to printer. The data line are able to operate in PS/2 compatible bi-directional mode.

Pin 03 - DATA1 Same as Pin 02

Pin 04 - DATA2 Same as Pin 02

Pin 05 - DATA3 Same as Pin 02

Pin 06 - DATA4 Same as Pin 02

Pin 07 - DATA5 Same as Pin 02

Pin 08 - DATA6 Same as Pin 02

Pin 09 - DATA7 Same as Pin 02

Pin 10 - ACK Signal from printer indicating that the printer has received the data and is ready to accept further data.

Pin 11 - BUSY Signal from printer indicating that the printer cannot accept further data.

Pin 12 - PE Signal from printer indicating that the printer is out of paper.

Pin 13 - SELECT Signal from printer to indicate that the printer is selected.

Pin 14 - AUTO FEED This active low output causes the printer to add a line feed after each line printed.

Pin 15 - ERR# Signal from printer indicating that an error has been detected.

Pin 16 - INIT# This active low output initialises (resets) the printer.

Pin 17 - SLIN# Signal to select the printer sent from CPU board to printer.

Pin 18 - GND Ground

Pin 19 - GND Ground

Pin 20 - GND Ground

Pin 21 - GND Ground

Pin 22 - GND Ground

Pin 23 - GND Ground

Pin 24 - GND Ground

Pin 25 - GND Ground

24P DVI-D & DVI-I

1 2 3 4 5 6 7 8 C1 C2

9 10 11 12 13 14 15 16 C5

17 18 19 20 21 22 23 24 C3 C4

Pin 01 T.M.D.S. Data2 - (Digital - RED link 1)

Pin 02 T.M.D.S. Data2 + (Digital + RED link 1)

Pin 03 T.M.D.S. Data2/4 Shield

Pin 04 T.M.D.S. Data4 - (Digital - GREEN link 2)

Pin 05 T.M.D.S. Data4 + (Digital + GREEN link 2)

Pin 06 DDC Clock

Pin 07 DDC Data

Pin 08 Analog Vertical Sync (DVI-I only)

Pin 09 T.M.D.S. Data1 - (Digital - GREEN link 1)

Pin 10 T.M.D.S. Data1 + (Digital + GREEN link 1)

Pin 11 T.M.D.S. Data1/3 Shield

Pin 12 T.M.D.S. Data3 - (Digital - BLUE link 2)

Pin 13 T.M.D.S. Data3 + (Digital + BLUE link 2)

Pin 14 +5V Power (for standby mode)

Pin 15 Ground (for +5V and analog sync)

Pin 16 Hot Plug Detect

Pin 17 T.M.D.S. Data0 - (Digital - BLUE link 1) and digital sync.

Pin 18 T.M.D.S. Data0 + (Digital + BLUE link 1) and digital sync.

Pin 19 T.M.D.S. Data0/5 Shield

Pin 20 T.M.D.S. Data5 - (Digital - RED link 2)

Pin 21 T.M.D.S. Data5 + (Digital - RED link 2)

Pin 22 T.M.D.S. Clock Shield

Pin 23 T.M.D.S. Clock + (Digital clock + (Links 1 and 2)

Pin 24 T.M.D.S. Clock - (Digital clock - (Links 1 and 2)

Pin C1 Analog RED

Pin C2 Analog GREEN

Pin C3 Analog BLUE

Pin C4 Analog Horizontal Sync.

Pin C5 Analog Ground (return for RGB signals)

DDC = Display Data Channel /// T.M.D.S = Transition Minimized Differential Signal /// PIN C1,C2,C3,C4 = Only present on DVI-I connectors.

NOTE: Connector shows a DUAL LINK design, but some units may not support it. Only products with 1920x1200 or more in resolution

require / support DUAL LINK.

Additional connector pinouts may be available in third party motherboard manuals, primarily for computers only.

Please see manual/drivercd delivered with your product or own section in this user manual.

IND100241-2

Appendix

49

Pin Assignments - Common Connectors (Additional)

Pin Assignments - 9P Serial COM RS422

5 4 3 2 1

9 8 7 6

Pin 01 - N/C Not Connected

Pin 02 - TX- Transmit Data Pin 03 - RX+ Receive Data +

Pin 04 - N/C Not Connected

Pin 05 - GND Ground

Pin 06 - N/C Not Connected

Pin 07 - TX+ Transmit Data +

Pin 08 - RX- Receive Data Pin 09 - N/C Not Connected

Pin Assignments - 9P Serial COM RS485

5 4 3 2 1

9 8 7 6

Pin 01 - N/C Not Connected

Pin 02 - N/C Not Connected

Pin 03 - DAT+ Data+

Pin 04 - N/C Not Connected

Pin 05 - GND Ground

Pin 06 - N/C Not Connected

Pin 07 - N/C Not Connected

Pin 08 - DAT- DataPin 09 - N/C Not Connected

Note: These pin assignments applies for products with customer specied COM ports (pre-setup by the factory).

These COM ports are set/congurable on the motherboard located inside the product. If the main cover of the product

has to be unmounted and removed, the warranty will be void.

IND100241-3

Appendix

50

Trouble-shooting

IND101744-1 rev 04 - 18 Sep 2014 - 6987/6923/363

RECOVERY / RESCUE IMAGE - QUICK START

The Recovery Kit (USB Flash) will attempt to restore the HDD/SSD partition back to factory default overwriting all

current data available on the HDD/SSD device. The recovery image is located either on a hidden partition image

located on the computer unit (HT/HM C01 with WinXP only) or it is included as a image on the USB Flash Kit for

HT 221, HT 216, HT B17, HT B18, HT B22 and HT/HM C01/C02 (Win7 only) computer models. The recovery

image le is not accessible from any operating system, only by the Recovery Kit (USB Flash) provided by Hatteland

Display. For more information, visit http://www.hatteland-display.com/os

Note that all les created after initial factory boot will be DELETED - make sure you do backup!

Restore from external USB recovery image:

1: Insert the USB Flash media into the computer usb connector.

2: Restart the computer.

3: On the rst screen that appear, press “Delete” or “F2” on the keyboard (depending on BIOS model) to bring up

the BIOS setup screen.

4: Select “Advanced BIOS features” or “Boot“ (depending on BIOS model).

5: Set “Harddisk boot priority” to “USB HDD” as number 1

or select "Hard Disk Drives", then modify "1 st" to "USB: ...." depending on BIOS model.

6: Press F10 and then Enter on keyboard, or “F4” to save settings (depending on BIOS model).

7: Follow the on screen instructions that will be executed from the USB Flash media, such as;

8: After the restore operation is complete, remove the USB Flash Media and restart.

9: The computer is now restored to its original factory state.

10: If rescue failed, an error message will be displayed.

GENERAL TROUBLE-SHOOTING

CD-ROM FAILURE OR READ/DETECTION PROBLEMS?

If the product are operated/located in a area with extreme condensation, the CD/DVD-ROM drive may not work

correctly due to condensation on the read head. Keep the product on for a while until it’s reached normal operating

temperature, and retry accessing discs. Otherwise, consider using USB memory sticks or alternative storage devices.

NO CD-ROM AVAILABLE ON YOUR PRODUCT FOR INSTALLING DRIVERS/SOFTWARE?

Please use USB memory sticks, USB Floppy drive, USB CD-Rom Drive or alternative storage devices to transfer or

install software on CD-ROM-less units. You may also download drivers from: http://www.hatteland-display.com/archive

RECOVERY/RESCUE IMAGE

IND100077-91

Appendix

51

Declaration of Conformity

We, manufacturer, Hatteland Display AS, Stokkastrandvegen 87B, N-5578 Nedre Vats, Norway

declare under our sole responsibility that the

JH MMD, JH MMC, JH STD, JH MIL, HM NMD, HM MIL, HM CMD, HT STD, HD MMD, HM MMD, HT MMC, HD MMC

and HT/HM (computers) product ranges is in conformity with the following standards in accordance with the EMC Directive.

Low Voltage Directive 2006/95/EC

EN 60950:2006/A2:2013

EMC Directive 2004/108/EC

EN 55022:2010 / AC:2011 Class A

EN 55024:2010

Signature:........................................................

Frode Grindheim

Vice President Product Management

Nedre Vats, Norway

CE MARK FIRST AFFIXED DATE (11 March 2010)

Signature:........................................................

Arne Kristiansen

Site Manager - Test & Commission Division

Oslo, Norway

Declaration of Conformity

We, manufacturer, Hatteland Display AS, Stokkastrandvegen 87B, N-5578 Nedre Vats, Norway

declare under our sole responsibility that the JH MMD, JH MMC, JH STD, JH MIL, HM NMD, HM MIL, HM CMD, HT STD,

HD MMD, HM MMD, HT MMC, HD MMC and HT/HM (computers) product ranges is in conformity with

IEC 60945 4th (EN 60945:2002) and IACS E10 (where applicable)

Declaration of Conformity

We, manufacturer, Hatteland Display AS, Stokkastrandvegen 87B, N-5578 Nedre Vats, Norway

declare under our sole responsibility that the products listed below comply with

FCC 47 CFR Part 15, Subpart B, Class A:

JH MMD, JH MMC, JH STD, JH MIL, HM NMD, HM MIL, HM CMD, HT STD, HD MMD,

HM MMD, HT MMC, HD MMC and HT/HM (computers) product ranges

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to

Signature:........................................................

Vice President Product Management

IND100237-1

cause harmful interference in which case the user will be required to correct the interference at his own expense.

Frode Grindheim

Nedre Vats, Norway

FCC MARK FIRST AFFIXED DATE (16 February 2012)

This document was last approved, reviewed and found valid on 06 Jan 2015 by the signed participants as stated above.

Signature:........................................................

Arne Kristiansen

Site Manager - Test & Commission Division

Oslo, Norway

Return Of Goods Information

Return of goods:

(Applies not to warranty/normal service/repair of products)

Hatteland Display referenced as “manufacturer” in this document.

Before returning goods, please contact your system supplier before sending anything directly to manufacturer. When

you return products after loan, test, evaulation or products subject for credit, you must ensure that all accessories

received from our warehouse is returned. This applies to cables, powermodules and additional equipment except

screws or similar, user manual, datasheets or other written paper documents. Furthermore, the product must not have

any minor / medium or severe scratches, chemical spills or similar on the backcover, front frame or glass.

This is needed to credit the invoice 100%. Missing parts will not be subject for credit, and you will not get total credit

for returned product. You will either be charged separately or the amount is withdrawn from the credit. If you decide to

ship the missing items on the after hand, you will get 100% credit for that particular invoice or items received at

manufacturer incoming goods control. Please contact our service/sales department if additional questions or review

the following links at bottom of page for more information online.

Handling and packing units for return/credit

To prevent damage during shipping and transportation, respect the guidelines below.

Make sure you surround the product with the following material (whenever possible):