HATO 400Y, HEL 11C User Manual

HATO 400Y HEL 11C

SLIDING GATE OPERATOR

USER’S MANUAL

2

OUTLINE

1. Important safety information………………………3

2. Main technical parameters ………………………3

3. Installation …………………………………………3

4. Connecting …………………………………………7

5. Control ……………………………………………10

6. Check ……………………………………………14

7. Maintenance………………………………………14

8.Troubleshooting …………………………………15

3

1.Important safety information

Carefully read and follow all safety precaution and warnings before attempting to install and use this operator, incorrect

installation can lead to severe injury.

The gate operator should be installed by a qualified technician; otherwise, serious personal injury or property

damage may occur.

The auto-reverse function must be checked during installation to ensure that the gate can auto-reverse in the

event of obstruction.

This auto-reverse function should be regularly inspected and adjusted, if necessary.

When opening or closing the gate, do not attempt to walk or drive through the gate.

Children should not be allowed to play near or operate automatic gates.

The automatic gate operator must be grounded.

Install the gate operator on the inside of the property, DO NOT install it on the outside of the property where the

public has access to it.

Be careful when in close proximity to moving parts where hands or fingers could be pinched.

Do not allow control devices to be placed so that a person can access them by reaching through the gate.

In the event of power failure, an emergency release key allows you to operate the gate manually.

The operator should be switched off before repairing it or opening its cover.

Please erase and reprogram the code after installing the operator.

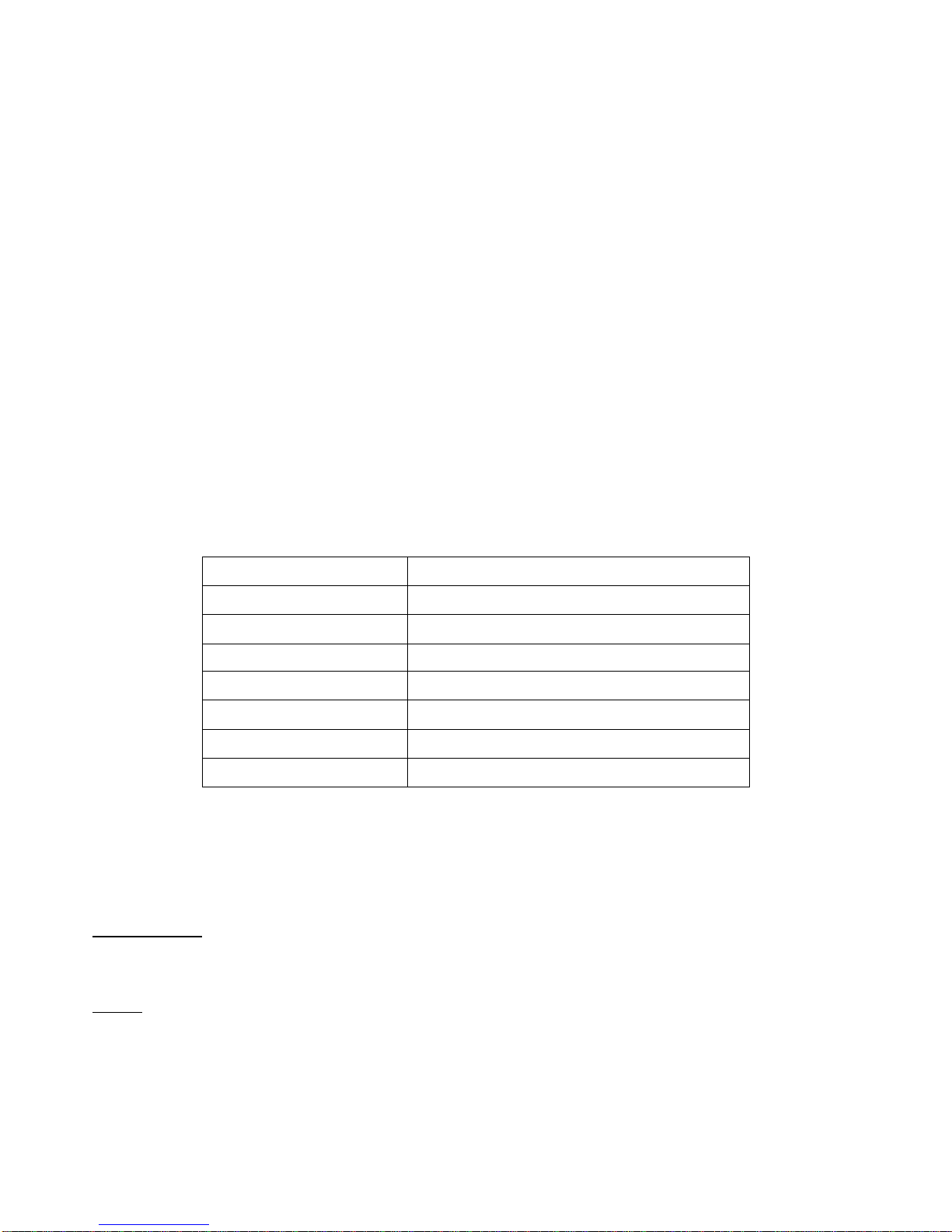

2. Main technical parameters

3. Installation

The HATO 400 Y rack-driven gate operator operates by forcing a drive rack past a drive gear. The entire configuration

is shown in Fig.1. The gate operator must be installed on the inside of the gate.

Gate preparation

Be sure the gate is properly installed and slides smoothly before installing the DKC400Y sliding gate operator. The

gate must be plumb, level, and move freely.

Conduit

In order to protect the wires, use PVC conduit for wires, conduit must be set into the concrete when it is poured. Wires

within the conduit shall be located or protected so that no damage can result from contact with any rough or sharp

part.

Type

HATO 400Y

Power supply

AC 220V, 50Hz

Motor speed

1400 r/min

Gate moving speed

11m/min (19 teeth)

Output torque

14N·m

Limit switch

Spring limit switch

Noise

≤62dB;

Environmental temperature

-20ºC~+50ºC

4

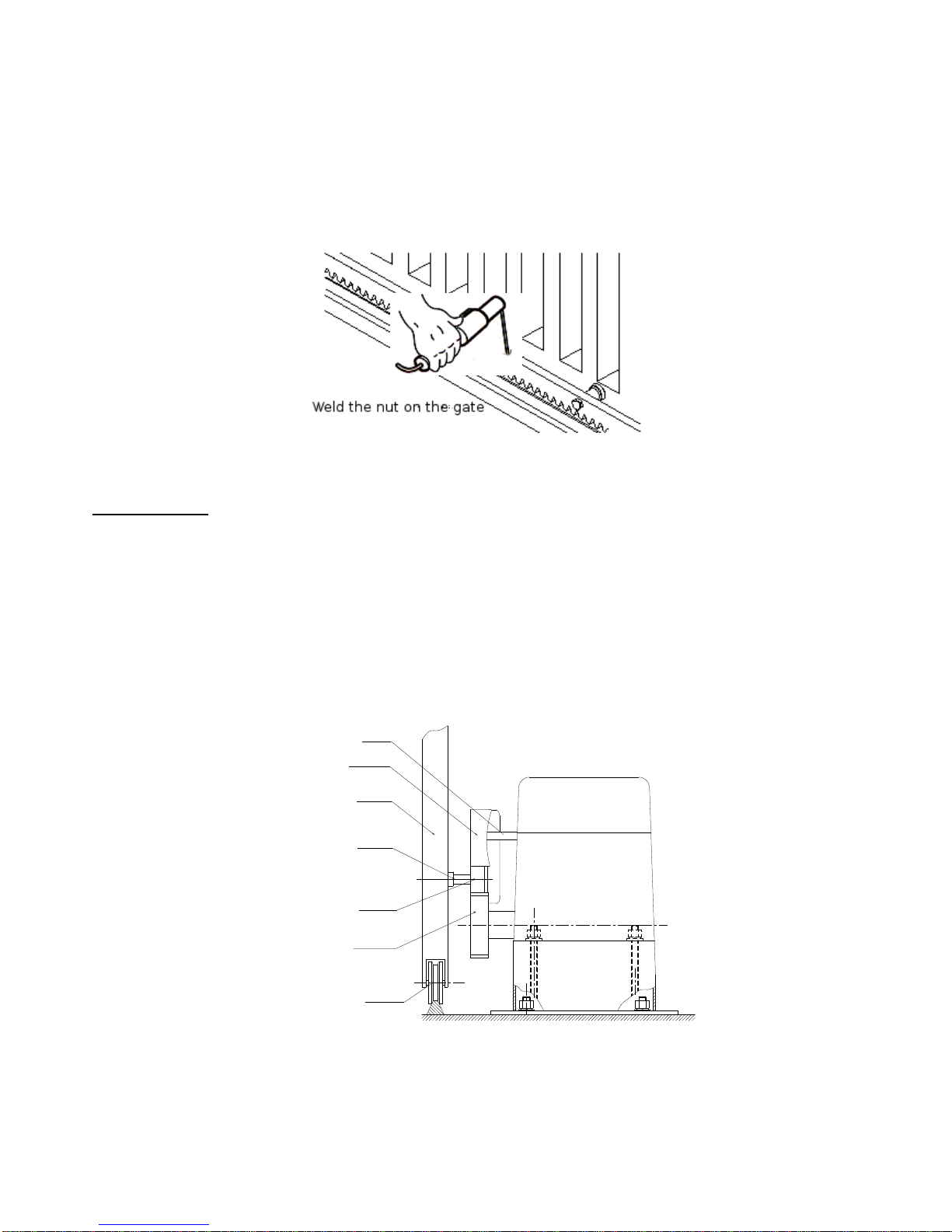

Fig.1

Concrete pad

The base unit of the gate operator requires a concrete pad in order to maintain proper stability. The concrete pad

should be approximately 300mm x 200mm x 200mm deep in order to provide for adequate operation.

Anchors

You can use the anchors, bolts, washers and nuts that are provided with the operator. These anchors must be set into

the concrete when it is poured, or you can use wedge anchors.

Operator

In locations where ground freeze is possible, mount the gate operator on installation pad as shown in Fig.2. Check the

operator and make sure it is lined up with the gate.

Conduit

Installation pad

Gate operator

Gear

Nut

Spring washer

Plain washer

Anchor

Bolt

Nut

Spring limit switch

Wires

Fig.2

Installation of rack (see Fig.3)

﹡ If you have installed an external

button switch, you must use two

conduits: one for main power wire,

another one for low voltage wire

(button switch).

5

Fix the three nuts (in the same package with rack) on the rack element.

Lay the first piece of rack on the gear and weld the first nut on the gate.

Move the gate manually, checking if the rack is resting on the gear, and weld the second and third nut.

Bring another rack element near to the previous one. Move the gate manually and weld the three nuts as the first

rack, thus proceeding until the gate is fully covered.

When the rack has been installed, to ensure it meshes correctly with the gear.

The space between rack and gear is about 1mm.

Fig.3

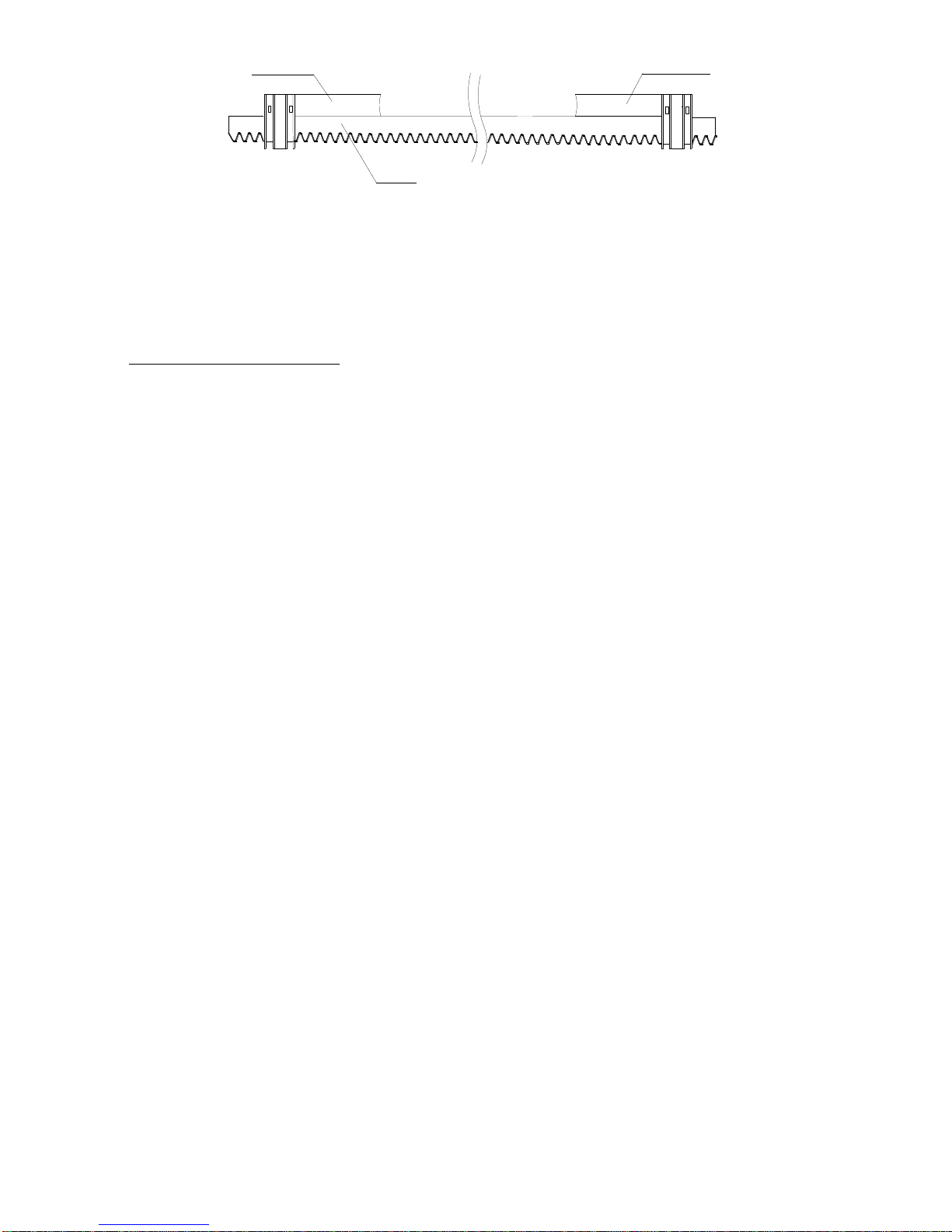

Spring limit switch

To ensure safety, it is recommended to install plastic blocks at both ends of the gate to prevent the gate from

sliding out of the rail. The rail must be installed horizontally.

Install the plastic block as shown in Fig.4 and Fig.5. The spring limit switch and blocks are used to control the

position of the gate.

Release the gear clutch with the key and push the sliding gate manually to pre-determine the position, fix the

block to the rack and then tighten the gear clutch with the key. Moving the gate electrically, adjust the block to the

proper position until the position of the opening and closing meet the requirement.

Block

Gate

Rack

Gear

Guide rail

Spring limit switch

Nut

Fig.4

6

Rack

Left block

Right block

Fig.5

CONFORMITY DECLARATION:

Motor Hato 400Y meets the requirements set out in the following provisions:

It’s in accordance with Machine Directive 2006/42/WE and following modify.

It’s in accordance with the following directive CE:

Electromagnetic compatibility Directive EMC 2014/30/UE and following modify.

Low tension Directive LDV 2014/35/UE and following modify.

Have been applied the following harmonized norms:

EN60335-1:2012, EN60335-2-103:2015-3, EN 55014-1:2012, EN 55014-2:2015-06,

EN 61000-3-2-2014-10, EN 61000-3-3:2013-10

Loading...

Loading...