Hatco IRNG-PB1-18 Installation Manual

hatcocorp.com

WARNING

ADVERTENCIA

Register Online!

(see page 2)

S’inscrire en ligne !

(voir page 16)

IRNG Series/Série, P Type/Type P

Installation and Operating Manual

Manuel d’installation et d’utilisation

Rapide Cuisine™

Induction Range

Cuisinière à induction

Do not operate this equipment unless you

have read and understood the contents

of this manual! Failure to follow the

instructions contained in this manual

may result in serious injury or death.

This manual contains important safety

information concerning the maintenance,

use, and operation of this product. If

you’re unable to understand the contents

of this manual, please bring it to the

attention of your supervisor. Keep this

manual in a safe location for future

reference.

P/N 07.04.762.00 © 2016 Hatco Corporation

English = p 2

No opere este equipo al menos que haya

leído y comprendido el contenido de este

manual! Cualquier falla en el seguimiento

de las instrucciones contenidas en

este manual puede resultar en un serio

lesión o muerte. Este manual contiene

importante información sobre seguridad

concerniente al mantenimiento, uso y

operación de este producto. Si usted

no puede entender el contenido de

este manual por favor pregunte a su

supervisor. Almacenar este manual en

una localización segura para la referencia

futura.

AVERTISSEMENT

Ne pas utiliser cet équipement sans avoir

lu et compris le contenu de ce manuel ! Le

non-respect des instructions contenues

dans ce manuel peut entraîner de

graves blessures ou la mort. Ce manuel

contient des informations importantes

concernant l’entretien, l’utilisation et le

fonctionnement de ce produit. Si vous ne

comprenez pas le contenu de ce manuel,

veuillez le signaler à votre supérieur.

Conservez ce manuel dans un endroit

sûr pour pouvoir vous y référer plus tard.

Français = p 16

CONTENTS

WARNING

CAUTION

English

Important Owner Information .............................................. 2

Introduction ...........................................................................2

Important Safety Information .............................................. 3

Model Description ................................................................4

Model Designation ...............................................................4

Specifications ....................................................................... 5

Plug Configurations ............................................................. 5

Electrical Rating Chart ......................................................... 5

Dimensions ......................................................................... 5

Installation .............................................................................6

General ................................................................................ 6

Installing Built-In Models .....................................................7

Installing the Control Panel .................................................9

IMPORTANT OWNER INFORMATION

Record the model number, serial number, voltage, and purchase

date of your strip heater in the spaces below (specification

label located on the underside of the unit). Please have this

information available when calling Hatco for service assistance.

Model No. ________________________________________

Serial No. _________________________________________

Voltage ___________________________________________

Operation .............................................................................10

General .............................................................................. 10

Changing Cooking Control Method ................................... 11

Using the Timer ................................................................. 11

Cooking with Menu Items .................................................. 12

Programming Menu Items ................................................. 12

Changing Operation Mode ................................................12

Changing Between Fahrenheit and Celsius ...................... 13

Updating Firmware ............................................................13

Maintenance ........................................................................ 14

General .............................................................................. 14

Daily Cleaning ...................................................................14

Troubleshooting Guide ......................................................14

Limited Warranty ................................................................15

Service Information ............................................................ 15

Business

Hours: 7:00 am to 5:00 pm Central Standard Time (CST)

(Summer Hours: June to September—

7:00 am to 5:00 pm CST Monday–Thursday

7:00 am to 4:00 pm CST Friday)

Telephone: 800-558-0607; 414-671-6350

E-mail: partsandservice@hatcocorp.com

Date of Purchase ___________________________________

Register your unit!

Completing online warranty registration will prevent delay in

obtaining warranty coverage. Access the Hatco website at

www.hatcocorp.com, select the Parts & Service pull-down

menu, and click on “Warranty Registration”.

INTRODUCTION

Hatco Induction Ranges offer a safe, quick, efficient, and

attractive way to prepare foods in commercial kitchens as

well as display cooking locations (omelet bars, buffets, etc...).

The high efficiency, accuracy, and speed of induction cooking

make Hatco Induction Ranges the perfect choice for quality

foodservice organizations.

Induction cooking relies on the creation of a magnetic field

between the induction coils below the glass surface of the

unit and an “induction-ready” pan sitting on top of the glass

surface. This magnetic field generates induction currents in

the base of the pan, which heat the pan instantly. That heat

then is transferred to the pan contents. Since the magnetic field

exists only between the induction coils and a magnetic material

(ferrous material), the glass surface between the two does not

become heated, eliminating heat loss and increasing efficiency.

When the magnetic field is “broken” by turning off the unit or

removing the pan, heat generation stops instantly.

Hatco Induction Ranges are products of extensive research and

field testing. The materials used were selected for maximum

durability, attractive appearance, and optimum performance.

Every unit is inspected and tested thoroughly prior to shipment.

24 Hour 7 Day Parts and Service

Assistance available in the United States

and Canada by calling 800-558-0607.

Additional information can be found by visiting our web site at

www.hatcocorp.com.

This device complies with Part 18 of the FCC Rules.

This manual provides the installation, safety, and operating

instructions for Hatco Induction Ranges. Hatco recommends

all installation, operating, and safety instructions appearing in

this manual be read prior to installation or operation of a unit.

Safety information that appears in this manual is identified by

the following signal word panels:

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE

NOTICE is used to address practices not related to personal

injury.

2

Form No. IRNGM-1016

English

WARNING

CAUTION

WARNING

IMPORTANT SAFETY INFORMATION

Read the following important safety information before using this equipment to avoid serious

injury or death and to avoid damage to equipment or property.

ELECTRIC SHOCK HAZARD:

• Plug unit into a properly grounded electrical receptacle

of the correct voltage, size, and plug configuration. If

plug and receptacle do not match, contact a qualified

electrician to determine and install proper voltage and

size electrical receptacle.

• Remote mounted control panel must be mounted on a

vertical wall and installed in vertical position. Mounting

control panel in horizontal position may result in

collection of liquids and lead to an electric shock.

• Turn OFF power switch, unplug power cord, and

allow unit to cool before performing any cleaning,

adjustments, or maintenance.

• DO NOT submerge or saturate with water. Do not allow

liquids to spill into unit. Unit is not waterproof. Do not

operate if unit has been submerged or saturated with

water.

• Unit is not weatherproof. Locate unit indoors where

ambient air temperature is a minimum of 70°F (21°C)

and a maximum of 124°F (51°C).

• Do not steam clean or use excessive water on the unit.

• This unit is not “jet-proof” construction. Do not use

jet-clean spray to clean this unit.

• Do not clean unit when it is energized or hot.

• Do not pull unit by power cord.

• Discontinue use if power cord is frayed or worn.

• Do not attempt to repair or replace a damaged power

cord. Cord must be replaced by an Authorized Hatco

Service Agent or a person with similar qualifications.

• This unit must be serviced by qualified personnel only.

Service by unqualified personnel may lead to electric

shock or burn.

• Use only Genuine Hatco Replacement Parts when

service is required. Failure to use Genuine Hatco

Replacement Parts will void all warranties and may

subject operators of the equipment to hazardous

electrical voltage, resulting in electrical shock or burn.

Genuine Hatco Replacement Parts are specified to

operate safely in the environments in which they are

used. Some after-market or generic replacement parts

do not have the characteristics that will allow them to

operate safely in Hatco equipment.

EXPLOSION HAZARD: Do not heat unopened containers

of food on unit. Sealed, heated containers may burst open.

ELECTROMAGNETIC INTERFERENCE HAZARD: This

unit generates close-range electromagnetic fields. It has

been designed to meet the applicable standards for noninterference with other electronic devices. Make sure other

electronic devices in the vicinity, including pacemakers

and other active implants, have been designed to meet

their corresponding applicable standards. As a precaution,

donot operate unitorcomewithin 12ʺ(305mm)of unit

with a pacemaker or other active implant.

This unit is not intended for use by children or persons

with reduced physical, sensory, or mental capabilities.

Ensure proper supervision of children and keep them

away from unit.

Form No. IRNGM-1016

FIRE HAZARD:

• Make sure to follow the installation information listed

below for specific induction ranges. If safe distances are

not maintained, discoloration or combustion could occur.

a. Locate countertop unit a minimum of 2″ (51 mm)

from combustible walls and materials.

b. Locatebuilt-inunitwitha minimum of 2″(51mm)

between front, sides, and bottom of unit and any

interior surface.

c. Locatebuilt-in unitwithaminimumof6″(152mm)

between back of unit and any interior surface.

• Do not obstruct air ventilation openings on sides and

bottom of unit. Unit combustion or malfunction may occur.

• Do not place unit near or underneath curtains or other

combustible materials. Items near or above unit could

catch fire causing injury and/or damage to unit.

Make sure all operators have been instructed on the safe

and proper use of the unit.

This unit has no “user-serviceable” parts. If service

is required on this unit, contact an Authorized Hatco

Service Agent or contact the Hatco Service Department at

800-558-0607 or 414-671-6350.

BURN HAZARD:

• Do not leave metal objects or utensils on or near

induction range. They may become hot.

• Use caution when wearing rings, watches, or other

ferrous objects around induction range. They may

become hot.

• Some exterior surfaces on unit will get hot. Use caution

when touching these areas.

Do not block or restrict air flow to air intake or exhaust

openings on bottom of unit.

Do not store anything on top of unit.

Locate unit at proper counter height in an area that is

convenient for use. Location should be level to prevent

unit or its contents from falling accidentally and strong

enough to support weight of unit and contents.

NOTICE

Plug unit into a dedicated circuit. Do not use multiple

appliances on same circuit.

Never use aluminum foil on induction range. Aluminum foil

will melt and damage unit.

Do not place objects with magnetic properties (credit cards,

cassette tapes, etc...) on or near unit during operation.

Use only wipes, pads, and cleaners designed specifically

for cleaning ceramic glass surfaces.

Use non-abrasive cleaners and cloths only. Abrasive

cleaners and cloths could scratch finish of unit, marring its

appearance and making it susceptible to soil accumulation.

This unit is intended for commercial use only—NOT for

household use.

3

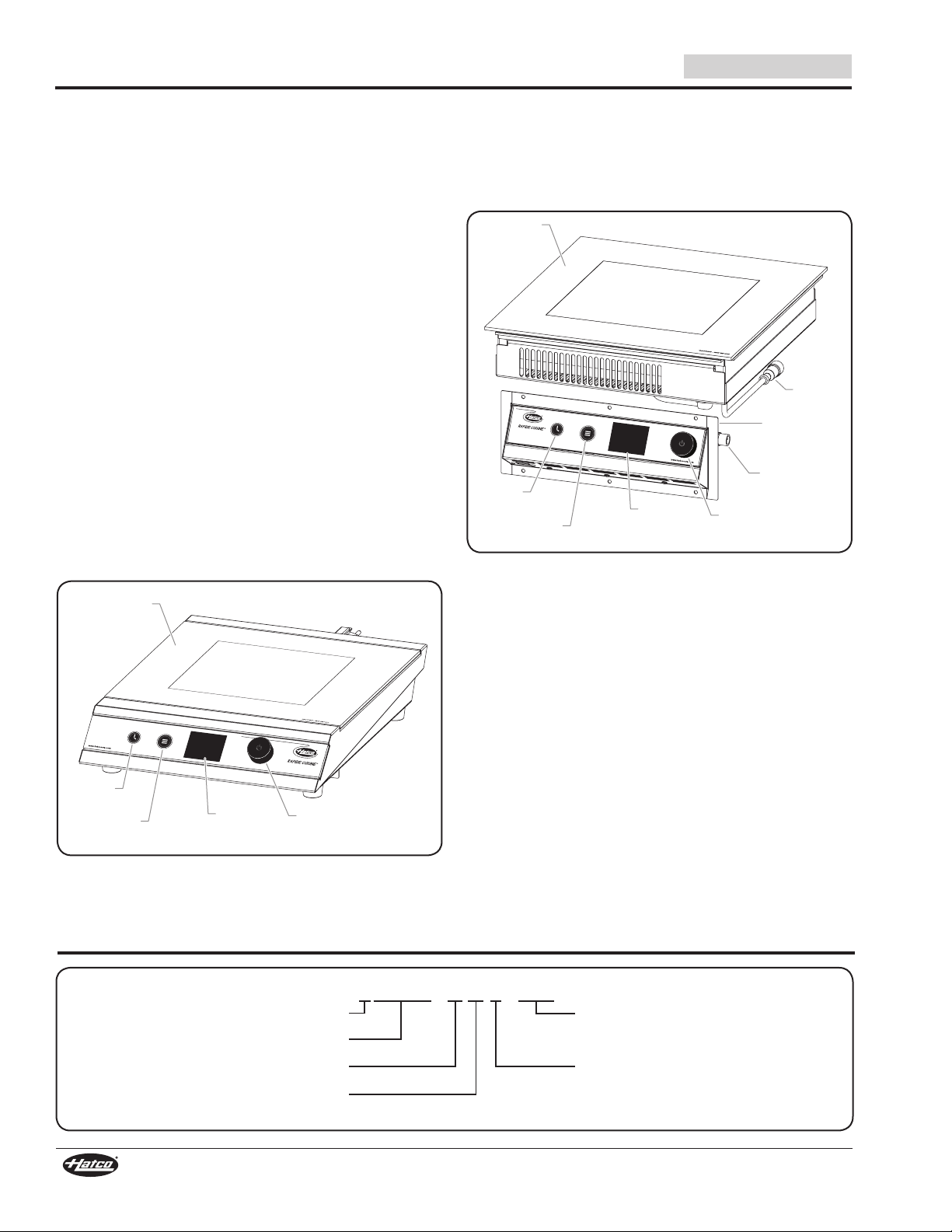

MODEL DESCRIPTION

Ceramic

Glass

Cooking

Surface

Timer

Button

Function

Button

Power/Control

Knob

Control

Display

Ceramic

Glass

Cooking

Surface

Timer

Button

Function

Button

Power/Control

Knob

Remote

Control

Panel

Control

Cable

Control

Cable

Control

Display

I R N G - P X 1 - X X

Induction

Unit Wattage

14 = 1440 W

18 = 1800 W

Single Coil

Programmable

Range

C = Countertop

B = Built-In

English

All Models

Hatco P Type Induction Ranges are equipped with a single

induction coil underneath a ceramic glass cooking surface.

Each model features a glass touch control panel with a

Function Button, a Timer Button, a Control Knob, and a Control

Display. All P Type Induction Ranges include an attached

71″ (1800 mm) power cord with plug.

NOTE: Refer to “Pan Specifications” in the OPERATION section

of this manual for details on “induction-ready” pans,

pans not suitable for induction cooking, and pan sizes.

Hatco P Type Induction Ranges have several safeguards built

into each unit that ensure protection to the unit as well as the

operators.

• A cross-flow fan ventilation system ensures that the

electronic circuits in the unit do no overheat. Temperature

probes monitor the electronic circuits and will signal the

unit to shut down if the circuits get too hot.

• A temperature probe in the cooking zone monitors the zone

temperature. This probe detects overheating in the cooking

zone due to an empty pan.

• Electronic circuitry in the cooking zone detects when a

small, ferrous object (such as a fork, spoon, or ring) is

placed on the unit, and the unit will not operate.

Countertop Models

Countertop P Type Induction Ranges models are portable,

countertop induction ranges.

Built-In Models

Built-In P Type Induction Ranges are designed to be installed

into a variety of solid material countertops. The unit includes a

remote control panel that connects to the induction range with

detachable control cables that combine for a total length of 71″

(1800 mm).

P Type Built-In Model

P Type Countertop Model

MODEL DESIGNATION

NOTE: For the latest firmware updates, cooking tips, and

more, go to the Hatco Induction Range website:

www.hatcocorp.com/rapide_cuisine

4

Form No. IRNGM-1016

English

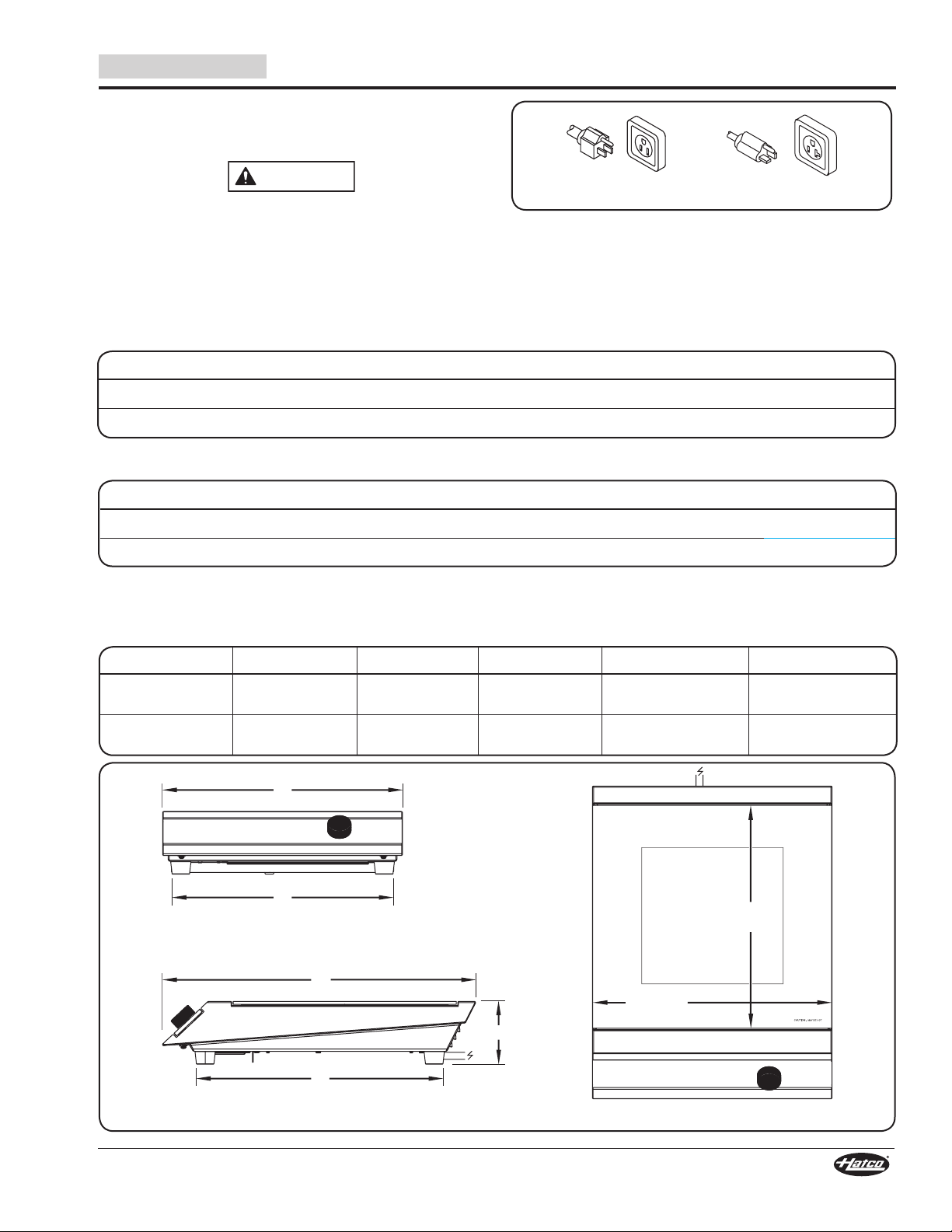

NEMA 5-15P

NEMA 5-20P

A

C

12"

(307 mm)

13"

(330 mm)

B

E

D

Front View

Side View

Top View

Plug Configurations

Units are supplied from the factory with an electrical cord and

plug installed. Plugs are supplied according to the application.

WARNING

SPECIFICATIONS

ELECTRIC SHOCK HAZARD: Plug unit into a properly

grounded electrical receptacle of the correct voltage,

size, and plug configuration. If plug and receptacle do not

match, contact a qualified electrician to determine and

install proper voltage and size electrical receptacle.

NOTE: Receptacle not supplied by Hatco. All units must be

connected to a dedicated circuit.

NOTE: The specification label is located on the bottom of the

unit. See label for serial number and verification of unit

electrical information.

Plug Configurations

Electrical Rating Chart — Countertop Models

Model Voltage Watts Amps Plug Configuration Shipping Weight

IRNG-PC1-14 120 1440 12 NEMA 5-15P 17 lbs. (8 kg)

IRNG-PC1-18 120 1800 15 NEMA 5-15P* 17 lbs. (8 kg)

Electrical Rating Chart — Built-In Models

Model Voltage Watts Amps Plug Configuration Shipping Weight

IRNG-PB1-14 120 1440 12 NEMA 5-15P 18 lbs. (8 kg)

IRNG-PB1-18 120 1800 15 NEMA 5-15P* 18 lbs. (8 kg)

* NEMA 5-20P for Canada.

NOTE: Shipping weight includes packaging.

Dimensions — Countertop Models

Model Width (A) Depth (B) Height (C) Footprint Width (D) Footprint Depth (E)

IRNG-PC1-14 13ʺ

(330 mm)

IRNG-PC1-18 13ʺ

(330 mm)

17ʺ

(431 mm)

17ʺ

(431 mm)

3-7/16ʺ

(86 mm)

3-7/16ʺ

(86 mm)

12ʺ

(304 mm)

12ʺ

(304 mm)

13-3/8ʺ

(339 mm)

13-3/8ʺ

(339 mm)

Form No. IRNGM-1016

5

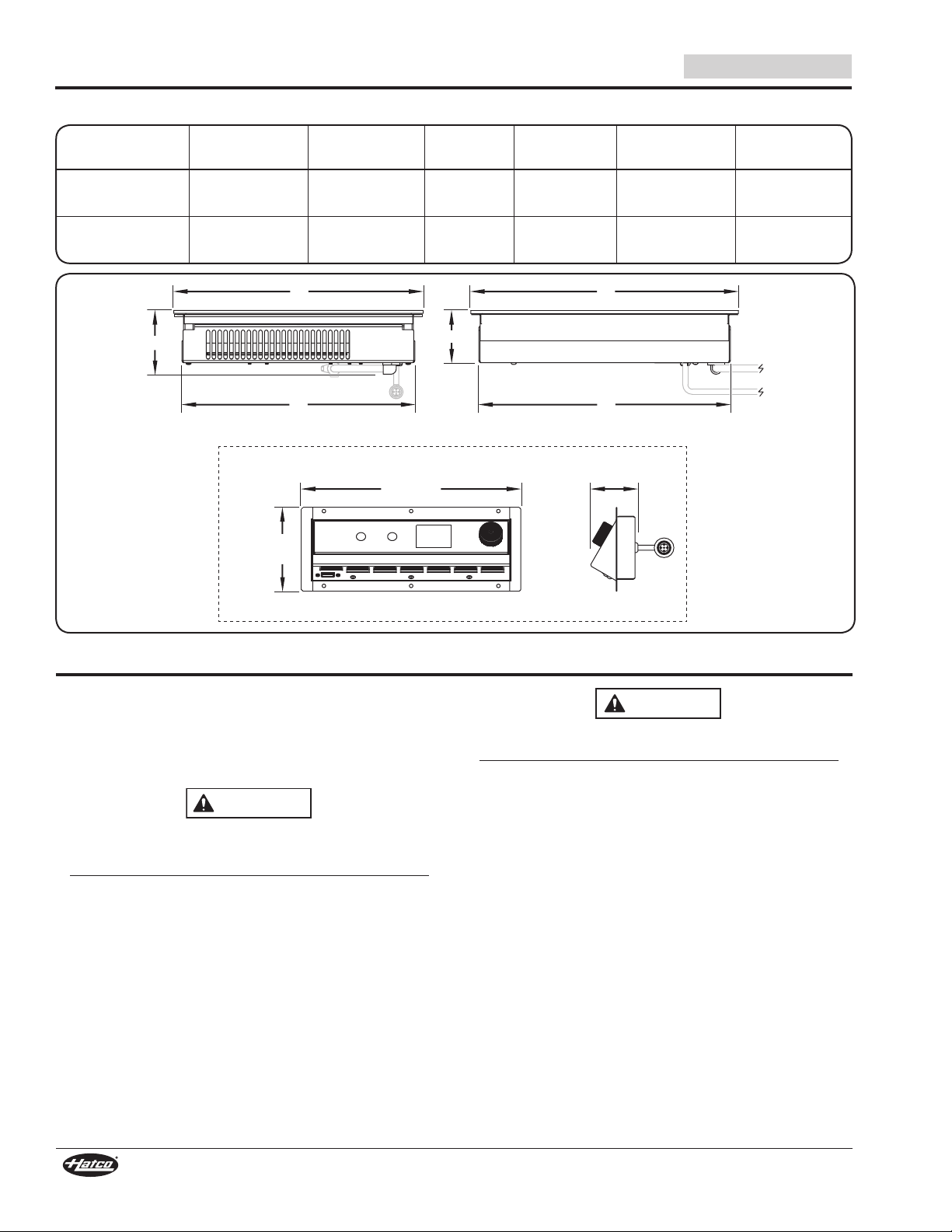

SPECIFICATIONS

A B

C

11-15/16"

(302 mm)

2-7/16"

(62 mm)

4-9/16"

(115 mm)

D

E F

Front View

Remote Control Panel

SideView

WARNING

CAUTION

Dimensions — Built-In Models

English

Cooking Surface

Model

IRNG-PB1-14 13-1/2ʺ

IRNG-PB1-18 13-1/2ʺ

Width (A)

(343 mm)

(343 mm)

Cooking Surface

Depth (B) Height (C)

14-1/2ʺ

(368 mm)

14-1/2ʺ

(368 mm)

3ʺ

(88 mm)

3ʺ

(88 mm)

Unit

Height (D)

2-7/8ʺ

(72 mm)

2-7/8ʺ

(72 mm)

Under-Counter

Width (E)

12-5/8ʺ

(320 mm)

12-5/8ʺ

(320 mm)

Under-Counter

Depth (F)

13-5/8ʺ

(346 mm)

13-5/8ʺ

(346 mm)

INSTALLATION

General

Induction Ranges are shipped completely assembled and

ready for use. Built-in units require installation into a countertop

(see procedures in this section). Care should be taken when

unpacking the shipping carton to avoid damage to the unit and

components enclosed.

ELECTRIC SHOCK HAZARD: Unit is not weatherproof.

Locate unit indoors where ambient air temperature is a

minimum of 70°F (21°C) and a maximum of 124°F (51°C).

FIRE HAZARD:

• Make sure to follow the installation information listed

below for specific induction ranges. If safe distances are

not maintained, discoloration or combustion could occur.

a. Locate countertop unit a minimum of 2″ (51 mm)

from combustible walls and materials.

b. Locatebuilt-inunitwithaminimumof2″(51mm)

between front, sides, and bottom of unit and any

interior surface.

c. Locatebuilt-inunit withaminimumof 6″(152mm)

between back of unit and any interior surface.

• Do not obstruct air ventilation openings on sides and

bottom of unit. Unit combustion or malfunction may occur.

• Do not place unit near or underneath curtains or other

combustible materials. Items near or above unit could

catch fire causing injury and/or damage to unit.

Do not block or restrict air flow to air intake or exhaust

openings on bottom of unit.

Locate unit at proper counter height in an area that is

convenient for use. Location should be level to prevent unit

or its contents from falling accidentally and strong enough

to support weight of unit and contents.

1. Remove the unit from the carton.

2. Remove tape and protective packaging from all surfaces of

the unit.

NOTE: To prevent delay in obtaining warranty coverage,

complete online warranty registration. See

IMPORTANT OWNER INFORMATION for details.

3. If the unit is a countertop model, place the unit in the

desired location. Make sure the location:

• is level and at the proper counter height.

• is strong enough to support the unit and its contents.

• provides a minimum of 2″ (51 mm) clearance from

• is large enough for all four feet of the unit to be positioned

4. If the unit is a built-in model, refer to the “Installing Built-In

6

combustible materials.

securely on the countertop.

Models” procedure in this section.

Form No. IRNGM-1016

English

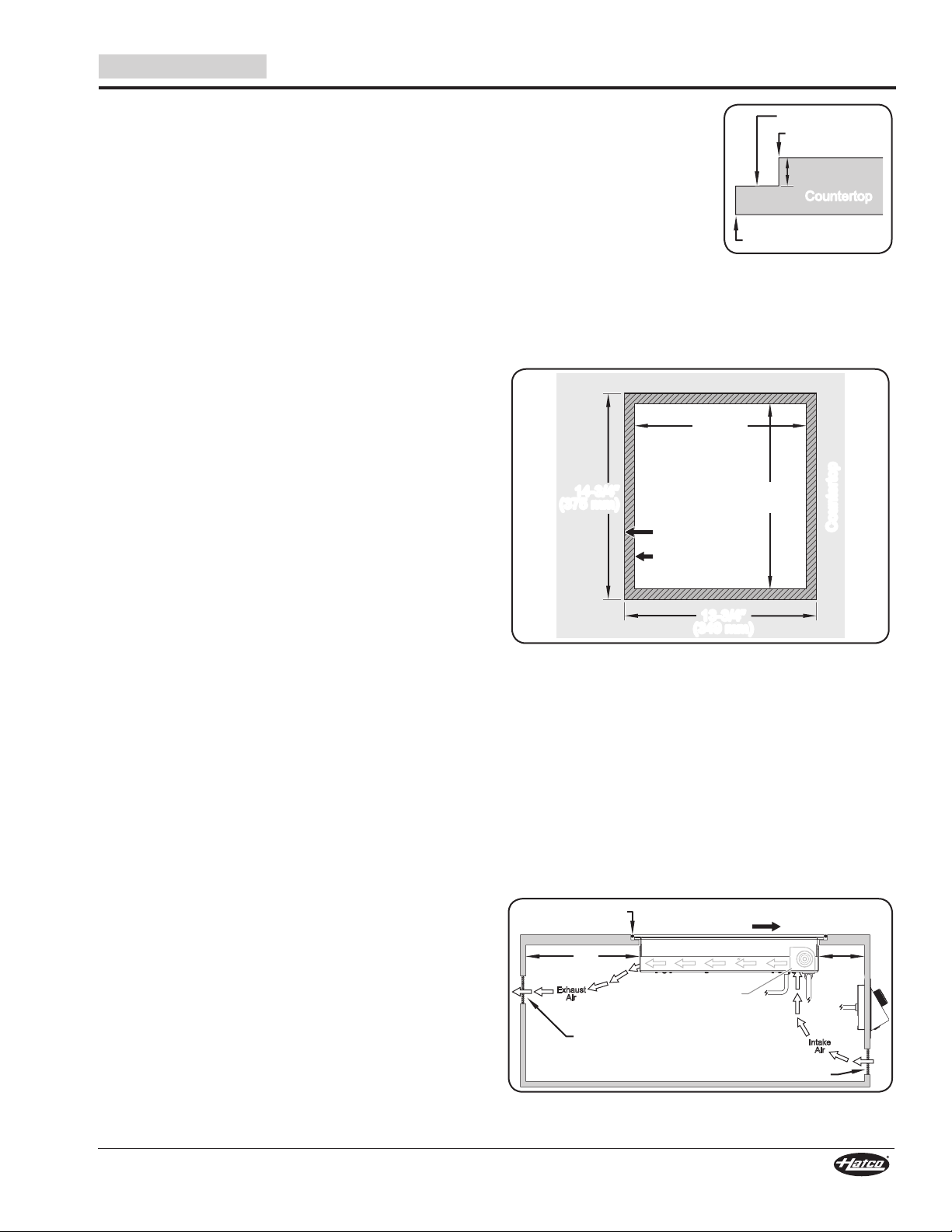

Outer Cutout

Step

Inner Cutout

Countertop

3/8" (9.5 mm)

13-3/4″

(349 mm)

14-3/4″

(375 mm)

13-7/8″

(352 mm)

12-7/8″

(327 mm)

Countertop

Inner Cutout

Outer Cutout

Ventilation Opening

Ventilation Opening

(Min. 20 in² [129 cm²])

Front of Unit

Silicone

6"

(152 mm)

Cooling Fan

(inside)

2"

(51 mm)

INSTALLATION

Installing Built-In Models

Built-In models require installation into a countertop before

operation. Two types of built-in installation are available, flush

mount and trim ring. Use the following information and the

appropriate procedure to install a built-in unit.

Preparing the Installation Site

Both types of built-in installation require the same general

cabinet specifications. The unit is designed to allow easy

removal of the electronic components from the underside of

the unit without having to remove the installed ceramic glass

top. Make sure that the installation location allows access to the

underside of the unit for maintenance and cleaning after it has

been placed into the countertop. Other specifications include:

• Make sure a grounded electrical receptacle of the correct

voltage, size, and plug configuration is within reach of the

unit’s 71″ (1800 mm) power cord inside the cabinet. See

the SPECIFICATIONS section for details.

• Make sure a vertical surface for control panel installation

is available in the cabinet within reach of the 71″

(1800 mm) control cable that connects the induction range

to the control panel.

• Make sure a minimum clearance of 2″ (51 mm) will be

available between the front, sides, and bottom of the unit

and any interior surface.

• Make sure a minimum clearance of 6″ (152 mm) will be

available between the back of the unit and any interior

surface.

• For installations where the cabinet has a shelf under the

unit, the shelf can extend only two-thirds of the distance

from the back of the cabinet to the front of the cabinet and

must be a minimum of 12″ (305 mm) below the bottom of

the unit.

• For installations where the cabinet has a partition under

the unit, the partition must have a ventilation opening

with a minimum size of 2″ x 10″/20 square inches

(5 x 25 cm/129 square cm) under the cooling fan on the

front of the unit. The partition must be a minimum of 6ʺ

(152 mm) below the bottom of the unit. Additionally, ventilation

openings with a minimum size of 2″ x 10″/20 square inches

(5 x 25 cm/129 square cm) must be installed in the front

and rear vertical sides of the cabinet. Louvered or grillstyle panels should be installed in the openings.

• For installations where the cabinet is against a wall and

no rear ventilation is possible, install a ventilation opening

in the front panel of the cabinet with a minimum size of

2″ x 10″/20 square inches (5 x 25 cm/129 square cm). Do

not install a shelf or partition underneath the unit.

a. Refer to the Flush Mount

Countertop Cutouts

illustration below for the

dimensions of each cutout.

• Two cutouts are

required; a partial

depth outer cutout, and

an inner cutout—the

material between the

cutouts is removed. This creates a step for the flange

of the Induction Range to sit on below the level of the

countertop.

b. Create the outer cutout down to a depth of 3/8"

(9.5 mm), followed by the inner cutout. Then, remove

the material in between the cutouts to create the step.

Flush Mount Countertop Cutouts

2. Cut and drill the appropriate holes in the vertical surface

where the control enclosure will be installed. Refer to

the “Installing the Control Panel” procedure for cutout

dimensions.

3. Cut the required openings in the cabinetry to provide

proper ventilation to the induction range. A ventilation

opening with a minimum size of 2″ x 10″/20 square inches

(5 x 25 cm/129 square cm) is required behind

the air exhaust openings on the back of the unit,

starting no more than 2″ (51 mm) down from the

top of the unit. An additional 2″ x 10″/20 square inch

(5 x 25 cm/129 square cm) ventilation opening is required in

the front of the cabinet to provide cool intake air. Louvered

or grill-style panels should be installed in the openings.

Flush Mount Installation

Flush mount installation requires a prepared, solid material

countertop and provides a seamless transition between the

countertop and the induction range. A special, “stepped” cutout

is required for flush mount installation.

1. Carefully measure and cut the step-style opening in the

countertop. The thickness of the solid material countertop

material should be a minimum of 13/16” (22 mm).

Form No. IRNGM-1016

Standard Flush Mount Installation

continued...

7

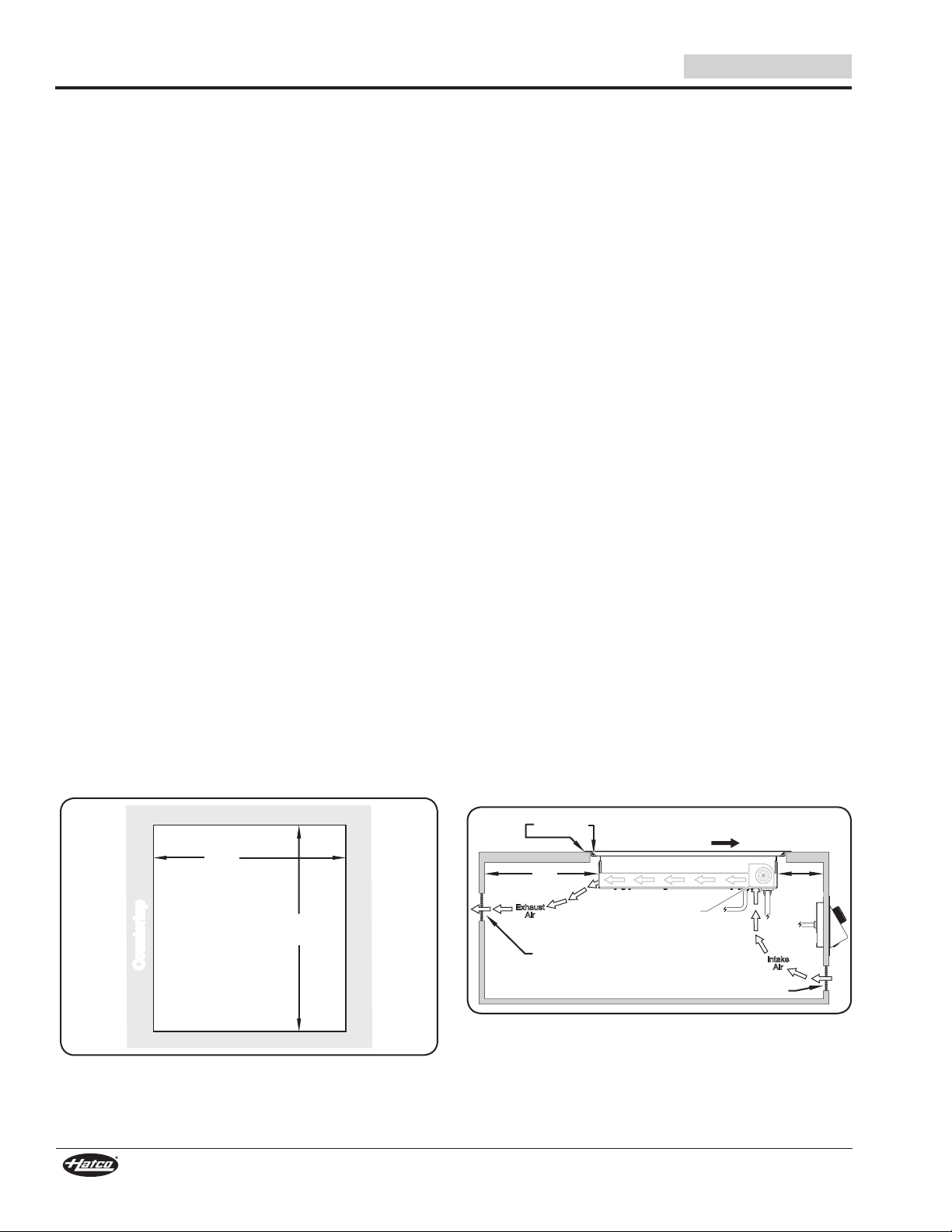

15″

(381 mm)

14″

(356 mm)

Countertop

Front of Unit

6"

(152 mm)

Cooling Fan

(inside)

2"

(51 mm)

Silicone

Ventilation Opening

(Min. 20 in² [129 cm²])

Ventilation Opening

INSTALLATION

English

NOTE: Make sure the interior temperature of the cabinet does

not rise above 124°F (51°C) while the induction range

is operating. If the temperature rises too high, additional

ventilation openings will be required.

4. If necessary, make structural modifications or add bracing

underneath the countertop to ensure the countertop will

support the weight of the unit and its contents.

NOTE: The countertop must be level to ensure proper operation

of the Induction Range.

5. Carefully lower the unit into the opening, making sure the

power cord and control cable do not get pinched.

6. Apply a bead of National Sanitation Foundation (NSF)approved silicone sealant in the gap between the

countertop and the induction range. To apply a clean,

consistent sealant bead:

a. Make sure the unit is centered in the countertop cutout.

b. Install masking tape on each side of the gap to define the

edge of the sealant.

c. Carefully apply sealant into the gap.

d. Quickly smooth the sealant surface.

e. Carefully remove the masking tape before the sealant

dries.

NOTE: The silicone sealant must be rated for use at

temperatures up to 250°F (121°C)

7. Install the control panel in the desired location. Refer to the

“Installing the Control Panel” procedure.

8. Plug the unit into a properly grounded electrical receptacle

of the correct voltage, size, and plug configuration. See the

SPECIFICATIONS section for details.

• A Welcome Screen will appear on the Control Display for

a few seconds, then the display will go blank.

Trim Ring Installation

Trim ring installation requires the purchase of the accessory trim

ring (TRIM-PB1-18) and can be performed in a solid material or

stainless stell countertop. Use the following procedure for trim

ring installation.

1. Carefully measure and cut the opening in the countertop.

3. Cut the required openings in the cabinetry to provide

proper ventilation to the induction range. A ventilation

opening with a minimum size of 2″ x 10″/20 square inches

(5 x 25 cm/129 square cm) is required behind

the air exhaust openings on the back of the unit,

starting no more than 2″ (51 mm) down from the

top of the unit. An additional 2″ x 10″/20 square inch

(5 x 25 cm/129 square cm) ventilation opening is required in

the front of the cabinet to provide cool intake air. Louvered

or grill-style panels should be installed in the openings.

NOTE: Make sure the interior temperature of the cabinet does

not rise above 124°F (51°C) while the induction range

is operating. If the temperature rises too high, additional

ventilation openings will be required.

4. If necessary, make structural modifications or add bracing

underneath the countertop to ensure the countertop will

support the weight of the unit and its contents.

NOTE: The countertop must be level to ensure proper operation

of the Induction Range.

5. Apply a bead of NSF-approved silicone sealant onto the

countertop material around the cutout opening.

6. Install the trim ring into the countertop opening.

7. Carefully lower the unit into the trim ring, making sure the

power cord and control cable do not get pinched.

8. Apply a bead of NSF-approved silicone sealant in the gap

between the trim ring and the induction range.

a. Make sure the unit is centered in the trim ring.

b. Install masking tape on each side of the gap to define the

edge of the sealant.

c. Carefully apply sealant into the gap.

d. Quickly smooth the sealant surface.

e. Carefully remove the masking tape before the sealant

dries.

9. Install the control panel in the desired location. Refer to the

“Installing the Control Panel” procedure.

10. Plug the unit into a properly grounded electrical receptacle

of the correct voltage, size, and plug configuration. See the

SPECIFICATIONS section for details.

• A Welcome Screen will appear on the Control Display for

a few seconds, then the display will go blank.

2. Cut and drill the appropriate holes in the vertical surface

where the control enclosure will be installed. Refer to

the “Installing the Control Panel” procedure for cutout

dimensions.

Trim Ring Installation Countertop Cutout

Standard Trim Ring Installation

8

Form No. IRNGM-1016

English

WARNING

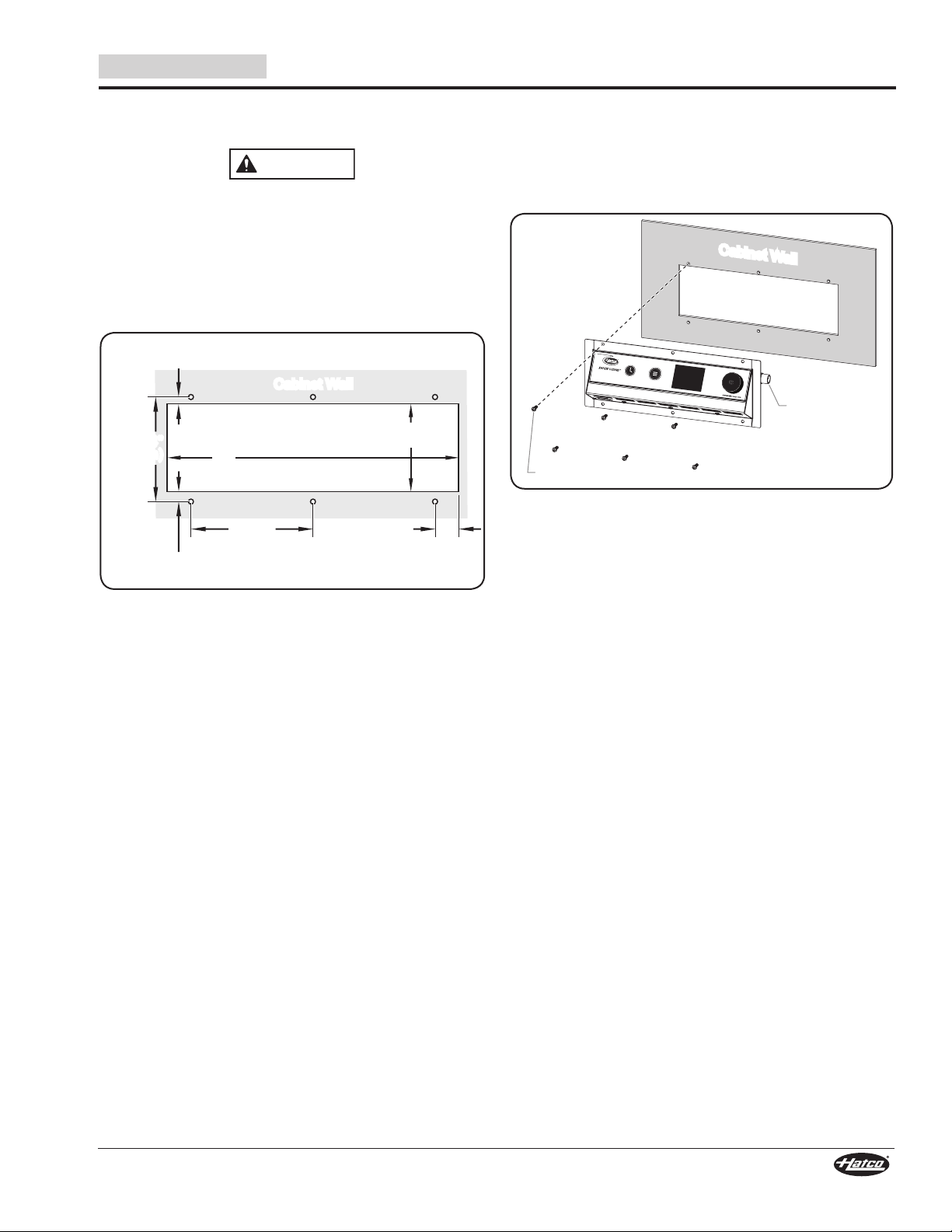

3-1/2″

(89 mm)

11″

(279 mm)

Cabinet Wall

4-3/4"

(120 mm)

3/4"

(20 mm)

4"

(103 mm)

9/32"

(7 mm)

13/32"

(9 mm)

Mounting Screw

Control Cable

(male)

Cabinet Wall

INSTALLATION

Installing the Control Panel

Use the following procedure to install the control panel.

Remote mounted control panel must be mounted on a

vertical wall and installed in vertical position. Mounting

control panel in horizontal position may result in collection

of liquids and lead to an electric shock.

1. Carefully measure and cut the opening in the cabinet wall

for the control panel.

2. Drill the appropriate holes around the cutout for the control

panel mounting screws (not supplied).

3. Position the control panel into the cutout opening through

the front of the cabinet.

4. Fasten the control panel to the vertical surface using six

mounting screws (not supplied).

5. Connect the male control cable on the control panel to the

female control cable on the induction range.

Installing the Control Panel

Control Panel Cutout and Screw Hole Dimensions

Form No. IRNGM-1016

9

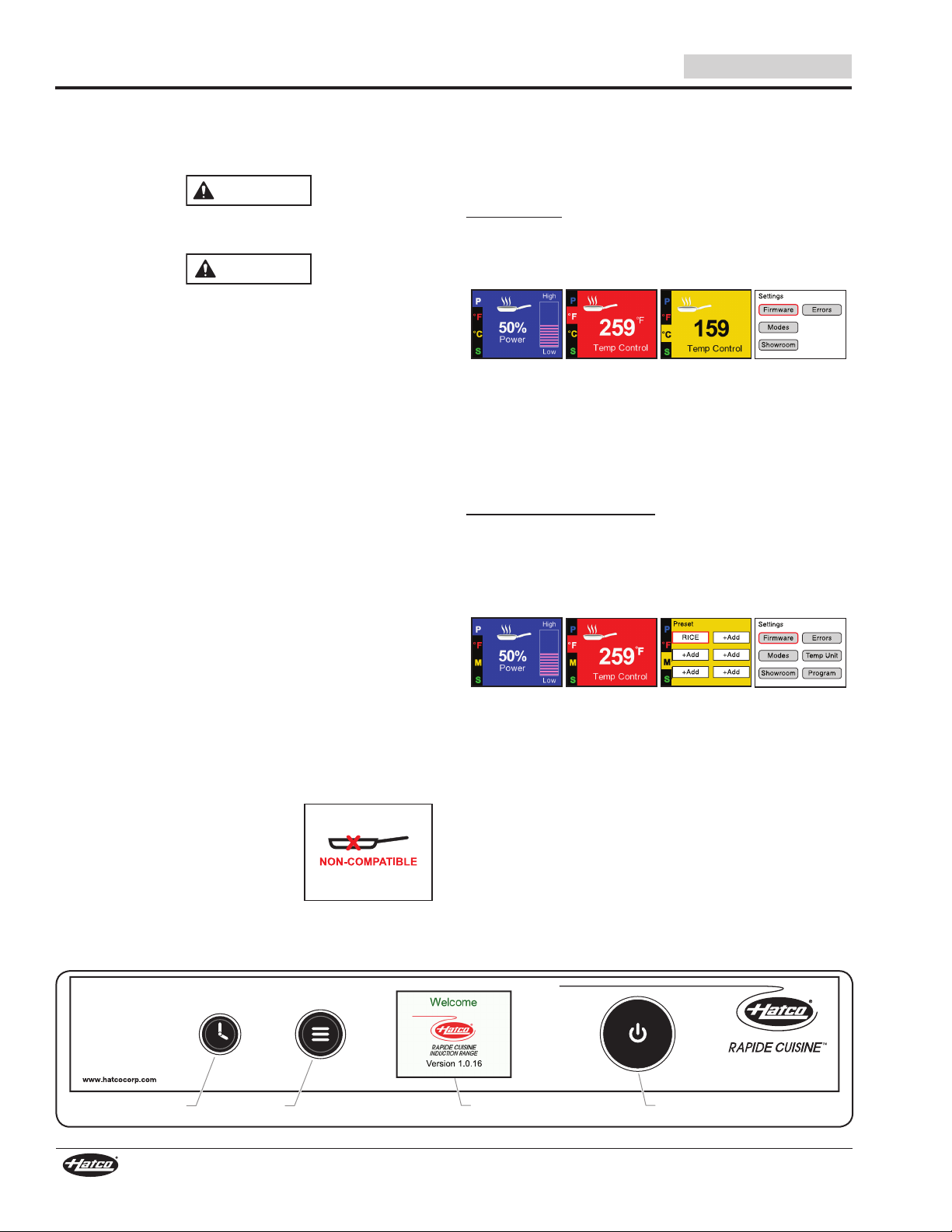

OPERATION

CAUTION

Timer

Button

Control Display

(showing Welcome Screen)

Control

Knob

Function

Button

English

General

Use the following information and procedures to operate both

countertop and built-in P Type Induction Ranges. NOTICE: Do

not move a countertop unit during operation.

WARNING

Read all safety messages in the IMPORTANT SAFETY

INFORMATION section before operating this equipment.

BURN HAZARD:

• Do not leave metal objects or utensils on or near

induction range. They may become hot.

• Use caution when wearing rings, watches, or other

ferrous objects around induction range. They may

become hot.

• Some exterior surfaces on unit will get hot. Use caution

when touching these areas.

Pan Specifications

Pans used with an Induction Range must meet the following

specifications:

• Made of material with magnetic properties (ferrous

material)

- Enameled Steel Pans

- Cast Iron Pans

- Stainless Steel Pans

- Aluminum Pans w/ferrous base

• Proper size (measurements given are the pan bottom

diameter)

- Minimum = 4" (102 mm), Maximum = 13″ (330 mm)

• Flat bottom

The following pans cannot be used with an Induction Range:

• Glass Pans

• Aluminum Pans without a ferrous base

• Earthenware Pans

• Ceramic Pans

• Copper Pans

NOTE: The Induction Range

automatically detects if a pan

is induction-ready. If a pan

is placed on the unit during

operation that is not inductionready, a pan icon with the

message “Non-Compatible”

will appear on the Control Display, and the unit will not

operate.

Operation Modes

Two operation modes are available on the Induction Range:

Standard Mode and Advanced Programming Mode. Review

the information below to determine which operation mode is

appropriate. Refer to “Changing Operation Mode” in this section

to change the unit between modes.

Standard Mode

Standard Mode offers basic cooking with manual cooking

control methods and a timer. Four screens are available on the

Control Display in Standard Mode: Power Control, Fahrenheit

Temperature Control, Celsius Temperature Control, and Settings.

Power Control

Screen

°F Temperature

Control Screen

°C Temperature

Control Screen

Settings

Screen

The Settings screen in Standard Mode offers the following

options:

FIRMWARE = Used for uploading firmware updates

MODES = Used to change between operation modes

SHOWROOM = Used for training or sales display—no heat

ERRORS = Shows the last six error codes

Advanced Programming Mode

Advanced Programming Mode increases the versatility of

the Induction Range by allowing preset, two-stage cooking

programs (menu items) to be created. Four screens are

available on the Control Display in Advanced Programming

Mode: Power Control, Temperature Control (Fahrenheit or

Celsius), Menu, and Settings.

Power Control

Screen

Temperature

Control Screen

Menu

Screen

Settings

Screen

The Settings screen in Advanced Programming Mode includes

all of the options from Standard Mode as well as the following

additions:

TEMP UNIT = Used to change temperature unit of measure

PROGRAM = Used to create custom menu items

Refer to “Programming Menu Items” in this section to create

custom menu items.

Startup

1. Before turning on the unit each day, clean the glass cooking

surface using an appropriate cleaning wipe, damp paper

towel, or a damp cloth. CAUTION! Wipe up all spills and

splashes immediately. Make sure unit is dry before

using. Do not allow liquid to run into air inlet filter on

bottom of unit.

P Type Induction Range Control Panel

10

Form No. IRNGM-1016

Loading...

Loading...