Page 1

GLO-RAY

™

Heated Glass Merchandisers

GR3SDH & GR3SDS Series

Installation &

Operating Manual

I&W #07.05.146.00

This manual contains important safety information

concerning the maintenance, use and operation of this

product. Failure to follow the instructions contained in this

manual may result in serious injury. If you’re unable to

understand the contents of this manual, please bring it to

the attention of your supervisor. Do not operate this

equipment unless you have read and understood the

contents of this manual.

Este manual contiene importante información sobre

seguridad concerniente al mantenimiento, uso y

operación de este producto. Cualquier falla en el

seguimiento de las instrucciones contenidas en este

manual puede resultar en un serio daño. Si usted no

puede entender el contenido de este manual por

favor pregunte a su supervisor. No opere este

equipo al menos que haya leído y comprendido el

contenido de este manual.

Page 2

Form No. GR3SDM-0606

i

CONTENTS

INTRODUCTION

IMPORTANT OWNER INFORMATION

Record the model number, serial number

(identification decal located on the rear of the unit),

voltage and purchase date of your Glo-Ray

®

Heated

Glass Merchandiser in the spaces below. Please

have this information available when calling Hatco

for service assistance.

Model No. ________________________________

Serial No. ________________________________

Voltage __________________________________

Date of Purchase __________________________

Business 8:00 a.m. to 5:00 p.m.

Hours: Central Standard Time

(Summer Hours: June to September –

8:00 a.m. to 5:00 p.m. C.D.T.

Monday through Thursday

8:00 a.m. to 2:30 p.m. C.D.T. Friday)

Telephone: (800) 558-0607; (414) 671-6350

Fax: (800) 690-2966 (Parts & Service)

(414) 671-3976 (International)

Additional information can be found by visiting our

web site at www.hatcocorp.com

24-Hour 7-Day Parts & Service

Assistance available in the United

States and Canada by calling

(800) 558-0607.

The Hatco Glo-Ray Heated Glass Merchandising

Warmers, GR3SDH (Horizontal Shelf) and GR3SDS

(Slant Shelf) are perfect for holding hot wrapped or

boxed foods on a buffet line or customer serving

points. A thermostatically controlled, hardcoated

heated base and unique patented heated glass

shelf hold hot wrapped or boxed food products and

keep them at optimum serving temperatures while

maintaining product quality.

These warmers offer an additional heated shelf on

the top, ideal for use of short term holding of food for

which serving temperature is not critical. The GloRay Heated Glass Merchandising Warmers are

guaranteed against breakage and burnout for one

year. These units also feature fluorescent display

lights along with a cord and plug set.

This manual provides the installation, safety and

operating instructions for the Glo-Ray Heated Glass

Merchandising Warmers. We recommend all

installation, operating and safety instructions

appearing in this manual be read prior to installation

or operation of your Hatco Heated Glass

Merchandising Warmers. Safety instructions that

appear in this manual after a warning symbol

and the words WARNING or CAUTION printed

in bold face are very important. WARNING

means there is the possibility of serious personal

injury or death to yourself or others. CAUTION

means there is the possibility of minor or moderate

injury. CAUTION without the symbol signifies the

possibility of equipment or property damage only.

Hatco Glo-Ray Heated Glass Merchandising

Warmers are a product of extensive research and

field testing. The materials used were selected for

maximum durability, attractive appearance and

optimum performance. Every unit is thoroughly

inspected and tested prior to shipment.

Important Owner Information...............................i

Introduction ...........................................................i

Important Safety Information ..............................1

Model Descriptions..............................................3

All Models........................................................3

GR3SDH Models.............................................3

GR3SDS Models.............................................3

Specifications.......................................................3

Plug Configurations.........................................3

Electrical Rating Charts...................................4

Dimensions GR3SDH Models .........................5

Dimensions GR3SDS Models.........................6

Installation............................................................7

All Models........................................................7

Location...........................................................8

Operation..............................................................9

Maintenance .......................................................10

Cleaning........................................................10

Display Light Bulb Replacement...................10

Accessories ........................................................11

Hatco Limited Warranty.....................................13

Authorized Parts Distributors............Back Cover

Page 3

Form No. GR3SDM-0606

1

IMPORTANT SAFETY INFORMATION

IMPORTANT! Read the following important safety instructions to avoid personal injury

or death, and to avoid damage to the equipment or property.

Model GR3SDS-33D, 120 volt has two circuits

and each circuit has a separate power supply

cord. Circuit One is rated 120 volt, 10.6 amps

and 1270 watts. Circuit Two is rated 120 volt,

7.8 amps, and 935 watts. For safe and proper

operation each circuit/power cord must be

plugged into a separate branch circuit rated

120 volts and a minimum of 15 amps.

Be sure to reinstall the protective lens cover.

Breakage of a bulb not properly covered

could result in personal injury and/or food

contamination.

This product has no “user” serviceable parts.

To avoid damage to the unit or injury to

personnel, use only Authorized Hatco Service

Agents and Genuine Hatco Replacement

Parts when service is required.

If service is required on this unit, contact your

Authorized Hatco Service Agent, or contact

the Hatco Service Department at 800-5580607 or 414-671-6350; fax 800-690-2966 or

International fax 414-671-3976.

Genuine Hatco Replacement Parts are

specified to operate safely in the

environments in which they are used. Some

aftermarket or generic replacement parts do

not have the characteristics that will allow

them to operate safely in Hatco equipment. It

is essential to use Hatco Replacement Parts

when repairing Hatco equipment. Failure to

use Hatco Replacement Parts may subject

operators of the equipment to hazardous

electrical voltage, resulting in electrical shock

or burn.

WARNINGS

To avoid any injury, turn the power switch

OFF, unplug the unit from the power source

and allow to cool completely before

performing any cleaning or maintenance.

Plug unit into a properly grounded electrical

outlet of the correct voltage, size and plug

configuration. If the plug and receptacle do

not match, contact a qualified electrician to

determine the proper voltage and size and

install the proper electrical outlet.

To avoid any injury, do not allow liquids to

spill onto the heated glass shelf.

T o avoid any injury, do not clean heated glass

shelf when unit is energized or hot.

Unit is not waterproof. To avoid electrical

shock or personal injury DO NOT submerge

in water. Do not operate if it has been

submerged in water.

To avoid electrical shock or personal injury,

do not steam clean or use excessive water on

the unit.

For safe and proper operation, the unit must

be located a reasonable distance from

combustible walls and materials. If safe

distances are not maintained, discoloration or

combustion could occur.

T o prevent any injury or damage to the unit do

not pull unit by power cord.

To prevent any injury, discontinue use if

power cord is frayed or worn.

For safe and proper operation do not place

food product directly onto glass or hardcoat

surface. Food product must be wrapped or

boxed.

The fluorescent light fixtures used have

plastic safety shields covering the

fluorescent bulbs to meet N.S.F. standards.

To avoid personal injury and/or food

contamination always operate the unit with

the plastic safety shield properly installed.

GR3SDS-33D rated for 120 volt has two power

supply cords. To avoid electrical shock or

personal injury disconnect both power

supply cords before servicing or repair.

Page 4

Form No. GR3SDM-0606

2

IMPORTANT SAFETY INFORMATION

CAUTIONS

Some exterior surfaces on the unit will get

hot. Use caution when touching these areas

to avoid injury.

To avoid any injury or damage locate the unit

at the proper counter height, in an area that is

convenient for use. The location should be

level to prevent the unit or its contents from

accidentally falling, and strong enough to

support the weight of the unit and food

displayed.

The National Sanitation Foundation (NSF)

requires units over 36" (914 mm) in length or

weighing more than 80 lbs. (36 kg) to be either

sealed or raised on the installation surface. If

this unit cannot be sealed at the point of use,

2-1/2" (64 mm) legs are included to allow for

proper cleaning access below unit.

Unit is not weatherproof. For safe and proper

operation locate the unit indoors where the

ambient air temperature is constant and is a

minimum of 70°F (21°C).

To avoid any injury, do not come in contact

with the heated glass shelf while unit is in

operation.

For safe and proper operation, the top side of

the upper most shelf is intended for short

term holding of food for which serving

temperature is not critical.

To allow for proper cleaning and operation

the lower vented side covers must be

removed before installing legs.

CAUTIONS

Use only non-abrasive cleaners. Abrasive

cleaners could scratch the finish marring its

appearance and making it susceptible to dirt

accumulation.

Only soft cleaning cloths, mild soap and

water should be used to clean breath

protector(s). Breath protector(s) are made of

shatterproof polycarbonate and will scratch

or crack if proper care is not taken.

Do not allow the glass shelf to overheat.

Overheating may cause the food containers

to melt or soften.

Do not lay unit on the side with the control

panel or damage to unit could occur.

Do not use food pans, ceramic dishes, or

abrasive materials on heated glass shelves.

Food pans, ceramic dishes, and abrasive

materials may scratch the glass shelf marring

its appearance and making it susceptible to

dirt accumulation. It is recommended that

glass shelves be used for food products

contained in disposable paper or plastic

containers or wrapping.

IMPORTANT! Read the following important safety instructions to avoid personal injury

or death, and to avoid damage to the equipment or property.

Page 5

Form No. GR3SDM-0606

3

MODEL DESCRIPTION

SPECIFICATIONS

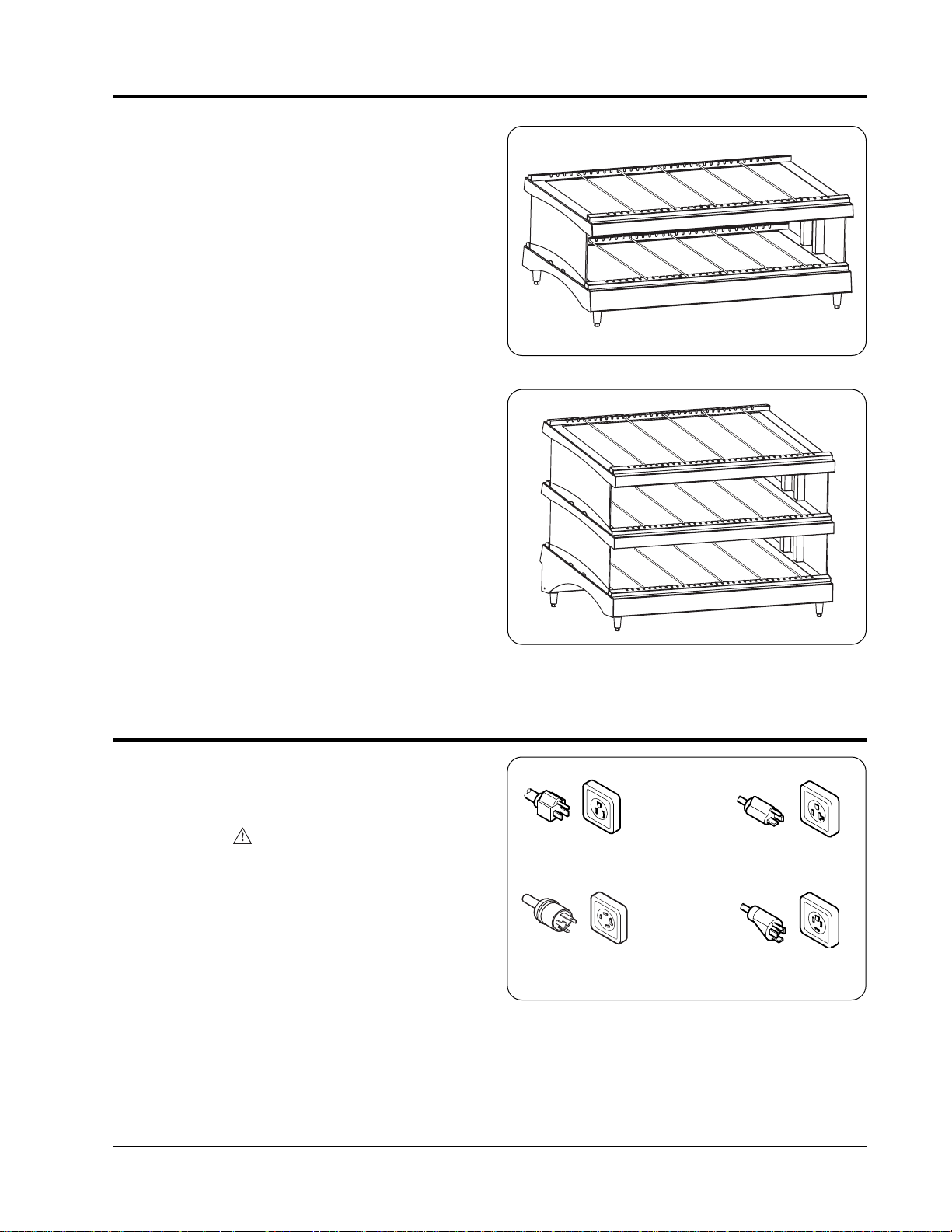

PLUG CONFIGURATIONS

Units are supplied from the factory with an electrical

cord and plug. (See Figure 3.)

WARNING

Plug unit into a properly grounded electrical

outlet of the correct voltage, size and plug

configuration. If the plug and receptacle do not

match, contact a qualified electrician to

determine the proper voltage and size and install

the proper electrical outlet.

NEMA 5-15P

Figure 3. Plug Configurations

NEMA 5-20P

NEMA 14-20P

(Optional)

NEMA L14-20P

ALL GR3SD MODELS

All GR3SD Models feature a thermostatically

controlled hardcoated heated base and glass dual

heat source which conducts heat upward to keep

the food on the glass shelf warm, and radiates heat

downward to blanket the product below. Units also

include tempered glass side panels, product divider

rods, fluorescent display lights, and a cord and

plug set.

GR3SDH MODELS

The GR3SDH Models are horizontal shelf warmers

designed to hold hot wrapped or boxed food

product.

These models are available in widths of 27-1/4,

33-1/4 and 39-1/4 inches (692, 845 and 997 mm)

and are available with a single or dual heated glass

shelf.

GR3SDS MODELS

The GR3SDS Models are slant shelf warmers

designed to hold hot wrapped or boxed food

product. The shelves are slanted for convenience of

self-serve.

These models are available in widths of 27-1/4,

33-1/4 and 39-1/4 inches (692, 845 and 997 mm)

and are available with a single or dual heated glass

shelf.

Figure 1. Glo-Ray Model GR3SDH - Single Shelf

Figure 2. Glo-Ray Model GR3SDS - Dual Shelf

Page 6

Form No. GR3SDM-0606

4

SPECIFICATIONS

Model Voltage Watts Amps Plug Configuration Shipping Weight

GR3SDS-27D 120 1790 14.9 NEMA 5-15P

†

128 lbs. (58 kg)

GR3SDS-33D 120

*

1270/935

*

10.6/7.8

*

NEMA 5-15P

*

140 lbs. (64 kg)

120/208 2210 10.3 NEMA L14-20P

•

140 lbs. (64 kg)

120/240 2210 10.3 NEMA L14-20P

•

140 lbs. (64 kg)

GR3SDS-39D 120/208 2660 12.4 NEMA L14-20P

•

158 lbs. (72 kg)

120/240 2660 12.4 NEMA L14-20P

•

158 lbs. (72 kg)

Model Voltage Watts Amps Plug Configuration Shipping Weight

GR3SDS-27 120 1010 8.4 NEMA 5-15P 72 lbs. (33 kg)

GR3SDS-33 120 1240 10.3 NEMA5-15P 80 lbs. (36 kg)

GR3SDS-39 120 1490 12.4 NEMA 5-15P

†

92 lbs. (42 kg)

Model Voltage Watts Amps Plug Configuration Shipping Weight

GR3SDH-27D 120 1790 14.9 NEMA5-15P

†

90 lbs. (41 kg)

GR3SDH-33D 120/208 2210 10.3 NEMA L14-20P

•

100 lbs. (45 kg)

120/240 2210 10.3 NEMA L14-20P

•

100 lbs. (45 kg)

GR3SDH-39D 120/208 2660 12.4 NEMA L14-20P

•

112 lbs. (51 kg)

120/240 2660 12.4 NEMA L14-20P

•

112 lbs. (51 kg)

Model Voltage Watts Amps Plug Configuration Shipping Weight

GR3SDH-27 120 1010 8.4 NEMA 5-15P 50 lbs. (23 kg)

GR3SDH-33 120 1240 10.3 NEMA 5-15P 58 lbs. (26 kg)

GR3SDH-39 120 1490 12.4 NEMA5-15P

†

66 lbs. (30 kg)

ELECTRICAL RATING CHART – GR3SDH MODELS - HORIZONTAL MODELS - SINGLE SHELF

ELECTRICAL RATING CHART – GR3SDH MODELS - HORIZONTAL MODELS - DUAL SHELF

†

NEMA 5-20P for Canada

†

NEMA 5-20P for Canada

ELECTRICAL RATING CHART – GR3SDS MODELS - SLANT MODELS - SINGLE SHELF

ELECTRICAL RATING CHART – GR3SDS MODELS - SLANT MODELS - DUAL SHELF

†

NEMA 5-20P for Canada

Unit is equipped with two cord and plug sets, requiring two separate 120 volt, 15 amp power circuits.

†

NEMA 5-20P for Canada

*

•

NEMA 14-20P is optional.

• NEMA 14-20P is optional.

Page 7

Form No. GR3SDM-0606

5

SPECIFICATIONS

DIMENSIONS - GR3SDH MODELS

Width Depth Height*

Model (A) (B) (C)

GR3SDH-27 27-1/4" 27-1/4" 16-1/8"

(692 mm) (692 mm) (410 mm)

GR3SDH-33 33-1/4" 27-1/4" 16-1/8"

(845 mm) (692 mm) (410 mm)

GR3SDH-39 39-1/4" 27-1/4" 16-1/8"

(997 mm) (692 mm) (410 mm)

GR3SDH MODELS SINGLE HORIZONTAL SHELF

* Height includes 2-1/2" (64 mm) legs attached.

Width Depth Height*

Model (A) (B) (C)

GR3SDH-27D 27-1/4" 27-1/4" 25-7/8"

(692 mm) (692 mm) (657 mm)

GR3SDH-33D 33-1/4" 27-1/4" 25-7/8"

(845 mm) (692 mm) (657 mm)

GR3SDH-39D 39-1/4" 27-1/4" 25-7/8"

(997 mm) (692 mm) (657 mm)

GR3SDH MODELS DUAL HORIZONTAL SHELF

* Height includes 2-1/2" (64 mm) legs attached.

A

B

A

C

B

C

NOTE: Usable Heated Shelf Space:

-27/-27D Models: 23-1/4" (591 mm) x 21-1/4" (540 mm)

-33/-33D Models: 29-1/4" (743 mm) x 21-1/4" (540 mm)

-39/-39D Models: 35-1/4" (895 mm) x 21-1/4" (540 mm)

Page 8

Form No. GR3SDM-0606

6

SPECIFICATIONS

DIMENSIONS - GR3SDS MODELS

Width Depth Height*

Model (A) (B) (C)

GR3SDS-27 27-1/4" 26-7/8" 20-1/2"

(692 mm) (683 mm) (521 mm)

GR3SDS-33 33-1/4" 26-7/8" 20-1/2"

(845 mm) (683 mm) (521 mm)

GR3SDS-39 39-1/4" 26-7/8" 20-1/2"

(997 mm) (683 mm) (521 mm)

GR3SDS MODELS SINGLE SLANTED SHELF

* Height includes 2-1/2" (64 mm) legs attached.

Width Depth Height*

Model (A) (B) (C)

GR3SDS-27D 27-1/4" 26-7/8" 30-1/2"

(692 mm) (683 mm) (775 mm)

GR3SDS-33D 33-1/4" 26-7/8" 30-1/2"

(845 mm) (683 mm) (775 mm)

GR3SDS-39D 39-1/4" 26-7/8" 30-1/2"

(997 mm) (683 mm) (775 mm)

GR3SDS MODELS DUAL SLANTED SHELF

* Height includes 2-1/2" (64 mm) legs attached.

A

B

C

C

A

B

NOTE: Usable Heated Shelf Space:

-27/-27D Models: 23-1/4" (591 mm) x 21-1/4" (540 mm)

-33/-33D Models: 29-1/4" (743 mm) x 21-1/4" (540 mm)

-39/-39D Models: 35-1/4" (895 mm) x 21-1/4" (540 mm)

Page 9

Form No. GR3SDM-0606

7

INSTALLATION

ALL MODELS

Glo-Ray®Heated Glass Merchandisers are shipped

with most components pre-assembled. Care should

be taken when unpacking shipping carton to avoid

damage to unit and components enclosed.

WARNING

To prevent any injury or damage to the unit do

not pull unit by power cord.

WARNING

To prevent any injury, discontinue use if power

cord is frayed or worn.

1. Remove unit from box.

2. Remove information packet. To prevent delay

in obtaining warranty coverage, fill out and

mail in the warranty card.

3. Remove tape and protective packaging from all

surfaces of unit.

CAUTION

The National Sanitation Foundation (NSF)

requires units over 36" (914 mm) in length or

weighing more than 80 lbs. (36 kg) to be either

sealed or raised on the installation surface. If

this unit cannot be sealed at the point of use,

2-1/2" (64 mm) legs are included to allow for

proper cleaning access below unit.

CAUTION

Do not lay unit on the side with the control panel

or damage to the unit could occur.

CAUTION

To allow for proper cleaning and operation the

lower vented side covers must be removed

before installing legs.

4. Before installing legs remove lower vented side

covers. (See Figure 4.)

5. Carefully lay unit on its side and install the four

legs. Return unit upright. (See Figure 5.)

6. Slide each side glass panel into the top channel,

then lower the panel into the bottom channel.

(See Figure 6.)

7. The unit is supplied with product divider rods. To

install them, place the rods in the channels

provided. (See Figure 7.) The rods can be readily

adjusted to separate your holding areas as

needed.

Figure 7. Installing Product Divider Rods

Figure 5. Leg Installation

Figure 4. Leg Installation

Figure 6. Side Glass Panel Installation

Lower Vented Side Cover

Model

GR3SDH Standard Number

or GR3SDS of Rods per Unit

-27 10 pc.

-33 12 Pc.

-39 14 pc.

-27D 15 pc.

-33D 18 pc.

-39D 21 pc.

Page 10

Form No. GR3SDM-0606

8

INSTALLATION

WARNING

For safe and proper operation, the unit must be

located a reasonable distance from combustible

walls and materials. If safe distances are not

maintained, discoloration or combustion could

occur.

CAUTION

To avoid any injury or damage locate the unit at

the proper counter height, in an area that is

convenient for use. The location should be level

to prevent the unit or its contents from

accidentally falling, and strong enough to

support the weight of the unit and food

displayed.

LOCATION

NOTE: Unit must be transported in the upright

position.

For proper operation and maximum performance,

locate the Heated Glass Merchandisers in an area

where the ambient air temperature is constant and

is a minimum of 70°F (21°C). Areas which are

susceptible to active air movements or currents

should be avoided, i.e., near exhaust fans or hoods

and air conditioning ducts.

WARNING

Plug unit into a properly grounded electrical

outlet of the correct voltage, size and plug

configuration. If the plug and receptacle do not

match, contact a qualified electrician to

determine the proper voltage and size and install

the proper electrical outlet.

WARNING

Model GR3SDS-33D, 120 volt has two circuits

and each circuit has a separate power supply

cord. Circuit One is rated 120 volt, 10.6 amps

and 1270 watts. Circuit Two is rated 120 volt, 7.8

amps, and 935 watts. For safe and proper

operation each circuit/power cord must be

plugged into a separate branch circuit rated 120

volts and a minimum of 15 amps.

CAUTION

Unit is not weatherproof. For safe and proper

operation locate the unit indoors

where the

ambient air temperature is constant and is

a minimum of 70°F (21°C).

Page 11

Form No. GR3SDM-0606

9

OPERATION

WARNING

To avoid any injury, do not allow liquids to spill

onto the heated glass shelf.

WARNING

Unit is not waterproof. To avoid electrical shock

or personal injury DO NOT submerge in water.

Do not operate if it has been submerged in

water.

WARNING

For safe and proper operation do not place food

product directly onto glass or hardcoat surface.

Food product must be wrapped or boxed.

CAUTION

Some exterior surfaces on the unit will get hot.

Use caution when touching these areas to avoid

injury.

CAUTION

To avoid any injury, do not come in contact with

the heated glass shelf while unit is in operation.

The Heated Glass Merchandising Warmers main

power is controlled by an ON/OFF rocker switch.

(See Figure 8.) The switch must be in the ON

position for the unit to function.

The hardcoat heated base can be set to any desired

heating level as indicated on the control plate. The

temperature range of the hardcoat heated base is

from the ambient room temperature to

200°F (93°C). (See Figure 8.)

The heated glass shelf or shelves are controlled by

switches that can be set to any desired heating level

as indicated on the control plate. (See Figure 8.)

The glass heated shelf is a dual heat source which

conducts heat upward to keep the food on the glass

Figure 8. Control Panel

shelf warm and radiates heat downward to blanket

the product below. The temperature range of the

glass shelves is from the ambient room temperature

to 200°F (93°C).

CAUTION

Do not allow the glass shelf to overheat.

Overheating may cause the food containers to

melt or soften.

The fluorescent display light(s) are controlled by an

ON/OFF rocker switch. (See Figure 8.) The unit can

be used for food warming with the light(s) on or off.

NOTE: To operate the unit for display only with no

heat, position the heat controls to the lowest or OFF

setting.

NOTE: Main power rocker switch must be in the ON

position for the heat or display light(s) to function.

CAUTION

For safe and proper operation, the top side of

the upper most shelf is intended for short term

holding of food for which serving temperature is

not critical.

CAUTION

Do not use food pans, ceramic dishes, or

abrasive materials on heated glass shelves.

Food pans, ceramic dishes, and abrasive

materials may scratch the glass shelf marring its

appearance and making it susceptible to dirt

accumulation. It is recommended that glass

shelves be used for food products contained in

disposable paper or plastic containers or

wrapping.

Lights ON/OFF Switch

Main ON/OFF Switch

Ground Fault Circuit Interrupt

(GFCI) Switch

Center Heat

Control Switch

Top Heat

Control Switch

Base Heat Control Switch

Page 12

Form No. GR3SDM-0606

10

MAINTENANCE

CLEANING

Hatco Glo-Ray®Heated Glass Merchandisers are

designed for maximum durability and performance,

with minimum maintenance.

WARNING

To avoid any injury, turn the power switch OFF,

unplug the unit from the power source and allow

to cool before performing any maintenance.

WARNING

GR3SDS-33D rated for 120 volt has two power

supply cords. To avoid electrical shock or

personal injury disconnect both power supply

cords before servicing or repair.

WARNING

To avoid any injury, do not allow liquids to spill

onto the heated glass shelf.

WARNING

To avoid electrical shock or personal injury, do

not steam clean or use excessive water on the

unit.

CAUTION

Use only non-abrasive cleaners. Abrasive

cleaners could scratch the finish marring its

appearance and making it susceptible to dirt

accumulation.

CAUTION

Only soft cleaning cloths, mild soap and water

should be used to clean breath protector(s).

Breath protector(s) are made of shatterproof

polycarbonate and will scratch or crack if proper

care is not taken.

WARNING

To avoid any injury, do not clean heated glass

shelf when unit is energized or hot.

To preserve the finish of the Glo-Ray Heated Glass

Merchandiser, it is recommended that the

hardcoated heated base shelf be wiped daily with

a clean, soft, damp cloth.

The glass side panels and heated glass shelves

should be cleaned daily with ordinary glass cleaner

and soft cloth or paper towel.

DISPLAY LIGHT BULB REPLACEMENT

The unit is equipped with 120 volt fluorescent light

tubes which illuminate the warming area. These

tubes have a special lens cover to guard against

injury and food contamination in the event of

breakage.

To replace a fluorescent light disconnect unit from

power supply and wait until the unit has cooled.

Remove the protective lens cover from the fixture

and carefully twist the fluorescent tube and pull to

remove it from the sockets.

WARNING

Be sure to reinstall the protective lens cover.

Breakage of a bulb not properly covered could

result in personal injury and/or food

contamination.

WARNING

The fluorescent light fixtures used have plastic

safety shields covering the fluorescent bulbs to

meet N.S.F. standards. To avoid personal injury

and/or food contamination always operate the

unit with the plastic safety shield properly

installed.

GROUND FAULT CIRCUIT INTERRUPT

The GR3SDH & GR3SDS Series warmers are

supplied with a built in Ground Fault Circuit Interrupt

(GFCI) which is designed to turn electrical power off

to the internal components when there is a short

circuit or electrical fault. (See Figure 8.)

To reset the “GFCI” push the red reset button in. If

the “GFCI” continues to trip, contact your local

Authorized Hatco Service Agency.

WARNING

If service is required on this unit, contact your

Authorized Hatco Service Agent, or contact the

Hatco Service Department at 800-558-0607 or

414-671-6350; fax 800-690-2966 or International

fax 414-671-3976.

WARNING

This product has no “user” serviceable parts. To

avoid damage to the unit or injury to personnel,

use only Authorized Hatco Service Agents and

Genuine Hatco Replacement Parts when service

is required.

WARNING

Genuine Hatco Replacement Parts are specified

to operate safely in the environments in which

they are used. Some aftermarket or generic

replacement parts do not have the

characteristics that will allow them to operate

safely in Hatco equipment. It is essential to use

Hatco Replacement Parts when repairing Hatco

equipment. Failure to use Hatco Replacement

Parts may subject operators of the equipment to

hazardous electrical voltage, resulting in

electrical shock or burn.

Page 13

Form No. GR3SDM-0606

11

ACCESSORIES

DISPLAY SIGN HOLDER

A display sign holder (sign not included) is available

for installation on top or intermediate shelf,

customer side. To install follow these steps and see

Figure 9.

1. Remove protective paper from acrylic surfaces.

2. Remove front divider.

3. Remove four acorn nuts from underside of shelf.

4. Remove channel divider brackets.

5. Place sign holder in position on shelf.

6. Reinstall channel divider brackets into same

holes and secure with acorn nuts.

7. Install acrylic sign guard and sign into holder.

8. Place sign holder cap over assembly.

9. Reinst all channel divider with slots facing inward.

CAUTION

Use only non-abrasive cleaners. Abrasive

cleaners could scratch the finish marring its

appearance and making it susceptible to dirt

accumulation.

BREATH PROTECTORS

Breath protector(s) are available from the factory for

the customer side. To install follow these steps and

see Figure 10.

1. Remove protective paper from acrylic surfaces.

2. Loosen 3 screws from underside of shelf. Slide

mounting bracket into position with studs facing

to the front and down. Tighten 3 screws.

3. Position the acrylic breath protector into the

channel on the warmer with the mounting holes

aligned.

4. Secure the breath protector using the acorn nuts

provided. Tighten until snug. Do not overtighten.

Figure 9. Display Sign Holder

Figure 10. Breath Protectors

CAUTION

Only soft cleaning cloths, mild soap and water

should be used to clean breath protector(s).

Breath protector(s) are made of shatterproof

polycarbonate and will scratch or crack if proper

care is not taken.

Page 14

Form No. GR3SDM-0606

12

ACCESSORIES

Figure 11. Flip-Up Doors

Figure 12. Flip-Up Doors with Bracket

FLIP-UP DOORS

Flip-up doors are available for installation on the

front or back side for units susceptible to active air

movements or air currents caused by exhaust fans,

hoods or air conditioning ducts.

1. Remove protective paper from acrylic surfaces.

2. Remove four screws (two on each side) from

underside of shelf.

3. Install one end bracket as shown in Figure 11

using the two screws removed in step 2.

4. Place one end of door mounting bracket into

installed end bracket. Place other end bracket

onto door mounting bracket and secure to

underside of shelf using other two screws

removed in step 2.

5. Door should swing fully up for product

placement.

6. When loading/unloading product, use bracket to

hold flip-up door in the open position.

(See Figure 12.)

CAUTION

Use only non-abrasive cleaners. Abrasive

cleaners could scratch the finish marring its

appearance and making it susceptible to dirt

accumulation.

4" (102 MM) ADJUSTABLE LEGS

Four inch (102 mm) legs are available in lieu of the

2-1/2" (64 mm) legs for installations that require

additional clearance between the unit and

countertop.

TEMPERATURE INDICATOR

NOTE: This option is factory installed only, not

available for retrofit.

Units may be equipped with a temperature indicator

which displays the coolest temperature on the shelf.

This indicator does not measure food temperature,

but is a reference to indicate shelf temperature only.

Page 15

Form No. GR3SDM-0606

13

HATCO LIMITED WARRANTY

1. PRODUCT WARRANTY

Hatco warrants the products that it manufactures

(the “Products”) to be free from defects in

materials and workmanship, under normal

use and service, for a period of one (1) year from

the date of purchase when installed and

maintained in accordance with Hatco’s written

instructions or 18 months from the date of

shipment from Hatco. Buyer must establish the

product’s purchase date by returning Hatco’s

Warranty Registration Card or by other means

satisfactory to Hatco in its sole discretion.

Hatco warrants the following Product components

to be free from defects in materials and

workmanship from the date of purchase (subject

to the foregoing conditions) for the period(s) of

time and on the conditions listed below:

a) One (1) Year Parts and Labor PLUS One

(1) Additional Year Parts-Only Warranty:

Toaster Elements (metal sheathed)

Drawer Warmer Elements (metal sheathed)

Drawer Warmer Drawer Rollers and Slides

Food Warmer Elements (metal sheathed)

Display Warmer Elements (met al sheathed

air heating)

Holding Cabinet Elements (metal sheathed

air heating)

Built-In Heated Well Elements

(metal sheathed)

b) One (1) Year Parts and Labor PLUS Four

(4) Years Parts-Only Warranty on

pro-rated terms that Hatco will explain

at Buyer’s request:

3CS and FR Tanks

c) One (1) Year Parts and Labor PLUS Nine

(9) Years Parts-Only Warranty on:

Electric Booster Heater Tanks

Gas Booster Heater Tanks

THE FOREGOING WARRANTIES ARE

EXCLUSIVE AND IN LIEU OF ANY OTHER

WARRANTY, EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY

IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE

OR PATENT OR OTHER INTELLECTUAL

PROPERTY RIGHT INFRINGEMENT. Without

limiting the generality of the foregoing, SUCH

WARRANTIES DO NOT COVER: Coated

incandescent light bulbs, fluorescent lights, lamp

warmer heat bulbs, glass components, Product

failure in booster tank, fin tube heat exchanger, or

other water heating equipment, caused

by liming, sediment buildup, chemical attack or

freezing, Product misuse, tampering or

misapplication, improper installation, or application

of improper voltage.

2. LIMITATION OF REMEDIES AND

DAMAGES

Hatco’s liability and Buyer’s exclusive remedy

hereunder will be limited solely, at Hatco’s option,

to repair or replacement by a Hatco-authorized

service agency (other than where Buyer is

located outside of the United States, Canada,

United Kingdom or Australia in which case

Hatco’s liability and Buyer’s exclusive remedy

hereunder will be limited solely to replacement of

part under warranty) with respect to any claim

made within the applicable warranty period

referred to above. Hatco reserves the right to

accept or reject any such claim in whole or in part.

Hatco will not accept the return of any Product

without prior written approval from Hatco, and all

such approved returns shall be made at Buyer’s

sole expense. HATCO WILL NOT BE LIABLE,

UNDER ANY CIRCUMSTANCES, FOR

CONSEQUENTIAL OR INCIDENTAL

DAMAGES, INCLUDING BUT NOT LIMITED TO

LABOR COSTS OR LOST PROFITS

RESUL TING FROM THE USE OF OR INABILITY

TO USE THE PRODUCTS OR FROM THE

PRODUCTS BEING INCORPORATED IN OR

BECOMING A COMPONENT OF ANY OTHER

PRODUCT OR GOODS.

Page 16

HATCO CORPORATION

P.O. Box 340500, Milwaukee, WI 53234-0500 U.S.A.

(800) 558-0607 (414) 671-6350

Parts & Service Fax (800) 690-2966 Int’l. Fax (414) 671-3976

www.hatcocorp.com

HATCO AUTHORIZED PARTS DISTRIBUTORS

Printed in U.S.A. June 2006

ALABAMA

Jones McLeod Appl. Svc.

Birmingham 205-251-0159

ARIZONA

Auth. Comm. Food Equip.

Phoenix 602-234-2443

Byassee Equipment Co.

Phoenix 602-252-0402

CALIFORNIA

Industrial Electric

Huntington Beach 714-379-7100

Chapman Appl. Service

San Diego 619-298-7106

P & D Appliance

S. San Francisco 650-635-1900

COLORADO

Hawkins Commercial Appliance

Englewood 303-781-5548

FLORIDA

Whaley Foodservice Repair

Jacksonville 904-725-7800

Universal Restaurant Services

Miami 305-593-5488

Nass Service Co., Inc.

Orlando 407-425-2681

B.G.S.I.

Pompano Beach 954-971-0456

Comm. Appliance Service

Tampa 813-663-0313

GEORGIA

TWC Services

Smyrna 770-438-9797

Heritage Service Group

Norcross 866-388-9837

Southeastern Rest. Svc.

Norcross 770-446-6177

HA

WAII

Burney’s Comm. Service, Inc.

Honolulu 808-848-1466

Food Equip Parts & Service

Honolulu 808-847-4871

ILLINOIS

Parts Town

Lombard 708-865-7278

Eichenauer Elec. Service

Decatur 217-429-4229

Midwest Elec. Appl. Service

Elmhurst 630-279-8000

Cone’s Repair Service

Moline 309-797-5323

INDIANA

GCS Service

Indianapolis 317-545-9655

IOW

A

Electric Motor Service Co.

Davenport 319-323-1823

Goodwin Tucker Group

Des Moines 515-262-9308

KENTUCKY

GCS Service

Louisville 502-367-1788

LOUISIANA

Chandlers Parts & Service

Baton Rouge 225-272-6620

MAR

YLAND

Electric Motor Service

Baltimore 410-467-8080

GCS Service

Silver Spring 301-585-7550

MASSACHUSETTS

Ace Service Co., Inc.

Needham 781-449-4220

MICHIGAN

Commercial Kitchen Service

Bay City 517-893-4561

Bildons Appliance Service

Detroit 248-478-3320

Midwest Food Equip. Service

Grandville 616-261-2000

MINNESOT

A

GCS Service

Minneapolis 612-546-4221

MISSOURI

General Parts

Kansas City 816-421-5400

Commercial Kitchen Services

St. Louis 314-890-0700

Kaemmerlen Parts & Service

St. Louis 314-535-2222

NEBRASKA

Anderson Electric

Omaha 402-341-1414

NEV

ADA

Burney’s Commercial

Las Vegas 702-736-0006

Hi. Tech Commercial Service

N. Las Vegas 702-649-4616

NEW JERSEY

Jay Hill Repair

Fairfield 973-575-9145

Service Plus

Flanders 973-691-6300

NEW

YORK

Acme American Repairs, Inc.

Brooklyn 718-456-6544

Alpro Service Co.

Brooklyn 718-386-2515

Appliance Installation

Buffalo 716-884-7425

Northern Parts Dist.

Plattsburgh 518-563-3200

J.B. Brady, Inc.

Syracuse 315-422-9271

NORTH CAROLINA

Authorized Appliance

Charlotte 704-377-4501

OHIO

Akron/Canton Comm. Svc. Inc.

Akron 330-753-6635

Certified Service Center

Cincinnati 513-772-6600

Commercial Parts and Service

Columbus 614-221-0057

Electrical Appl. Repair Service

Independence 216-459-8700

E. A. Wichman Co.

Toledo 419-385-9121

OKLAHOMA

Hagar Rest. Service, Inc.

Oklahoma City 405-235-2184

Krueger, Inc.

Oklahoma City 405-528-8883

OREGON

Ron’s Service, Inc.

Portland 503-624-0890

PENNSYL

VANIA

Elmer Schultz Services

Philadelphia 215-627-5401

FAST Comm. Appl. Service

Philadelphia 215-288-4800

Appliance Installation & Service

Pittsburgh 412-809-0244

K & D Service Co.

Harrisburg 717-236-9039

Electric Repair Co.

Reading 610-376-5444

RHODE ISLAND

Marshall Electric Co.

Providence 401-331-1163

SOUTH CAROLINA

Whaley Foodservice Repair

W. Columbia 803-791-4420

TENNESSEE

Camp Electric

Memphis 901-527-7543

TEXAS

Stove Parts Supply

Fort Worth 817-831-0381

Armstrong Repair Service

Houston 713-666-7100

Commercial Kitchen Repair Co.

San Antonio 210-735-2811

UT

AH

La Monica’s Rest. Equip. Service

Murray 801-263-3221

VIRGINIA

Daubers

Norfolk 757-855-4097

Daubers

Springfield 703-866-3600

W

ASHINGTON

Restaurant Appl. Service

Seattle 206-524-8200

WISCONSIN

A.S.C., Inc.

Madison 608-246-3160

A.S.C., Inc.

Milwaukee 414-543-6460

CANADA

ALBERTA

Key Food Equipment Service

Edmonton 780-438-1690

BRITISH COLUMBIA

Key Food Equipment Service

Vancouver 604-433-4484

ONT

ARIO

R.G. Henderson Ltd.

Toronto 416-422-5580

Choquette CKS

Ottawa 613-739-8458

QUÉBEC

Choquette CKS

Montreal 514-722-2000

Choquette CKS

Québec City 418-681-3944

Part No. 07.04.370.00 Form No. GR3SDM-0606

Loading...

Loading...