Hatco FSCD-2PD Installation Manual

Register Online!

hatcocorp.com

WARNING

ADVERTENCIA

AVERTISSEMENT

(see page 2)

S'inscrire en ligne!

(voir page 16)

Convected Display Cabinet

FSCD and FSCDH Series/Série

Installation and Operating Manual

Manuel d'installation et d'utilisation

®

FLAV-R-SAVOR

Vitrine à Convection

Do not operate this equipment unless you

have read and understood the contents of

this manual! Failure to follow the

instructions contained in this manual may

result in serious injury or death. This

manual contains important safety

information concerning the maintenance,

use, and operation of this product. If

you’re unable to understand the contents

of this manual, please bring it to the

attention of your supervisor. Keep this

manual in a safe location for future

reference.

P/N 07.04.590.00 © 2016 Hatco Corporation

English = p 2

No opere este equipo al menos que haya

leído y comprendido el contenido de este

manual! Cualquier falla en el seguimiento

de las instrucciones contenidas en este

manual puede resultar en un serio lesión

o muerte. Este manual contiene

importante información sobre seguridad

concerniente al mantenimiento, uso y

operación de este producto. Si usted no

puede entender el contenido de este

manual por favor pregunte a su

supervisor. Almacenar este manual en

una localización segura para la referencia

futura.

Ne pas utiliser cet équipement sans avoir

lu et compris le contenu de ce manuel !

Le non-respect des instructions

contenues dans ce manuel peut entraîner

de graves blessures ou la mort. Ce

manuel contient des informations

importantes concernant l'entretien,

l'utilisation et le fonctionnement de ce

produit. Si vous ne comprenez pas le

contenu de ce manuel, veuillez le signaler

à votre supérieur. Conservez ce manuel

dans un endroit sûr pour pouvoir vous y

référer plus tard.

Français = p 16

24 Hour 7 Day Parts and Service

Assistance available in the United States

and Canada by calling 800-558-0607.

WARNING

CAUTION

NOTICE

CONTENTS

English

Important Owner Information ..............................................2

Introduction...........................................................................2

Important Safety Information ..............................................3

Model Description.................................................................4

Model Designation................................................................4

Specifications .......................................................................5

Plug Configurations .............................................................5

Electrical Rating Chart .........................................................5

Dimensions ..........................................................................5

Installation.............................................................................6

General ................................................................................6

Assembling the Unit.............................................................6

Installing the Leg Skirt .........................................................8

IMPORTANT OWNER INFORMATION

Record the model number, serial number, voltage, and

purchase date of the unit in the spaces below (specification

label located on the back of the unit). Please have this

information available when calling Hatco for service assistance.

Model No. ________________________________________

Serial No. ________________________________________

Voltage __________________________________________

Operation...............................................................................9

General ................................................................................9

Setting the Air Temperature ...............................................10

Setting the Humidity Level.................................................10

Food Holding Guide...........................................................10

Maintenance ........................................................................11

General ..............................................................................11

Daily Cleaning ....................................................................11

Cleaning the Stone Surface...............................................11

Draining the Water Reservoir.............................................11

Removing Lime and Mineral Deposits...............................12

Replacing Xenon Display Lights........................................12

Troubleshooting Guide ......................................................13

Options and Accessories...................................................14

Limited Warranty.................................................................15

Authorized Parts Distributors............................Back Cover

Business

Hours: 7:00

(Summer Hours: June to September—

7:00

7:00

Telephone: 800-558-0607; 414-671-6350

e-mail: partsandservice@hatcocorp.com

AM to 5:00 PM Central Standard Time (CST)

AM to 5:00 PM CST Monday–Thursday

AM to 4:00 PM CST Friday)

Date of Purchase __________________________________

Register your unit!

Completing online warranty registration will prevent delay in

obtaining warranty coverage. Access the Hatco website at

www.hatcocorp.com, select the Parts & Service pull-down

menu, and click on “Warranty Registration”.

INTRODUCTION

Hatco Flav-R-Savor®Convected Display Cabinets are designed

to hold prepared foods for prolonged periods of time while

maintaining that “just-made” quality. Convected Display

Cabinets provide the best environment for food products by

regulating the air temperature while at the same time balancing

the humidity level. Units can be configured with or without a

humidity system. The use of controlled, moisturized heat

maintains serving temperature and food texture longer than

conventional dry holding equipment.

The Flav-R-Savor air flow pattern is designed to maintain

consistent cabinet temperature without drying out foods. The

precise combination of heat and humidity creates a “blanket”

effect around the food. The air flow rate enables the cabinet to

recover temperature rapidly after opening and closing a door.

Hatco Flav-R-Savor Convected Display Cabinets are products

of extensive research and field testing. The materials used were

selected for maximum durability, attractive appearance, and

optimum performance. Every unit is inspected and tested

thoroughly prior to shipment.

Additional information can be found by visiting our web site at

www.hatcocorp.com.

This manual provides the installation, safety, and operating

instructions for Flav-R-Savor Convected Display Cabinets.

Hatco recommends all installation, operating, and safety

instructions appearing in this manual be read prior to

installation or operation of a unit.

Safety information that appears in this manual is identified by

the following signal word panels:

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE is used to address practices not related to personal

injury.

2

Form No. FSCDM-1016

English

CAUTION

NOTICE

WARNING

WARNING

IMPORTANT SAFETY INFORMATION

Read the following important safety information before using this equipment to avoid serious

injury or death and to avoid damage to equipment or property.

ELECTRIC SHOCK HAZARD:

• Plug unit into a properly grounded electrical receptacle of

the correct voltage, size, and plug configuration. If plug

and receptacle do not match, contact a qualified electrician

to determine and install proper voltage and size electrical

receptacle.

• Turn OFF power switch, unplug power cord, and allow unit

to cool before performing any cleaning, adjustments, or

maintenance.

• DO NOT submerge or saturate with water. Unit is not

waterproof. Do not operate if unit has been submerged or

saturated with water.

• Unit is not weatherproof. Locate unit indoors where

ambient air temperature is a minimum of 70°F (21°C).

• This unit is not “jet-proof” construction. Do not use jetclean spray to clean this unit.

• Do not steam clean or use excessive water on unit.

• Do not overfill water reservoir. Overfilling can cause

electrical shock. Water reservoir is full when “LO H2O”

stops flashing on CABINET TEMPERATURE display. Stop

filling when “LO H2O” stops flashing on display.

• Turn power switch OFF and allow unit to cool before

draining water reservoir.

• Do not pull unit by power cord.

• Discontinue use if power cord is frayed or worn.

• Do not attempt to repair or replace a damaged power cord.

Cord must be replaced by Hatco, an Authorized Hatco

Service Agent, or a person with similar qualifications.

• This unit must be serviced by qualified personnel only.

Service by unqualified personnel may lead to electric

shock or burn.

• Use only Genuine Hatco Replacement Parts when service

is required. Failure to use Genuine Hatco Replacement

Parts will void all warranties and may subject operators of

the equipment to hazardous electrical voltage, resulting in

electrical shock or burn. Genuine Hatco Replacement Parts

are specified to operate safely in the environments in

which they are used. Some aftermarket or generic

replacement parts do not have the characteristics that will

allow them to operate safely in Hatco equipment.

FIRE HAZARD:

• Locate unit a minimum of 1″ (25 mm) from combustible

walls and materials. If safe distances are not maintained,

discoloration or combustion could occur.

• Do not place anything on top of unit.

Make sure food product has been heated to the proper foodsafe temperature before placing in unit. Failure to heat food

product properly may result in serious health risks. This unit

is for holding pre-heated food product only.

Hatco Corporation is not responsible for actual food product

serving temperature. It is the responsibility of the user to ensure

that food product is held and served at a safe temperature.

The light fixtures in this unit have safety shields covering the

light bulbs to meet National Sanitation Foundation (NSF)

standards. To avoid personal injury and/or food

contamination, always operate the unit with the safety shields

properly installed.

Make sure all operators have been instructed on the safe and

proper use of the unit.

This unit is not intended for use by children or persons with

reduced physical, sensory, or mental capabilities. Ensure

proper supervision of children and keep them away from the

unit.

This unit has no “user-serviceable” parts. If service is

required on this unit, contact an Authorized Hatco Service

Agent or contact the Hatco Service Department at

800-558-0607 or 414-671-6350.

BURN HAZARD: Some exterior surfaces on the unit will get

hot. Use caution when touching these areas.

Locate unit at proper counter height in an area that is

convenient for use. Location should be level to prevent unit or

its contents from falling accidentally and strong enough to

support the weight of the unit and contents.

The National Sanitation Foundation (NSF) requires that units

over 36″ (914 mm) in width or weighing more than 80 lbs.

(36 kg) either be sealed to or raised above the installation

surface. 4″ (102 mm) legs are included to allow for proper

cleaning access below unit.

Do not move or relocate the unit for cleaning. The unit is bulky

and heavy.

Transport unit in upright position only. Before moving or

tipping unit, secure all glass surfaces, doors, pan rails, and/or

skirts with tape; and drain water from humidified units. Failure

to do so may result in damage to unit or personal injury.

Make sure to clean and sanitize stone surface properly after

deep cleaning the surface using abrasives and before placing

food product on unit.

Use non-abrasive cleaners and cloths only. Abrasive cleaners

and cloths could scratch finish of unit, marring its appearance

and making it susceptible to soil accumulation.

Do not lay unit on the side with the control panel or on the front

of a curved glass unit. Damage to unit could occur.

Do not slide pans across glass surface, use rough-bottomed

pans, or drop anything on glass surface. Scratching or

breakage may occur. Damage to glass surface or breakage of

glass caused by misuse is not covered under warranty.

Use of distilled water in water reservoir of humidified units is

recommended to preserve life of electrical and mechanical

components. If non-distilled water is used, reservoir will

require periodic cleaning and deliming (refer to

MAINTENANCE section for cleaning procedure). Unit failure

due to lime or mineral deposits is not covered under warranty.

Do not use deionized water. Deionized water will shorten life

of water reservoir and heating elements.

Clean unit daily to avoid malfunctions and maintain

sanitary

operation.

Form No. FSCDM-1016

3

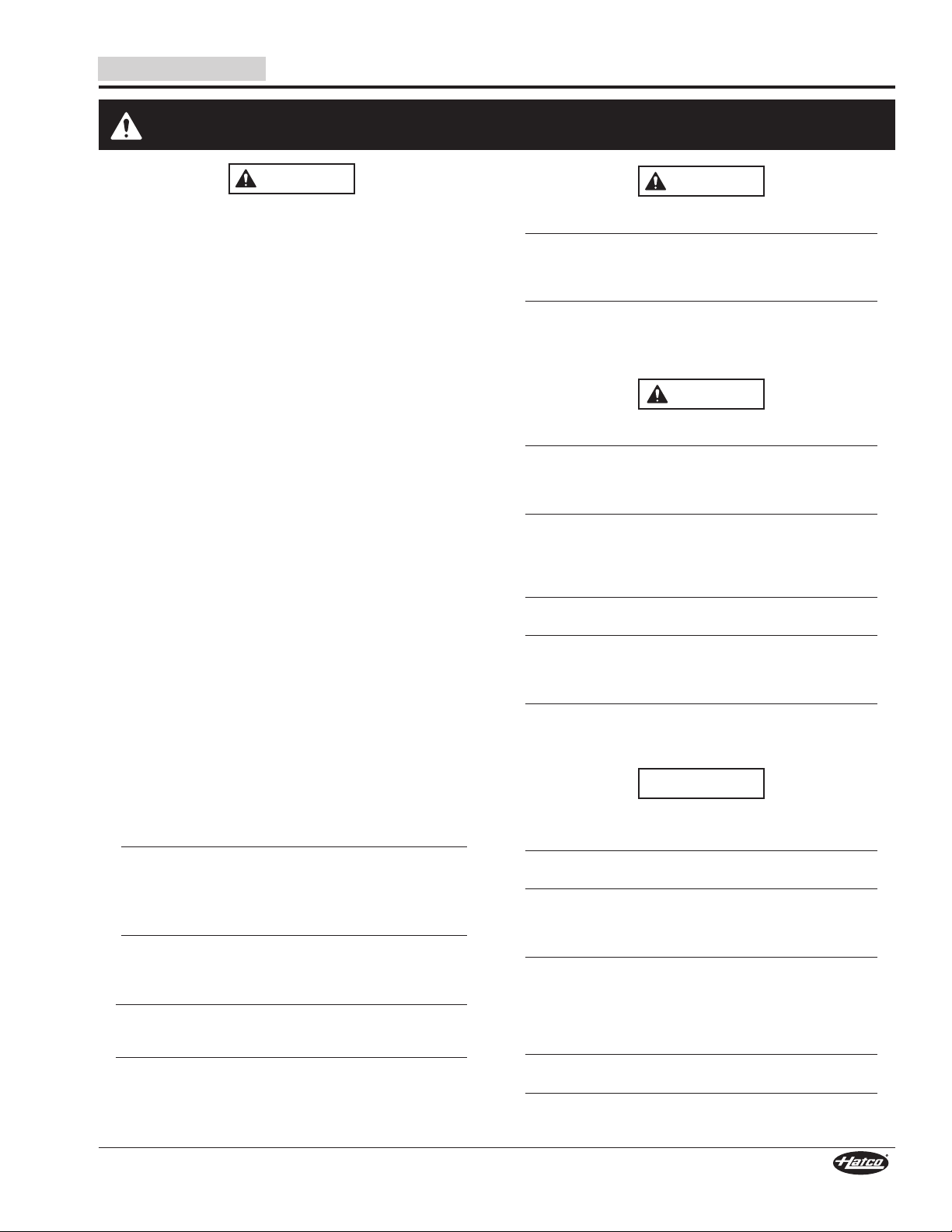

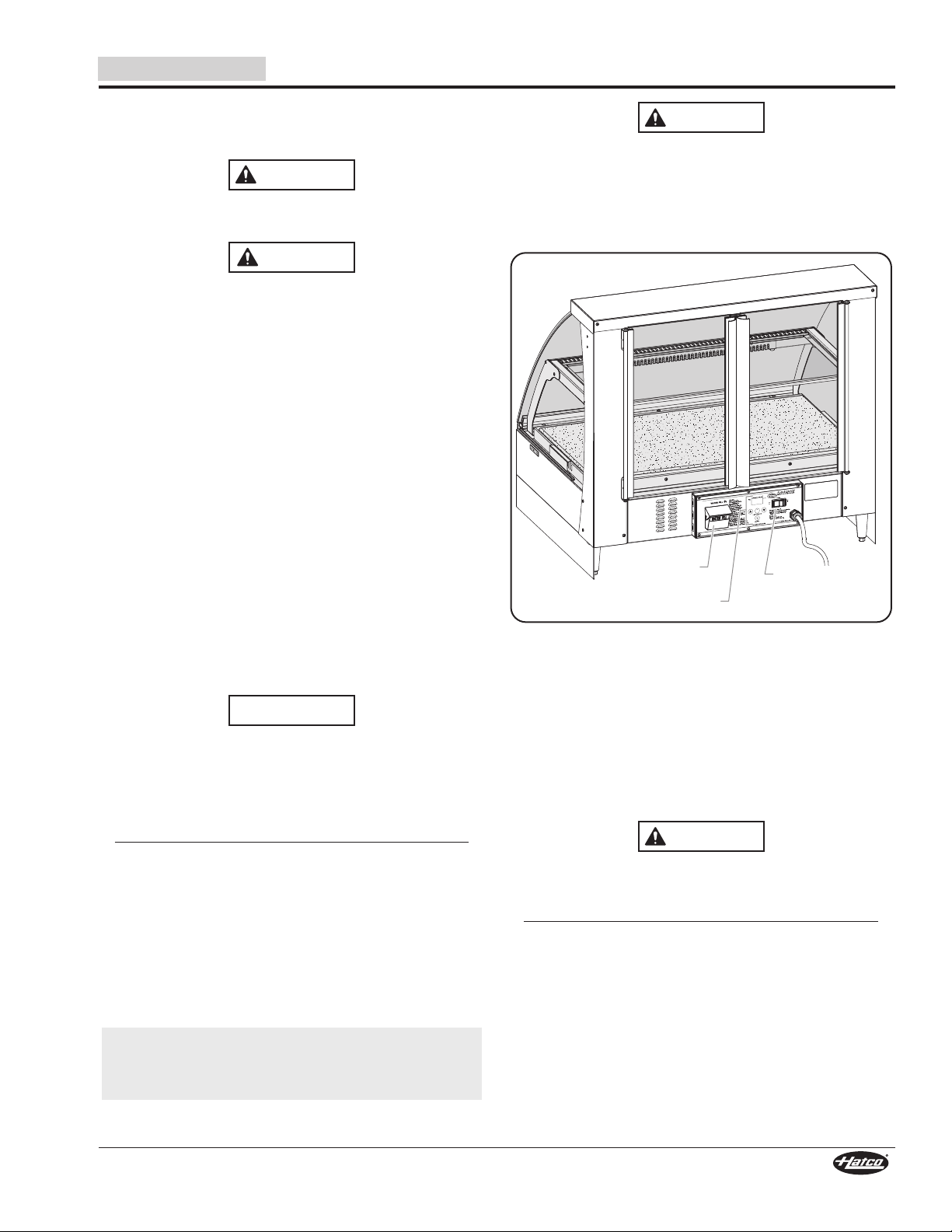

MODEL DESCRIPTION

Stone Base

Shelf

Curved Front

Glass Panel

French-Style

Glass Rear Doors

Optional

Glass

Top Shelf

Digital Temperature

Controller

POWER ON/OFF

(I/O) Switch

Power

Cord

Curved Glass

Retaining Clip

Sign

Holder

Leg Skirt

Perforated

Top Shelf

WATER FILL

Cup

F S C D H - 2 P D

Flav-R-Savor

Convected Display Cabinet

H = Humidified

No Character = Non-Humidified

2-Pan Capacity

Dual Shelf

Flav-R-Savor®Convected Display Cabinets are constructed of

stainless steel and aluminum with tempered glass side panels,

front sign holder, leg skirt, french-style glass rear doors, and

curved front glass panel with retaining clips. They come

standard with a black, powdercoated finish and are available in

several other Designer colors.

All models feature a digital temperature controller, a lighted

POWER ON/OFF (I/O) switch, an air heating/circulation system,

and Xenon display lights. The cabinet interior is made of easyto-clean stainless steel. The shelves consist of a removeable

stone base shelf and a perforated stainless steel or glass top

shelf.

The capacity of the unit is determined by using standard food

pan sizes. The base shelf capacity is two full size food pans,

and the top shelf capacity is one full size food pan plus a 1/3size food pan.

NOTE: Stone surfaces are a simulated stone solid surface.

Units can be configured with or without a humidity system and

are equipped with a 6' (1829 mm) power cord with plug.

Refer to the OPTIONS AND ACCESSORIES section for details

on additional configurations available.

English

MODEL DESIGNATION

Front and Rear view of Model FSCDH-2PD

4

Form No. FSCDM-1016

English

WARNING

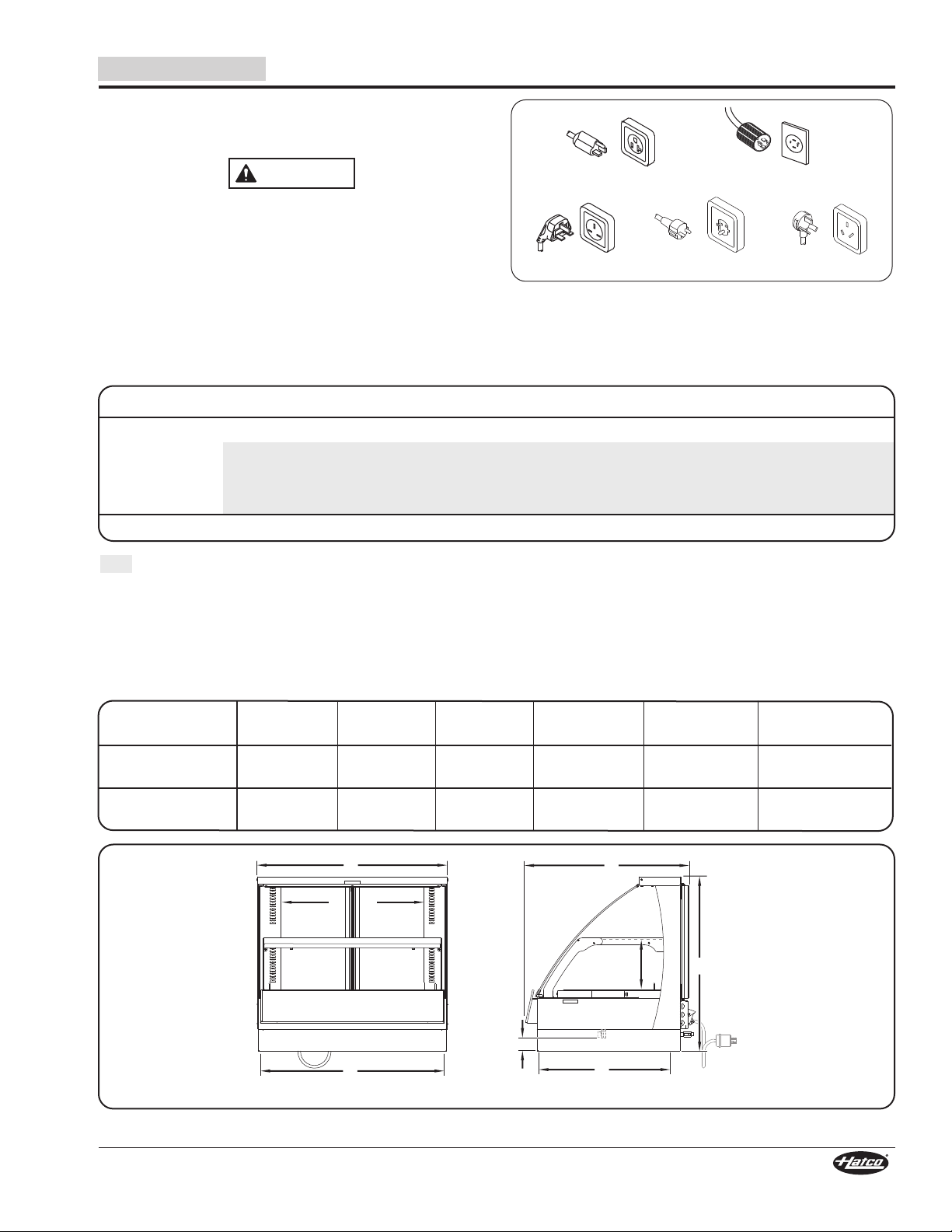

NEMA 5-20P

NEMA L14-20P

BS-1363 AS-3112

CEE 7/7 Schuko

A

B

E

D

25-7/8″

(657 mm)

25-7/8″

(657 mm)

C

F

Front View

Side View

8-7/8″

(225 mm)

SPECIFICATIONS

Plug Configurations

Units are supplied from the factory with an electrical cord and

plug installed (plugs are supplied according to the application).

ELECTRIC SHOCK HAZARD: Plug unit into a properly

grounded electrical receptacle of the correct voltage, size,

and plug configuration. If plug and receptacle do not

match, contact a qualified electrician to determine and

install proper voltage and size electrical receptacle.

NOTE: Specification label located on the back of the unit. See

label for serial number and verification of unit electrical

information.

NOTE: Receptacle not supplied by Hatco.

Plug Configuration

Electrical Rating Chart

Model Voltage Watts Amps Plug Configuration Shipping Weight

FSCD-2PD 120 1800 15 NEMA 5-20P 205 lbs. (93 kg)

220 1768 8.0 BS-1363, CEE 7/7 Schuko, AS-3112 205 lbs. (93 kg)

230 1932 8.4 BS-1363, CEE 7/7 Schuko, AS-3112 205 lbs. (93 kg)

240 2104 8.8 BS-1363, CEE 7/7 Schuko, AS-3112 205 lbs. (93 kg)

FSCDH-2PD 120/208–240 2805 13.3 NEMA L14-20P 190 lbs. (86 kg)

The shaded areas contain electrical information for International models only.

NOTE: Shipping weight includes packaging.

Dimensions

Model

FSCD-2PD

FSCDH-2PD

Width

(A)

34-3/8″

(872 mm)

34-3/8″

(872 mm)

Depth

(B)

29-5/8″

(752 mm)

30-5/8″

(778 mm)

Height

(C)

31-9/16″

(801 mm)

31-9/16″

(801 mm)

Footprint

Width (D)

33-1/16″

(840 mm)

33-1/16″

(840 mm)

Footprint

Depth (E)

23-7/16″

(595 mm)

23-7/16″

(595 mm)

Drain

Clearance (F)

---

2-3/8″

(60 mm)

Form No. FSCDM-1016

5

INSTALLATION

WARNING

CAUTION

Rotate forward.

Curved Front

Glass Panel

Lift straight up.

Fixed

Hinge

NOTICE

English

General

The Flav-R-Savor®Convected Display Cabinets are shipped

with most components installed and ready for operation. Care

should be taken when unpacking shipping carton to avoid

damage to unit and the components enclosed. The following

installation instructions must be performed before connecting

electricity and operating the cabinet.

ELECTRIC SHOCK HAZARD: Unit is not weatherproof.

Locate unit indoors where ambient air temperature is a

minimum of 70°F (21°C).

FIRE HAZARD:

• Locate unit a minimum of 1″ (25 mm) from combustible

walls and materials. If safe distances are not

maintained, discoloration or combustion could occur.

• Do not place anything on top of unit.

Locate unit at proper counter height in an area that is

convenient for use. Location should be level to prevent unit

or its contents from falling accidentally and strong enough

to support the weight of the unit and contents.

The National Sanitation Foundation (NSF) requires that

units over 36″ (914 mm) in width or weighing more than

80 lbs. (36 kg) either be sealed to or raised above the

installation surface. If unit cannot be sealed at the point of

use, 4″ (102 mm) legs are included to allow for proper

cleaning access below unit.

1. Open and remove the top and sides of the shipping carton.

NOTICE: Do not remove unit from carton before

installing legs.

NOTE: Humidified units have a drain valve installed on the

NOTE: To prevent delay in obtaining warranty coverage,

• Locate the unit in an area where the ambient air

• Make sure the unit is at the proper counter height in an

• Make sure the countertop is level and strong enough to

bottom of the unit. The valve will be crushed if the unit

is removed from the carton and set down before

installing the legs.

2. Perform the “Assembling the Unit” procedure in this

section. Two or more people are required for this

procedure.

3. Remove any remaining tape and protective film from all

surfaces of unit.

complete online warranty registration. See the

IMPORTANT OWNER INFORMATION section for

details.

4. Place the unit in the desired location.

temperature is constant and a minimum of 70°F (21°C).

Avoid areas that may be subject to active air movements

or currents (i.e., near exhaust fans/hoods and air

conditioning ducts).

area convenient for use.

support the weight of the unit and food product.

5. Plug the unit into a properly grounded electrical receptacle

of the correct voltage, size, and plug configuration. See the

SPECIFICATIONS section for details.

Assembling the Unit

Use the following procedure to install the legs, top shelf (glass

or stainless steel), and side air deflectors on the unit. These

items are secured to the base shelf for shipping. Removal of

other components is required to prevent damage when tipping

the unit for leg installation.

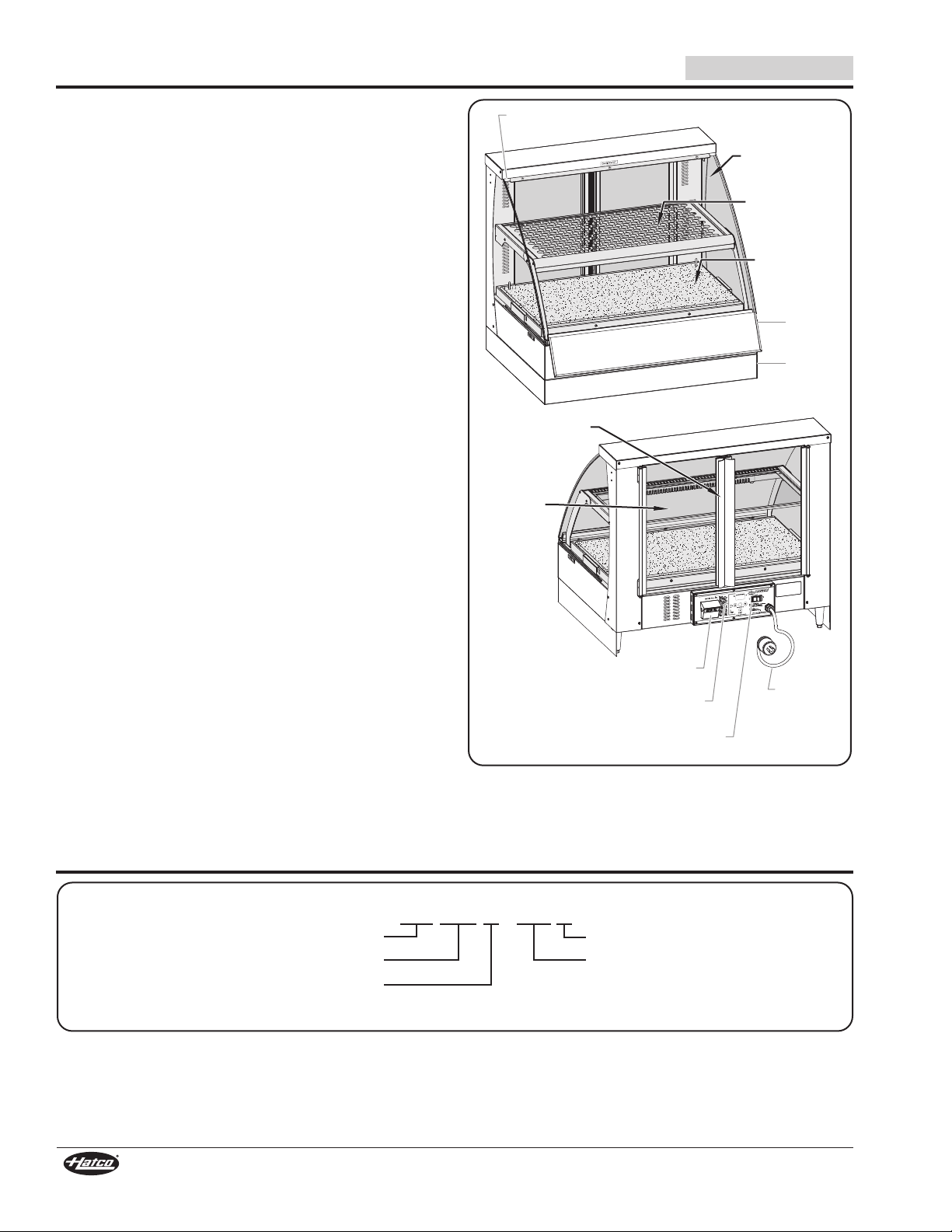

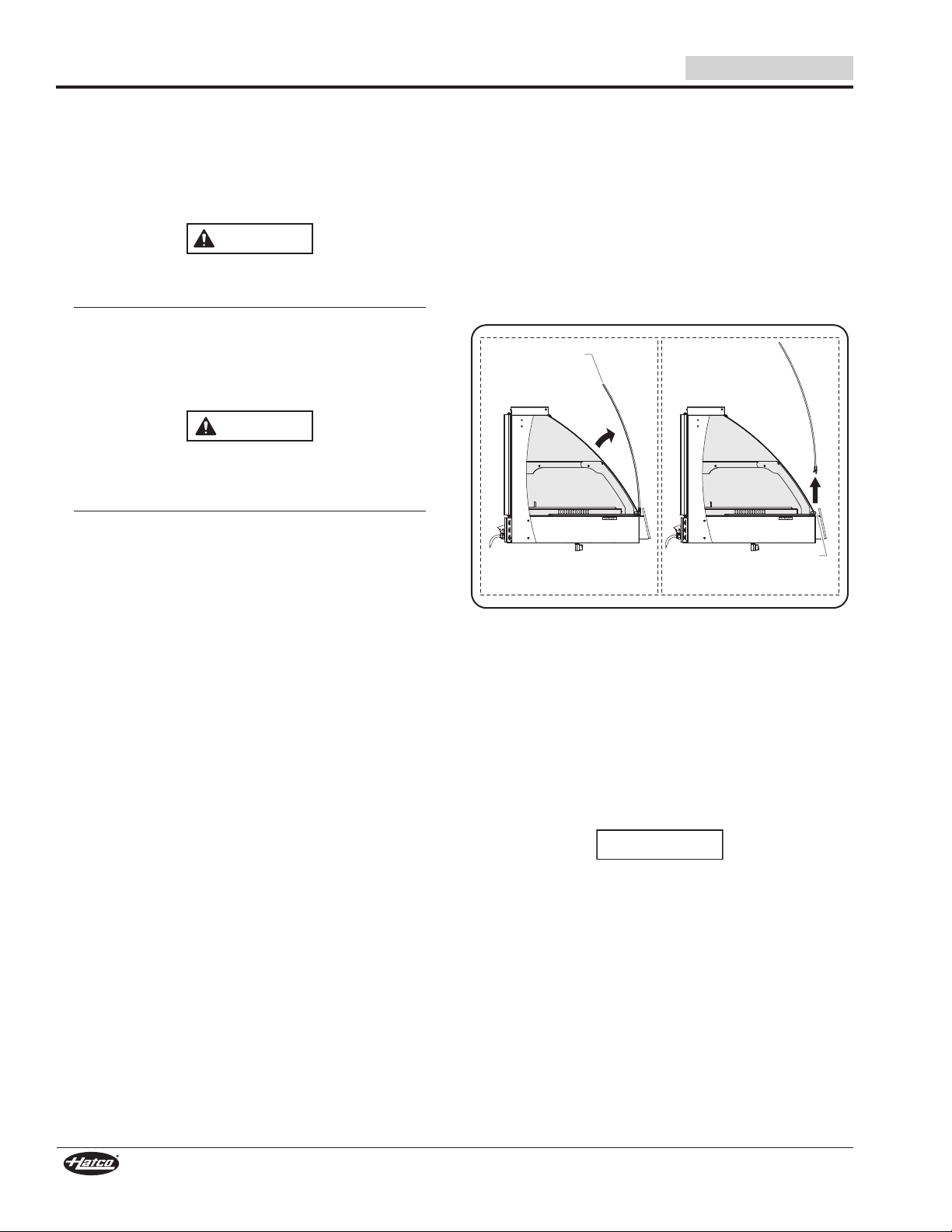

1. Remove the curved front glass panel.

a. Loosen the thumbscrews holding the curved glass

retaining clips on each side of the panel.

b. Rotate the curved glass panel partially forward and lift

straight up and off the fixed hinge. Discard the rubber

packing strips.

Removing the Curved Front Glass Panel

2. Remove the plastic bags containing the 4″ (102 mm)

adjustable legs, the two side air deflectors, and the leg skirt

from inside the unit.

3. Remove the top shelf (glass or stainless steel) from inside

the unit. If the top shelf is glass, there also is a vent panel

to remove.

4. Remove the front air deflector from the front edge of the

base inside the unit.

5. Carefully remove the stone base shelf by lifting it up and off

the locating pegs at the rear of the base.

Do not lay unit on the side with the control panel or on the

front of a curved glass unit. Damage to unit could occur.

6

Form No. FSCDM-1016

English

Vent Panel

Stone Base

Glass Top Shelf

Side

Air Deflector

Front

Air Deflector

Locating

Peg

4″

(102 mm)

Legs

Perforated

Stainless Steel

Top Shelf

Sign Holder

removed

for clarity.

Lengthen

Shorten

Adjustable

Foot

4″ Leg

Drain Valve

Components

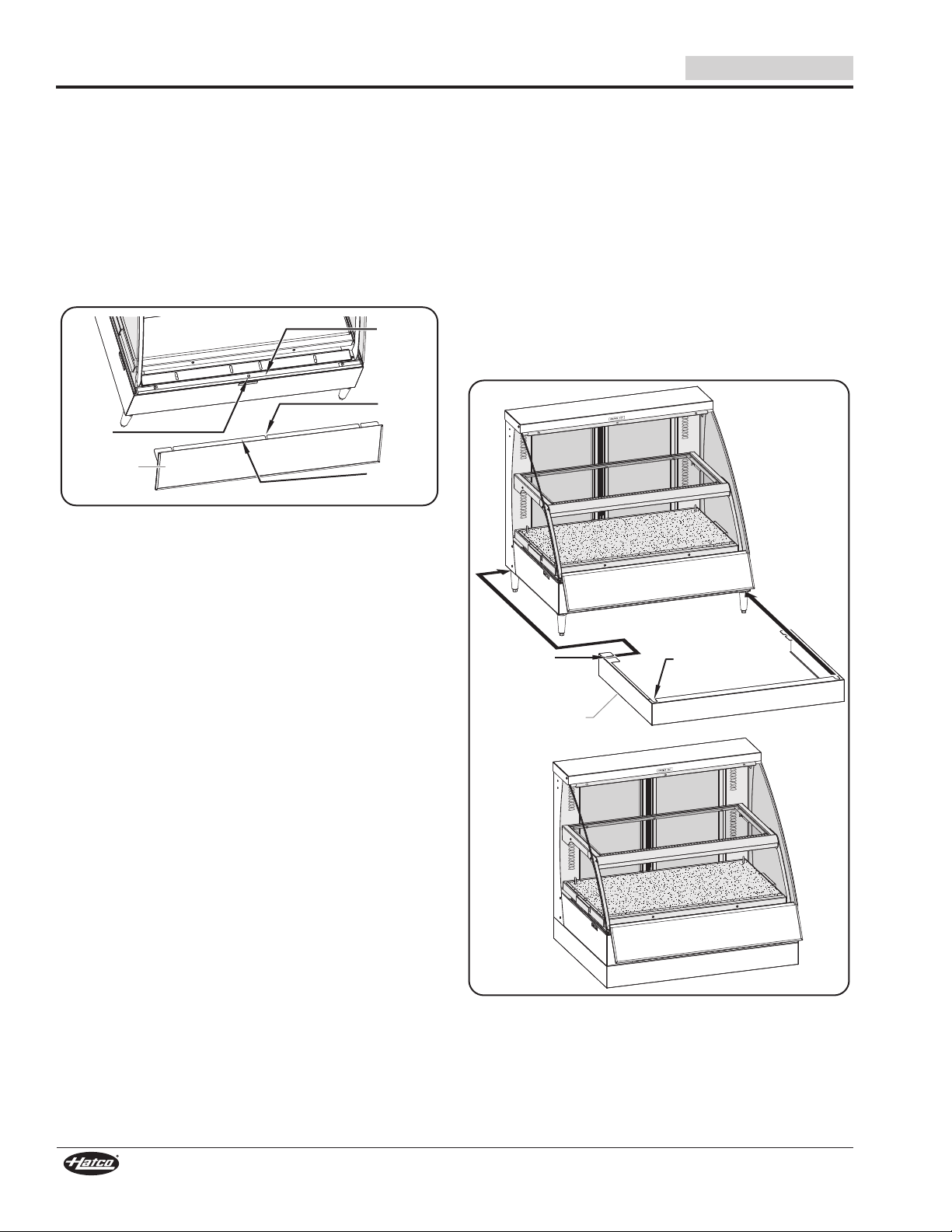

6. Install the included 4″ (102 mm) legs (two people are

required for this step).

a. Tape the rear glass doors together to prevent them from

opening while tipping.

b. Carefully tip the unit onto its side and rest it on top of

cardboard on a flat surface.

c. At each corner, thread a 4″ (102 mm) leg into the bottom

of the unit. Hand-tighten until almost snug. Do not over-

tighten.

d. Return the unit to the upright position.

e. Remove the tape from the doors.

NOTE: The feet on the 4″ (102 mm) legs are adjustable for

leveling the unit. Use a 9/16″ (14 mm) open-end wrench

to make leveling adjustments once the unit is placed in

its final position.

INSTALLATION

Leg Installation

7. Reinstall the stone base shelf.

a. Remove all tape and protective packaging from the shelf.

b. Align the two holes on the back edge of the shelf with

the locating pegs on the base.

c. Carefully lower the shelf into position.

8. Reinstall the front air deflector along the front edge of the

base. Long slots on air deflector should face to the front.

9. Install the side air deflectors.

• The side deflectors rest between two screw heads on

each side of the base, directly in front of the side air

vents. The flat edge of the deflector should be positioned

against the glass side panel.

10. Install the top shelf.

• If the unit is configured with a glass top shelf, install the

vent panel along the front edge of the top shelf frame.

Then, install the glass shelf.

• If the unit is configured with a perforated stainless steel

top shelf, install the shelf directly into the top shelf frame.

Perforated stainless steel top shelves are designed to

allow proper air flow without the use of the vent panel.

continued...

Form No. FSCDM-1016

7

INSTALLATION

Front Sign

Holder

Hinge

Screw

Fixed

Hinge

Screw

Cutout

Mounting

Flange

Leg Skirt

Front

Leg Cutout

Rear Leg

Cutout

English

11. Install the front sign holder.

a. Loosen, but do not remove the three hinge screws that

secure the fixed hinge to the base. Loosen until there is

enough room to slip the sign holder mounting flange

between the fixed hinge and the base.

b. Align the screw cutouts on the sign holder mounting

flange with the three screws on the fixed hinge.

c. Slide the sign holder mounting flange between the fixed

hinge and the base. Slide in the sign holder until it stops.

d. Tighten the three hinge screws to secure the fixed hinge

and the front sign holder to the base.

Installing Front Sign Holder (view from above)

12. Reinstall the curved front glass panel.

a. Lower the hinge bracket on the glass panel onto the

fixed hinge on the front edge of the base.

b. Carefully rotate the panel toward the unit until it rests

against the upper frame and the glass side panels.

c. Tighten the thumbscrews holding the curved glass

retaining clips on each side of the panel.

Installing the Leg Skirt

The leg skirt hides the 4″ (102 mm) legs and drain (humidified

units) from view when looking from the customer side. Use the

following procedure to install the leg skirt.

1. Loosen the 4″ (102 mm) legs until there is enough room

between the legs and the bottom of the unit for the leg skirt

to slide between.

2. From the front of the unit, pull out on each side of the leg

skirt to wrap it around the sides of the unit.

3. Slide the front leg cutouts on the leg skirt between the front

legs and the bottom of the unit.

4. Slide the rear leg cutouts on the leg skirt between the rear

legs and the bottom of the unit.

5. Tighten the 4″ (102 mm) legs to secure the leg skirt in

position.

Leg Skirt Installation

8

Form No. FSCDM-1016

English

WARNING

CAUTION

NOTICE

POWER ON/OFF

(I/O) Switch

Digital Temperature Controller

WATER FILL

Cup

WARNING

WARNING

OPERATION

General

Use the following procedures to operate a Flav-R-Savor

Convected Display Cabinet.

Read all safety messages in the IMPORTANT SAFETY

INFORMATION section before operating this equipment.

BURN HAZARD: Some exterior surfaces on the unit will get

hot. Use caution when touching these areas.

Startup

1. Clean and sanitize the stone base shelf using a clean,

damp cloth and a sanitizer approved for food contact

surfaces.

2. Plug the unit into a properly grounded electrical receptacle

of the correct voltage, size and plug configuration. See the

SPECIFICATIONS section for details.

3. Move the POWER ON/OFF (I/O) switch to the ON (I)

position.

• The display lights will turn on and the heating system will

start up.

• On non-humidified units, the CABINET TEMPERATURE

display will show the current temperature of the cabinet

or “LO”. “LO” indicates the cabinet temperature is below

70°F (21°C).

• On humidified units, the CABINET TEMPERATURE

display will flash “LO H2O” four times and then flash the

cabinet temperature. It will continue to alternate this way

until the water reservoir is filled. Once the reservoir is

full, “LO H2O” will stop flashing and the display will show

the current temperature of the cabinet .

Use of distilled water in water reservoir of humidified units

is recommended to preserve life of electrical and

mechanical components. If non-distilled water is used,

reservoir will require periodic cleaning and deliming (refer

to MAINTENANCE section for cleaning procedure). Unit

failure due to lime or mineral deposits is not covered under

warranty.

Do not use deionized water. Deionized water will shorten

life of water reservoir and heating elements.

NOTE: Unit failure caused by deionized water is not covered by

warranty.

4. For humidified units, fill the water reservoir with clean water.

To fill the reservoir:

a. Lift up the WATERFILL cup cover and pull forward.

b. Slowly pour water into the cup until “LO H2O” stops

flashing on the CABINET TEMPERATURE display.

IMPORTANT NOTE

When using distilled water, add one teaspoon of salt to the

water reservoir during the initial water fill only. This will ensure

proper operation of the water level sensors.

®

ELECTRIC SHOCK HAZARD: Do not overfill water reservoir.

Overfilling can cause electrical shock. Water reservoir is full

when “LO H2O” stops flashing on CABINET TEMPERATURE

display. Stop filling when “LO H2O” stops flashing on display.

NOTE: The capacity of the water reservoir is six (6) quarts

(5.7 liters).

Controls

5. Set the air temperature to the desired temperature (refer to

the “Setting the Air Temperature” procedure in this section).

See the “Food Holding Guide” for recommendations.

6. On humidified units, set the humidity to the desired level

(refer to the “Setting the Humidity Level” procedure in this

section). See the “Food Holding Guide” for

recommendations.

7. Allow the unit 30 minutes to reach operating temperature

before loading the cabinet with pre-heated food product.

Make sure food product has been heated to the proper

food-safe temperature before placing in unit. Failure to heat

food product properly may result in serious health risks.

This unit is for holding pre-heated food product only.

BURN HAZARD: Some exterior surfaces on the unit will get

hot. Use caution when touching these areas.

Shutdown

1. Move the POWER ON/OFF (I/O) Switch to the OFF (O)

position and allow the unit to cool.

2. Perform the “Daily Cleaning” procedure in the

MAINTENANCE section of this manual.

Form No. FSCDM-1016

9

OPERATION

English

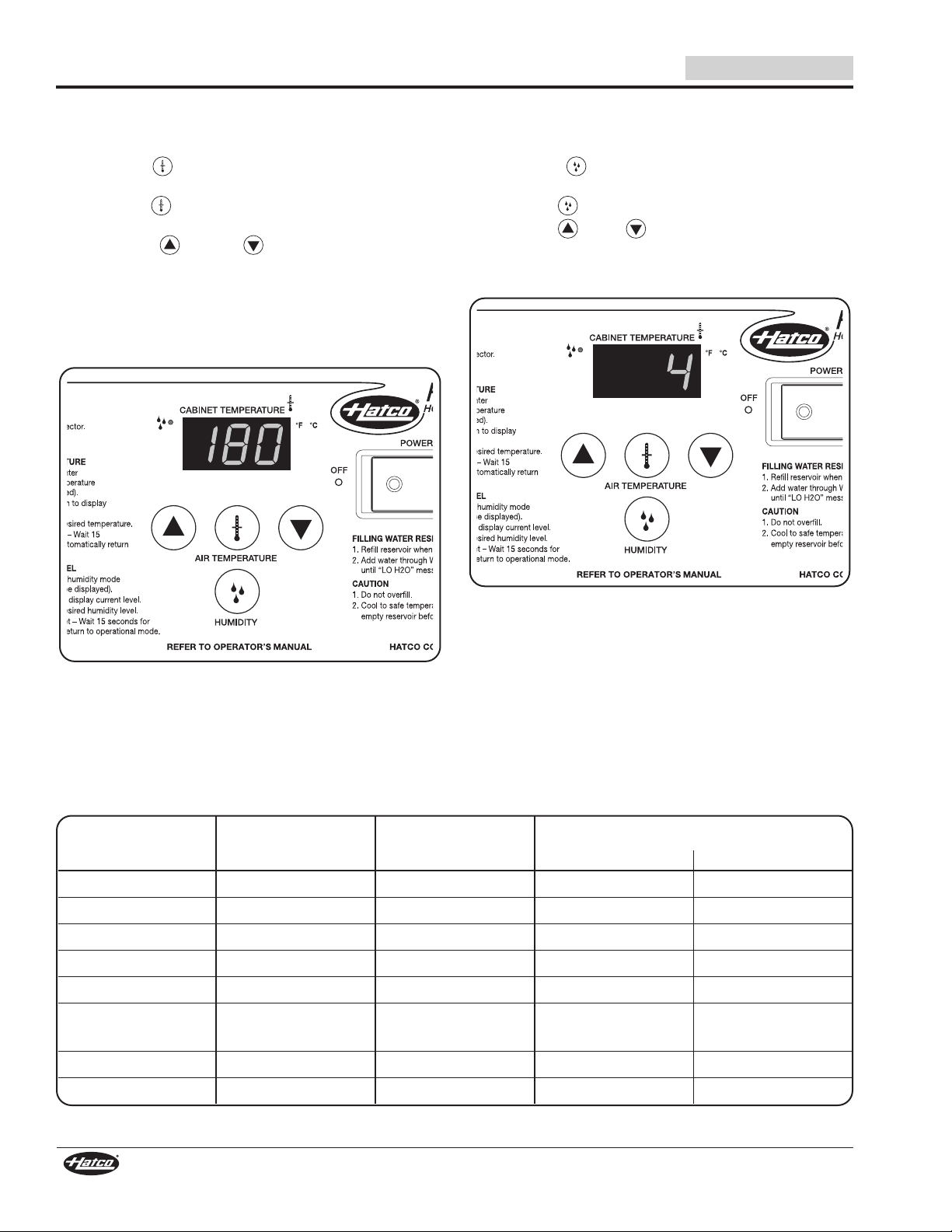

Setting the Air Temperature

Use the following procedure to set or change the air

temperature.

1. Press the key to enter temperature mode (“tSP” will

appear on the CABINET TEMPERATURE display).

2. Press the key again to show the current temperature

setting.

3. Press the key or key to reach the desired

temperature. The temperature range is 80°–195°F

(27°–91°C) in single degree increments. See the “Food

Holding Guide” in this section for recommendations.

4. After the desired temperature is set, wait 15 seconds

without pushing any keys for the cabinet temperature

display to return automatically to operational mode.

Setting the Humidity Level

Use the following procedure to set the humidity level on

humidified units.

1. Press the key to enter humidity mode (“hSP” will

appear on the CABINET TEMPERATURE display).

2. Press the key again to show the current humidity level.

3. Press the key or key to reach the desired humidity

level. Humidity range is 0 through 5 (0 is no humidity, 1 is the

lowest amount of humidity, and 5 is the highest). See the

“Food Holding Guide” in this section for recommendations.

Setting the Humidity Level

4. After the desired humidity level is set, wait 15 seconds

without pushing any keys for the cabinet temperature

display to return automatically to operational mode.

Setting the Air Temperature

NOTE: Temperature and humidity settings may vary depending

upon product make-up and consistency. The CABINET

TEMPERATURE display shows the lowest temperature

point inside the cabinet, not the product temperature.

The capacity of the water reservoir permits uninterrupted

operation for approximately five hours, depending on the

settings as well as how frequently the doors are opened. When

“LO H2O” is flashing on the CABINET TEMPERATURE display,

add water to the reservoir. The water reservoir refill capacity is

approximately six (6) quarts (5.7 liters). WARNING! ELECTRIC

SHOCK HAZARD—Do not overfill water reservoir.

Food Holding Guide

Type of Food

Biscuits 4 Hours 4 130 55

Chicken Pieces (Fried) 4 Hours 5 175 80

Croissants 4 Hours 1 140 60

Fruit Pies 3-1/2 Hours 4 140 60

Onion Rings 1/2 to 2 Hours 1 175 80

Pizza — Thick Crust

Thin Crust

Pretzels 3 Hours 4 140 60

Wrapped Sandwiches 2 Hours 4 180 82

Maximum

Holding Time

1 Hour

1 Hour

Humidity

Setting

4

5

Air Temperature Setting

°F °C

185

180

85

82

NOTE: All times and settings are recommendations only and may vary depending on product preparation, cooking time, and

internal food temperature.

10

Form No. FSCDM-1016

Loading...

Loading...