Page 1

HYDRO-HEATER

Food Rethermalizers/Hot Food Table Heater

FFR2 Series

Installation & Operating Manual &

Replacement Parts List

I&W #07.05.125.00

This manual contains important safety information

concerning the maintenance, use and operation

of this product. Failure to follow the instructions

contained in this manual may result in serious injury.

If you are unable to understand the contents of this

manual, please bring it to the attention of your

supervisor. Do not operate this equipment unless

you have read and understood the contents of

this manual.

Este manual contiene importante información sobre

seguridad concerniente al mantenimiento, uso

y operación de este producto. Cualquier falla en

el seguimiento de las instrucciones contenidas en

este manual puede resultar en un serio daño. Si usted

no puede entender el contenido de este manual por

favor pregunte a su supervisor. No opere este equipo

al menos que haya leído y comprendido el contenido

de este manual.

Page 2

i

INTRODUCTION

Falcon FFR2 Hydro-Heater Food Rethermalizers/Hot

Food Table Heaters are designed to supply temperaturecontrolled water to a holding vessel (sink or tank)

located above the heater. Water flows by natural

convection from the holding vessel directly into

a tubular water chamber with heating elements uniquely

wrapped on the outside of the flow tube. The heating

elements do not come in direct contact with the water

eliminating sediment and lime buildup on the element,

resulting in longer life. The heated water flows upward

and returns to the holding vessel. A special electronic

controller maintains the setpoint temperature assuring

a responsive and efficient operation.

The unit electrical and plumbing connections

are factory-assembled and ready for installation.

This manual provides the installation, safety

and operating instructions for the Hydro-Heater Food

Rethermalizers/Hot Food Table Heaters. We recommend

all installation, operating and safety instructions

appearing in this manual be read prior to installation

or operation of your Falcon Hydro-Heater. Safety

instructions that appear in this manual after a warning

symbol and the words WARNING or CAUTION

printed in bold face are very important.

WARNING means there is the possibility of serious

injury or death to yourself or others. CAUTION

means there is the possibility of minor or moderate

injury. CAUTION without the symbol signifies the

possibility of equipment or property damage only.

Falcon Hydro-Heaters are a product of extensive

research and field testing. The materials used were

selected for maximum durability, attractive appearance

and optimum performance. Every unit is thoroughly

inspected and tested prior to shipment.

CONTENTS

Important Owner Information.....................................i

Introduction ...................................................................i

Important Safety Instructions .....................................1

Model Descriptions .......................................................2

All Models ..............................................................2

FFR2 Models ..........................................................2

Units with Built-In Temperature Control................2

Units with Remote Temperature Control................2

Specifications.................................................................3

Electrical Rating Chart - FFR2 Models..................3

Sizing Information ..................................................4

Dimensions..............................................................4

Electrical .................................................................4

Installation.....................................................................5

Plumbing .................................................................5

Auto-Fill..................................................................6

Operation.......................................................................7

Start-Up Procedures ................................................7

Minutes to Heat Table.............................................8

Maintenance ..................................................................9

General ....................................................................9

Daily........................................................................9

Weekly...................................................................10

Deliming Instructions............................................10

Replacement Parts List ..............................................11

IMPORTANT OWNER INFORMATION

Record the model number, serial number (identification

plate located on the lower right hand side, front corner

of the unit), voltage and purchase date of your

Hydro-Heater in the spaces below. Please have this

information available when calling Falcon for service

assistance.

Model No. ____________________________________

Serial No. ____________________________________

Voltage ______________________________________

Date of Purchase ______________________________

Contact the Hatco Corporation for Service Assistance,

Replacement Parts and Warranty Information.

Phone: (800) 558-0607; (414) 671-6350

Fax: (800) 690-2966; (414) 671-3976

Additional information can be found by visiting our

web site at www.hatcocorp.com.

Form No. FFR2M-1103

Page 3

CAUTIONS

Water in the unit and holding vessel is very hot.

Wear protective gloves and proper attire when

operating to avoid injury.

Do not use extension pipes on the inlet and outlet

connections on heater units. Poor performance

or unsafe conditions may occur.

CAUTIONS

Do not overtighten unions or nuts. Overtightening

may cause leaks.

Do not turn the electrical current to the unit

on until the holding vessel has been filled with

water or element burnout may occur.

Inspect weekly for lime buildup inside unit.

Excessive amounts can affect unit performance

and reduce the operating life of the unit.

To avoid any damage to the heater unit

use only delimers that are non-corr

osive

to aluminum, brass and stainless steel. Damage

caused by corrosive material or solutions

is not covered under warranty.

Drain holding vessel with power to the unit off,

or element burnout may occur.

Water Quality Requirements - Incoming water

in excess of 3.0 grains of hardness per gallon

(GPG) (.75 grains of hardness per liter) must

be treated or softened before being supplied

to a Hydro-Heater. Water containing over

3.0 GPG (.75 GPL) will decrease the efficiency

and reduce the operating life of the unit.

IMPORTANT SAFETY INSTRUCTIONS

1

WARNINGS

Falcon FFR2 series units are designed

for commercial use only by properly trained

personnel!

To avoid any injury, turn the power switch

off at the fuse disconnect switch/circuit breaker

or unplug the unit from the power source

and allow to cool completely before performing

any maintenance or cleaning.

For proper electrical installation conforming

to local electrical codes, consult a licensed

electrical contractor.

Units are designed to heat water up to 190ºF

(88ºC). DO NOT set temperature controls

to a setting higher than 190ºF (88ºC).

For proper plumbing installation conforming

to local plumbing codes consult a licensed

plumbing contractor.

If service is required on this unit, contact your

Authorized Falcon Service Agent, or contact

the Falcon Service Department at 513-752-1894;

fax 513-752-1891.

This product has no “user” serviceable parts. To

avoid damage to the unit or injury to personnel,

use only Authorized Falcon Service Agents and

Genuine Falcon Parts when service is required.

Genuine Falcon Replacement Parts are specified

to operate safely in the environments in which

they are used. Some aftermarket or generic

replacement parts do not have the characteristics

that will allow them to operate safely in

Falcon equipment. It is essential to use

Falcon Replacement Parts when repairing Falcon

equipment. Failure to use Falcon Replacement

Parts may subject operators of the equipment

to hazardous electrical voltage, resulting

in electrical shock or burn.

Form No. Form No. FFR2M-1103

IMPORTANT! Read the following important safety instructions to avoid personal injury or death,

and to avoid damage to the equipment or property.

Page 4

MODEL DESCRIPTIONS

2

ALL MODELS

The Hydro-Heater mounts easily to the underside

of a holding vessel, leaving the entire vessel area free.

Units are shipped ready to install with all gaskets

and fittings. Hydro-Heaters include a stainless steel

front, powder coated body, a low-water cut-off system

and a convenient drain outlet.

FFR2 MODELS

The Falcon FFR2 model heaters are designed

to be used with a Bain-Marie or Food Rethermalizer

to heat or hold foods at temperatures between 140ºF

(60ºC) and 190ºF (88ºC). The desired holding

temperature is maintained by a special electronic

controller and “free flow”technology.

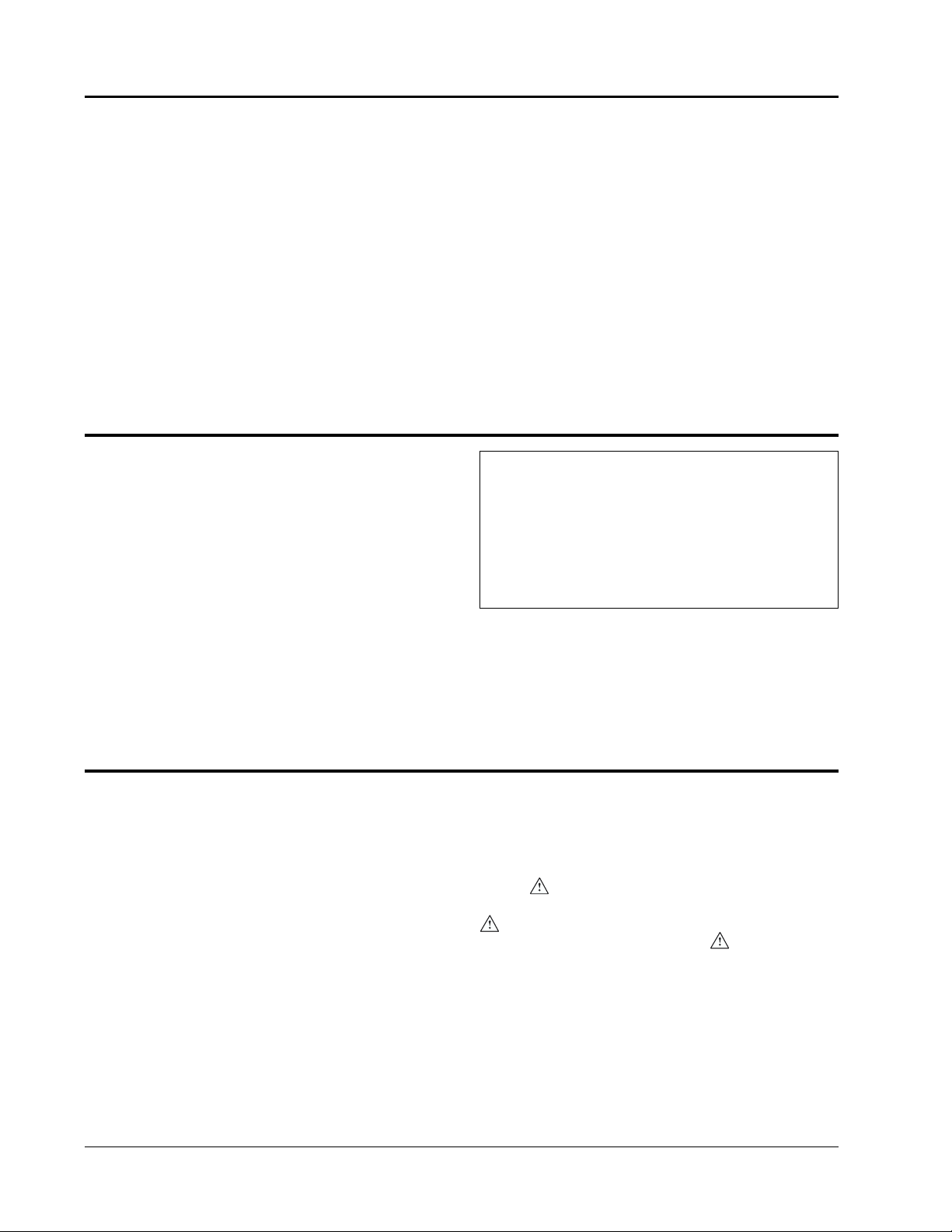

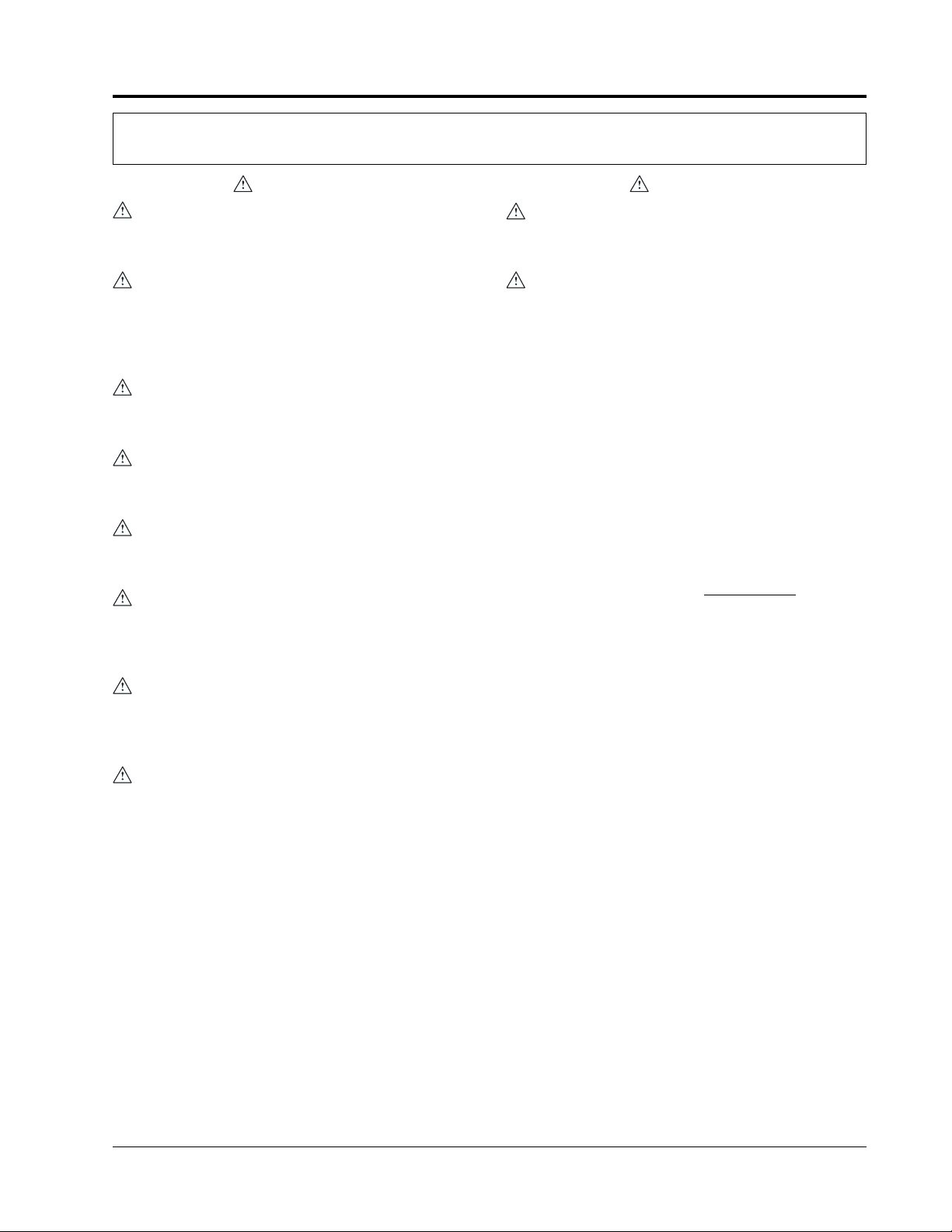

UNITS WITH BUILT-IN TEMPERATURE

CONTROL

Units with built-in electronic temperature controller

and display are excellent for installations where the unit

is easily accessible and viewing is not obstructed.

UNITS WITH REMOTE TEMPERATURE

CONTROL

Units supplied with remote electronic temperature

controller and display allow for easy operator

monitoring and temperature control.

Figure 1. Hydro-Heater

with Built-In Temperature Controller

Figure 2. Hydro-Heater

with Remote Electronic Controller

Form No.

Form No. FFR2M-1103

Page 5

SPECIFICATIONS

3

Form No. Form No. FFR2M-1103

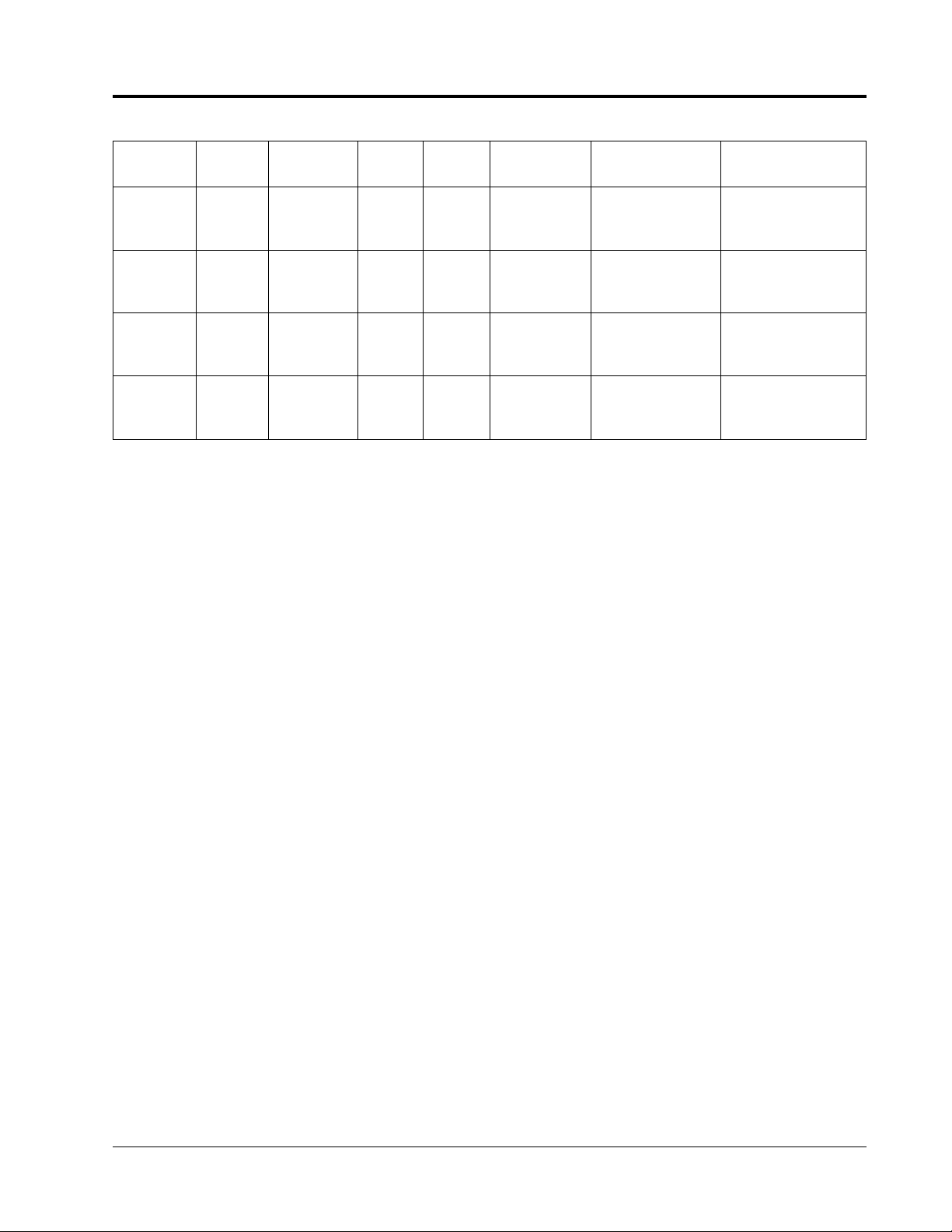

Kilowatts Wire Sizing Fuse or

Model Voltage (kW) Phase Amps AWG

*

†

Circuit Breaker

*

Shipping Weight

FFR2-3 208 3 1 14.5 14 20 24 lbs. (11 kg)

240 3 1 12.5 14 20 24 lbs. (11 kg)

FFR2-4 208 4 1 19.2 12 30 24 lbs. (11 kg)

240 4 1 16.7 12 30 24 lbs. (11 kg)

FFR2-6 208 6 3 16.7 12 30 27 lbs. (12 kg)

240 6 3 14.5 14 20 27 lbs. (12 kg)

FFR2-9 208 9 3 25.0 10 40 27 lbs. (12 kg)

240 9 3 21.7 10 30 27 lbs. (12 kg)

ELECTRICAL RATING CHART – FFR2 MODELS

NOTE: Models with “A” suffix equipped with auto-fill. Models with “R” suffix equipped with remote temperature

control. Models with “AR” suffix equipped with auto-fill and remote temperature control.

*

Based upon NEC 2002 Code

†

Based upon THHN wire rated 90ºC.

Page 6

SPECIFICATIONS

DIMENSIONS

A

C

B

ELECTRICAL

Install a fused disconnect switch or circuit breaker sized

according to the applicable Electrical Rating Chart.

The wiring from the switch or circuit breaker to the

Falcon unit must be in accordance with local electrical

requirements and codes.

WARNING

For proper electrical installation conforming

to local electrical codes, consult a licensed

electrical contractor.

Models come complete with all electrical wiring

and are equipped with three electrical knockouts, one

at the rear and one on each side towards the rear. When

performing installation, run electrical connections

through one of these knockouts.

NOTE: FFR2 Series units equipped with auto-fill have

two electrical knockouts; one at the rear and one

on the right, when facing control side.

NOTE: FFR2 Series units with remote electronic

controller require that the controller with 8 terminal

plug be connected to the 8 terminal receptacle located

on the front of the heater unit. Before mounting

controller, make sure it is located close enough

to the heater so the lead wires can be

properly connected.

4

Form No.

Form No. FFR2M-1103

Width (A) Depth (B) Height (C)

8-1/2" 17-1/8" 12-3/4"

(216 mm) (435 mm) (324 mm)

Figure 2. Dimensions

SIZING INFORMATION

Falcon recommends the following guidelines be used

to ensure proper operation and sanitation.

For FFR2 Series in a Bain-Marie or Steam Table

Application

• Minimum 750 watts (.75 kW) per square foot

(0.8 watts per sq. cm) of vessel top.

For FFR2 Series in a Food Rethermalizer

Application

• Minimum 2000 watts per square foot

(2.2 watts per sq. cm) of vessel top.

NOTE: Use the FFR2 unit for a vessel up to 6'

(1829 mm) long. Over 6' (1829 mm) minimum

two units required.

See the Minutes To Heat Table to determine the amount

of time required to heat water using a FFR2 series

in a Bain-Marie or Steam Table application.

Page 7

INSTALLATION

5

Form No. Form No. FFR2M-1103

PLUMBING

An adhesive backed paper template is shipped with

the unit and is used to locate the sink strainer holes.

Use the following procedure to install the heater unit

to the holding vessel.

NOTE: The FFR2 heater should be positioned with

no more than 3' (914 mm) on either side when mounted

under holding vessel. See Figure 4. A perforated water

baffle (not supplied with unit) must be used to distribute

the heated water properly.

NOTE: Use one FFR2 for a Hot Food Table

up to 6' (1829 mm) long. Over 6' (1829 mm) minimum

2 units required.

CAUTION

Do not use extension pipes on the inlet and outlet

connections on heater units. Poor performance

or unsafe conditions may occur.

1. Expose the adhesive back of the paper template

and stick the template on the bottom of the holding

vessel. Center the template with the words “Front

Cover” positioned against the front inside wall

of the vessel.

2. Center punch and drill a 3/4" (19 mm) pilot hole

at each of the two center marks on the template.

3. Remove the template and cut a 2" (51 mm) diameter

hole at each pilot hole location using a standard

#ATV1756 Greenlee cutter.

NOTE: If a #ATV1756 Greenlee cutter is not available,

use a standard Greenlee 1-1/2" conduit cutter

#500-6978, which is slightly under 2" (51 mm) diameter.

File or ream holes as necessary to 2" (51 mm) diameter

required for mounting sink strainers.

4. See Figure 5. In each of the holes, install a male

threaded sink strainer with a thin gasket between

the strainer flange and the bottom of the holding

vessel.

5. Install two thick gaskets at the underside

of the holding vessel along with a thin fiber gasket,

and secure finger tight with the nut.

6. Attach the heater to the strainers loosely with

the union nuts and 1-3/4" (45 mm) rubber gaskets.

NOTE: Make sure rubber gaskets are positioned inside

the union nuts and are not crimped.

3" (76 mm)

Thin rubber washer

Thick rubber

washers

(Qty. 2)

Thin fiber

washer

1/8" (3 mm)

offset

Sink or tank

Nut

Union nut

Union Gasket

Figure 5. Installing Sink Strainer

7. Tighten nuts on strainers securely.

8. Tighten union nuts securely.

9. Fill the holding vessel with water and check

for leaks.

CAUTION

Do not overtighten unions or nuts. Overtightening

may cause leaks.

NOTE: A 3/4" (19 mm) hose or pipe may be connected to the

heater sump drain and run to an open sight drain. The sump

drain should not be permanently connected to the sanitary

drain system. Check local plumbing code for proper drain

installation. See MAINTENANCE for more information.

Figure 4. Hydro-Heater Water Baffle

3'

3'

3/4" (19 mm) holes

around periphery on

6" (152 mm) centers

Dotted line

indicates the position of

perforated water baffle

3/4" (19 mm) high baffle

with divider wall between

inlet and outlet

(914 mm)

MAX

(

914 mm)

MAX

Page 8

INSTALLATION

6

Form No.

FFR2M-1103

CAUTION

Water Quality Requirements - Incoming water

in excess of 3.0 grains of hardness per gallon (GPG)

(.75 grains of hardness per liter) must be treated

or softened before being supplied to a

Hydro-Heater. Water containing over 3.0 GPG

(.75 GPL) will decrease the efficiency and reduce

the operating life of the unit.

AUTO-FILL

Units with the Auto-fill option require

the following

steps be completed before start-up.

WARNING

For proper plumbing installation conforming

to local plumbing codes consult a licensed

plumbing contractor.

1. Supply 1/4" NPT copper water supply line to inlet

of solenoid valve on heater.

NOTE: Ball valve or gate valve, line strainer, union(s)

and vacuum breaker or other anti-siphon device must

be supplied by table manufacturer or installer

if required.

2. Locate a point 2" (51 mm) up from the bottom

of the tank.

3. Mark and drill a 13/16" (21 mm) hole

into the sidewall of the tank.

4. Weld probe fitting (supplied) into sidewall of tank.

5. Install probe into tank using thread sealant.

6. Tighten until snug. Be careful not to overtighten nut.

Overtightening may cause leaks.

7. Turn on water and check for leaks.

8. Connect wire lead to probe.

Page 9

OPERATION

7

WARNINGS

Falcon FFR2 series units are designed for

commercial use only by properly trained personnel!

WARNINGS

Units are designed to heat water up to 190ºF (88ºC).

DO NOT set temperature controls to a setting higher

than 190ºF (88ºC).

CAUTION

Water in the unit and holding vessel is very hot.

Wear protective gloves and proper attire when

operating to avoid injury.

CAUTION

Do not turn the electrical current to the unit

on until the holding vessel has been filled with water

or element burnout may occur.

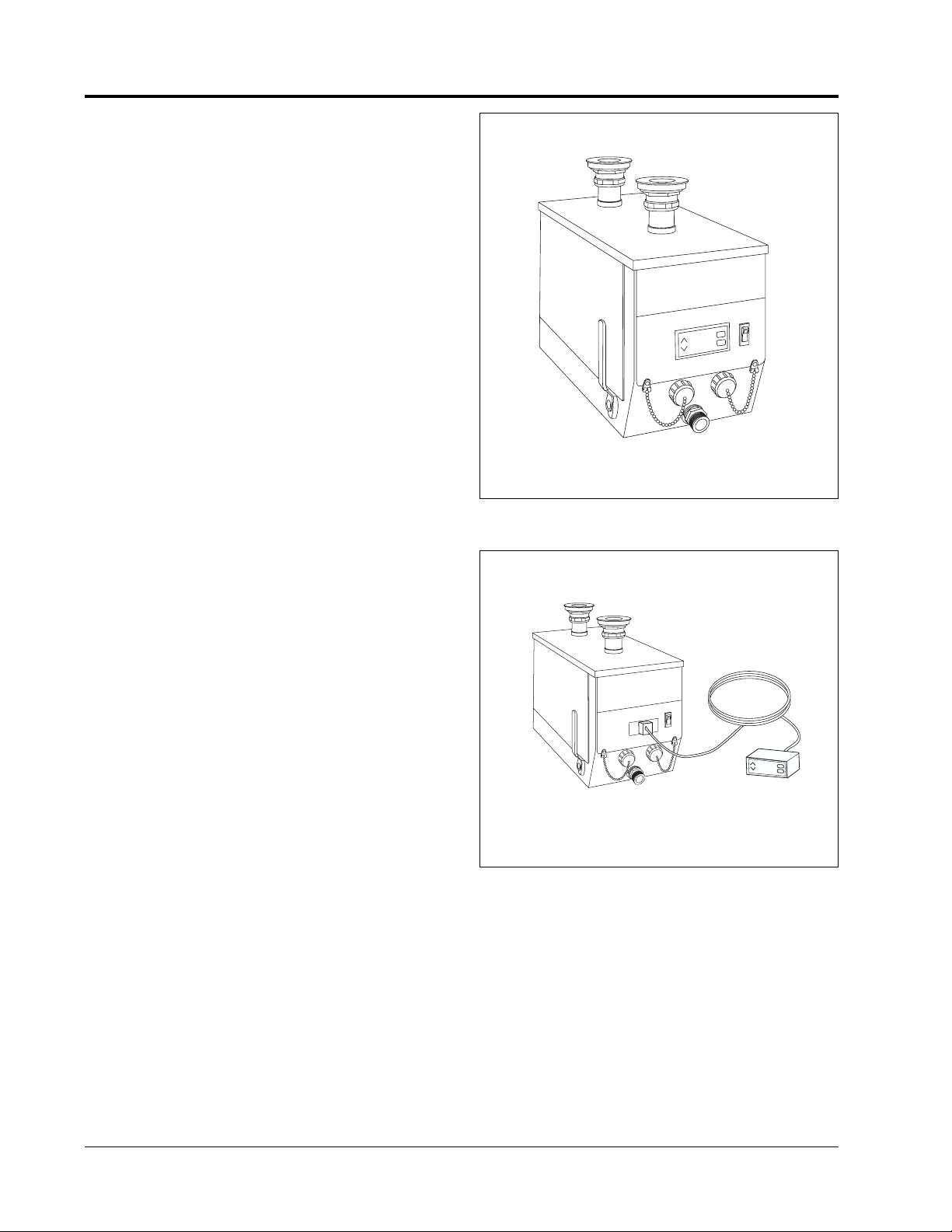

START-UP PROCEDURES

1. Make sure clean-out cap(s) (2-3 element units only)

are securely tightened. See Figure 6.

2. Close sump drain by moving handle all of the way

forward until it stops. See Figure 6.

3. Fill the holding vessel with hot tap water to normal

operating level.

4. Check that the fused disconnect switch or circuit

breaker is on, or if equipped with power cord

and plug make sure unit is plugged into proper

receptacle.

5. Turn power switch to ON position. The electronic

display will glow to indicate power is supplied.

6. To set the controller to the desired temperature press

“Set” button once; unit will display “SP1.”

See Figure 7.

7. Press “Set” button again; unit displays

current setpoint.

8. Press “Up” or “Down” arrow to change and display

desired setpoint.

9. Press “Set” button again until display goes blank.

After 5 seconds unit will display current operating

temperature.

NOTE: If steps 6-9 are interrupted or no changes

are made for 15 seconds the controller will go back

to its original setting without accepting the change.

Figure 7. Controller

Figure 6. Hydro-Heater Side View

Form No.

FFR2M-1103

SP1

Sump Drain Handle

(Closed)

Sump Drain Outlet

Power Switch

INLET

OUTLET

Clean-out Cap

(2- or 3-element

units only)

ADJUST

N

E

P

O

SP1

SET

Page 10

OPERATION

8

Water

Temp. At

Start-Up

Temperature °F (°C) Water Heated To:

Water

Temp. At

Start-Up

Temperature °F (°C) Water Heated To:

MINUTES TO HEAT TABLE

Form No. FFR2M-1103

9" (23 cm) DEEP WATER - 750 WATTS PER SQUARE FOOT OF VESSEL TOP

70 80 90 100 110 120 130 140 150 160 170 180

(21) (27) (32) (38) (43) (49) (54) (60) (66) (71) (77) (82)

60°F (16°C)

12 23 35 47 60 72 85 100 116 136 162 211

70°F (21°C) 12 24 36 49 61 74 89 105 125 151 200

80°F (27°C) 12 24 37 49 62 77 93 113 139 188

90°F (32°C) 12 25 34 50 65 85 101 127 176

100°F (38°C) 13 28 38 53 69 89 115 164

110°F (43°C) 12 25 40 56 66 102 151

120°F (48°C) 13 28 44 64 90 139

130°F (54°C) 15 31 51 77 126

140°F (60°C) 16 36 62 111

150°F (65°C) 20 46 95

160°F (71°C) 26 75

170°F (76°C) 49

6" (15 cm) DEEP WATER - 750 WATTS PER SQUARE FOOT OF VESSEL TOP

70 80 90 100 110 120 130 140 150 160 170 180

(21) (27) (32) (38) (43) (49) (54) (60) (66) (71) (77) (82)

60°F (16°C)

8 15 23 61 40 48 57 67 77 90 108 140

70°F (21°C) 8 16 24 33 40 49 59 70 83 100 133

80°F (27°C) 8 16 25334151 6275 92125

90°F (32°C) 8 17233343 5467 84117

100°F (38°C) 9 171535 4559 76109

110°F (43°C) 8 17 27 37 44 68 100

120°F (48°C) 9192942 6092

130°F (54°C) 10 21 34 51 84

140°F (60°C) 11 24 41 74

150°F (65°C) 13 31 63

160°F (71°C) 17 50

170°F (76°C) 33

Page 11

MAINTENANCE

9

GENERAL

WARNING

To avoid any injury, turn the power switch

off at the fuse disconnect switch/circuit breaker

or unplug the unit from the power source

and allow to cool completely before performing

any maintenance or cleaning.

Recommended Cleaning Schedule

Complete draining and cleaning should be done

• On a daily basis.

• Whenever food particles accumulate in the tank.

• Whenever a spill occurs.

• Whenever the unit is to be stored or shipped,

especially in freezing temperatures.

Helpful Hints

• Keep inlet and outlet free of debris.

• Keep false bottoms in place and free of debris.

• Delime unit using a non-corrosive deliming solution.

CAUTION

Inspect daily for lime buildup inside unit. Excessive

amounts can affect unit performance and reduce

the operating life of the unit.

DRAINING & CLEANING ALL MODELS

NOTE: The holding vessel should be drained through

its own drain valve to discharge debris and water that

remains in it.

CAUTION

Drain holding vessel with power to the unit off,

or element burnout may occur.

DAILY (See Figure 8)

1. Turn power switch to the OFF position.

2. Drain holding vessel to discharge visible water

and debris. Close drain when finished

3. Wipe visible deposits from the sink or tank.

4. Dissolve a safe, non-toxic, non-corrosive sanitizer

into 1 gallon (3.7 L) of hot water and pour into tank.

Refill the tank 1/2" (1 cm) above the false bottom

with hot water and soak for at least 15 minutes.

NOTE: Follow the sanitizers instructions for the proper

mixture of water and sanitizer.

5. Connect one end of a drain hose onto the sump drain

outlet with the other end in a bucket or open site

drain in a manner according to local plumbing codes.

6. To drain the unit open the sump drain valve by

moving the valve handle backwards until it

completely stops. Water will now flow from the

drain hose.

7. Thoroughly wash unit with fresh water until

discharge is clear and all sanitizers have been

removed and rinsed.

8. Close sump drain by moving handle all of the way

forward until it stops. See Figure 8.

9. Reinstall perforated water baffle/false bottom

in correct position.

10. Follow normal operation instructions.

Figure 8. Hydro-Heater Side View

Form No.

FFR2M-1103

Sump Drain Handle

(Closed)

Sump Drain Outlet

Power Switch

INLET

OUTLET

Clean-out Cap

(2- or 3-element

units only)

N

E

P

O

Page 12

WEEKLY (See Figure 8)

1. Turn power switch to the OFF position.

2. Drain holding vessel to discharge visible water

and debris.

3. Wipe visible deposits from the sink or tank.

4. Remove clean-out caps (2- or 3-element units only).

5. Inspect for lime and sediment build-up at the sump

drain outlet and heating element chamber outlets

(2 or 3 element units only have heating element

chamber outlets).

6. Remove any visible lime sediment or debris deposits

from the outlets using the cleaning brush supplied

with the unit, Falcon part number 03.40.060.00.

To remove, insert brush into the clean-out and sump

drain outlets and use a scrubbing motion until clean.

7. Remove brush and flush clean water through

the chambers until discharge is clear.

8. Reinstall clean-out caps removed in step 4.

9. Close all drains and fill with water before restarting.

DELIMING INSTRUCTIONS

CAUTION

Inspect weekly for lime buildup inside unit.

Excessive amounts can affect unit performance

and reduce the operating life of the unit.

NOTE: Product failure caused by liming or sediment

buildup is not covered under warranty.

CAUTION

To avoid any damage to the heater unit use only

delimers that are non-corr

osive to aluminum, brass

and stainless steel. Damage caused by corrosive

material or solutions is not covered under warranty.

The amount of lime and mineral content in the water

and how often the unit is operated will dictate how often

the unit needs to be delimed.

Units supplied with water that contains high lime and

mineral content may require deliming on a daily basis.

NOTE: The delimer used should be a safe, non-toxic,

non-corrosive solution. Follow the delimer’s

instructions.

In order to dissolve water scale, lime and rust deposits

from the heating chamber, thermostat probes and interior

surfaces of the unit, perform the following procedure:

MAINTENANCE

10

1. Disconnect power supply to heater at breaker

and turn power switch to OFF position.

2. Connect one end of a drain hose onto the sump

drain outlet with the other end in a bucket or open

site drain in a manner according to local

plumbing codes.

3. Open sump drain valve and drain all water.

4. When draining is finished, close sump drain valve.

5. Slowly add delimer and water mixture into heat tank

through sink strainer assemblies. Allow the unit

to stand with the mixture in the reservoir for the

recommended period of time.

NOTE: The time required will vary depending on the

solution used and amount of deposits in the reservoir.

6. After cleaning, drain all expended solution from

the unit through the sump drain.

7. Thoroughly wash heater tank with fresh water

for several minutes until discharge is clear and all

deliming solution has been removed and rinsed.

8. Close sump drain by moving handle all of the way

forward until it stops.

9. Follow normal operation instructions.

CAUTION

Do not turn the electrical current to the unit

on until the holding vessel has been filled with water

or element burnout may occur.

WARNING

If service is required on this unit, contact your

Authorized Falcon Service Agent, or contact

the Falcon Service Department at 513-752-1894;

fax 513-752-1891.

WARNING

This product has no “user” serviceable parts.

To avoid damage to the unit or injury to personnel,

use only Authorized Falcon Service Agents

and Genuine Falcon Parts when service is required.

WARNING

Genuine Falcon Replacement Parts are specified

to operate safely in the environments in which they

are used. Some aftermarket or generic replacement

parts do not have the characteristics that will allow

them to operate safely in Falcon equipment. It

is essential to use Falcon Replacement Parts when

repairing Falcon equipment. Failure to use Falcon

Replacement Parts may subject operators

of the equipment to hazardous electrical voltage,

resulting in electrical shock or burn.

Form No. FFR2M-1103

Page 13

REPLACEMENT PARTS LIST

11

Form No.

FFR2M-1103

FALCON FFR-2 Series

Food Rethermalizer/Bain Marie Heater

CAUTION - Use of replacement parts other

than those supplied by Falcon Corporation

may result in damage to the unit or injury

to personnel.

Model Designation

FFR2-XB

F = Falcon

F = Food

R = Rethermalizer

2 = 2nd Generation

X = Kilowatts

B = Balanced

Three-Phase

37

22

27

29

30

28

25

34

1

44

40

32

11

19

10

12

33

2

41

14

9

9

15

26

35

5

4

13

7

6

31

38

36

21

20

43

42

16

18

17

45

46

47

34

48

49

39

3

8

24

14

23

Page 14

12

Form No. FFR2M-1103

1 Temperature Probe 02.01.166.00 1

2 Probe, Low Water Cut Off 02.40.015.00 1

3 Ball Valve, Threaded 03.02.001.00 1

4 Ball Valve Handle 03.02.001B.00 1

5 Ball Valve, Hex Extension 03.02.029.00 1

6 Ball Valve, Stop Plate 03.02.030.00 1

7 3" (8 cm) Valve Extension 03.02.031.00 1

8 3/4" x 3/4" Brass Hex Nipple 03.05.057.00 1

9 O-Ring 03.40.059.00 2-6

10 Hose Clamp, S.S. 03.40.061.00 4

11 Inlet Hose 03.40.062F.00 1

12 Outlet Hose 03.40.062R.00 1

13 Rubber Gasket 05.06.006.00 1

14 Keps Nut 05.04.205.00 4

15 Rod, Threaded 05.04.419.00 2

16 Contactor - 3 Pole 02.01.167.00 1

17 Fuse, 2 Amp (2 per pack) R02.03.014.02 1

18 Fuse Block 02.03.022.00 1

19 Transformer, 208/240 - 24 Volt 02.17.046.00 1

20 On/Off Switch 02.19.081.00 1

21 Electronic Temperature

Controller 02.01.165R.00 1

22 Strainer Assembly with

Gaskets R05.30.009.00 2

23 Terminal Block - 3 Pole R02.15.035.00 1

24 Brass Hose Connector

with Shoulder 03.05.058.00 1

25 Cleaning Brush 03.40.060.00 1

26 Flush Hose Assembly 05.06.010.00 1

27 1-3/8" (4 cm) Rubber Stopper 05.06.026.00 1

28 Union Gasket 05.06.009.00 1

29 Strainer Gasket Kit! R00.05.0002.00 1

30 Brass Locknut 05.30.009A.00 2

31 Jacket, Black 04.06.220.00 1

32 Front Head Strap 04.06.223.00 2

33 Rear Head Strap 04.06.224.00 2

34 Side Panel, Black 04.06.222.00 2

35 Bottom Access Panel, Black 04.06.228.00 1

36 Front Control Panel 04.06.221.00 1

37 Top Assembly, S.S. 04.06.225.00 1

38 Drain Switch Kit R02.19.162.00 1

PARTS COMMON TO ALL FFR-2 MODELS

ITEM DESCRIPTION PART NO. QTY.

REPLACEMENT PARTS LIST

Note: S.S. is an abbreviation for stainless steel.

! Includes all gaskets for both strainers.

Page 15

PARTS SPECIFIC TO MODEL FFR2-3

ITEM DESCRIPTION

13

Form No. FFR2M-1103

REPLACEMENT PARTS LIST

240V with

Built-In

Electronic

Controller

240V with

Remote

Electronic

Controller

240V with

Built-In

Electronic

Controller

& Autofill

240V with

Remote

Electronic

Controller

& Autofill

208V with

Remote

Electronic

Controller

& Autofill

208V with

Remote

Electronic

Controller

208V with

Built-In

Electronic

Controller

208V with

Built-In

Electronic

Controller

& Autofill

R02.06.003F.00

03.17.001.00

03.17.002.00

---

---

---

02.01.212.00

---

---

---

---

HS1-5357

R02.06.003F.00

03.17.001.00

03.17.002.00

---

---

---

02.01.212.00

02.20.112.00

R02.18.133.00

---

---

10.01.043.00

R02.06.003F.00

03.17.001.00

03.17.002.00

---

---

---

02.01.121.00

---

---

02.40.001.00

03.02.033.00

10.01.044.00

R02.06.003F.00

03.17.001.00

03.17.002.00

---

---

---

02.01.121.00

02.20.112.00

R02.18.133.00

02.40.001.00

03.02.033.00

10.01.045.00

R02.06.001F.00

03.17.001.00

03.17.002.00

---

---

---

02.01.212.00

---

---

---

---

HS1-5357

R02.06.001F.00

03.17.001.00

03.17.002.00

---

---

---

02.01.212.00

02.20.112.00

R02.18.133.00

---

---

10.01.043.00

R02.06.001F.00

03.17.001.00

03.17.002.00

---

---

---

02.01.121.00

---

---

02.40.001.00

03.02.033.00

10.01.044.00

R02.06.001F.00

03.17.001.00

03.17.002.00

---

---

---

02.01.121.00

02.20.112.00

R02.18.133.00

02.40.001.00

03.02.033.00

10.01.045.00

39 Heating Element (Qty. 1)

40 Front Head

41 Rear Head

42 Cap, Clean Out

43 Gasket, Cap

44 Pipe, Clean Out

45 Low Water Cutt Off Board

46 8 Terminal Receptacle

47 Cable with Male Plug

48 Probe, Upper

49 Solenoid Valve

Electrical Diagram

PARTS SPECIFIC TO MODEL FFR2-4

ITEM DESCRIPTION

240V with

Built-In

Electronic

Controller

240V with

Remote

Electronic

Controller

240V with

Built-In

Electronic

Controller

& Autofill

240V with

Remote

Electronic

Controller

& Autofill

208V with

Remote

Electronic

Controller

& Autofill

208V with

Remote

Electronic

Controller

208V with

Built-In

Electronic

Controller

208V with

Built-In

Electronic

Controller

& Autofill

R02.06.004F.00

03.17.001.00

03.17.002.00

---

---

---

02.01.212.00

---

---

---

---

HS1-5357

R02.06.004F.00

03.17.001.00

03.17.002.00

---

---

---

02.01.212.00

02.20.112.00

R02.18.133.00

---

---

10.01.043.00

R02.06.004F.00

03.17.001.00

03.17.002.00

---

---

---

02.01.121.00

---

---

02.40.001.00

03.02.033.00

10.01.044.00

R02.06.004F.00

03.17.001.00

03.17.002.00

---

---

---

02.01.121.00

02.20.112.00

R02.18.133.00

02.40.001.00

03.02.033.00

10.01.045.00

R02.06.003F.00

03.17.001.00

03.17.002.00

---

---

---

02.01.212.00

---

---

---

---

HS1-5357

R02.06.003F.00

03.17.001.00

03.17.002.00

---

---

---

02.01.212.00

02.20.112.00

R02.18.133.00

---

---

10.01.043.00

R02.06.003F.00

03.17.001.00

03.17.002.00

---

---

---

02.01.121.00

---

---

02.40.001.00

03.02.033.00

10.01.044.00

R02.06.003F.00

03.17.001.00

03.17.002.00

---

---

---

02.01.121.00

02.20.112.00

R02.18.133.00

02.40.001.00

03.02.033.00

10.01.045.00

39 Heating Element (Qty. 1)

40 Front Head

41 Rear Head

42 Cap, Clean Out

43 Gasket, Cap

44 Pipe, Clean Out

45 Low Water Cutt Off Board

46 8 Terminal Receptacle

47 Cable with Male Plug

48 Probe, Upper

49 Solenoid Valve

Electrical Diagram

Page 16

14

Form No. FFR2M-1103

PARTS SPECIFIC TO MODEL FFR2-6

ITEM DESCRIPTION

240V with

Built-In

Electronic

Controller

240V with

Remote

Electronic

Controller

240V with

Built-In

Electronic

Controller

& Autofill

240V with

Remote

Electronic

Controller

& Autofill

208V with

Remote

Electronic

Controller

& Autofill

208V with

Remote

Electronic

Controller

208V with

Built-In

Electronic

Controller

208V with

Built-In

Electronic

Controller

& Autofill

R02.06.004F.00

03.17.003.00

03.17.004.00

03.40.063.00

05.06.066.00

03.11.013.00

02.01.212.00

---

---

---

---

HS1-5378

R02.06.004F.00

03.17.003.00

03.17.004.00

03.40.063.00

05.06.066.00

03.11.013.00

02.01.212.00

02.20.112.00

R02.18.133.00

---

---

10.01.046.00

R02.06.004F.00

03.17.003.00

03.17.004.00

03.40.063.00

05.06.066.00

03.11.013.00

02.01.121.00

---

---

02.40.001.00

03.02.033.00

10.01.047.00

R02.06.004F.00

03.17.003.00

03.17.004.00

03.40.063.00

05.06.066.00

03.11.013.00

02.01.121.00

02.20.112.00

R02.18.133.00

02.40.001.00

03.02.033.00

10.01.048.00

R02.06.003F.00

03.17.003.00

03.17.004.00

03.40.063.00

05.06.066.00

03.11.013.00

02.01.212.00

---

---

---

---

HS1-5378

R02.06.003F.00

03.17.003.00

03.17.004.00

03.40.063.00

05.06.066.00

03.11.013.00

02.01.212.00

02.20.112.00

R02.18.133.00

---

---

10.01.046.00

R02.06.003F.00

03.17.003.00

03.17.004.00

03.40.063.00

05.06.066.00

03.11.013.00

02.01.121.00

---

---

02.40.001.00

03.02.033.00

10.01.047.00

R02.06.003F.00

03.17.003.00

03.17.004.00

03.40.063.00

05.06.066.00

03.11.013.00

02.01.121.00

02.20.112.00

R02.18.133.00

02.40.001.00

03.02.033.00

10.01.048.00

39 Heating Element (Qty. 3)

40 Front Head

41 Rear Head

42 Cap, Clean Out

43 Gasket, Cap

44 Pipe, Clean Out

45 Low Water Cutt Off Board

46 8 Terminal Receptacle

47 Cable with Male Plug

48 Probe, Upper

49 Solenoid Valve

Electrical Diagram

PARTS SPECIFIC TO MODEL FFR2-9

ITEM DESCRIPTION

240V with

Built-In

Electronic

Controller

240V with

Remote

Electronic

Controller

240V with

Built-In

Electronic

Controller

& Autofill

240V with

Remote

Electronic

Controller

& Autofill

208V with

Remote

Electronic

Controller

& Autofill

208V with

Remote

Electronic

Controller

208V with

Built-In

Electronic

Controller

208V with

Built-In

Electronic

Controller

& Autofill

R02.06.003F.00

03.17.003.00

03.17.004.00

03.40.063.00

05.06.066.00

03.11.013.00

02.01.212.00

---

---

---

---

HS1-5379

R02.06.003F.00

03.17.003.00

03.17.004.00

03.40.063.00

05.06.066.00

03.11.013.00

02.01.212.00

02.20.112.00

R02.18.133.00

---

---

10.01.049.00

R02.06.003F.00

03.17.003.00

03.17.004.00

03.40.063.00

05.06.066.00

03.11.013.00

02.01.121.00

---

---

02.40.001.00

03.02.033.00

10.01.050.00

R02.06.003F.00

03.17.003.00

03.17.004.00

03.40.063.00

05.06.066.00

03.11.013.00

02.01.121.00

02.20.112.00

R02.18.133.00

02.40.001.00

03.02.033.00

10.01.051.00

R02.06.001F.00

03.17.003.00

03.17.004.00

03.40.063.00

05.06.066.00

03.11.013.00

02.01.212.00

---

---

---

---

HS1-5379

R02.06.001F.00

03.17.003.00

03.17.004.00

03.40.063.00

05.06.066.00

03.11.013.00

02.01.212.00

02.20.112.00

R02.18.133.00

---

---

10.01.049.00

R02.06.001F.00

03.17.003.00

03.17.004.00

03.40.063.00

05.06.066.00

03.11.013.00

02.01.121.00

---

---

02.40.001.00

03.02.033.00

10.01.050.00

R02.06.001F.00

03.17.003.00

03.17.004.00

03.40.063.00

05.06.066.00

03.11.013.00

02.01.121.00

02.20.112.00

R02.18.133.00

02.40.001.00

03.02.033.00

10.01.051.00

39 Heating Element (Qty. 3)

40 Front Head

41 Rear Head

42 Cap, Clean Out

43 Gasket, Cap

44 Pipe, Clean Out

45 Low Water Cutt Off Board

46 8 Terminal Receptacle

47 Cable with Male Plug

48 Probe, Upper

49 Solenoid Valve

Electrical Diagram

REPLACEMENT PARTS LIST

Loading...

Loading...