Page 1

WARNING

Register Online!

www.hatcocorp.com

ATENÇÃO

(see page 2)

Registre-se Online!

(veja na página 18)

®

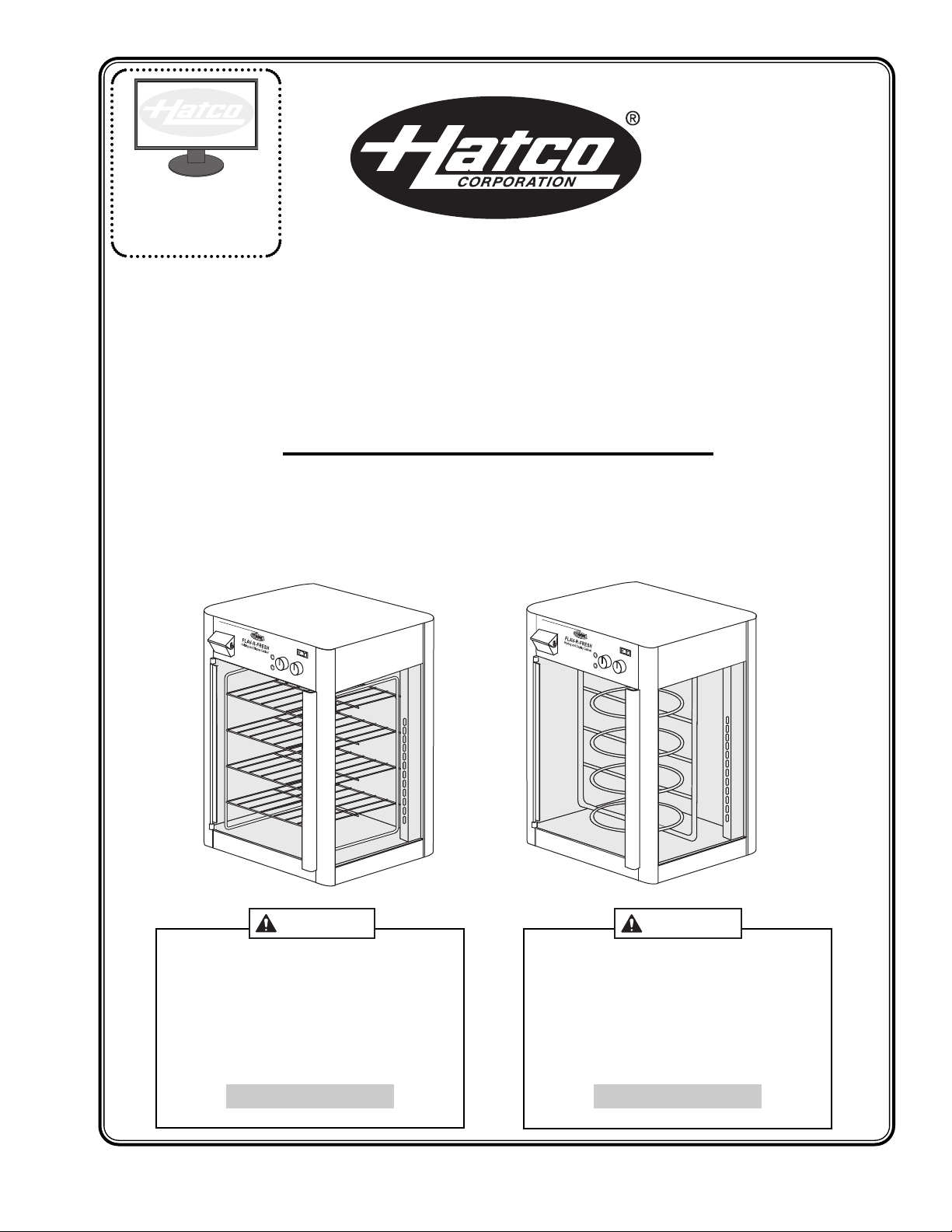

FLAV-R-FRESH

Humidified Impulse Display Cabinets

Vitrines Umidificadas Impulse

FDWDE Series/Séries

Installation and Operating Manual

Manual de Instalação e Operação

P/N 07.04.424.00

Do not operate this equipment unless you have read

and understood the contents of this manual! Failure

to follow the instructions contained in this manual

may result in serious injury or death. This manual

contains important safety information concerning

the maintenance, use, and operation of this product.

If you’re unable to understand the contents of this

manual, please bring it to the attention of your

supervisor. Keep this manual in a safe location for

future reference.

English = p 2

Não opere este equipamento antes de ter lido e

compreendido o conteúdo deste manual! Não

seguir as instruções deste manual pode resultar em

ferimentos graves ou morte. Este manual contém

informações importantes de segurança relativas à

manutenção, uso e operação deste produto. Caso

você não consiga entender o conteúdo deste

manual, leve ao conhecimento de seu supervisor.

Mantenha este manual em lugar seguro para futuras

consultas.

Português = p 18

© 2013 Hatco Corporation

Page 2

NOTICE

CAUTION

WARNING

24 Hour 7 Day Parts and Service

Assistance available in the United States

and Canada by calling 800-558-0607.

CONTENTS

English

Important Owner Information ..............................................2

Introduction...........................................................................2

Important Safety Information...............................................3

Model Description.................................................................4

Model Designation................................................................4

Specifications........................................................................5

Plug Configurations ............................................................5

Electrical Rating Chart........................................................5

Dimensions.........................................................................6

Installation.............................................................................7

General...............................................................................7

Reversing the Access Door................................................8

Relocation the Proximity Switch .........................................9

IMPORTANT OWNER INFORMATION

Record the model number, serial number, voltage, and

purchase date of the unit in the spaces below (specification

label located on the ceiling sheet inside of the unit). Please

have this information available when calling Hatco for service

assistance.

Model No. ________________________________________

Serial No. ________________________________________

Voltage __________________________________________

Date of Purchase __________________________________

Operation.............................................................................10

General.............................................................................10

Food Holding Guide..........................................................11

Maintenance ........................................................................11

General .............................................................................11

Daily Cleaning...................................................................11

Removing the Glass Panels .............................................12

Removing the Rotating Rack............................................12

Draining the Water Reservoir ...........................................12

Removing Lime and Mineral Deposits..............................13

Replacing a Display Light.................................................13

Troubleshooting Guide ......................................................14

Options and Accessories...................................................15

Limited Warranty.................................................................17

Service Information ............................................................17

Authorized Parts Distributors..............................Back Page

Business

Hours: 8:00

Telephone: 800-558-0607; 414-671-6350

e-mail: partsandservice@hatcocorp.com

Fax: 800-690-2966 (Parts and Service)

AM to 5:00 PM Central Standard Time (CST)

(Summer Hours: June to September—

8:00

AM to 5:00 PM CST Monday–Thursday

8:00

AM to 2:30 PM CST Friday)

414-671-3976 (International)

Register your unit!

Completing online warranty registration will prevent delay in

obtaining warranty coverage. Access the Hatco website at

www.hatcocorp.com, select the Parts & Service pull-down

menu, and click on “Warranty Registration”.

INTRODUCTION

Hatco Flav-R-Fresh®Humidified Impulse Display Cabinets are

designed to hold prepared foods for prolonged periods of time

while maintaining that “just-made” quality. Hatco Humidified

Impulse Display Cabinets provide the best environment for food

products by regulating the air temperature while at the same

time balancing the humidity level. The use of controlled,

moisturized heat maintains serving temperature and food

texture longer than conventional dry holding equipment.

The Flav-R-Fresh air flow pattern is designed to maintain

consistent cabinet temperature without drying out foods. The

precise combination of heat and humidity creates a “blanket”

effect around the food. The air flow rate enables the cabinet to

recover temperature rapidly after opening and closing the door.

Hatco Flav-R-Fresh Humidified Impulse Display Cabinets are

products of extensive research and field testing. The materials

used were selected for maximum durability, attractive

appearance and optimum performance. Every unit is inspected

and tested thoroughly prior to shipment.

Additional information can be found by visiting our web site at

www.hatcocorp.com.

tin

a

r

e

p

o

d

n

ty, a

fe

, sa

n

tio

lla

sta

s in

e

vid

o

r

l p

a

u

n

is ma

Th

in

C

sa

installation or operation of the unit.

Safety information that appears in this manual is identified by

the following signal word panels:

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

str

a

b

fe

ctio

u

e

in

ty in

n

ts. H

str

Fla

r

fo

s

r

tco

a

s a

n

ctio

u

Fr

-

R

v-

mme

co

e

in

r

a

e

p

p

u

H

sh

e

ll in

s a

d

n

th

in

g

mid

sta

is ma

ifie

lla

d

tio

u

n

a

Imp

n

l b

, o

lse

u

r

e

p

a

e

r

e

la

isp

D

n

, a

g

tin

a

to

r

io

r

p

d

g

y

d

NOTICE is used to address practices not related to

personal injury.

2

Form No. FDWDEM-0313

Page 3

NOTICE

CAUTION

WARNING

WARNING

English

IMPORTANT SAFETY INFORMATION

Read the following important safety information before using this equipment to avoid

serious injury or death and to avoid damage to equipment or property.

ELECTRIC SHOCK HAZARD:

• Plug unit into a properly grounded electrical receptacle

of the correct voltage, size, and plug configuration. If

plug and receptacle do not match, contact a qualified

electrician to determine and install the proper voltage

and size electrical receptacle.

• Turn OFF power switch, unplug power cord, and allow

unit to cool before performing any cleaning,

adjustments, or maintenance.

• Unit is not weatherproof. Locate unit indoors where

ambient air temperature is a minimum of 70°F (21°C).

• DO NOT submerge or saturate with water. Unit is not

waterproof. Do not operate if unit has been submerged

or saturated with water.

• Do not steam clean or use excessive water on unit.

• Turn OFF power switch and allow unit to cool before

draining water reservoir.

• Do not pull unit by power cord.

• Discontinue use if power cord is frayed or worn.

• Do not attempt to repair or replace a damaged power

cord. The cord must be replaced by Hatco, an

Authorized Hatco Service Agent, or a person with

similar qualifications.

• This unit must be serviced by qualified personnel only.

Service by unqualified personnel may lead to electric

shock or burn.

• Do not overfill water reservoir. Overfilling can cause

electrical shock. Water reservoir is full when LOW

WATER indicator light turns off.

• Use only Genuine Hatco Replacement Parts when

service is required. Failure to use Genuine Hatco

Replacement Parts will void all warranties and may

subject operators of the equipment to hazardous

electrical voltage, resulting in electrical shock or burn.

Genuine Hatco Replacement Parts are specified to

operate safely in the environments in which they are

used. Some aftermarket or generic replacement parts

do not have the characteristics that will allow them to

operate safely in Hatco equipment.

FIRE HAZARD: Locate unit a minimum of 1″ (25 mm) from

combustible walls and materials. If safe distances are not

maintained, discoloration or combustion could occur.

Use only light bulbs that meet or exceed National

Sanitation Foundation (NSF) standards and are specifically

designed for food holding areas. Breakage of light bulbs

not specially-coated could result in personal injury and/or

food contamination.

Make sure all operators have been instructed on the safe

and proper use of the unit.

This unit is not intended for use by children or persons

with reduced physical, sensory, or mental capabilities.

Ensure proper supervision of children and keep them away

from the unit.

Make sure food product has been heated to the proper

food-safe temperature before placing in unit. Failure to heat

food product properly may result in serious health risks.

This unit is for holding pre-heated food product only.

Hatco Corporation is not responsible for the actual food

product serving temperature. It is the responsibility of the

user to ensure that the food product is held and served at

a safe temperature.

This unit has no “user-serviceable” parts. If service is

required on this unit, contact an Authorized Hatco Service

Agent or contact the Hatco Service Department at

800-558-0607 or 414-671-6350; fax 800-690-2966; or

International fax 414-671-3976.

BURN HAZARD: Some exterior surfaces on the unit will get

hot. Use caution when touching these areas.

Locate unit at proper counter height in an area that is

convenient for use. Location should be level to prevent unit

or its contents from falling accidentally and strong enough

to support weight of unit and contents.

Transport unit in upright position only. Before moving or

tipping unit, secure all glass surfaces with tape and drain

water from humidified units. Failure to do so may result in

personal injury and damage to unit.

Use non-abrasive cleaners and cloths only. Abrasive cleaners and cloths could scratch finish of unit, marring its appearance and making it susceptible to soil accumulation.

Clean unit daily to avoid malfunctions and maintain

sanitary operation.

Do not lay unit on the side with control panel. Damage to

unit could occur.

Use of distilled water in water reservoir of humidified units

is recommended to preserve the life of electrical and

mechanical components. If non-distilled water is used,

reservoir will require periodic cleaning and deliming (refer

to MAINTENANCE section for cleaning procedure). Unit

failure due to lime or mineral deposits is not covered under

warranty.

Do not use deionized water. Deionized water will shorten

life of water pan and heating element.

Form No. FDWDEM-0313

3

Page 4

MODEL DESCRIPTION

F D W D E - 1 X

Flav-R-Fresh

Warmer

Display

Designer

Econoline

Door Quantity

No Motorized

Rack Rotation

English

All Models

All Flav-R-Fresh®Humidified Impulse Display Cabinets have an

air heating system, humidity system with low water control

protection, incandescent lamps, tempered glass sides, and a

door. The standard access door can be hinged left or right. The

pretzel tree display rack is stainless steel and the other display

racks are nickel-plated. All units are available in several

Designer colors.

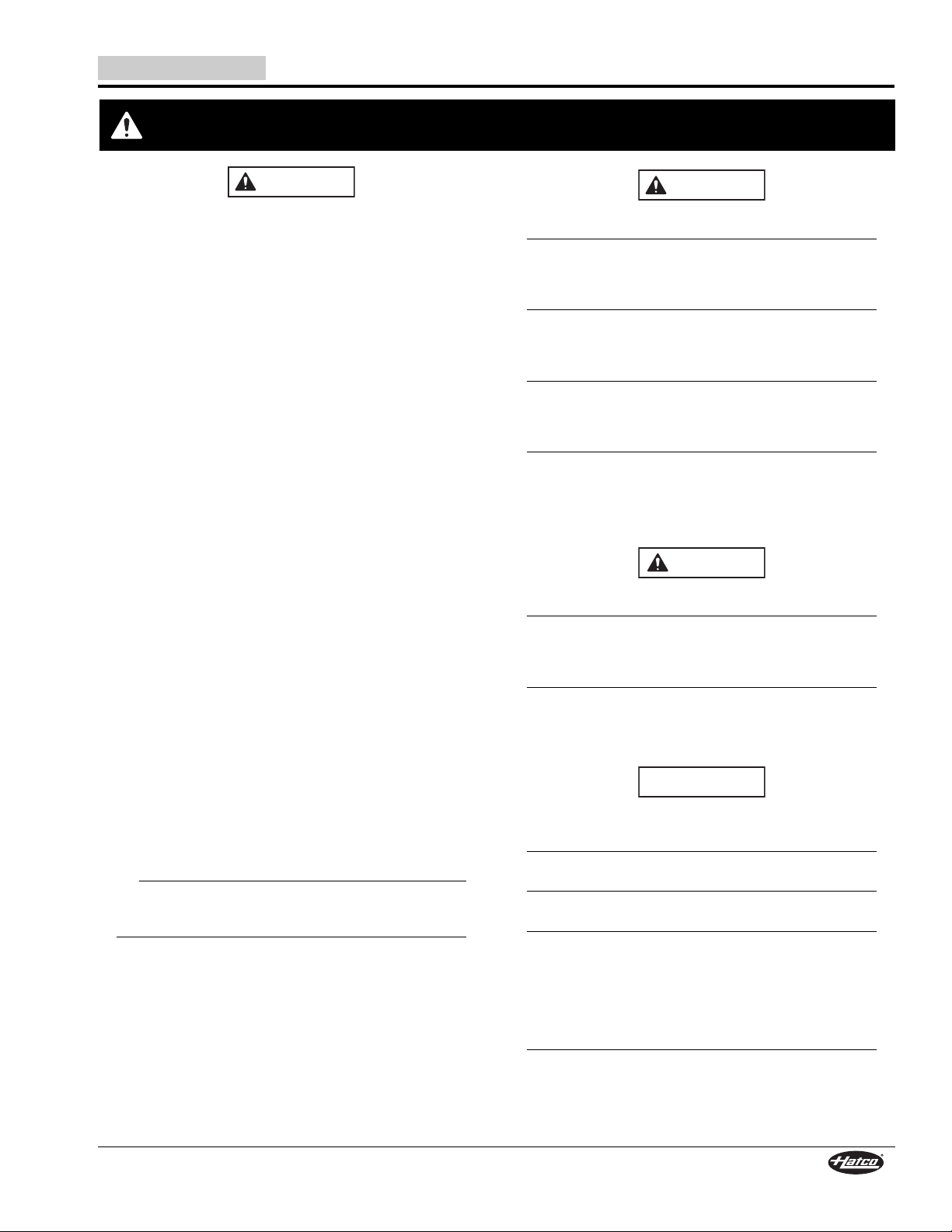

Model FDWDE-1

Model FDWDE-1 is a single door model with a motorized

rotating display. It comes standard with a pizza rack that holds

up to four (4) round pizza pans with a maximum diameter of 15″

(381 mm). The rotating rack stops automatically when the door

is opened. An optional rotating pretzel tree or a 4-shelf multipurpose stationary rack is also available.

Model FDWDE-1X

Model FDWDE-1X is similar to the FDWDE-1, but features a

4-shelf, multi-purpose stationary rack instead of the rotating

display. The rack can hold pans with a maximum width of 13″

(330 mm) and a depth of 18″ (457 mm).

NOTE: A FDWDE-1X model cannot be converted to FDWDE-1,

FDWDE-2, or FDWDE-2X models.

Model FDWDE-2X

Model FDWDE-2X is similar to the FDWDE-2, but features a 4shelf, multi-purpose stationary rack instead of the rotating

display. The rack can hold pans with a maximum width of 13″

(330 mm) and a depth of 18″ (457 mm).

NOTE: A FDWDE-1 model cannot be converted to FDWDE-2

Model FDWDE-2

Model FDWDE-2 has the same features as the FDWDE-1, but

includes an additional door on the opposite side of the controls

for pass-through convenience.

NOTE: A FDWDE-2 model cannot be converted to FDWDE-1

MODEL DESIGNATION

FDWDE-1

or FDWDE-2X models.

or FDWDE-1X models.

FDWDE-1X

NOTE: A FDWDE-2X model cannot be converted to FDWDE-1,

NOTE: Refer to the OPTIONS AND ACCESSORIES section

4

FDWDE-1X, or FDWDE-2 models.

in this manual for additional options available for the

above models.

Form No. FDWDEM-0313

Page 5

English

WARNING

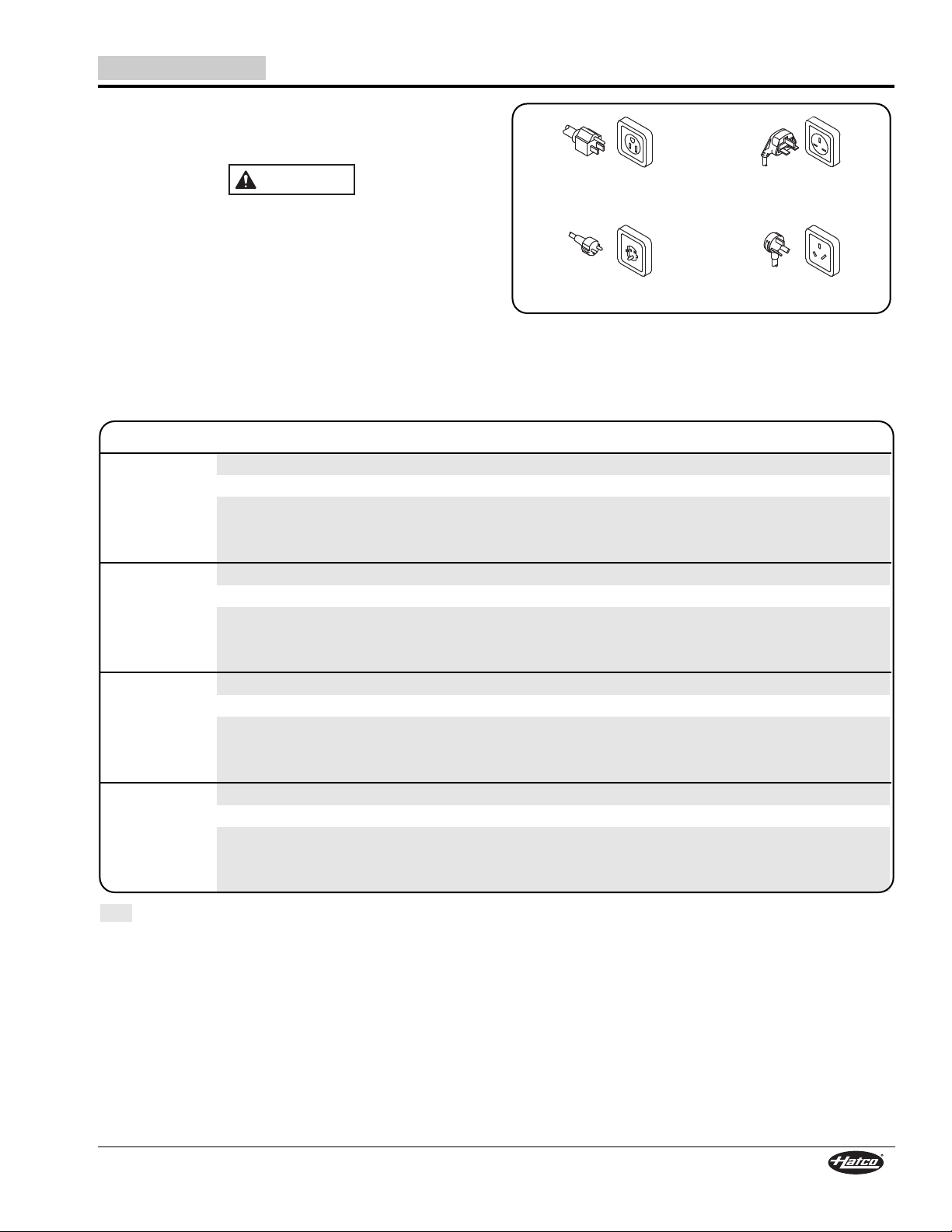

NEMA 5-15P

CEE 7/7 Schuko AS 3112

BS-1363

SPECIFICATIONS

Plug Configurations

Units are supplied from the factory with an electrical cord and

plug installed. Plugs are supplied according to the applications.

ELECTRIC SHOCK HAZARD: Plug unit into a properly

grounded electrical receptacle of the correct voltage, size,

and plug configuration. If plug and receptacle do not

match, contact a qualified electrician to determine and

install the proper voltage and size electrical receptacle.

NOTE: Specification label is located on the ceiling sheet inside

of the unit. See label for serial number and verification

of unit electrical information.

Plug Configurations

NOTE: Receptacle not supplied by Hatco.

Electrical Rating Chart

Model Voltage Watts Amps Plug Configuration Shipping Weight

FDWDE-1 100 1440 14.4 NEMA 5-15P 92 lbs. (42 kg)

(with humidity) 120 1420 11.8 NEMA 5-15P 92 lbs. (42 kg)

220 1470 6.7 CEE 7/7 Schuko or BS-1363 92 lbs. (42 kg)

220-230 1470-1607 6.7-7.0 CEE 7/7 Schuko 92 lbs. (42 kg)

230-240 1350-1470 5.9-6.1 BS-1363 or AS 3112 92 lbs. (42 kg)

FDWDE-1 100 1115 11.2 NEMA 5-15P 92 lbs. (42 kg)

(no humidity) 120 1095 9.1 NEMA 5-15P 92 lbs. (42 kg)

220 1145 5.2 CEE 7/7 Schuko or BS-1363 92 lbs. (42 kg)

220-230 1145-1251 5.2-5.4 CEE 7/7 Schuko 92 lbs. (42 kg)

230-240 1052-1145 4.6-4.8 BS-1363 or AS 3112 92 lbs. (42 kg)

FDWDE-2 100 1440 14.4 NEMA 5-15P 90 lbs. (41 kg)

(with humidity) 120 1420 11.8 NEMA 5-15P 90 lbs. (41 kg)

220 1470 6.7 CEE 7/7 Schuko or BS-1363 90 lbs. (41 kg)

220-230 1470-1607 6.7-7.0 CEE 7/7 Schuko 90 lbs. (41 kg)

230-240 1350-1470 5.9-6.1 BS-1363 or AS 3112 90 lbs. (41 kg)

FDWDE-2 100 1115 11.2 NEMA 5-15P 90 lbs. (41 kg)

(no humidity) 120 1095 9.1 NEMA 5-15P 90 lbs. (41 kg)

220 1145 5.2 CEE 7/7 Schuko or BS-1363 90 lbs. (41 kg)

220-230 1145-1251 5.2-5.4 CEE 7/7 Schuko 92 lbs. (42 kg)

230-240 1052-1145 4.6-4.8 BS-1363 or AS 3112 92 lbs. (42 kg)

The shaded areas contain electrical information for International models only.

Form No. FDWDEM-0313

5

Page 6

C

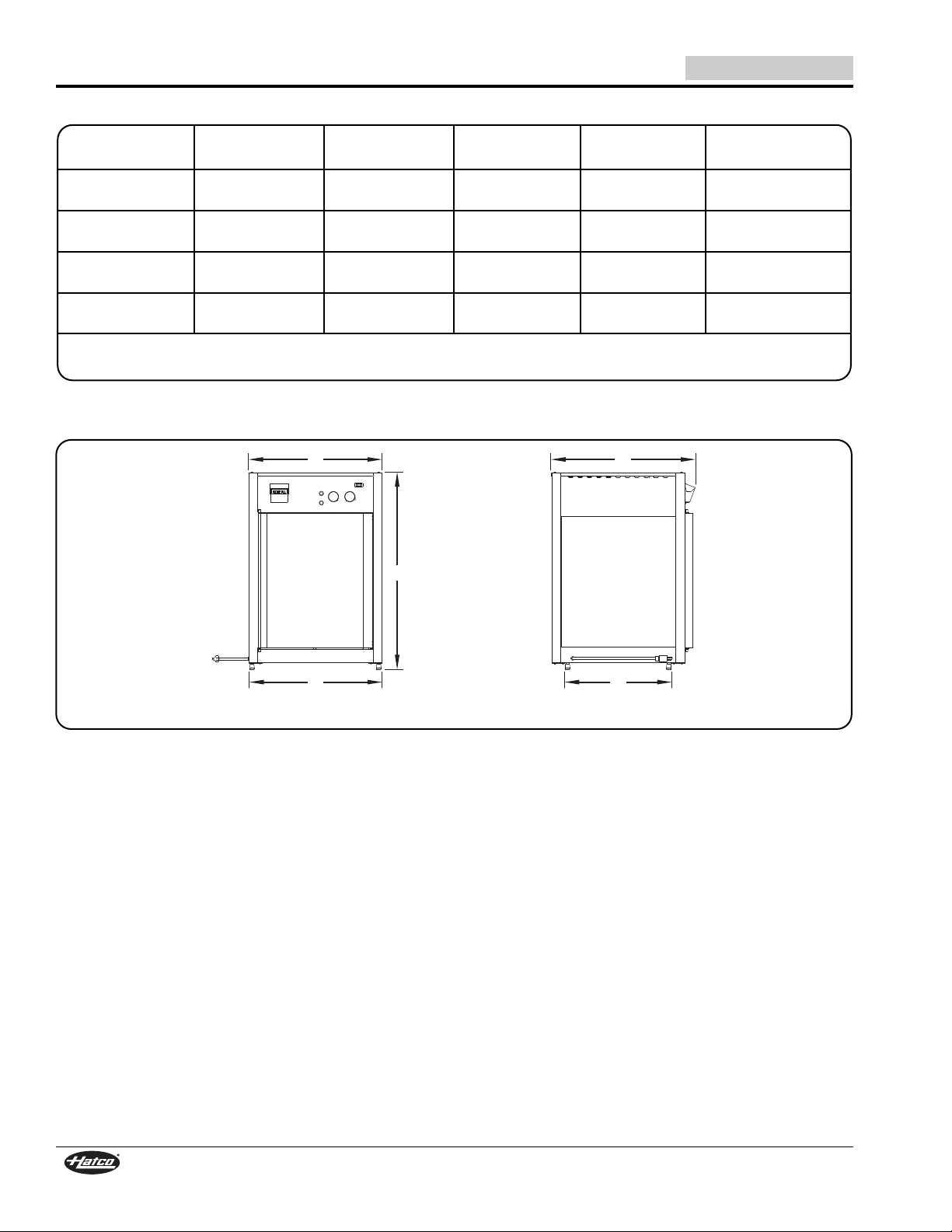

Front View Side View

D

E

A B

SPECIFICATIONS

Dimensions

English

Width

Model

FDWDE-1 19-3/8″

FDWDE-1X 19-3/8″

FDWDE-2 19-3/8″

FDWDE-2X 19-3/8″

Cabinet Openings:

FDWDE-1, -1X, -2, -2X = 15-3/4″ W x 19-3/4″ H (400 x 502 mm)

* Add 3″ (76 mm) to Height (C) of the unit if the 4″ (102 mm) leg option is installed.

(A)

(492 mm)

(492 mm)

(492 mm)

(492 mm)

Depth

(B)

20-7/8″

(530 mm)

20-7/8″

(530 mm)

22″

(559 mm)

22″

(559 mm)

Height

(C)*

28-5/8″

(727 mm)

28-5/8″

(727 mm)

28-5/8″

(727 mm)

28-5/8″

(727 mm)

Footprint

Width (D)

16-3/16″

(411 mm)

16-3/16″

(411 mm)

16-3/16″

(411 mm)

16-3/16″

(411 mm)

Footprint

Depth (E)

16-1/4″

(413 mm)

16-1/4″

(413 mm)

16-1/4″

(413 mm)

16-1/4″

(413 mm)

6

Form No. FDWDEM-0313

Page 7

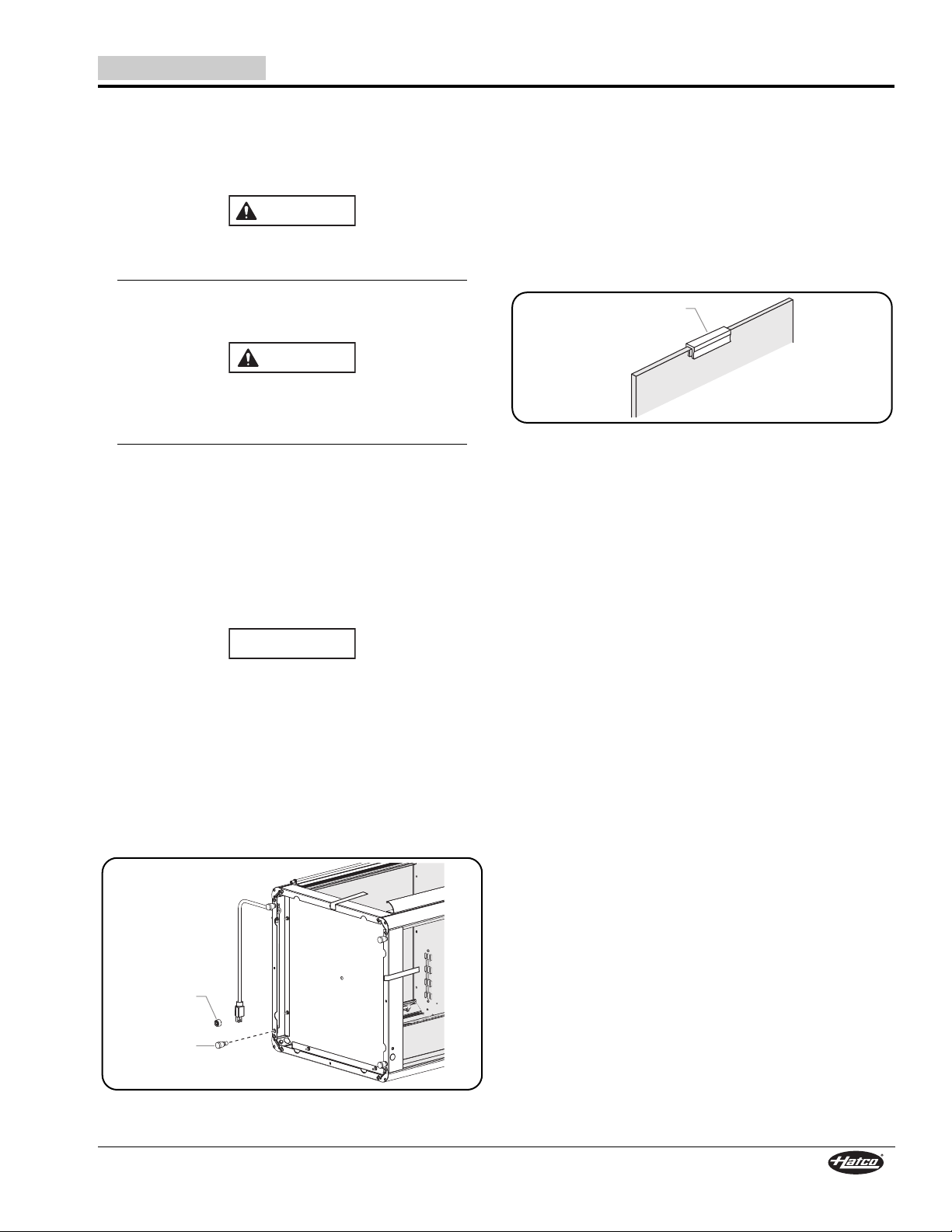

Rubber Tab

CAUTION

WARNING

NOTICE

Shipping

Foot

1" Foot

English

INSTALLATION

General

Flav-R-Fresh®Humidified Impulse Display Cabinets are

shipped with most components installed and ready for

operation. The following installation instructions must be

performed before plugging in and operating this unit.

ELECTRIC SHOCK HAZARD: Unit is not weatherproof.

Locate unit indoors where ambient air temperature is a

minimum of 70°F (21°C).

FIRE HAZARD: Locate unit a minimum of 1″ (25 mm) from

combustible walls and materials. If safe distances are not

maintained, discoloration or combustion could occur.

Locate unit at proper counter height in an area that is

convenient for use. Location should be level to prevent

unit or its contents from falling accidentally and strong

enough to support weight of unit and contents.

Transport unit in upright position only. Before moving or

tipping unit, secure all glass surfaces with tape and drain

water from humidified units. Failure to do so may result in

personal injury and damage to unit.

1. Remove the unit from the carton. Two people are required

for this step.

NOTE: To prevent delay in obtaining warranty coverage,

complete online warranty registration. See the

IMPORTANT OWNER INFORMATION section for

details.

NOTE: For cabinets with the optional 4″ (102 mm) adjustable

legs, see the OPTIONS AND ACCESSORIES section

for installation instructions. Do not remove glass

protection until leg installation is complete.

3. Remove all tape and protective packaging from all surfaces

of the unit, shelves, and any accessories.

• Glass Panels—The cabinets have tempered glass

panels that are protected during shipping using rubber

tabs along the glass edges and tape to hold the panels

securely. These tabs and tape must be removed prior to

cabinet operation.

Shipping Tab for Glass Panels

4. Place the unit in the desired location. Two people are

required for this step.

• Locate the unit in an area where the ambient air

temperature is constant and a minimum of 70°F (21°C).

Avoid areas that may be subject to active air movements

or currents (i.e., near exhaust fans/hoods and air

conditioning ducts).

• Make sure the unit is at the proper counter height in an

area convenient for use.

• Make sure the countertop is level and strong enough to

support the weight of the unit and food product.

Do not lay unit on the side with control panel. Damage to

unit could occur.

2. Install the four 1″ (25 mm) metal, screw-type feet. To install:

a. Make sure all glass sides and doors are secure with

tape. Lay the unit on its side.

b. Unscrew and remove the four rubber shipping feet.

c. Screw the 1″ (25 mm) feet into the holes where the

shipping feet were located.

d. After all the feet are tightened, return the unit to its

upright position.

Installing the 1″ (25 mm) Feet

Form No. FDWDEM-0313

7

Page 8

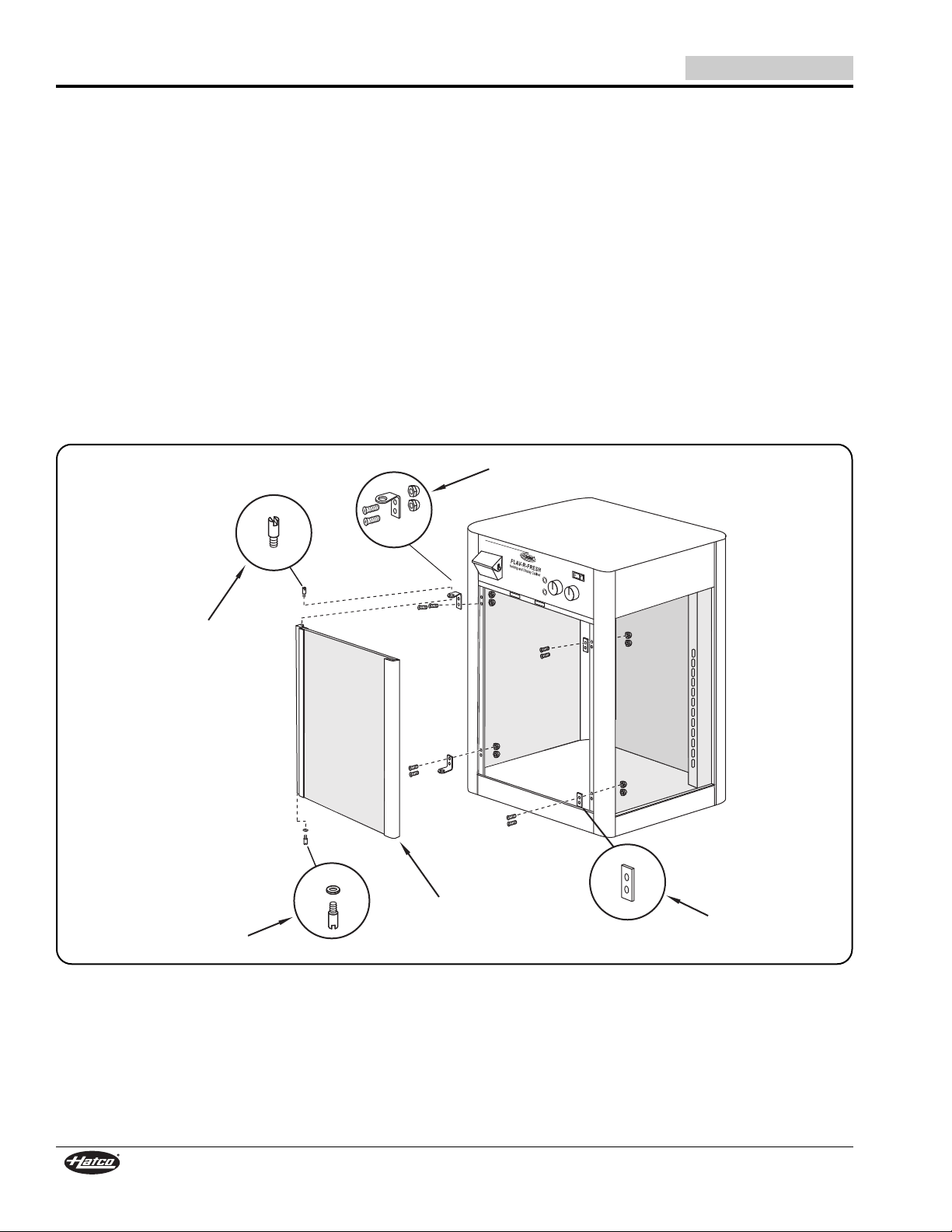

Striker Plate

Glass Door

Hinge Bracket Assembly

Hinge Pin Screw

Hinge Pin Screw

INSTALLATION

English

Reversing the Access Door

The Flav-R-Fresh©access door(s) may be hinged on either the

left or right side for convenience. Use the following procedure

to reverse the access door.

NOTE: For models equipped with a motorized rotating rack

(FDWDE-1 and FDWDE-2), the “Relocating the

Proximity Switch” procedure in this section must be

performed after reversing the access door(s).

1. Remove the top hinge pin screw that holds the door to the

hinge.

2. Tip the door assembly forward (away from cabinet) and lift

gently to clear the bottom hinge assembly. Remove the

nylon washer(s).

3. Reinstall the top hinge pin screw that was removed in Step 1.

4. Remove the screws holding the hinges to the cabinet.

5. Remove the screws from the striker plates on the non-hinge

side of the cabinet.

6. Install the striker plates on the opposite side of the cabinet

where the hinges were previously mounted.

7. Install the hinges on the opposite side of the cabinet where

the striker plates were previously mounted using the original

hinge mounting screws.

8. Carefully rotate the door 180°.

9. Remove the hinge pin screw from the end that is now the

top.

10. Carefully place the door assembly with the nylon washer(s)

into the bottom hinge.

11. Tip/tilt the door assembly towards the cabinet and align the

door top with the hinge. Reinstall the top door hinge pin

screw through the hinge and into the door top.

Reversing the Access Door

8

Form No. FDWDEM-0313

Page 9

Proximity Switch

Mounting with Door

Opening from Left-

Hinged Right

Proximity Switch

Mounting with Door

Opening from Right-

Hinged Left

Screw

English

INSTALLATION

Relocating the Proximity Switch

(Rack Motor Models Only)

Units equipped with a rack motor will require relocating the

proximity switch(es) after reversing the door(s).

The proximity switch signals the rack motor to stop when a door

is opened and to start when the door is closed. Follow the steps

listed below to move the proximity switch(es) to the proper

position after reversing the door(s). Unit requires one switch per

door.

1. Turn off the unit. Unplug the unit from the power source.

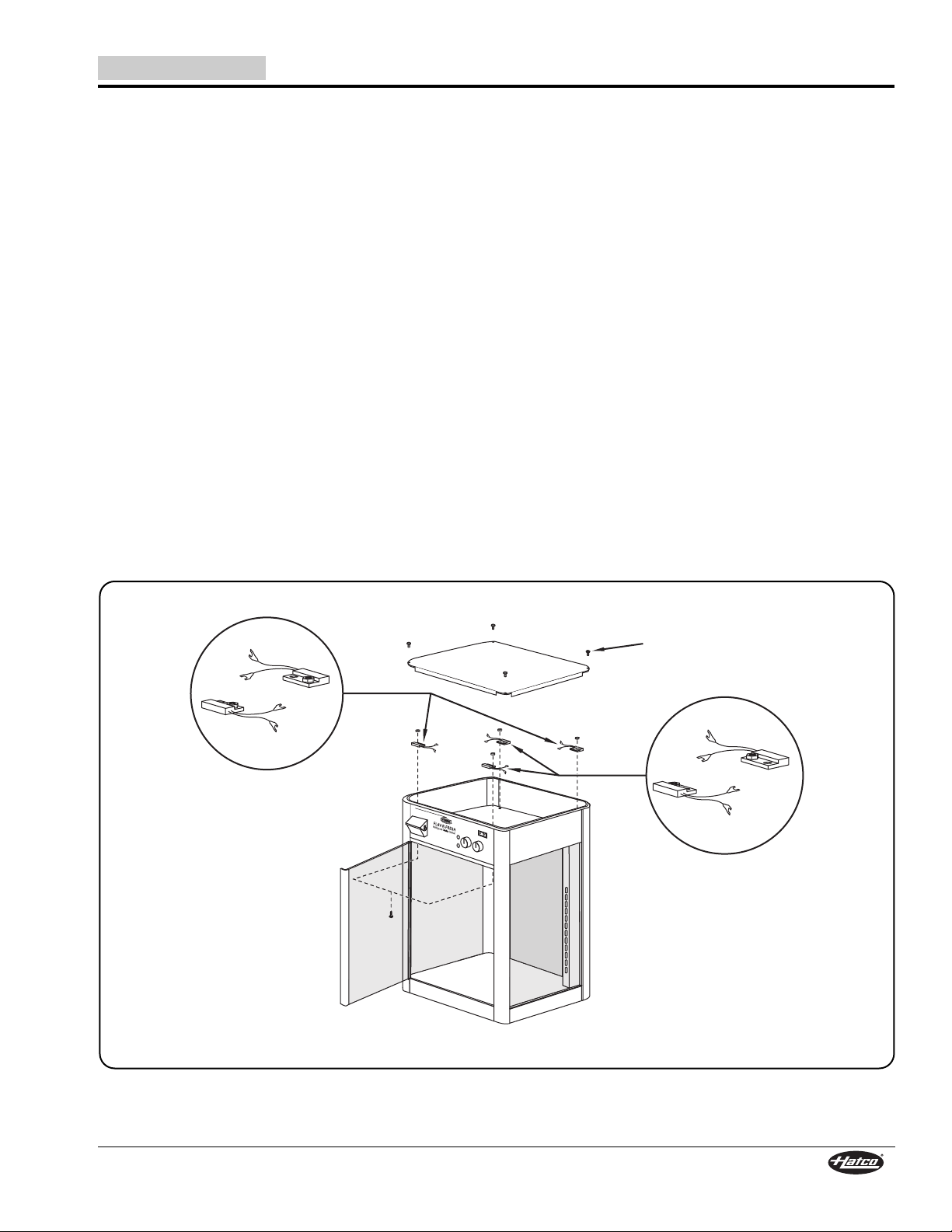

2. Remove the four screws and top cover.

3. Remove the screw and nut securing the proximity switch to

the cabinet ceiling sheet. The screw is accessed from inside

the cabinet. Reinstall screw and nut into hole after removing

switch.

4. Cut the cable tie securing the proximity switch wires to the

wiring harness. Mark the two wires for reassembly and

unplug the wires from the proximity switch wire leads. Route

the wires to the opposite corner and reattach the wires to

the switch wire leads.

NOTE: Make sure to install the proximity switch in the

orientation shown below for the specific installation

location. Incorrect orientation will result in malfunction of

the proximity switch.

5. Remove the screw and nut from the new mounting hole.

Secure the proximity switch to the mounting hole with the

screw and nut. Make sure to maintain proper switch

orientation when tightening the hardware.

6. Make sure wires do not interfere with the other components

inside the cabinet, then secure switch wires to wiring

harness with a cable tie (not supplied).

NOTE: On models equipped with two doors, it may be

necessary to move the air chamber to access the

proximity switch on the customer-side door. Drain all

water from the unit, remove the drain plug from inside

the cabinet, and remove the four screws securing the air

chamber assembly to the cabinet. Carefully move the

air chamber out of the way to access the proximity

switch. Reassemble after relocating switch.

7. Install the top cover and four screws.

8. Plug the unit into the proper power source.

9. Turn on the unit and test the operation of the proximity

switch(es) by making sure the rack rotates when the doors

are closed and stops rotating when a door is opened.

Form No. FDWDEM-0313

Relocating the Proximity Switch

9

Page 10

NOTICE

WARNING

CAUTION

WARNING

!

25

364

1

!

!

1

7

26

35

4

OPERATION

English

General

Use the following procedures to operate Flav-R-Fresh

Humidified Impulse Display Cabinets.

Read all safety messages in the IMPORTANT SAFETY

INFORMATION section before operating this equipment.

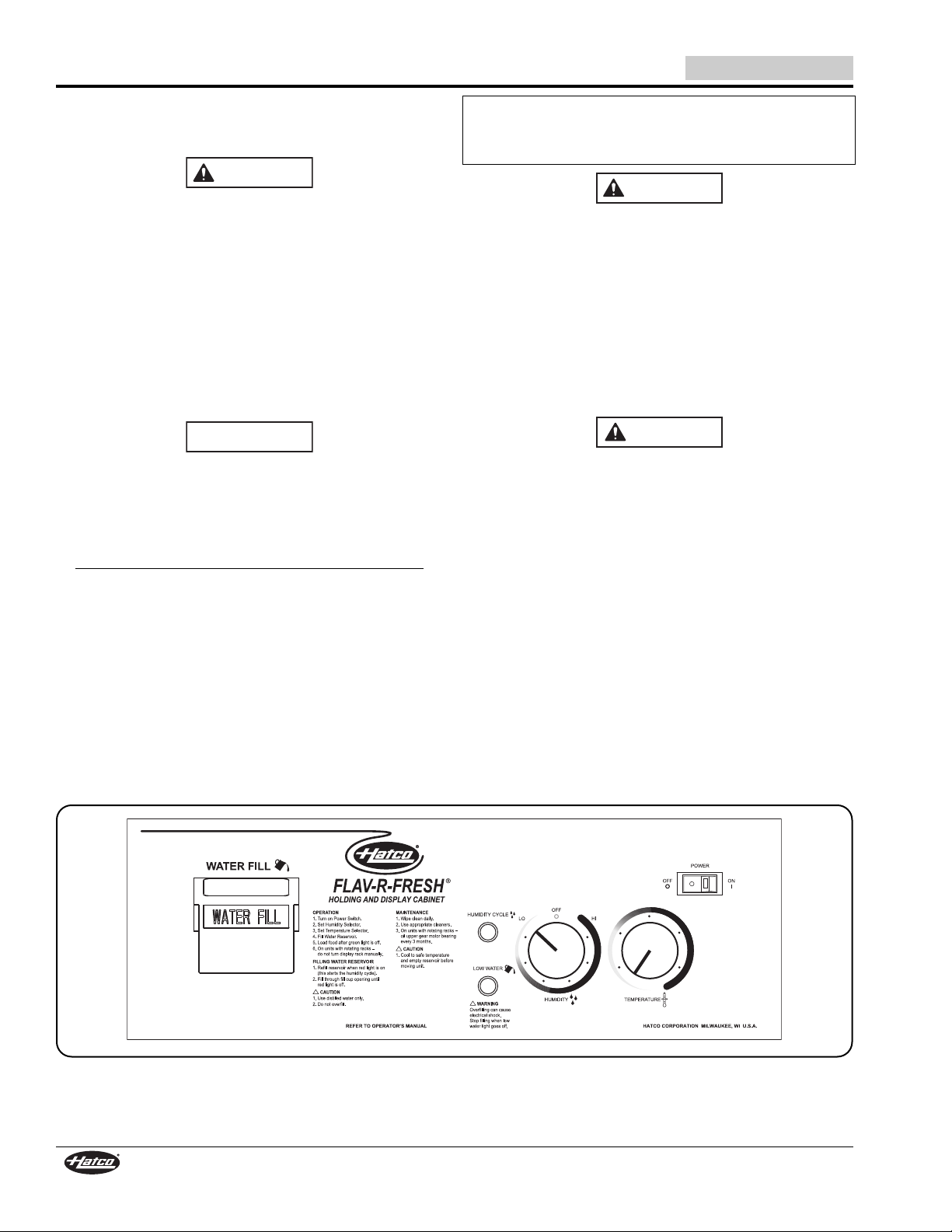

Startup

1. Plug unit into a properly grounded electrical receptacle of

the correct voltage, size, and plug configuration. See the

SPECIFICATIONS section for details.

2. Move the POWER ON/OFF (I/O) switch to the ON (I)

POSITION.

• The display lights will turn on and the heating system will

start up.

• The HUMIDITYCYCLE (if humidified) and LOW WATER

indicator lights will turn on.

Use of distilled water in water reservoir of humidified units

is recommended to preserve the life of electrical and

mechanical components. If non-distilled water is used,

reservoir will require periodic cleaning and deliming (refer

to MAINTENANCE section for cleaning procedure). Unit

failure due to lime or mineral deposits is not covered under

warranty.

Do not use deionized water. Deionized water will shorten

life of water pan and heating element.

NOTE: Unit failure caused by deionized water is not covered by

warranty.

3. On humidified units, fill the water reservoir with clean water.

To fill the reservoir:

a. Lift up the fill cup cover and pull forward.

b. Slowly pour the water into the cup until the LOW WATER

indicator light goes off.

*IMPORTANT NOTE*

When using distilled water, add one teaspoon of salt to the

®

water reservoir during the initial water fill only. This will ensure

proper operation of the water level sensors.

ELECTRIC SHOCK HAZARD: Do not overfill water reservoir.

Overfilling can cause electrical shock. Water reservoir is full

when LOW WATER indicator light turns off.

NOTE: On the initial fill, the water reservoir capacity is 80

ounces or 2-1/2 quarts (2.3 liters).

4. On humidified units, set the HUMIDITY control to the desired

setting. See the “Food Holding Guide” for recommendations.

5. Set the TEMPERATURE control to the desired setting. See

the “Food Holding Guide” for recommendations.

6. Allow the unit 20 minutes to reach operating temperature

before loading the cabinet with pre-heated food product.

BURN HAZARD: Some exterior surfaces on the unit will get

hot. Use caution when touching these areas.

NOTE: Temperature and humidity settings may vary depending

upon product make-up and consistency. The

thermometer shows the temperature inside the cabinet,

not the product temperature.

The capacity of the water reservoir permits uninterrupted

operation for approximately 3–6 hours, depending on the

settings and how frequently the door is opened. When the LOW

WATER indicator light is lit, add water to the reservoir. The water

reservoir refill capacity is approximately 64 ounces, or two (2)

quarts (1.9 liters). WARNING! ELECTRIC SHOCK HAZARD—

Do not overfill water reservoir.

Flav-R-Fresh Control Panel

10

Form No. FDWDEM-0313

Page 11

English

WARNING

NOTICE

OPERATION

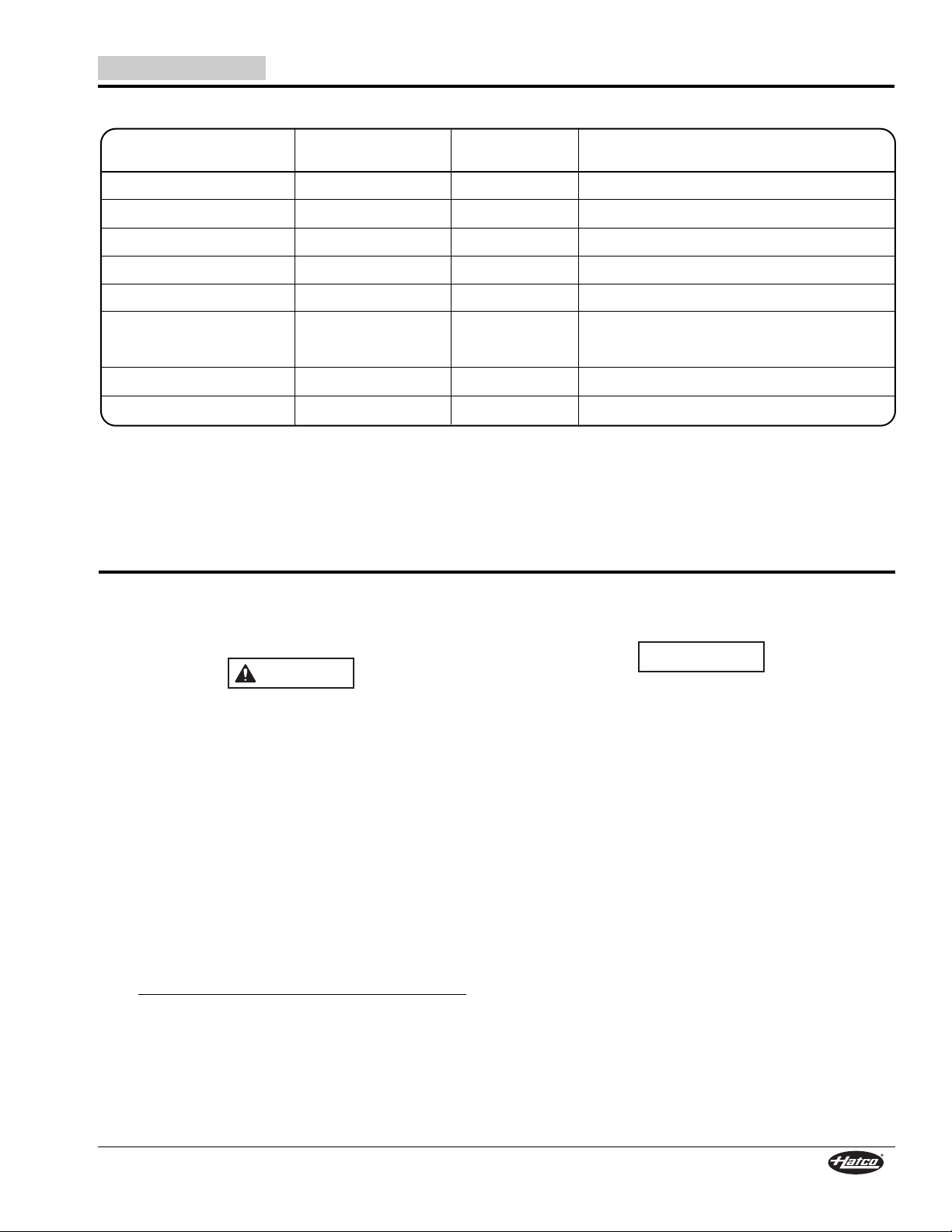

Food Holding Guide

Maximum Humidity Temperature

Type of Food Holding Time Setting °F °C

Biscuits 4 Hours 4 130 55

Chicken Pieces (Fried) 4 Hours 7 175 80

Croissants 4 Hours 1 140 60

Fruit Pies 3-1/2 Hours 4 140 60

Onion Rings 1/2 to 1 Hour 1 175 80

Pizza — Thick Crust 1 Hour 4 185 85

Thin Crust 1 Hour 5 180 82

Pretzels 3 Hours 4 140 60

Wrapped Sandwiches 2 Hours 4 180 82

NOTE: All times and settings are recommendations only and may vary depending on product preparation, cooking time, and

internal food temperature.

MAINTENANCE

General

Hatco Flav-R-Fresh®Humidified Impulse Display Cabinets are

designed for maximum durability and performance, with

minimum maintenance.

ELECTRIC SHOCK HAZARD:

• Turn OFF power switch, unplug power cord, and allow

unit to cool before performing any cleaning,

adjustments, or maintenance.

• DO NOT submerge or saturate with water. Unit is not

waterproof. Do not operate if unit has been submerged

or saturated with water.

• Do not steam clean or use excessive water on unit.

• Use only Genuine Hatco Replacement Parts when

service is required. Failure to use Genuine Hatco

Replacement Parts will void all warranties and may

subject operators of the equipment to hazardous

electrical voltage, resulting in electrical shock or burn.

Genuine Hatco Replacement Parts are specified to

operate safely in the environments in which they are

used. Some aftermarket or generic replacement parts

do not have the characteristics that will allow them to

operate safely in Hatco equipment.

This unit has no “user-serviceable” parts. If service is

required on this unit, contact an Authorized Hatco Service

Agent or contact the Hatco Service Department at 800-5580607 or 414-671-6350; fax 800-690-2966; or International fax

414-671-3976.

Daily Cleaning

To preserve the finish of the unit, perform the following cleaning

procedure daily.

Use non-abrasive cleaners and cloths only. Abrasive

cleaners and cloths could scratch finish of unit, marring its

appearance and making it susceptible to soil accumulation.

1. Turn off the unit, unplug the power cord, and allow the unit

to cool.

2. Remove and wash all food pans.

3. Wipe down all interior and exterior metal surfaces with a

damp cloth. Stubborn stains may be removed with a good

non-abrasive cleaner. Clean hard to reach areas using a

small brush and mild soap.

NOTE: Both the rotating display rack and the stationary rack

are removable for cleaning, if necessary. Refer to the

“Removing the Rotating Rack” procedure in this section

for removal.

4. Clean the glass side panels and door panel(s) using

ordinary glass cleaner and a damp, soft cloth or paper towel.

The side panels are removable for detailed cleaning, if

necessary. Refer to the “Removing the Glass Panels”

procedure in this section for removal.

Form No. FDWDEM-0313

11

Page 12

Connecting

Coupling

Connecting

Pin

Rack

Shaft

Bottom Point

WARNING

Valve

Open

Valve

Closed

MAINTENANCE

English

Removing the Glass Panels

1. Lift the glass panel out of the bottom channel of the cabinet.

2. Pull the lower edge away from the cabinet.

3. Carefully lower the glass until the top clears the cabinet.

Replacing the Glass Panel

1. Position the glass panel with the top edge under the top

cabinet lip, and raise the glass until it clears the bottom

channel of the cabinet.

2. Move the bottom of the glass towards the cabinet until the

glass rests against the cabinet frame.

3. Carefully lower the glass until it rests in the bottom channel

of the cabinet.

Removing the Rotating Rack

(Models FDWDE-1 and FDWDE-2)

1. Open the front access door.

2. Remove the two (2) connecting pins from the connecting

coupling located at the top of the rack inside the cabinet.

3. Lower the connecting coupling until it is free of the motor

shaft and remove the rack from the cabinet.

Draining the Water Reservoir

On humidified units, the water reservoir must be drained prior

to moving the cabinet as well as during the “Removing Lime

and Mineral Deposits” procedure.

ELECTRIC SHOCK HAZARD: Turn OFF power switch,

unplug power cord, and allow unit to cool before

performing any cleaning, adjustments, or maintenance.

1. Move the POWER ON/OFF (I/O) switch to the OFF (O)

position and unplug the power cord. Allow the unit to cool.

2. Locate the valve inside the cabinet on the underside of the

ceiling sheet. CAUTION! BURN HAZARD—Ceiling sheet

and water in reservoir are hot during operation. Allow to

cool before draining.

3. Position a one gallon (four liter) container under the valve.

4. Turn the valve handle from the horizontal position (closed)

to the vertical position (open) to drain the reservoir.

5. Once the reservoir is empty, return the valve handle to the

closed position.

Removing Motorized Display Racks

Replacing the Rotating Rack

1. With the connecting coupling in position on the top rack

shaft, insert the rack into the cabinet through the access

door and place the rack bottom point in the dimple located

at the center of the cabinet floor.

2. Slide the connecting coupling up onto the motor shaft and

align the coupling holes.

3. Insert the two (2) connecting pins. The top connecting pin

goes through the connecting coupling and the motor shaft.

The bottom connecting pin goes through the connecting

coupling and the rack shaft.

Draining Reservoir Valve

NOTE: If the water used has an excessive amount of lime or

mineral content, follow the “Removing Lime and Mineral

Deposits” procedure for periodic cleaning and deliming

of the water reservoir.

NOTE: Unit failure caused by liming or sediment buildup is not

covered under warranty.

12

Form No. FDWDEM-0313

Page 13

English

MAINTENANCE

Removing Lime and Mineral Deposits

Use the following procedure for periodic cleaning and de-liming

of the water reservoir on humidified models.

NOTE: The lime and mineral content of the water used for daily

operation will determine how often the deliming

procedure must be performed.

NOTE: Perform this procedure when the unit will not be used

for a period of time, such as the end of the day.

1. Move the POWER ON/OFF (I/O) switch to the OFF (O)

position and unplug the power cord. Allow the unit to cool.

2. After the unit has cooled down, perform the “Draining the

Water Reservoir” procedure in this section.

3. Fill the water reservoir with a mixture of 75% water and 25%

white vinegar. Do not use flavored vinegar.

4. Plug in and turn on the unit.

5. Set both the air temperature and humidity to their highest

settings and allow the unit to run for 30 minutes.

6. Move the POWER ON/OFF (I/O) switch to the OFF (O)

position and unplug the power cord. Allow the unit to cool.

7. Perform the “Draining the Water Reservoir” procedure to

empty the deliming solution from the water reservoir.

8. Continue to fill and drain the water reservoir with clean

water until the deliming solution is rinsed through and the

reservoir is clean.

9. Plug the unit into its power source and fill the reservoir as

usual for daily operation using the procedure in the

OPERATION section of this manual.

Replacing A Display Light

Units are equipped with an incandescent bulb that illuminates

the warming area. Each bulb has a special coating to guard

against injury and food contamination in the event of breakage.

Use the following procedure to replace an incandescent bulb.

1. Turn off the unit, unplug the power cord, and allow the unit

to cool.

2. Unscrew the light bulb from the unit and replace it with a

new, specially-coated incandescent light bulb.

NOTE: Hatco shatter-resistant light bulbs meet NSF standards

for food holding and display areas. For 120 V

applications, use Hatco P/N 02.30.043.00. For 220,

220–230, and 230–240 V, use Hatco P/N 02.30.058.00.

Form No. FDWDEM-0313

13

Page 14

WARNING

WARNING

TROUBLESHOOTING GUIDE

English

This unit must be serviced by trained and qualified

personnel only. Service by unqualified personnel may lead

to electric shock or burn.

ELECTRIC SHOCK HAZARD: Turn OFF power switch,

unplug power cord, and allow unit to cool before

performing any cleaning, adjustments, or maintenance.

Symptom Probable Cause Corrective Action

Incandescent bulb not working. Bulb loose or defective. Re-install or replace incandescent bulb.

Unit operates, but is not circulating

air inside cabinet.

Unit is plugged in, but nothing

works.

Unit is operational, but rotating rack

(if equipped) does not turn.

Blower motor is defective. Contact Authorized Service Agent or Hatco for

The correct voltage may not be supplied

to blower.

No power to unit. Check electrical receptacle and verify that

Power cord connections are loose or

disconnected.

Power cord is damaged. Contact Authorized Service Agent or Hatco for

Defective ON/OFF switch. Contact Authorized Service Agent or Hatco for

Proximity switch was not relocated after

door reversal.

assistance.

Contact Authorized Service Agent or Hatco for

assistance.

power supply matches specifications on unit.

If receptacle is not working, check circuit

breaker and reset, or plug unit into a different

known working receptacle.

Contact Authorized Service Agent or Hatco for

assistance.

assistance.

assistance.

See “Relocating the Proximity Switch” in the

INSTALLATION section of this manual.

Unit is not producing any “hot air”

inside cabinet.

Unit is heating, but is producing too

much humidity inside the cabinet

causing steam inside unit.

Unit is heating, but is not producing

humidity inside cabinet. Low water

light is off, and unit is full of water.

Unit is heating, but is not producing

humidity inside cabinet. Low water

light is on and unit is full of water.

Proximity magnet or proximity switch not

working properly.

Incorrect voltage is supplied to rack

motor.

Safety high-limit is tripped or open. Contact Authorized Service Agent or Hatco for

Incorrect voltage supplied to heating

element.

Blower motor is not working. Check blower motor—refer to Symptom “Unit

Air heating element is defective. Contact Authorized Service Agent or Hatco for

Humidity control is set too high. Adjust the humidity control to a lower setting.

Air temperature is set too low. Adjust the temperature to a higher setting.

Humidity control is defective. Contact an Authorized Hatco Service Agent or

Incorrect voltage supplied to water

heating element or heating element is

defective.

When using distilled water, no minerals are

being sensed by low water probe.

Low water protection system is

malfunctioning.

Contact Authorized Service Agent or Hatco for

assistance.

Contact Authorized Service Agent or Hatco for

assistance.

assistance.

Contact Authorized Service Agent or Hatco for

assistance.

operates, but is not circulating air inside

cabinet.”

assistance.

Hatco for assistance.

Contact Authorized Service Agent or Hatco for

assistance.

On initial fill, add one teaspoon of salt to the

water reservoir.

Contact Authorized Service Agent or Hatco for

assistance.

14

Form No. FDWDEM-0313

Page 15

NOTICE

Mounting

Bracket

4" Leg

Corner Post

Screw

Mounting Nut

Mounting

Post

Shipping

Foot

Lengthen

Shorten

Adjustable

Foot

4-Shelf

Multi-Purpose Rack

Model FDW4SMP

3-3/4” (95 mm) opening

between shelves.

2nd and 4th shelves

are removable.

3-Tier Pretzel Tree*

Model FDW3TPT

5-7/8” (149 mm) opening

between racks.

*Racks designed for use with motorized display.

4-Tier Circle Rack

with Retainers*

Model FDWD4TCRR

3-1/4” (83mm) opening

between racks.

Max. 15” (381 mm)

diameter pans.

Motorless

Rack Coupling

English

OPTIONS AND ACCESSORIES

4″ (102 mm) Adjustable Legs

The 4″ (102 mm) adjustable legs are used to add additional

height to the unit.

Do not lay unit on the side with control panel. Damage to

unit could occur.

1. Secure all glass sides and doors with tape. Lay the unit on

its side.

2. Unscrew and remove the four rubber shipping feet or the

four 1″ (25 mm) feet, depending on which are installed.

3. Install a leg mounting bracket at each corner of the unit. To

install:

a. Remove the two outside corner post screws.

b. Remove the two mounting nuts from the mounting posts

in the recessed area of the base.

c. Align the mounting bracket on the mounting posts, and

reinstall the mounting nuts. Tighten securely.

d. Insert the two corner post screws. Tighten securely.

Display Racks

Several display racks are available to “customize” Flav-R-

®

Fresh

to specific foodservice operations. All are nickel-plated

except the pretzel tree, which is stainless steel.

Installation of 4″ Legs

4. Screw the 4″ (102 mm) legs into

the holes in the middle of each

mounting bracket.

5. After all the legs are tightened,

return the unit to its upright

position. If the unit is not level or

rocks, turn the adjustable tip of the

appropriate leg to level the unit.

Form No. FDWDEM-0313

Display Racks

Motorless Rack Coupling

The motorless rack coupling allows the

stationary installation of a circle rack or

pretzel tree in cabinets that do not have a

rack motor (FDWDE-1X and -2X).

15

Page 16

Decal

Hood Mounting

Screw

Display

Sign Holder

WARNING

OPTIONS AND ACCESSORIES

English

Merchandising Decal

Self-adhesive merchandising decals are available to promote

food products. The decals are designed to be installed on three

(3) sides of the cabinet above the glass panels. Merchandising

decals are red with yellow letters reading HOT PIZZA or HOT

PRETZELS. A graphic decal featuring pizza illustrations is also

available.

Decal Installation

1. Before installing decals, clean the side panels with a nonoily cleaner, such as isopropyl alcohol (rubbing alcohol).

2. After the cleaned surfaces have dried, remove the

protective backing from the decal and apply to the panel.

3. Any air pockets or bubbles behind the decal can be

removed by rubbing gently with a soft cloth from the center

towards the outer edges.

Decal Installation

Sign Holders

(FDWDE-1, FDWDE-1X, FDWDE-2, and FDWDE-2X)

Use the following procedures to install either a Display Sign

Holder(s) or the Three-Sided Sign Holder.

ELECTRIC SHOCK HAZARD: Turn OFF power switch,

unplug power cord, and allow unit to cool before

performing any cleaning, adjustments, or maintenance.

Display Sign Holder Installation

Display Sign Holders can be installed on any side of the unit

except the control side. Up to three Display Sign Holders can be

installed on a unit. There are two height sizes available for

display sign holders, 3″ (76 mm) and 6-3/8″ (162 mm).

NOTE: Signage not supplied by Hatco. Sign dimensions are:

3″ Holder = 19-1/16″ W (484 mm) x 3-1/4″ H (83 mm)

6-3/8″ Holder = 19-1/16″ W (484 mm) x 6-3/8″ H (162 mm)

Order custom signs for Hatco equipment at

www.hatcographics.com.

1. Remove the appropriate hood mounting screws from the

cabinet hood. The screws that need to be removed are

determined by the location and number of sign holders

being installed.

2. Align the mounting holes on the sign holder(s) with the

mounting holes in the cabinet hood.

3. Insert the hood mounting screws through the holes in the

sign holder(s) and into the cabinet hood. Tighten securely.

NOTE: If more than one display sign holder is being installed,

some of the hood mounting screws may need to thread

through and secure two display sign holders.

4. Place the polycarbonate window(s) into sign holder.

16

Display Sign Holder Installation

Form No. FDWDEM-0313

Page 17

English

LIMITED WARRANTY

1. PRODUCT WARRANTY

Hatco warrants the products that it manufactures (the

“Products”) to be free from defects in materials and

workmanship, under normal use and service, for a period of

one (1) year from the date of purchase when installed and

maintained in accordance with Hatco’s written instructions or

18 months from the date of shipment from Hatco. Buyer must

establish the Product’s purchase date by registering the

Product with Hatco or by other means satisfactory to Hatco in

its sole discretion.

Hatco warrants the following Product components to be free

from defects in materials and workmanship from the date of

purchase (subject to the foregoing conditions) for the period(s)

of time and on the conditions listed below:

a) One (1) Year Parts and Labor PLUS One (1) Additional

Year Parts-Only Warranty:

Conveyor Toaster Elements (metal sheathed)

Drawer Warmer Elements (metal sheathed)

Drawer Warmer Drawer Rollers and Slides

Strip Heater Elements (metal sheathed)

Display Warmer Elements (metal sheathed air heating)

Holding Cabinet Elements (metal sheathed air heating)

Heated Well Elements — HW and HWB Series

(metal sheathed)

b) One (1) Year Parts and Labor PLUS Four (4) Years

Parts-Only Warranty:

3CS and FR Tanks

c) One (1) Year Parts and Labor PLUS Nine (9) Years

Parts-Only Warranty on:

Electric Booster Heater Tanks

Gas Booster Heater Tanks

d) Ninety (90) Day Parts-Only Warranty:

Replacement Parts

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN

LIEU OF ANY OTHER WARRANTY, EXPRESSED OR

IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE OR PATENT OR OTHER

INTELLECTUAL PROPERTY RIGHT INFRINGEMENT.

Without limiting the generality of the foregoing, SUCH

WARRANTIES DO NOT COVER: Coated incandescent light

bulbs, fluorescent lights, heat lamp bulbs, coated halogen light

bulbs, halogen heat lamp bulbs, xenon light bulbs, LED light

tubes, glass components, and fuses; Product failure in booster

tank, fin tube heat exchanger, or other water heating equipment

caused by liming, sediment buildup, chemical attack, or

freezing; or Product misuse, tampering or misapplication,

improper installation, or application of improper voltage.

2. LIMITATION OF REMEDIES AND DAMAGES

Hatco’s liability and Buyer’s exclusive remedy hereunder will be

limited solely, at Hatco’s option, to repair or replacement using

new or refurbished parts or Product by Hatco or a Hatcoauthorized service agency (other than where Buyer is located

outside of the United States, Canada, United Kingdom, or

Australia, in which case Hatco’s liability and Buyer’s exclusive

remedy hereunder will be limited solely to replacement of part

under warranty) with respect to any claim made within the

applicable warranty period referred to above. Hatco reserves

the right to accept or reject any such claim in whole or in part.

In the context of this Limited Warranty, “refurbished” means a

part or Product that has been returned to its original

specifications by Hatco or a Hatco-authorized service agency.

Hatco will not accept the return of any Product without prior

written approval from Hatco, and all such approved returns shall

be made at Buyer’s sole expense. HATCO WILL NOT BE

LIABLE, UNDER ANY CIRCUMSTANCES, FOR

CONSEQUENTIAL OR INCIDENTAL DAMAGES, INCLUDING

BUT NOT LIMITED TO LABOR COSTS OR LOST PROFITS

RESULTING FROM THE USE OF OR INABILITY TO USE THE

PRODUCTS OR FROM THE PRODUCTS BEING

INCORPORATED IN OR BECOMING A COMPONENT OF

ANY OTHER PRODUCT OR GOODS.

The warranty on Hatco Flav-R-Fresh®Humidified Impulse

Display Cabinets is for one year from date of purchase or

eighteen months from date of shipping from Hatco, whichever

occurs first.

If you experience a problem with a Flav-R-Fresh® cabinet

during the warranty period

, please do the following:

Contact Local Hatco Dealer

When contacting the Hatco dealer for service assistance, please

supply the dealer with the following information to ensure prompt

processing:

• Model of unit

• Serial number (located on the side of the unit)

• Specific problem with the unit

• Date of purchase

• Name of business

• Shipping address

• Contact name and phone number

Form No. FDWDEM-0313

SERVICE INFORMATION

The Hatco dealer will do the following:

• Provide replacement part(s) as required

• Submit warranty claim to Hatco for processing

Non-Warranty Problems

If you experience a non-warranty problem that requires assistance, please contact the nearest Authorized Hatco Service

Agency.

To locate the nearest Service Agency:

• access our website at www.hatcocorp.com, select the

Resources pull-down menu, and click on “Find Service

Agent/Distributor”

• call Hatco Service at 414-671-6350

• e-mail Hatco Service at partsandservice@hatcocorp.com

17

Page 18

CONTEÚDO

AVISO

CUIDADO

ATENÇÃO

Português

Informações Importantes para o Comprador ..................18

Introdução ...........................................................................18

Informações Importantes de Segurança ..........................19

Descrição do Modelo .........................................................20

Designação do Modelo ......................................................20

Especificações....................................................................21

Configurações de Tomada ...............................................21

Tabela de Características Elétricas ..................................21

Dimensões........................................................................22

Instalação ............................................................................23

Visão Geral.......................................................................23

Inversão da porta de acesso ............................................24

Relocação dos interruptores de proximidade...................25

Operação .............................................................................26

Visão Geral.......................................................................26

Guia de armazenamento de alimentos.............................27

Manutenção.........................................................................27

Visão Geral.......................................................................27

Limpeza Diária .................................................................27

Remoção dos painéis de vidro .........................................28

Remoção do rack rotativo.................................................28

Drenagem do reservatório de água..................................28

Remoção de calcificações e de depósitos minerais.........29

Substituição de uma lâmpada da vitrine...........................29

Guia de Solução de Problemas.........................................30

Opções e acessórios..........................................................32

Garantia Internacional Limitada ........................................34

Informações de Serviço .....................................................34

INFORMAÇÕES IMPORTANTES PARA O COMPRADOR

Anote o modelo, número de série, tensão e a data da compra

nos espaços abaixo (etiqueta de especificações localizada na

chapa superior no interior da unidade). Deixe estas

informações à mão quando entrar em contato com a Hatco

para assistência técnica.

Nº do Modelo ____________________________________

Nº de Série ______________________________________

Tensão __________________________________________

Data da Compra __________________________________

Horário de

Atendimento: de 8:00 às 17:00 Hora Central Padrão (CST)

(Horário de Verão: de Junho a Setembro—

de 8:00 às 17:00 CST de segunda a quinta

de 8:00 às 14:30 CST às sextas

Telefone: 414-671-6350

E-mail: partsandservice@hatcocorp.com

Fax: 414-671-3976 (Peças e Assistência)

Informações adicionais podem ser encontradas visitando

nosso site www.hatcocorp.com.

Registre sua unidade!

O preenchimento do registro de garantia vai evitar atrasos

na obtenção da cobertura da garantia. Acesse o site da

Hatco em www.hatcocorp.com, selecione o menu de cortina

Parts & Service, e clique em “Warranty Registration”.

INTRODUÇÃO

As Vitrines Umidificadas Impulse Flav-R-Fresh®da Hatco foram

projetadas para armazenar alimentos preparados por longos

períodos enquanto mantém aquela qualidade de "recémpreparado". As Vitrines Umidificadas Impulse da Hatco

fornecem o melhor ambiente para produtos alimentícios

regulando a temperatura do ar enquanto ao mesmo tempo

equilibram o nível de umidade. O uso do calor umidificado e

controlado mantém a textura do alimento e a temperatura ideal

para servir por mais tempo do que o equipamento de

armazenamento convencional seco.

O padrão de fluxo de ar do Flav-R-Fresh foi projetado para

manter uma temperatura homogênea na vitrine sem ressecar

os alimentos. A precisa combinação de calor e umidade cria

um efeito "cobertor" em torno dos alimentos. A vazão do fluxo

de ar permite que a vitrine recupere rapidamente a temperatura

após a abertura e fechamento da porta.

As Vitrines Umidificadas Impulse Flav-R-Fresh da Hatco são

produto de extensas pesquisas e testes de campo. Os

materiais usados foram selecionados para ter máxima

durabilidade, aparência atraente e ótimo desempenho. Cada

unidade é inspecionada e totalmente testada antes do

fornecimento.

Es

a

r

e

p

o

tco

a

H

operação

da

antes

As informações de segurança que aparecem neste manual são

identificadas pelos seguintes sinais:

ATENÇÃO indica uma situação perigosa que, se não for

evitada, pode resultar em morte ou ferimentos graves.

CUIDADO indica uma situação perigosa que, se não for

evitada, pode resultar em ferimentos menores ou

moderados.

AVISO é usado para tratar de práticas não relacionadas a

ferimentos pessoais.

çã

r

o

co

e

i

s Vitr

a

d

d

n

me

segurança

e

aç

tal

ns

a

ão ou

in

q

e

s U

u

mid

to

e

que

operaç

a

d

ifica

s in

s a

a

d

aparecem

da

ão

s Imp

str

nest

uni

lse

u

çõ

u

e

dade.

manual

e

Fla

s d

R

v-

in

e

sej

Fr

sta

e

am

. A

sh

çã

la

das

i

l

d

s

e

õ

ç

tru

s

in

s

a

d

e

a

ç

n

ra

u

g

e

s

,

o

ã

ç

la

ta

s

in

a

d

ta

a

tr

l

a

u

n

a

m

te

e

,

o

18

Formulário Nº FDWDEM-0313

Page 19

Português

CUIDADO

AVISO

ATENÇÃO

ATENÇÃO

INFORMAÇÕES IMPORTANTES DE SEGURANÇA

Leia as informações importantes de segurança a seguir antes de usar este equipamento para

evitar ferimentos graves ou morte e para evitar danos aos equipamentos ou à propriedade.

PERIGO DE CHOQUE ELÉTRICO:

• Conecte a tomada macho em um receptáculo elétrico

aterrado com tensão, dimensões e configuração de

tomada corretas. Se tomada e receptáculo não

corresponderem, consulte um eletricista qualificado

para determinar e instalar o receptáculo elétrico correto.

• DESLIGUE o interruptor de energia, desconecte o

plugue de energia e deixe a unidade resfriar antes de

executar qualquer limpeza, ajuste ou manutenção.

• A unidade não é à prova de intempéries. Coloque a

unidade em locais fechados onde a temperatura

ambiente seja no mínimo de 21°C (70°F).

• NÃO mergulhe ou encharque com água. A unidade não

é à prova d'água. Não opere se a unidade tiver sido

mergulhada ou encharcada com água.

• Não limpe a unidade com vapor ou muita água.

• DESLIGUE o interruptor de energia e deixe a unidade

resfriar antes de drenar o reservatório de água.

• Não puxe a unidade pelo cabo de alimentação.

• Interrompa o uso se o cabo de alimentação estiver

rachado ou gasto.

• Não tente consertar ou substituir um cabo de

alimentação danificado. O cabo deve ser substituído

pela Hatco, uma Assistência Técnica Autorizada ou

uma pessoa com qualificações semelhantes.

• Esta unidade deve ser atendida apenas por pessoal

qualificado. Assistência técnica por pessoal não

qualificado pode levar a um choque elétrico ou

queimadura.

• Não encha demais o reservatório de água. O

enchimento excessivo pode causar choques elétricos.

O reservatório de água estará cheio quando o indicador

de POUCA ÁGUA se apagar.

• Use apenas Peças de Reposição Genuínas Hatco

quando a manutenção for necessária. Não usar peças

de reposição Genuínas Hatco irá anular todas as

garantias e pode sujeitar o operador do equipamento à

tensão elétrica perigosa, resultando em choque elétrico

ou queimadura. As Peças de Reposição Genuínas

Hatco são especificadas para operar em segurança nos

ambientes nos quais são usadas. Algumas peças de

reposição genéricas ou de revendas não tem as

características que irão permitir que operem em

segurança nos equipamentos Hatco.

RISCO DE INCÊNDIO: Coloque a unidade no mínimo a

25 mm (1″) de paredes e materiais combustíveis. Se as

distâncias seguras não forem mantidas, pode ocorrer

combustão ou descoloração.

Use apenas lâmpadas que atendam ou excedam os

padrões da National Sanitation Foundation (NSF) e sejam

especificamente projetados para áreas de armazenamento

de alimentos. A quebra de lâmpadas não revestidas pode

resultar em ferimentos e/ou contaminação dos alimentos.

Assegure-se de que todos os operadores tenham sido

instruídos sobre a segurança e o uso adequado da unidade.

Esta unidade não deve ser usada por crianças ou pessoas

com as capacidades físicas, sensoriais ou mentais reduzidas. Garanta uma supervisão apropriada das crianças e mantenha-nas longe da unidade.

Assegure-se de que os produtos alimentícios tenham sido

aquecidos a uma temperatura segura para alimentos antes

de colocá-los na unidade. Não aquecer adequadamente os

produtos alimentícios pode resultar em riscos graves à

saúde. Esta unidade foi projetada apenas para manter

produtos preaquecidos.

A Hatco Corporation não é responsável pela temperatura ideal

para servir os produtos alimentícios. É responsabilidade do

usuário garantir que os produtos alimentícios sejam mantidos

e servidos a uma temperatura segura.

Esta unidade não tem peças "reparáveis pelo usuário". Se

precisar de manutenção para esta unidade, entre em

contato com a Assistência Técnica Autorizada Hatco ou o

Departamento de Manutenção Hatco pelo 414-671-6350;

fax 414-671-3976.

RISCO DE QUEIMADURA: Algumas superfícies exteriores

da unidade podem ficar quentes. Tenha cuidado ao tocar

nestas áreas.

Coloque a unidade em um balcão de altura adequada em uma

área que seja conveniente ao uso. O local deve ser nivelado para evitar que a unidade ou seus componentes caiam

acidentalmente, e forte o suficiente para suportar o peso da

unidade e seus componentes.

Só transporte a unidade na posição vertical. Antes de

mover ou inclinar a unidade, firme as superfícies de vidro

com uma fita adesiva e drene a água das unidades

umidificadas. A recusa em fazê-lo pode resultar em

ferimentos ou danos à unidade.

Use apenas limpadores não abrasivos e panos.

Limpadores abrasivos e panos podem arranhar o

acabamento da unidade, estragar sua aparência e deixá-la

sujeita ao acúmulo de poeira.

Limpe a unidade diariamente para evitar o mau

funcionamento e para manter a operação higiênica.

Não coloque a unidade apoiada sobre o painel de controle.

Podem ocorrer danos à unidade.

Recomenda-se o uso de água destilada no reservatório da

unidade para preservar a vida útil dos componentes

elétricos e mecânicos. Se não for usada água destilada, o

reservatório vai exigir limpeza e descalcificação periódicas

(consulte a seção de manutenção para os procedimentos

de limpeza). A falha da unidade devido à calcificação ou ao

depósito de minerais não será coberta pela garantia.

Não use água deionizada. A água deionizada irá abreviar a vida

útil do reservatório de água e do elemento de aquecimento.

Formulário Nº FDWDEM-0313

19

Page 20

DESCRIÇÃO DO MODELO

F D W D E - 1 X

Flav-R-Fresh

Aquecedor

Vitrine

Designer

Econo line

Quantidade de portas

Sem rack rotativo

motorizado

Português

Todos os Modelos

Todas as Vitrines Umidificadas Impulse Flav-R-Fresh®possuem

sistema de aquecimento de ar, de umidificação com controle de

baixo nível de água, lâmpadas incandescentes, vidros

temperados e uma porta. A porta de acesso padrão pode ser

aberta para a direita ou para a esquerda. O rack para pretzels

é feito de aço inox e os outros racks de exibição são

niquelados. Todas as unidades estão disponíveis em várias

cores Designer:

Modelo FDWDE-1

O modelo FDWDE-1 possui uma só porta e um exibidor

rotativo. Vem com um rack padrão para pizzas que suporta até

quatro (4) pizzas redondas com um diâmetro máximo de

381 mm (15″). O rack rotativo para automaticamente quando a

porta é aberta. Um suporte rotativo opcional para pretzels ou

um rack estacionário multiuso com 4 prateleiras também estão

disponíveis.

Modelo FDWDE-1X

O modelo FDWDE-1X é similar ao FDWDE-1, mas apresenta

um rack estacionário multiuso de 4 prateleiras, ao invés de um

exibidor rotativo. O rack pode suportar recipientes com uma

largura máxima de 330 mm (13″) e uma profundidade de

457 mm (18″).

OBSERVAÇÃO:Um modelo FDWDE-1X não pode ser conver-

tido em modelos FDWDE-1, FDWDE-2, ou

FDWDE-2X.

Modelo FDWDE-2X

O modelo FDWDE-2X é similar ao FDWDE-2, mas apresenta

um rack estacionário multiuso de 4 prateleiras, ao invés de um

exibidor rotativo. O rack pode suportar recipientes com uma

largura máxima de 330 mm (13″) e uma profundidade de

457 mm (18″).

OBSERVAÇÃO:Um modelo FDWDE-1 não pode ser convertido

Modelo FDWDE-2

O modelo FDWDE-2 tem as mesmas características do

FDWDE-1, mas inclui uma porta adicional do lado oposto aos

controles para facilidade de acesso.

OBSERVAÇÃO: Um modelo FDWDE-2 não pode ser convertido

DESIGNAÇÃO DO MODELO

FDWDE-1

em modelos FDWDE-2 ou FDWDE-2X.

em modelos FDWDE-1 ou FDWDE-1X.

FDWDE-1X

OBSERVAÇÃO:Um modelo FDWDE-2X não pode ser

OBSERVAÇÃO:Consulte a seção opções e ACESSÓRIOS

20

convertido em modelos FDWDE-1, FDWDE-1X,

ou FDWDE-2.

deste manual para as opções adicionais

disponíveis para os modelos acima.

Formulário Nº FDWDEM-0313

Page 21

Português

ATENÇÃO

NEMA 5-15P

CEE 7/7 Schuko AS 3112

BS-1363

ESPECIFICAÇÕES

Configurações de Tomada

As unidades são fornecidas de fábrica com um cabo de

alimentação e tomada instalados. As tomadas são fornecidas

de acordo com a aplicação.

PERIGO DE CHOQUE ELÉTRICO: Conecte a tomada

macho em um receptáculo elétrico aterrado com tensão,

dimensões e configuração de tomada corretas. Se tomada

e receptáculo não corresponderem, consulte um eletricista

qualificado para determinar e instalar o receptáculo

elétrico correto.

OBSERVAÇÃO:A etiqueta de especificações localizada na

chapa superior no interior da unidade. Consulte

a etiqueta para ver o número de série e as

especificações elétricas.

OBSERVAÇÃO:Receptáculo não fornecido pela Hatco.

Configurações de Tomada

Tabela de Características Elétricas

Modelo Tensão Watts Amperes Configurações de Tomada Peso de transporte

FDWDE-1 100 1440 14.4 NEMA 5-15P 42 kg (92 lbs.)

(com 120 1420 11.8 NEMA 5-15P 42 kg (92 lbs.)

umidificação)

FDWDE-1

(sem 120 1095 9.1 NEMA 5-15P 42 kg (92 lbs.)

umidificação) 220 1145 5.2 CEE 7/7 Schuko 42 kg (92 lbs.)

FDWDE-2

(com 120 1420 11.8 NEMA 5-15P 41 kg (90 lbs.)

umidificação)

FDWDE-2

(sem 120 1095 9.1 NEMA 5-15P 41 kg (90 lbs.)

umidificação)

220 1470 6.7 CEE 7/7 Schuko 42 kg (92 lbs.)

220-230 1470-1607 6.7-7.0 CEE 7/7 Schuko ou BS-1363 42 kg (92 lbs.)

230-240 1350-1470 5.9-6.1 BS-1363 42 kg (92 lbs.)

100 1115 11.2 NEMA 5-15P 42 kg (92 lbs.)

220-230 1145-1251 5.2-5.4 CEE 7/7 Schuko ou BS-1363 42 kg (92 lbs.)

230-240 1052-1145 4.6-4.8 BS-1363 42 kg (92 lbs.)

100 1440 14.4 NEMA 5-15P 41 kg (90 lbs.)

220 1470 6.7 CEE 7/7 Schuko 41 kg (90 lbs.)

220-230 1470-1607 6.7-7.0 CEE 7/7 Schuko ou BS-1363 41 kg (90 lbs.)

230-240 1350-1470 5.9-6.1 BS-1363 41 kg (90 lbs.)

100 1115 11.2 NEMA 5-15P 41 kg (90 lbs.)

220 1145 5.2 CEE 7/7 Schuko 41 kg (90 lbs.)

220-230 1145-1251 5.2-5.4 CEE 7/7 Schuko ou BS-1363 41 kg (90 lbs.)

230-240 1052-1145 4.6-4.8 BS-1363 41 kg (90 lbs.)

As áreas sombreadas contêm informações elétricas apenas para modelos internacionais.

Formulário Nº FDWDEM-0313

21

Page 22

ESPECIFICAÇÕES

C

Vista Frontal Vista Lateral

D

E

A B

Dimensões

Português

Largura

Modelo

FDWDE-1 492 mm

FDWDE-1X 492 mm

FDWDE-2 492 mm

FDWDE-2X 492 mm

Abertura das vitrines:

FDWDE-1, -1X, -2, -2X = 400 mm W x 502 mm H (15-3/4″ x 19-3/4″)

* Adicionar 76 mm (3″) à altura (C) da unidade, se a opção de pés de 102 mm (4″) estiver instalada.

(A)

(19-3/8″)

(19-3/8″)

(19-3/8″)

(19-3/8″)

Profundidade

(B)

530 mm

(20-7/8″)

530 mm

(20-7/8″)

559 mm

(22″)

559 mm

(22″)

Altura

(C) *

727 mm

(28-5/8″)

727 mm

(28-5/8″)

727 mm

(28-5/8″)

727 mm

(28-5/8″)

Largura

Ocupada (D)

411 mm

(16-3/16″)

411 mm

(16-3/16″)

411 mm

(16-3/16″)

411 mm

(16-3/16″)

Profundidade

Ocupada (E)

413 mm

(16-1/4″)

413 mm

(16-1/4″)

413 mm

(16-1/4″)

413 mm

(16-1/4″)

22

Formulário Nº FDWDEM-0313

Page 23

Português

Aba de borracha

CUIDADO

ATENÇÃO

Pés

fornecidos

Pé de1″

INSTALAÇÃO

Visão Geral

As Vitrines Umidificadas Impulse Flav-R-Fresh®são fornecidas

com a maior parte dos componentes instalados e prontos para

a operação. As instruções de instalação a seguir devem ser

seguidas antes de ligar e operar esta unidade.

PERIGO DE CHOQUE ELÉTRICO: A unidade não é à prova de

intempéries. Coloque a unidade em locais fechados onde a

temperatura ambiente seja no mínimo de 21°C (70°F).

RISCO DE INCÊNDIO: Coloque a unidade no mínimo a

25 mm (1″) de paredes e materiais combustíveis. Se as

distâncias seguras não forem mantidas, pode ocorrer

combustão ou descoloração.

Coloque a unidade em um balcão de altura adequada em

uma área que seja conveniente ao uso. O local deve ser nivelado para evitar que a unidade ou seus componentes caiam

acidentalmente, e forte o suficiente para suportar o peso da

unidade e seus componentes.

Só transporte a unidade na posição vertical. Antes de

mover ou inclinar a unidade, firme as superfícies de vidro

com uma fita adesiva e drene a água das unidades

umidificadas. A recusa em fazê-lo pode resultar em

ferimentos ou danos à unidade.

1. Remova a unidade da caixa. São necessárias duas

pessoas para esta operação.

OBSERVAÇÃO:Para evitar atrasos na obtenção da cobertura

da garantia, preencha o registro de garantia.

Consulte a seção INFORMAÇÕES

IMPORTANTES PARA O PROPRIETÁRIO

para mais detalhes.

2. Instale os quatro pés metálicos de 25 mm (1″)

aparafusáveis. Para instalar:

a. Assegure-se de que todos os vidros e portas estejam

fixados com fita adesiva. Deite a unidade de lado.

b. Desatarraxe e remova os quatro pés de borracha

fornecidos.

c. Aparafuse os pés de 25 mm (1″) nos furos onde

estavam os pés de borracha.

d. Após os pés estarem apertados, recoloque a unidade

em sua posição normal.

OBSERVAÇÃO:Para vitrines com os pés opcionais ajustáveis

de 4″ (102 mm), consulte a seção OPÇÕES E

ACESSÓRIOS para instruções de instalação.

Não remova as proteções dos vidros até que

a instalação dos pés esteja concluída.

3. Remova todas as fitas e o material de proteção de todas as

superfícies da unidade, prateleiras e quaisquer acessórios.

• Painéis de vidro— As vitrines possuem painéis de vidro

que são protegidos durante o transporte com abas de

borracha e fitas adesivas para manter os painéis firmes.

Estas abas e as fitas devem ser removidas antes da

operação da vitrine.

Aba de transporte dos painéis de vidro

4. Coloque a unidade no local desejado. São necessárias

duas pessoas para esta operação.

• Coloque a unidade em uma área em que a temperatura

ambiente seja constante e no mínimo de 21°C (70°F).

Evite as áreas sujeitas a movimentos ou correntes de

ar (i.é, perto de ventiladores/coifas de exaustão e dutos

de ar condicionado).

• Assegure-se de que a unidade esteja em um balcão de

altura adequada em uma área conveniente para o uso.

• Assegure-se de que o balcão esteja nivelado e seja forte

o bastante para suportar o peso da unidade e os

produtos alimentares.

Instalação dos pés de 1″ (25 mm)

Formulário Nº FDWDEM-0313

23

Page 24

INSTALAÇÃO

Placa limite

Porta de vidro

Conjunto da cantoneira da dobradiça

Parafuso do pino

da dobradiça

Parafuso do pino

da dobradiça

Português

Inversão da porta de acesso

A(s) porta(s) de acesso do Flav-R-Fresh®podem ser abertas

tanto para a esquerda como para a direita para sua

conveniência. Siga o procedimento abaixo para inverter a porta

de acesso.

OBSERVAÇÃO: Para o s modelos equipados com um rack

motorizado rotativo (FDWDE-1 e FDWDE-2), o

procedimento "Relocação dos interruptores de

proximidade" desta seção precisa ser

executado após inverter a(s) porta(s) de

acesso.

1. Remove o parafuso do pino da dobradiça superior que

prende a porta à dobradiça.

2. Incline a porta para frente (para longe da vitrine) e levante

com cuidado para liberar o conjunto da dobradiça inferior.

Remova a(s) arruela(s) de náilon.

3. Reinstale o parafuso do pino da dobradiça que foi removido

no passo 1.

4. Remova os parafusos que fixam as dobradiças à vitrine.

5. Remova os parafusos que fixam as placas limite no lado

sem dobradiças da vitrine.

6. Instale as placas limite no lado oposto da vitrine onde as

dobradiças estavam montadas.

7. Instale as dobradiças no lado oposto da vitrine onde as

placas limite estavam montadas usando os parafusos

originais das dobradiças.

8. Gire a porta cuidadosamente em 180°.

9. Remova o parafuso do pino da dobradiça do lado que agora

está para cima.

10. Coloque cuidadosamente o conjunto da porta com a(s)

arruela(s) de náilon na dobradiça inferior.

11. Incline o conjunto da porta em direção à vitrine e alinhe a

parte superior da porta com a dobradiça. Reinstale o

parafuso do pino da dobradiça superior da porta através

desta e no topo da porta.

Inversão da porta de acesso

24

Formulário Nº FDWDEM-0313

Page 25

Português

Montagem do interruptor de

proximidade com a porta

abrindo da esquerda -

pivotada na direita

Montagem do interruptor de

proximidade com a porta

abrindo da direita -

pivotada na esquerda

Parafuso

INSTALAÇÃO

Relocação dos interruptores de proximidade

(Apenas para modelos com rack motorizado)

As unidades equipadas com rack motorizado necessitam da

relocação dos interruptores de proximidade após a reversão

das portas.

Os interruptores de proximidade sinalizam para que o motor

do rack pare quando uma porta for aberta e religue quando ela

for fechada. Siga os passos listados abaixo para mover o(s)

interruptor(es) de proximidade para a posição correta após

inverter a(s) porta(s). A unidade exige um interruptor por porta.

1. Desligue a unidade. Remova a tomada do receptáculo.

2. Remova os quatro parafusos da tampa superior.

3. Remova os parafusos e porcas que fixam interruptores de

proximidade à chapa superior da vitrine. O parafuso é