Page 1

Register Online!

hatcocorp.com

WARNING

ADVERTENCIA

AVERTISSEMENT

(see page 2)

S'inscrire en ligne!

(voir page 19)

®

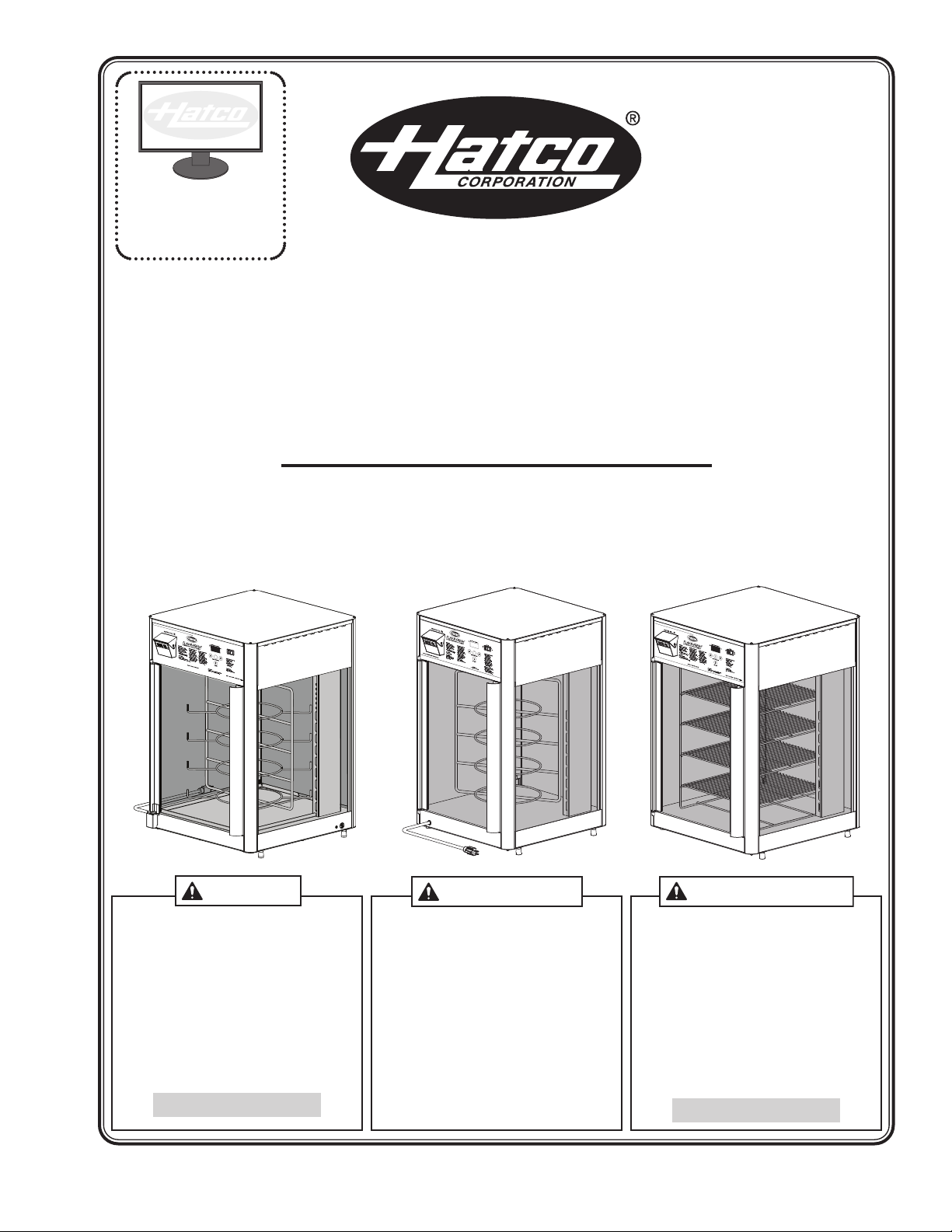

FLAV-R-FRESH

Humidified Impulse Display Cabinets

Armoires d'exposition avec système

d'humidification

FDWD Series • Série FDWD

Installation and Operating Manual

Manuel d'installation et d'utilisation

P/N 07.04.406.00

Do not operate this equipment unless you

have read and understood the contents of

this manual! Failure to follow the

instructions contained in this manual may

result in serious injury or death. This

manual contains important safety

information concerning the maintenance,

use, and operation of this product. If

you’re unable to understand the contents

of this manual, please bring it to the

attention of your supervisor. Keep this

manual in a safe location for future

reference.

English = p 2

No opere este equipo al menos que haya

leído y comprendido el contenido de este

manual! Cualquier falla en el seguimiento

de las instrucciones contenidas en este

manual puede resultar en un serio lesión

o muerte. Este manual contiene

importante información sobre seguridad

concerniente al mantenimiento, uso y

operación de este producto. Si usted no

puede entender el contenido de este

manual por favor pregunte a su

supervisor. Almacenar este manual en

una localización segura para la referencia

futura.

Ne pas utiliser cet équipement sans avoir

lu et compris le contenu de ce manuel !

Le non-respect des instructions

contenues dans ce manuel peut entraîner

de graves blessures ou la mort. Ce

manuel contient des informations

importantes concernant l'entretien,

l'utilisation et le fonctionnement de ce

produit. Si vous ne comprenez pas le

contenu de ce manuel, veuillez le signaler

à votre supérieur. Conservez ce manuel

dans un endroit sûr pour pouvoir vous y

référer plus tard.

Français = p 19

© 2015 Hatco Corporation

Page 2

NOTICE

CAUTION

WARNING

24 Hour 7 Day Parts and Service

Assistance available in the United States

and Canada by calling 800-558-0607.

CONTENTS

English

Important Owner Information ..............................................2

Introduction...........................................................................2

Important Safety Information...............................................3

Model Description.................................................................4

Model Designation................................................................5

Specifications........................................................................5

Plug Configurations..............................................................5

Electrical Rating Chart .........................................................5

Dimensions ..........................................................................6

Installation.............................................................................7

General ................................................................................7

Reversing the Access Door..................................................8

Relocating the Proximity Switch...........................................9

Operation.............................................................................10

General ..............................................................................10

Setting the Air Temperature................................................11

IMPORTANT OWNER INFORMATION

Record the model number, serial number, voltage, and

purchase date of the unit in the spaces below (specification

label located on the ceiling sheet inside of the unit). Please

have this information available when calling Hatco for service

assistance.

Model No. ________________________________________

Serial No. ________________________________________

Voltage __________________________________________

Date of Purchase __________________________________

Setting the Humidity Level .................................................11

Food Holding Guide ...........................................................11

Maintenance ........................................................................12

General ..............................................................................12

Daily Cleaning....................................................................12

Removing the Glass Panels...............................................12

Removing the Rotating Rack .............................................12

Draining the Water Reservoir.............................................13

Removing Lime and Mineral Deposits ...............................13

Replacing a Display Light ..................................................13

Troubleshooting Guide ......................................................14

Error Codes........................................................................15

Options and Accessories...................................................15

Limited Warranty.................................................................18

Authorized Parts Distributors............................Back Cover

Business

Hours: 7:00

Telephone: 800-558-0607; 414-671-6350

e-mail: partsandservice@hatcocorp.com

Fax: 800-690-2966 (Parts and Service)

AM to 5:00 PM Central Standard Time (CST)

(Summer Hours: June to September—

7:00

AM to 5:00 PM CST Monday–Thursday

7:00

AM to 4:00 PM CST Friday)

414-671-3976 (International)

Register your unit!

Completing online warranty registration will prevent delay in

obtaining warranty coverage. Access the Hatco website at

www.hatcocorp.com, select the Parts & Service pull-down

menu, and click on “Warranty Registration”.

INTRODUCTION

Hatco Flav-R-Fresh®Humidified Impulse Display Cabinets are

designed to hold prepared foods for prolonged periods of time

while maintaining that “just-made” quality. Hatco Humidified

Impulse Display Cabinets provide the best environment for food

products by regulating the air temperature while at the same

time balancing the humidity level. The use of controlled,

moisturized heat maintains serving temperature and food

texture longer than conventional dry holding equipment.

The Flav-R-Fresh air flow pattern is designed to maintain

consistent cabinet temperature without drying out foods. The

precise combination of heat and humidity creates a “blanket”

effect around the food. The air flow rate enables the cabinet to

recover temperature rapidly after opening and closing the door.

Hatco Flav-R-Fresh Humidified Impulse Display Cabinets are

products of extensive research and field testing. The materials

used were selected for maximum durability, attractive

appearance and optimum performance. Every unit is inspected

and tested thoroughly prior to shipment.

Additional information can be found by visiting our web site at

www.hatcocorp.com.

tin

a

r

e

p

o

d

n

ty, a

fe

, sa

n

tio

lla

sta

s in

e

vid

o

r

l p

a

u

n

is ma

Th

in

C

sa

installation or operation of the unit.

Safety information that appears in this manual is identified by

the following signal word panels:

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

str

a

b

fe

ctio

u

e

in

ty in

n

ts. H

str

Fla

r

fo

s

r

tco

a

s a

n

ctio

u

Fr

-

R

v-

mme

co

e

in

r

a

e

p

p

u

H

sh

e

ll in

s a

d

n

th

in

g

mid

sta

is ma

ifie

lla

d

tio

u

n

a

Imp

n

l b

, o

lse

u

r

e

p

a

e

r

e

la

isp

D

n

, a

g

tin

a

to

r

io

r

p

d

g

y

d

NOTICE is used to address practices not related to

personal injury.

2

Form No. FDWDM-0915

Page 3

English

NOTICE

CAUTION

WARNING

WARNING

IMPORTANT SAFETY INFORMATION

Read the following important safety information before using this equipment to avoid serious

injury or death and to avoid damage to equipment or property.

ELECTRIC SHOCK HAZARD:

• Plug unit into a properly grounded electrical receptacle

of the correct voltage, size, and plug configuration. If

plug and receptacle do not match, contact a qualified

electrician to determine and install proper voltage and

size electrical receptacle.

• Turn OFF power switch, unplug power cord, and allow

unit to cool before performing any cleaning,

adjustments, or maintenance.

• Unit is not weatherproof. Locate unit indoors where

ambient air temperature is a minimum of 70°F (21°C).

• DO NOT submerge or saturate with water. Unit is not

waterproof. Do not operate if unit has been submerged

or saturated with water.

• Do not steam clean or use excessive water on unit.

• Do not overfill water reservoir. Overfilling can cause

electrical shock. Water reservoir is full when “LO H2O”

stops flashing on CABINET TEMPERATURE display.

Stop filling when “LO H2O” stops flashing on display.

• Turn OFF power switch and allow unit to cool before

draining water reservoir.

• Do not pull unit by power cord.

• Discontinue use if power cord is frayed or worn.

• Do not attempt to repair or replace a damaged power

cord. Cord must be replaced by Hatco, an Authorized

Hatco Service Agent, or a person with similar

qualifications.

• This unit must be serviced by qualified personnel only.

Service by unqualified personnel may lead to electric

shock or burn.

• Use only Genuine Hatco Replacement Parts when

service is required. Failure to use Genuine Hatco

Replacement Parts will void all warranties and may

subject operators of the equipment to hazardous

electrical voltage, resulting in electrical shock or burn.

Genuine Hatco Replacement Parts are specified to

operate safely in the environments in which they are

used. Some aftermarket or generic replacement parts

do not have the characteristics that will allow them to

operate safely in Hatco equipment.

FIRE HAZARD: Locate unit a minimum of 1″ (25 mm) from

combustible walls and materials. If safe distances are not

maintained, discoloration or combustion could occur.

Make sure protective lamp cover(s) are installed in front of

fluorescent lamp(s). Breakage of fluorescent lamps not

properly protected could result in personal injury and/or

food contamination.

Make sure food product has been heated to the proper

food-safe temperature before placing in unit. Failure to

heat food product properly may result in serious health

risks. This unit is for holding pre-heated food product only.

Make sure all operators have been instructed on the safe

and proper use of the unit.

This unit is not intended for use by children or persons

with reduced physical, sensory, or mental capabilities.

Ensure proper supervision of children and keep them away

from the unit.

Hatco Corporation is not responsible for the actual food

product serving temperature. It is the responsibility of the

user to ensure that the food product is held and served at

a safe temperature.

This unit has no “user-serviceable” parts. If service is

required on this unit, contact an Authorized Hatco Service

Agent or contact the Hatco Service Department at

800-558-0607 or 414-671-6350; fax 800-690-2966; or

International fax 414-671-3976.

BURN HAZARD: Some exterior surfaces on unit will get

hot. Use caution when touching these areas.

Locate unit at the proper counter height in an area that is

convenient for use. The location should be level to prevent

the unit or its contents from falling accidentally and strong

enough to support the weight of the unit and contents.

Transport unit in upright position only. Before moving or

tipping unit, secure all glass surfaces with tape and drain

water from water reservoir. Failure to do so may result in

damage to unit or personal injury.

Use of distilled water in the water reservoir of humidified

units is recommended to preserve the life of electrical and

mechanical components. If non-distilled water is used, the

reservoir will require periodic cleaning and deliming (refer

to the MAINTENANCE section for cleaning procedure). Unit

failure due to lime or mineral deposits is not covered under

warranty.

Do not use deionized or reverse osmosis water. It will

shorten the life of the water pan and heating element.

Do not lay unit on the side with the control panel. Damage

to unit could occur.

Use non-abrasive cleaners and cloths only. Abrasive

cleaners and cloths could scratch the finish of the unit,

marring its appearance and making it susceptible to soil

accumulation.

Clean unit daily to avoid malfunctions and maintain

sanitary operation.

Locate in an area that avoids air current around unit. Avoid

areas that may be subject to active air movements or

currents (i.e, near exhaust fans/hoods, exterior doors, and

air conditioning ducts).

Form No. FDWDM-0915

3

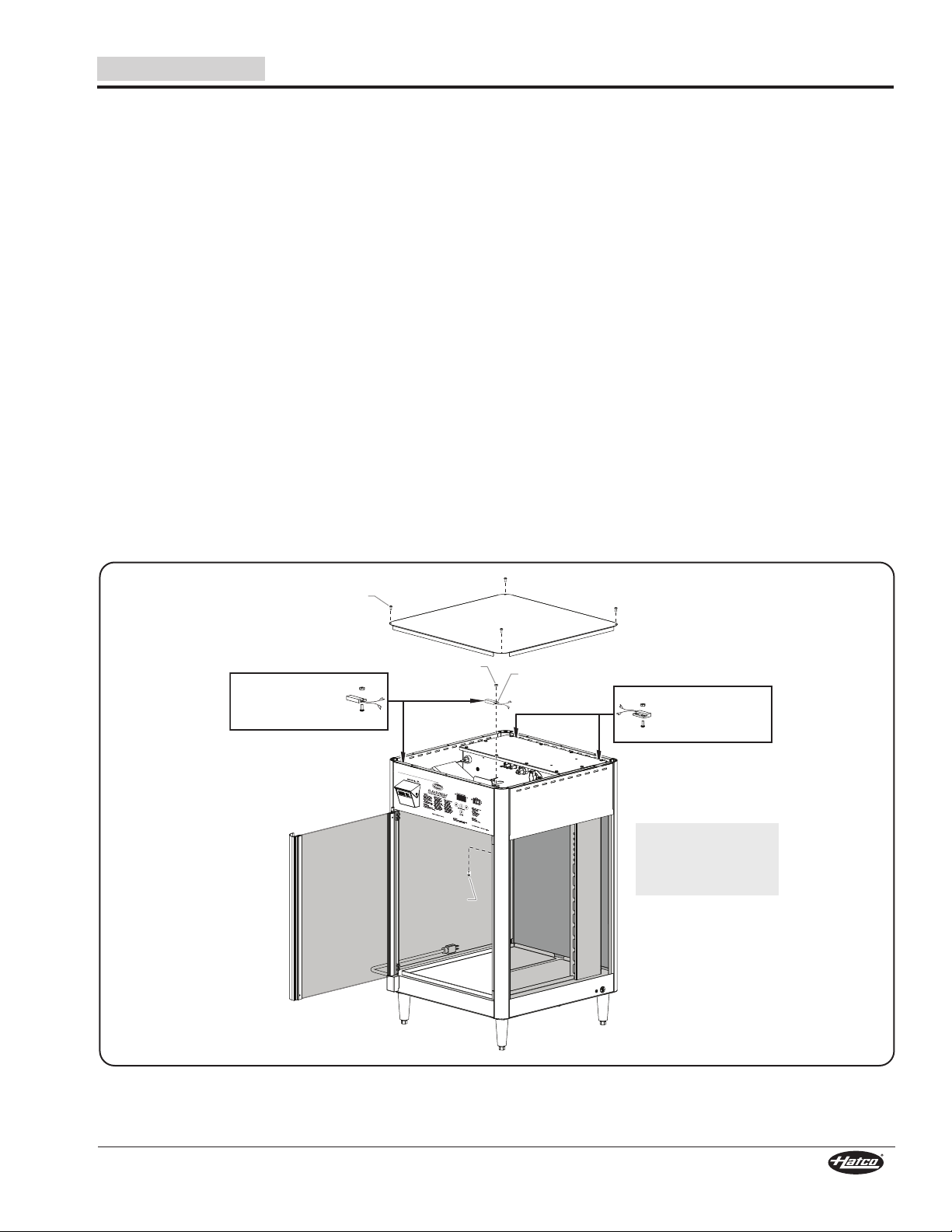

Page 4

MODEL DESCRIPTION

English

All Models

All Flav-R-Fresh®Humidified Impulse Display Cabinets have an

air heating system, humidity system with low water control

protection, fluorescent lamps, tempered glass sides, and a

door. Units can be configured with or without a humidity system

with low water control protection. The standard access door can

be hinged left or right. All available display racks are nickelplated except the pretzel tree display rack, which is stainless

steel. All units are available in several Designer colors.

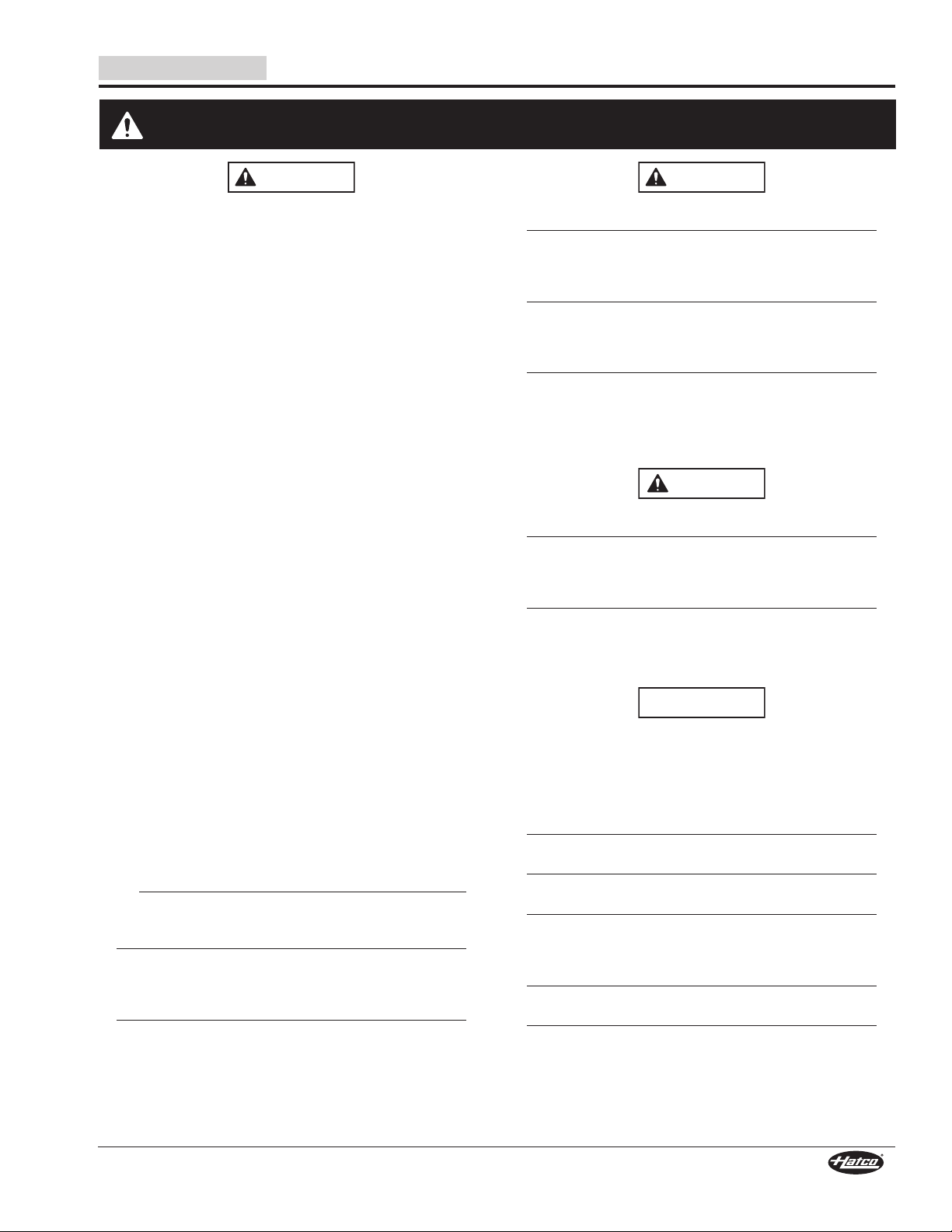

Model FDWD-1

Model FDWD-1 is a single door model with a motorized rotating

display. It comes standard with a pizza rack that holds up to

four (4) round pizza pans with a maximum diameter of 15″

(381 mm). The rotating rack stops automatically when the door

is opened. An optional rotating pretzel tree or a 4-shelf multipurpose stationary rack is available also.

FDWD-1

NOTE: Model FDWD-1 cannot be converted to a model

FDWD-2 or FDWD-2X.

Model FDWD-2

Model FDWD-2 has the same features as the FDWD-1, but

includes an additional door on the opposite side of the controls

for pass-through convenience.

Model FDWD-1X

Model FDWD-1X is similar to the FDWD-1, but features a

4-shelf, multi-purpose stationary rack instead of the motorized

rotating display. The rack can hold pans with a maximum width

of 13″ (330 mm) and a depth of 18″ (457 mm).

Model FDWD-2X

Model FDWD-2X has the same features as the FDWD-1X, but

includes an additional door on the opposite side of the controls

for pass-through convenience.

NOTE: Model FDWD-2X cannot be converted to a model

FDWD-2, FDWD-1, or FDWD-1X.

Model FDWD-12-1

Model FDWD-12 has the same features as the FDWD-1, but

has a smaller frame with a reduced footprint. This unit holds

pizza pans with a maximum diameter of 12″ (305 mm). Optional

rotating pretzel tree is not available.

FDWD-12-1

Model FDWD-12-1X

Model FDWD-12-1X is similar to the FDWD-12-1, but features

a 4-shelf, multi-purpose stationary rack instead of the motorized

rotating display. The rack can hold pans with a maximum width

of 13″ (330 mm) and a depth of 16″ (406 mm).

Model FDWD-12-2X

The FDWD-12-2X has the same features as the FDWD-12-1X,

but includes an additional door on the opposite side of the

controls for pass-through convenience.

NOTE: Refer to the OPTIONS AND ACCESSORIES section

in this manual for additional options available for the

above models.

FDWD-1X

NOTE: Model FDWD-1X cannot be converted to a model

FDWD-1, FDWD-2, or FDWD-2X.

4

Form No. FDWDM-0915

Page 5

English

WARNING

NEMA 5-15P

CEE 7/7 Schuko AS-3112

BS-1363

F D W D - 1 X

Flav-R-Fresh Display Warmer

Designer

1 = One Door

2 = Two Doors

12-1 = Small Frame, One Door

12-2 = Small Frame, Two Doors

No Character = With Rack Motor

X = No Rack Motor

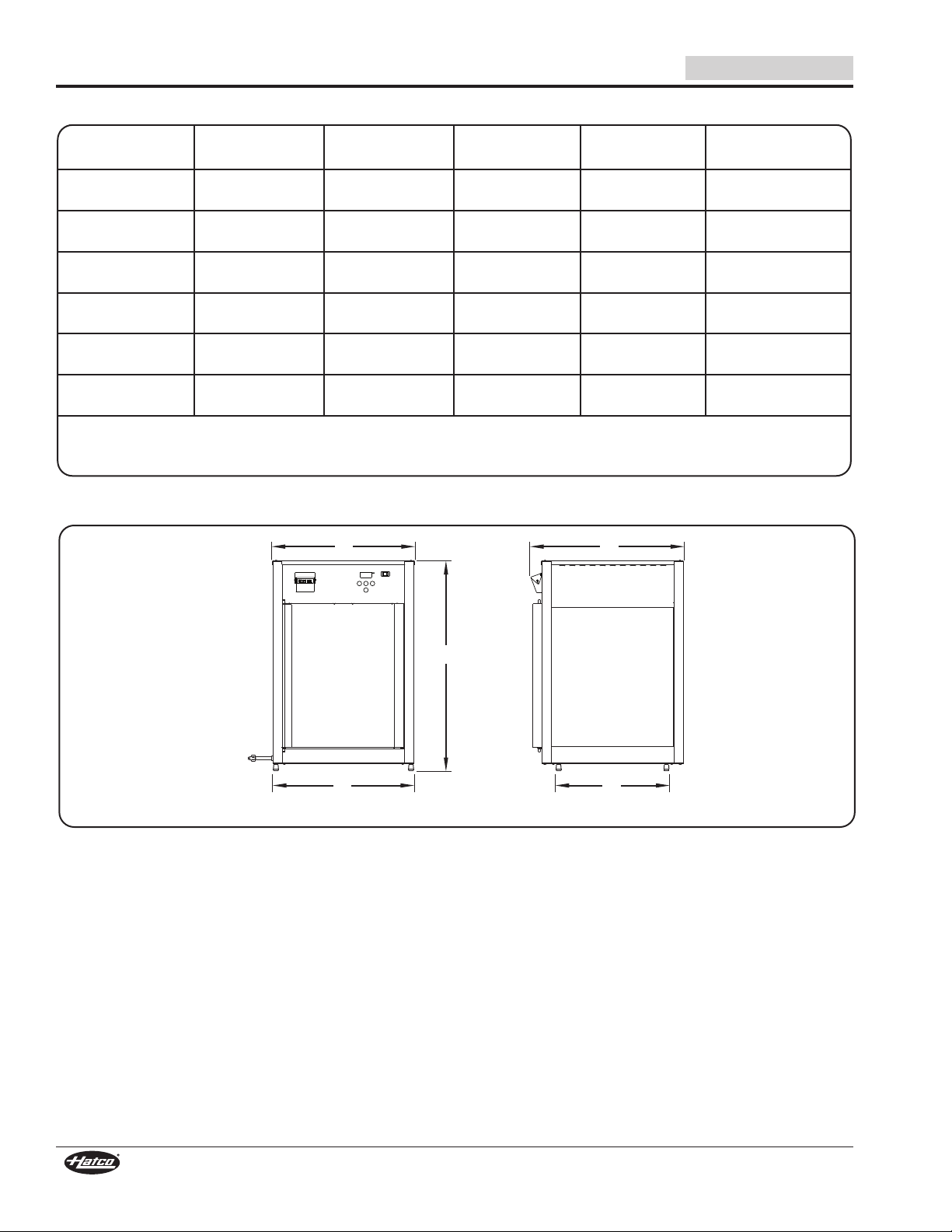

Plug Configurations

Units are supplied from the factory with an electrical cord and

plug installed. Plugs are supplied according to the applications.

ELECTRIC SHOCK HAZARD: Plug unit into a properly

grounded electrical receptacle of the correct voltage, size,

and plug configuration. If plug and receptacle do not

match, contact a qualified electrician to determine and

install the proper voltage and size electrical receptacle.

NOTE: Specification label is located on the ceiling sheet inside

of the unit. See label for serial number and verification

of unit electrical information.

MODEL DESIGNATION

SPECIFICATIONS

Plug Configurations

NOTE: Receptacle not supplied by Hatco.

Electrical Rating Chart

Model Voltage Watts Amps Plug Configuration Shipping Weight

FDWD-1,

FDWD-1X,

FDWD-2, and

FDWD-2X

(with humidity)

220–230 (CE) 1440–1574 6.5–6.8 CEE 7/7 Schuko 90 lbs. (41 kg)

230–240 (CE) 1323–1440 5.8–6.0 BS-1363 90 lbs. (41 kg)

FDWD-1,

FDWD-1X,

FDWD-2, and

FDWD-2X

(no humidity)

220–230 (CE) 1115–1219 5.1–5.3 CEE 7/7 Schuko 90 lbs. (41 kg)

230–240 (CE) 1024–1115 4.5–4.6 BS-1363 90 lbs. (41 kg)

FDWD-12 Series

(with humidity)

FDWD-12 Series

(no humidity)

The shaded areas contain electrical information for International models only.

Form No. FDWDM-0915

220–230 (CE) 1210–1322 5.5–5.7 CEE 7/7 Schuko, BS-1363, AS 3112 98 lbs. (44 kg)

230–240 (CE) 1322–1440 5.7–6.0 CEE 7/7 Schuko, BS-1363, AS 3112 98 lbs. (44 kg)

220–230 (CE) 937–1024 4.2–4.4 CEE 7/7 Schuko, BS-1363, AS 3112 98 lbs. (44 kg)

230–240 (CE) 1024–1115 4.4–4.6 CEE 7/7 Schuko, BS-1363, AS 3112 98 lbs. (44 kg)

100 1440 14.4 NEMA 5-15P 90 lbs. (41 kg)

120 1390 11.6 NEMA 5-15P 90 lbs. (41 kg)

220 1440 6.5 CEE 7/7 Schuko or BS-1363 90 lbs. (41 kg)

240 1440 6.0 CEE 7/7 Schuko or AS 3112 90 lbs. (41 kg)

100 1115 11.2 NEMA 5-15P 90 lbs. (41 kg)

120 1065 8.9 NEMA 5-15P 90 lbs. (41 kg)

220 1115 5.1 CEE 7/7 Schuko or BS-1363 90 lbs. (41 kg)

240 1115 4.6 CEE 7/7 Schuko or AS 3112 90 lbs. (41 kg)

120 1390 11.6 NEMA 5-15P 98 lbs. (44 kg)

120 1065 8.9 NEMA 5-15P 98 lbs. (44 kg)

5

Page 6

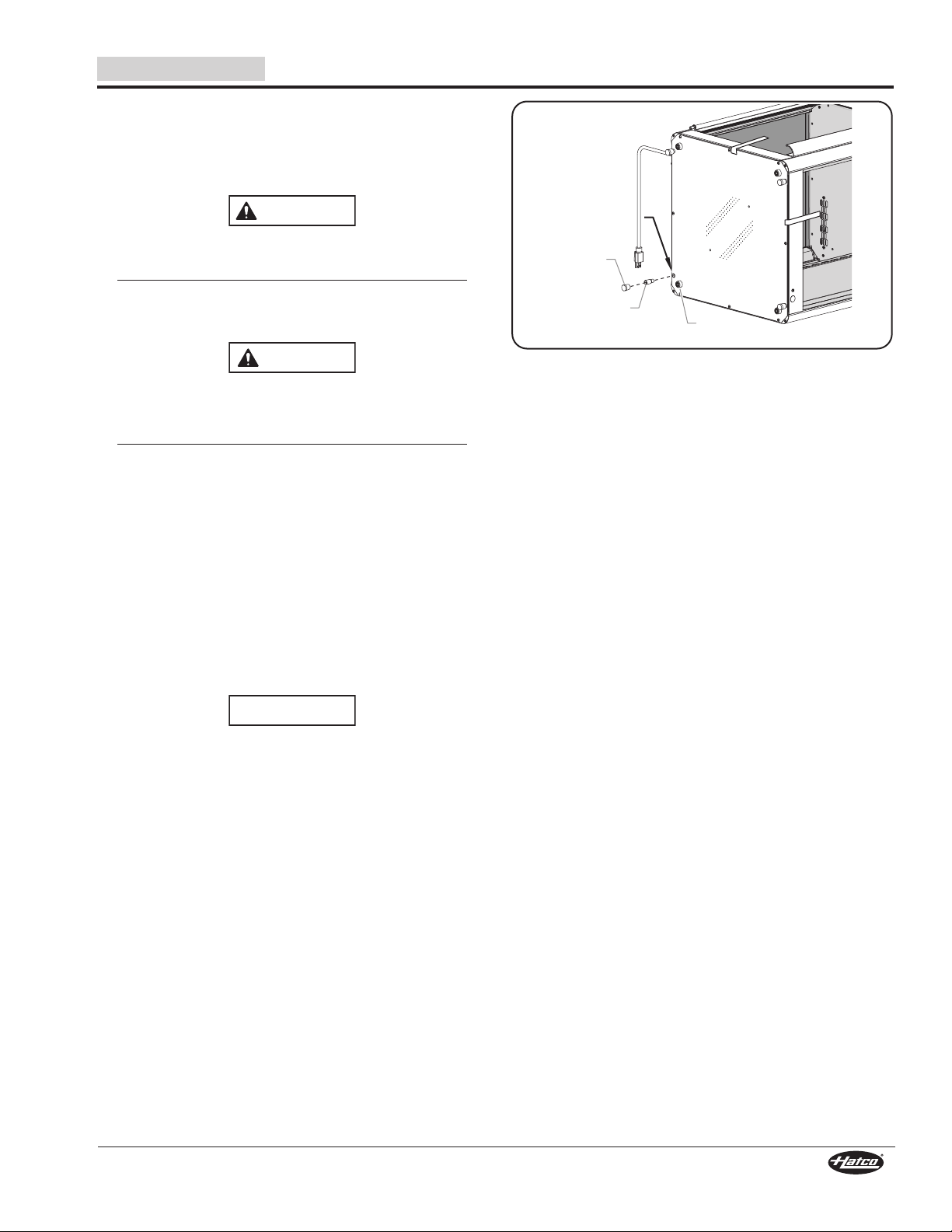

SPECIFICATIONS

A

D E

B

C

Front View Side View

Dimensions

English

Width

Model

FDWD-1 19-3/8″

FDWD-1X 19-3/8″

FDWD-2 19-3/8″

FDWD-2X 19-3/8″

FDWD-12-1

FDWD-12-1X

FDWD-12-2X 17-1/2″

Cabinet Openings:

FDWD-1, -1X, -2, -2X = 15-3/4″ W x 19-3/4″ H (400 x 502 mm)

FDWD-12-1, -12-1X, -12-2X = 14″ W x 19-3/4″ H (356 x 502 mm)

* Add 3″ (76 mm) to Height (C) of the unit if the 4″ (102 mm) leg option is installed.

(A)

(492 mm)

(492 mm)

(492 mm)

(492 mm)

17-1/2″

(445 mm)

(445 mm)

Depth

(B)

20-7/8″

(530 mm)

20-7/8″

(530 mm)

22″

(559 mm)

22″

(559 mm)

19-1/8″

(486 mm)

19-7/8″

(506 mm)

Height

(C)*

28-5/8″

(727 mm)

28-5/8″

(727 mm)

28-5/8″

(727 mm)

28-5/8″

(727 mm)

28-5/8″

(727 mm)

28-5/8″

(727 mm)

Footprint

Width (D)

19-1/16″

(485 mm)

19-1/16″

(485 mm)

19-1/16″

(485 mm)

19-1/16″

(485 mm)

17-3/8″

(441 mm)

17-3/8″

(441 mm)

Footprint

Depth (E)

15-3/8″

(390 mm)

15-3/8″

(390 mm)

15-3/8″

(390 mm)

15-3/8″

(390 mm)

13-11/16″

(348 mm)

13-11/16″

(348 mm)

6

Form No. FDWDM-0915

Page 7

English

Shipping

Foot

Rubber

Tip

1″ (25 mm)

Metal Foot

Threaded

Hole

Threaded

Hole

CAUTION

WARNING

NOTICE

General

Flav-R-Fresh®Humidified Impulse Display Cabinets are

shipped with most components installed and ready for

operation. The following installation instructions must be

performed before plugging in and operating this unit.

ELECTRIC SHOCK HAZARD: Unit is not weatherproof.

Locate unit indoors where the ambient air temperature is a

minimum of 70°F (21°C).

FIRE HAZARD: Locate unit a minimum of 1″ (25 mm) from

combustible walls and materials. If safe distances are not

maintained, discoloration or combustion could occur.

Locate unit at the proper counter height in an area that is

convenient for use. The location should be level to prevent

the unit or its contents from falling accidentally and strong

enough to support the weight of the unit and contents.

Transport unit in upright position only. Before moving or

tipping unit, secure all glass surfaces with tape and drain

water from water reservoir. Failure to do so may result in

damage to unit or personal injury.

1. Remove the unit from the carton. Two people are required

for this step.

NOTE: To prevent delay in obtaining warranty coverage,

complete online warranty registration. See the

IMPORTANT OWNER INFORMATION section for

details.

2. Remove the rack from the unit.

3. Install the four 1″ (25 mm) metal, screw-type feet and rubber

tips (both included with unit). To install:

Do not lay unit on the side with the control panel. Damage

to unit could occur.

a. Make sure all glass sides and doors are secure with

tape. Lay the unit on its side.

b. Screw the 1″ (25 mm) feet into the threaded holes near

each corner of the unit. Tighten securely.

c. Place a rubber tip over each foot.

d. Return the unit to its upright position.

INSTALLATION

Installing the 1″ (25 mm) Feet

NOTE: If installing 4″ (102 mm) legs, do not remove glass

protection until leg installation is complete. See the

OPTIONS AND ACCESSORIES section for installation

instructions.

4. Remove tape and protective packaging from all surfaces of

the unit, shelves, and any accessories.

• Floor Sheet — The stainless steel floor in all cabinets is

protected during shipping with a sheet of corrugated

cardboard. This protection must be removed prior to

cabinet operation.

• Display Racks — The display racks have packing

material and cardboard attached for protection during

shipping. This protection must be removed prior to

cabinet operation.

• Glass Panels — The cabinets have tempered glass

panels that are protected during shipping with foamed

tape to hold the panels securely. All tape must be

removed prior to cabinet operation.

5. Place the unit in the desired location. Two people are

required for this step.

• Locate the unit in an area where the ambient air

temperature is constant and a minimum of 70°F (21°C).

Avoid areas that may be subject to active air movements

or currents (i.e., near exhaust fans/hoods, air

conditioning ducts, drive-through windows, exterior

doors).

• Make sure the unit is at the proper counter height in an

area convenient for use.

• Make sure the countertop is level and strong enough to

support the weight of the unit and food product.

Form No. FDWDM-0915

7

Page 8

INSTALLATION

Hinge Asse mbly

Bottom Hinge Pin Screw and

Nylon Washer(s)

Door Rotated 180°

Top Hinge

Pin Screw

Lamp

Cover

Striker Plate and

Hardware

English

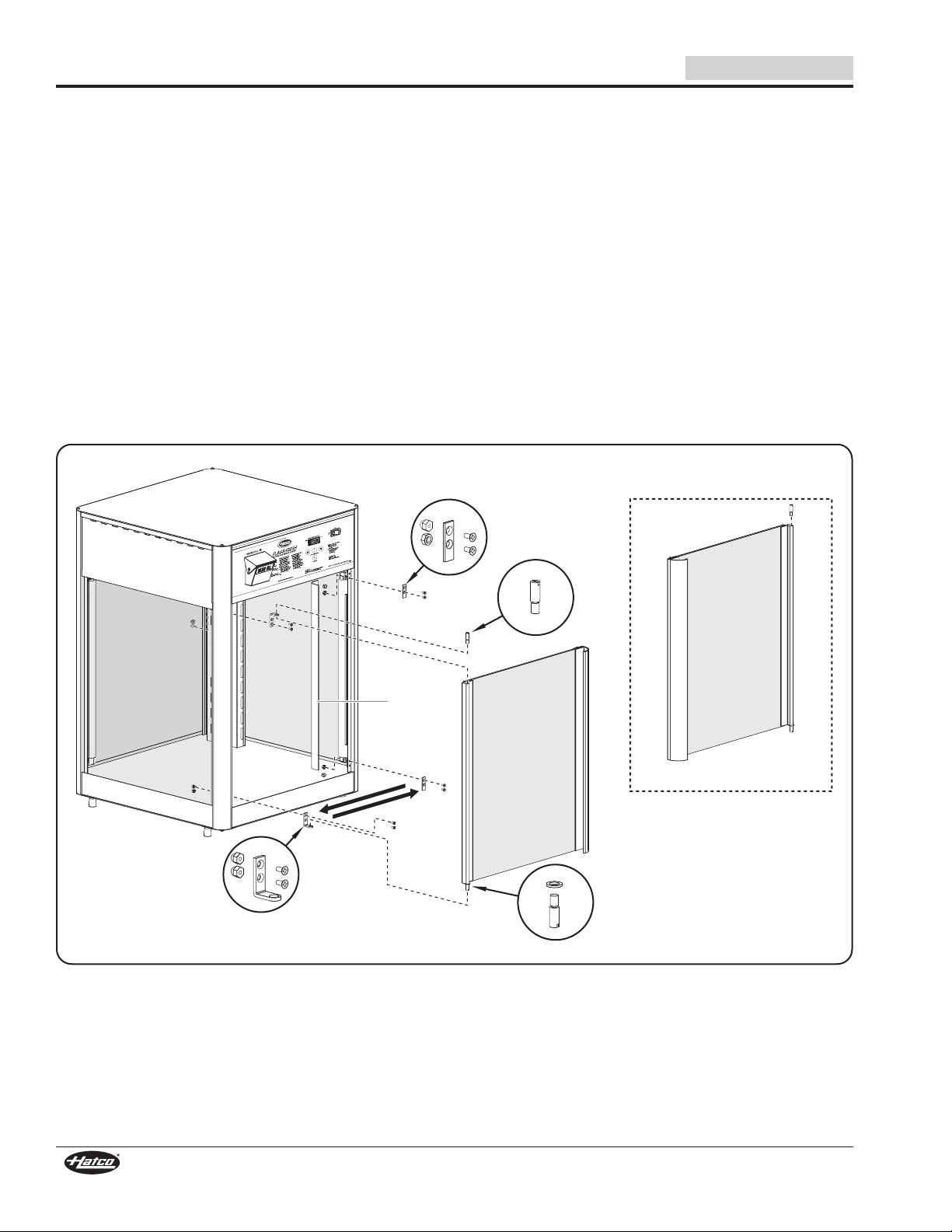

Reversing the Access Door

The Flav-R-Fresh access door(s) may be hinged on either the

left or right side for convenience. Use the following procedure

to reverse the access door.

NOTE: For models equipped with a motorized rotating rack

(FDWD-1, FDWD-2, and FDWD-12-1), the “Relocating

the Proximity Switch” procedure in this section must be

performed after reversing the access door(s).

1. Remove the top hinge pin screw that holds the door to the

hinge bracket.

2. Tip the door assembly forward (away from cabinet) and lift

gently to clear the bottom hinge bracket. Remove the nylon

washer(s).

3. Reinstall the top hinge pin screw.

4. Remove the fluorescent lamp cover to allow access to the

hinge bracket/striker plate hardware.

5. Remove the screws holding the hinge brackets to the cabinet.

6. Remove the screws from the striker plates on the non-hinge

side of the cabinet.

7. Install the striker plates on the opposite side of the cabinet

where the hinge brackets were previously mounted.

8. Install the hinges on the opposite side of the cabinet where

the striker plates were previously mounted using the original

hinge bracket mounting screws.

9. Replace the fluorescent lamp cover.

10. Carefully rotate the door 180°.

11. Remove the hinge pin screw from the end that is now the

top.

12. Carefully place the door assembly with the nylon washer(s)

into the bottom hinge bracket.

13. Tip/tilt the door assembly towards the cabinet and align the

door top with the hinge bracket. Reinstall the top door hinge

pin screw through the hinge bracket and into the door top.

Reversing the Access Door

8

Form No. FDWDM-0915

Page 9

English

Orientation of

proximity switch

for control-side

door installations.

Orientation of

proximity switch

for customer-side

door installations.

Proximity

Switch

Screw

Proximity

Switch

Screw

Proximity

Switch

Screw

Proximity switch(es)

should be installed

on the same side as

the door handle.

One switch per door.

Cover Screw

Proximity

Switch

Proximity

Switch Nut

INSTALLATION

Relocating the Proximity Switch

(Rotating Rack Models Only)

Units equipped with a rotating rack will require relocating the

proximity switch(es) after reversing the door(s).

The proximity switch signals the rack motor to stop when a door

is opened and to start when the door is closed. Follow the steps

listed below to move the proximity switch(es) to the proper

position after reversing the door(s). Unit requires one switch per

door.

1. Turn off the unit and unplug the unit from the power source.

2. Remove the four screws and top cover.

3. Remove the screw and nut securing the proximity switch to

the cabinet ceiling sheet. The screw is accessed from inside

the cabinet. Reinstall screw and nut into hole after removing

switch.

4. Cut the cable tie securing the proximity switch wires to the

wiring harness. Mark the two wires for reassembly and

unplug the wires from the proximity switch wire leads. Route

the wires to the opposite corner and reattach the wires to

the switch wire leads.

NOTE: Make sure to install the proximity switch in the

orientation shown below for the specific installation

location. Incorrect orientation will result in malfunction of

the proximity switch.

5. Remove the screw and nut from the new mounting hole.

Secure the proximity switch to the mounting hole with the

screw and nut. Make sure to maintain proper switch

orientation when tightening the hardware.

6. Make sure wires do not interfere with the other components

inside the cabinet, then secure switch wires to wiring

harness with a cable tie (not supplied).

NOTE: On models equipped with two doors, it may be

necessary to move the air chamber to access the

proximity switch on the customer-side door. Drain all

water from the unit, remove the drain valve from inside

the cabinet, and remove the four screws securing the air

chamber assembly to the cabinet. Carefully move the

air chamber out of the way to access the proximity

switch. Reassemble after relocating switch.

7. Install the top cover and four screws.

8. Plug the unit into the proper power source.

9. Turn on the unit and test the operation of the proximity

switch(es) by making sure the rack rotates when the doors

are closed and stops rotating when a door is opened.

Form No. FDWDM-0915

Relocating the Proximity Switch (one door, left-hinged installation shown)

9

Page 10

OPERATION

NOTICE

WARNING

WARNING

WARNING

English

General

Use the following procedures to operate Flav-R-Fresh

Humidified Impulse Display Cabinets.

Read all safety messages in the IMPORTANT SAFETY

INFORMATION section before operating this equipment.

Startup

1. Plug unit into a properly grounded electrical receptacle of

the correct voltage, size, and plug configuration. See the

SPECIFICATIONS section for details.

2. Move the POWER ON/OFF (I/O) switch to the ON (I)

POSITION.

• The display lights will turn on and the heating system will

start up.

• On humidified units, the cabinet temperature display will

flash “LO H2O” four times and then flash the cabinet

temperature. It will continue to alternate this way until the

water reservoir is filled. Once the reservoir is full, “LO

H2O” will stop flashing and the display will show the

cabinet temperature.

Use of distilled water in the water reservoir of humidified

units is recommended to preserve the life of electrical and

mechanical components. If non-distilled water is used, the

reservoir will require periodic cleaning and deliming (refer

to the MAINTENANCE section for cleaning procedure). Unit

failure due to lime or mineral deposits is not covered under

warranty.

Do not use deionized or reverse osmosis water. It will

shorten the life of the water pan and heating element.

NOTE: Unit failure caused by deionized or reverse osmosis

water is not covered by warranty.

3. On humidified units, fill the water reservoir with clean water.

To fill the reservoir:

a. Lift up the fill cup cover and pull forward.

b. Slowly pour the water into the cup until “LO H2O” stops

flashing on the cabinet temperature display.

IMPORTANT NOTE

®

When using distilled water, add one teaspoon of salt to the

water reservoir during the initial water fill only. This will ensure

proper operation of the water level sensors.

ELECTRIC SHOCK HAZARD: Do not overfill water reservoir.

Overfilling can cause electrical shock. Water reservoir is full

when “LO H2O” stops flashing on CABINET TEMPERATURE

display. Stop filling when “LO H2O” stops flashing on display.

NOTE: On the initial fill, the water reservoir capacity is

Make sure food product has been heated to the proper

food-safe temperature before placing in unit. Failure to heat

food product properly may result in serious health risks.

This unit is for holding pre-heated food product only.

Hatco Corporation is not responsible for the actual food

product serving temperature. It is the responsibility of the

user to ensure that the food product is held and served at

a safe temperature.

BURN HAZARD: Some exterior surfaces on the unit will get

hot. Use caution when touching these areas.

80 ounces or 2-1/2 quarts (2.3 liters).

4. On humidified units, set the humidity to the desired level (refer

to the “Setting the Humidity Level” procedure in this section).

See the “Food Holding Guide” for recommendations.

5. Set the air temperature to the desired temperature (refer to

the “Setting the Air Temperature” procedure in this section).

See the “Food Holding Guide” for recommendations.

6. Allow the unit 20 minutes to reach operating temperature

before loading the cabinet with pre-heated food product.

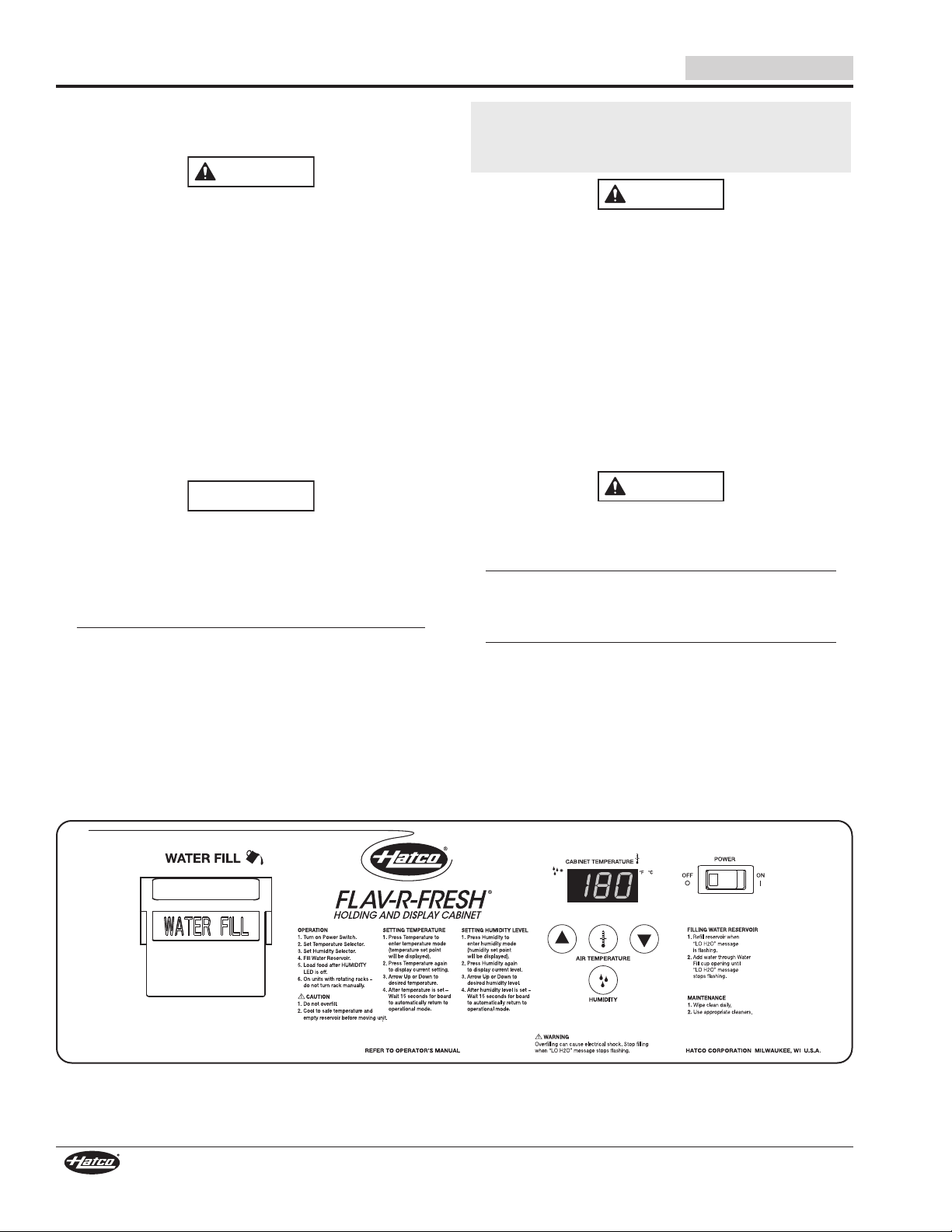

Flav-R-Fresh Control Panel

10

Form No. FDWDM-0915

Page 11

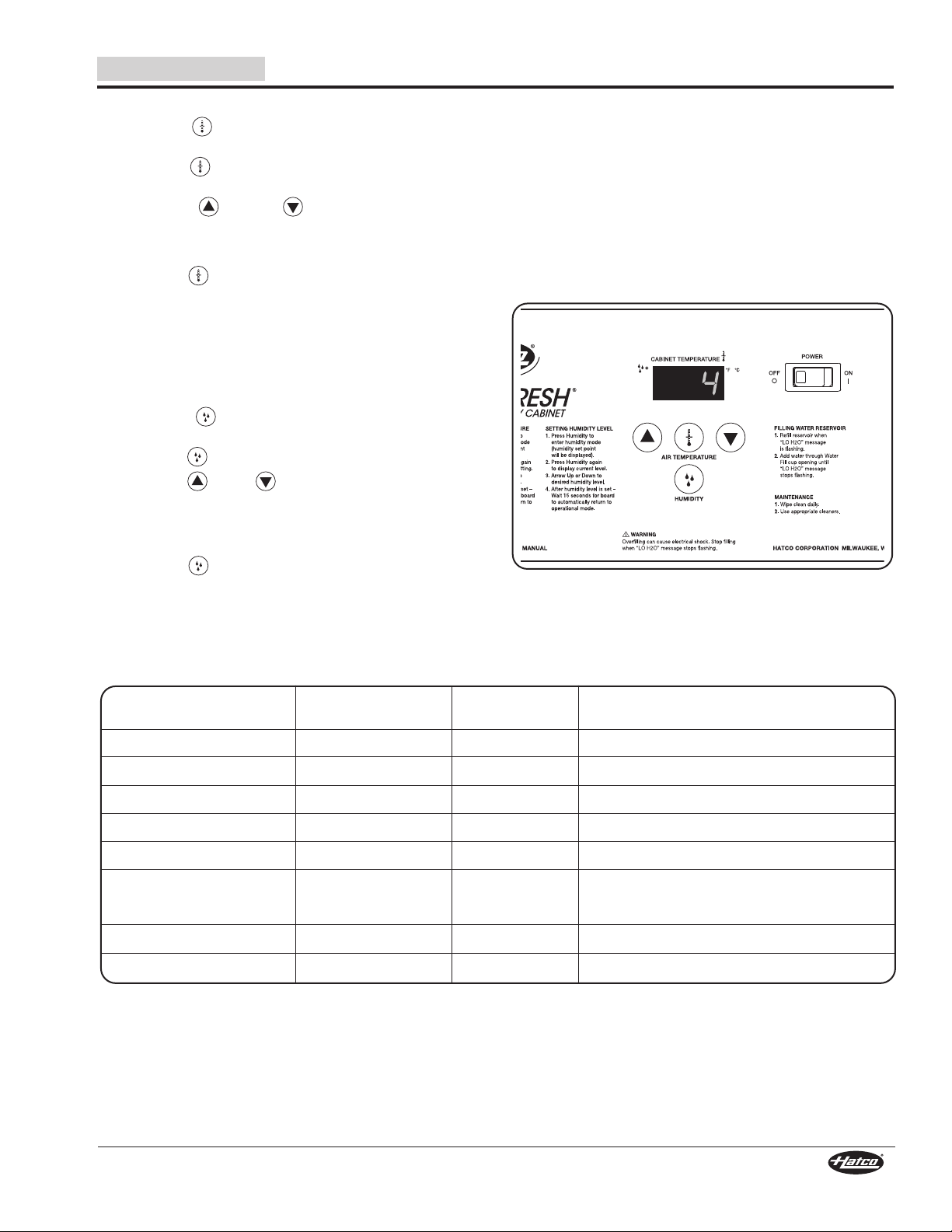

English

OPERATION

Setting the Air Temperature

1. Press the key to enter temperature mode (“tSP” will

appear on the CABINET TEMPERATURE display).

2. Press the key again to show the current temperature

setting.

3. Press the key or key to reach the desired

temperature. The temperature range is 80°–195°F

(27°–91°C) in single degree increments. See the “Food

Holding Guide” in this section for recommendations.

4. Press the key to save the setting.

5. After the desired temperature is set, wait 15 seconds

without pushing any keys for the cabinet temperature

display to return automatically to operational mode.

Setting the Humidity Level

Use the following procedure to set the humidity level on

humidified units.

1. Press the key to enter humidity mode (“hSP” will

appear on the CABINET TEMPERATURE display).

2. Press the key again to show the current humidity level.

3. Press the key or key to reach the desired humidity

level. Humidity range is 0 through 5 (0 is no humidity, 1 is

the lowest amount of humidity, and 5 is the highest). See

the “Food Holding Guide” in this section for

recommendations.

4. Press the key to save the setting.

5. After the desired humidity level is set, wait 15 seconds

without pushing any keys for the CABINET TEMPERATURE

display to return automatically to operational mode.

NOTE: Temperature and humidity settings may vary depending

upon product make-up and consistency. The CABINET

TEMPERATURE display shows the lowest temperature

point inside the cabinet, not the product temperature.

The capacity of the water reservoir permits uninterrupted

operation for approximately 3–6 hours, depending on the

settings and how frequently the door is opened. When “LO

H2O” is flashing on the CABINET TEMPERATURE display, add

water to the reservoir. The water reservoir refill capacity is

approximately 64 ounces, or two (2) quarts (1.9 liters).

WARNING! ELECTRIC SHOCK HAZARD — Do not overfill

water reservoir.

Control Panel

Food Holding Guide

Maximum Humidity Temperature

Type of Food Holding Time Setting °F °C

Biscuits 4 Hours 4 130 55

Chicken Pieces (Fried) 4 Hours 5 175 80

Croissants 4 Hours 1 140 60

Fruit Pies 3-1/2 Hours 4 140 60

Onion Rings 1/2 to 1 Hour 1 175 80

Pizza — Thick Crust 1 Hour 4 185 85

Thin Crust 1 Hour 5 180 82

Pretzels 3 Hours 4 140 60

Wrapped Sandwiches 2 Hours 4 180 82

NOTE: All times and settings are recommendations only and may vary depending on product preparation, cooking time, and

internal food temperature.

Form No. FDWDM-0915

11

Page 12

MAINTENANCE

NOTICE

WARNING

Unlocked Position

Locked Position

Decompressed

Coupling

Motor Shaft

Rack

Shaft

Compressed

Coupling

Rack

Shaft

Motor Shaft

Bow

Cotter Pin

Bow

Cotter Pin

English

General

Hatco Flav-R-Fresh®Humidified Impulse Display Cabinets are

designed for maximum durability and performance, with

minimum maintenance.

ELECTRIC SHOCK HAZARD:

• Turn OFF power switch, unplug power cord, and allow

unit to cool before performing any cleaning, setup, or

maintenance.

• DO NOT submerge or saturate with water. Unit is not

waterproof. Do not operate if unit has been submerged

or saturated with water.

• Do not steam clean or use excessive water on unit.

• Use only Genuine Hatco Replacement Parts when

service is required. Failure to use Genuine Hatco

Replacement Parts will void all warranties and may

subject operators of the equipment to hazardous

electrical voltage, resulting in electrical shock or burn.

Genuine Hatco Replacement Parts are specified to

operate safely in the environments in which they are

used. Some aftermarket or generic replacement parts

do not have the characteristics that will allow them to

operate safely in Hatco equipment.

This unit has no “user-serviceable” parts. If service is

required on this unit, contact an Authorized Hatco Service

Agent or contact the Hatco Service Department at 800-5580607 or 414-671-6350; fax 800-690-2966; or International

fax 414-671-3976.

Removing the Glass Panels

1. Lift the glass panel out of the bottom channel of the cabinet.

2. Pull the lower edge away from the cabinet.

3. Carefully lower the glass until the top clears the cabinet.

Replacing the Glass Panel

1. Position the glass panel with the top edge under the top

cabinet lip, and raise the glass until it clears the bottom

channel of the cabinet.

2. Move the bottom of the glass towards the cabinet until the

glass rests against the cabinet frame.

3. Carefully lower the glass until it rests in the bottom channel

of the cabinet.

Removing the Rotating Rack

(FDWD-1, FDWD-2, and FDWD-12-1 Models)

1. Open the front access door.

2. Pull down the spring-mounted coupling to compress.

3. Tip the rack until the rack shaft clears the motor shaft.

NOTE: Do not remove the bow cotter pin from the rack shaft.

Daily Cleaning

To preserve the finish of the Display Cabinet, perform the

following cleaning procedure daily.

Use non-abrasive cleaners only. Abrasive cleaners could

scratch the finish of the unit, marring its appearance and

making it susceptible to soil accumulation.

1. Turn off the unit, unplug the power cord, and allow the unit

to cool.

2. Remove and wash all food pans.

3. Wipe down all interior and exterior metal surfaces with a

damp, non-abrasive cloth. Stubborn stains may be removed

with a good non-abrasive cleaner. Clean hard to reach

areas using a small brush and mild soap.

NOTE: Both the rotating display rack and the stationary rack

are removable for cleaning, if necessary. Refer to the

“Removing the Rotating Rack” procedure in this section

for removal.

4. Wipe dry the entire unit using a clean and dry, non-abrasive

cloth.

5. Clean the glass side panels and door panel(s) using

ordinary glass cleaner and a damp, soft cloth or paper

towel. The side panels are removable for detailed cleaning,

if necessary. Refer to the “Removing the Glass Panels”

procedure in this section for removal.

Removing Motorized Display Racks

Replacing the Rotating Rack

1. Insert the rack into the cabinet and place the rack bottom

point in the dimple located at the center of the cabinet floor.

2. Pull down the spring-mounted coupling to compress.

3. Tip the rack to line up the rack shaft with the motor shaft pin.

4. Decompress the spring-mounted coupling until the coupling

is locked in place with the motor shaft pin.

12

Form No. FDWDM-0915

Page 13

English

Valve

Open

Valve

Closed

WARNING

WARNING

MAINTENANCE

Draining the Water Reservoir

On humidified units, the water reservoir must be drained prior

to moving the cabinet as well as during the “Removing Lime

and Mineral Deposits” procedure.

ELECTRIC SHOCK HAZARD: Turn the power switch OFF,

unplug the power cord, and allow the unit to cool before

performing any maintenance or cleaning.

1. Move the POWER ON/OFF (I/O) switch to the OFF (O)

position and unplug the power cord. Allow the unit to cool.

2. Locate the valve inside the cabinet on the underside of the

ceiling sheet. CAUTION! BURN HAZARD—Ceiling sheet

and water in reservoir are hot during operation. Allow to

cool before draining.

3. Remove the rack from the unit.

4. Position a one gallon (four liter) container under the valve.

5. Turn the valve handle from the horizontal position (closed)

to the vertical position (open) to drain the reservoir.

6. Once the reservoir is empty, return the valve handle to the

closed position.

7. Replace the rack.

Removing Lime and Mineral Deposits

Use the following procedure for periodic cleaning and de-liming

of the water reservoir on humidified models.

NOTE: The lime and mineral content of the water used for daily

operation will determine how often the deliming

procedure must be performed.

NOTE: Perform this procedure when the unit will not be used

for a period of time, such as the end of the day.

1. Move the POWER ON/OFF (I/O) switch to the OFF (O)

position and unplug the power cord. Allow the unit to cool.

2. After the unit has cooled down, perform the “Draining the

Water Reservoir” procedure in this section.

3. Fill the water reservoir with a mixture of 75% water and 25%

white vinegar. Do not use flavored vinegar.

4. Plug in and turn on the unit.

5. Set both the air temperature and humidity to their highest

settings and allow the unit to run for 30 minutes.

6. Move the POWER ON/OFF (I/O) switch to the OFF (O)

position and unplug the power cord. Allow the unit to cool.

7. Perform the “Draining the Water Reservoir” procedure to

empty the deliming solution from the water reservoir.

8. Continue to fill and drain the water reservoir with clean

water until the deliming solution is rinsed through and the

reservoir is clean.

9. Replace the rack.

10. Plug the unit into its power source and fill the reservoir as

usual for daily operation using the procedure in the

OPERATION section of this manual.

Draining Reservoir Valve

NOTE: If the water used has an excessive amount of lime or

mineral content, follow the “Removing Lime and Mineral

Deposits” procedure for periodic cleaning and deliming

of the water reservoir.

NOTE: Unit failure caused by liming or sediment buildup is not

covered under warranty.

Replacing A Display Light

Make sure protective lamp cover(s) are installed in front of

fluorescent lamp(s). Breakage of fluorescent lamps not

properly protected could result in personal injury and/or

food contamination.

Units are equipped with two fluorescent lamps that illuminate

the warming area. These lamps have a special lamp cover to

guard against injury and food contamination in the event of

breakage. When replacing a fluorescent lamp, use Hatco P/N

02.30.074.00. Use the following procedure to replace a

fluorescent lamp.

1. Turn off the unit, unplug the power cord, and allow the unit

to cool.

2. Remove the lamp cover from in front of the fluorescent

lamp.

3. Carefully twist the fluorescent lamp and pull out to remove

it from the sockets on each end.

4. Align the tabs on each end of the new fluorescent lamp

with the channels on each socket, and push the lamp into

the sockets.

5. Carefully twist the fluorescent lamp in the sockets until it

“snaps” into position.

6. Replace the lamp cover in front of the fluorescent lamp.

Form No. FDWDM-0915

13

Page 14

TROUBLESHOOTING GUIDE

WARNING

WARNING

English

This unit must be serviced by trained and qualified

personnel only. Service by unqualified personnel may lead

to electric shock or burn.

ELECTRIC SHOCK HAZARD: Turn OFF power switch,

unplug power cord, and allow unit to cool before

performing any cleaning, adjustments, or maintenance.

Symptom Probable Cause Corrective Action

Fluorescent lamp not working. Lamp loose or defective. Re-install or replace fluorescent lamp.

Ballast defective. Contact Authorized Service Agent or Hatco for assistance.

Light socket defective. Contact Authorized Service Agent or Hatco for assistance.

Unit operates, but is not

circulating air inside cabinet.

Unit is plugged in, but nothing

works.

Unit is operational, but rotating

rack (if equipped) does not

turn.

Blower motor is defective. Contact Authorized Service Agent or Hatco for assistance.

The correct voltage may not be

supplied to blower.

No power to unit. Check electrical receptacle and verify that power supply

Power cord connections are loose

or disconnected.

Power cord is damaged. Contact Authorized Service Agent or Hatco for assistance.

Defective ON/OFF (I/O) switch. Contact Authorized Service Agent or Hatco for assistance.

Proximity switch was not relocated

after door reversal.

Contact Authorized Service Agent or Hatco for assistance.

matches specifications on unit. If receptacle is not

working, check circuit breaker and reset, or plug unit into

a different known working receptacle.

Contact Authorized Service Agent or Hatco for assistance.

See “Relocating the Proximity Switch” in the

INSTALLATION section of this manual.

Unit is not producing any “hot

air” inside cabinet.

Unit is heating, but is producing

too much humidity inside the

cabinet causing steam inside

unit.

Unit is heating, but is not

producing humidity inside

cabinet. ‘LO H20’ is not

flashing, and unit is full of water.

Proximity magnet or proximity

switch not working properly.

Incorrect voltage is supplied to rack

motor.

Rack motor defective. Contact Authorized Service Agent or Hatco for assistance.

Safety high-limit is tripped or open. Contact Authorized Service Agent or Hatco for assistance.

Incorrect voltage supplied to

heating element.

Blower motor is not working. Contact Authorized Service Agent or Hatco for assistance.

Air heating element is defective. Contact Authorized Service Agent or Hatco for assistance.

Control board defective. Contact Authorized Service Agent or Hatco for assistance.

Temperature probe defective. Contact Authorized Service Agent or Hatco for assistance.

Humidity control is set too high. Adjust the humidity control to a lower setting.

Air temperature is set too low. Adjust the temperature to a higher setting.

Humidity control is defective.

Incorrect voltage supplied to water

heating element or heating element

is defective.

Humidity element defective. Contact Authorized Service Agent or Hatco for assistance.

Contact Authorized Service Agent or Hatco for assistance.

Contact Authorized Service Agent or Hatco for assistance.

Contact Authorized Service Agent or Hatco for assistance.

Contact Authorized Service Agent or Hatco for assistance.

Contact Authorized Service Agent or Hatco for assistance.

14

Form No. FDWDM-0915

Page 15

English

4″ (102 mm)

Leg

1″ (25 mm)

Metal

Foot

Bottom

Cover

Lengthen

Shorten

Adjustable Tip

TROUBLESHOOTING GUIDE

Symptom Probable Cause Corrective Action

Unit is heating, but is not

producing humidity inside

cabinet. ‘LO H20’ is flashing,

and unit is full of water.

When using distilled water, no

minerals are being sensed by low

water probe.

Low water protection system is

malfunctioning.

Probes have lime buildup. Refer to “Removing Lime and Mineral Deposits”

Error Codes

The following error codes may appear on the digital display to

indicate an error in the operating condition of the unit.

LO H20 = Low water probe does not detect water. Refill water

reservoir — refer to instructions in OPERATION section of this

manual.

E1 = Air temperature sensor malfunctioning. Contact

Authorized Service Agent or Hatco for assistance.

E2 = Humidity sensor malfunctioning. Contact Authorized

Service Agent or Hatco for assistance.

dE-L = Water reservoir needs deliming. Contact Authorized

Service Agent or Hatco for assistance.

Add one teaspoon of salt to the water reservoir.

Contact Authorized Service Agent or Hatco for

assistance.

procedure in the MAINTENANCE section to remove lime.

Troubleshooting Questions?

If you continue to have problems resolving an issue, please contact the nearest Authorized Hatco Service Agency or Hatco for

assistance. To locate the nearest Service Agency, log onto the

Hatco website at www.hatcocorp.com and click on

Find Service Agent, or contact the Hatco Parts and Service

Team at:

Telephone: 800-558-0607 or 414-671-6350

e-mail: partsandservice@hatcocorp.com

Fax: 800-690-2966 or 414-671-3976

4″ (102 mm) Adjustable Legs

The 4″ (102 mm) adjustable legs are used to add additional

height to the unit.

1. Remove the rack from the unit.

2. Secure all glass sides and doors with tape. Lay the unit

down on a side without controls or doors.

3. Remove the four 1″ (25 mm) metal screw-type feet.

Installation of 4″ (102 mm) Legs

Form No. FDWDM-0915

OPTIONS AND ACCESSORIES

4. Screw the 4″ (102 mm) legs into

the holes in the middle of each

corner on the bottom cover. After

all the legs are tightened, return

the unit to its upright position. If the

unit is not level or rocks, turn the

adjustable tip of the appropriate

leg to level the unit.

15

Page 16

OPTIONS AND ACCESSORIES

4-Shelf

Multi-Purpose Rack

Model FDW4SMP

3-3/4" (95 mm) opening

between shelves.

1st and 3rd shelves

are removable.

3-Tier Pretzel Tree*

Model FDW3TPT

5-7/8" (149 mm) opening

between racks.

*Racks designed for use with motorized display.

4-Shelf Circle Rack

with Retainers*

Model FDWD4TCRR

3-1/4" (83 mm) opening

between racks.

Max. 15" (381 mm)

diameter pans.

Motorless

Rack Coupling

WARNING

Hood

Mounting

Screw

Display

Sign Holder

Cabinet

Hood

English

Display Racks

Several display racks are available to “customize” Flav-R-

®

Fresh

to specific foodservice operations. All are nickel-plated

except the pretzel tree, which is stainless steel.

Display Racks

Motorless Rack Coupling

The motorless rack coupling allows the

stationary installation of a 4-tier circle rack or

3-tier pretzel tree in cabinets that do not

have a rack motor (FDWD-1X and -2X).

Sign Holders

(FDWD-1, FDWD-1X, FDWD-2, and FDWD-2X)

Use the following procedures to install a Display Sign Holder.

ELECTRIC SHOCK HAZARD: Turn the power switch OFF,

unplug the power cord, and allow the unit to cool before

performing any maintenance or cleaning.

One-Sided and Control-Side Sign Holder Installation

One-sided and control-side sign holders are available as

options.

One-Sided Sign Holders can be installed on any side of the unit

except the control side. Up to three One-Sided Sign Holders

can be installed on a unit. There are two height sizes available

for one-sided sign holders, 3″ (76 mm) and 6-3/8″ (162 mm).

Control-side sign holders are installed only on the control side.

The sign must be slid out of the sign holder to access the

controls and water fill cup. Control-side sign holders are 6-3/8″

(162 mm) in height.

Sign Holders are available in all Designer colors to match the

unit.

NOTE: Signage not supplied by Hatco. Sign dimensions are:

3″ (76 mm) Holder = 19-1/16″ W x 3-1/4″ H (484 x 83 mm)

6-3/8″ (162 mm) Holder = 19-5/16″ W x 6-1/4″ H (491 x 159 mm)

1. Remove the appropriate hood mounting screws from the

cabinet hood. The screws that need to be removed are

determined by the location and number of sign holders

being installed.

2. Align the mounting holes on the sign holder(s) with the

mounting holes in the cabinet hood.

3. Insert the hood mounting screws through the holes in the

sign holder(s) and into the cabinet hood. Tighten securely.

NOTE: If more than one display sign holder is being installed,

some of the hood mounting screws may need to thread

through and secure two display sign holders.

4. Place the polycarbonate window(s) into sign holder.

16

Display Sign Holder Installation

Form No. FDWDM-0915

Page 17

English

Cover

Screw

Spring

Cover

Cover

Screw

Spring

Cover

Spring

Short end

of spring in

notch.

Long end

of spring in

notch.

SpringSpring

Bracket

Notch

Door Plate

Notch

Door Plate

Notch

SpringLong

Hinge

Pin

FDWD-

INSET1

FDWD-

INSET2

FDWD-2CB

FDWD-1CB

FDWD-SQB

FDWD-CTLH FDWD-CUSH

NOTE: Make sure to specify color when ordering.

OPTIONS AND ACCESSORIES

Self-Closing Door

An optional factory installed self-closing door is available for

FDWD-1, -1X, -2, and -2X models.

NOTE: A self-closing door cannot be reversed.

Cleaning a Self-Closing Door

The spring cover and spring needs to be removed for cleaning.

Use the following procedure to clean a self-closing door.

1. Turn off and unplug the unit. Allow the unit to cool

completely.

2. Remove all pans and racks from the inside of the cabinet.

3. Drain the water reservoir completely. Refer to the

MAINTENANCE section for details.

4. Carefully lay down the unit so that the door being worked

on is facing up. If the unit must be laid on the control panel

side, take precautions to avoid damaging the fill cup and the

controls.

5. Remove the spring cover by unscrewing the cover screw.

Decorative Kits

Several decorative kits are available for FDWD-1, -1X, -2, and

-2X models. Installation instructions included with kits.

FDWD-2 with Decorative Kits Installed

Top Cover Kits

FDWD-CTLH = Curved Hinge Header, Control Side

FDWD-CUSH = Curved Header, Non-Control Side

Side Inset Kits

FDWD-INSET1 = Two Crescent Inset Panels

FDWD-INSET2 = Two Wave Inset Panels

6. Remove the spring from the long hinge pin.

a. Remove both ends of the spring from the bracket notch

b. Slide the spring off of the pin.

7. Clean the spring and cover bracket.

8. Re-install the spring and spring cover.

and the door plate notch (use a needle nose pliers for a

better grip).

Base Skirt Kits (requires 4″ [102 mm] legs, not

included)

FDWD-SQB = Flat Front, Back, and Side Panels

FDWD-1CB = Curved Front Panel, Flat Back Panel, and Flat

Side Panels

FDWD-2CB = Curved Front and Back Panels, Flat Side Panels

Form No. FDWDM-0915

Decorative Kits

17

Page 18

LIMITED WARRANTY

English

1. PRODUCT WARRANTY

Hatco warrants the products that it manufactures (the

“Products”) to be free from defects in materials and

workmanship, under normal use and service, for a period of

one (1) year from the date of purchase when installed and

maintained in accordance with Hatco’s written instructions or

18 months from the date of shipment from Hatco. Buyer must

establish the Product’s purchase date by registering the

Product with Hatco or by other means satisfactory to Hatco in

its sole discretion.

Hatco warrants the following Product components to be free

from defects in materials and workmanship from the date of

purchase (subject to the foregoing conditions) for the period(s)

of time and on the conditions listed below:

a) One (1) Year Parts and Labor PLUS One (1) Additional

Year Parts-Only Warranty:

Conveyor Toaster Elements (metal sheathed)

Drawer Warmer Elements (metal sheathed)

Drawer Warmer Drawer Rollers and Slides

Strip Heater Elements (metal sheathed)

Display Warmer Elements (metal sheathed air heating)

Holding Cabinet Elements (metal sheathed air heating)

Heated Well Elements — HW and HWB Series

(metal sheathed)

b) One (1) Year Parts and Labor PLUS Four (4) Years

Parts-Only Warranty:

3CS and FR Tanks

c) One (1) Year Parts and Labor PLUS Nine (9) Years

Parts-Only Warranty on:

Electric Booster Heater Tanks

Gas Booster Heater Tanks

d) Ninety (90) Day Parts-Only Warranty:

Replacement Parts

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN

LIEU OF ANY OTHER WARRANTY, EXPRESSED OR

IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE OR PATENT OR OTHER

INTELLECTUAL PROPERTY RIGHT INFRINGEMENT.

Without limiting the generality of the foregoing, SUCH

WARRANTIES DO NOT COVER: Coated incandescent light

bulbs, fluorescent lights, heat lamp bulbs, coated halogen light

bulbs, halogen heat lamp bulbs, xenon light bulbs, LED light

tubes, glass components, and fuses; Product failure in booster

tank, fin tube heat exchanger, or other water heating equipment

caused by liming, sediment buildup, chemical attack, or

freezing; or Product misuse, tampering or misapplication,

improper installation, or application of improper voltage.

2. LIMITATION OF REMEDIES AND DAMAGES

Hatco’s liability and Buyer’s exclusive remedy hereunder will be

limited solely, at Hatco’s option, to repair or replacement using

new or refurbished parts or Product by Hatco or a Hatcoauthorized service agency (other than where Buyer is located

outside of the United States, Canada, United Kingdom, or

Australia, in which case Hatco’s liability and Buyer’s exclusive

remedy hereunder will be limited solely to replacement of part

under warranty) with respect to any claim made within the

applicable warranty period referred to above. Hatco reserves

the right to accept or reject any such claim in whole or in part.

In the context of this Limited Warranty, “refurbished” means a

part or Product that has been returned to its original

specifications by Hatco or a Hatco-authorized service agency.

Hatco will not accept the return of any Product without prior

written approval from Hatco, and all such approved returns shall

be made at Buyer’s sole expense. HATCO WILL NOT BE

LIABLE, UNDER ANY CIRCUMSTANCES, FOR

CONSEQUENTIAL OR INCIDENTAL DAMAGES, INCLUDING

BUT NOT LIMITED TO LABOR COSTS OR LOST PROFITS

RESULTING FROM THE USE OF OR INABILITY TO USE THE

PRODUCTS OR FROM THE PRODUCTS BEING

INCORPORATED IN OR BECOMING A COMPONENT OF

ANY OTHER PRODUCT OR GOODS.

18

Form No. FDWDM-0915

Page 19

Français

AVERTISSEMENT

ATTE NTION

AVIS

Service d'assistance et de pièces de

rechange disponible 7j/7, 24h/24 aux

États-Unis et au Canada en composant

le 800-558-0607.

SOMMAIRE

Informations Importantes pour le Propriétaire ................19

Introduction.........................................................................19

Consignes de Sécurité Importantes .................................20

Description du Modèle .......................................................21

Désignation du Modèle ......................................................22

Caractéristiques Techniques.............................................22

Configuration des Fiches ...................................................22

Tableau des valeurs nominales électriques.......................22

Dimensions ........................................................................23

Installation...........................................................................24

Généralités.........................................................................24

Inversion de la porte d'accès .............................................25

Déplacement du commutateur de proximité......................26

Mode d'emploi.....................................................................27

Généralités.........................................................................27

Réglage de la température de l'air ....................................28

INFORMATIONS IMPORTANTES POUR LE PROPRIÉTAIRE

Notez le numéro de modèle, le numéro de série, la tension et la

date d'achat de l'appareil dans les espaces ci-dessous (l'étiquette

des caractéristiques se situe dans la partie supérieure à l'intérieur

de l'appareil). Veuillez avoir cette information à portée de la main

si vous appelez Hatco pour assistance.

Modèle No. ______________________________________

Numéro de série __________________________________

Voltage __________________________________________

Date d’achat ______________________________________

Réglage du taux d'humidité ...............................................28

Guide de maintien au chaud des aliments ........................28

Maintenance ........................................................................29

Généralités.........................................................................29

Nettoyage quotidien...........................................................29

Retrait des panneaux en verre...........................................29

Retrait du présentoir rotatif ................................................29

Vidange du réservoir d'eau ................................................30

Élimination des dépôts de tartre et de calcaire..................30

Remplacement du tube d'éclairage ...................................30

Guide de Dépannage ..........................................................31

Codes d'erreur ...................................................................32

Options et accessoires ......................................................32

Garantie Limitée..................................................................35

Autorisés Distributeurs de Pièces ........Couverture Arrière

Horaires

ouvrables: 7h00 à 17h00

Heure du Centre des États-Unis (CST)

(Horaires d’été : juin à septembre—

7h00 à 17h00 CST du lundi au jeudi

7h00 à 16h00 CST le vendredi)

Téléphone : 800-558-0607; 414-671-6350

Courriel : partsandservice@hatcocorp.com

Télécopieur : 800-690-2966 (Pièces et Service après-vente)

414-671-3976 (International)

Enregistrez votre appareil!

Remplissez la garantie en ligne pour éviter les retards pour

faire jouer la garantie. Accédez au site Web Hatco

www.hatcocorp.com, sélectionnez le menu déroulant Parts

& Service, puis cliquez sur Warranty Registration.

Les armoires d'exposition avec système d'humidification FlavR-Fresh

préparés pendant des périodes relativement longues, tout en

maintenant leur fraîcheur intacte. Les armoires d'exposition

avec système d'humidification de Hatco offrent le meilleur

environnement pour conserver les produits alimentaires en

réglant la température de l'air tout en maintenant un niveau

d'humidité équilibré. L'utilisation d'une chaleur humide et

contrôlée permet de maintenir la température de service et de

préserver la texture des aliments plus longtemps qu'avec un

équipement traditionnel de conservation des aliments au sec.

Le schéma de flux d'air des appareils Flav-R-Fresh est conçu

pour maintenir une température constante dans l'armoire sans

dessécher les aliments. L'association précise de la chaleur et

l'humidité crée un effet de « couverture » autour des aliments.

L’intensité du flux d’air permet à la température interne de

l'armoire de se restabiliser rapidement après l'ouverture et la

fermeture de la porte.

Les armoires d’exposition avec système d'humidification FlavR-Fresh de Hatco sont des produits résultant de recherches et

d'essais de terrain extensifs. Les matériaux utilisés ont été

sélectionnés pour une durabilité maximum, une apparence

séduisante et des performances optimum. Chaque unité est

inspectée et testée minutieusement avant d'être expédiée.

Formulaire n° FDWDM-0915

®

de Hatco sont conçues pour conserver des plats

Des renseignements supplémentaires sont disponibles sur

notre site Web à www.hatcocorp.com.

INTRODUCTION

n

om

sé

a

ve

m

cu

ande

éc

c systè

ité

r

Ce m

n

fo

e

d

di

i

d'hum

mb

se

n

e

l'

fonctionnement contenues dans ce manuel avant d'installer et

d'utiliser appareil.

Les consignes de sécurité qui apparaissent dans ce manuel sont

identifiées par les mots indicateurs suivants :

AVERTISSEMENT indique une situation dangereuse qui, si

elle n’est pas évitée, peut provoquer la mort ou des

blessures graves.

ATTENTION indique une situation dangereuse qui, si elle

n’est pas évitée, peut provoquer des blessures légères ou

moyennes.

AVIS est utilisé pour des questions sans rapport avec des

blessures corporelles.

19

ctio

f

me

e

n

n

on

i

at

c

i

s in

e

d

le

Fl

t d

n

av

str

s a

e

-R-Fres

ctio

u

r

n

mo

s d

s d

e

ir

Hatc

h.

sta

'in

sitio

o

xp

’e

rec

ous

v

o

lla

tio

e

, d

n

on, de s

ati

l

tal

ns

i

d’

ons

ti

ruc

t

ns

i

es

ent l

onti

c

anuel

uri

e

de

é et

t

t d

me

i

l

re

e

Page 20

CONSIGNES DE SÉCURITÉ IMPORTANTES

ATTENTION

AVIS

AVERTISSEMENT

AVERTISSEMENT

Lisez l'information de securite importante suivante avant d'utiliser cet équipement pour éviter

des dommages ou la mort sérieux et pour éviter d'endommager l'équipement ou la propriété.

Français

DANGER DE DÉCHARGE ÉLECTRIQUE :

• Brancher l’appareil sur une prise de courant avec terre de

tension, de format et de configuration des broches corrects. Si

la fiche et la prise ne se correspondent pas, s’adresser à un

électricien qualifié pour déterminer et installer une prise de

courant de format et de tension corrects.

• Éteignez l’appareil et débranchez le cordon d'alimentation de

la prise secteur et laissez refroidir avant une maintenance ou

un nettoyage.

• L’appareil n’est pas à l’épreuve des intempéries. Placer

l’appareil à l’intérieur à une température ambiante de 21°C

minimum.

• NE PAS immerger l’appareil ni le saturer d’eau. L’appareil n’est

pas étanche à l’eau. Ne pas le faire fonctionner s’il a été

immergé ou saturé d’eau.

• Cet appareil n’est pas étanche aux jets. Ne pas utiliser de jet

sous pression pour nettoyer l’appareil.

• Ne pas trop remplir le réservoir d'eau. Un remplissage excessif

peut causer une électrocution. La réservoir d'eau est plein

quand « LO H2O » cesse de clignoter sur l'affichage CABINET

TEMPERATURE (température de l'armoire). Arrêter de remplir

quand « LO H2O » cesse de clignoter sur l'affichage.

• Couper l'alimentation et laisser l'appareil refroidir avant de

vider l'eau du réservoir.

• Ne pas tirer l’appareil par son cordon électrique.

• Ne pas utiliser l’appareil si le cordon est endommagé ou usé.

• Ne pas tenter de réparer ni de changer un cordon électrique

endommagé. Ce cordon doit être changé par Hatco, par un

réparateur Hatco agréé ou par une personnes de qualifications

comparables.

• Cet appareil doit uniquement être réparé par un personnel

qualifié. Toute réparation par un personnel non qualifié peut

entraîner une électrocution et des brûlures.

• Utilisez uniquement des pièces de rechange d'origine Hatco

lorsque l'entretien est nécessaire. Utilisez des pièces

détachées Hatco authentiques sous peine d'annuler toutes les

garanties et d'exposer l’utilisateur à des tensions électriques

dangereuses pouvant entraîner une électrocution ou des

brûlures. Les pièces de rechange authentiques Hatco sont

spécifiées pour fonctionner en toute sécurité dans les

environnements dans lesquels elles sont utilisées. Certaines

pièces de rechange génériques ou d'après-vente n'ont pas les

caractéristiques qui leur permettent d'opérer en toute sécurité

dans les équipements Hatco.

DANGER D’INCENDIE : Placer l’appareil à un minimum de 25 mm

des parois et matières combustibles. Si une distance sûre n’est

pas maintenue, la chaleur peut provoquer une combustion ou une

altération de couleur.

S'assurer que le(s) écran(s) de protection de la lampe est/sont

installé(s) devant la/les lampe(s) fluorescente(s). La casse de

lampes fluorescentes non spécifiquement protégées pourrait

engendrer des lésions corporelles et/ou une contamination de la

nourriture.

S'assurer que le produit alimentaire a été chauffé à une

température adaptée au maintien de sa salubrité avant de le mettre

dans l'appareil sous peine de risques graves pour la santé. Cet

appareil est destiné au maintien au chaud de produits alimentaires

préchauffés uniquement.

Assurez-vous que tous les opérateurs ont été formés à l'utilisation

sûre et correcte de l'appareil.

Cet appareil ne doit pas être utilisé par des enfants ou des

personnes avec des capacités physiques, sensorielles ou

mentales diminuées. Assurez-vous que les enfants sont bien

surveillés et tenez-les à l'écart de l'appareil.

Hatco n'est pas responsable de la température de service du

produit alimentaire elle-même. Il incombe à l'utilisateur de

s'assurer que le produit alimentaire est maintenu et servi à une

température sûre.

Cet appareil ne contient aucune pièce réparable par l’utilisateur.

Si cet appareil doit être réparé, contacter un réparateur Hatco

agréé ou le Service après-vente Hatco au

800-558-0607 ou 414-671-6350 ; télécopieur 800-690-2966;

télécopieur internationale 414-671-3976.

DANGER DE BRÛLURE : Certaines surfaces extérieures de

l’appareil deviennent chaudes. Toucher ces zones de l’appareil

avec précaution.

Placer l’appareil sur un plan de travail de hauteur correcte à un

endroit qui convient pour son utilisation. Le support doit être de

niveau pour éviter toute chute accidentelle du grille-pain ou de son

contenu et suffisamment solide pour résister au poids de l’appareil

et de son contenu.

Transporter l'appareil à la verticale seulement. Avant de déplacer

ou basculer l'appareil, fixer toutes les surfaces en verre avec du

ruban adhésif et vider l'eau du réservoir sous peine

d'endommagement de l'appareil ou de blessures personnelles.

L'emploi d'eau distillée dans le réservoir d'eau des modèles

humides est recommandé pour préserver la durée de vie des

composants électriques et mécaniques. Si de l'eau non distillée

est utilisée, le réservoir exigera un nettoyage et un détartrage

périodiques (pour la procédure de nettoyage, voir la section

Maintenance). Les pannes d'appareil faute d'avoir enlevé le tartre

ou les dépôts calcaires ne sont pas couvertes par la garantie.

N'utilisez pas d'eau déionisée ou purifiée par osmose inverse. Cela

raccourcirait la durée de vie du réservoir d'eau et de l'élément

chauffant.

Ne couchez pas l'unité sur le côté comportant le panneau de

commande. L'appareil pourrait être endommagé.

Utiliser uniquement des produits nettoyants non abrasifs. Les

produits nettoyants abrasifs peuvent rayer la finition de l’appareil,

ce qui altère son apparence et le rend plus susceptible

d’accumuler la saleté.

Nettoyer chaque jour l'appareil pour éviter les dysfonctionnements

et maintenir l'hygiène.

Ne pas placer l'appareil dans un endroit où la circulation de l'air est

trop forte.

Installer l'appareil dans une zone à l'écart des courants d'air. Éviter

les zones pouvant être soumises à des mouvements d'air ou à des

courants d'air actifs (c.-à-d. à proximité des ventilateurs/hottes

d'aspiration, des portes et des conduites de climatisation).

20

Formulaire n° FDWDM-0915

Page 21

Français

Tous les Modèles

Toutes les armoires d’exposition avec système d'humidification

Flav-R-Fresh

d'un système d'humidification avec protection du contrôle du

bas niveau d'eau, de lampes fluorescentes, de parties latérales

en verre trempé et d'une porte. Les appareils peuvent être

configurés avec ou sans système d'humidification avec

protection du contrôle du bas niveau d'eau. La porte d’accès

standard peut être montée pour s’ouvrir vers la gauche ou vers

la droite. Tous les présentoirs disponibles sont chromés, à

l'exception des présentoirs pour bretzels qui sont en acier

inoxydable. Tous les appareils sont disponibles dans plusieurs

couleurs Designer.

®

sont équipées d'un système de chauffage à air,

DESCRIPTION DU MODÈLE

Modèle FDWD-1

Le modèle FDWD-1 est doté d’une porte simple et d’un

présentoir rotatif motorisé. Il est vendu avec un présentoir à

pizza pouvant accueillir jusqu’à quatre (4) plateaux à pizza

ronds d’un diamètre maximal de 381 mm (15"). Le présentoir

rotatif s’arrête automatiquement à l’ouverture de la porte. Un

ensemble rotatif à bretzels et un ensemble à 4 étagères fixes

multi-usages sont également proposés en option.

FDWD-1

NOTA: Le modèle FDWD-1 ne peut pas être converti en

modèle FDWD-2 ou FDWD-2X.

Modèle FDWD-2

Le modèle FDWD-2 est équivalent au modèle FDWD-1, mais

est doté d’une porte supplémentaire sur le côté opposé au

panneau de commande, permettant une fluidité pratique du

mouvement à travers l’armoire.

FDWD-1X

NOTA: Le modèle FDWD-1X ne peut pas être converti en

modèle FDWD-1, FDWD-2 ou FDWD-2X.

Modèle FDWD-2X

Le modèle FDWD-2X est équivalent au modèle FDWD-1X,

mais est doté d’une porte supplémentaire sur le côté opposé

au panneau de commande, permettant une fluidité pratique du

mouvement à travers l’armoire.

NOTA: Le modèle FDWD-2X ne peut pas être converti en

modèle FDWD-2, FDWD-1 ou FDWD-1X.

Modèle FDWD-12-1

Le modèle FDWD-12 est équivalent au modèle FDWD-1 mais

son cadre est plus petit et son encombrement réduit. L'appareil

peut accueillir des plateaux à pizzas d’un diamètre maximum de

30,5 cm. L'ensemble rotatif à bretzels en option n'est pas

disponible.

Modèle FDWD-1X

Le modèle FDWD-1X est équivalent au modèle FDWD-1, mais

est doté d’un ensemble de 4 étagères fixes multi-usages au

lieu de l’ensemble d’étagères rotatives. Le présentoir peut