Hastings HFM-I-405, HFM-I-401 User Manual

TELEDYNE

HASTINGS

INSTRUMENTS

INSTRUCTION MANUAL

HFM-I-401 AND HFM-I-405

INDUSTRIAL

FLOW METERS

- i -

Manual Print History

The print history shown below lists the printing dates of all revisions and addenda created for

this manual. The revision level letter increases alphabetically as the manual undergoes

subsequent updates. Addenda, which are released between revisions, contain important change

information that the user should incorporate immediately into the manual. Adde nda are

numbered sequentially. When a new revision is created, all addenda associated with the

previous revision of the manual are incorporated into the new revision of the manual. Each new

revision includes a revised copy of this print history page.

Revision A (Document Number 171-042008) .......................................................................March 1999

Visit www.teledyne-hi.com for WEEE disposal guidance.

Description of Symbols and Messages used in this manual

WARNING

CAUTION

NOTE

Teledyne Hastings Instruments reserves the right to change or modify the design of its

equipment without any obligation to provide notification of change or intent to change.

This indicates a potential personnel hazard. It calls attention

to a procedure, practice, condition or the like, which, if not

correctly performed or adhered to, could result in injury to

personnel.

This indicates a potential equipment hazard. It calls attention

to an operating procedure, practice, or the like, which, if not

correctly performed or adhered to, could result in damage to

or destruction of all or part of the product.

This indicates important information. It calls attention to a

procedure, practice, condition or the like, which is worthy of

special mention.

- ii -

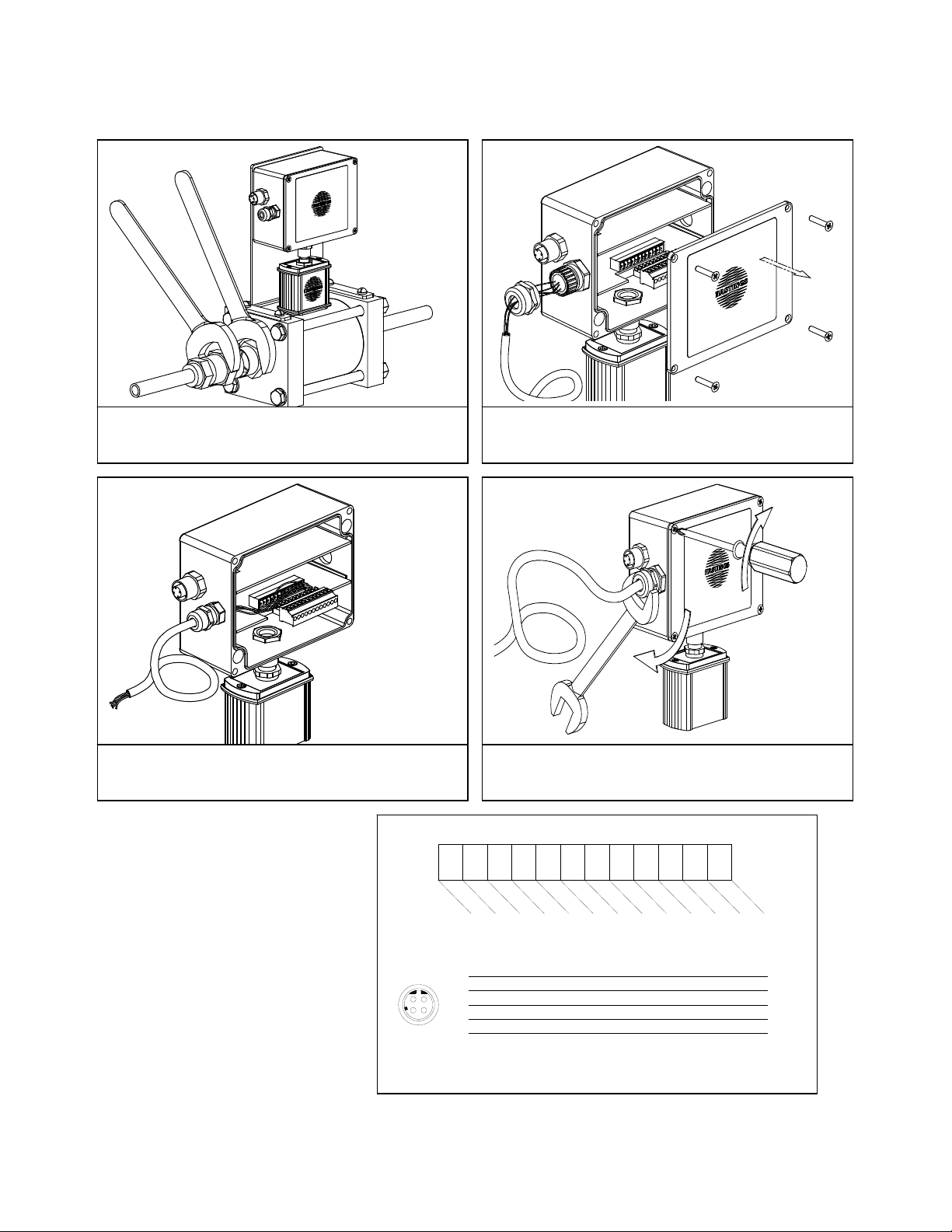

Quick Start Instructions

General Information

Connect dry, clean gas and ensure connections are

leak free.

Check that electrical connections are correct.

(See diagrams below)

Terminal Strip

Connect Cable for power and analog signal output.

Replace front cover and cable feed-through ensuring

gasket is seated and fasteners are secure.

112

DCOM

Z

A

A

A

LA

LA

R

M

-

E

LA

R

R

R

M2

M1

O

A

A

A OUTA OU

I

I

N

N

+

+

T

VSUP

-

VSUP

+

-

Digital Connector

12

3

4

PINS

SHIELD

1

2

3

4

RS232

GROUND

TRANSMIT

RECEIVE

UNUSED

UNUSED

RS485

GROUND

TX+ (A)

RX+ (A)

TX- (B)

RX- (B)

ETHERNET

GROUND

TD+

RD+

TDRD-

For detailed set up instructions, see Section 2-Installation

- iii -

This instrument is available with multiple pin-outs.

Ensure electrical connections are correct.

CAUTION

CAUTION

NOTE

The 400-I series flow meters are designed for IEC

Installation/Over voltage Category II – single phase receptacle

connected loads.

The Hastings 400 Series flow meters are designed for

INDOOR and OUTDOOR operation.

CAUTION

CAUTION

In order to maintain the integrity of the Electrostatic Discharge

immunity both parts of the remote mounted version of the

HFM-I-400 instrument must be screwed to a well grounded

structure.

In order to maintain the environmental integrity of the

enclosure the power/signal cable jacket must have a diameter

of .157 - .315” (4 – 11 mm). The nut on the cable gland must

be tightened down sufficiently to secure the cable. This cable

must be rated for at least 85°C.

- iv -

General Information

Table of Contents

GENERAL INFORMATION.....................................................................................................................................1

1. GENERAL INFORMATION ....................................................................................................................................1

1.1. OVERVIEW......................................................................................................................................................1

1.1.1. 400 Series Family..................................................................................................................................1

1.1.2. 400 Series Meters ..................................................................................................................................1

1.1.3. Measurement Approach.........................................................................................................................1

1.1.4. Additional Functions..............................................................................................................................2

1.2. SPECIFICATIONS .............................................................................................................................................2

INSTALLATION.........................................................................................................................................................4

2. INSTALLATION....................................................................................................................................................4

2.1. RECEIVING INSPECTION..................................................................................................................................4

2.2. ENVIRONMENTAL AND GAS REQUIREMENTS..................................................................................................4

2.3. MECHANICAL CONNECTIONS .........................................................................................................................4

2.4. MOUNTING THE ELECTRONICS REMOTELY .....................................................................................................5

2.5. ELECTRICAL CONNECTION .............................................................................................................................5

2.5.1. Power Supply.........................................................................................................................................6

2.5.2. Analog Output........................................................................................................................................6

2.5.2.1. Current Loop Output .........................................................................................................................6

2.5.2.2. Voltage output....................................................................................................................................8

2.6. DIGITAL CONNECTION....................................................................................................................................8

2.7. DIGITAL CONFIGURATION ..............................................................................................................................8

2.7.1. RS-232 ...................................................................................................................................................8

2.7.2. RS-485 ...................................................................................................................................................9

2.7.3. Ethernet .................................................................................................................................................9

2.8. ALARM OUTPUT CONNECTION .....................................................................................................................10

2.9. AUXILIARY INPUT CONNECTION ..................................................................................................................11

2.10. ROTARY GAS SELECTOR...........................................................................................................................11

2.11. ELECTRICAL REMOTE ZERO CONNECTION ...............................................................................................11

2.12. CHECK INSTALLATION PRIOR TO OPERATION...........................................................................................12

OPERATION.............................................................................................................................................................14

3. OPERATION ......................................................................................................................................................14

3.1. ENVIRONMENTAL AND GAS CONDITIONS .....................................................................................................14

3.2. INTERPRETING THE ANALOG OUTPUT ..........................................................................................................14

3.3. DIGITAL COMMUNICATIONS.........................................................................................................................14

3.3.1. Digitally Reported Flow Output..........................................................................................................15

3.3.2. Digitally Reported Analog Input..........................................................................................................15

3.4. ZEROING THE INSTRUMENT ..........................................................................................................................15

3.4.1. Preparing for a Zero Check.................................................................................................................15

3.4.2. Adjusting Zero .....................................................................................................................................16

3.5. HIGH PRESSURE OPERATION ........................................................................................................................16

3.5.1. Zero Shift .............................................................................................................................................16

3.5.2. Span Shift.............................................................................................................................................16

3.6. WARNINGS/ALARMS ....................................................................................................................................17

3.7. MULTI-GAS CALIBRATIONS..........................................................................................................................17

3.8. FLOW TOTALIZATION ...................................................................................................................................18

3.9. ADDITIONAL DIGITAL CAPABILITIES............................................................................................................18

PARTS AND ACCESSORIES.................................................................................................................................19

4. PARTS & ACCESSORIES.....................................................................................................................................19

4.1. POWER POD – POWER & DISPLAY UNITS ......................................................................................................19

4.2. FITTINGS.......................................................................................................................................................20

4.3. CABLES ........................................................................................................................................................20

WARRANTY.............................................................................................................................................................21

5. WARRANTY......................................................................................................................................................21

- v -

WARRANTY REPAIR POLICY.........................................................................................................................21

5.1.

5.2. NON-WARRANTY REPAIR POLICY................................................................................................................21

APPENDICES............................................................................................................................................................22

6. APPENDICES .....................................................................................................................................................22

6.1. APPENDIX 1- VOLUMETRIC VERSUS MASS FLOW.........................................................................................22

6.2. APPENDIX 2 - GAS CONVERSION FACTORS...................................................................................................23

- vi -

General Information

1. General Information

1.1. Overview

1.1.1. 400 Series Family

The Hastings 400 Series is a family of flow instruments which is specifically designed to meet

the needs of the industrial gas flow market. The “I” family in the 400 Series features an IP-65

enclosure which allows the use of the instrument in a wide variety of environments. The 400 I

products consist of four configurations: a flow meter, HFM-I-401, which has a nominal nitrogen

full scale between 10 SLM and 300 SLM and a corresponding flow controller, the HFC-I-403; a

larger flow meter, HFM-I-405, which ranges from 100 SLM to 2500 SLM, and a c or responding

flow controller, the HFC-I-407. These instruments are configured in a convenient in-line flowthrough design with standard fittings. Each instrument in the series can be driven by either a

+24 VDC power supply or a bipolar ±15 volt supply. The electrical connection can be made via

either a terminal strip located inside the enclosure or optionally through an IP-65 compatible

electrical connector. Also, these instruments include both analog and digital communications

capabilities.

1.1.2. 400 Series Meters

The Hastings HFM-I-401 and HFM-I-405 thermal ma ss flow meters are designed to provide very

accurate measurements over a wide range of flow rates and environmental conditions. The

design is such that no damage will occur from moderate overpressure or overflows and no

maintenance is required under normal operating conditions when using clean gases.

1.1.3. Measurement Approach

The instrument is based on mass flow sensing. This is accomplished by combining a hi gh-speed

thermal transfer sensor with a parallel laminar flow shunt (see Figure 1-1). The flow through

the meter is split between the sensor and shunt in a constant ratio set by the full scale range.

The thermal sensor consists of a stainless steel tube with a heater at its center and two

thermocouples symmetrically located upstream and downstream of the heater. The ends of the

sensor tube pass through an aluminum block and into the stainless steel sensor base. With no

flow in the tube the thermocouples report the same elevated temperature; however a forward

flow cools the upstream thermocouple relative to the downstream. This temperature

difference generates a voltage signal in the sensor which is digitized and trans ferred to the

main processor in the electronics enclosure. The processor uses this real-time information and

the sensor/shunt characteristics stored in non-volatile memory to calculate and report the

flow.

To ensure an inherently linear response to flow, both the thermal sensor and the shunt have

been engineered to overcome problems common to other flow meter designs. For example,

nonlinearities and performance variations often arise in typical flow meters due to pressurerelated effects at the entrance and exit areas of the laminar flow shunt. Hastings has designed

the 400 Series meters such that the flow-critical splitting occurs at locations safely downstream

from the entrance effects and well upstream from the exit effects. This vastly improve s the

stability of the flow ratio between the sensor and shunt. The result of this design feature is a

better measurement when the specific gravity of the flowing medium varies, for instance due

to changes in pressure or gas type. Also, a common problem in typical flow meters is a slow

response to flow changes. To improve response time, some flow meter designs introduce

impurities such as silica gel. Alternatively, Hastings has designed the 400 Series sensor with

reduced thermal mass to improve the response time without exposing additional materials to

the gas stream.

- 1 -

1.1.4. Additional Functions

These instruments contain a number of functions in addition to reporting flow which include:

• Settable alarms and warnings with semiconductor switch outputs

• A digitally reported status of alarms and warnings such as overflow/underflow

• A flow totalizer to track the amount of gas added to a system

• A digitizing channel for an auxiliary analog signal

• An internal curve fitting routine for “fine tuning” the base calibration

• An alternate calibration set of 8 different ranges/gases

1.2. Specifications

WARNING

Do not operate this instrument in excess of the specifications

listed below. Failure to heed this warning can result in serious

personal injury and/or damage to the equipment.

Performance

Full Scale Flow Ranges

)

(in N

2

Accuracy1

Optional: ± (0.5% reading + 0.2%FS) Optional: ± (0.5% reading + 0.2%FS)

Repeatability ± 0.1% of F.S. ± 0.1% of F.S.

Operating Temperature -20 to 70°C -20 to 70°C

Warm up time 30 min for optimum accuracy 30 min for optimum accuracy

2 min for ± 2% of full scale 2 min for ± 2% of full scale

Settling Time/Reponse

Time

Temperature Coefficient

of Zero

Temperature Coefficient

of Span

Operating Pressure Maximium

Optional: 1500 psig Optional: 1000 psig

Pressure Coefficient of

Span < 0.01%of reading /psi (N

Pressure Drop(N2@14.7

psia) < 1.1 psi at full scale flow < 5.1 psi at full scale flow

Attitude Sensitivity of

Zero < 2% of F.S. < 2% of F.S.

Electrical

Power Requirements

Analog Output

0-10 slm up to 0-350 slm 0-100 slm up to 0-2500 slm

Standard: ± 1% full scale Standard: ± 1% full scale

< 2.5 seconds (to within ± 2% of full scale) < 2.5 seconds (to within ± 2% of full scale)

< ±0.05% of Full Scale /°C < ±0.05% of Full Scale /°C

< ±0.16% of reading/°C < ±0.16% of reading/°C

Standard: 500 psig Standard: 500 psig

18-38 VDC, 3.5 watts(Ethernet) 2.5

watts(RS232/485)

Standard: 4 – 20 mA Standard: 4 – 20 mA

HFM-I-401 HFM-I-405

, 0-1000 psig) < 0.01%of reading /psi (N2, 0-1000 psig)

2

18-38 VDC, 3.5 watts(Ethernet) 2.5

watts(RS232/485)

Optional: 0-10 VDC, 0-20 mA, 0-5 VDC, 1-5 VDC Optional: 0-10 VDC, 0-20 mA, 0-5 VDC, 1-5 VDC

Digital Output

Optional: RS 485 Optional: RS 485

Optional: Ethernet Optional: Ethernet

Analog Connector

Optional: 12 pin Circular Connector Optional: 12 pin Circular Connector

Standard: RS 232 Standard: RS 232

Std: Terminal Block – PG 9 Cable Gland Std: Terminal Block – PG 9 Cable Gland

- 2 -

Digital Connector 4 pin, D-coded M12 4 pin, D-coded M12

Mechanical

Fittings

Standard: 1/2" Swagelok Standard: 1" Swagelok

Optional: ½" VCO®, ½" VCR®, ¾” Swagelok, Optional: 1" VCO®,1" VCR®, ¾” Swagelok, ,

10mm Swagelok, 3/8" male NPT, ½” male NPT 1" male NPT, ¾” male NPT, 1 5/16"-12 straight

12mm Swagelok, ¾"-16 SAE/MS straight thread thread

Leak Integrity < 1x10

-8

sccs He < 1x10

-8

sccs He

Wetted Materials 316L SS, Nickel 200, 302 SS, Viton® 316L SS, Nickel 200, 302 SS, Viton®

Weight (approx.) 12 lb (5.5 kg) 18 lb (8 kg)

®

Viton

is a trademark of DuPont Dow Elastomers, LLC.

Swagelok

®

, VCO®and VCR® are trademarks of the Swagelok Company.

- 3 -

Installation

2. Installation

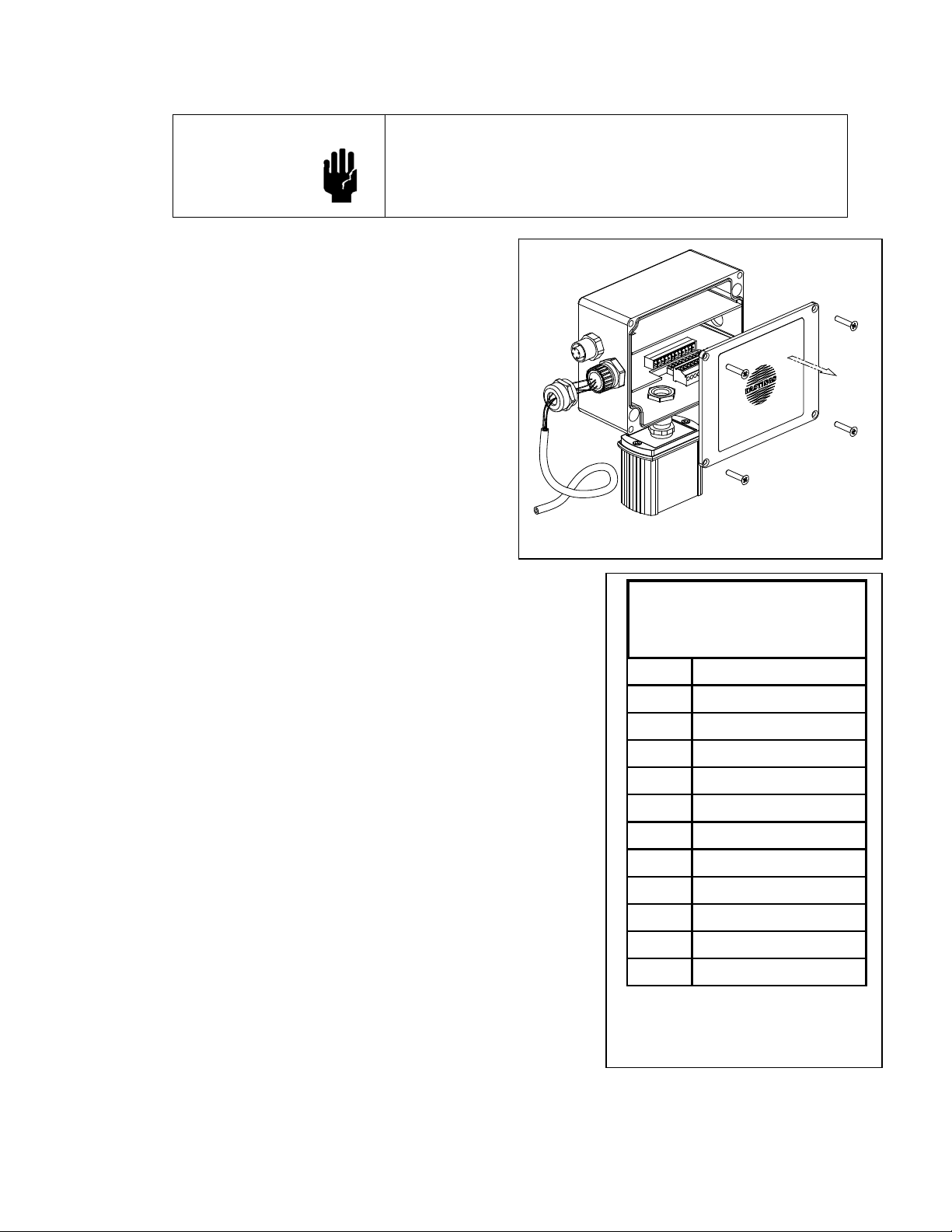

Many of the functions described in this section require

removing the enclosure front plate. Care must be taken when

reinstalling this plate to ensure that the sealing gasket is

properly positioned and the fasteners are secure to maintain

CAUTION

2.1. Receiving Inspection

Your instrument has been manufactured, calibrated, and carefully packed so it is ready for

operation. However, please inspect all items for any obvious signs of damage due to shipment.

Immediately advise Teledyne Hastings and the carrier if any damage is suspected.

Use the packing slip as a check list to ensure all parts are present (e.g. flow meter, power

supply, cables etc.) and that the options are correctly configured (output, range, gas,

connector).

If a return is necessary, obtain an RMA (Return Material Authorization) number from Teledyne

Hastings’ Customer Service Department at 1-800-950-2468 or

hastings_instruments@teledyne.com

2.2. Environmental and Gas Requirements

an IP65 compliant seal.

.

Use the following guidelines prior to installing the flow meter:

• Ensure that the temperature of all components and gas supply are

between -20° and 70° C

• Ensure that the gas line is free of debris and contamination

• Ensure that the gas is dry and filtered (water and debris may clog the

meter and/or affect its performance)

• If corrosive gases are used, purge ambient (moist) air from the gas lines

2.3. Mechanical Connections

The meter can be mounted in any orientation unless using dense gases or pressures higher than

250 psig in which case a “flow horizontal” orientation is required. The meter’s measured flow

direction is indicated by the arrow on the electronics enclosure.

A straight run of tubing upstream or downstream is not necessary for proper operation of the

meter. The flow meter incorporates elements that pre-condition the flow profile before the

measurement region. So for example, an elbow may be installed upstream from the flow meter

entrance port without affecting the flow performance.

Compression fittings should be connected and secured according to recommended procedures

for that fitting. Two wrenches should be used when tightening fittings (as shown in the Quick

Start Guide on page iii) to avoid subjecting the flow meter body to undue torque and related

stress.

The fittings are not intended to support the weight of the meter. For mechanical structural

support, four mounting holes (#1/4-20 thread, 3/8” depth) are located in the bottom of the

meter. The position of these holes is documented on the outline drawing in Appendix 3 (Section

6.3).

Leak-check all fittings according to an established procedure appropriate for the facility.

- 4 -

2.4. Mounting the Electronics Remotely

In order to maintain the integrity of the Electrostatic Discharge

immunity both parts of the remote mounted version of the

HFM-I-400 instrument must be screwed to a well grounded

structure. The ferrite that is shipped with the instrument must

CAUTION

The electronics enclosure can be separated and

relocated up to 30 feet away from the flow

meter base. This requires a cable which is

supplied with the instrument if ordered as a

cable mounted unit. Alternatively, a 2, 5, or 10

meter cable can be purchased separately. See

section 4.2 for ordering information and part

numbers.

When remote mounting the electronics

enclosure, the support bracket can remain

attached to either the flow meter base or the

electronics. To separate the electronics

enclosure from the support bracket, remove

the two screws located on the back of the

support bracket. To separate the flow meter

base from the support bracket, remove the four

screws that mount the bracket to the top of the

flow meter base. Unscrew the electrical

connector between electronics enclosure and the flow

meter base. Remove the electronics enclosure from the

flow meter base. Connect the female end of the remote

electronics cable to the flow meter base and the male end

to the electronics enclosure. The electronics enclosure can

be mounted remotely by using the two threaded holes in

the enclosure. The size and spacing of these two holes are

specified on the outline drawing in Appendix 3 (Section

6.3). These holes may be used by inserting fasteners from

behind through a new mounting bracket or they may be

accessed from the front side by temporarily removing the

enclosure panel. This enables mounting the enclosure to a

wall or other solid structure. Alternatively, if the

instrument was originally configured as a bracket mounted

unit the bracket may be directly mounted to a support

structure. The bracket mounting holes locations are the

same as those for the flow meter base mounting. (See the

outline drawing in Appendix 3, Section 6.3.)

be installed on the cable next to the electronics enclosure.

Figure 2-1 Accessing the terminal strip

Terminal Strip Pin-out

(Pins numbered right to left as

viewed from the front)

1 - Power Supply

2 + Power Supply

3- Flow Output

4+ Flow Output

5+ Auxiliary Input

6- Auxiliary Input

7 No Connection

8 Digital Common

9 Remote Zero

10 Alarm 1

2.5. Electrical Connection

There are two electrical connectors on the Hastings 400-I

Series flow meters—an analog terminal strip (located within

the electronics enclosure) and a digital connector. The

analog connector provides for the power supply to the

meter along with analog signals and functions. As such, its

use is required for operation. The digital connector is used

for communications in either of RS232, RS485, or Ethernet

mode depending on the instrument’s configuration. The digital connector does not have to be

used if the meter is operated as an analog-only instrument.

11 Alarm 2

12 Alarm Common

Figure 2-2 Electrical

connections for analog

inputs/outputs and power

- 5 -

Loading...

Loading...