Hastings DAVC-4, DAVC-6, DAVC-5 User Manual

TELEDYNE

HASTINGS

INSTRUMENTS

INSTRUCTION MANUAL

DIGITAL AVC

(DAVC-4, DAVC-5, DAVC-6)

ISO 9001

CERTIFIED

Manual Print History

The print history shown below lists the printing dates of all revisions and addenda created for this manual.

The revision level letter increases alphabetically as the manual undergoes subsequent updates. Addenda,

which are released between revisions, contain important change information that the user should incorporate

immediately into the manual. Addenda are numbered sequentially. When a new revision is created, all

addenda associated with the previous revision of the manual are incorporated into the new revision of the

manual. Each new revision includes a revised copy of this print history page.

Revision A (Document Number 174-062009).....................................................................June 2009

Revision B (Document Number 174-072009)......................................................................July 2009

Revision C (Document Number 174-072009) .....................................................................July 2009

Revision D (Document Number 174-062010) ....................................................................June 2010

Revision E (Document Number 174-082010)................................................................. August 2010

Visit www.teledyne-hi.com for WEEE disposal guidance.

Hastings Instruments reserves the right to change or modify the design of its equipment

without any obligation to provide notification of change or intent to change.

174-082010_Digital AVC Page 2 of 17

Table of Contents

1.0 GENERAL INFORMATION ............................................................................................................................ 4

1.1 FEATURES ....................................................................................................................................................... 4

1.2 SPECIFICATIONS ............................................................................................................................................. 4

1.3 COMPLIANCE DATA ........................................................................................................................................ 5

1.4 SAFETY ........................................................................................................................................................... 5

ACCESSORIES ............................................................................................................................................................... 5

2.0 INSTALLATION............................................................................................................................................... 7

2.1 POWER-I/O CABLE.......................................................................................................................................... 7

2.2 POWER REQUIREMENTS & PIN OUT............................................................................................................... 7

2.3 SERIAL COMMUNICATIONS PIN OUT ............................................................................................................. 7

2.4 ANALOG OUTPUT PIN OUT............................................................................................................................ 7

2.5 PRESSURE ALARMS PIN OUT.......................................................................................................................... 7

3.0 VACUUM GAUGE OPERATION.................................................................................................................... 9

3.1 QUICK START................................................................................................................................................. 9

3.2 ANALOG PRESSURE MEASUREMENT .............................................................................................................. 9

3.3 ALARM SET POINT........................................................................................................................................ 12

3.4 DIGITAL COMMUNICATIONS. ...................................................................................................................... 12

3.5 OPERATION AND PERFORMANCE ................................................................................................................. 14

3.6 GAUGE TUBE OPERATING PRINCIPLE.......................................................................................................... 15

3.7 CALIBRATION PROCEDURE .......................................................................................................................... 15

4.0 WARRANTY.................................................................................................................................................... 17

4.1 WARRANTY REPAIR POLICY......................................................................................................................... 17

4.2 NON-WARRANTY REPAIR POLICY................................................................................................................ 17

174-082010_Digital AVC Page 3 of 17

1.0 General Information

This manual contains technical and general information relating to the installation, operation, and

calibration of vacuum gauges and gauge tubes manufactured by Teledyne Hastings Instruments (THI).

For best performance, THI vacuum gauges should be operated with the appropriate THI gau ge tube.

Attempting to use a THI vacuum gauge with another manufacturer’s tubes may result in damage to both

the gauge and tube.

1.1 Features

The THI Digital AVC (DAVC), is a digital readout version of THI’s AVC vacuum gauge. The heated gauge

tube supplies an analog signal that is amplified for a zero to one volt signal out put. A precision A/D

converter, in conjunction with a microprocessor, measures the gauge tube’s signal output, converts the

measurement to a pressure reading using the gauge tube’s well defined output/pressure function, and then

provides the result to the end user through a serial communications port.

The DAVC is available for use with two of THI’s most popular gauge tube families: The DV-6 and DV-4.

The DV-6 range is 1.0 - 1000 mTorr. The DV-4 range is 0.2 - 20 Torr. All gauge-t ubes used with the Digital

AVC feature long life and minimal maintenance due to the use of rugged, noble-metal, thermocouple (TC)

gauge tubes that are designed specifically for each range.

1.2 Specifications

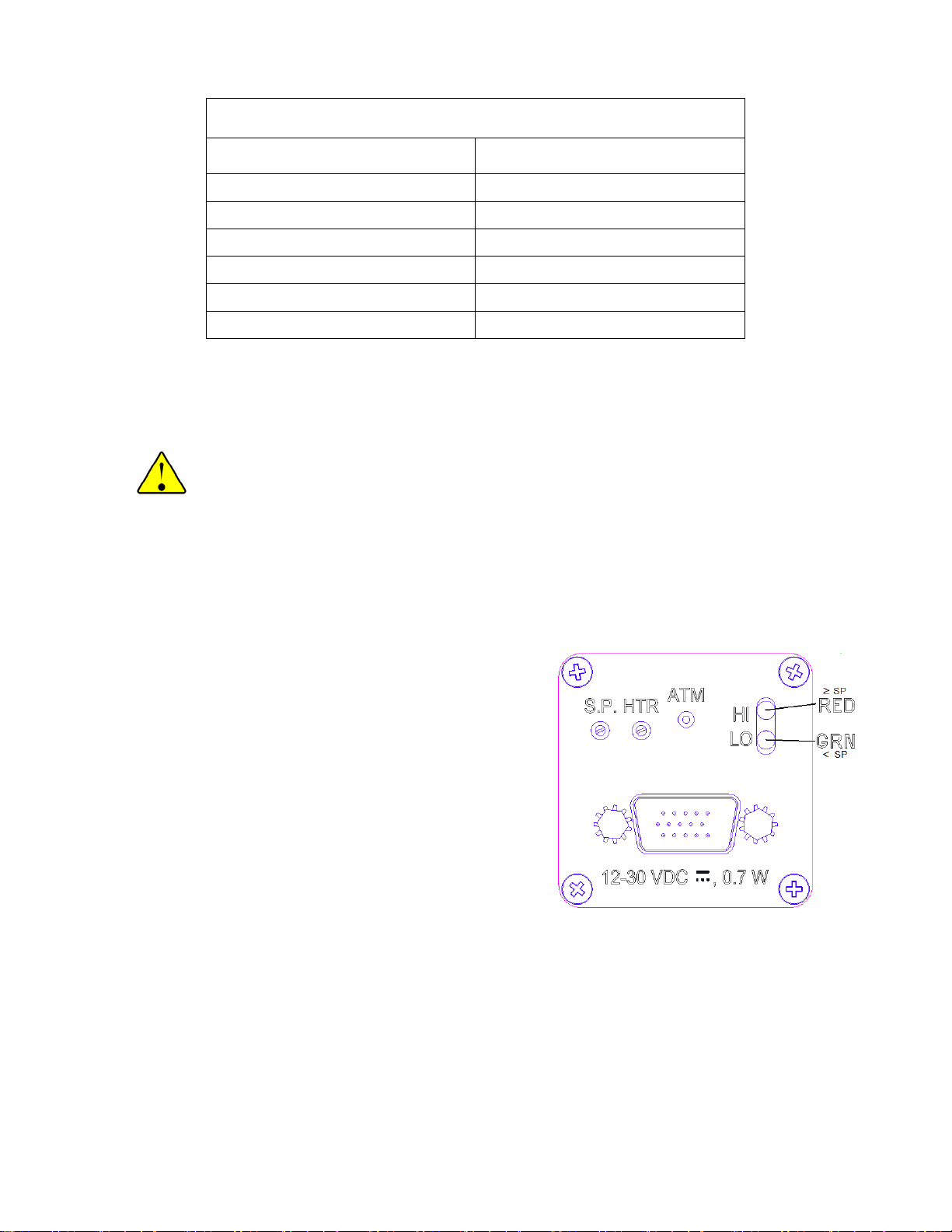

Input Power............................................................................................................................12 – 30 VDC

.................................................................................................................................................... 0.7 Watts

Cable.............................................................Combination power and RS232 cable, 1.5 meters, included

..................................................................... For CE Compliance, cable should never exceed 3.0 meters

Weight (Approx.) .......................................................................22 Oz’s (624 Grams) W/O Tube & Cable

Height (Length) .................................................................................................... 2.6”, W/O Tube & Cable

Width / Depth .................................................................................................................................... 1.75”

Operating temperature Range ............................................................................................ -20°C to 70°C

Standard Metal Gauge Tube.............................................................................. (DV-6R, DV-5M, DV-4R):

Overpressure (Gauge tubes) ................................................................................................. 50 psig max.

Material of Construction................................................................................... DAVC Housing: Aluminum

............................................................................................................Thermocouple: Glass, Noble Metal

Connections.........................................................................................High Density, 15-Pin, D Connector

.........................................................................................................Octal Tube Socket for Thermocouple

Alarms..............................................................................................................................0.50 Amps, max.

-8

Tube Leak Test.......................................................................................................<1x10

atm cc/sec He

See tube Product Bulletin for available tube connection configurations.

174-082010_Digital AVC Page 4 of 17

1.3 Compliance data

1.4 Safety

The following symbols and terms may be found on THI products and/or in THI manuals and indicate

important information.

The WARNING label indicates important information that should be heeded for safe and proper

performance of the device.

CE Standard Compliance

Test Standard

SAFETY EN61010

EMC/EMI Family EN61326

CONDUCTED/RADIATED EN55011

ESD EN61000-4-2

RF EN61000-4-3

CONDUCTED IMMUNITY EN61000-4-6

When found on the device, this symbol indicates that the operator should refer to the manual for

important instructions on the proper use of this device. When found in a manual, this symbol

indicates that the reader should understand the implications contained in the text before

operating the device.

The label, CAUTION, is used to indicate that damage to the power supply or equipment connected to it,

could occur if directions are not followed. Warranty could be invalidated if the instructions in this manual are

not followed.

Accessories

1.4.1 Installation Accessories

THI offers a complete line of system attachments that

permit easy maintenance for contaminated operations.

Gauge tubes are offered with various system fittings to

match almost any system requirement. Additionally,

THI’s complete line of quick disconnect attachments

allows customers to install these special fittings and

easily replace sensors without vacuum sealant or

Teflon® tape. For particularly dirty systems, Hastings

offers a particle dropout trap containing a series of nine

separate baffles which prevent solid contaminants from

having a direct path to the sensor’s thermopile.

1.4.2 DV-6S: New DV-6 tube For Severe

Environments

Hastings Instruments has developed a new gauge tube, the DV-6S, which is specifically designed for

outdoor use on cryogenic tanks including railcar and tanker truck applications. In addition to the DAVC, the

gauge tube is compatible with the hand-held HPM-4/6 and the analog VT-6.

The DV-6S is supplied with a protective cap. The o-ring-sealed cap protects the gauge tube pins from

moisture thus significantly reducing corrosion. A metal lanyard prevents cap loss. The tube is provided with

a standard 1/8” NPT fitting; however special fitting requests can often be met.

174-082010_Digital AVC Page 5 of 17

1.4.3 Calibration Reference

Tubes

THI Reference Tubes employ the

same metal thermopiles used in all

THI Vacuum Gauge Tubes. The

thermopile is sealed in a glass

capsule that has been evacuated,

baked, out-gassed, and then aged to

ensure long-term stability. The sealed

capsule is then housed in a protective

metal shell to provide a rugged,

trouble-free assembly.

Once assembled, the reference

gauge tube is accurately calibrated to

precisely simulate a gauge tube at a

given operating pressure. It provides

quick and easy instrument recalibration by merely plugging the

instrument and, in the case of the

DAVC, adjusting the HTR

potentiometer until the display reads

the exact pressure noted on the

reference tube.

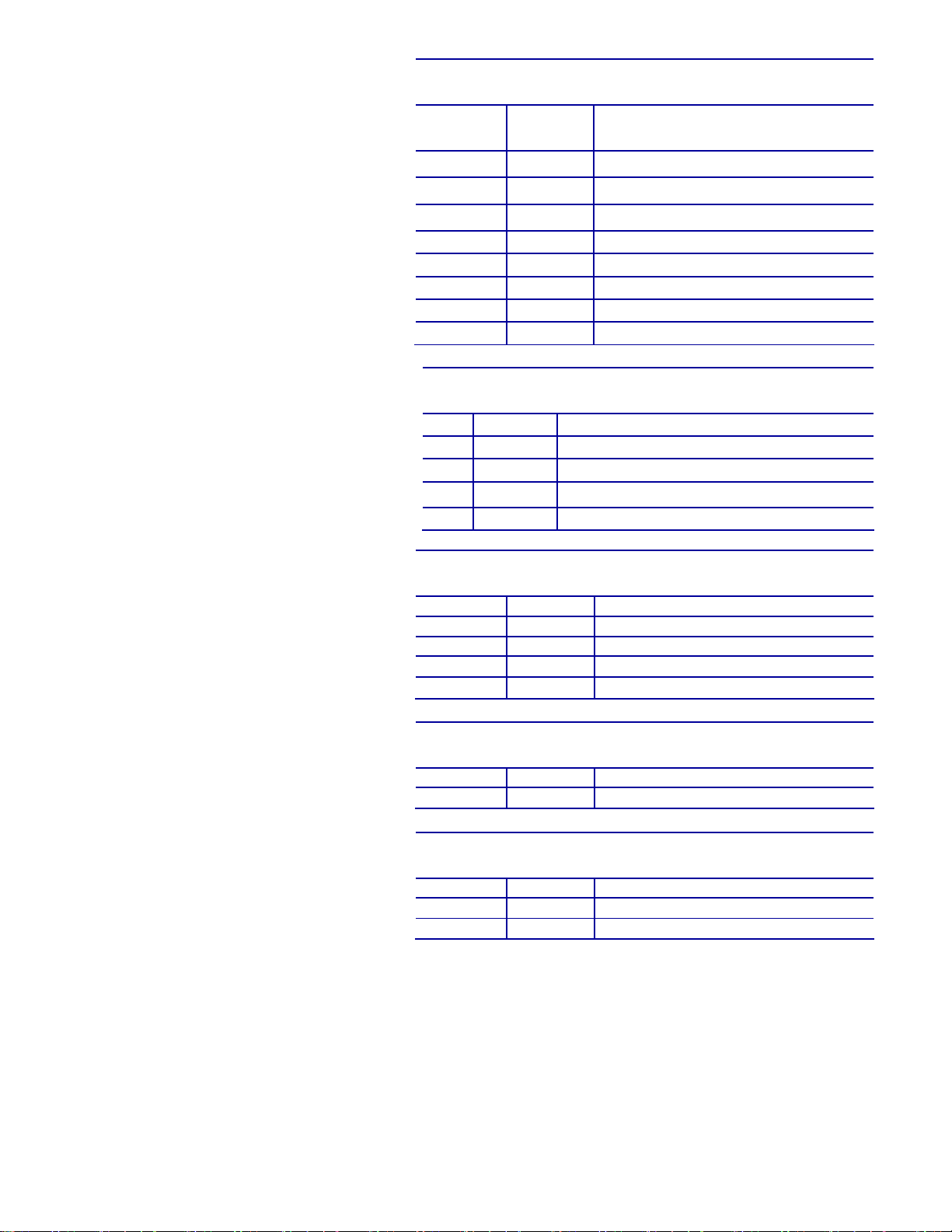

Vacuum Gauge Tubes 1000 mTorr Range

Stock # Model # Description

55-38 DV-6M 1/8” NPT Standard (Yellow base)

55-38R DV-6R 1/8” Ruggedized

55-38RS DV-6 1/8” NPT Rohs Rugged

55-38S DV-6S 1/8” NPT Rugged/Vibration

55-251 DV-6-KF-16 KF-16TM

55-267 DV-6-KF-25 KF-25TM

55-283 DV-6-VCR VCRTM

55-38R-CF DV-6R-CF Mini ConflatTM

Extension Cables for VT Series (DAVC)

55-3 OM-8-OFV 8 Ft Extension Cable

55-22 OM-12-OFV 12 Ft Extension Cable

65-53 OM-25-OFV 25 Ft Extension Cable

65-102 OM-50-OFV 50 Ft Extension Cable

55-142 OM-100-OFV 100 Ft Extension Cable

Vacuum Gauge Tubes 20Torr Range

55-19 DV-4D 1/8” NPT (Purple Base)

55-19R DV-4R 1/8” NPT Ruggedized

55-258 DV-4D-KF-16 KF-16TM

55-266 DV-4D-KF-25 KF-25TM

55-227 DV-4D-VCR VCRTM

Vacuum Gauge Tubes 100 mTorr Range

55-19 DV-5M 1/8” NPT (Red Base)

55-230 DV-5M -VCR VCRTM

Reference Tubes for use with DAVC

55-104 DB-20 Ref Tube (DV-6) for DAVC-6 Calibration

55-101 DB-16D Ref Tube (DV-4D) for DAVC-4 Calibration

55-103 DB-18 Ref Tube (DV-5) for DAVC-5 Calibration

174-082010_Digital AVC Page 6 of 17

Loading...

Loading...