Hastings 210, 212 User Manual

TELEDYNE

HASTINGS

INSTRUMENTS

INSTRUCTION MANUAL

210/212 SERIES

FLOW METERS/CONTROLLERS

ISO 9001

CERTIFIED

Manual Print History

The print history shown below lists the printing dates of all revisions and addenda created for this manual. The

revision level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are

released between revisions, contain important change information that the user should incorporate immediately

into the manual. Addenda are numbered sequentially. When a new revision is created, all addenda associated

with the previous revision of the manual are incorporated into the new revision of the manual. Each new

revision includes a revised copy of this print history page.

Revision A (Document Number 168-112007).................................................................. November 2007

Revision B (Document Number 168-062008)............................................................................ June 2008

Revision C (Document Number 168-092008) .................................................................September 2008

Revision D (Document Number 168-102009) ..................................................................... October 2009

Revision E (Document Number 168-082010)........................................................................August 2010

Visit www.teledyne-hi.com for WEEE disposal guidance.

CAUTION:

CAUTION:

CAUTION:

The instruments des cribed in this manual are av ailable w ith multiple pin- outs .

Ensure that all electrical connections are correct.

The instruments des cribed in this manual are designed for INDO O R us e only .

The instruments described in this manual are designed for Class 2 installations

in accordance with IAW/IPC standards

Hastings Instruments reserves the right to change or modify the design of its equipment without

any obligation to provide notification of change or intent to change.

168-082010_ 210-212 Meter/Controller Page 2 of 17

Table of Contents

1.

GENERAL INFORMATION............................................................................................................................................ 4

1.1. FEATURES.................................................................................................................................................................... 4

1.2. SPECIFICATIONS...........................................................................................................................................................5

1.3. OPTIONAL 4-20 MA CURRENT OUTPUT .......................................................................................................................5

1.4. OTHER ACCESSORIES...................................................................................................................................................6

2. INSTALLATION AND OPERATION............................................................................................................................. 7

2.1. RECEIVING INSPECTION ............................................................................................................................................... 7

2.2. POWER REQUIREMENTS ...............................................................................................................................................7

2.3. OUTPUT SIGNAL...........................................................................................................................................................7

2.4. MECHANICAL CONNECTIONS....................................................................................................................................... 7

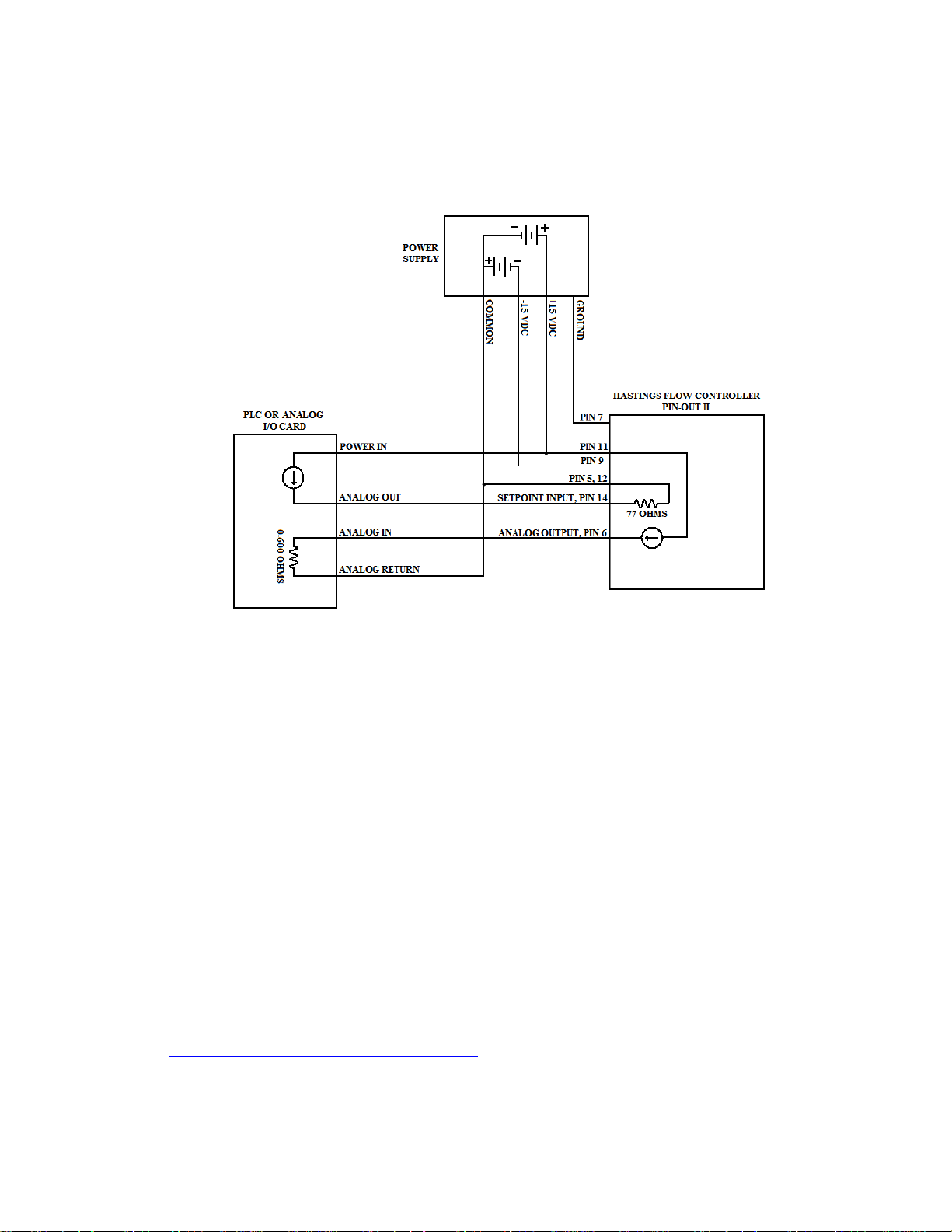

2.5. ELECTRICAL CONNECTIONS......................................................................................................................................... 8

2.6. OPERATION.................................................................................................................................................................. 8

2.7. OPERATION WITH EXTERNAL DEVICES ........................................................................................................................9

2.8. RANGE CHANGING:.................................................................................................................................................... 10

3. THEORY OF OPERATION...........................................................................................................................................12

3.1. OVERALL FUNCTIONAL DESCRIPTION: ...................................................................................................................... 12

3.2. SENSOR:..................................................................................................................................................................... 12

3.3. ELECTRONICS: ........................................................................................................................................................... 12

3.4. SHUNT: ...................................................................................................................................................................... 13

3.5. VALVE:...................................................................................................................................................................... 13

4. MAINTENANCE..............................................................................................................................................................14

4.1. AUTHORIZED MAINTENANCE.....................................................................................................................................14

4.2. TROUBLESHOOTING ...................................................................................................................................................14

4.3. ADJUSTMENTS......................................................................................................................................................15

4.4. FITTING AND SHUNT CHANGES:.................................................................................................................................16

4.5. PRINTED CIRCUIT BOARD REPLACEMENT.................................................................................................................. 16

4.6. SENSOR REPLACEMENT: ............................................................................................................................................ 16

4.7. ORIFICE CHANGES:.................................................................................................................................................... 16

5. WARRANTY AND REPAIR..........................................................................................................................................17

5.1. WARRANTY REPAIR POLICY ......................................................................................................................................17

5.2. NON-WARRANTY REPAIR POLICY ............................................................................................................................. 17

168-082010_ 210-212 Meter/Controller Page 3 of 17

1. General Information

The Hastings HFM-210 mass Flowmeter and HFC-212 flow controller are designed to accurately measure

and control mass flow over the range of 10 sccm to 30 slm, without corrections or compensations for gas

pressure and temperature with an accuracy of better than ±1% FS. Hastings mass flow instruments do not

require any periodic maintenance under normal operating conditions with clean gases. No damage will occur

from the use of moderate overpressures (~500 psi/3.45MPa) or overflows. Instruments are normally

calibrated with the appropriate standard calibration gas (nitrogen) then a correction factor is used to adjust the

output for the intended gas.

1.1. Features

• LINEAR BY DESIGN. The HFM-210/HFC-212 series is inherently linear (no linearization circuitry is

employed). Should recalibration in the field be desired (a calibration standard is required), the customer

needs to simply set the zero and span points. There will be no appreciable linearity change of the instrument

when the flowing gas is changed.

• MODULAR SENSOR. The HFM-210/HFC-212 series incorporates a removable/replaceable sensor module.

Field repairs to units can be achieved with a minimum of production line downtime.

• METER SETTLING TIME. Changes in flow rate for the HFM-210 are detected in less than 2 seconds when

using the fast-response circuitry.

• LOW TEMPERATURE DRIFT. The temperature coefficient of span for the HFM-210/HFC-212 series is

typically less than 0.08% of full scale/°C from 15-45°C. The temperature coefficient of zero is typically less

than 0.15 % of reading/°C from 0-50°C.

• CURRENT LOOP. The 4-20 mA option gives the user the advantages of a current loop output to minimize

environmental noise pickup.

168-082010_ 210-212 Meter/Controller Page 4 of 17

1.2. Specifications HFM-210

Accuracy1 and Linearity ........................................................................................................................±1% F.S.

Repeatability ......................................................................................................................... ±0.05% F.S. (max.)

Standard Pressure Rating ....................................................................................................................... 500 psig

Pressure Coefficient .................................................................................... +0.0067% Rdg/psi (0-1000 psig N

High-Pressure Option ................................................................................................... Proof tested to 1500 psig

Leak Integrity ..................................................................................................................................< 1x10

Temperature Coefficient ........................................................................................ Zero ±0.08% F.S./°C (max.)

............................................................................................................... (0°-50°C) Span ±0.15% Rdg/°C (max.)

STP .........................................................................................................................................0°C and 760 Torr

Input Power ............................................................................................................±15 VDC at ±30 mA (max.)

Flow Signal ..................................................................................... 0-5.00 VDC or 4-20 mA (inherently linear)

2

Wetted Material

..........................................................................................316 SS, Viton®, 82/18 Au/Ni Braze

Connector ........................................................................................................................15 pin Subminiature D

Fittings Available ................................................................................... Swage (1/8”, 1/4” & 3/8”), VCO, VCR

Weight (approx.) ......................................................................................................................... 1.8 lb (0.82 kg)

1.3. Specifications HFC-212

-9

sccs

)

2

Accuracy

1

and Linearity ........................................................................................................................±1% F.S.

Repeatability ......................................................................................................................... ±0.05% F.S. (max.)

Standard Pressure Rating ....................................................................................................................... 500 psig

Pressure Coefficient .................................................................................... +0.0067% Rdg/psi (0-1000 psig N

Control Valve DP

* ............................................................................................................. Per customer request

)

2

High-Pressure Option ................................................................................................... Proof tested to 1500 psig

-9

Leak Integrity ..................................................................................................................................< 1x10

sccs

Temperature Coefficient ......................................................................................... Zero ±0.08% F.S./°C (max.)

............................................................................................................... (0°-50°C) Span ±0.15% Rdg/°C (max.)

STP .........................................................................................................................................0°C and 760 Torr

Input Power ............................................................................................ ±15 VDC at +60 mA/-185 mA (max.)

Flow Signal ..................................................................................... 0-5.00 VDC or 4-20 mA (inherently linear)

Command Input ............................................................................................ 0-5.00 VDC or 4-20 mA available

2

Wetted Material

..............................................................................316 SS, Nickel, Viton®, 82/18 Au/Ni Braze

Connector ........................................................................................................................15 pin Subminiature D

Fittings Available ................................................................................... Swage (1/8”, 1/4” & 3/8”), VCO, VCR

Weight (approx.) ......................................................................................................................... 1.8 lb (0.82 kg)

1

Stated accuracy is for nitrogen or other gas specific calibration and use with this gas only.

2

Other materials are available. Viton is the standard O-ring option.

* Specifications may vary for instruments with ranges greater than 10 SLM.

1.4. Optional 4-20 mA Current Output

An option to the standard 0-5 VDC output is the 4-20 mA current output that is proportional to flow. The 4 20 mA signal is produced from the 0 - 5 VDC output of the Flowmeter. The current loop output is useful for

remote applications where pickup noise could substantially affect the stability of the voltage output.

The current loop signal replaces the voltage output on pin 6 of the “D” connector. The current loop may be

returned to either the power supply ground or the -15 VDC connections on the power supply. If the current

168-082010_ 210-212 Meter/Controller Page 5 of 17

loop is returned to the power supply ground, the load must be between 0 and 600 ohm. If it is returned to the

-15VDC, the load must be between 600 and 1200 ohm. Failure to meet these conditions will cause failure of

the loop transmitter.

The 4-20 mA I/O option can accept a current input. The 0-5 VDC command signal on pin 6 can be replaced

by a 4-20mA command signal. The loop presets an impedance of 75 ohms and is returned to the power

supply through the valve common.

1.5. Other Accessories

1.5.1. Hastings Power Supplies

Hastings Power Pod power supply/display units are available in one and four channel versions. They convert

100, 115 or 230VAC to the ±15 VDC required to operate the flow meter and provide a digital indication of

the flow rate. Interface terminals for the retransmission of the flow meter analog output signal are located on

the rear of the panel.

The Power Pod 100 and 400 models are built with controllers in mind but will work with meters as well. The

Model 40 is for flow meters only. Throughout this manual, when reference is made to a power supply, it is

assumed the customer is using a Hastings power supply. Hastings PowerPod-100 and PowerPod-400 power

supplies are CE marked, but the Model 40 does not meet CE standards at this time. The Model 40 and

PowerPod-100 are not compatible with 4–20 mA analog signals. With the PowerPod 400, individual channels’

input signals, as well as their commands, become 4–20 mA compatible when selected. The PowerPod-400 also

sports a Totalizer feature. More information about the Power Pods can be found on the Hastings web site.

http://www.teledyne-hi.com/products/powerpod-series.htm

1.5.2. Interconnecting Cables

Cables are available from Hastings, in various lengths, to connect from the 15 pin "D" connector on the back of

the Power Pod directly to any of the 200 series and 300 series flow instruments (including digital versions).

More information about the available cables can be found in the Power Pod 400 bulletin on the Hastings web

site. http://www.teledyne-hi.com/pdfs/bulletins.htm

168-082010_ 210-212 Meter/Controller Page 6 of 17

Loading...

Loading...