Hasler WJ185, WJ220, WJ250 User Manual

1

ORIG0140-1

4127718F/B

02/26/2007

INTRODUCTION

Congratulations on choosing the Hasler WJ185/220/250 mailing

machine. The WJ185/220/250 is the result of the expertise and

innovative capabilities of a worldwide Hasler group and, using ink

jet technology, it will integrate into your working environment to

enhance your mail processing operation.

The WJ185/220/250 has many capabilities that will be important

to your business:

As well as being productive (up to 250 letters per minute for

machine only, and up to 125 letters per minute in dynamic scale

mode), the WJ185/220/250 is designed to be a user friendly

machine that can fit into any working environment with its innovative

and attractive design, simple user settings and very low noise

level. The high volume capacity and sealed ink system makes it

easy and safe to handle, and the user interface is particularly clear

with a graphic interface, pop up menus and 10 memories to store

favorite jobs.

The WJ185/220/250 is adaptable and as such can handle many

different types of mail. The optional feeder can be used to

process, in a continuous cycle, items of different sizes (ranging

from postcards to large flats in portrait format) and thick items (up

to 5/8 inch), with automatic imprint shift. For thicker mail items or

packages, adhesive labels can be automatically dispensed.

The WJ185/220/250 is connectable. It can exchange data with

Hasler scales printers and PC's in order to provide optimal mail

processing and reporting.

Finally, the WJ185/220/250 is a unique communication tool for

your company. Its high quality printing combined with its integrated

library of advertisement messages, mail class dies and free

format text will afford you extra tools to enhance your company’s

image and the impact of your mail.

You will very soon discover for yourself that the WJ185/220/250 is

the ultimate in quality and productivity for mail processing

equipment.

2

ORIG0140-2

4127718F/B

02/26/2007

WARNING!

Do not remove any secured covers or attempt to repair the WJ185/

220/250, there are no user serviceable parts contained and the

WJ185/220/250 product is licensed for use under the conditions of the

Post Office. This license is issued subject to the product being secure

at all times. Any removal of covers or dis-assembly of the product will

result in the license being revoked and may result in the Post Office

requesting Hasler to remove the product from use.

The inking system used within the WJ185/220/250 contains Post

Office approved ink. This cartridge should not be tampered with in any

way or the use of non approved inks be attempted. This will breach any

Post Office licence agreement on the product and may result in the

Post Office requesting Hasler to remove the product from use.

FCC COMPLIANCE STATEMENT

This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with this

instruction manual, may cause harmful interferences to radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference, in which case the user will be required

to correct the interferences at his own expense.

The internal modem of this equipment complies with Part 68 of the

FCC rules.

INSTALLATION

The power plug on this equipment is intended to serve as the device

for isolation of the electrical supply. The equipment should be installed

in close proximity to easily accessible electrical outlet and telephone

wall connector.

No part of this document may be reproduced or transmitted in any

form or by means, electronic or mechanical, for any purpose without

the express written permission of Hasler.

Copyright© Hasler 2004

3

ORIG0140-3

4127718F/B

02/26/2007

TABLE OF CONTENTS

GETTING STARTED .............................................9

SECTION A: BASIC FUNCTIONS ......................11

1. OVERALL PRESENTATION ................................................13

1.1 Overview ................................................................ 13

1.1.1 Overall view (mailing machine and optional

standard automatic feeder) ............................ 13

1.1.2 Overall inside view with optional standard

automatic feeder............................................ 14

1.1.3 Mixed-mail feeder (optional)........................... 15

1.1.4 T ouch screen and keyboard........................... 16

1.2 Installation ..............................................................18

1.2.1 Preparation of the mailing machine ................18

1.2.2 Installation with the feed platform .................... 18

1.2.3 Installation of the standard automatic feeder

(optional: available on WJ185 only) ................ 19

1.2.4 Installation of the mixed-mail feeder (optional) 20

1.2.5 Installation of the dynamic scale (optional) ...... 23

1.2.6 Connections at the rear of the units................. 25

1.2.7 Ink tank and printhead .................................... 28

1.2.8 Installation of the Weighing Platform ............... 31

1.3 Envelope feeding ................................................... 36

1.3.1 With the standard automatic feeder................ 36

1.3.2 With a mixed-mail feeder ............................... 38

1.3.3 With feed platform alone ................................41

1.4 Label feeding ......................................................... 42

1.5 Filling of the removable water bottle ........................ 43

1.5.1 Standard automatic feeder............................. 43

1.5.2 Mixed-mail feeder .......................................... 44

4

ORIG0140-4

4127718F/B

02/26/2007

1.6 Envelope moistening .............................................. 44

1.6.1 Standard automatic feeder............................. 44

1.6.2 Mixed-mail feeder .......................................... 45

1.7 Operation with an inserter ....................................... 48

2. PROTECTION BY AN ACCESS PIN CODE .......................50

3. USING A SCALE ...................................................................51

3.1 Using dynamic scale ..............................................53

3.1.1 Dynamic scale OFF mode ............................. 53

3.1.2 Dynamic scale ON mode ............................... 53

3.1.3 Dynamic scale batch mode ............................ 54

3.2 Operation with an external weighing platform .......... 54

3.2.1 WP standard mode........................................ 54

3.2.2 Differential Weighing Mode............................ 56

3.2.3 WP piece counting mode............................... 6 1

3.2.4 Manual weight entry mode..............................63

3.3 Country and insurance ............................................ 65

4. ENTERING POSTAGE VALUE AND MAIL PROCESSING 68

4.1 Entering postage value ........................................... 68

4.1.1 Manually......................................................... 6 8

4.1.2 With an external scale .................................... 68

4.1.3 With a dynamic scale ..................................... 68

4.2 Mail processing...................................................... 72

4.2.1 Envelopes with Autofeed Sealer (except batch

mode) ............................................................ 72

4.2.2 Envelopes with dynamic scale in batch mode. 72

4.2.3 With the feed platform alone........................... 73

4.2.4 Labels............................................................ 73

5. MODIFICATION OF THE IMPRINT .....................................74

6. USING DEPARTMENTS ......................................................76

7. OPERATION WITH AN EXTERNAL PC REMOTE

CONTROL ............................................................................77

5

ORIG0140-5

4127718F/B

02/26/2007

8. TELE-METER SETTING® CONNECTION ........................78

8.1 Adding Postage ..................................................... 78

8.2 Clearing a PO lockout ............................................ 79

8.3 Completing an interrupted add postage transaction 80

9. ONLINE SERVICES .............................................................80

10. OPERATION WITH A ROLL TAPE DISPENSER (RTD) ..... 81

10.1 Overview ................................................................ 81

10.2 Connections at the rear of the units ......................... 82

10.3 Loading label roll .................................................... 82

10.4 Using the RTD ........................................................ 84

10.5 Maintenance........................................................... 85

SECTION B: ADVANCED FUNCTIONS ............. 89

1. FURTHER FUNCTIONS ......................................................91

1.1 Mode...................................................................... 91

1.1.1 Pass through (seal only , no postage) mode .... 91

1.1.2 Dating mode.................................................. 92

1.2 Mailing machine general configuration.................... 92

1.3 Configuration of the main screen display ................93

2. JOB MEMORY SAVING .......................................................95

2.1 Storing in user memory "0" ..................................... 95

2.2 Recalling memories................................................ 95

3. REPORT PRINTING ............................................................97

3.1 Operating mode: .................................................... 97

3.2 Batch Registers.................................................... 100

3.3 Automatic Call List ............................................... 101

3.4 Active Feature List ............................................... 102

3.5 Modules Details ...................................................102

3.6 Activity Error List .................................................. 103

3.7 Activity History Report ..........................................105

6

ORIG0140-6

4127718F/B

02/26/2007

4. SUPERVISOR MODE ........................................................106

4.1 Enabling the supervisor mode .............................. 106

4.2 Automatic date advance ....................................... 110

4.3 User setup (in supervisor mode) ........................... 113

4.4 Supervisor setup .................................................. 113

4.4.1 Security........................................................ 114

4.4.2 Time ............................................................ 115

4.4.3 Timeout........................................................ 116

4.4.4 Load rate table............................................. 117

4.4.5 Dynamic Scale T ests.................................... 117

4.4.6 T ouchscreen calibration................................ 118

4.4.7 Serial port setup........................................... 119

4.5 Display setup ....................................................... 119

4.6 Departments ........................................................120

4.7 Printing inker servicing ......................................... 122

4.8 Reports ................................................................ 123

4.9 Ink information ...................................................... 125

4.10 Postal services..................................................... 125

4.10.1 Audit ............................................................ 128

4.10.2 Update registers .......................................... 129

4.11 Online services ..................................................... 129

4.12 Downloading an advertisement slogan or a mini die. 129

4.13 Rate configuration ................................................ 131

4.14 Dynamic scale high accuracy configuration mode. 131

4.15 Programming memories 1 to 9 ............................. 133

4.16 Text modification...................................................135

4.17 Exiting the supervisor mode.................................. 136

7

ORIG0140-7

4127718F/B

02/26/2007

SECTION C: MAINTENANCE ADVICE ........... 137

1. TROUBLE SHOOTING .....................................................139

1.1 Misfeed................................................................ 139

1.1.1 In the standard automatic feeder .................. 139

1.1.2 In the mixed-mail feeder ...............................139

1.1.3 In the mailing machine.................................. 139

1.1.4 In the dynamic scale ..................................... 141

1.2 Problems machine and feeder.............................. 142

1.3 Problems roll tape dispenser ................................ 145

1.4 Problem dynamic scale ........................................ 149

2. GENERAL MAINTENANCE ...............................................150

2.1 Replacement of the brush and moistening sponges150

2.2 Mixed-mail feeder................................................. 151

2.3 Cleaning of the rollers ........................................... 153

2.4 Cleaning the printhead.......................................... 154

2.5 Replacing the envelope pressure units (dynamic

scale) ...................................................................155

2.6 Removal of the postage meter .............................. 156

2.7 T ouchscreen precautions ...................................... 157

SECTION D: MAINTAINING YOUR TELE-

METER SETTING® ACCOUNT.................. 159

1. ACCOUNT NUMBER .........................................................161

2. ACCOUNT BALANCE ........................................................161

3. STATEMENTS ....................................................................161

4. POST OFFICE REGULATIONS ........................................162

5. POSTAGE NOW ................................................................. 162

6. STANDARD TMS® BANK ACCOUNTS............................163

7. WHERE TO MAIL YOUR DEPOSIT: ................................. 165

8

ORIG0140-8

4127718F/B

02/26/2007

INTERNATIONAL LETTER POST COUNTRY

CODE CHART .............................................. 167

SPECIFICATIONS ............................................ 169

ORDERING SUPPLIES ..................................... 1 72

CONTACT INFORMATION............................... 173

INDEX ................................................................ 174

Getting Started 9

ORIG0140-9

4127718F/B

02/26/2007

GETTING STARTED

1 Switch on the machine;

2 Enter your PIN number using the numeric keys and validate by

touching

OK

(see "Specifications" for initial access code);

3 Enter the postage print value using the numeric keys;

4 Place an envelope on the feed platform;

5 Press

START

STOP

.

Congratulations! You have succeeded in metering an envelope.

10

ORIG0140-10

4127718F/B

02/26/2007

Special icons

Signals an essential piece of information that cannot be

missed.

Signals an important issue.

Indicates an interesting idea or trick

Illustration through an example

According to the machine configuration, the menu lists

may change.

11

ORIG0140-11

4127718F/B

02/26/2007

SECTION A: BASIC FUNCTIONS

1. OVERALL PRESENT A TION .............................................13

1.1 Overview 13

1.1.1 Overall view (mailing machine and optional

standard automatic feeder) 13

1.1.2 Overall inside view with optional standard

automatic feeder 14

1.1.3 Mixed-mail feeder (optional) 15

1.1.4 T ouch screen and keyboard 16

1.2 Installation 18

1.2.1 Preparation of the mailing machine 18

1.2.2 Installation with the feed platform 18

1.2.3 Installation of the standard automatic feeder

(optional: available on WJ185 only) 19

1.2.4 Installation of the mixed-mail feeder

(optional) 20

1.2.5 Installation of the dynamic scale (optional) 23

1.2.6 Connections at the rear of the units 25

1.2.7 Ink tank and printhead 28

1.2.8 Installation of the Weighing Platform 31

1.3 Envelope feeding 36

1.3.1 With the standard automatic feeder 3 6

1.3.2 With a mixed-mail feeder 38

1.3.3 With feed platform alone 41

1.4 Label feeding 42

1.5 Filling of the removable water bottle 43

1.5.1 Standard automatic feeder 43

1.5.2 Mixed-mail feeder 44

1.6 Envelope moistening 44

1.6.1 Standard automatic feeder 44

1.6.2 Mixed-mail feeder 45

1.7 Operation with an inserter 48

2. PROTECTION BY AN ACCESS PIN CODE ......................50

3. USING A SCALE .............................................................. 51

3.1 Using dynamic scale 53

3.1.1 Dynamic scale OFF mode 5 3

3.1.2 Dynamic scale ON mode 53

3.1.3 Dynamic scale batch mode 54

12

ORIG0140-12

4127718F/B

02/26/2007

3.2 Operation with an external weighing platform 54

3.2.1 WP standard mode 54

3.2.2 Differential Weighing Mode 56

3.2.3 WP piece counting mode 61

3.2.4 Manual weight entry mode 6 3

3.3 Country and insurance 65

4. ENTERING POST AGE V ALUE AND MAIL PROCESSING 68

4.1 Entering postage value 6 8

4.1.1 Manually 68

4.1.2 With an external scale 68

4.1.3 With a dynamic scale 68

4.2 Mail processing 72

4.2.1 Envelopes with Autofeed Sealer

(except batch mode) 72

4.2.2 Envelopes with dynamic scale in batch

mode 72

4.2.3 With the feed platform alone 73

4.2.4 Labels 73

5. MODIFICA TION OF THE IMPRINT...................................74

6. USING DEP ARTMENTS ...................................................76

7. OPERA TION WITH AN EXTERNAL PC REMOTE

CONTROL ........................................................................ 77

8. TELE-METER SETTING® CONNECTION .........................78

8.1 Adding Postage 78

8.2 Clearing a PO lockout 79

8.3 Completing an interrupted add postage transaction 80

9. ONLINE SERVICES.......................................................... 80

10. OPERATION WITH A ROLL TAPE DISPENSER (RTD)....81

10.1 Overview 81

10.2 Connections at the rear of the units 82

10.3 Loading label roll 82

10.4 Using the RTD 84

10.5 Maintenance 85

Overall presentation 13

ORIG0140-13

4127718F/B

02/26/2007

1. OVERALL PRESENTATION

1.1 Overview

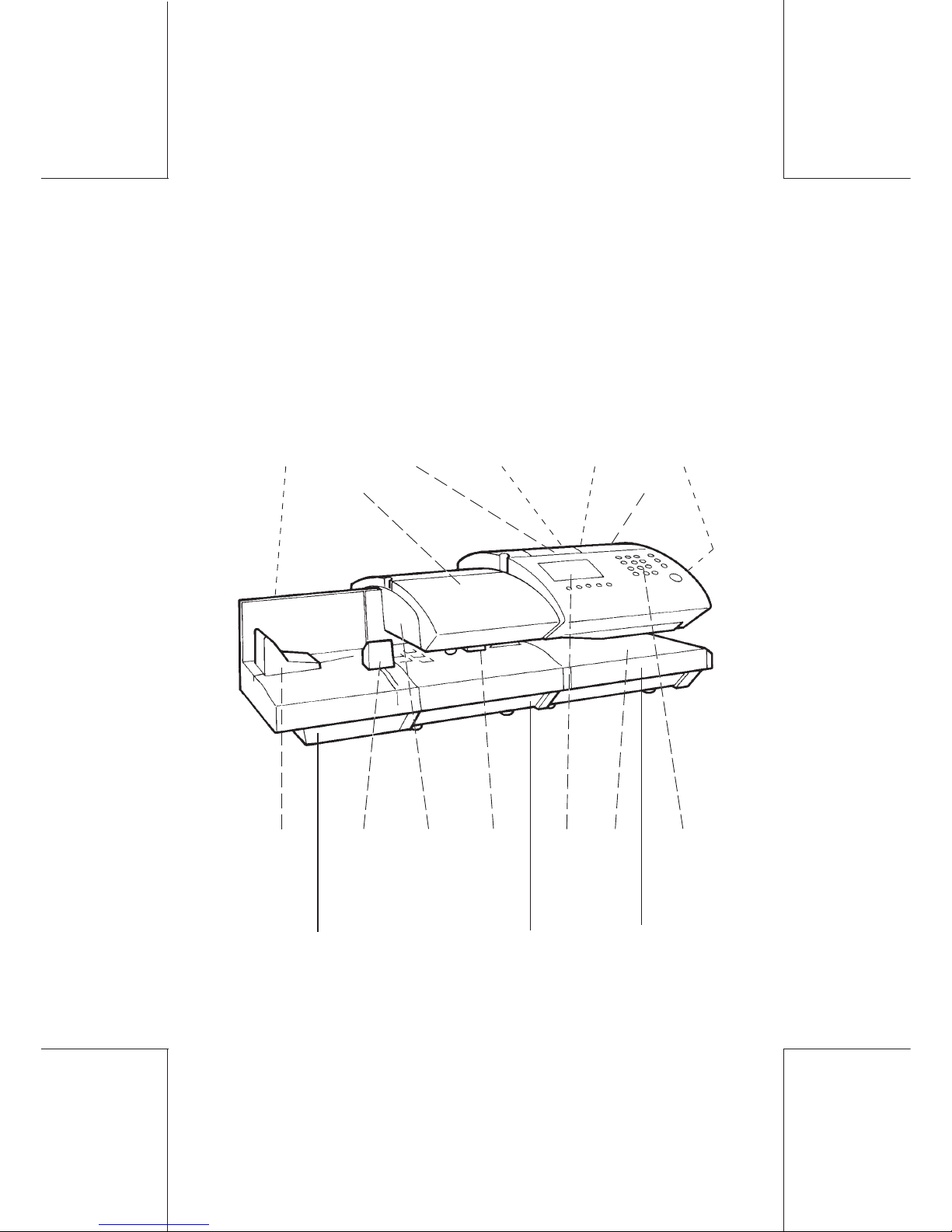

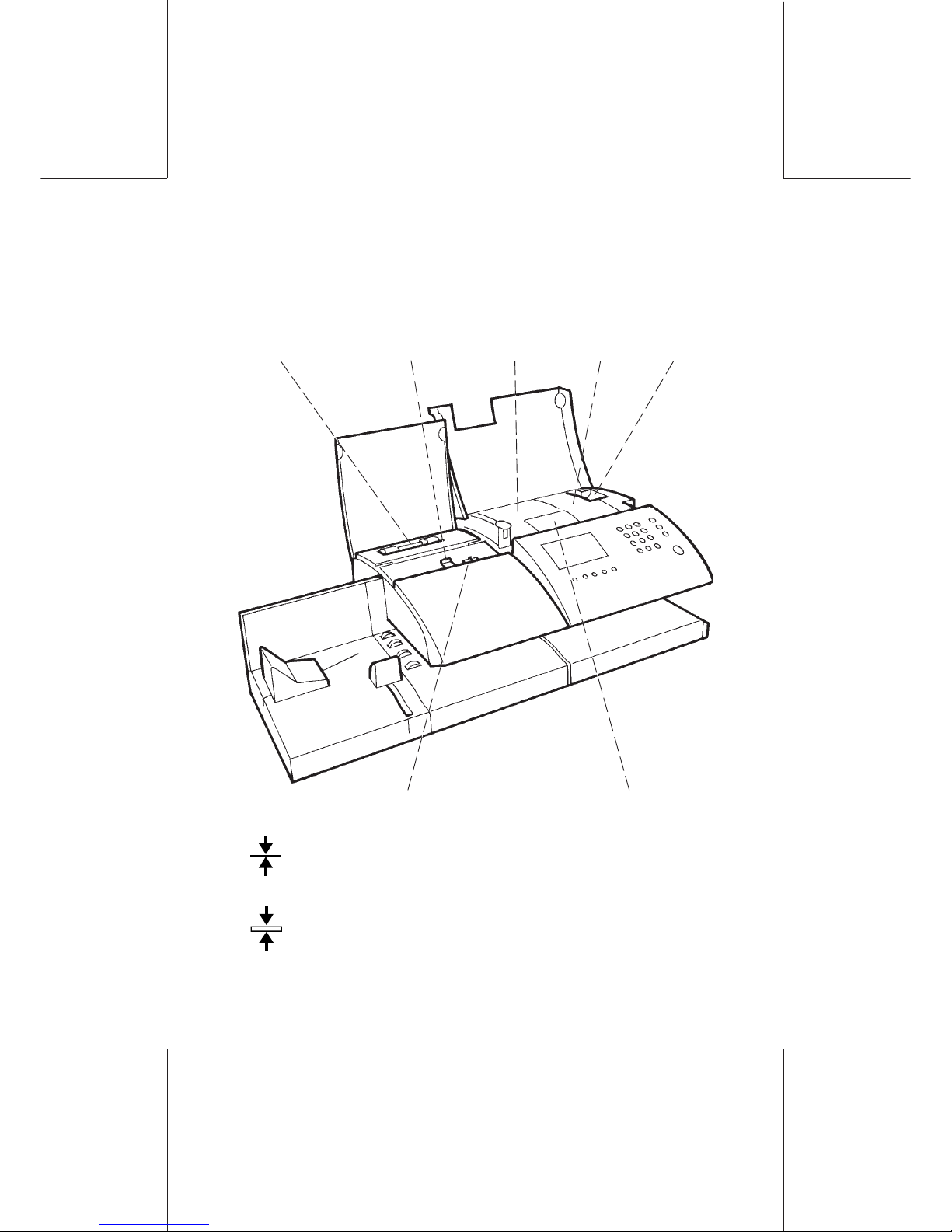

1.1.1 Overall view (mailing machine and optional standard automatic feeder)

cover

pre-cut

label

dispenser

touch

graphic

screen

keyboard

ON/OFF

switch

(rear)

memory

card

reader

adjustable

side

guide

conveyorfront

guide

cover

removable

rear

guide

accessories

and

documentation

area

feed

platform

autofeed

sealer

mailing

machine

table

modem

connector

(rear)

Overall presentation14

ORIG0140-14

4127718F/B

02/26/2007

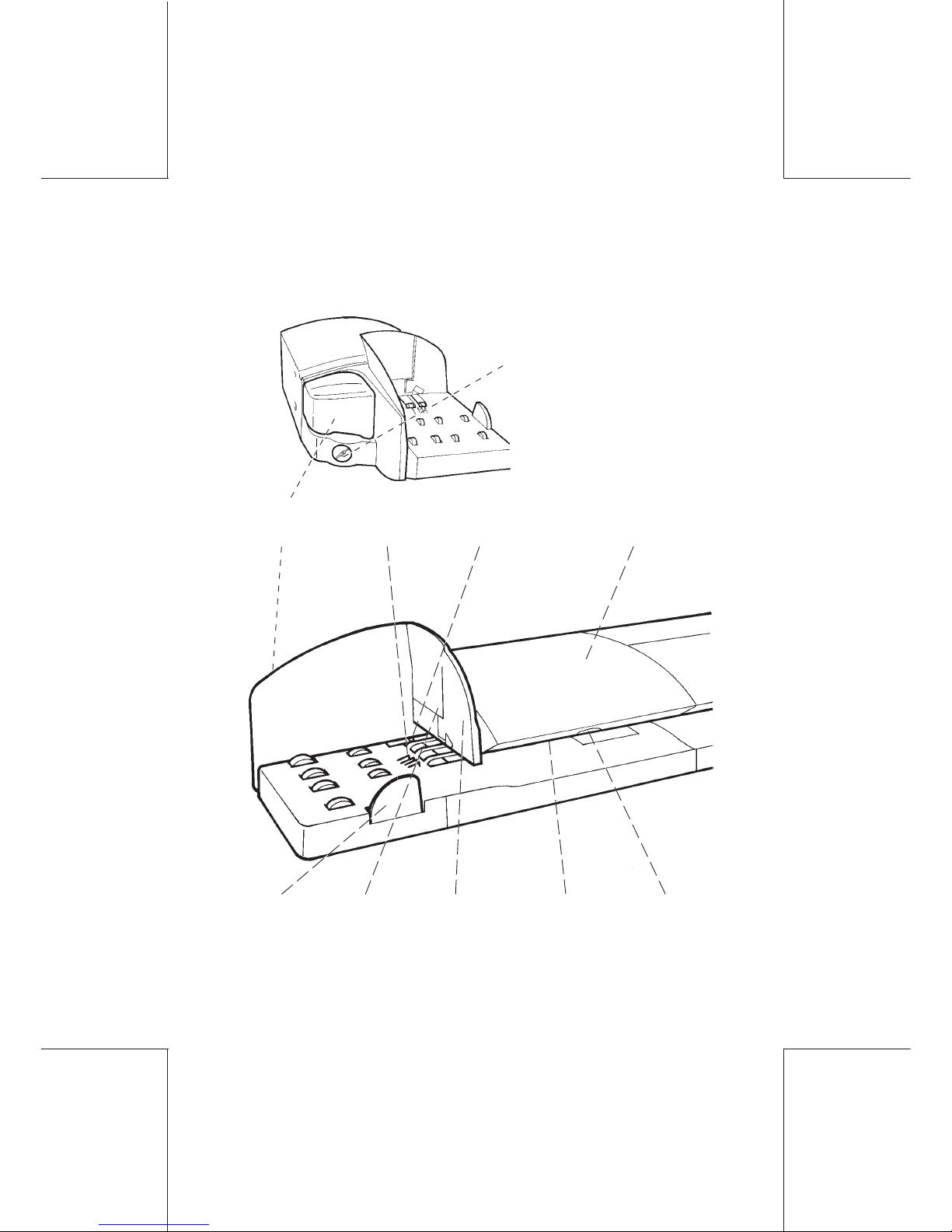

1.1.2 Overall inside view with optional standard

automatic feeder

postage

meter

ink

tank

blue button for

conveyor release

device

removable

water bottle

-

A

(left) : up to 3/8 inch

-

B

(right) : from 3/8 to 5/8 inch without the dynamic scale and

from 3/8 to 1/2 inch with the dynamic scale

label dispenser flap

thickness adjustment

2 positions blue button:

printhead

Overall presentation 15

ORIG0140-15

4127718F/B

02/26/2007

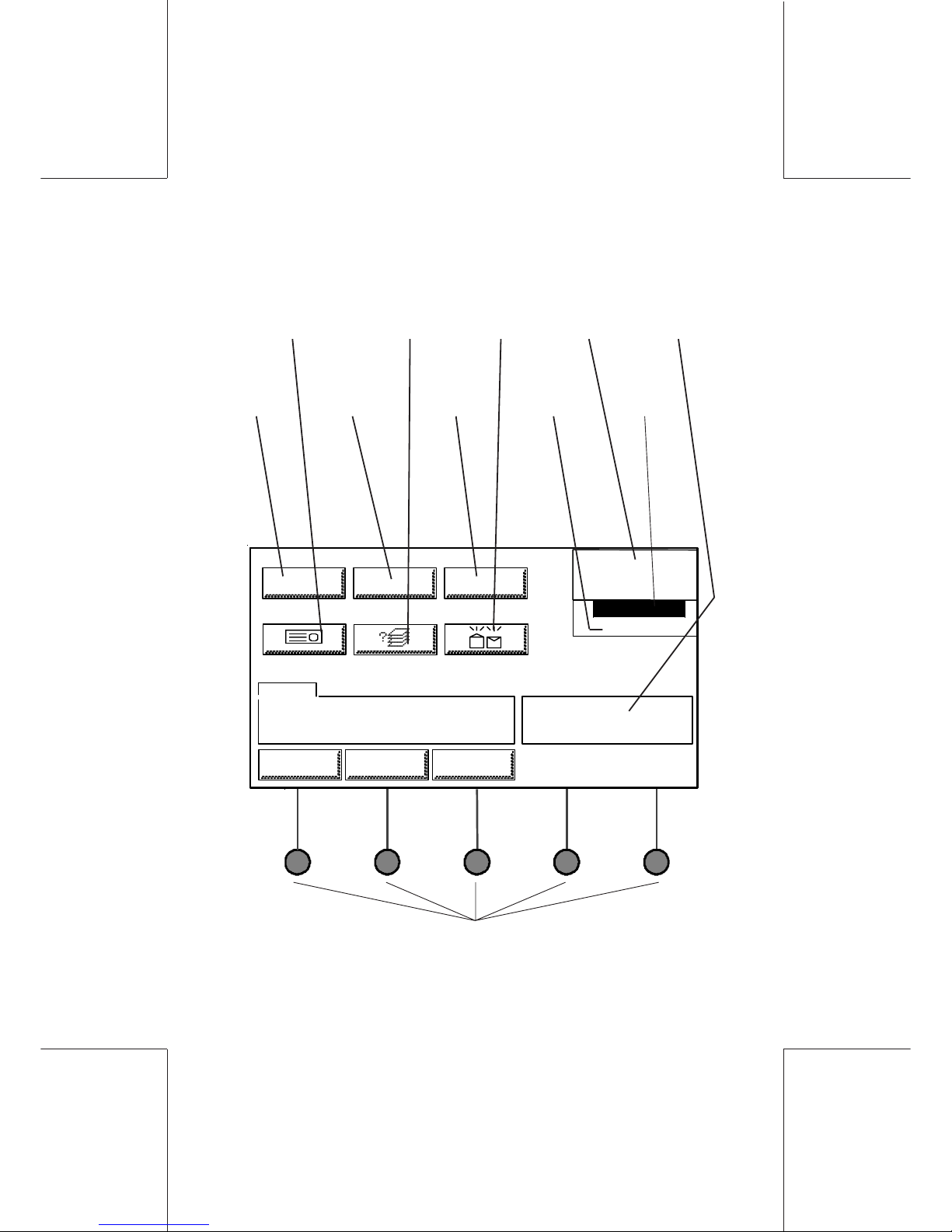

1.1.3 Mixed-mail feeder (optional)

cover

large

envelope

side guide

front

guide

small and

medium

envelope

side guide

water

bottle

anti-skew

levers

tightening

knob

cover

release

handle

conveyor

sensor

Overall presentation16

ORIG0140-16

4127718F/B

02/26/2007

0

0

.

0

0

0

LOW CREDIT

XX-XX-XX

LABEL SCALE SEALER

RATE

DEPT

MARKETING

TOI XXXXXX

BTO XXXXX

TEXT

LOGINJOBSMENU

INFO

AD DIE MAIL D

RATE NAME USER RATE

WGH MAN 30 lb 0.8 oz

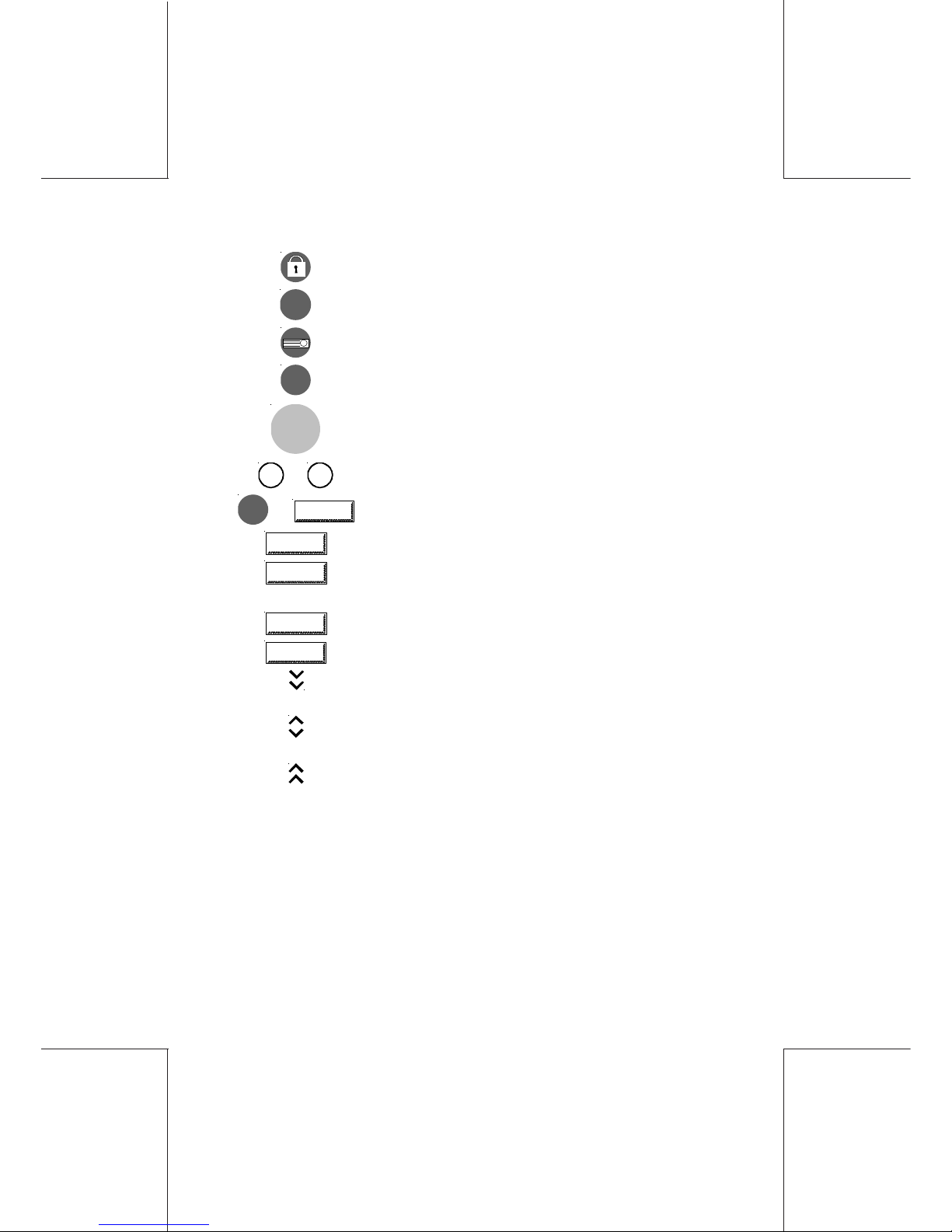

1.1.4 Touch screen and keyboard

advertisement

postage

value

date

menu selection keys,

or

touch keys on the screen

mail

class

die

warning

message

user

definable

parameter

to select

sealing

dynamic

scale

to select

RTD or

precut label

text

Overall presentation 17

ORIG0140-17

4127718F/B

02/26/2007

:locking and standby mode

RESET

: return to main menu with default settings

: label mode selection

C

: input value reset (including postage)

START

STOP

: switching on/off envelope or label feed

0

to

9

: numeric entry keys

OK

or

OK

: validating a selection

ESCAPE

:return to previous menu with no validation

HOME

:return to main menu with no validation (except

timeout)

LOGIN

:access to Supervisor mode every time

LOGOUT

:return to User mode

:indicates that there are other choices settable in

the next page

:indicates that there are other choices settable in

the next and previous pages

:indicates that there are other choices settable in

the previous page

Overall presentation18

ORIG0140-18

4127718F/B

02/26/2007

1.2 Installation

1.2.1 Preparation of the mailing machine

The mailing machine should be installed on a flat horizontal

surface.

Allow sufficient free space as follows:

- above the machine to enable the opening of the covers

- at the rear for the machine cooling.

With the O/I switch in the “ O ” (OFF) position, connect the power

cord to the rear of the machine and to an 110V AC electrical outlet.

Insert one end the telephone cable into the modem connector at

the rear of the machine and the other to an analog telephone wall

jack for Tele-Meter Setting® resetting connection.

For security purposes, please ensure that all the items are

correctly assembled prior to switch on the configuration.

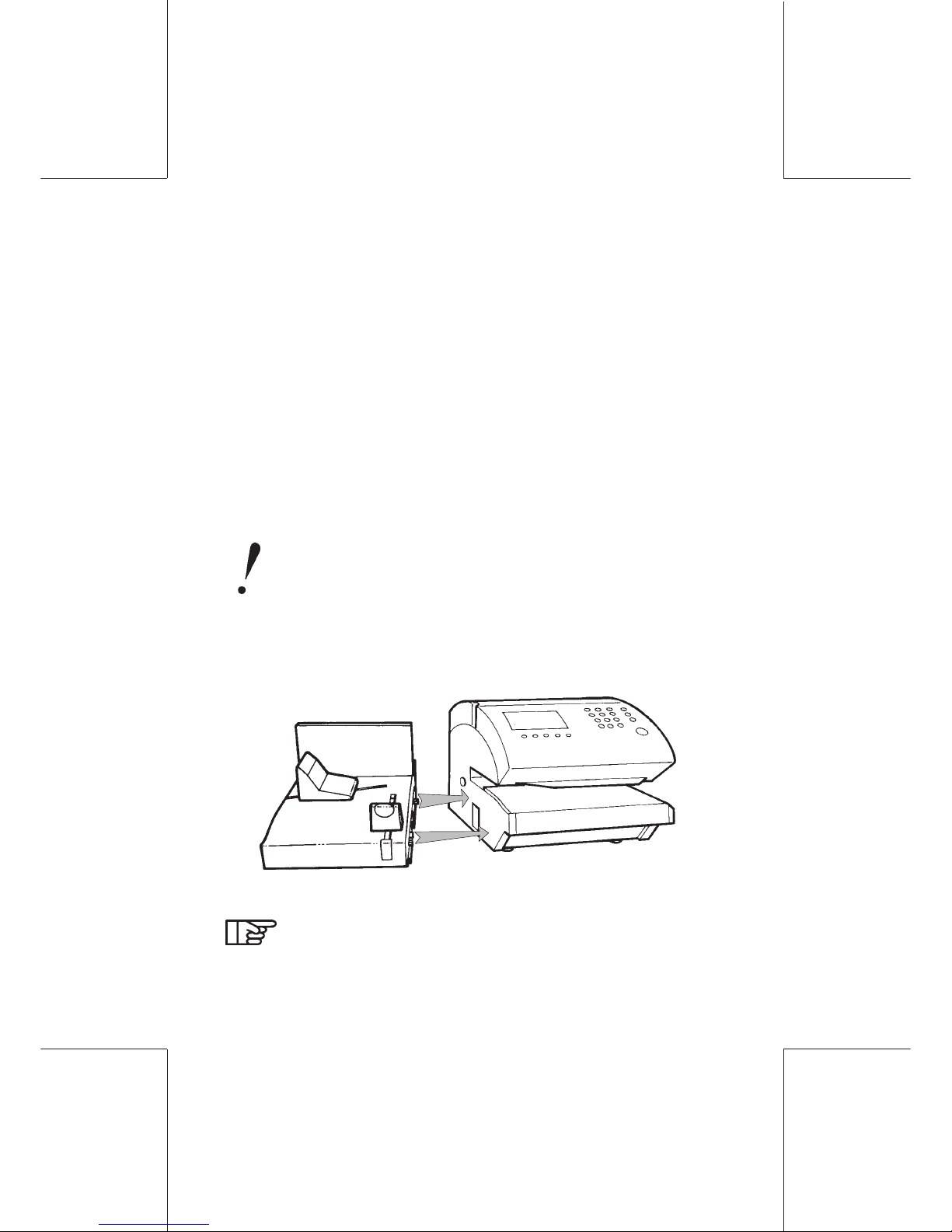

1.2.2 Installation with the feed platform

Assemble the feed platform with the mailing machine.

Prior to moving the whole machine, you must separate

the mailing machine from the feed platform.

Overall presentation 19

ORIG0140-19

4127718F/B

02/26/2007

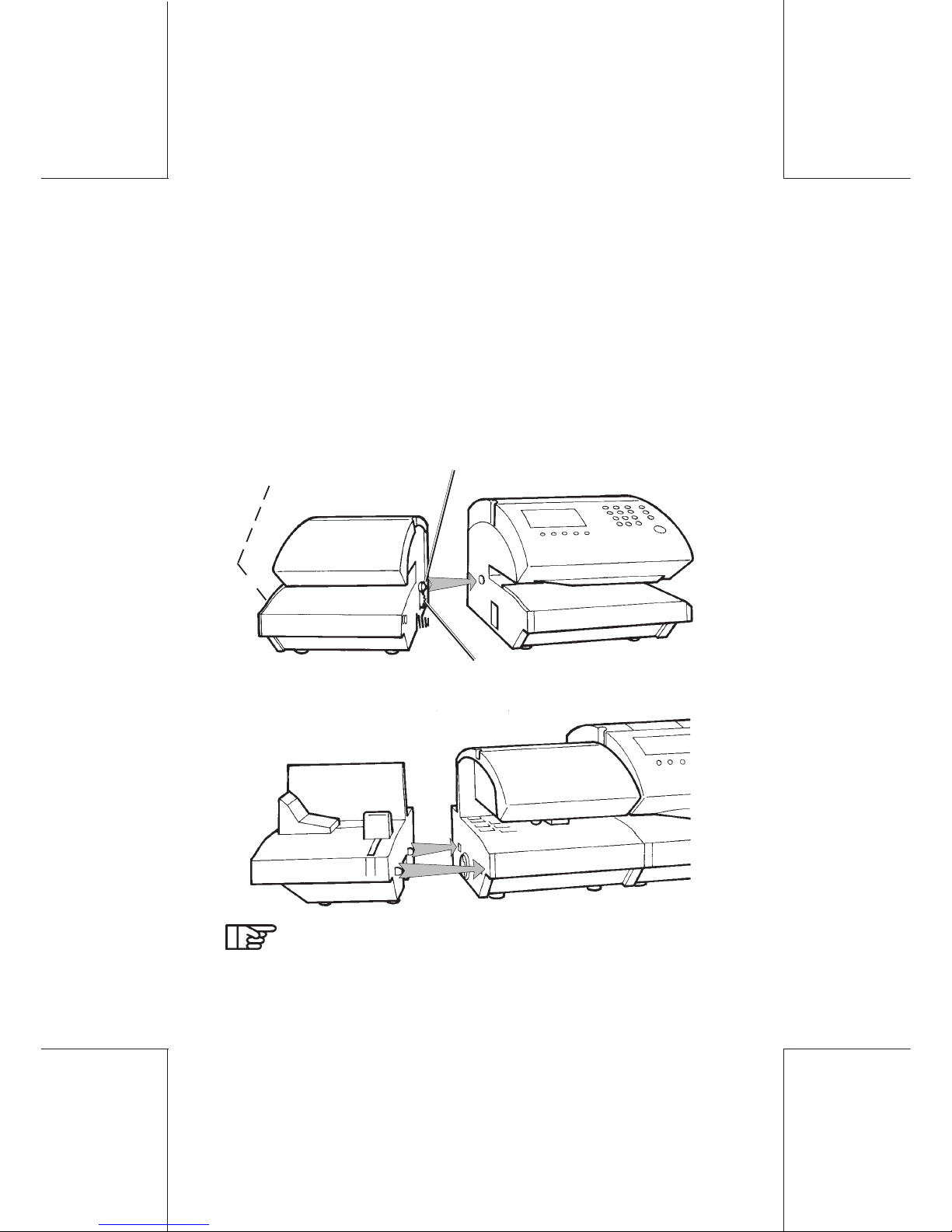

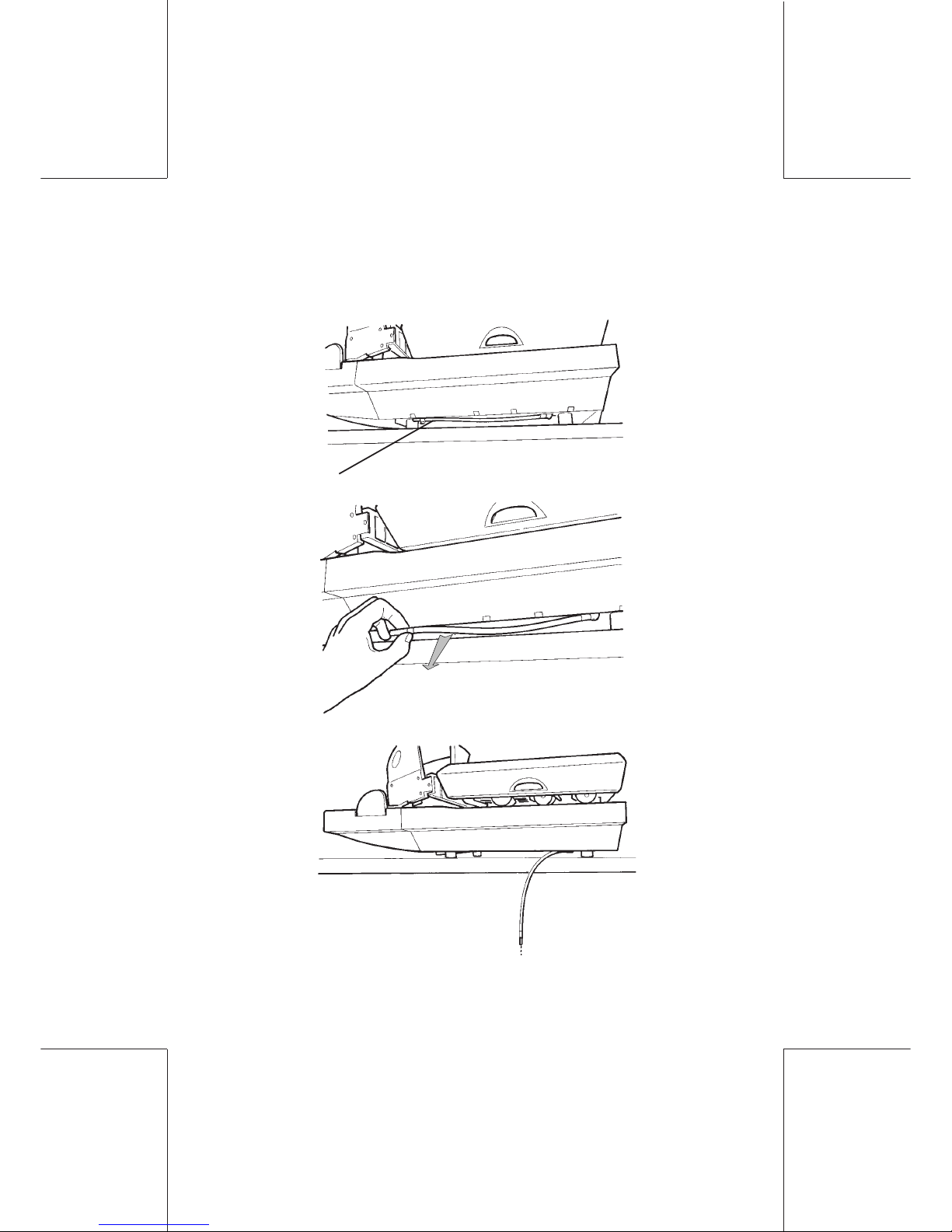

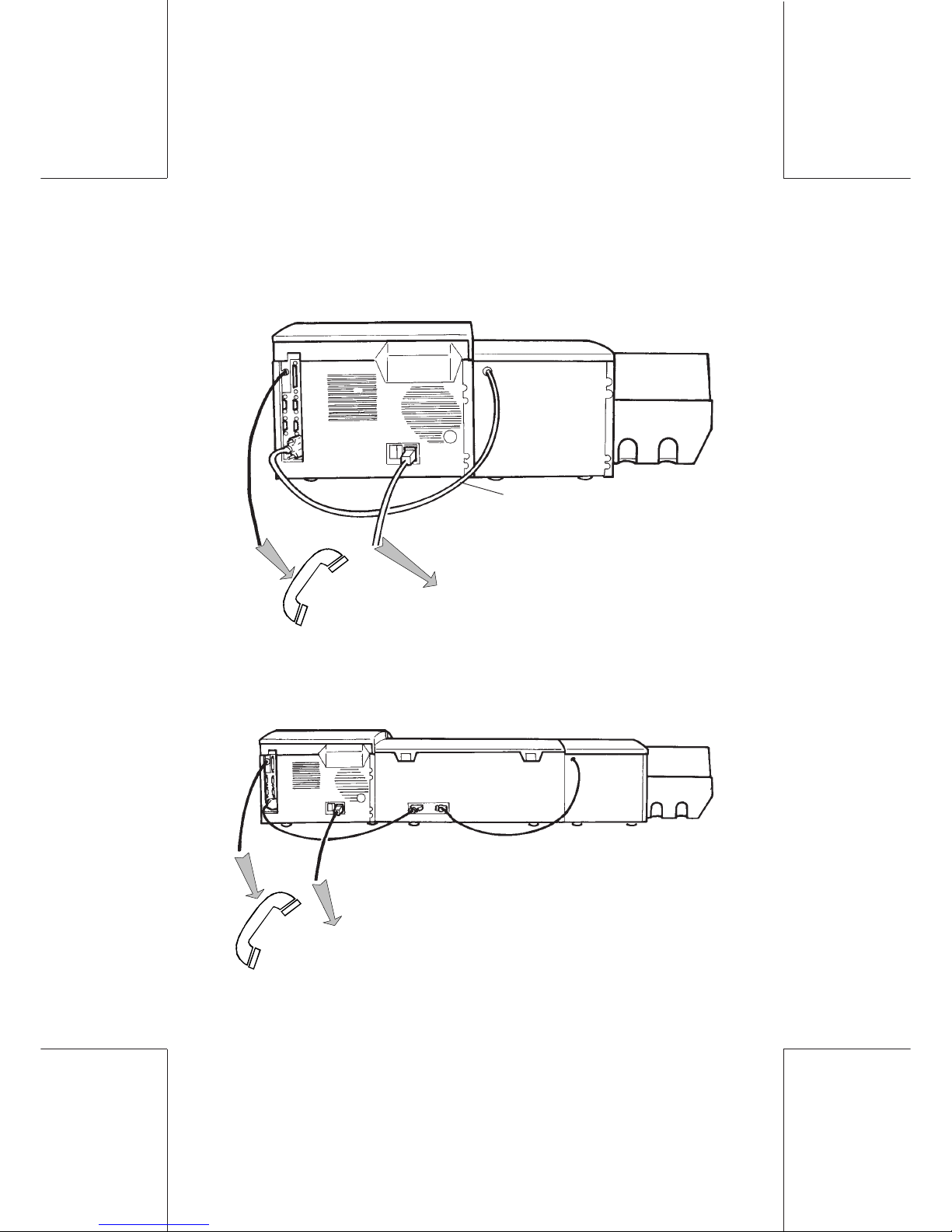

1.2.3 Installation of the standard automatic feeder

(optional: available on WJ185 only)

- Align the feeder with the mailing machine;

- Push the feeder towards the machine, taking care to keep the

centering pin aligned as indicated;

- Thread the feeder screw in the mailing machine. Then, using the

knurled tightening knob, push and screw to lock (if the two

devices are not closing properly, slightly rotate the gear protruding

from the feeder and repeat the operation).

centering pin

tightening knob

(on the side)

(gear)

Prior to moving the whole machine, the mailing machine,

the feeder and the platform must be separated.

- Assemble the feed platform with the feeder as indicated.

Overall presentation20

ORIG0140-20

4127718F/B

02/26/2007

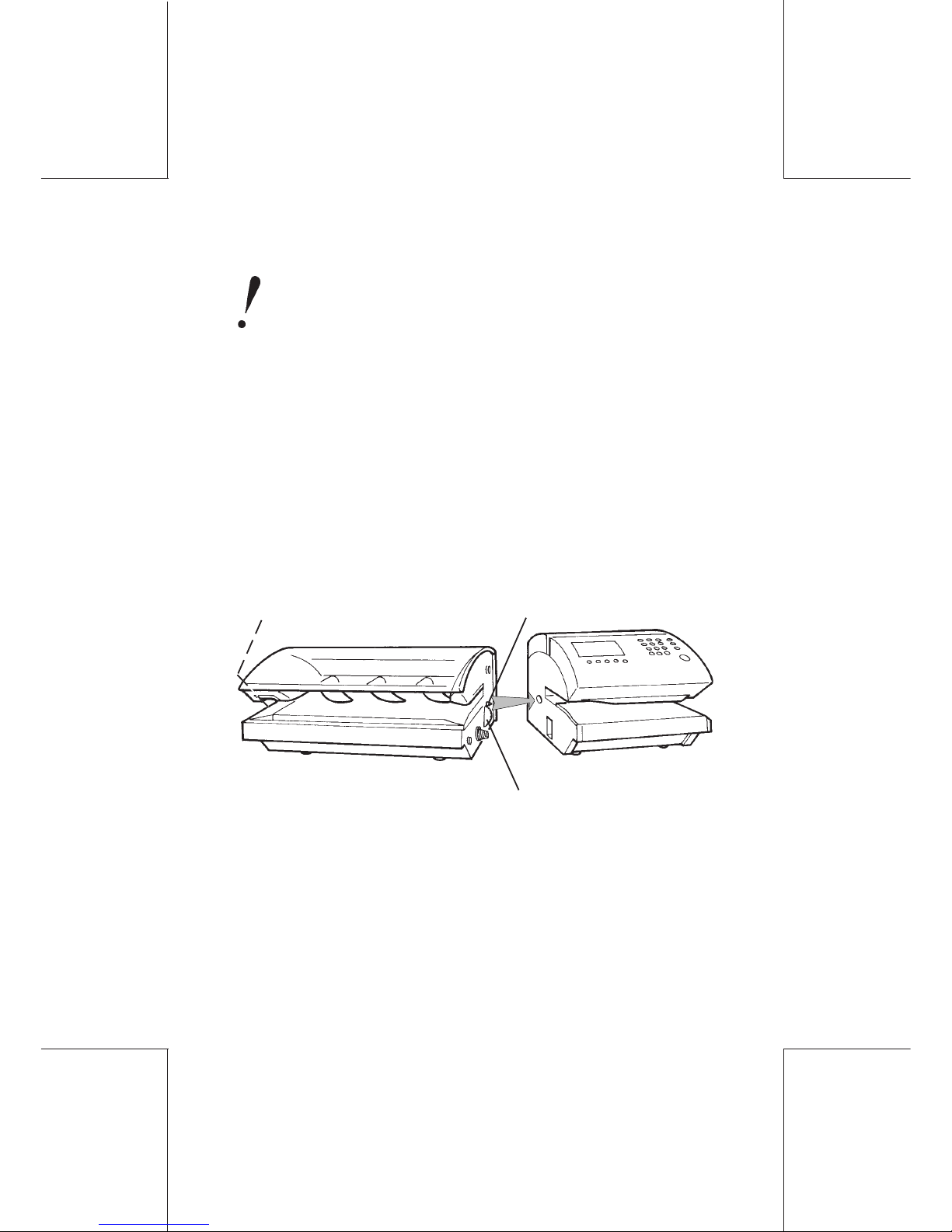

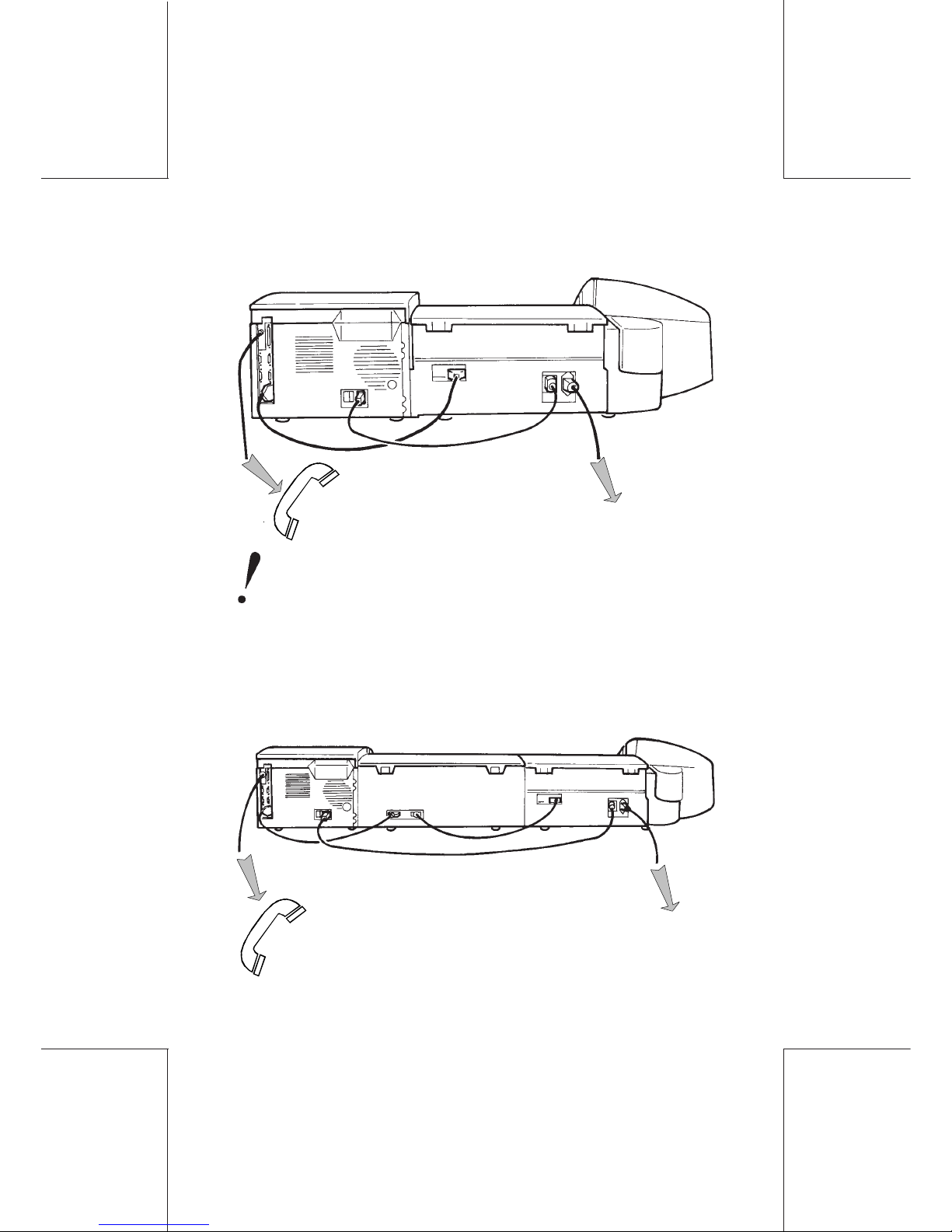

1.2.4 Installation of the mixed-mail feeder (optional)

The mixed-mail feeder operates with an optical sensor

next to the feed platform. Thus, it should not be installed

in an area exposed to any excessive light source.

- Align as much as possible the feeder with the mailing machine;

- Push the feeder towards the mailing machine (or the dynamic

scale), taking care to keep the alignment using the centering

pin;

- Insert the feeder screw into the mailing machine (or the dynamic

scale), then using the knob, tighten while pressing the screw to

lock it (if the units are not properly brought close together, gently

turn the gear protruding from the feeder and repeat the procedure):

centering pin

tightening knob (on the side)

(gear)

Overall presentation 21

ORIG0140-21

4127718F/B

02/26/2007

When the whole assembly needs to be moved, the units

should be separated:

-Separate the units;

-Disconnect the cables at the rear;

-Remove the feeder water bottle;

-Move the feeder to the edge of the table;

Cont'd

Overall presentation22

ORIG0140-22

4127718F/B

02/26/2007

-take the pipe under the unit and remove the plug (hold

the pipe upwards so as not to get wet);

-empty the water remaining the feeder;

pipe

-insert the plug and put the pipe back in its place.

Overall presentation 23

ORIG0140-23

4127718F/B

02/26/2007

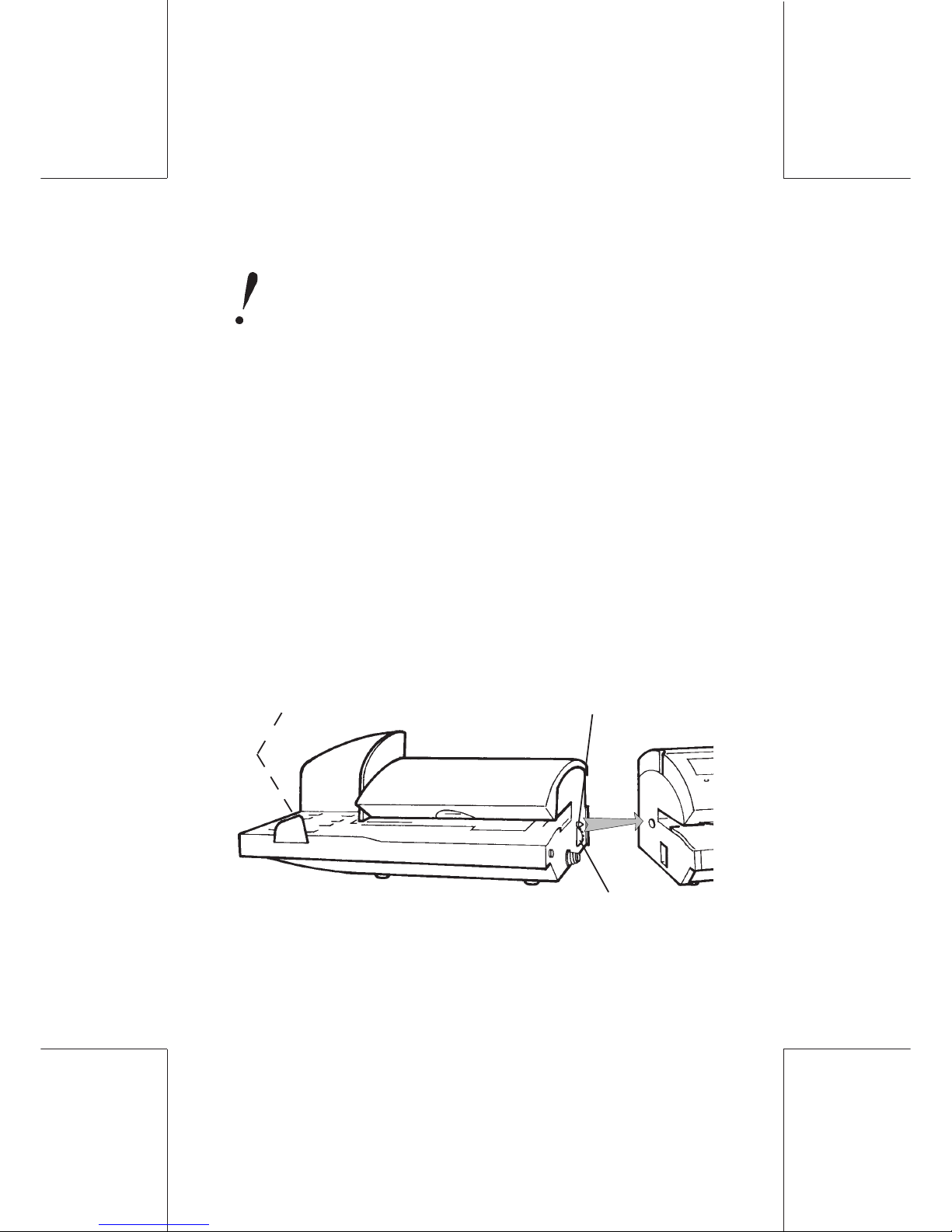

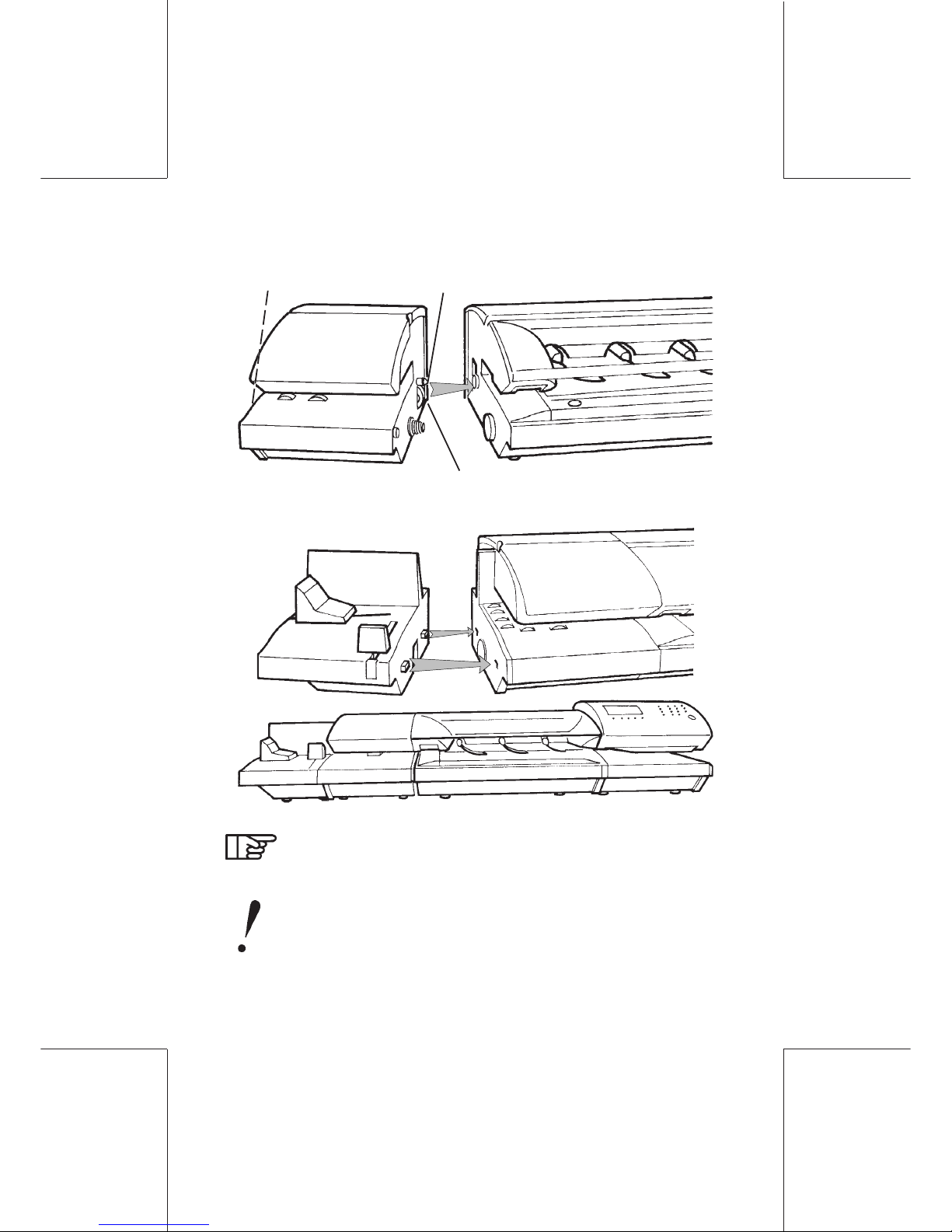

1.2.5 Installation of the dynamic scale (optional)

The equipment including a dynamic scale (the whole

system representing approximately 120 lbs) requires the

use of a steady and rigid table, in order to prevent any

weighing problem. Be sure not to install the machine in

an area exposed to the sunlight or to excessive air

currents.

- Align the dynamic scale with the mailing machine;

- Push the dynamic scale towards the machine, taking care to

keep the centering pin aligned as indicated;

- Thread the dynamic scale screw in the mailing machine. Then,

using the knurled tightening knob, push and screw to lock (if the

two devices are not closing properly, slightly rotate the gear

protruding from the dynamic scale and repeat the operation).

centering pin

tightening knob

(on the side)

(gear)

- Align the feeder with the dynamic scale;

- Push the feeder towards the dynamic scale, taking care to keep

the centering pin aligned as indicated;

- Thread the feeder screw in the dynamic scale. Then, using the

knurled tightening knob, push and screw to lock (if the two

devices are not closing properly, slightly rotate the gear protruding

from the feeder and repeat the operation).

Overall presentation24

ORIG0140-24

4127718F/B

02/26/2007

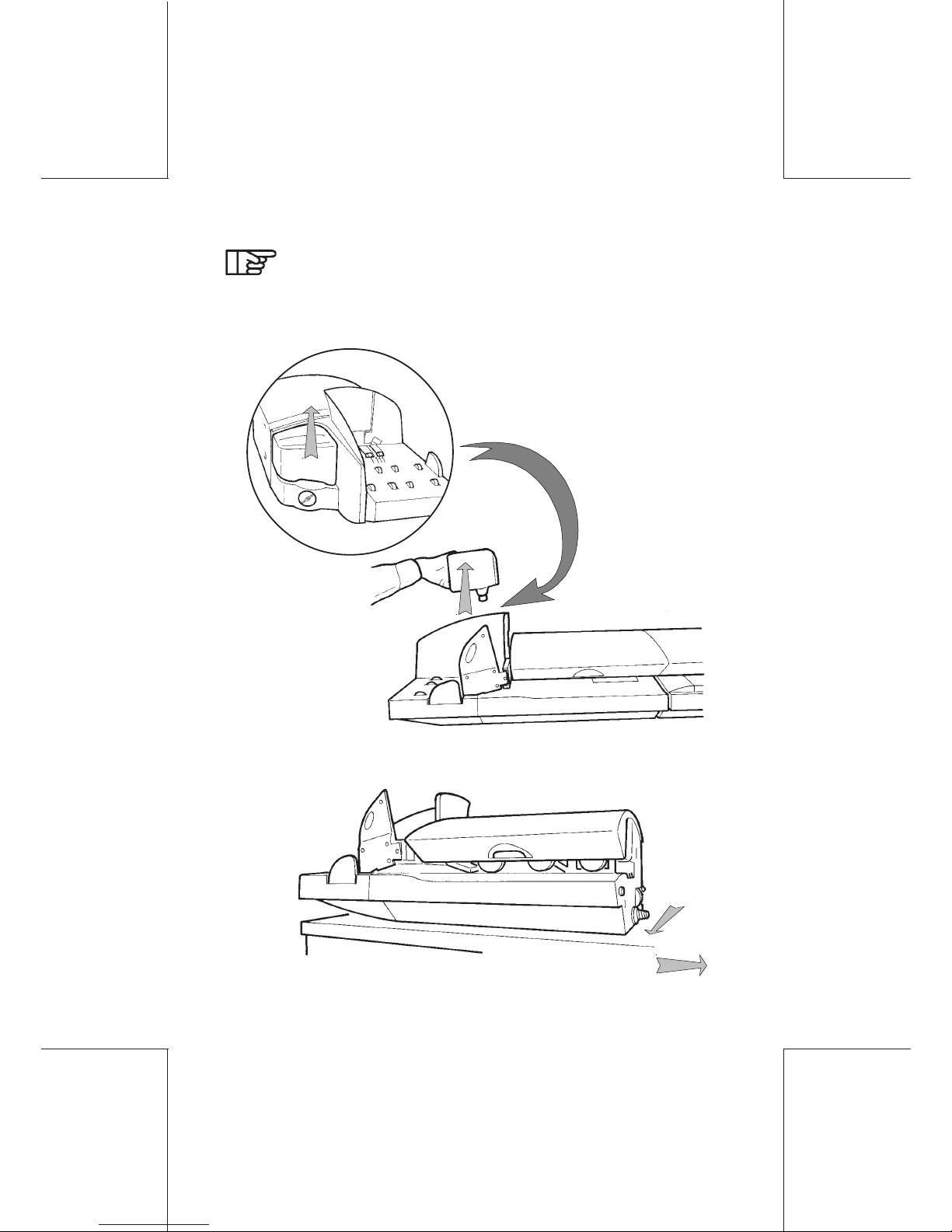

When the whole system needs to be shifted manually, the

mailing machine, the dynamic scale, the feeder and the

platform should be separated from one another.

When the machine is to be moved using any mechanical

equipment, please, contact the customer service.

centering pin

tightening knob

(on the side)

(gear)

- Assemble the feed platform with the feeder as indicated:

Whole configuration

Overall presentation 25

ORIG0140-25

4127718F/B

02/26/2007

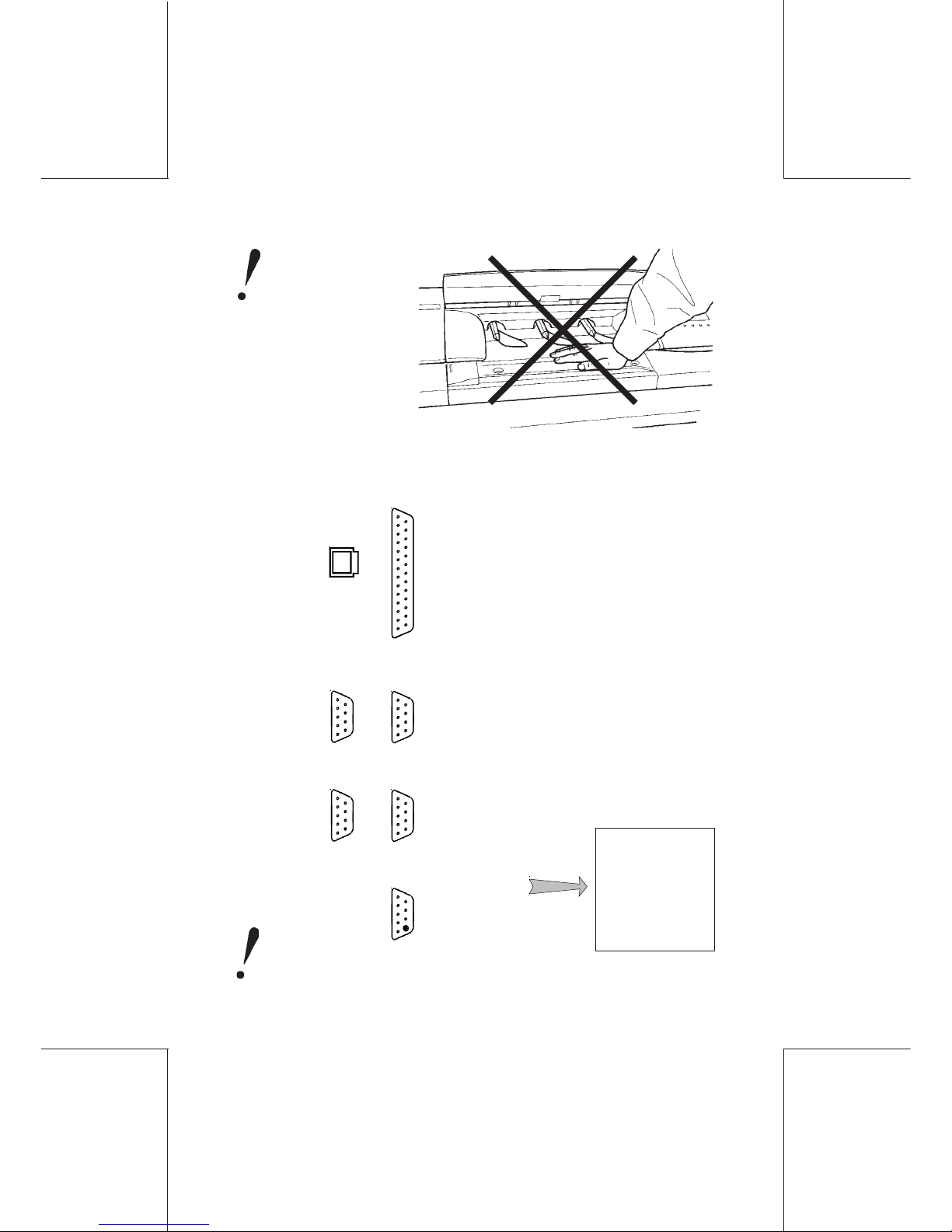

be sure to install

the black

terminator plug

on the feeder

connector when

the feeder or the

dynamic scale is

not used .

Printer

Feeder,

Dynamic

Scale,or

Terminator

Port 4:

-PC

- RTD (Roll tape dispenser)

- Scanner

- Scale

- Weighing Platform

A connection error may generate a failure.

Do not apply

pressure on the

dynamic scale

tray.

1.2.6 Connections at the rear of the units

Connections at the rear of the mailing machine

Modem

Port 2:

-PC

- RTD

- Scanner

- Scale

- Weighing

Platform

Port 1:

- PC (PC link and /or Reports to PC)

- Scanner

- Scale

- Weighing Platform

Port 3:

-PC

- Scanner

- Scale

- Weighing

Platform

²

Overall presentation26

ORIG0140-26

4127718F/B

02/26/2007

Connections with a standard automatic feeder

The feeder will automatically be switched on at the same time as

the mailing machine.

AC power outlet

Feeder

connection

cable

Connections with a standard automatic feeder and a

dynamic scale

The feeder and the dynamic scale will automatically be switched

on at the same time as the mailing machine.

AC power outlet

Overall presentation 27

ORIG0140-27

4127718F/B

02/26/2007

power outlet

Connections with a mixed-mail feeder

Connections with a mixed-mail feeder and a dynamic

scale

The dynamic scale will automatically be switched on at the same

time as the mailing machine.

power outlet

The mixed-mail feeder remains energized (when

connected to the power outlet) even if the mailing machine is turned off.

Overall presentation28

ORIG0140-28

4127718F/B

02/26/2007

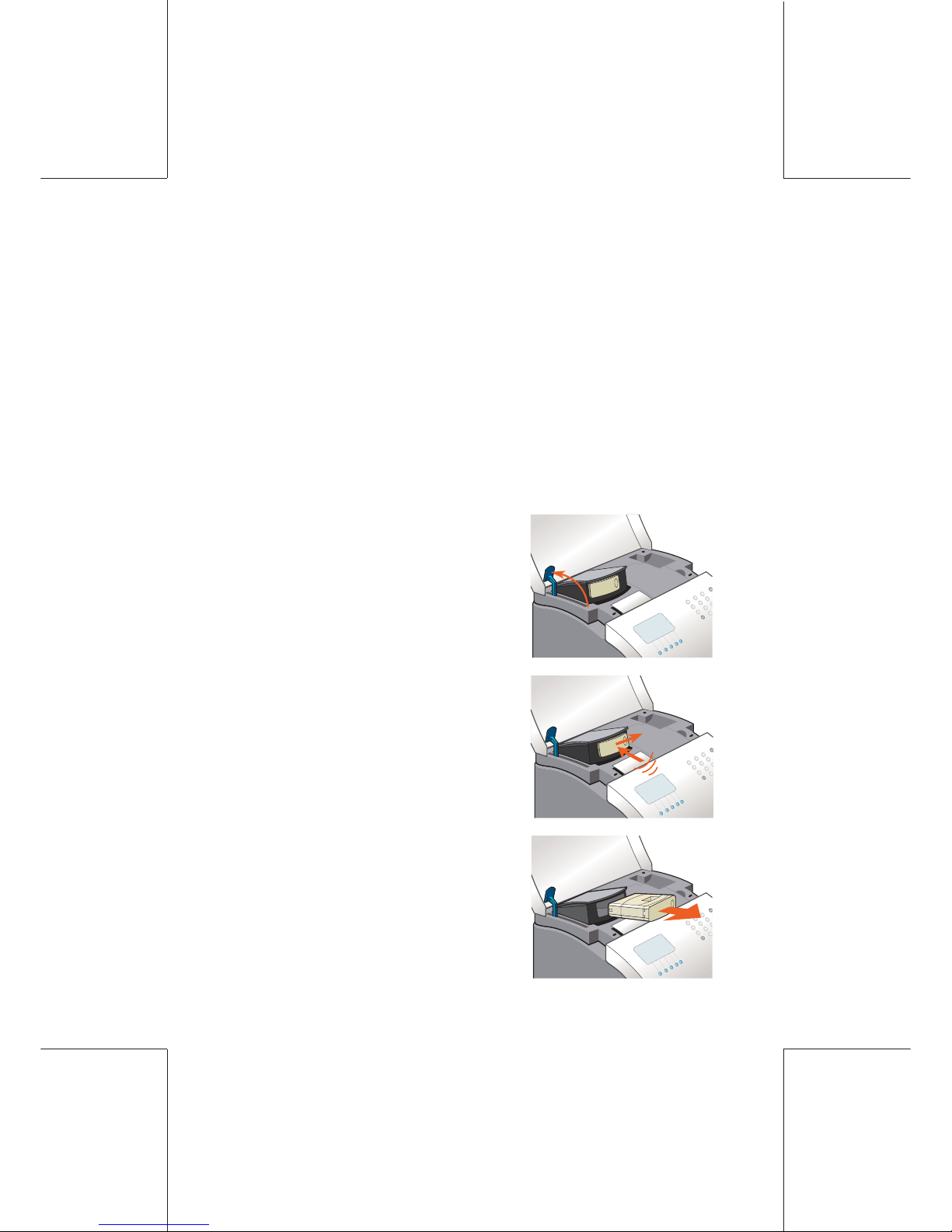

1.2.7 Ink tank and printhead

- When the message "ink low" is displayed, it is possible to

continue to print;

- When the message "ink very low" is displayed, it is possible to

continue to print, but it is strongly recommended to replace the

ink tank;

- When the message “ink out” appears, there is no more possibility

to print.

INK TANK REPLACEMENT (WJ220/110)

- Open the top cover and lift up the

blue lever;

- Press on the front of the ink cartridge

(1), then on the right hand side (2) in

order to remove it;

- Remove it;

(2)

(1)

Overall presentation 29

ORIG0140-29

4127718F/B

02/26/2007

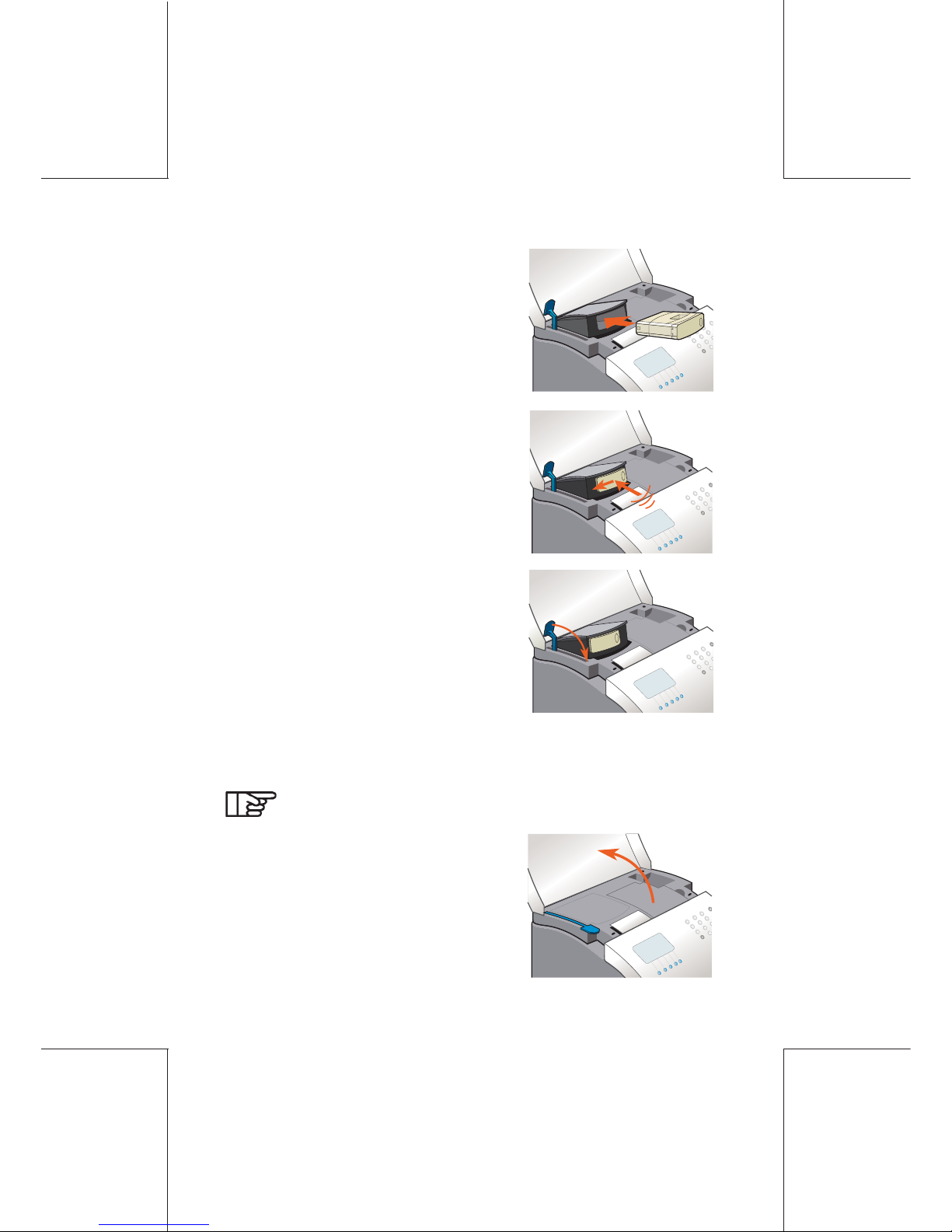

- Open the top cover and printhead

cover: the printhead will move to the

“replacement” position;

- Insert the new ink cartridge;

- Press on the front of the ink cartridge

(1), then on the left hand side (2) in

order to lock it;

- Lay down the blue lever and close

the top cover;

PRINTHEAD REPLACEMENT (WJ185/220/250)

The machine must be switched on.

(2)

(1)

Overall presentation30

ORIG0140-30

4127718F/B

02/26/2007

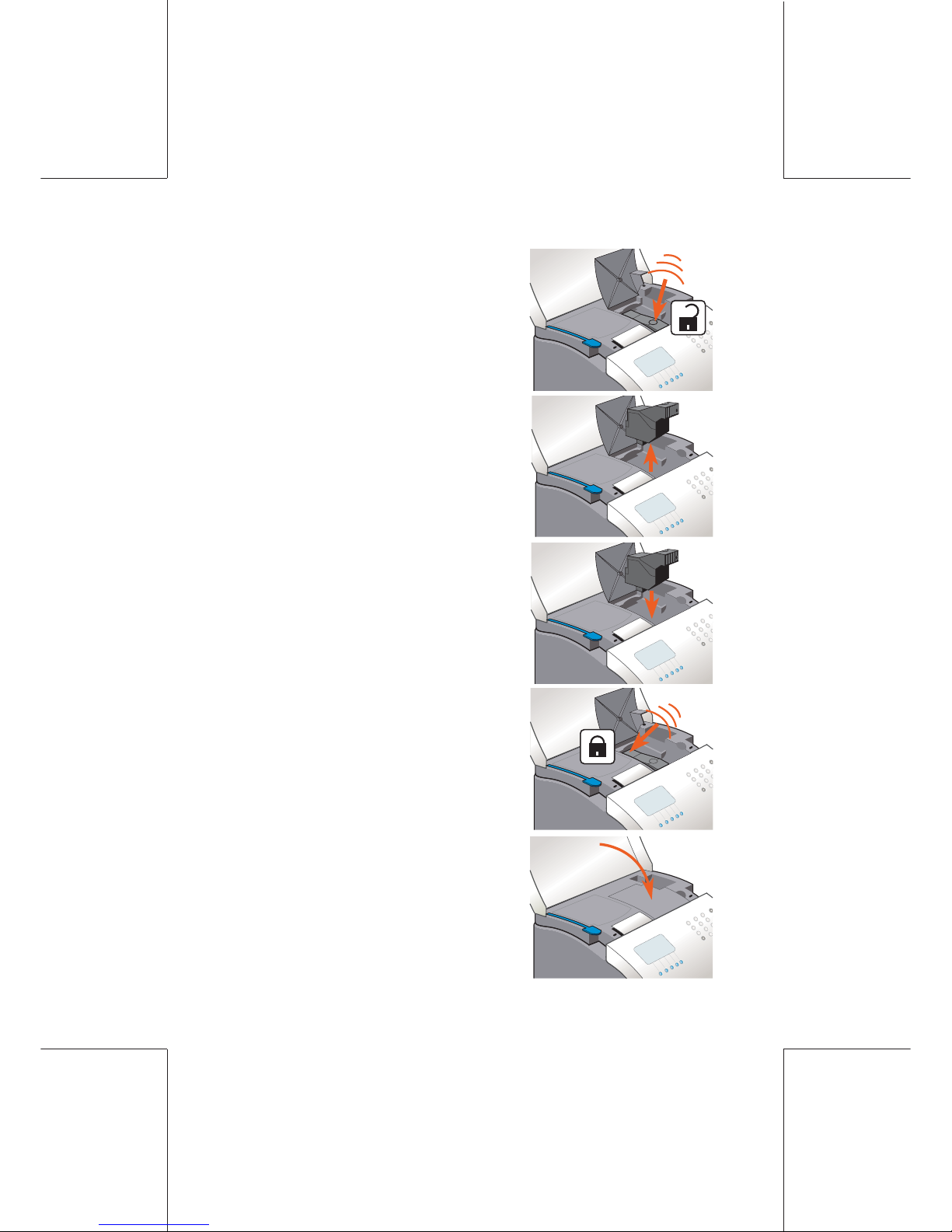

- Press on the front of the printhead in

order to remove it;

- Remove it;

- Insert the new printhead;

- Lock it in position by pinching the

rear of the printhead;

- Close the printhead cover and top

cover (the printhead is automatically

reset in the “protection” position).

Loading...

Loading...