Page 1

Notes before it uses it

Thank you very much for having brought our products.

Don′t fail to fulfill the matters that demand special attention to be mentioned below so that

you could put this machine to use for a long time with safety.

Don′t fail to read the user′s manual first of all when you′ve come to hand the machine. Ensure

the machine type you′re brought prior to use, as this user′s manual is the one for the HP-900LF(S)

HP-600LF(S).

Ensure ration table of the main unit of the machine as well as style and design of the manipulation

panel or those of the unit, referring to the illustrations on the user′s manual or the catalogue.

Don′t use the machine and bring into contact with the store you had bought it as early as possible

when you've found your machine to be different from the very one you had ordered and so forth.

Keep this user's manual with care and read it as occasion demands.

Bussiness office 7-6,Ryoge Gifu city,Japan

Tel:81-(0)58-245-4501 Fax:81-(0)58-247-6666

Sales Dep. Tel:81-(0)58-247-8400 Fax:81-(0)58-240-5775

Email:info@hashima.co.jp

Ibi factory 1030Danshita aza ueno ibigawa cho,Ibigun,Japan

Tel:81-(0)58-522-6678 Fax:81-(0)58-522-6699

Osaka branch 110-1higashihanda,Sakai city

Tel:072-276-6678 Fax:072-276-7751

Kyuushuu branch 4-21 4chome miihatazaki kurume city

Tel:0942-45-5028 Fax:0942-45-5029

Singapore HASHIMA SINGAPORE PTE.,LTD.12 Tannery road,#04-05

hbcenter, Singapore 347722

Tel:65-6285-8131 Fax:65-6285-8132

Attn:Mr Tsunoda

URL:http://www.hashima.com.sg/

U.S.A. HASHIMA AMERICAS LLC10675,N.W.37th Terrace,Doral,MIAMI,FI33178

Tel:786-390-4171

E-mail:inoue@hashima.co.jp

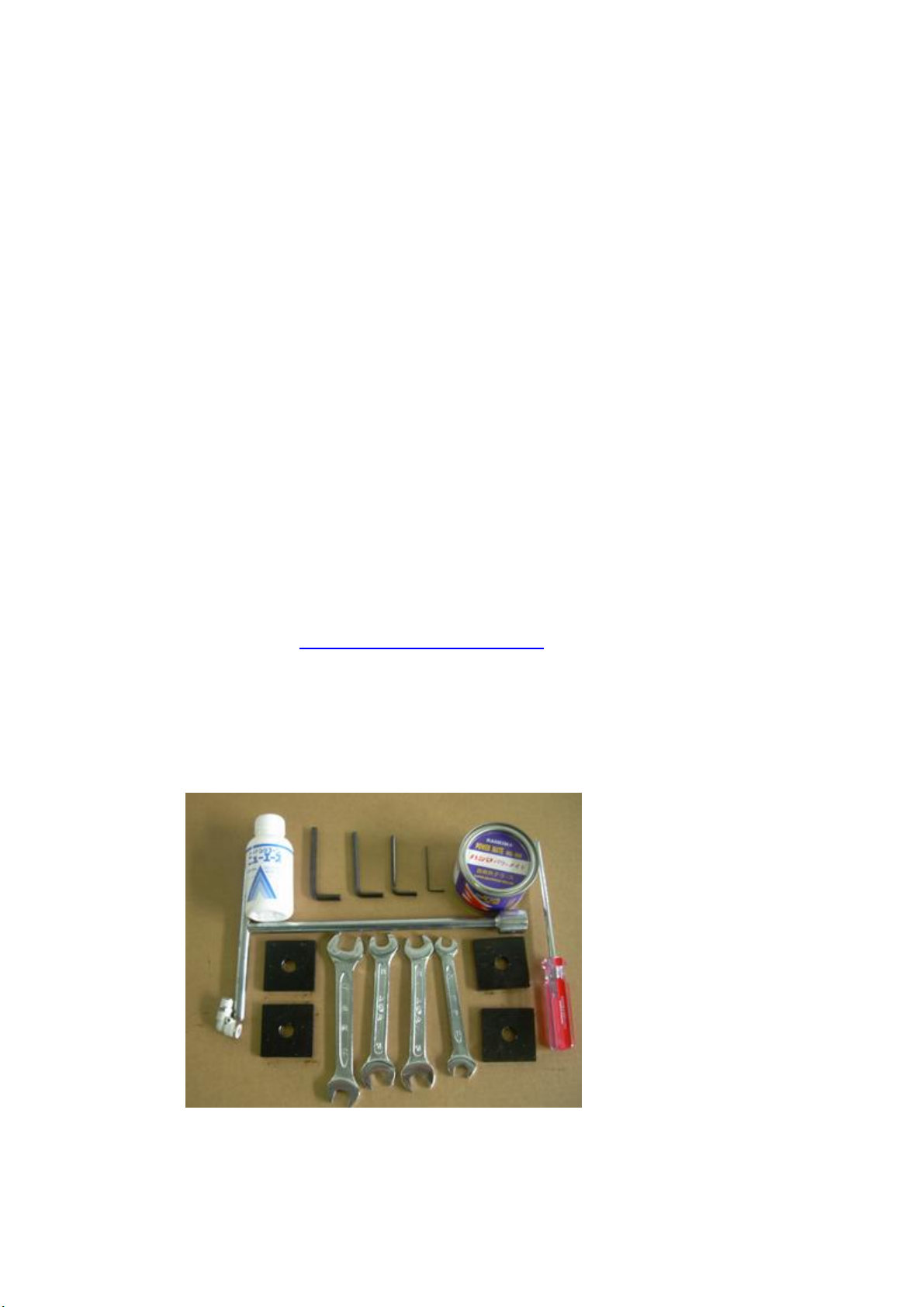

Ensure the accessories things

Page 2

ATTENTIONS TO BE PAID FOR SAFETY

DON`T FAIL TO FULFILL

You should fulfill following explanations for the prevention of the user and the others from

being hurt and the proprieties from being damaged.

■ We divide and explain you the degrees of peril and damage to be taken place when you′ll

neglect the contents of the display and use the machine erroneously .

DANGER

WARNING

CAUTION

■ We divide and explain you the contents you should fulfill in accordance with the following

illustration (Following is an example of the illustrations).

This display tells you contents that imagine〞the imminence of

the danger that might result in death or a serious injury〞.

The display tells you contents that imagine〞the possibility of

death or a serious injury〞.

This display tells you the contents that imagine〞the possibility of

resulting in be to handicapped or material damages exclusively〞.

Don′t get the children to use where the

injury.

Don ′ t disassemble and

repair absolutely except

the repair technician.

injury due to unusual

movement.

Disassembly prohibited

(Contact to the dealer for repair in

the case of damage and troubles.)

DANGER

infants can make contact with.

For fear of burn, electric shock and

WARNING

For fear off fire and

This illustration tells you the contents〞that demand attention〞you must pay.

This illustration tells you the contents of〞prohibition you should not do at all.

This illustration tells you the contents of〞enforcement〞you should executive

without fail.

Connect with the power

source with ratio

consumption suitable to the

machine and don′t fail to

ground.

when you put the machine to

use along with other

apparatus.

(Contact to the electric construction

work shops nearest by.)

Never reform at all

For fear of fire and injury due to

unusual movement.

Disassembly prohibited.

Unusual heat might in

fire or electric leak

Disconnect the power

source (the plug and

installed breaker)out of the

origin.

For fear of burn as

well as electric shock

and leak in fire.

Page 3

WARNING

Please maintain the machine after

cutting the power supply breaker, and

falling the temperature of the

machine.

It causes the burn and the

injury.

Don′t mount nor put things on

the main unit.

For fear of high

temperature might

result in burn and

fire there is a

possibility of falling

down to be injured..

Please don′t touch the

machine and belt by your hand.

It causes the burn and

the injury.

Be careful enough when you

touch the machine

Install the machine on the

robust or onto the floor

horizontally..

For fear of

overturning or falling

down resulting in injury.

Be careful enough when you

insert the material.

It causes the burn and

the injury because apart of

clothing or body is sandwiched

between machine parts.

Be careful enough when you

touch the machine.

Don′t. Put things easy to

burn around the machine.

For fear of causing

fire and so on.

CAUTION

■ Don′t install the machine to the site high humidity(For fear of causing electric leaks)

■ Don′t bend nor crush the power source cord.(For fear of electric shock and shortage, resulting in fire.)

■ When a manual handle is used it turns off power without fail. Moreover, a manual handle removes things

except use and the hole cover is put without fail.(The manual handle rotates and there is rapidly injured

fear.)

■ Don′t let the people go near by except operator.

PETITION

◆ There is a thing that the cover becomes very hot depending on the use temperature because this

machine is used according to the high temperature. Please note a burn and combustible clothes,

etc. Enough.

◆ Please confirm the thing that stops with the timer, and cut the power supply breaker after the

end of work.

◆ Please cut the power supply breaker without fail, and go in the state that the temperature of the

machine gets cold then the material that caught under around the strip off device or scraper are

removed. Moreover, when you take the finished material out of the exit, pay attention not to be

caught in the strip off device.

◆ Clean the belt with a well dried floor cloth when the operation is over. But, reduce the belt speed

whit sufficient attentions at the exit side of the finished material of the machine for feat of such

accidents as burn and caught-in.

◆ Please check the belt cleaner every day. Moreover, please refuel to each part once a month to

prevent the accident occurs. You must keep the electric source off and be sure the machine is cool.

◆ Please understand enough, and operate working of switches.

◆ Please open space necessary for maintenance in surroundings of this machine.

◆ The machine have emergency stop switch when the belt over moves left or right.

Please take out the material with the manual handle of the attachment after it turns off power

without fail when a material stops in the machine due to the emergency switch works or the

power.

Page 4

By putting “alarm label” onto every part of the machine, we rouse you to prevent the user and

others from being hurt and proprieties from being damaged.

■ Ensure the position and contents in regard to the “alarm label” prior to the use.

■ Never remove nor reform the “alarm label”.

■ Put a new one as early as possible, when the old “alarm label” is hard to read or when

it is come off.

1、

2、

3、

①

⑥

By the way, the repair technicians should pay attention to the fact that the

“alarm labels” are put even within the machine in addition.

②

4、

5、

6、

③

④

⑤

Page 5

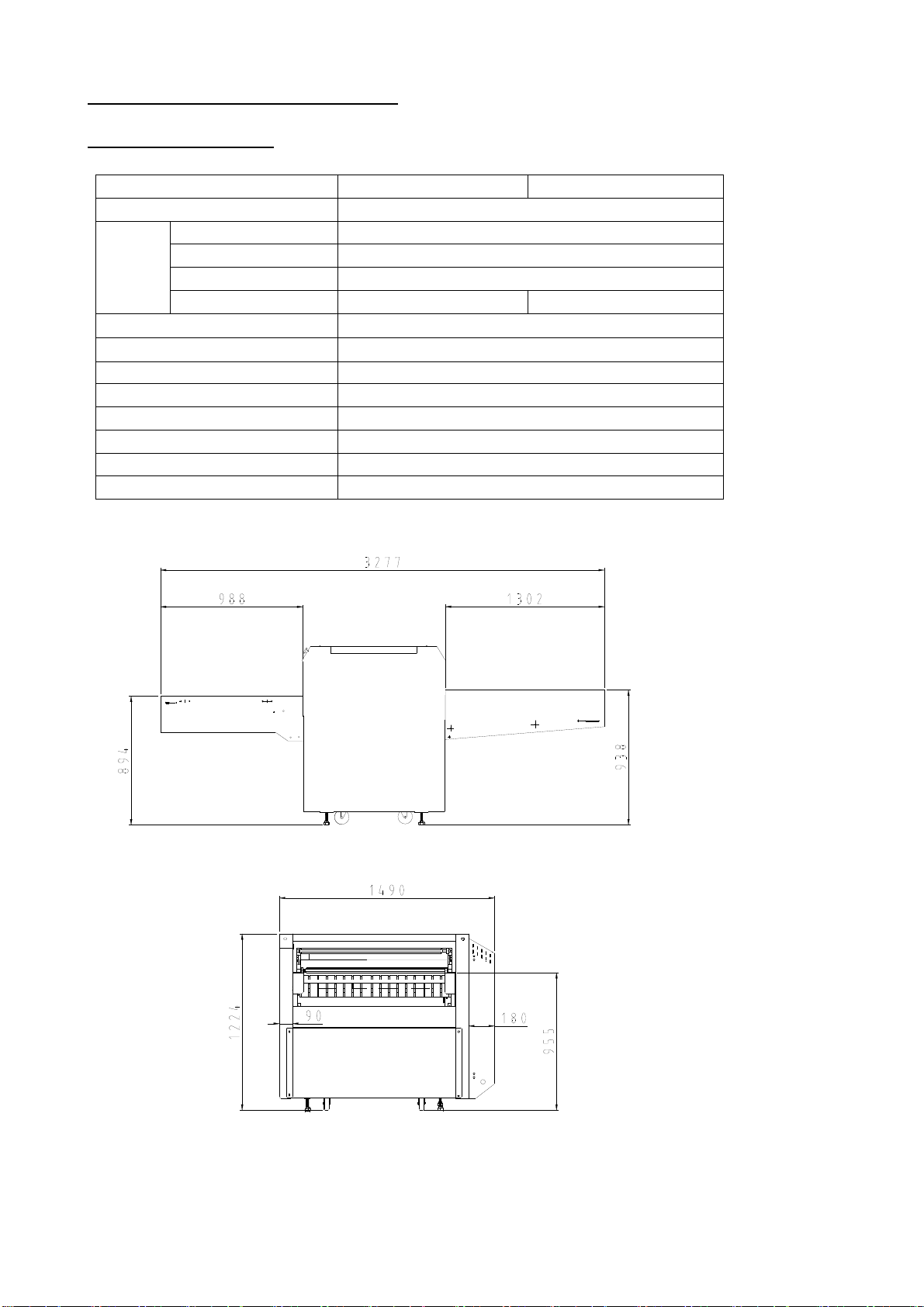

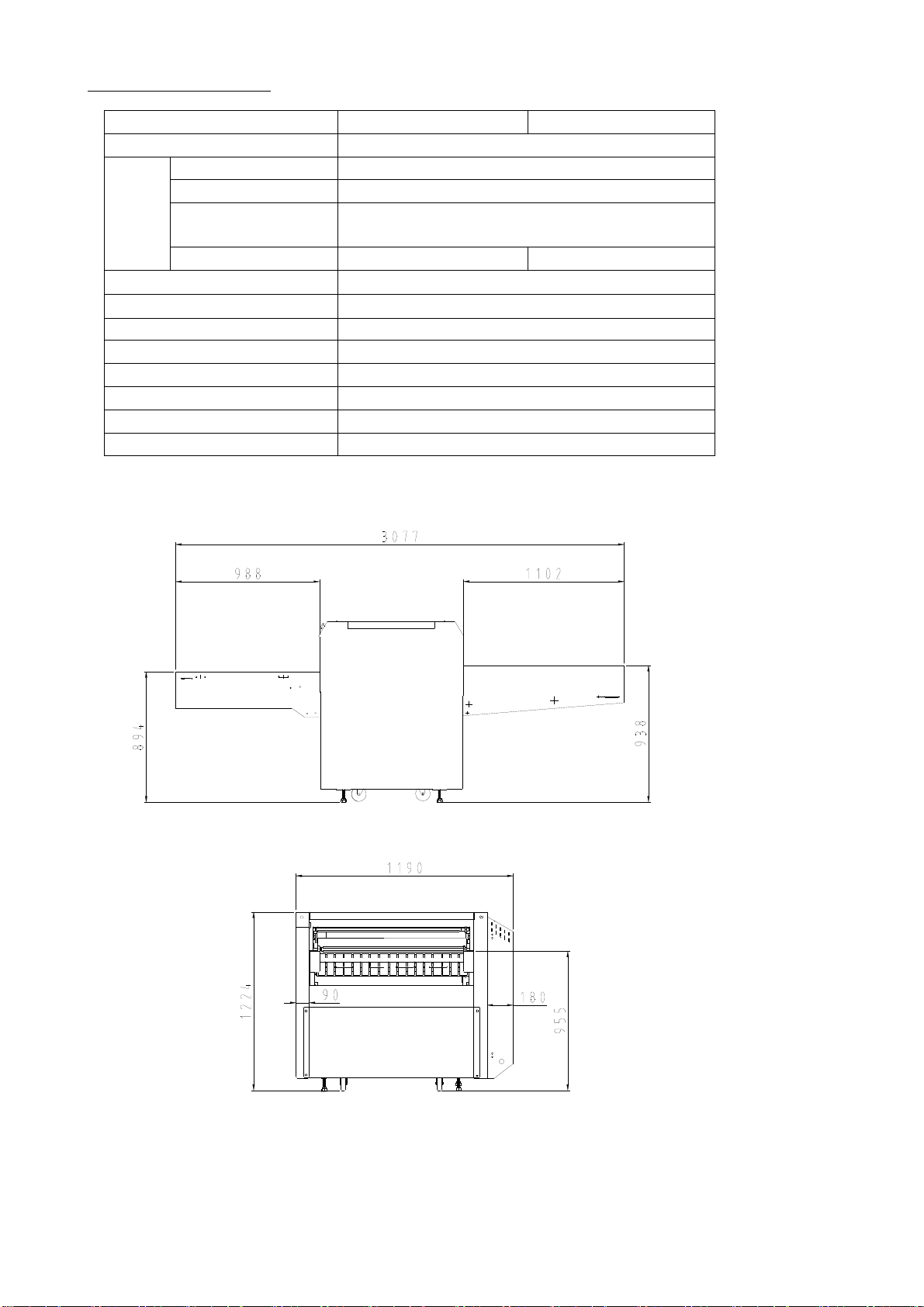

1. SPECIFICATION DESIGN FEATURES

HP-900LF・LFS

MODEL HP-900LF HP-900LFS

POWER SUPPLY 3 PHASE

HEATER 1 2KW

RATED DRIVING MOTOR 200W

OUTPUT BWP MOTOR 25W X 2

STRIP-OFF MOTOR 25W

HEATING TIME 6 – 2 8sce

PURESSURE (GAUGE) 0 - 0.4M pa

MAX PRESSURE 0 - 4 1N/cm (4.0kgf/cm)

FUSING WIDTH 9 0 0 mm

BELT SPEED MAX 12.7m/MIN.

TEMPERATURE MAX 1 9 5℃

DIMENSIONS 1244(H)X 1490(W)X 3277(D)mm

WEIGHT 4 5 0 Kg

Page 6

HP-600LF・LFS

MODEL HP-600LF HP-600LFS

POWER SUPPLY 3 PHASE

HEATER 8.4KW

RATED DRIVING MOTOR 200W

OUTPUT BWP MOTOR 25W X 2

STRIP-OFF MOTOR 25W

HEATING TIME 6 – 2 8sce

PURESSURE (GAUGE) 0 - 0.4M pa

MAX PRESSURE 0 - 4 1N/cm (4.0kgf/cm)

FUSING WIDTH 600mm

BELT SPEED MAX 12.7m/MIN.

TEMPERATURE MAX 1 9 5℃

DIMENSIONS 1224(H)X 1190(W) X 3077(D)mm

WEIGHT 3 8 0 Kg

Dimensions

Page 7

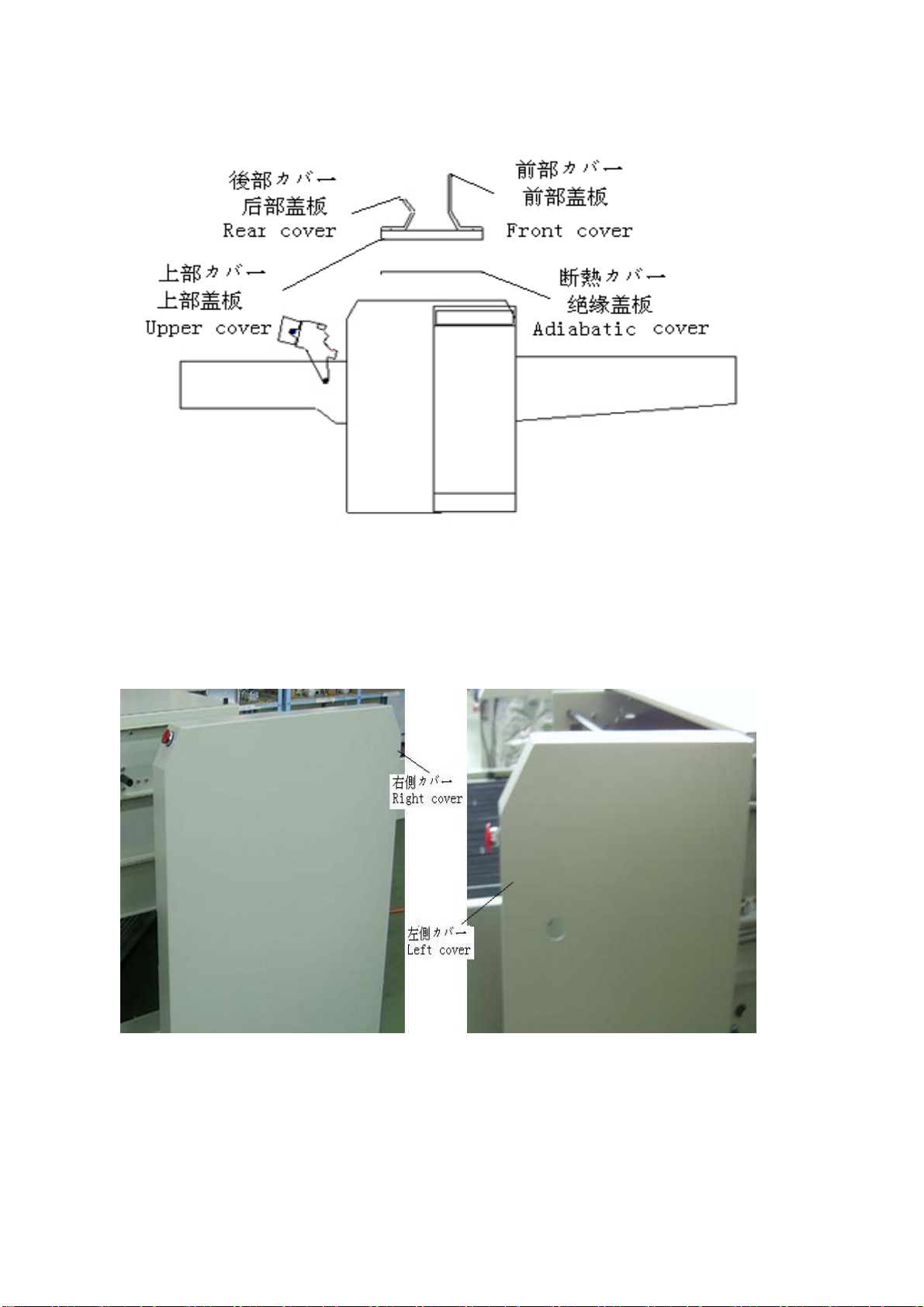

2.Outer component parts name

⑩

⑥

④

①

②

⑭

⑪

1. OPERATION PANEL 2. UPPER COVER

3. FRONT COVER 4. REAR COVER

5. RIGHT COVER 6. LEFT COVER

7. STRAIGHT CONVEYOR 8. WORK TABLE

9. WORK TABLE FRAME 10.STRAIGHT CONVEYOR FRAME

11. WIRING BOX KNOB 12. CIRCUIT BREAKER

13.EMERGENCY SWITCH 14.EMERGENCY HANDLE POSITION

⑫

③

⑨

⑬

⑤

⑧ ⑦

3. INSTALLATION INSTRUCTION

※ Don’t fail to entrust the electric construction work shop with the power source before

you’ll install the power source for exclusive use. And don’t fail to ground with sure,

and then confirm whether there exists the electric leak breaker or not, before you’ll

entrust with it without fail, if necessary.

※ Install the machine with the weight of 450kg to the solid location on the floor .

1. Decide the installation place of the machine.

2. Put the fixing plates (provided) under the adjusting bolts properly.

3. Install the work table. (Straight rite, Return rite only)

4. Level the machine precisely with a level, adjusting the adjusting bolts. Put the level

on the work table for front side leveling, and put the level on the power pressure roller

for rear side leveling.

5. Don’t fail to take the plastic film off cleaner of the Teflon belt, which is covered

with the plastic film before you connect the power source.

6. Put the HASHIMA grease in four sites of the bearing of the pressure roller.

圧力ローラー

压

力胶辊

PRESSURE

注油

加油

REFUE

L

Page 8

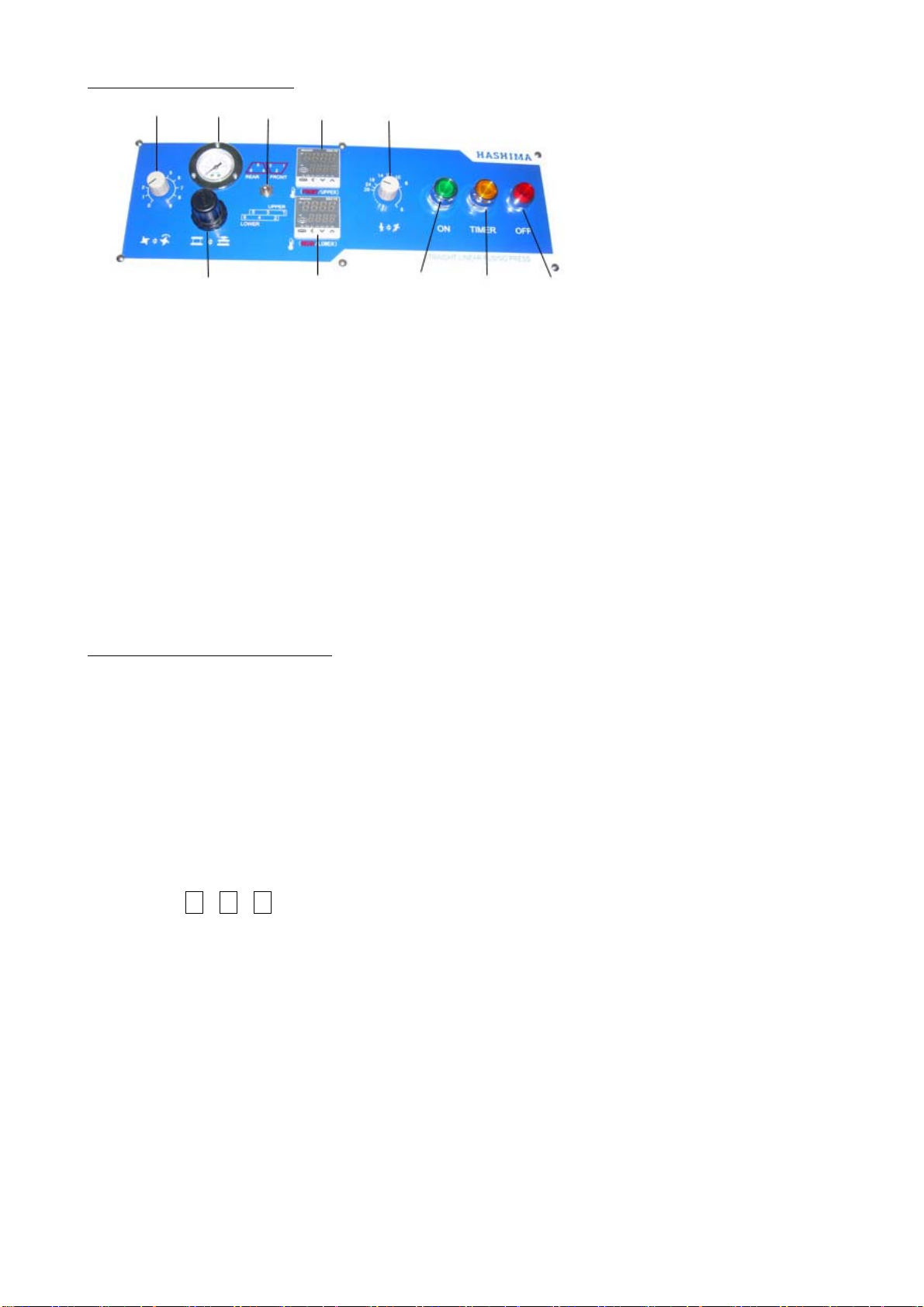

4. OPERATION PANEL

⑩ ⑤ ⑦

⑧ ④

⑨ ⑥ ①②③

1.POWER SWITCH When turns on switch, switch will light up.

2.TIMER SWITCH This timer is to keep the machine operating, after completion of

the work until the belts are cooled to certain temperature in

order to insure a long belt life.

3.STOP SWITCH When push the switch, machine will stop.

4.SPEED CONTROL KNOB It is control knob for fusing time.

5.THERMOSTAT Heater control for upper or front part

6.THERMOSTAT Heater control for lower or rear part

7.HEATER SELECT SWITCH The temperature of front and rear heaters can be controlled by

pushing up the snap switch, and by pushing down it, the

temperature of upper and lower heaters can be controlled.

8.PRESSURE METER 0.1Mpa to 0.4Mpa(MAX)

9.PRESSURE CONTROL KNOB

10.ROTARY STRIP OFF SPEED CONTROLLER

5. OPERATION INSTRUCTIONS

○ Make sure, prior to use, whether or not there is a container contained flashing,

combustible, ignitable and water on or around the machine, and also make sure that there

is no any object which may involve into feeding or exit side of the machine. Remove them

when you’ve found them.

○ The personnel should pay attention to his clothes not to be caught in the machine.

1. Turn on the circuit breaker switch on the right under the wiring box of the machine.

2. Turn on the power switch (push button switch)

※ The push button of the switch will light up.

※ The motor runs simultaneously.

3. Set the heater selector switch on the front/rear heater.

※ When using upper/lower heaters, turn the snap switch downward.

4. Set the < > ∧ button of thermostat, and set the front/rear or the upper/lower

heaters to the proper temperature.

5. Turn the dial of the fusing timer, and set to the proper fusing time.

※ The fusing time ranges from 5 sec, minimum to 35sec. Maximum.

6. Turn the pressure knob on the operation panel, and set to the proper pressure level.

Usually, enough pressure for fusing is given at the position 0.1~0.3Mpa. The pressure

is adjustable within a range from 0Mpa minimum to 4.0Mpa maximum.

7. If the machine is equipped with the strip-off device, turn the dial of the strip-off speed

controller to set the position to a little faster than the running speed of the Teflon

belt.

8. Please push the timer switch After completion of work. The actual temperature of the

thermostat will go down. When the actual temperature of the thermostat goes down to

90℃,the power will automatically turn off.

9. When the time switch has terminated, set the power source breaker to OFF.

Page 9

6. NOTE

○ Setting combinations of the temperature, pressure and heating time for fusing interlinings

are made according to interlining and fabric materials used.

Check carefully proper fusing condition (temperature, pressure and heating time.)

○ Although, the belt is coated with Teflon to insure heat-proof, it is breakable by cutlery

or broken pieces of metals. Be extra-careful not to put needles, ball point pens or scissors

in the belt.

○ Do not place the interlinings upside down on the belt, or the products may be caught in

the tension roller for the upper belt.

○ If there is excessive interlining, the products may be caught in the tension roller

for the lower belt even when the interlining is properly placed on the belt.

○ From time to time, remove the side cover, and check that the products are not caught

in the tension rollers. In case of the trouble, me d it immediately.

○ Replace the cloth of the cleaner with a new one before it gets dirty.

○ Clean the exfoliation device clean

○ It is very hard to remove the resins adhered to the belt, but it can be cleaned up easily

with HASHIMA NEW CLEAN.

○ Lubricates the bearings and gears every one or two months.

○ Pour the accessory the HASIMA gear oil to four sites of bearing support with which the

pressure roller is provided.

○ Ensure for safety that the covers and others are normally provided with, as the interior

of the machine is under condition of very high temperature and high voltage. Don’t use

machine when the covers are open. It is dangerous.

Attention to be paid when using manual handle.

The machine is equipped with the emergency stop function in response to warping of the

belt. Moreover, it is possible to unload the finished fabric within the machine using the

accessory manual handle., when the machine has stopped due to an electric failure and so on.

But disconnect the power source from its origin, when using the manual handle as it is very

dangerous. When you resume to drive the machine, ensure the reasons why it has stopped and

make sure of safety before inputting the power source.

with a well dried floor cloth.

7. HOW TO CHANGE BELT CLEANER

※ Exchange the belt cleaner for a new one when the heat on the machine unit is cooled enough,

as it is dangerous. Set the original power source to OFF.

1. The cleaner is installed together with the strip-off device in the rear side of the machine.

2. Pull down the strip-off device.

3. The cleaner has been set at a position touching the upper/lower belts properly.

4. The cleaner can be removed easily by setting it after pulling out the lock pin.

5. The cleaner shaft is covered with left and replacement cloth covered the felt.

6. Coarse cloth such as a towel is suitable as replacement cloth, but do not use thick cloth,

which may be damage the belt.

7. Do not cover too much cloth, which may lead to an uneven separation of material or cause

the strip-off device not to return to its original position. The upper cleaner of rotary

strip-off device can be removed by pulling the left knob.

Page 10

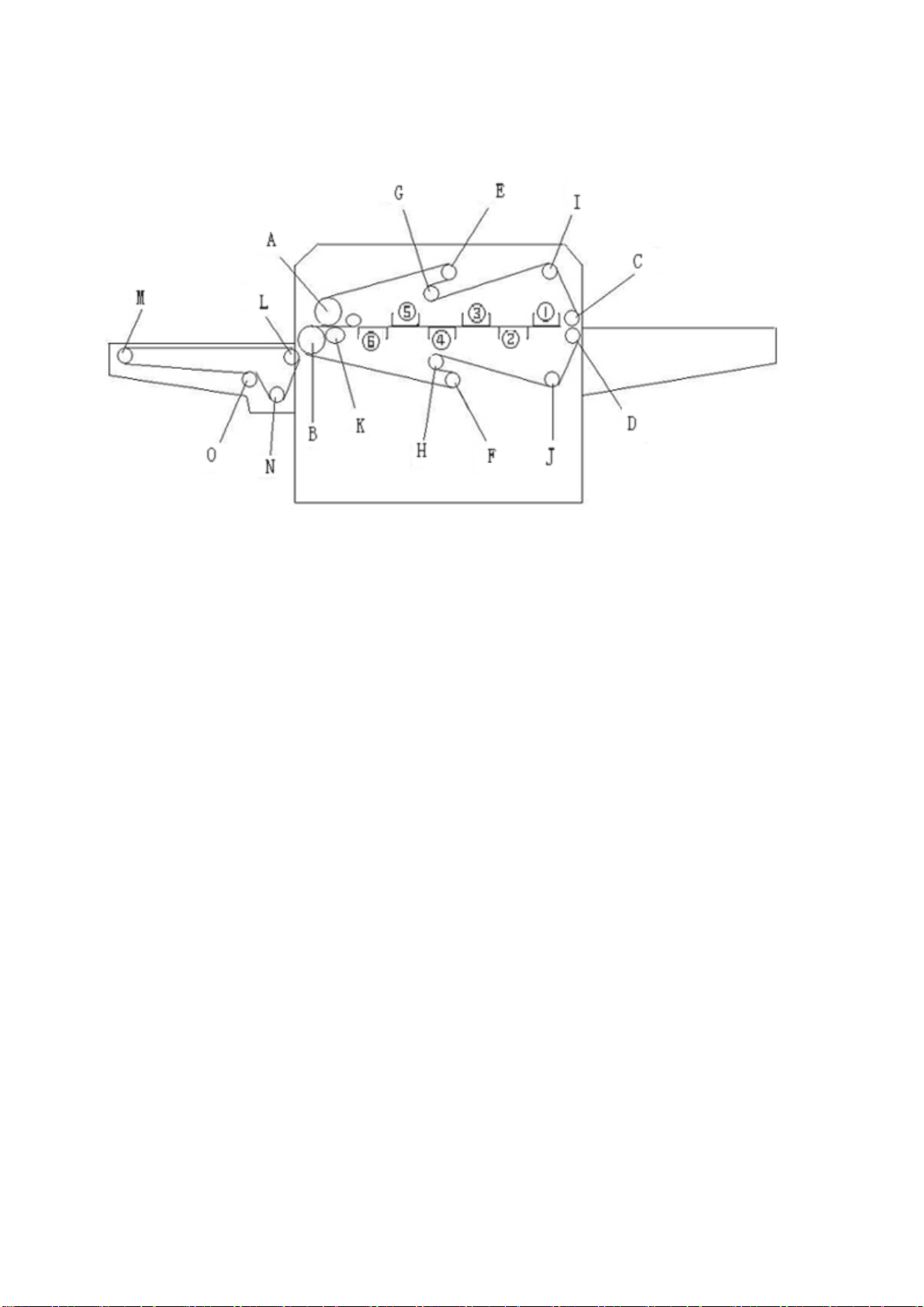

INNER COMPONENTS

A. Pressure roller (Upper)

B. Pressure roller (lower)

C. Feed-in roller (upper)

D. Feed-in roller (lower)

E. Sub tension roller (upper)

F. Sub tension roller (lower)

G. Tension roller (upper)

H. Tension roller (lower)

I. Belt warping prevention roller (upper)

J. Belt warping prevention roller (lower)

K. Anti-puckering roller

L. Conveyor driving roller

M. Conveyor roller

N. Conveyor tension roller

O. Conveyor guide roller

● Roller E.F can be adjusted to slide forward and backward

● Roller C.K can be adjusted to slide up and down

Setting combination of the heaters

Heater with sensor①.④

FRONT/REAR COMBINATION UPPER/LOWER COMBINATION

①②③ Front ①③⑤ Upper

④⑤⑥ Rear ②④⑥ Lower

Page 11

How to belt exchange

1.Make space for belt exchange operation.

2.Pull down the strip off device toward the rear side of machine.

3.Open the front and the rear covers, and pull them out sideways.

4.Lift the upper and the adiabatic covers.

5.Turn the pressure to “0” position.

6. Remove the left and the right covers with lifting them.

7. Take off the screws with lifting the rear conveyor little. There are 4 screws. 2

each on both the left and the right side.

8. Take off the screws with lifting the work table little. There are 4 screws, 2 each

on the both the left and right side.

Page 12

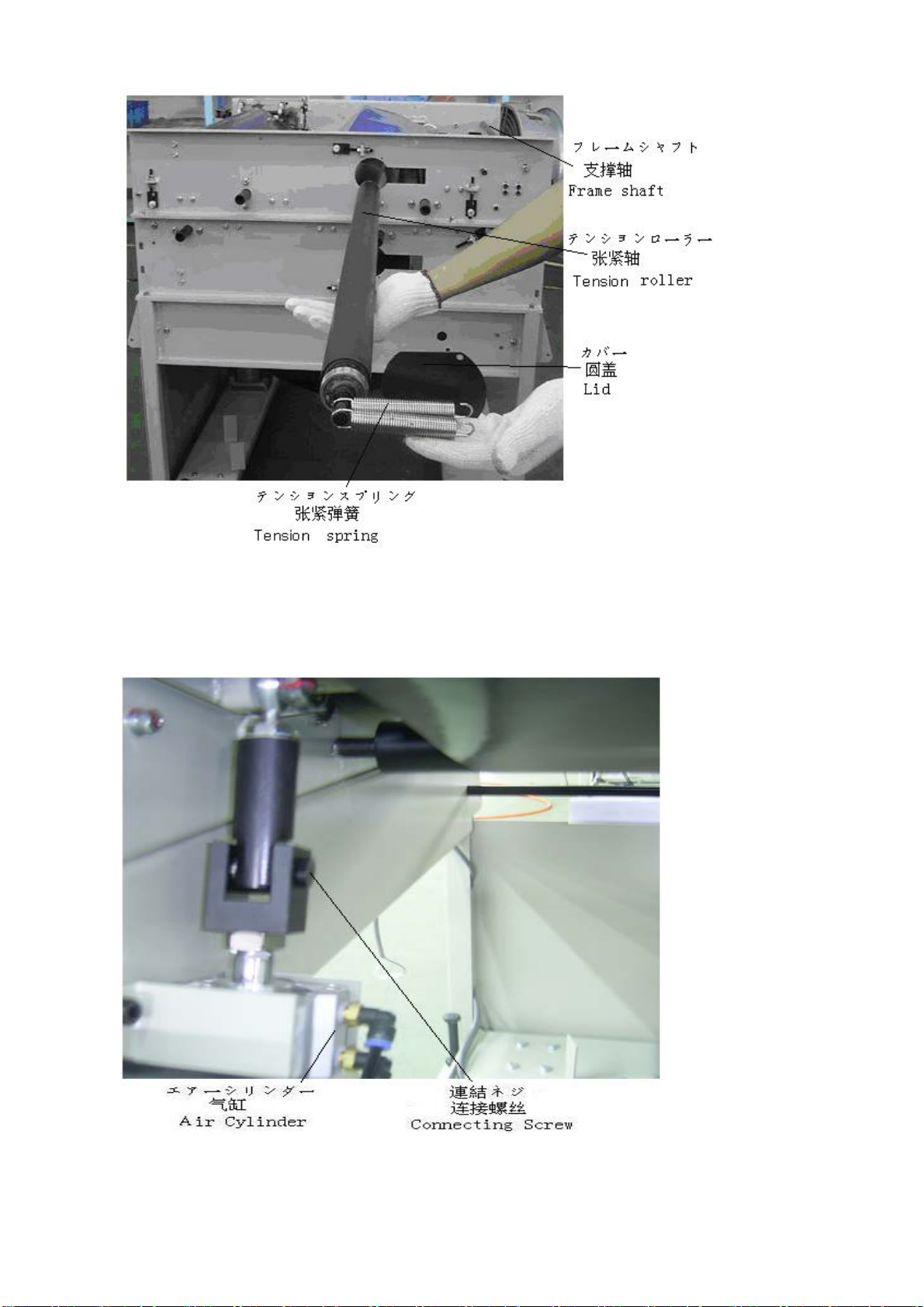

9.Remove the lid on the outlet for the tension roller.

10. Take off the tension spring and tension roller.

11. Remove the frame shaft.

12. Take off the nuts of the air cylinder connecting screws.

Page 13

13. Remove 5 bolts fixing the upper and the lower frames.

14. Lift the belt changing pipe, and set the stand supporter on the end of the pipe,

And then pull out the belt through an opening between the frame

NOTE

● When the belt is pulled out, be careful not to let the belt touch the belt warping

limit switch.

● There are setting marks on the frames. To assemble the machine, be sure to fit

the marks, then fasten the bolt for the frames.

● After the belt is replaced with new one, set the both left and the right side tension

springs at the same time. After completion of assembling, set the belt speed at

35 sec. And await until the belt makes slow 2 rounds rotation.

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

2.支架和脚轮

序号 部品编号 部品名 部品名 Parts name Q'ty 備考

1 LF02001

2 LF02002

3 LF02003

4 LF02004

5 LF02005

6 LF02006 底部固定前支架 下固定用フレーム(前) lower fixing frame(F) 1

7 LF02007 底部固定后支架 下固定用フレーム(後ろ) lower fixing frame(B) 1

8 LF02008 台板骨架固定 テーブル固定用シャフト table fixing shaft 2

9 LF02009 台板支撑轴 テーブルシャフト table shaft 2

10 LF02010

11 LF02011

12 LF02012

13 LF02013 传输骨架固定 輸送テーブル固定用シャフト work table fixing shaft 2

14 LF02014 置放架 ベルト交換パイプ置き pipe stand 2

15 LF02015

16 LF02016

17 LF02017

18 LF02018

19 LF02019 脚轮 キャスター caster 4

20 LF02020

21 LF02021

22 LF02022

23 LF02023

24 LF02024

25

26 LF02026

27 LF02027

28 LF02028 皮带更换套管 ベルト交換用パイプ belt exchange pipe 4

LF02025

机身侧板(右上)

机身侧板(右下)

机身侧板(左)

脚架(右)

脚架(左)

骨架固定轴(A) フレーム固定用シャフト(A)

骨架固定轴(B) フレーム固定用シャフト(B)

辅助罗拉轴(A) フレーム補助シャフト(A)

出料台侧板(左)

出料台侧板(右)

台板固定架(左)

台板固定架(右)

平垫圈 M8

标准型弹簧垫圈 M8

六角头螺栓 M8*20

六角螺母 M8

六角螺母 M16

六角头螺丝 M16*120

皮带安装支撑脚(A) ベルト交換用支柱(A)

皮带安装支撑脚(B) ベルト交換用支柱(B)

フレーム(右上) frame(Right uppre) 1

フレーム(右下) frame(right lower) 1

フレーム(左) frame (left) 1

フレーム(右) frame (Right) 1

フレーム(左) frame (left) 1

輸送テーブルフーレム(左) rear conveyor frame(L) 1

輸送テーブルフーレム(右) rear conveyor frame( R) 1

ワークテーブルフーレム(左) work table frame(L) 1

ワークテーブルフーレム(右) work table frame ( R) 1

平座金 plain washer 108

スプリングワッシャー spring washer 108

外六角ネジ hex bolt 88

六角ナット

六角ナット

外六角ネジ hex bolt 4

frame fixing shaft (A) 3

frame fixing shaft( B) 1

frame sub shaft(A) 3

hex nut

ex nut

h

belt exchange stand(A) 2

belt exchange stand(B) 2

20

4

Page 27

(HP-1000LR-Ⅰ/Ⅱ、HP-120

0

序号 部品编号 部品名 部品名 Parts name Q'ty 備考

1 LF03001 马达 モーター motor 1

2 LF03002 平键 キー key 1 8*7*45

3 LF03003

4 LF03004 驱动马达皮带轮 駆動モータープーリー driving motor pully 1

5 LF03005 V型带 駆動Vベルト driving V belt 1 A-47

6 LF03006 驱动皮带轮 駆動プーリー driving rpully 1

7 LF03007

8 LF03008 驱动压力齿轮 駆動压力ギア driving pressure gear 1

9 LF03009

10 LF03010

11 LF03011

12 LF03012

13 LF03013

14 LF03014 上胶辊调节块 ゴムローラーストッパー

15 LF03015 胶辊固定座 軸受け bearing stand 2

16 LF03016 滚针轴承 ベアリング bearing 2 6206.C3

19 LF03019 平键 キー key 1 5*5*50

20 LF03020 上胶辊 ゴムローラー

22 LF03021

23 LF03022

24 LF03023

25 LF03024

26 LF03025 驱动皮带盘盖 手動ハンドルナット handling nut 1

内六角凹端紧定螺钉 M8*8

内六角凹端紧定螺钉 M8*12

内六角凹端紧定螺钉 M8*10

平垫圈 M6

标准型弹簧垫圈 M6

内六角圆柱头螺丝 M6*20

内六角圆柱头螺丝 M6*15

内六角圆柱头螺丝 M8*30

平垫圈 M8

标准型弹簧垫圈 M8

六角螺母 M8

六角穴付止メネジ hex holed set screw 1

六角穴付止メネジ hex holed set screw 1

六角穴付止メネジ hex holed set screw 1

平座金 plain washer 8

スプリングワッシャー spring washer 12

六角穴付ボルト hex holed bolt 4

六角穴付ボルト hex holed bolt 8

rubber roller stopper

rubber roller

六角穴付ボルト hex holed bolt 4

平座金 plain washer 4

スプリングワッシャー spring washer 4

六角ナット

hex nut

2

1

4

Page 28

4. 压力部分

序号 部品编号 部品名 部品名 Parts name Q'ty 備考

1 LF04001 加圧胶辊 加圧ゴムローラー pressure roller 1

3 LF04003 驱动压力齿轮 駆動压力ギア driving pressure gear 1

4 LF04004

5 LF04005

6 LF04006

7 LF04007

10 LF04010 滚珠轴承 ベアリング bearing 2

13 LF04013 平键 キー key 1

14 LF04014 汽缸固定件 シリンダー固定ステー cylinder fixing stay 2

15 LF04015 汽缸 エアーシリンダー air cylinder 2

16 LF04016

17 LF04017

18 LF04018

19 LF04019

20 LF04020

21 LF04021

22 LF04022

23 LF04023 支撑罗拉调节块 ロッドガイド

24 LF04024 汽缸连接销 ピン

25 LF04025 汽缸压力棒 シリンダー ロッド cylinder lod 2

26

27 LF04027 压力杠杆轴 圧力ローラースタンド pressure roller stand 1

28 LF04028 胶辊固定座 ベアリング受け bearing stand 2

29 LF04029

LF04026

内六角凹端紧定螺丝 M8*10

六角螺母(左旋) M10

标准型弹簧垫圈 M8

内六角圆柱头螺丝 M8*20

平垫圈 M10

六角锁紧螺母 M10

标准型弹簧垫圈 M8

内六角圆柱头螺丝 M8*30

平垫圈 M8

标准型弹簧垫圈 M8

内六角圆柱头螺丝 M8*30

关节轴承 ロッドエンド

C型垫圈

六角穴付止メネジ hex holed set screw 1

六角ナット

スプリングワッシャー spring washer 6

六角穴付ボルト hex holed bolt 6

平座金 plain washer 10

六角ナット

スプリングワッシャー spring washer 8

六角穴付ボルト hex holed bolt 8

平座金 plain washer 8

スプリングワッシャー spring washer 8

六角穴付ボルト hex holed bolt 8

Cリング

hex nut

hex nut

lod guide

pin

lod end

c-ring

2

2

2

2

2

2

Page 29

5.蛇形修正装置

序号 部品编号 部品名 部品名 Parts name Q'ty 備考

1 LF05001 蛇形修正罗拉 蛇行修正ローラー belt warping prevention roller 2

2 LF05002 滚珠轴承 ベアリング bearing 4 6205.C3

3 LF05003 轴卡簧 Cリング c-ring 4

4 LF05004

5 LF05005

6 LF05006

7 LF05007 带座轴承 フランジブロック flange black 4 UP001

8 LF05008

9 LF05009 蛇形修正锥形齿轮

10 LF05010

11 LF05011

12 LF05012

13 LF05013 链条 チェーン chain 1

14 LF05014

15 LF05015 带座轴承 フランジブロック flange black 4 UP000

16 LF05016

17 LF05017

18 LF05018 蛇形调整支撑座 蛇行修正スイッチベース switch base 2

19 LF05019

20 LF05020

21 LF05021

22 LF05022

23

24 LF05024

25 LF05025 蛇形修正垫块 蛇行修正ブロックカラー BWP brock coller 4

26 LF05026

27 LF05027

28 LF05028

29 LF05029

LF05023

蛇形修正固定件(C) 蛇行修正ステー(C)

蛇形修正调整块(A) 蛇行修正ブロック(A)

蛇形修正调整螺杆(A) 粗 蛇行修正シャフト(A)(太)

轴承座垫块(A) ピロ受け台(A)

蛇行修正辺べベルギア(B)

蛇形修正锥形齿轮(马达) 蛇行修正辺べベルギア(A)

蛇形修正链轮(A) 蛇行修正スプロケット(A) BWP sprocket(A)

蛇形修正链轮(B) 蛇行修正スプロケット(B) BWP sprocket(B)

轴承座垫块(B) ピロ受け台(B)

蛇形修正调整螺杆(B) 细 蛇行修正シャフト(B)(細)

内六角凹端紧定螺钉 M6*10

内六角凹端紧定螺钉 M6*6

蛇形修正调整块(B)

蛇形修正固定件(下)

平垫圈 M4

标准型弹簧垫圈 M4

十字盘头螺丝 M4*10

平垫圈 M8

标准型弹簧垫圈 M8

六角头螺栓 M8*20

平垫圈 M6

蛇行修正スイッチステーブロック bwp switch stay brock 2

六角穴付止メネジ hex holed set screw 8

六角穴付止メネジ hex holed set screw 8

蛇行修正ステー belt warping prevention stay 1

平座金 plain washer 8

スプリングワッシャー spring washer 8

ナベ小ネジ pan screw 8

平座金 plain washer 6

スプリングワッシャー spring washer 6

外六角ネジ

平座金 plain washer 50

belt warping prevention stay 2

bwp brock(A) 2

bwp shaft (A) 2

pyro stand(A) 8

BWP bevel gear(B) 2 φ12

BWP bevel gear(A) 2 φ10

pyro stand(B) 8

bwp shaft (B) 2

hex screw

2

2

6

φ25

Page 30

5.蛇形修正装置

序号 部品编号 部品名 部品名 Parts name Q'ty 備考

30 LF05030

31 LF05031

32 LF05032

33 LF05033

34 LF05034

35 LF05035

36 LF05036

37 LF05037

38 LF05038

39 LF05039

40 LF05040

41 LF05041 马达 モーター motor 2

42 LF05042 蛇形调整马达板 蛇行修正モーターベース motor base 2

43 LF05043 蛇形修正补孔板 蛇行修正モーターベース小板 motor base plate 2

44 LF05044

45 LF05045

46 LF05046 蛇形修正罗拉固定销 蛇行修正ローラー受けピン pin 2

47 LF05047 刮板轴卡子 割ピン split pin 2

48 LF05048 限位开关 リミットスイッチ limit switch 2 D2RV-L111

49 LF05049

50 LF05050

51 LF05051

52 LF05052 蛇形修正罗拉轴 蛇行修正ローラーシャフト bwp roller shaft 2

标准弹簧垫圈 M6

内六角圆柱头螺丝 M6*30

六角头螺栓 M6*15

平垫圈 M5

标准弹簧垫圈 M5

十字盘头螺丝 M5*12

十字盘头螺丝 M5*55

六角螺母 M5

蛇形修正固定件(上) 蛇行スイッチステーブロック板上側(B)

限位开关固定件(上) 蛇行スイッチチステーブロック板上側(A)

六角螺母 M6

蛇形修正固定件(B)

蛇形修正固定件(A) 蛇行修正ステー(A)

平垫圈 M3

标准弹簧垫圈 M3

十字盘头螺丝 M3*16

スプリングワッシャー spring washer 50

六角穴付ボルト hex holed bolt 8

ネジ screw 30

平座金 plain washer 20

スプリングワッシャー spring washer 20

ナベ小ネジ pan screw 4

ナベ小ネジ pan screw 8

六角ナット

六角ナット

蛇行修正ステー(B) belt warping prevention stay(B) 2

平座金 plain washer 4

スプリングワッシャー spring washer 4

ナベ小ネジ pan screw 4

hex nut

BWP switch sub stay(B) 1

BWP switch sub stay (A) 1

hex nut

belt warping prevention stay(A) 2

8

12

Page 31

6.皮带张紧装置

序号 部品编号 部品名 部品名 Parts name Q'ty 備考

1 LF06001 张紧罗拉 テンションローラー tension roller 2

2 LF06002 辅助罗拉 ローラー roller 2

3 LF06003 轴承 ベアリング bearing 8 6205.C3

4 LF06004 轴卡簧 Cリング c-ring 8 Φ25

5 LF06005 拉紧弹簧 テンションバネ tension spring 8

6 LF06006

7 LF06007

8 LF06008

9 LF06009

10 LF06010 无接缝皮带 シームレスベルト seamless belt 2 915*2450

11 LF06011

12 LF06012 支撑罗拉调节块 ローラーアジャストステー roller adjust stay 2

13 LF06013

14 LF06014

15 LF06015

16 LF06016

17 LF06017

18 LF06018

19 LF06019 限位开关 リミットスイッチ limit switch 2 AH70195

20 LF06020 限位开关固定件 リミットスイッチステー

21 LF06021 张紧罗拉轴 テンションローラーシャフト tension roller shaft 2

22 LF06022 辅助罗拉轴 ローラーシャフト roller shaft 2

23 LF06023

24 LF06024 轴承 ベアリング bearing 4

25 LF06025 轴卡簧 Cリング c-ring 8 Φ20

内六角圆柱头螺丝钉 M8*60

平垫圈 M8

标准型弹簧垫圈 M8

六角螺母 M8

六角头螺丝 M8*20

平垫圈 M6

标准型弹簧垫圈 M6

六角头螺丝 M6*15

平垫圈 M3

标准型弹簧垫圈 M3

十字盘头螺丝 M3*16

六角头螺丝 M8*25

六角穴付ボルト hex holed bolt 4

平座金 plain washer 16

スプリングワッシャー spring washer 10

六角ナット

六角ボルト hex bolt 2

平座金 plain washer 4

スプリングワッシャー spring washer 4

六角ボルト hex bolt 4

平座金 plain washer 4

スプリングワッシャー spring washer 4

ナベ小ネジ pan screw 4

六角ボルト hex bolt 2

hex nut

limit switch stay

12

2

6204.C4

Page 32

7.剥离装置

序号 部品编号 部品名 部品名 Parts name Q'ty 備考

1 LF07001 回转剥离骨架 固定用シャフト fixing shaft 1

2 LF07002 回转剥离驱动轴 回転剥離駆動ローラーシャフト rotary blade sprocket roller 1

3 LF07003 回转剥离轴 回転剥離ローラーシャフト rotary blade roller 2

4 LF07004

5 LF07005

6 LF07006 回转剥离片 ハネ brade 8

7 LF07007 回转轴辅助支撑件 回転軸固定ステー rotary shaft fixing stay 1

8 LF07008

9 LF07009

10 LF07010

11 LF07011 线缆护套 コードブッシュ coad bush 1 TB-1520

12 LF07012 挡套 ブッシュ bush 1

13 LF07013 回转剥离驱动轴链轮 スプロケット sprocket 1

14 LF07014 回转剥离链轮 スプロケット rotary blade sprocket 3

15 LF07015 刮板轴卡子 割ピン split pin 4

16 LF07016

17 LF07017 无油轴承 メタル metal 1

18 LF07018 链条 チエーン chain 1

19 LF07019

20 LF07020

21 LF07021

22 LF07022

23 LF07023

24 LF07024

25 LF07025

26 LF07026 回转轴固定件 チェーンテンションレバー chain tension lever 1

27 LF07027

28 LF07028

29 LF07029

30 LF07030 皮带清洁方管 ベルトクリーナ belt cleaner 2

剥离回转轴带压板(B)

剥离回转轴带螺纹压板(A)

开口挡圈φ12 軸用Cリング

内六角凹端紧定螺丝 M6*6

回转剥离同步带轮(B)

内六角圆柱头螺丝 M8*50

内六角圆柱头螺丝 M8*25

平垫圈 M8

轴套φ15

内六角圆柱头螺丝 M6*30

回转剥离弹簧(1)

六角螺母 M6

标准型弹簧垫圈 M6

回转剥离轴块(A)

小轴套φ10

平垫圈 M10

タイミングプーリー(B) timing pully (B) 1

ハネ押え blade plate 4

ハネ押え blade plate 4

六角穴付止メネジ hex holed set screw 14

六角穴付ボルト hex holed bolt 1 特制

六角穴付ボルト hex holed bolt 1 特制

平座金 plain washer 5

ブッシュ bush 3 R-BRF1510

六角穴付ボルト hex holed bolt 2

回転剥離スプリング rotary blade spring 1

六角ナット

スプリングワッシャー spring washer 22

回転ハネ軸受け rotary brade shaft reciever 4

ブッシュ bush 4 KBF-T-1015

平座金 plain washer 8

c-ring 3 JIS B-2804

hex nut

6

Page 33

7.剥离装置

序号 部品编号 部品名 部品名 Parts name Q'ty 備考

31 LF07031

32 LF07032

33 LF07033

34 LF07034

35 LF07035

36 LF07036

37 LF07037

38 LF07038

39 LF07039 回转剥离支撑棒 ハンドル handle 2

40 LF07040 回转马达散热罩 回転剥離モーターカバー motor cover 1

41 LF07041 回转剥离马达 回転剥離モーター rotary blade sprocket motor 1

42 LF07042 回转剥离马达座 回転剥離モーターベース motor base 1

43 LF07043

44 LF07044

45 LF07045 回转同步皮带 回転剥離タイミングベルト rotary blade sprocket timing belt 1

46 LF07046

47 LF07047

48 LF07048

49 LF07049

50 LF07050

51 LF07051 波形旋钮 波型ワッシャー wave washer 1

52 LF07052

53 LF07053

54 LF07054

六角螺母 M4

内六角圆柱头螺 M10*80

锁紧螺母 M10

标准型弹簧垫圈 M8

六角头螺丝 M8*20

平垫圈 M6

六角螺母 M8

六角头螺丝 M6*15

内六角圆柱头螺丝 M6*45

回转剥离同步带轮(A) タイミングプーリー(A)

平垫圈 M5

标准型弹簧垫圈 M5

十字盘头螺丝 M5*10

十字盘头螺丝 M5*25

回转剥离弹簧(2)

十字盘头螺丝 M4*30

回转剥离弹簧(3)

标准型弹簧垫圈 M4

六角ナット

六角穴付ボルト hex holed bolt 2

ナット nut 2

スプリングワッシャー spring washer 3

六角ボルト hex bolt 2

平座金 plain washer 21

六角ナット

六角ボルト hex bolt 12

ネジ screw 4

平座金 plain washer 2

スプリングワッシャー spring washer 26

ナベ小ネジ pan screw 4

ナベ小ネジ pan screw 25

回転剥離スプリング rotary blade spring 1

ナベ小ネジ pan screw 4

回転剥離スプリング rotary blade spring 4

スプリングワッシャー spring washer 4

hex nut

hex nut

timing pully (A) 1

4

1

Page 34

8.输送台

序号 部品编号 部品名 部品名 Parts name Q'ty 備考

1 LF08001 输出驱动轴 輸出駆動ローラー exrt driving roller 1

4 LF08004 传输骨架固定 輸送テーブル固定用シャフト belt fixing shaft 2

5 LF08005 轴承端盖 ベアリング受け bearing reciever 2

6 LF08006 滚珠轴承 ベアリング bearing 8 6205.C3

7 LF08007 输出轴端封盖 ベアリング受け板 bearing recive plate 2

8 LF08008 轴卡簧 Cリング c-ring 6

9 LF08009 驱动旁齿轮固定件 ギアレバー gear lever 1

10 LF08010 中间齿轮 ギア gear 1

11 LF08011

12 LF08012 驱动齿轮 駆動ギア driving gear 1

13 LF08013 油料盒 油受け oil reciever 1

14 LF08014 齿轮盖 ギアカバー gear cover 1

15 LF08015 冷却板 クーリング板 cooling plate 1

16 LF08016

17 LF08017

18 LF08018

19 LF08019

20 LF08020

21 LF08021

22 LF08022

23 LF08023

24 LF08024

25 LF08025

26 LF08026 橡胶脚垫 回転剥離装置受け stand 2 K322

29 LF08029 平键 キー key 1 5*5*35

30 LF08030 轴套 ブッシュ bush 1 IR15*18*12.5

31 LF08031 滚针轴承 ベアリング bearing 1 KH1815(内径φ15)

32 LF08032 辅助罗拉轴 シャフト shaft 2

34 LF08034

35 LF08035 输送皮带张紧弹簧 輸送ベルトテンションスプリング conveyor belt tension spring 2

36 LF08036 输送皮带张紧轴 輸送ベルトテンションシャフト conveyor belt tension shaft 1

37 LF08037

38 LF08038 皮带导向架 ガイダー guider 2

39 LF08039 输送皮带张紧罗拉轴 輸送ベルトテンションローラーシャフト conveyor belt tension roller shaft 1

40 LF08040 棉布带 輸送ベルト conveyor belt 16 50*2080

41 LF08041

内六角凹端紧定螺钉 M8*8

平垫圈 M6

标准型弹簧垫圈 M6

六角头螺丝 M6*15

平垫圈 M8

标准型弹簧垫圈 M8

六角头螺丝 M8*20

平垫圈 M5

标准型弹簧垫圈 M5

十字盘头螺丝 M5*10

十字盘头螺丝 M5*25

轴承 6200ZZ

并行罗拉(A)

加宽垫圈 M8

六角穴付止メネジ hex holed set screw 2

平座金 plain washer 8

スプリングワッシャー spring washer 8

外六角ネジ hex screw 8

平座金 plain washer 15

スプリングワッシャー spring washer 15

外六角ネジ hex screw 15

平座金 plain washer 4

スプリングワッシャー spring washer 4

ナベ小ネジ pan screw 2

ナベ小ネジ pan screw 2

ベアリング bearing 2 6200ZZ

並ローラー

ワツシャー

roller roller

washer

3 L=1065

2

Page 35

9.罩壳

序号 部品编号 部品名 部品名 Parts name Q'ty 備考

1 LF09001 后盖板 後部カバー rear cover 1

2 LF09002 上盖板 上部カバー upper cover 1

3 LF09003 前盖板 前部カバー front cover 1

4 LF09004 上部隔热板 上部断熱板 upper heat brock cover 1

5 LF09005

6 LF09006 进料口台板 テーブル work table 1

7 LF09007 底部前方盖板 脚前方カバー front lower cover 1

8 LF09008 电箱固定架 電気ボックス受け wiring box stand 1

9 LF09009 电箱盖板 電気ボックスカバー wiring box cover 1

10 LF09010

11 LF09011 底部后方盖板 脚後方カバー rear lower cover 1

12 LF09012 上盖板支撑件 上カバー受け upper cover reciever 2

13 LF09013 铰链 蝶番 wing plate 4

14 LF09014

15 LF09015 隔热板垫块 断熱材カラー insulation coller 4

16 LF09016

17 LF09017

18 LF09018

19 LF09019

20 LF09020

21 LF09021

22 LF09022

23 LF09023

24 LF09024

25 LF09025

26 LF09026

27 LF09027

28 LF09028

29 LF09029

30 LF09030

机身封板(右)

机身封板(左)

十字半圆头螺丝 M4*15

平垫圈 M6

标准型弹簧垫圈 M6

六角头螺丝 M6*45

内六角圆柱头螺丝 M6*20

六角螺母 M6

十字盘头螺丝 M6*15

木螺丝 M4*15

平垫圈 M8

标准型弹簧垫圈 M8

六角头螺丝 M8*20

平垫圈 M4

标准型弹簧垫圈 M4

十字盘头螺丝 M4*10

六角头螺丝 M6*15

六角锁紧螺母 M8

右側カバー right cover 1

左側カバー left cover 1

ネジ screw 12

平座金 plain washer 24

スプリングワッシャー spring washer 22

六角穴付止メネジ hex holed set screw 4

六角穴付ボルト hex holed bolt 4

六角ナット

ナベ小ネジ pan screw 8

木ネジ screw 12

平座金 plain washer 18

スプリングワッシャー spring washer 16

六角穴付止メネジ hex holed set screw 14

平座金 plain washer 12

スプリングワッシャー spring washer 12

ナベ小ネジ pan screw 12

六角穴付止メネジ hex holed set screw 2

六角ナット

hex nut

hex nut

6

4

Page 36

9.罩壳

序号 部品编号 部品名 部品名 Parts name Q'ty 備考

31 LF09031 电箱固定件 電気ボックス固定ステー fixing stay 2

32 LF09032 U形把手 上カバーハンドル upper cover handle 1

33 LF09033

34 LF09034 配电柜用合页 蝶番 wing plate 2

35 LF09035 电箱固定销 ピン pin 2

36 LF09036 锁具 電気ボックスカバーハンドル handle 1 A-380-2B

37 LF09037

38 LF09038 操作面板 操作パネル operation panel 1

39 LF09039 电箱锁扣件 電気ボックスカバーハンドル受け box cover stand 1

40 LF09040 急停开关 緊急停止スイッチ emergency switch 4

六角法兰面螺丝 M5*8

六角法兰面螺丝 M5*5

ネジ screw 2 把手原配

ネジ screw 2 锁具原配

Page 37

10.刮板装置

序号 部品编号 部品名 部品名 Parts name Q'ty 備考

1 LF10001 刮板剥离支架(左) スクレーパ剥離フレーム〔左) spring washer strip-off frame(L) 1

2 LF10002 刮板轴卡子 割ピン split pin 2

3 LF10003 皮带清洁方管 クリーナパイプ cleaner paipe 2

4 LF10004 清洗骨架轴心 シャフト shaft 1

5 LF10005 刮板剥离固定件 スクレーパ剥離ステー spring washer strip-off stay 2

6 LF10006 刮板 スクレーパ scraper 2

7 LF10007 清洗方管压片 クリーナーフェルト cleaner felt 8

8 LF10008

9 LF10009

10 LF10010 刮板剥离支架(右) スクレーパ剥離フレーム〔右) spring washer strip-off frame(R)1

11 LF10011 平垫圈 平座金 plain washer 2

12 LF10012

13 LF10013

14 LF10014 平垫圈 平座金 plain washer 8

15 LF10015

16 LF10016

17 LF10017 锁紧螺母 パイプエンドメタル paipe end metal 2

18 LF10018 平垫圈 平座金 plain washer 4

19 LF10019

标准型弹簧垫圈M4

十字盘头螺丝 M4*6

标准型弹簧垫圈M8

六角头螺丝 M8*20

标准型弹簧垫圈M6

六角头螺丝 M6*15

内六角圆柱头螺丝M10*60

スプリングワッシャー spring washer 8

ナベ小ネジ pan screw 8

スプリングワッシャー spring washer 2

六角穴付止メネジ hex holed set screw 2

スプリングワッシャー spring washer 8

六角穴付止メネジ hex holed set screw 8

六角穴付ボルト hex holed bolt 2

Page 38

11. 电 装

序号 部品编号 部品名 部品名 Parts name Q'ty 備考

1 LF11001 空气开关 ブレーカー breaker 1

2 LF11002 防水线扣 ゴムブッシュ bush 1

3 LF11003 橡胶电缆 コード code 8

4 LF11004 外六角组合螺丝 ネジ screw 14

5 LF11005 操作面板 操作パネル opartion panel 1

6 LF11006 停止按钮 停止スイッチ stop switch 1

7 LF11007 时间按钮 タイマースイッチ timer switch 1

8 LF11008 启动按钮 スタートスイッチ

9 LF11009 驱动电位计旋钮 ツマミ knob 1

10 LF11010 温控仪 サーモスタット thermostat 2

11 LF11011 拨位开关 切り替えスイッチ select switch 1

12 LF11012 压力表 圧力メーター pressure meter 1

13 LF11013 剥离电位计旋钮 ツマミ knob 1

14 LF11014 调压旋钮 圧力調整ボリューム volume 1

15 LF11015 变频器 インバーター invertor 1

16 LF11016

17 LF11017 线槽 ダクト duct 0.75

18 LF11018 固态继电器 SSR 420B SSR 420b 4

19 LF11019 剥离电容 回転剥離コンデンサー rotary blade condenser 1

20 LF11020 蛇行修正电容 蛇行修正コンデンサー belt warping prevention condenser 2

21 LF11021 组合端子台 端子台 terminal 4

22 LF11022 组合端子台 端子台 terminal 9

23 LF11023 端子台 端子台 terminal 1

24 LF11024 熔断器 ヒューズベース fuse stand 4

25 LF11025 熔断器 ヒューズベース fuse stand 2

26 LF11026 接触器 マグネットスイッチ magnet switch 1

27 LF11027 接触器 マグネットスイッチ magnet switch 3

28 LF11028 时间继电器 タイマースイッチ timer switch 1

29 LF11029 剥离调速箱 剥離スピードコントロール speed contlor 1

30 LF11030

蛇行修正PCB板

加热板垫块(A) ヒーター板固定ボス(A)

コントロール基板 control PCB 2

start switch

heater plate fixing( A) 6

1

Page 39

11. 电 装

序号 部品编号 部品名 部品名 Parts name Q'ty 備考

31 LF11031

32 LF11032-a 加热板 ヒーター板センサー付 heater unit 2

LF11032-b 加热板 ヒーター板 heater unit 4

33 LF11033 限位开关固定件 ステー stay 2

34 LF11034 限位开关 リミットスイッチ

35 LF11035 螺母 ナット nut 2

36 LF11036 弹垫 スプリングワッシャー spring washer 2

37 LF11037 十字盘头螺丝 ナベ小ネジ pan screw 2

38 LF11038 航空插头 コネクター connector 1

39 LF11039 蛇行修正马达 蛇行修正モーター belt warping prevention motor 2

40 LF11040 端子台 端子台 terminal 1

41 LF11041 端子台 端子台 terminal 2

42 LF11042 端子台固定座 端子台受け terminal stand 2

43 LF11043 螺母 ナット nut 1

44 LF11044 弹垫 スプリングワッシャー spring washer 1

45 LF11045 外六角螺丝 ネジ screw 1

46 LF11046 控制变压器 トランス transformer 1

47 LF11047 蛇行修正变压器 蛇行修正トランス belt warping prevention transformer 1

48 LF11048 加热板固定件 ヒーター板ステー heater unit stay 12

49 LF11049 电位器 ボリューム volume 2

50 LF11050 保险丝 ヒューズ fuse 4

51 LF11051 电磁阀 電磁弁 solennoid valve 1

52 LF11052 保险丝 ヒューズ fuse

53 LF11053 保险丝 ヒューズ fuse

54 LF11054 保险丝座 ヒューズホルダー fuse holder

加热板垫块(B) ヒーター板固定ボス(B)

heater plate fixing (B) 6

limit switch

2

1

1

2

Loading...

Loading...