Harwil Q-8DS Installation Instruction Sheet

MODEL Q-8DS

INSTALLATION INSTRUCTION SHEET

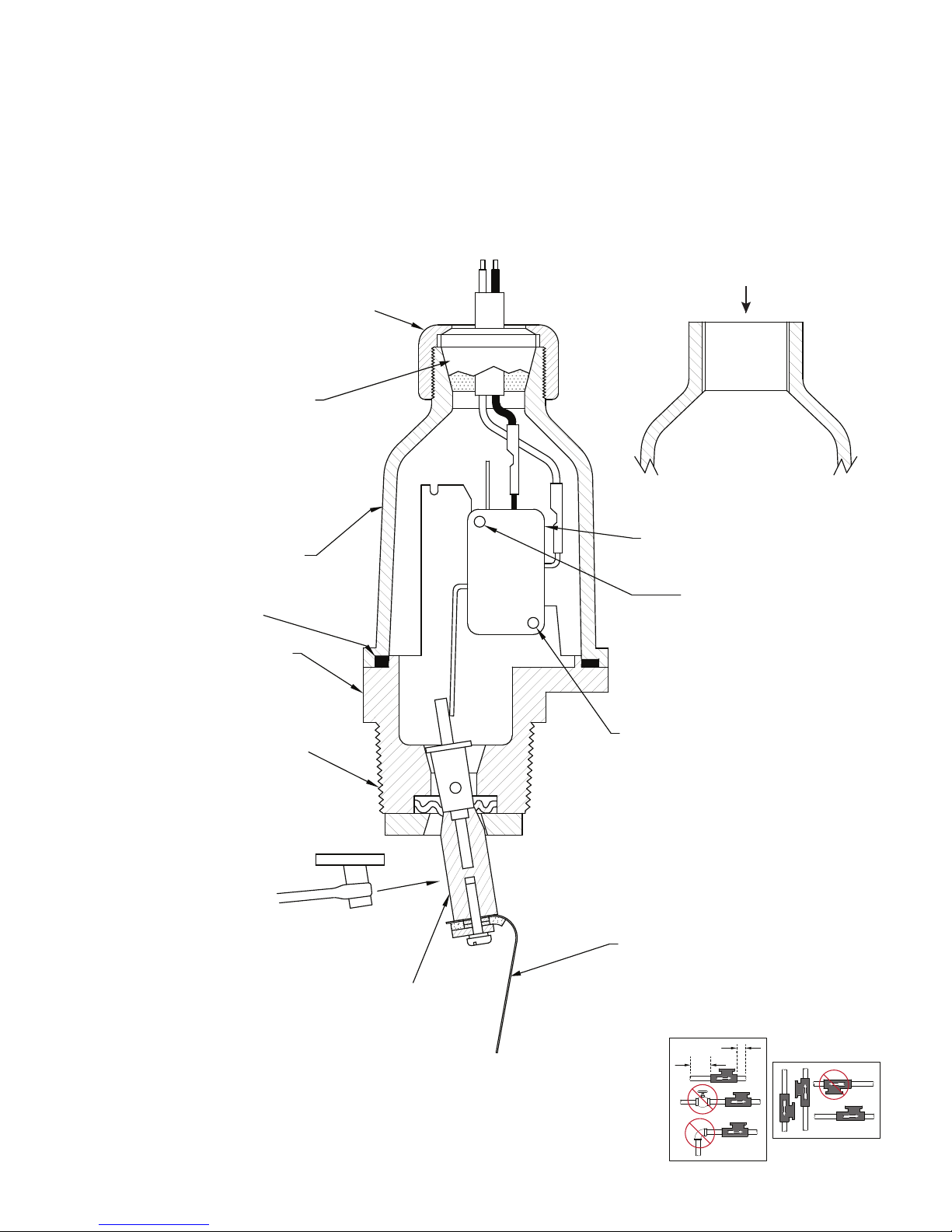

STRAIN RELIEF NUT

GROMMET ‘A’

GROMMET ‘AA’

GROMMET ‘B’

GROMMET ‘C’

SWITCH COVER

4 RETAINING SCREWS

(NOT SHOWN)

“F” COVER

O-RING

BODY, COMPLETE WITH

FEED THRU SHAFT ASSEMBLY

(SEE PARTS LIST)

HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

“F” COVER TO SUIT CUSTOMER

SUPPLIED FITTING FOR ½”

FLEXIBLE CONDUIT

MICROSWITCH COMPLETE

W/ 2 SLIP-ON TERMINALS

SCREW x ¾” LG

NUT

PLAIN WASHER

SPLIT LOCKWASHER

1” NPT

DO NOT ATTEMPT TO REMOVE

DRAG STRIP WITHOUT FIRST

GRIPPING SEAL SHAFT TO

PREVENT BREAKING OF SEAL

BY UNTHREADING FROM FEED

THRU SHAFT.

FLUID FLOW SWITCH

PARTS LIST

SCREW x 7/8” LG

NUT

PLAIN WASHER

SPLIT LOCKWASHER

DRAG STRIP

CLAMP WASHER

DAMPENER WASHER

SCREW x 3/8” LG

2 PLAIN WASHERS

SPLIT LOCKWASHER

2D

5D

TURBULENT

FLOW REDUCTION

MOUNT IN

THREE POSITIONS

ULTRA RELIABLE SINCE 1956 P. 1

HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

MODEL Q-8DS

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

INSTALLATION INSTRUCTIONS

Model Q-8DS is normally mounted in a 1½” x 1½” x 1” or 2” x 1” SST PVC Tee, which may be

plumbed into the system in vertical or horizontal lines, right side up or inverted using normal PVC

pipe cement. Make sure that flow direction arrow on the cover is aligned with the flow in the pipe.

An unmounted Q-8DS should be threaded into the 1” NPT stem of the Tee after checking for uniform

coating of threads with Teflon tape. Tighten sufficiently to produce a leak-tight seal and continue tightening up to one full turn to align flow direction arrow on cover parallel with flow axis of Tee. Check

through open end of Tee that drag strip moves freely and is perpendicular to the flow axis. Install in

pipe with flow direction arrows pointing correctly in flow direction.

ELECTRICAL WIRING

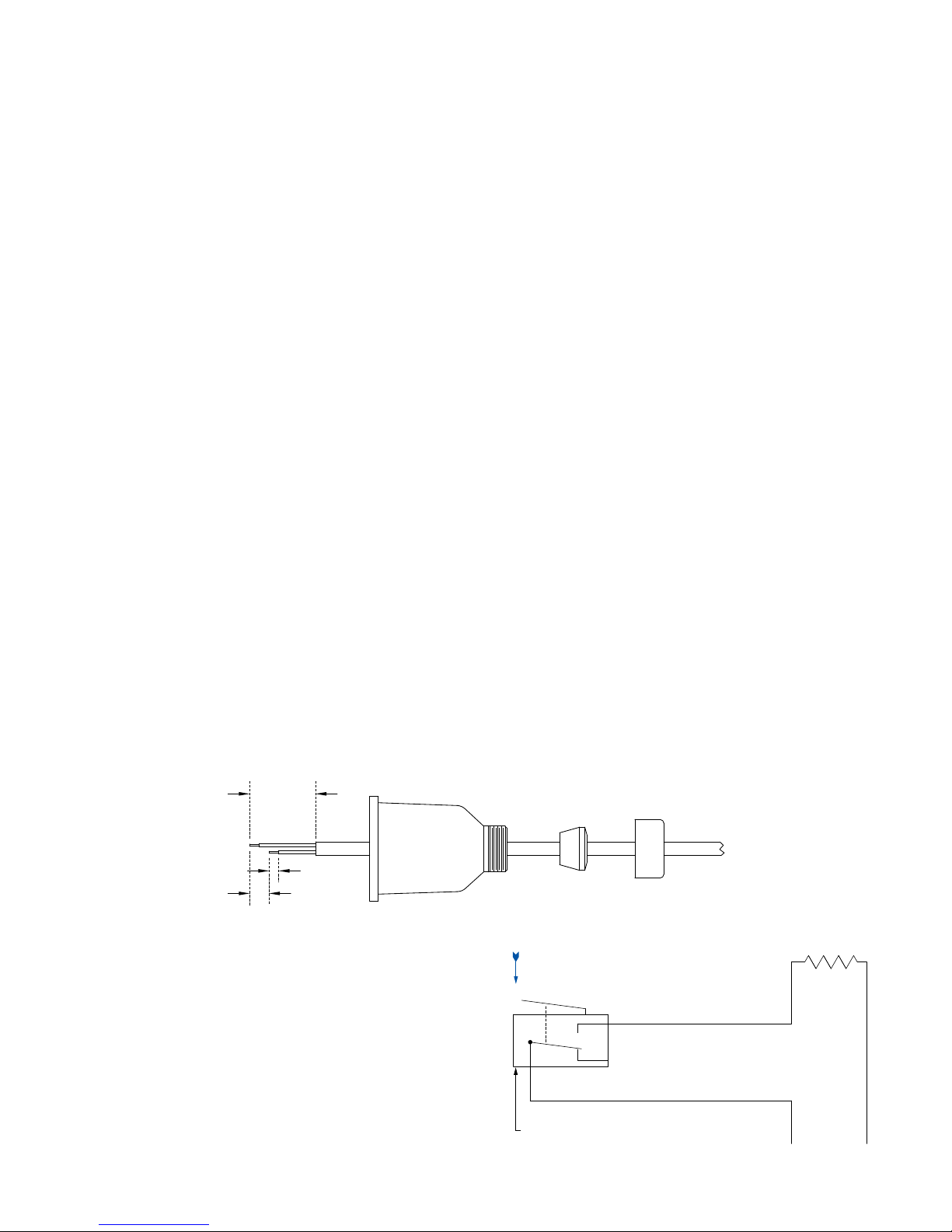

1. Remove strain relief nut, grommet, and switch

cover.

2. Strip outer jacket of electrical cord back approximately 1¼”, stagger ½” and strip leads

¼”.

3. Remove slip-on connectors from microswitch

terminals and crimp or solder to leads.

4. Feed cable through strain relief nut, grommet,

and cover.

5. Apply slip-on connectors to appropriate terminals of microswitch. Slide cover down cable

and fasten to body with 4 screws. Slide grom-

1¼”

¼”

½”

met down cable until small end is level with

outer jacket. Push grommet into tapered hole

of cover, hold cable jacket to prevent rotation

and tighten strain relief firmly.

6. If type “F” cover is supplied, connect desired

conduit fitting to cover. Prepare leads, attach

to slip-on connectors per STEP 2 and apply

to appropriate microswitch terminals. Attach

electrical conduit-to-conduit fitting. Exercise

reasonable care when assembling metal flexible conduit to prevent fracture of plastic cover.

Rigid conduit is not recommended.

WIRING SCHEMATIC

Contacts are closed when flow rate is above

microswitch set point (15-20 GPM). Power to load

interrupted when flow decreases below this point.

INCREASING FLOW MOVES

ACTUATOR IN DIRECTION

SHOWN

NC

NO

HOT

COM

MICROSWITCH

ULTRA RELIABLE SINCE 1956P. 2

LOAD

LINE

Loading...

Loading...