Harwil Q-5SS Installation Manual

MODEL Q-5SS

INSTALLATION INSTRUCTION SHEET

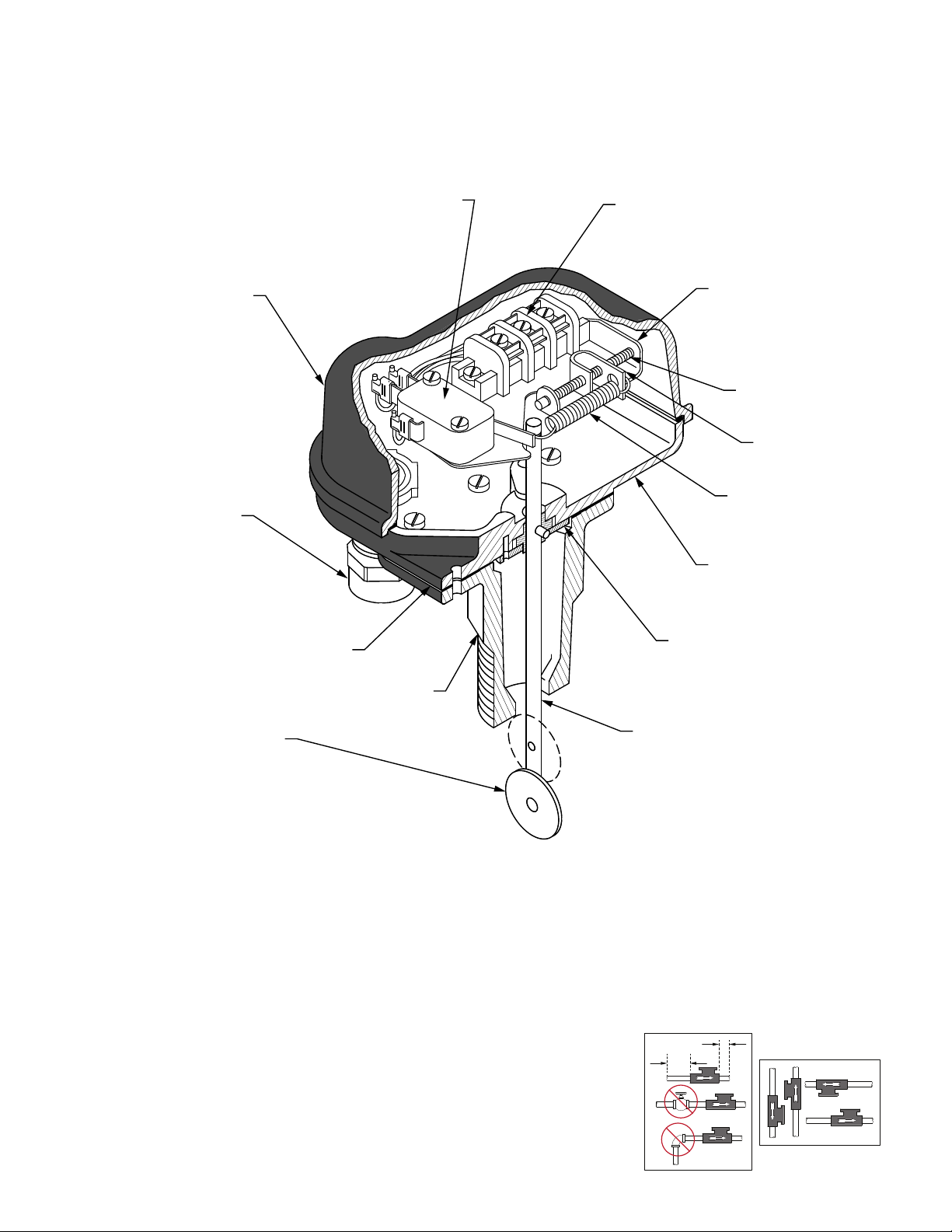

SPDT 15 AMP MICROSWITCH 125/240 VAC (2 REQ'D FOR QD-5SS)

DRY CIRCUIT MICROSWITCH SPDT 0.1A 125 VAC (OPTIONAL)

3 WIRES WITH CRIMPED TERMINALS (6 TERMS. ONLY QD-5SS)

2 SCREWS, NUTS & LOCKWASHERS

HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

TERMINAL STRIP

(NOT SUPPLIED WITH QD-5SS)

COVER CASTING,

SEAL, SCREW ASSEMBLY

CABLE STRAIN RELIEF

DRAG DISK 1

DRAG DISK 2

DRAG DISK 3

DRAG DISK 4

DRAG DISK 5

DRAG DISK 6

GASKET

BODY CASTING

BRACKET

2 SPACERS

2 SCREWS & LOCKWASHERS

LEADSCREW

LEADSCREW NUT

SPRING

LID CASTING

7 SCREWS & LOCKWASHERS

CLAMP WASHER

3 SCREWS & LOCKWASHERS

FEED THRU SHAFT ASSEMBLY

MODEL Q5SS/3

MODEL Q5SS/5

MODEL Q5SS/7

This parts list applies to all models of Q-5SS and QD-5SS uid ow switches: Q-5SS/5, Q-5SS/7,

QD-5SS/3, and QD-5SS/7. All letters and numbers added to model number after the above numbers

apply to optional drag strips and electrical strain relief connectors.

PARTS LIST

FLUID FLOW SWITCH

2D

5D

TURBULENT

FLOW REDUCTION

MODELS

Q-5SS

QD-5SS

MOUNT IN

ANY POSITION

ULTRA RELIABLE SINCE 1956 P. 1

HARWIL CORPORATION

MODEL Q-5SS

INSTALLATION INSTRUCTION SHEET

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

INSTALLATION AND OPERATING INSTRUCTIONS

The gasket seal located between the main body casting and the lid casting is a cork-rubber composition, which is subject to a slight creep for a short period after application of the initial clamping load.

All gaskets are properly clamped before shipment, however during shipping and storage, the gasket

may compress, allowing the body-lid clamp bolts to become slightly loose. Tighten these bolts before

assembling the ow switch in-system. No further creep of gasket will occur after second tightening. The

Q-5SS uid ow switch is supplied with a male 1” NPT which is threaded into an appropriate pipe tee,

large pipe with reducer bushing, or directly into a hole threaded 1” NPT in the wall of the pipe. Turn

until tight and arrow on body casting is pointed in direction of ow.

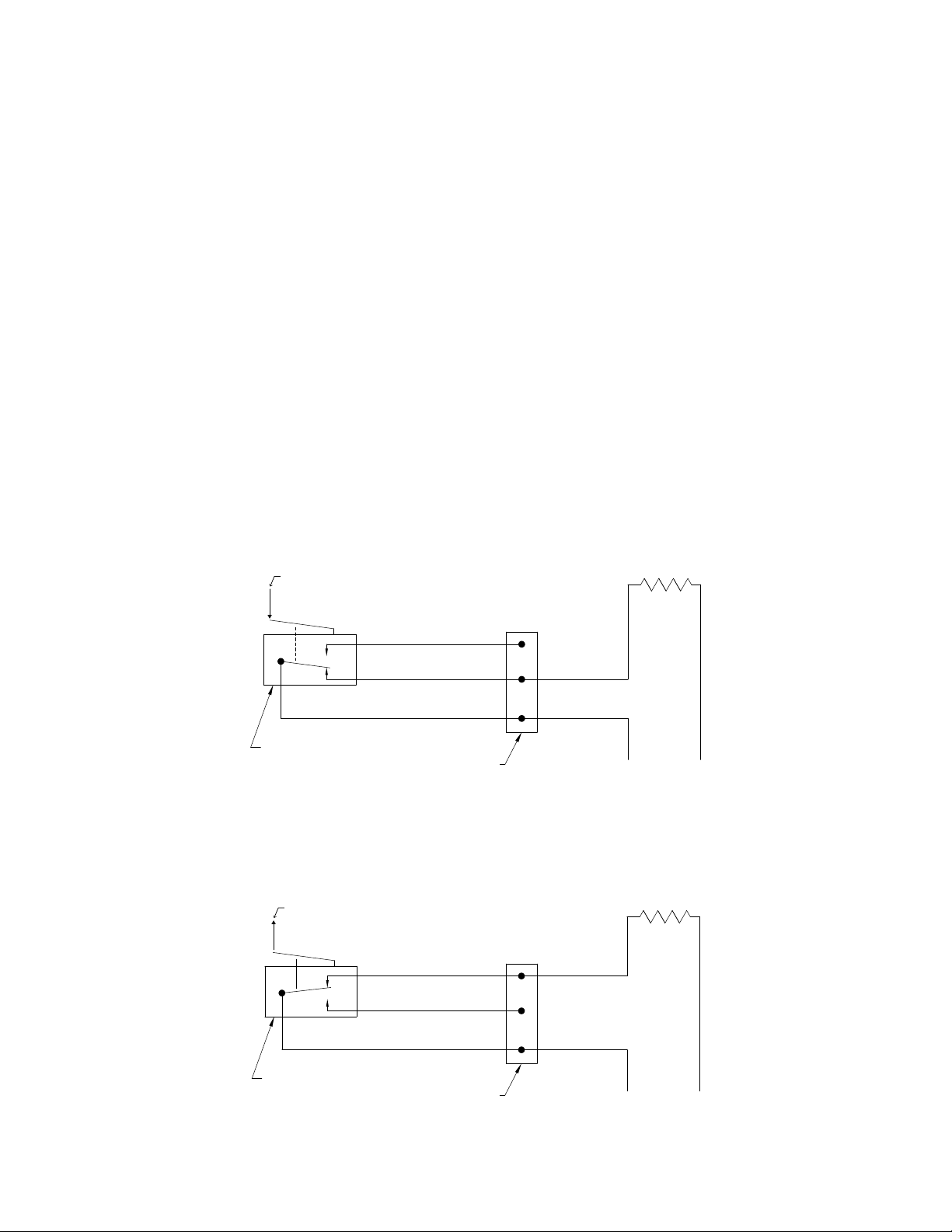

ELECTRICAL WIRING

FIGURE 1: Wiring schematic for power applied to load when ow is GREATER than the set point (power to load interrupted when ow is LESS than set point).

INCREASING FLOW MOVES

ACTUATOR IN DIRECTION SHOWN

NC (ORANGE)

NO (WHITE)

COM (BLACK)

MICROSWITCH

(HOT)

TERMINAL STRIP

LOAD

LINE

FIGURE 2: Wiring schematic for power applied to load when ow is LESS than the set point (power to

load interrupted when ow is GREATER than set point).

DECREASING FLOW MOVES

ACTUATOR IN DIRECTION SHOWN

NC (ORANGE)

NO (WHITE)

LOAD

MICROSWITCH

COM (BLACK)

ULTRA RELIABLE SINCE 1956P. 2

TERMINAL STRIP

(HOT)

LINE

MODEL Q-5SS

INSTALLATION INSTRUCTION SHEET

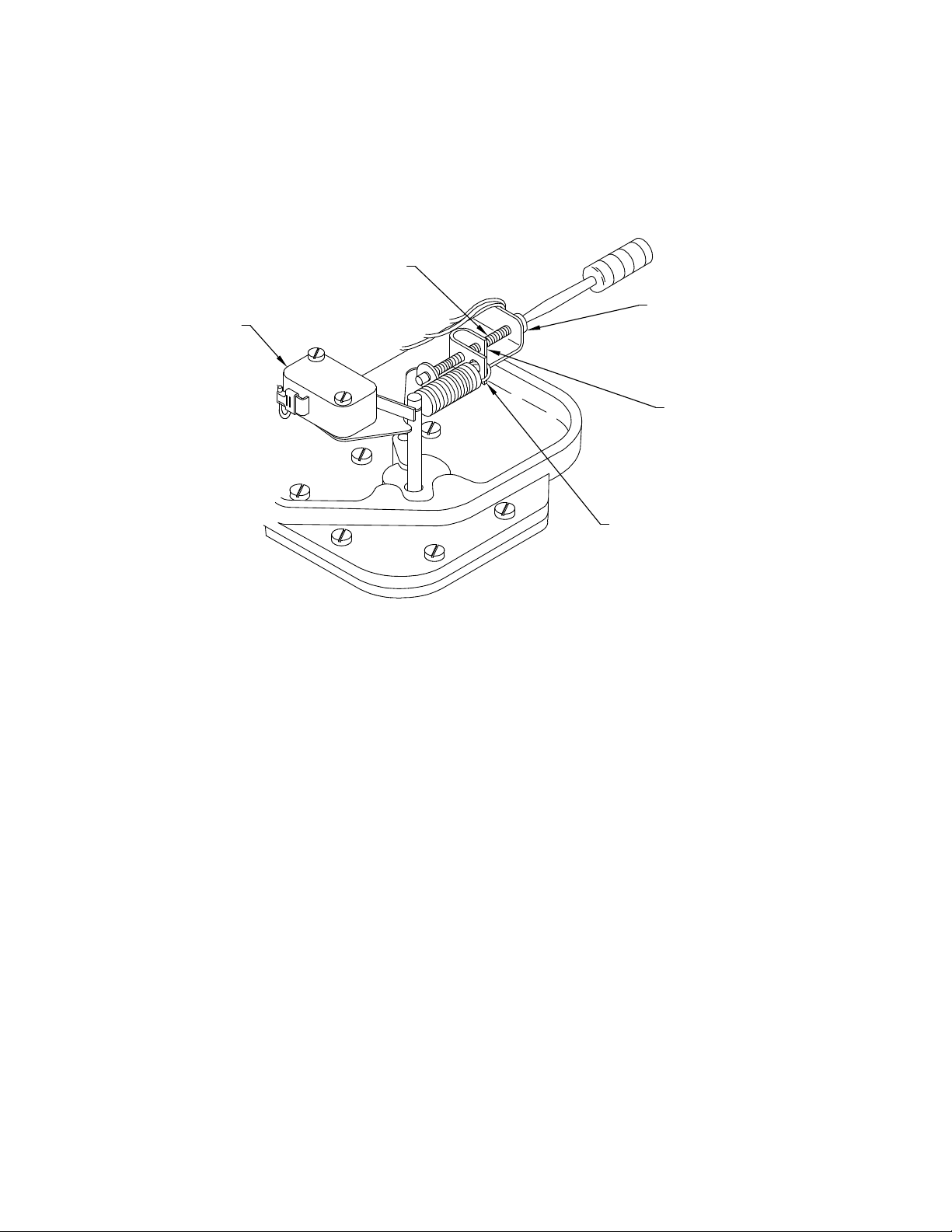

FLOW SWITCH OPERATIONAL ADJUSTMENT

REMOVE COVER

LEADSCREW

MICROSWITCH

HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

ADJUST LEADSCREW

BEST ADJUSTMENT POINT

(CENTERED)

SPRING POSITION

WHEN DELIVERED

EMAIL: HARWIL@HARWIL.COM

SWITCH POINT ADJUSTMENT

1. Remove cover.

2. Adjust uid ow in system to desired rate WITHOUT regard to Q-5SS switch point setting.

3. The switch point adjusting mechanism consists of an adjusting screw, a “U” shaped lead screw nut,

and a helical spring.

CLOCKWISE rotation of the adjusting screw changes the microswitch actuation point toward HIGHER

ow rates.

NOTES: All Q-5SS units are factory set at the lower end of the ow range, e.g. the adjusting screw is

set at the low ow counter-clockwise position.

The lead screw nut locks the adjusting screw in position, maintaining the ow switch set point under all

environmental conditions.

4. Turn the adjusting screw in a clockwise direction until the microswitch is actuated, while maintaining

the desired uid ow rate in the system. Turn the adjusting screw TWO (2) additional turns in the

clockwise direction and then slowly back off in a counter-clockwise direction, until the microswitch

is again actuated. The Q-5SS ow switch is now set for maximum sensitivity for detecting small ow

changes.

5. When set for maximum sensitivity (100% point) as described above, ow turbulence may cause

rapid on/off switching (dithering) of the microswitch contacts, resulting in reduced switch contact life

ULTRA RELIABLE SINCE 1956 P. 3

Loading...

Loading...