MODEL Q-12

REED SWITCH

Q-12N, Q-12CR, Q-12 DS (TEMPERATURE: QT-12)

INSTALLATION INSTRUCTION SHEET

HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

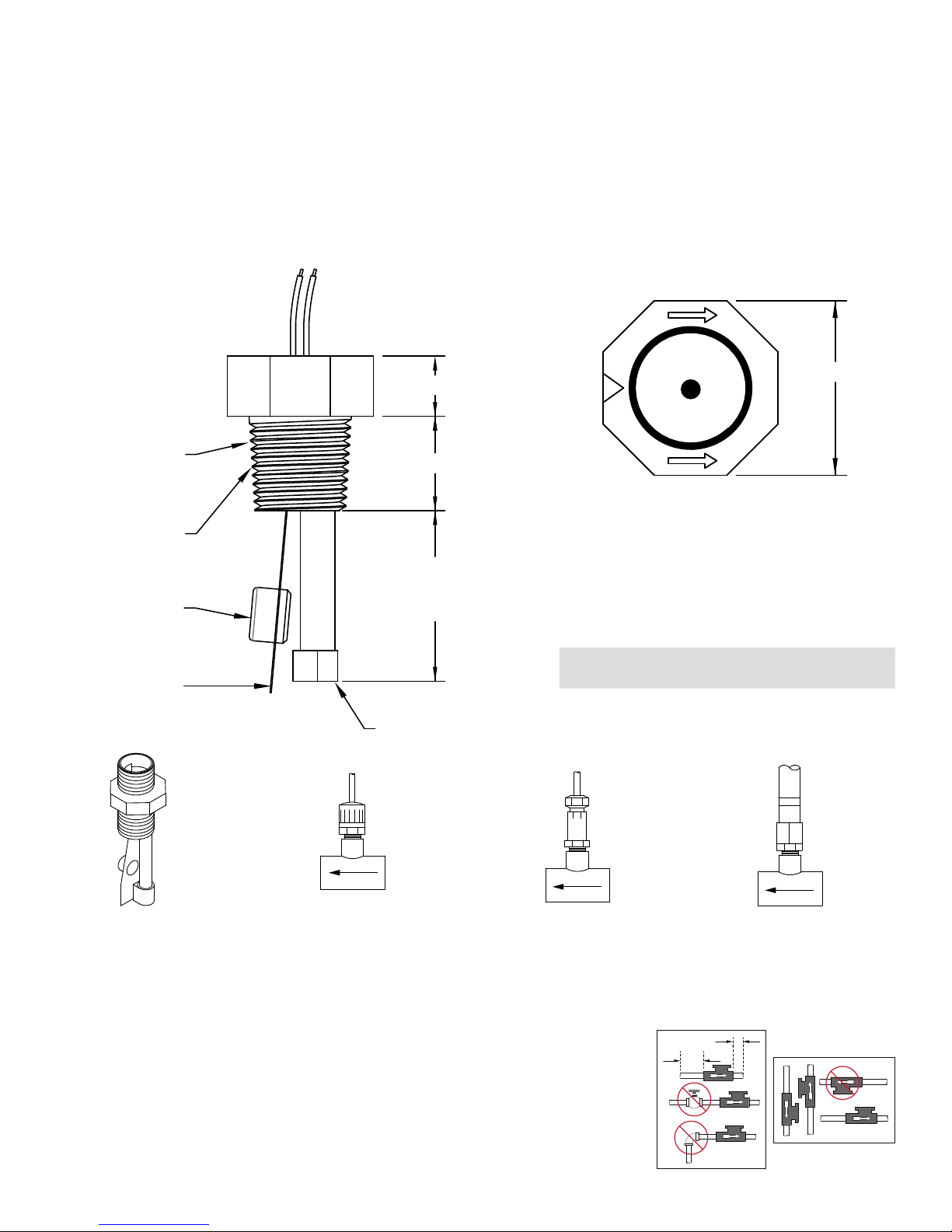

½” OR ¾” NPT

APPLY TEFLON

SEALING TAPE

AS REQUIRED

(2-3 LAYERS)

ENCAPSULATED

MAGNET

ONE PIECE

BENDING BEAM

TARGET AND

MAGNET

SIDE VIEW

0.5”

0.65”

1.1” SMALL BODY

1.4” MEDIUM BODY

1.8” LARGE BODY

ENCAPSULATED

TOP VIEW

1.2”

• Pressure drop typically less than 1.0 psi

at rated flow.

• Mount in any position.

OPTION 3 GROMMET SELECTION CHART

Grommet

Size

A 0.25” B 0.375”

AA 0.33” C 0.50”

Cable OD Grommet

Size

Cable OD

OPTION 1

BASIC UNIT SUPPLIED WITH

TWO 0.187 x 0.020 MALE

SPADE TERMINALS RECESSED

IN ½” NPT NIPPLE SECTION.

OPTION 2

BASIC UNIT WITH TWOCONDUCTOR INSTRUMENT

CABLE POTTED IN PLACE.

PVC TEE OPTIONAL.

FLUID FLOW SWITCH

ULTRA RELIABLE SINCE 1956 P. 1

OPTION 3

BASIC UNIT W/ DMP TAPERED

RUBBER GROMMET ATTACHMENT

FOR WATERTIGHT SEAL & STRAIN

RELIEF. PVC TEE OPTIONAL.

OPTION 4

BASIC UNIT WITH ½” FLEXIBLE

SPIRADUCT PLASTIC CONDUIT &

FITTINGS. ELECTRICAL CABLE NOT

SUPPLIED. PVC TEE OPTIONAL.

2D

5D

TURBULENT

FLOW REDUCTION

MOUNT IN

THREE POSITIONS

MODEL Q-12

Q-12N, Q-12CR, Q-12 DS (TEMPERATURE: QT-12)

INSTALLATION INSTRUCTIONS

HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

Flow switch should be mounted at least 5 pipe diameters

downstream and 2 pipe diameters upstream of any source

of turbulence, such as valves, elbows, reducers, etc.

1. Remove unit from shipping box and inspect it for possible damage (i.e., cracks, damaged threads, deformed

bending beam, etc.)

2. Check model number on label with that shown on

packing list vs. configuration actually received (return to

supplier if discrepancy is found).

3. Place a multimeter or equivalent test meter across the

two wire leads coming from the unit and check for

proper switch operation by gently moving bending

beam and magnetic assembly toward switch support

tube. Switch should activate when separation is in the

range ⁄” to ⁄”.

4. If no discrepancy is found, thread unit into appropriate

tee.

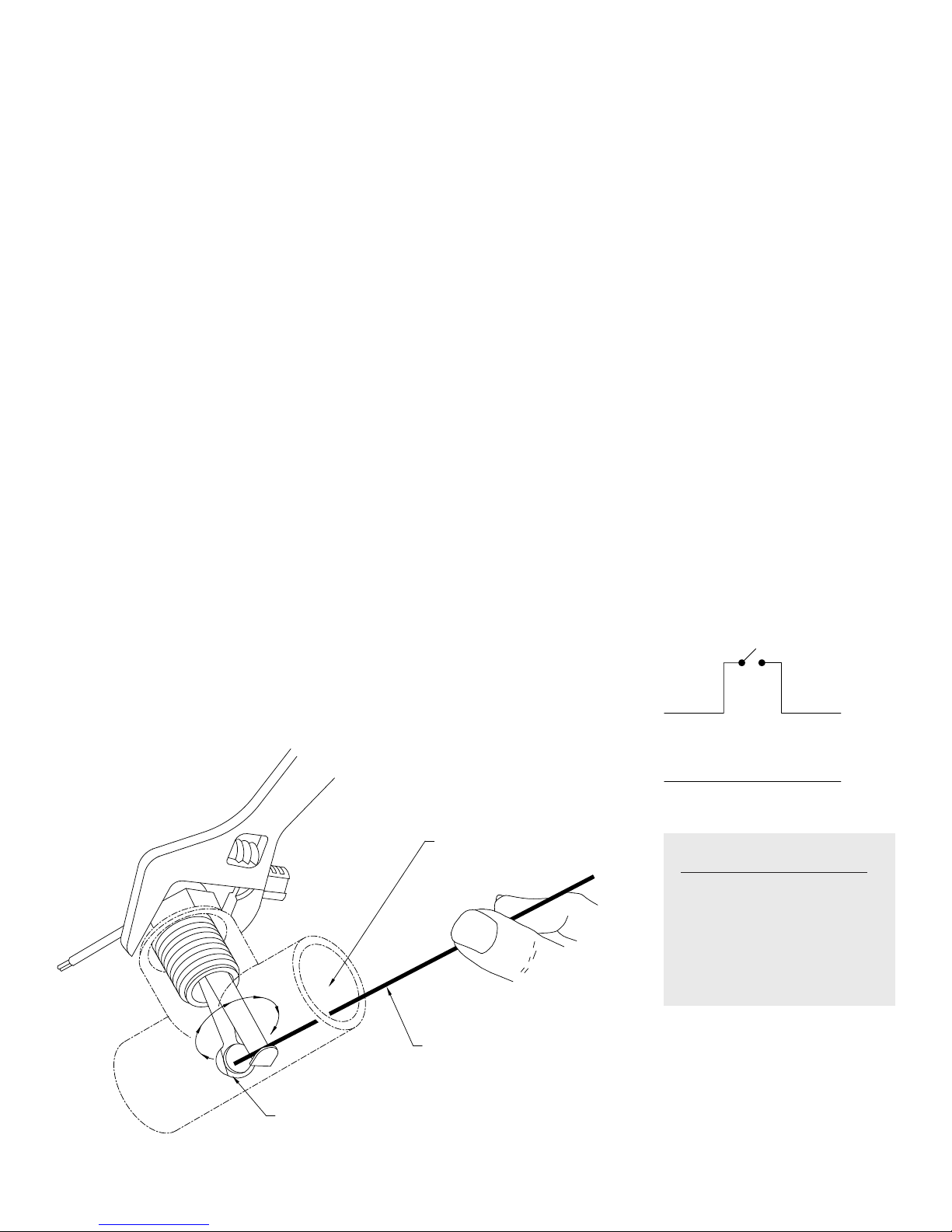

5. Care must be exercised during threading operation to

CAUTION

INSTALLATION

OR REMOVAL

OF FLOW

SWITCH FROM

SMALL TEE

insure threads are not crossed and the bending beam

target assembly does not touch the inside surface of the

tee.

NOTE: It may be necessary to test fit the unit in a tee

identical to the tee mounted in the flow line to ensure

adequate clearance during rotational insertion sequence.

For black iron and galvanized tees, check for possible hang

up of bending beam due to attraction of magnet to interior

metal wall.

6. Tighten unit in tee until fluid leaks are eliminated, flow

target is approximately centered along axis of pipe

and flow direction arrows located on unit are aligned

parallel with flow in pipe. When threading into PVC fittings 2-3 layers of Teflon sealing tape is recommended.

Tighten 2-3 turns beyond finger tight.

7. Complete wiring to signal processor, light, relay, etc.

per local code.

WIRING DIAGRAM

FLOW SWITCH

HOT

FROM POWER

SOURCE

TO LOAD

CORNER OF BLADE MAY HANG UP

WATCH THE BLADE TURNING

Temperature QT-12

A temperature sensor is

included on the QT models.

The wiring is Black-Red for

the switch and Green-White

for the temperature sensor.

USE A ROD OR SUITABLE TOOL

TO FREE ANY HANG UP IF IT OCCURS

ULTRA RELIABLE SINCE 1956P. 2

CERTIFICATE OF CONFORMANCE

All Harwil Corporation (“HARWIL”) products are manufactured using new materials and components.

Our products meet the applicable performance and materials specifications indicated in our current

Specifications Sheets and Parts List. HARWIL endeavors to obtain its materials and components from

American Companies.

DOMINANCE OF HARWIL LIMITED EXPRESS WARRANTY

Each user MUST make appropriate analysis and tests to determine the suitability of the HARWIL product

for the intended use prior to purchase.

HARWIL warrants that all HARWIL products will be free from defects in material and workmanship for a

period of one year from the date of original shipment. This Warranty shall be LIMITED to the replacement

and reconditioning of our products and parts. HARWIL reserves the right and sole discretion to modify

or change the composition, design and appearance of its products at anytime.

THIS WARRANTY SHALL BE IN LIEU OF ALL WARRANTIES OF MERCHANTABILITY AND OF ALL WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE RELATING TO HARWIL PRODUCTS AND PARTS.

BUYER’S SOLE REMEDY SHALL BE REPLACEMENT OR RECONDITIONING AS SET FORTH HEREIN.

HARWIL SHALL INCUR NO OBLIGATIONS HEREUNDER AND NO LIABILITY IN THE EVENT OF (1)

BUYER NOT FULFILLING ITS RESPONSIBILITIES; INCLUDING AS SET FORTH HEREIN; (2) NEGLECT,

ALTERATION OR IMPROPER PRODUCT USE, INCLUDING USE WITH NON-COMPATIBLE DEVICES OR

CHEMICALS; OR (3) REPAIR BY ANOTHER COMPANY OR PERSON THAN HARWIL.

ANY LAWSUIT RELATING TO THIS LIMITED EXPRESS WARRANTY MUST BE COMMENCED WITHIN

ONE YEAR OF THE DATE THE LAWSUIT ACCRUES.

HARWIL provides NO WARRANTY and ASSUMES NO RESPONSIBILITY for corrosive attack on

any material, component or design features associated with any of its products.

Corrosion resistance information listed in HARWIL specification sheets, information sheets and product

brochures is solely for general background information. This information table has been compiled from

literature published by various material suppliers and by equipment manufacturers who use these materials in their products. Inasmuch as these data are based on tests by entities over which HARWIL has no

control, HARWIL DOES NOT GUARANTEE AND DOES NOT ACCEPT ANY RESPONSIBILITY FOR THE

ACCURACY OF SUCH THIRD PARTY TESTING. When using the table, please remember that in any

given case several factors such as concentration, temperature, degrees of agitation and presence of impurities influence the rate of corrosion. The information table is intended, in a general way, to rate materials

for resistance to chemicals which contain their usual impurities and for types of equipment in common

use. Ratings should be used only as a general tool to first approximation of your material requirements

rather than as the final answer.

WHEN IN DOUBT, TEST MATERIALS BEFORE INSTALLATION.

AFTER INSTALLATION, FOLLOW UP WITH SCHEDULED PREVENTATIVE MAINTENANCE AND

PERIODIC INSPECTION.

ULTRA RELIABLE SINCE 1956P. 3 ULTRA RELIABLE SINCE 1956

163 06

Loading...

Loading...