Harwil L-30 Installation And Operating Instruction Manual

MODEL L-30

L-30N, L-30R, L-30CR, VERTICAL L-30NV, L-30CRV

INSTALLATION AND OPERATING INSTRUCTIONS

HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

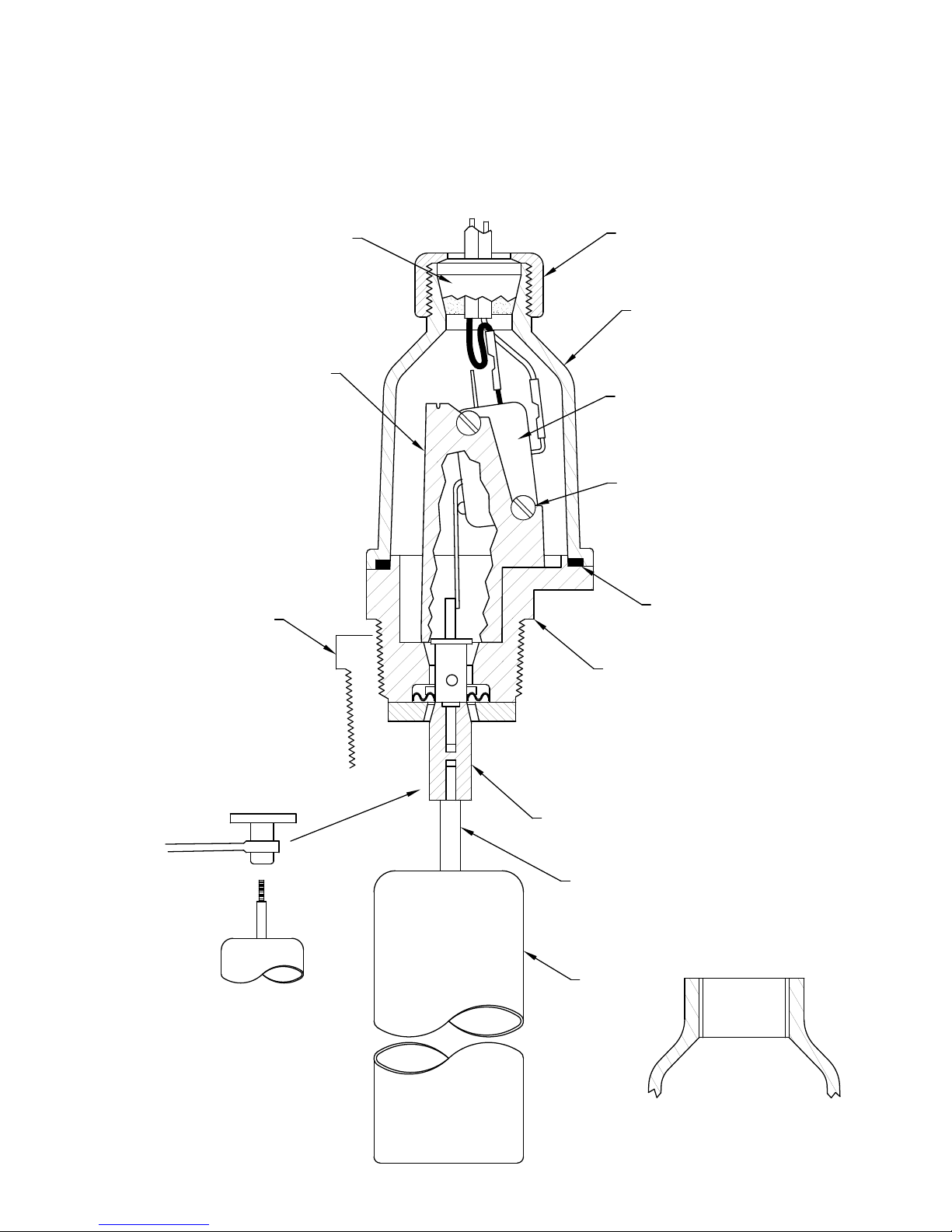

GROMMET ‘A’

GROMMET ‘AA’

GROMMET ‘B’

GROMMET ‘C’

MICROSWITCH BRACKET

1¼” x 1” BUSHING

STRAIN RELIEF NUT

COVER

4 RETAINING SCREWS

(NOT SHOWN)

MICROSWITCH 15A SPDT

WITH 2 SLIP-ON TERMINALS

DRY CIRCUIT SPDT 0.1A 125 VAC

MICROSWITCH

2 SCREWS

2 NUTS

SPLIT LOCKWASHERS

1 PLAIN WASHER

O-RING

BODY COMPLETE WITH

A) SEAL SHAFT

B) DIAPHRAGM

C) DIAPHRAGM WASHER

D) FEED THRU SHAFT

E) PIVOT PIN

F) CAP (SONICALLY WELDED)

NOTE: SEAL SHAFT MUST BE GRIPPED DURING

REMOVAL OR INSERTION OF FLOAT SHAFT.

FAILURE TO GRIP SHAFT SECURELY WILL CAUSE

LEAKAGE OF INTERNAL ELASTOMER SEAL.

GRIPPING FLATS

FLOAT SHAFT

FLOAT SHAFT

EXTENDED LENGTH

FLOAT

‘F’ COVER TO SUIT CUSTOMER

SUPPLIED FITTING FOR ½”

FLEXIBLE CONDIUT

ULTRA RELIABLE SINCE 1956 P. 1

HARWIL CORPORATION

¼”

541 KINETIC DRIVE, OXNARD, CA 93030

MODEL L-30

L-30N, L-30R, L-30CR, VERTICAL L-30NV, L-30CRV

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

INSTALLATION AND OPERATING INSTRUCTIONS

The L-30 liquid level switch is supplied with a 1½” or 1¼” x 1” bushing, threaded in place with 2 to

3 wraps of Teflon tape, which must be intact or renewed if the bushing and switch are separated before assembly in the tank. Care must be taken when threading the bushing into plastic or metal fittings.

Apply a minimum of 2 to a maximum of 3 wraps of Teflon tape to the threads of the bushing–this is

especially important if the unit is to be used in metal fittings where coarse METAL THREADS could gall

plastic if not lubricated. The plastic bushing CAN BE CRACKED if the main body of the flow switch is

tightened into it FIRST. Cracking will not occur if the bushing is FIRST tightened into the pipe or tank fitting and THEN the L-30 body is tightened into the bushing.

Thus:

1. Teflon tape thread and tighten plastic bushing into pipe or tank fitting.

2. Teflon tape thread and tighten L-30 switch into a PLASTIC bushing by applying a wrench to

the hexagonal section. Repeat steps 1 and 2 until the ARROW on the body points UPWARD

and threads are leak tight.

Plumber’s tools, such as pipe wrenches, are not recommended. If possible, use a “rigid” type wrench

where the smooth jaws closely fit the hexagonal section.

ELECTRICAL WIRING

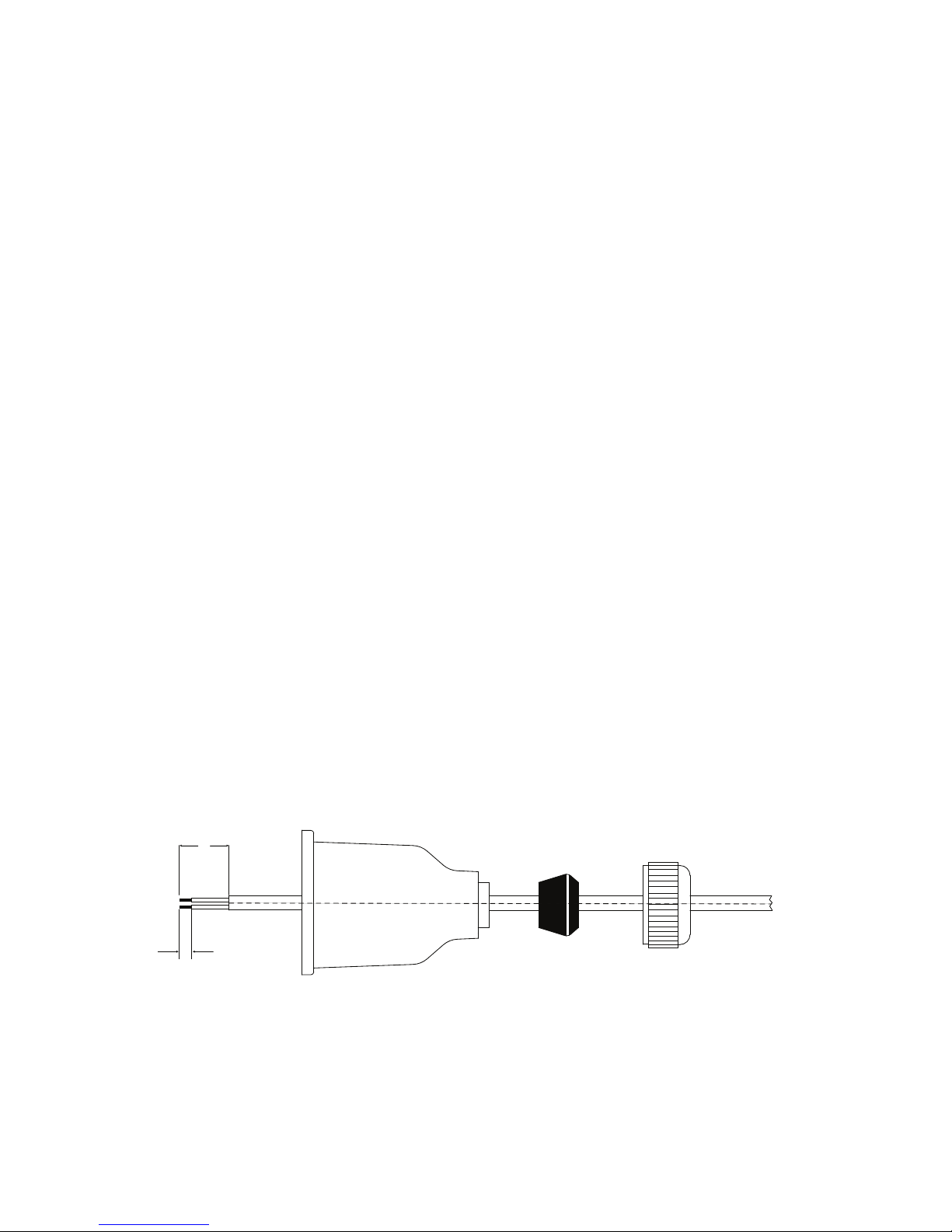

1. Remove the gland nut, grommet, and switch cover.

2. Strip the outer jacket of the electrical cord back approximately 1¼”. Strip the insulation from individual conductors back approximately ¼”.

3. Slip on terminals are supplied with each switch. Remove from switch terminals and crimp on or solder them to the electrical leads.

4. Feed the electrical cable through the gland nut, grommet, and switch cover as shown.

1¼”

5. Apply slip on terminals to appropriate contacts of the microswitch. Slide the cover down the cable

and fasten it to the body of the switch with the four screws provided. Push the grommet into the

tapered end of the cover. Hold the cable jacket to prevent rotation and thread the gland nut firmly

onto the cover.

ULTRA RELIABLE SINCE 1956P. 2

Loading...

Loading...