Harwil L-21 Installation And Operating Instructions Manual

MODEL L-21

INSTALLATION AND OPERATING INSTRUCTIONS

HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

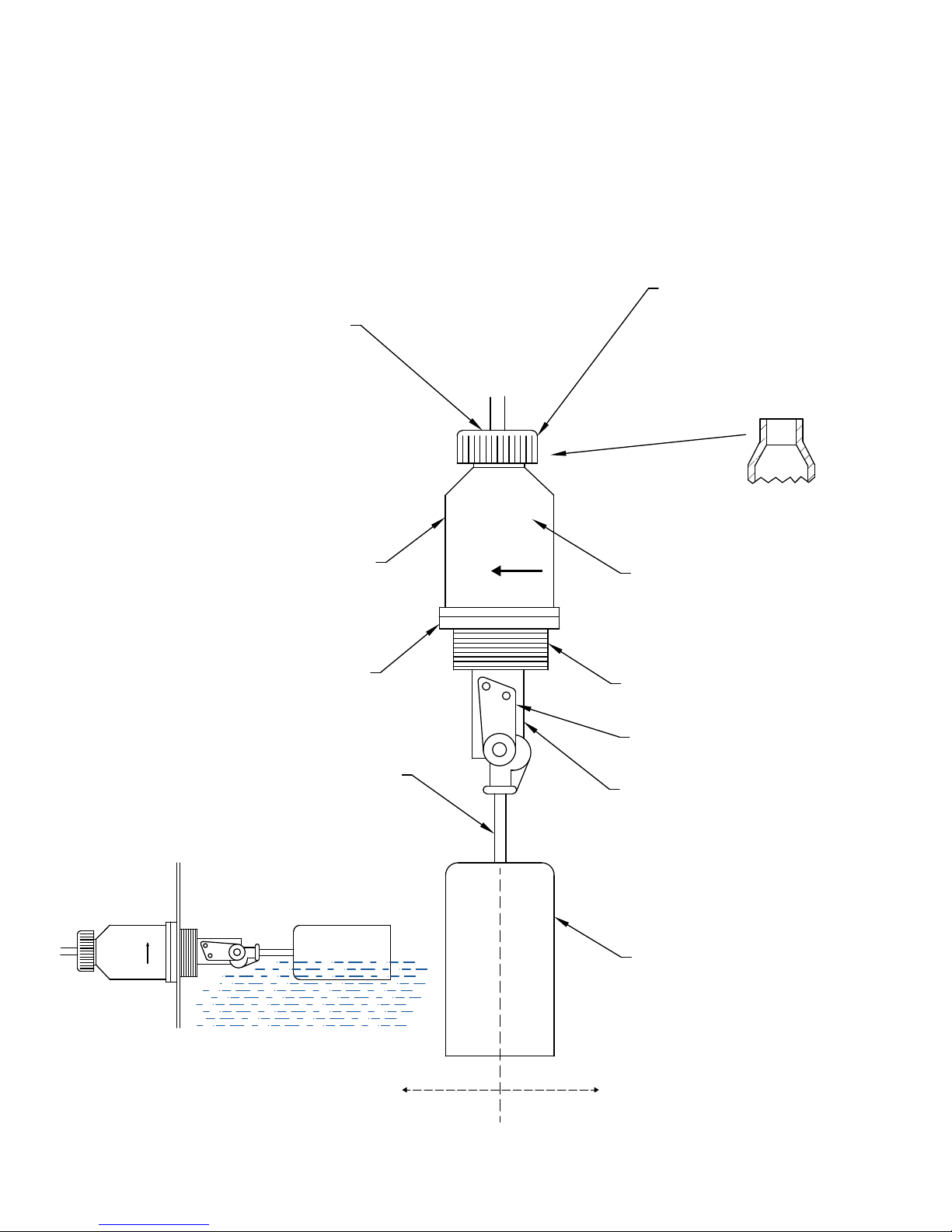

CABLE GROMMET 'A'

CABLE GROMMET 'AA'

CABLE GROMMET 'B'

CABLE GROMMET 'C'

COVER, INCLUDING O-RING

SEAL, RETAINING SCREWS

THREADED BODY COMPLETE,

INCLUDING SWITCH BRACKET

FLOAT SHAFT

FLOAT SHAFT

EXTENDED LENGTH

OR

UP

STRAIN RELIEF NUT

½” INTERNAL THREADS FIT

STANDARD ½” ELECTRICAL

AND PLUMBING FITTINGS

‘F’ COVER

INTERNAL 15A MICROSWITCH

1¼” NPT THREAD

PIVOT SUPPORT

MAGNET HOUSING

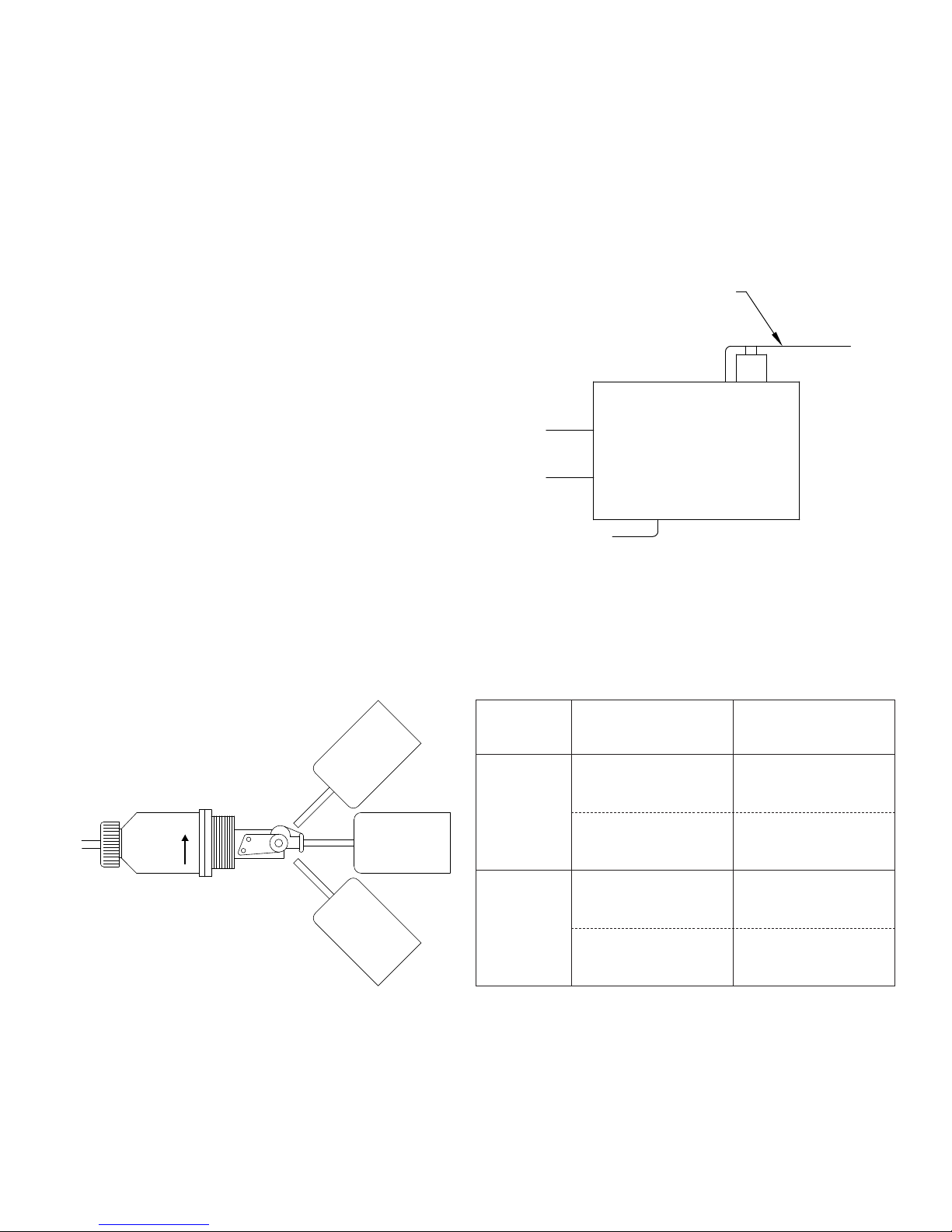

10652-12-1 1.0” DIFF.

10652-12-2 2.0” DIFF.

10652-12-3 3.0” DIFF.

10652-12-5 5.0” DIFF.

UP

FLOAT

FLOAT DOWNFLOAT UP

ULTRA RELIABLE SINCE 1956 P. 1

MODEL L-21

INSTALLATION AND OPERATING INSTRUCTIONS

1. If the shipping container and contents are received damaged, immediately call the shipping

company for damage inspection and file the appropriate report, sending a copy to Harwil Corp.

for product replacement and insurance adjustment.

2. If the contents are not damaged, inspect the units

received against the packing list and the original

purchase order. If incorrect units are received,

call Harwil Corp. immediately for resolution of

the problem.

3. Check for damage or scuffing on the Teflon

tape applied to the 1¼” NPT threads of the

switch body. Re-tape as required with 2 to 3 layers wound clockwise (looking at the end of the

threaded body with the float toward the viewer).

4. Remove the cover and check switch action with a

multimeter while moving the float up and down.

HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

ACTUATION ARM

NORMALLY CLOSED (NC)

NORMALLY OPEN (NO)

COMMON

FLOAT UP/DOWN CONFIGURATION

FLOAT

POSITION

UP

UP

DOWN

5. Replace the domed cover on the unit and insert the float through the 1¼” NPT hole in the tank.

Mate the switch body threads with tank threads and tighten with an appropriate wrench until the

thread joint is leak-tight and the arrow on the cover label is pointing vertically upward.

NOTE: Model L-21 can be supplied with 1½” x 1¼” or larger reducer bushings as required to fit existing

large holes in a tank wall.

6. Remove the cover and wire as indicated on page 3.

MULTIMETER

CONNECTION METER READING

COMM. AND NO

TERMINALS

COMM. AND NC

TERMINALS

COMM. AND NO

TERMINALS

COMM. AND NC

TERMINALS

CONTINUITY

OPEN CIRCUIT

OPEN CIRCUIT

CONTINUITY

ULTRA RELIABLE SINCE 1956P. 2

MODEL L-21

HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

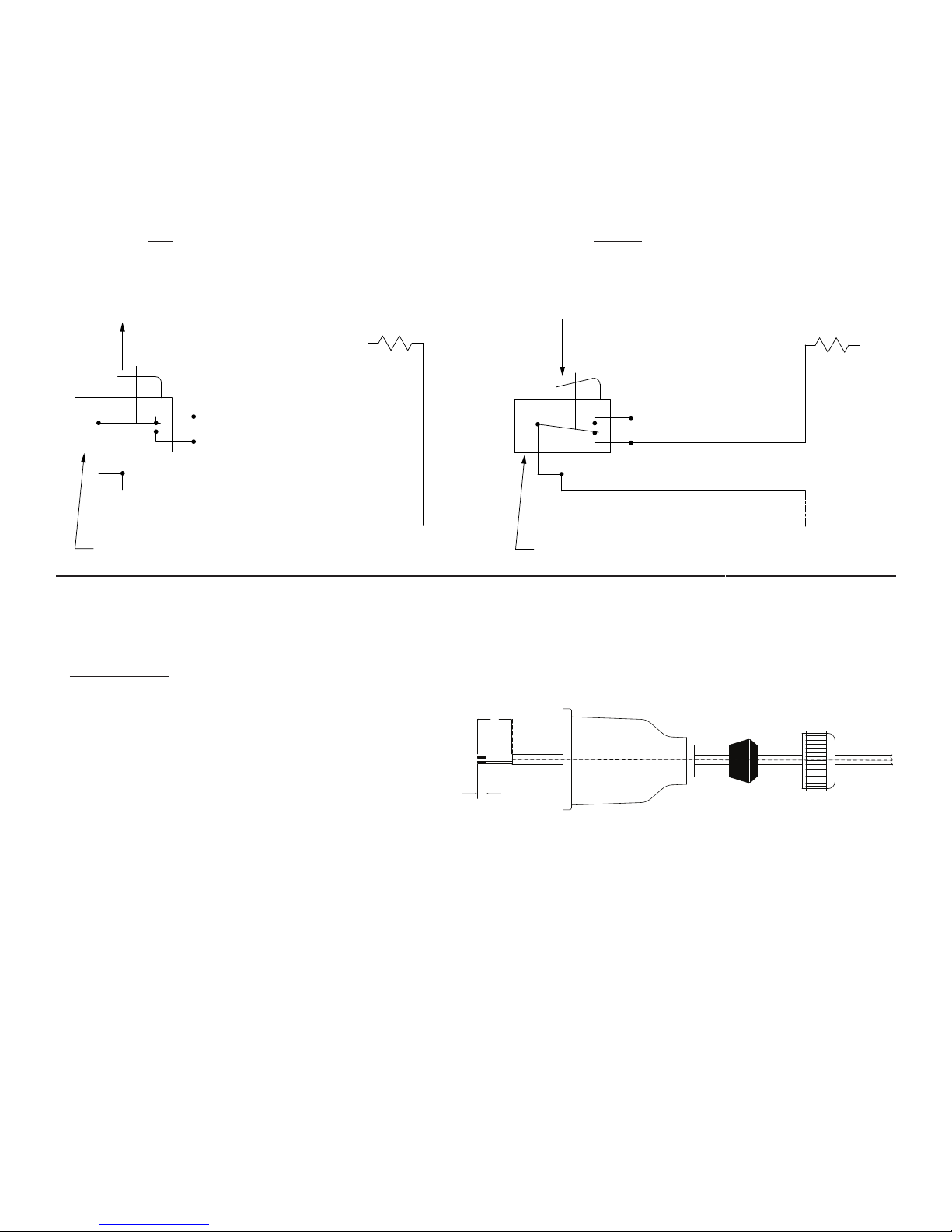

LOW LIQUID LEVEL ALARM

Fig 1: Wiring schematic for power applied to load when

liquid level is less than set point (power to load interrupted

when level increases to above set point).

Decreasing liquid level moves actuator in direction shown.

LOAD

NC

HIGH LIQUID LEVEL ALARM

Fig 2: Wiring schematic for power applied to load when

liquid level is greater than set point (power to load interrupted when level decreases to below set point).

Increasing liquid level moves actuator in direction shown.

LOAD

NC

NO

NO

COM

MICROSWITCH

Microswitch actuation point may be monitored by an audible click or with an ohmmeter before connecting line power to the

switch terminals or by monitoring the voltage supplied to the load through the microswitch.

(HOT)

LINE

COM

MICROSWITCH

(HOT)

LINE

* Pump Up wiring diagram same as low level alarm shown in Fig. 1

* Pump Down wiring diagram same as high level alarm shown in Fig. 2

* Electrical Wiring (Strain Relief Grommet):

Step 1) Remove the gland nut, grommet, and switch cover.

Step 2) Strip the outer jacket of the electrical cord back

approximately 1¼” (inches). Strip insulation from

individual conductors back approximately ¼”

(inch).

Step 3) Slip-on terminals are supplied with each switch.

Remove from switch terminals and crimp on or solder to electrical leads.

Step 4) Feed the electrical cable through the strain relief nut, grommet, and switch cover.

Step 5) Apply slip-on terminals to appropriate contacts of microswitch. Slide cover down the cable and fasten it to the body

of the switch with four (4) screws provided. Slide grommet down the cable and push the grommet into the tapered

end of the cover. Hold the cable jacket to prevent rotation and thread gland nut firmly onto cover.

* Electrical Wiring (‘F’ Cover):

Step 1) Remove switch cover.

Step 2) Strip the outer jacket of the electrical cord back

approximately 1¼” (inches). Strip insulation from individual conductors back approximately ¼” (inch).

Step 3) Slip-on terminals are supplied with each switch. Re-

move from switch terminals and crimp on or solder

to electrical leads.

Step 4) Thread user supplied ½” flexible conduit fitting into

½” female thread on end of cover. Feed electrical

1¼”

¼”

cable through conduit fitting.

Step 5) Apply slip-on terminals to appropriate male spade

contacts on microswitch. Slide cover down cable

and fasten to body of switch with four (4) screws

provided. Be sure to install the “O” ring between

the body and cover. Connect flexible ½” metal or

plastic conduit-to-conduit fitting on end of cover per

standard procedure.

ULTRA RELIABLE SINCE 1956 P. 3

Loading...

Loading...