Harvia harmonia, festia, termia, nostalgia mini, harvia 650 Instructions For Installation And Use Manual

...

16042003W

HARVIA FIREPLACES, FIREPLACE

INSERTS AND IRON STOVES

Instructions for installation and use

EN

Harvia Oy

PL 12

FIN-40951 Muurame

www.harvia.fi

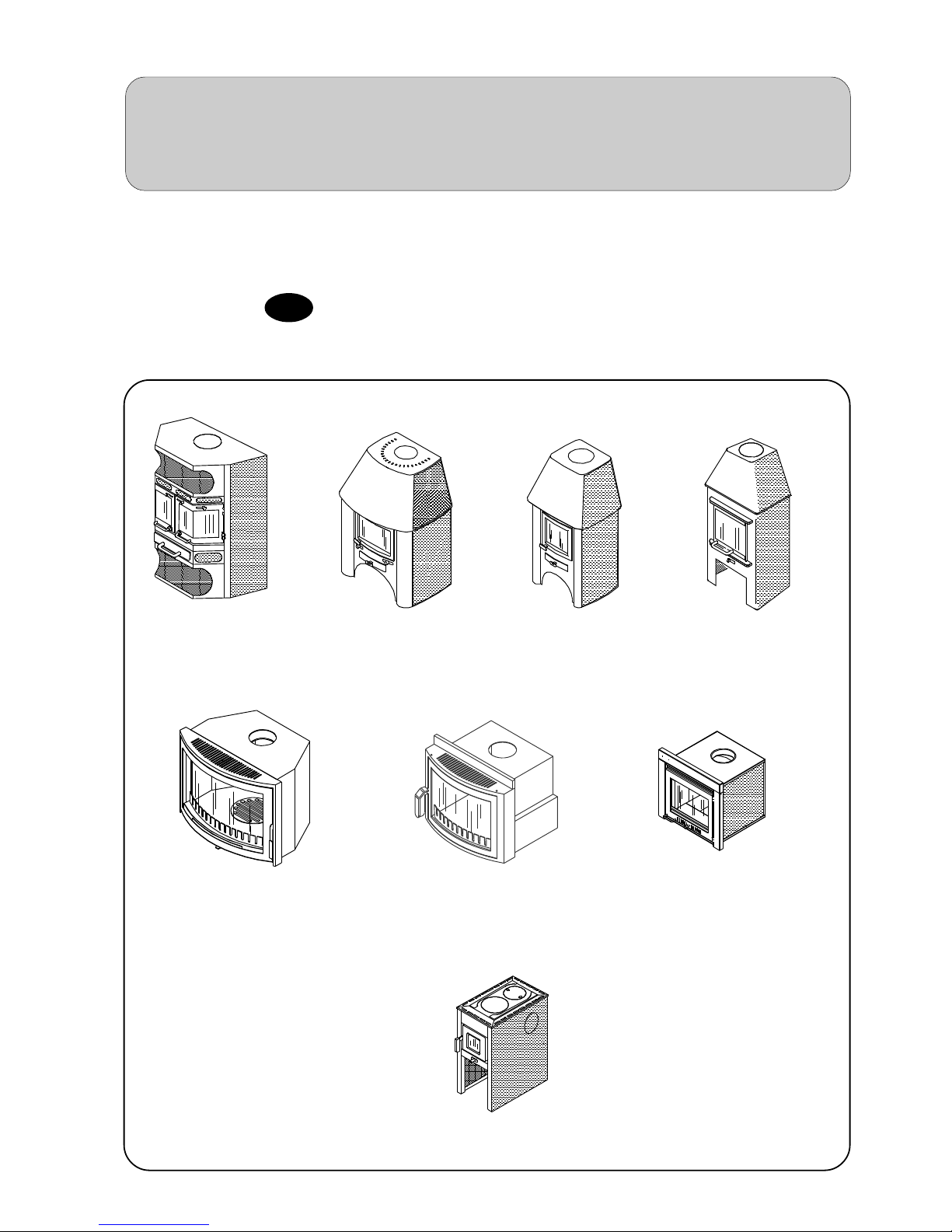

FIREPLACE INSERTS

FIREPLACES

IRON STOVE

HARMONIA

FESTIA

TERMIA

NOSTALGIA MINI

HARVIA 550

HARVIA 400

HARVIA 10

HARVIA 650

3

EN

TABLE OF CONTENTS

Harvia fireplaces and iron stoves.................................... 4

Fireplace structure .................................................. 4

Iron stove structure ................................................ 4

Input of combustion air ............................................ 4

Using Harvia fireplaces and iron stoves ........................... 5

Fuel ...................................................................... 5

Heating .................................................................5

Removing the ash ................................................... 5

Maintenance ..........................................................5

Spare parts............................................................ 5

Installing Harvia fireplaces and iron stoves ....................... 6

Smoke flue ............................................................6

Installation location .................................................6

Moving the flue connecting piece to the top or side ........6

Connection to a masonry flue .................................... 6

Installation of Harvia fireplace inserts .............................7

Lightweight shields and safety distances ......................... 7

Technical data ............................................................ 9

4

EN

Congratulations on a good choice of fireplace and thank

you for your confidence in Harvia’s products. Read

these instructions carefully before using the fireplace

and save them for future reference.

Fireplaces and iron stoves are long-lasting and

reliable heat sources when used correctly. Harvia’s

fireplaces and iron stoves are designed to be safe and

easy to use, while also looking good.

Fireplace structure

To increase safety and comfort of use, all Harvia

fireplaces feature double sheathing. This allows the air

circulating between the heating chamber and the outer

casing to efficiently cool the casing. The fireplace also

recycles and heats the room air.

The big and sturdy doors, fitted with ceramic glass,

increase the safety of the fireplaces and decrease the

intensity of the fire. The warm glow of fire through the

glass adds to the atmosphere. Combustion can be

controlled with the draught adjustment outlets and the

doors prevent sparks from flying into the room.

The frame and outer casing of the fireplaces are

made of steel plate painted with heat-resistant paint.

Depending on the model, the heating chamber is made

of either cast iron or strong steel plate protected by

heat-resistant ceramic brick.

All Harvia fireplaces feature a specially designed

heating chamber in which the fire can burn over a wide

surface, distributing heat evenly to the inner parts of

the fireplace. Thanks to the design of the flue bridge

and the top part of the heating chamber, the

combustion gases are efficiently conducted into the

smoke flue. The front part of the chamber has been

designed to prevent the embers from sliding against the

doors and to direct the air needed for combustion

straight into the embers.

All Harvia fireplaces equipped with a cast iron grate

have a big cinder box, which makes it easy to remove

excess cinder from the heating chamber.

Iron stove structure

The air circulating between the heating chamber and

the outer casing efficiently heats the room.

The sturdy and extremely tight cast iron doors are

equipped with a vertical latching device.

The iron stoves have a frame of steel board and an

outer casing of painted steel. The heating chamber is

made of either cast iron protected by firebrick at the

bottom.

The extended flame channel in the top part of the

heating chamber contributes to the efficiency of the

hot plates in the iron stoves and makes the stoves

excellent for heating room air.

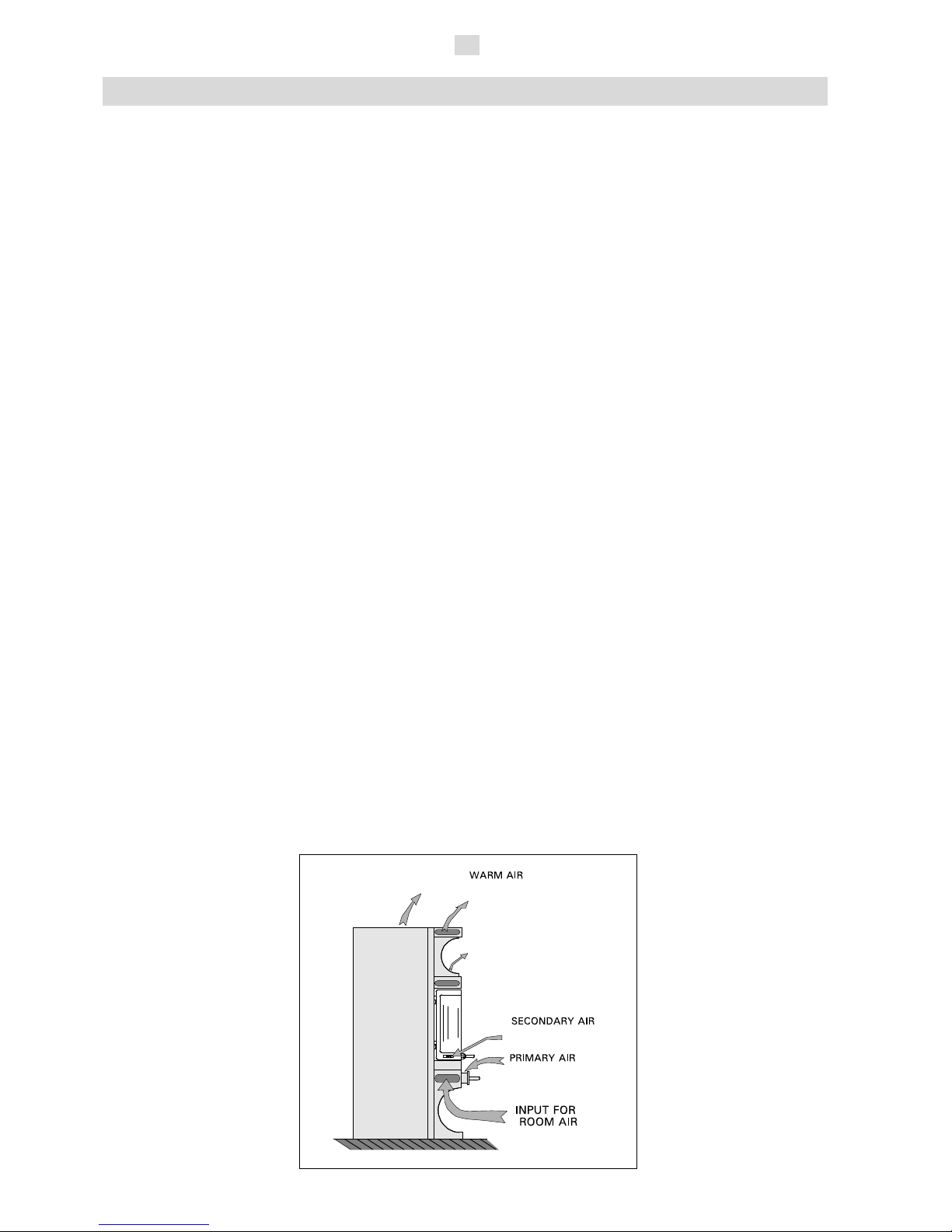

Input of combustion air

In theory, a kilogram of wood needs some 3.7 m3 of air

for burning. In practice, however, the air coefficient

used for fireplaces with doors is 2–2.5 - that is, the

amount of air used per kilogram of wood is 7.5–10 m3.

The air coefficient of open fireplaces is 10–30, which

translates to 40–110 m 3 of air per kilogram of wood.

Combustion air is divided into two parts: primary air

and secondary air. Primary air is conveyed into the

lower part of the heating chamber either from

underneath the chamber or from the front. Secondary

air is conducted into the top part of the chamber to

ensure that all the gases are fully burned out.

In the Harvia fireplaces equipped with a grate, the

primary air is conducted into the chamber under the

grate and through the cinder box. In the models without

grates, the primary air is conducted through a channel

into the front part of the chamber, which is designed to

direct the air into the embers.

The amount of primary air needed for burning can be

adjusted by pulling the cinder box a maximum of 3 cm

outwards. Air outlets in or under the doors are used to

control the primary air in fireplaces and iron stoves

without grates.

The secondary air is conveyed into the heating

chamber through adjustable air outlets in the doors or

right under them. The secondary air cannot be

separately adjusted in iron stoves.

Harvia fireplaces and iron stoves

Loading...

Loading...