HARVEY Hydroclave MC8, Hydroclave MC10 Owner's And Operator's Manual

BARNSTEAD THERMOLYNE CORPORATION

®

Harvey

Hydroclave MC8

Hydroclave MC10

Steam Sterilizer

(With Optional Non-Recirculating System)

OWNER AND OPERATOR MANUAL

1

Table of Contents

Introduction ........................................................................................................................................................ 4

Operation Overview ..................................................................................................................................... 4

Hydroclave MC8 and MC10 Steam Sterilizer ........................................................................................4

Drying Cycle .......................................................................................................................................... 6

Operator Maintenance ................................................................................................................................. 6

Daily ...................................................................................................................................................... 6

Weekly .................................................................................................................................................. 7

Safety Information .............................................................................................................................................. 8

Declaration of Conformity ............................................................................................................................ 8

Description of Symbols on the Equipment ................................................................................................... 9

General Description ......................................................................................................................................... 11

Intended Use ............................................................................................................................................. 11

General Usage .......................................................................................................................................... 11

Operating Features .................................................................................................................................... 11

Printer ........................................................................................................................................................ 14

Non-Recirculating Water Accessory .......................................................................................................... 14

Recommended Steam Sterilization Monitoring Program ........................................................................... 14

Operation ......................................................................................................................................................... 16

Power On/Controls On .............................................................................................................................. 17

Filling Reservoir ......................................................................................................................................... 18

Filling Non-Recirculating Tank (Option) ..................................................................................................... 19

Emptying Collection Bottle ......................................................................................................................... 19

Installing Overflow Tube (Optional) ........................................................................................................... 20

Load Chart ................................................................................................................................................. 20

Preparing Items for Sterilization ................................................................................................................ 22

Loading ...................................................................................................................................................... 22

Selecting Cycle .......................................................................................................................................... 23

Starting Cycle ............................................................................................................................................ 24

Drying Phase ............................................................................................................................................. 24

Open Door Drying ...................................................................................................................................... 25

Removing Load ........................................................................................................................................ .26

Additional Information ...................................................................................................................................... 27

Cancel Cycle ............................................................................................................................................. 27

Emergency Power Off................................................................................................................................ 27

Power Failure During Cycle ....................................................................................................................... 27

Diagnostic Messages ....................................................................................................................................... 28

Troubleshooting ............................................................................................................................................... 29

Printer............................................................................................................................................................... 30

Installation ................................................................................................................................................. 30

MC8 ..................................................................................................................................................... 30

MC10 ................................................................................................................................................... 30

Operation ................................................................................................................................................... 30

Paper Roll Replacement ............................................................................................................................ 31

Ribbon Replacement ................................................................................................................................. 31

Printer Removal (MC10) ............................................................................................................................ 32

Operator Maintenance ..................................................................................................................................... 33

Daily ........................................................................................................................................................... 33

2

TABLE OF CONTENTS

Cleaning Door Gasket ......................................................................................................................... 33

Weekly ....................................................................................................................................................... 33

Cleaning Chamber, Trays and Rack ................................................................................................... 33

Cleaning and Disinfecting Exterior Surfaces ....................................................................................... 34

Every 25 Cycles ......................................................................................................................................... 34

Cleaning Reservoir .............................................................................................................................. 34

Draining Reservoir .............................................................................................................................. 34

Cleaning Reservoir Filter ..................................................................................................................... 35

Cleaning Chamber Filter Screen ......................................................................................................... 36

When Required .......................................................................................................................................... 37

Emptying Non-Recirculating Collection Bottle ..................................................................................... 37

Cleaning Printer Recess (MC10) ........................................................................................................ 37

Replacing Door Gasket ....................................................................................................................... 37

Every 6 Months .......................................................................................................................................... 38

Cleaning Non-Recirculating Water Cooling Tank ................................................................................ 39

Recommended Spare Parts ............................................................................................................................. 40

Installation ........................................................................................................................................................ 41

Leveling Sterilizer Cabinet/Clearance/Electrical Connection .....................................................................41

Non-Recirculating Water Accessory Installation ........................................................................................ 42

Setting the Clock/Calendar ........................................................................................................................ 43

Technical Data .................................................................................................................................................. 48

Appendix .......................................................................................................................................................... 49

Voltage Conversion (Dual Voltage Models Only) ....................................................................................... 49

115 VAC to 230 VAC.................................................................................................................................. 50

Parts Required .................................................................................................................................... 50

230 VAC to 115 VAC.................................................................................................................................. 53

Parts Required .................................................................................................................................... 53

Two-Year Limited Warranty .............................................................................................................................. 56

3

Introduction

As leaders in the field of sterilization, our goal is

to engineer and manufacture safe, efficient,

quality sterilization products. We are certain you

will agree that this sterilizer meets our goal.

Regardless of how well a piece of equipment is

designed, misuse, abuse, or neglect will deny its

owner the safe, efficient, quality service

expected. Often, misuse, abuse or neglect occurs

unintentionally because the operator is unaware

of the proper operating and maintenance

procedures. This manual provides you with the

information required to properly operate and

routinely maintain your sterilizer. The information

included in this manual applies to all models

unless noted for specific models.

We urge you to read this manual carefully before

operating the unit, and retain it for future

reference.

Operation Overview

Hydroclave MC8 and MC10

Steam Sterilizer

The MC8 and MC10 sterilizer operates on the

principle of heated water converted to steam in a

sealed pressure chamber.

What happens when the controls are turned

on?

• The chamber vent valve opens and the

heater turns on to warm up the chamber.

The items to be sterilized are placed on

4

INTRODUCTION

the trays and the trays are placed

inside the sterilizer chamber. (Certain

parameters such as positioning and

size of the load must be observed for

proper operation and satisfactory

result.) Then, the door is closed and

latched, and the “START” button

pressed to start the cycle.

What happens when the cycle starts?

• The water fill valve opens and the

proper amount of water automatically

flows from the reservoir into the

chamber.

• The water in the chamber begins to

heat. As the water turns to steam, the

temperature and pressure increase,

forcing air from the chamber.

• When the temperature in the chamber

reaches the proper temperature (121

or 135°C) the exposure timer begins.

During this exposure time, the

temperature in the chamber is

automatically maintained at either 121

or 135°C, plus or minus about two

degrees.

• At the completion of the exposure time

a solenoid valve opens, allowing the

steam and water to vent back into the

reservoir. The steam reenters the

5

INTRODUCTION

reservoir through tubing below the water

level in the reservoir. The water in the

reservoir condenses the steam to a

liquid for reuse in the next cycle.

When the one minute timed vent is

complete an indicator light on the control

panel lights to alert the operator that the

cycle is complete.

Drying cycle

At the completion of the sterilization cycle, the

drying cycle automatically begins. This cycle

continues until the selected time has elapsed or

the door is opened.

To restart a drying cycle that has been terminated

by opening the door; close the door (DO NOT

LATCH) and press the “START” button.

Operator Maintenance

It is important to establish the maintenance

schedule called for in the Operator Maintenance

section of this manual.

Daily

Before each days use: Check the water level in

the reservoir. Refill with distilled or deionized

water if needed. Clean the door gasket and its

mating surface.

6

INTRODUCTION

Weekly

Clean the chamber, rack and trays once a week

to prevent a buildup of mineral deposits inside

the chamber. Normal tap water contains

chemicals and minerals, chlorine being the

most common. Chlorine is especially corrosive

to the stainless steel chamber, trays and rack

when water is turned to steam during the

sterilization process. It is important to remove

any mineral deposits regularly to ensure peak

operating efficiency.

Distilled or deionized water should always be

used in the MC8 and MC10 steam sterilizer.

Even when distilled or deionized water is used,

some contaminants can collect in the chamber,

rack and trays.

Clean the reservoir, reservoir filter and chamber

screen at least every 25 cycles. A clogged filter

and/or screen will result in restricted water flow

and prolong the time it takes to fill the chamber.

Maintaining a clean reservoir, filter and

chamber screen is especially important. Foreign

particles, such as bits of oil, adhesives,

amalgam, etc., can be picked up from items

being sterilized and returned to the reservoir,

clogging the filter and screen.

The daily and weekly maintenance should be

performed as outlined above to ensure long,

trouble-free service. Failure to routinely perform

maintenance procedures could result in

processing delays or equipment down time and

possible equipment repairs.

Detailed maintenance procedures for those

listed above and also other “as required” items

are shown in the Operator Maintenance

section of this manual.

7

Safety Information

Alert Signals

Warning

Warnings alert you to a

possibility of personal injury.

Caution

Cautions alert you to possibility

of damage to the equipment.

Note

Notes alert you to pertinent

facts and conditions.

Hot Surface

Hot Surfaces alert you to a

possibility of personal injury if

you come in contact with a

surface during use or for a

period of time after use.

The special safety information instructions that

follow appear within the manual. Read them

carefully before operating the unit and follow

instructions.

Declaration of Conformity

Barnstead/Thermolyne hereby declares under its

sole responsibility that this product conforms with

the technical requirements of the following

standards (applies to -33 model(s) only):

EMC: EN 55011 Emission Standard

EN 60801 Immunity Standard

Safety: EN 60601 Medical Electrical

IEC 601-1 Equipment; Part 1:

General

Requirements for

Safety

per the provisions of the Electromagnetic

Compatibility Directive 89/336/EEC, as amended

by 92/31/EEC, and per the provisions of the Low

Voltage Directive 73/23/EEC, as amended by 93/

68/EEC.

8

Copies of the Declaration of Conformity are

available upon request.

SAFETY INFORMATION

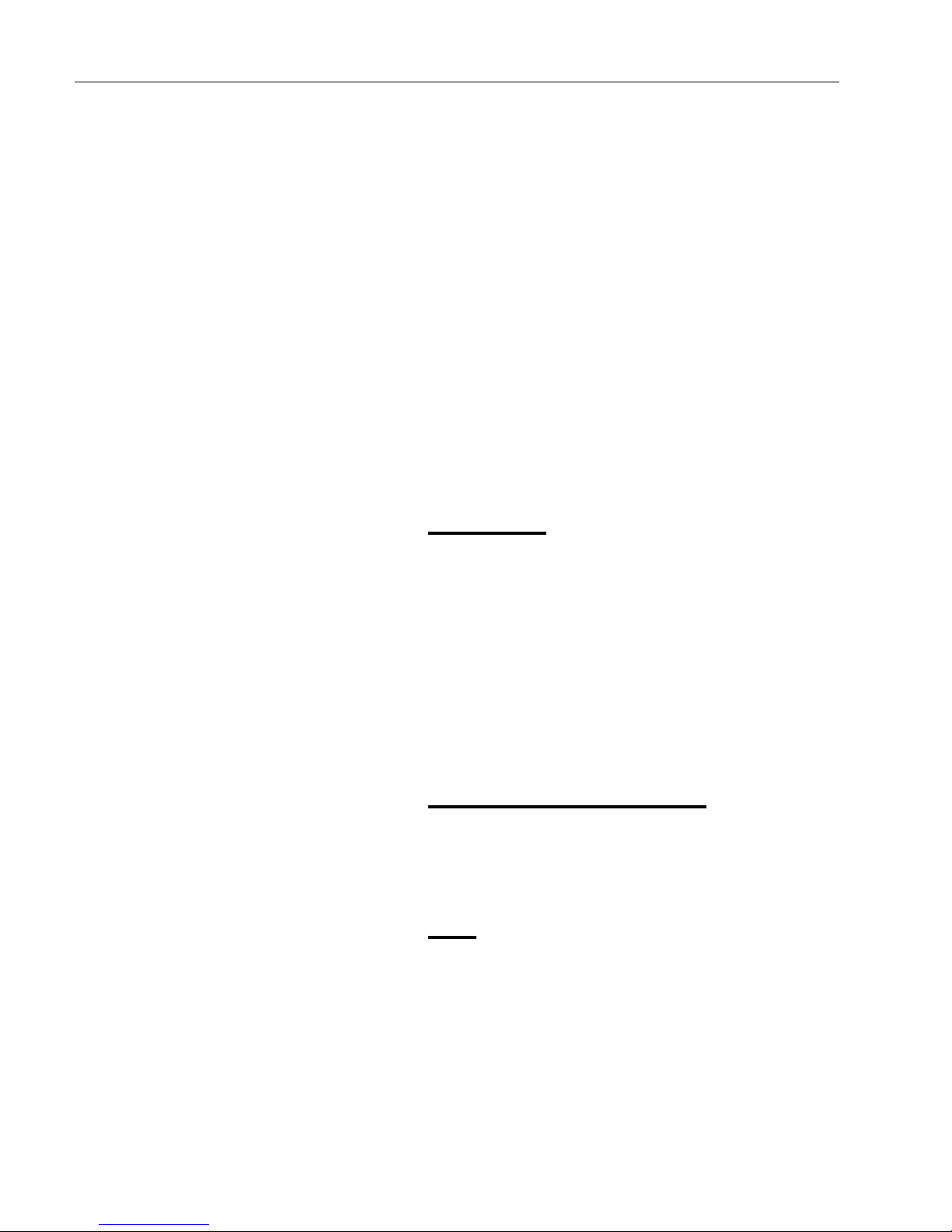

Description of Symbols on the

Equipment

Hot Surface

Printer Receptacle

Fuse Type and Rating

Attention: Consult Accompanying Documents

(Refer to Warning and Caution notes in this

manual.)

Type B Equipment, Class I

(Refer to IEC Standard 601-1.)

OFF (Only for a part of equipment.)*

ON (Only for a part of equipment.)*

Paper Feed

* Does not disconnect equipment from mains voltage (AC

power)

9

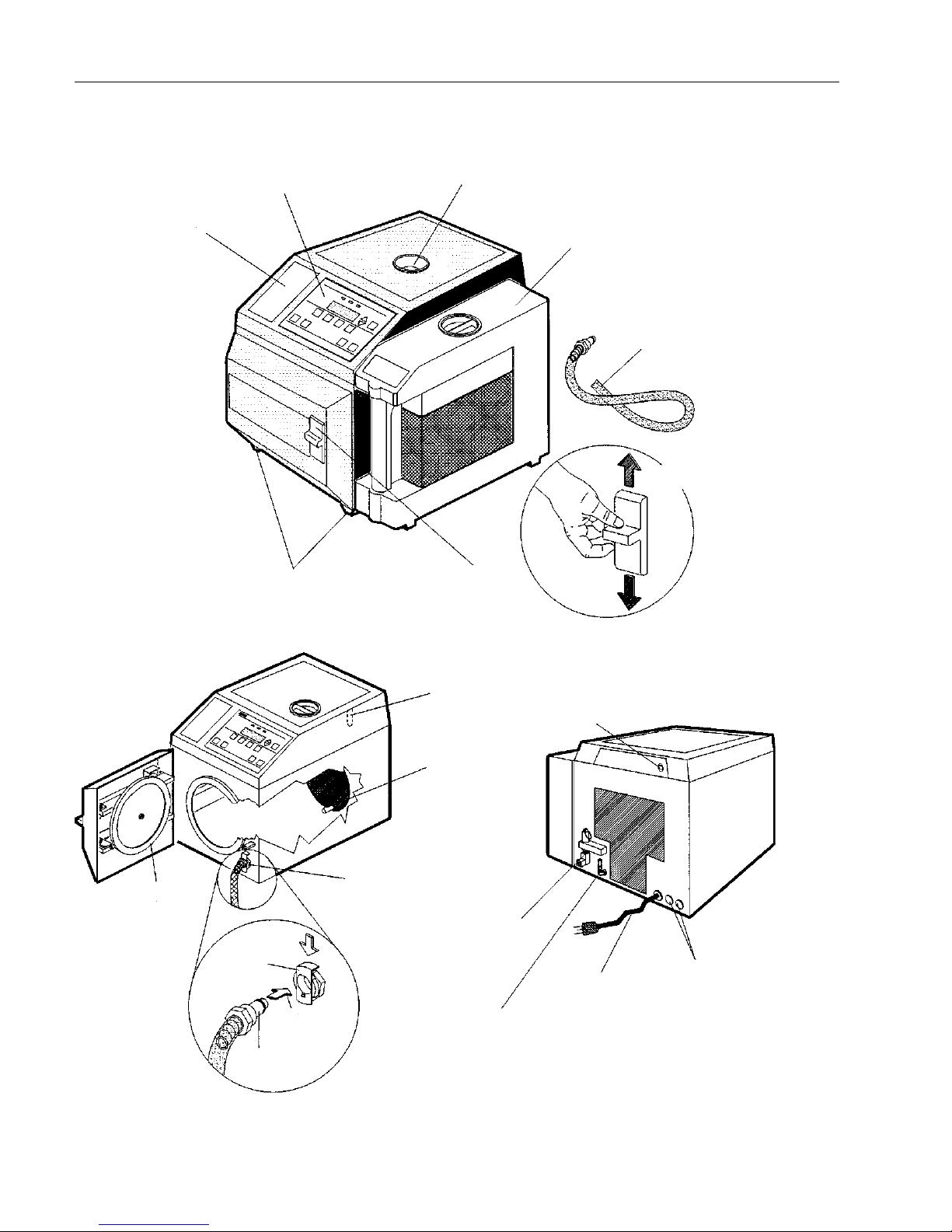

MC10

Printer

(Optional)

Control Panel

Reservoir

Fill Funnel

Non-Recirculating

Water Accessory

(Optional)

Drain

Tube

Open

Door

Gasket

Release

Tab

Drain

Fitting

Leveling

Feet

Push To

Release

Click In

To Drain

Reservoir

Drain Valve

Locking

Handle

Reservoir

Filter

Screen

Water Fill

Port &

Chamber

Filter Screen

Pressure

Relief

Valve

Discharge Port

Non-Recirculating

Lock

Printer

Receptacle

(MC8)

Fuses

Power Cord

Hydroclave MC8/MC10 Sterilizer Overview

10

General Description

Intended Use

The Hydroclave MC8 and MC10 Sterilizers

have been designed for use in medical and

dental offices, hospitals, clinics, laboratories

and other facilities where a variety of materials

require processing.

This steam sterilizer can be used for wrapped

or unwrapped instruments, linen packs, and

liquids. Glassware may be processed using the

liquids cycle.

Warning

Volatile Reaction: Do not use

this sterilizer for processing

volatile substances or for any

purpose other than its intended

design. Failure to heed this

warning could cause personal

injury to personnel or damage to

equipment.

General Usage

Do not use this product for anything other than

its intended use.

Operating Features

• Four preset sterilizing cycles—

unwrapped instruments, wrapped

instruments, packs and liquids.

Exposure and drying times are

adjustable.

• Automatic closed door drying and

optional open door drying (except for

liquid cycle). Drying times are

adjustable.

• Cycle runs automatically when START

switch is pressed.

• Optional printer records temperature

and pressure during cycle.

• Chamber temperature may be

displayed in °C or °F.

• Chamber temperature is displayed

continuously throughout cycle

(excluding dry phase) and may be

displayed in psi, kPa or bars.

11

GENERAL DESCRIPTION

Note

Refer to Service Manual for

setup of temperature unit, pressure units, language, and clock

format.

• Messages may be displayed in English,

French, Spanish or German.

• Clock format may be 12-hour or 24-hour.

• Non-recirculating discharge of steam is

available as an option. This option may

be installed in the field by a service

technician or purchased and installed by

the owner/operator.

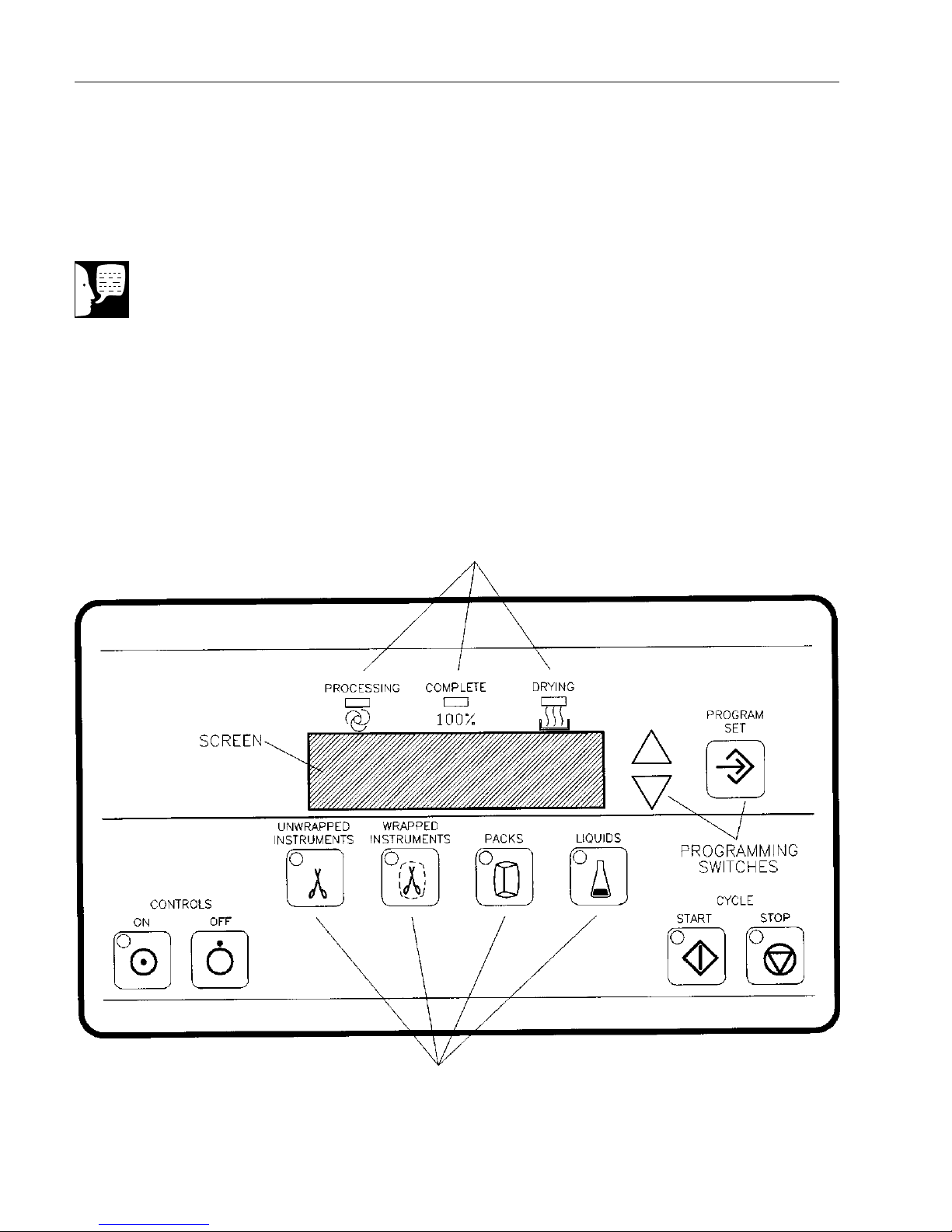

Cycle Phase Indicators

Harvey

Hydroclave MC8

Figure 1

Control Panel

12

Cycle Select Switches

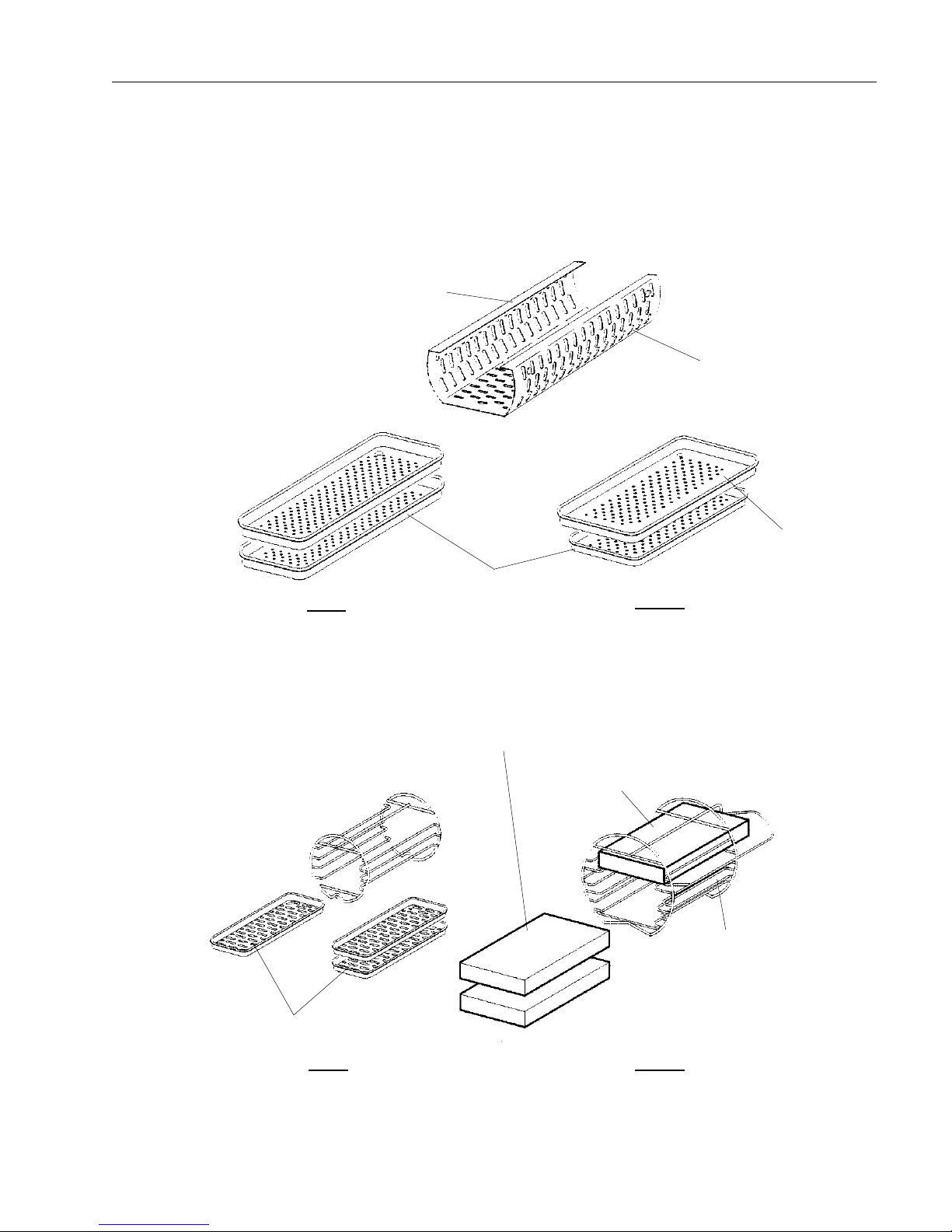

MC8

Support

Flange

Small Tray

(Part No. 265001)

GENERAL DESCRIPTION

Tray Rack

(MC8 - Part No. 265002)

(MC10 - Part No. 2-513025)

Large Tray

(Part No. 2-57811)

MC10

Figure 2

Standard Accessories

(MC8 - Part No. 265024)

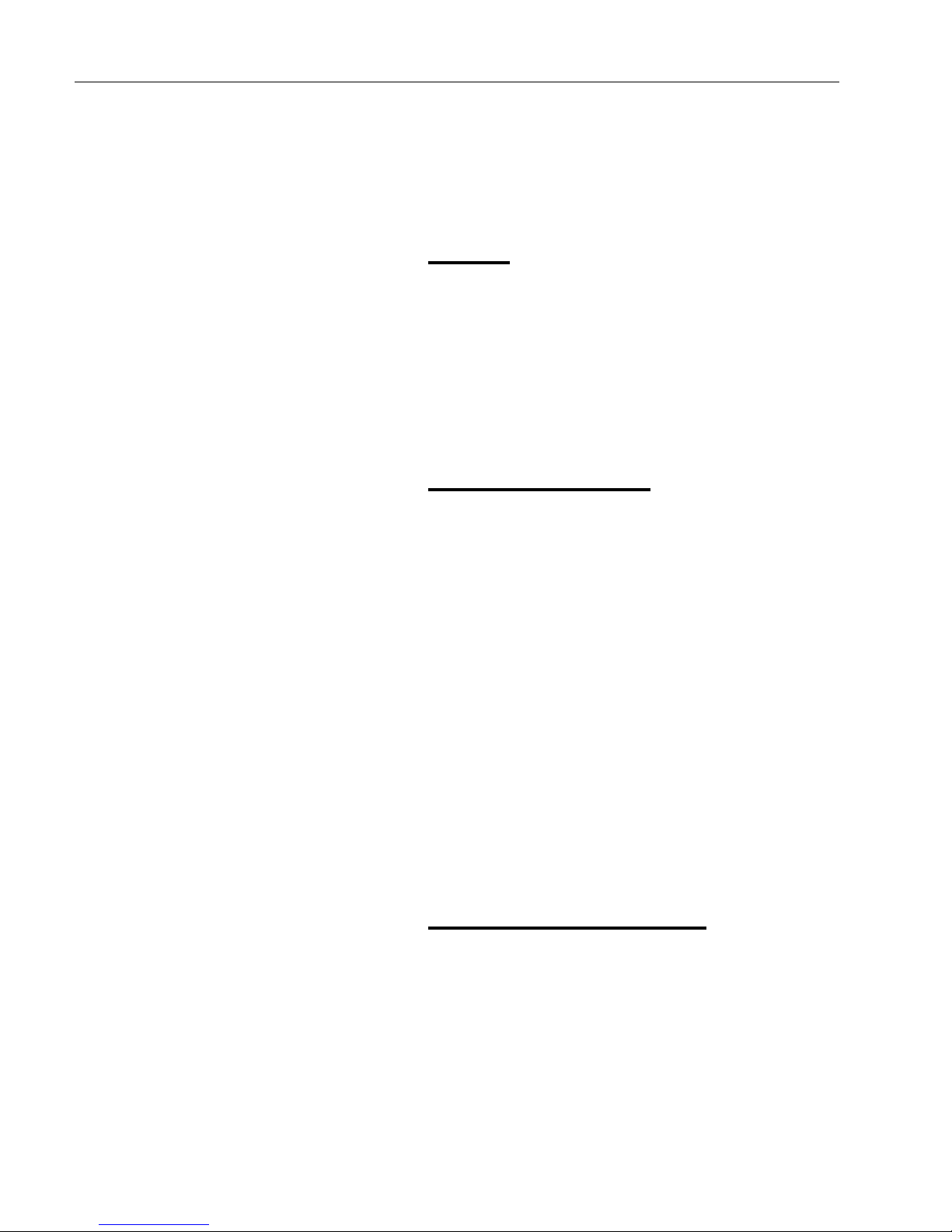

IMS Cassette

Four

Tray Rack

Trays

(Not Sold By B/T)

Wrapped

Cassette

MC8 MC10

IMS

Cassette Rack (Holds

MC10 - Part No. 260761)

Figure 3

Optional Accessories

13

GENERAL DESCRIPTION

Figure 4

MC8 Printer

MC8

Printer

Printer

The MC8 printer is a separate unit connected to

the sterilizer by a plug-in cable. The optional

MC10 printer is an integral part of the Control

Panel.

Non-Recirculating

Water Accessory

Standard MC8 and MC10 sterilizers discharge

steam back into the reservoir. For sterilizers with

the non-recirculating system, the distilled water is

used to make steam in the chamber for one cycle

only. Used water (steam) is exhausted into the

cooling tank which then overflows into the

collection bottle. The collection bottle is then

emptied when full.

Waste Water

Optional

Overflow

Drain

From

Sterilizer

Figure 5

Non-Recirculating Water Accessory

14

Cooling

Ta nk

Collection

Bottle

An optional overflow tube is provided for

connection to the back of the cooling tank. This

feature allows the excess water to drain directly

into a sink or drain (if available), eliminating the

need to periodically empty the collection bottle.

Recommended Steam

Sterilization Monitoring Program

All functions of the sterilizer should be monitored

to provide maximum sterilization assurance.

The Joint Commission on Accreditation of

Hospitals and the American Dental Association

recommends that biological indicators be used at

least weekly to check the effectiveness of steam

GENERAL DESCRIPTION

sterilizers to sterilize; i.e., to kill test organisms

of a known high resistance. (Bacillus

stearothermophilus is the recommended test

organism for monitoring steam sterilization.)

We recommend the use of process indicators

such as the B T Check Indicator within each

package of each cycle. For additional

assurance that minimum sterilizing conditions

have been achieved, a biological indicator such

as B T Sure should be used at least once a

week.

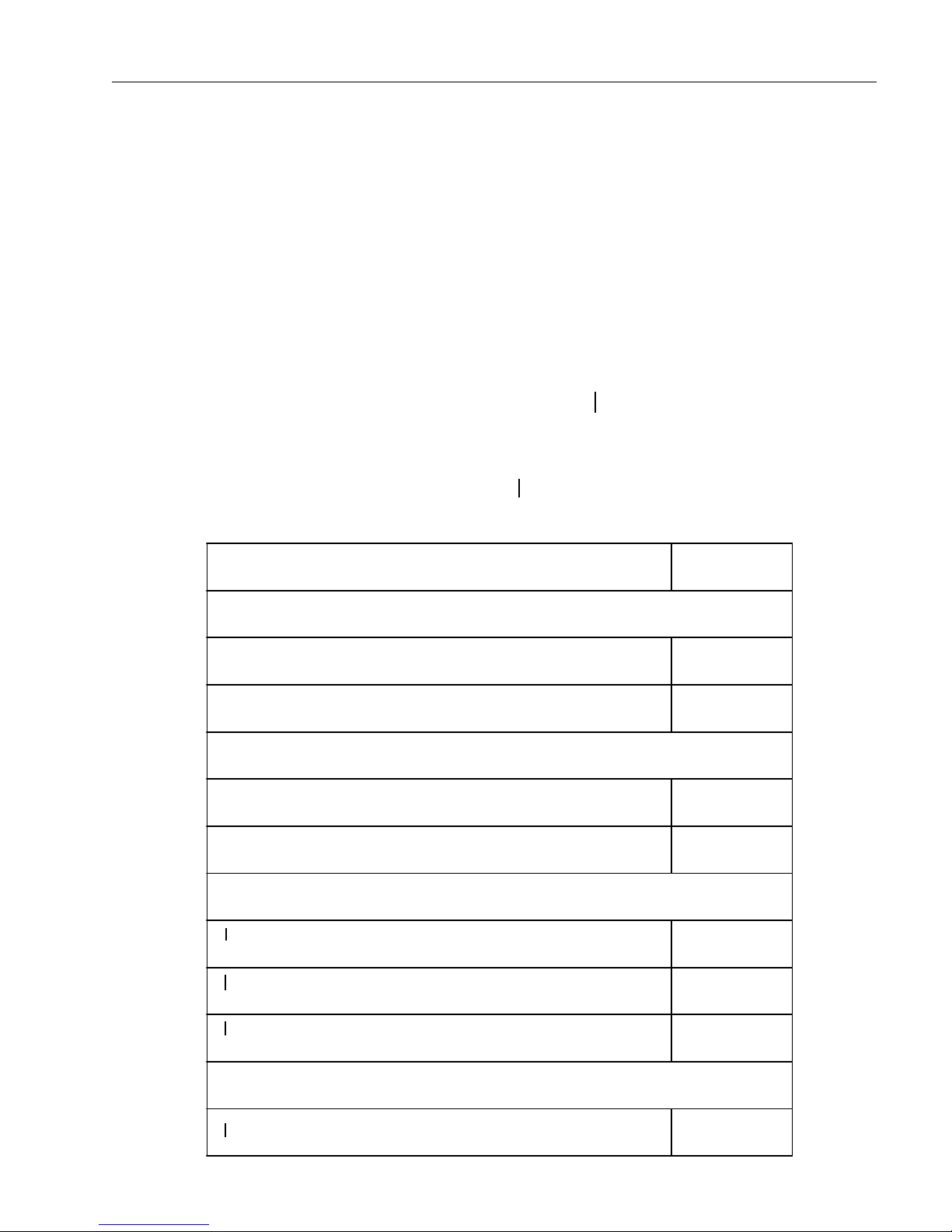

noitpircseD rebmuNtraP

sgaBgnilaeS-fleStsetimehC

)xobrep051("2/1-51x"2x"5:eziSyarT 100003032

)xobrep052("2/1-01x"2/1-1x"2/1-2:eziStnemurtsnI 100103032

sehcuoProtacidnIurhT-eeStsetimehC

)xobrep051("2/1-51x"5:eziSyarT 100203032

)xobrep052("21x"3:eziStnemurtsnI 100303032

srotacidnIlacigoloiB

5

01noitalupoPeropS

5

01noitalupoPeropS

)slaivrotacidnI5foxoB(rotacidnIlacigoloiBeruSTB

)slaivrotacidnI001foxoB(rotacidnIlacigoloiBeruSTB

1X957YA

3X957YA

6

01noitalupoPeropS

srotacidnIssecorP

rotacidnIlacimehCeruSTB 2X957YA

)slaivrotacidnI001foxoB(rotacidnIlacigoloiBeruSTB

8X957YA

15

Operation

1. Press Controls ON.

Warning

Patient Safety Zone: Do not

operate this sterilizer within 6 ft.

(2 m) of patient treatment point.

2. Fill Reservoir.

3. Load Chamber.

4. Lock Door.

5. Select Cycle.

6. Press START.

7. Open Door to Dry.*

8. Remove Load.

* Optional—Drying phase, if selected, will start

automatically without opening the door. Opening the door,

however, may improve drying efficiency.

Operation

16

Power On/Controls On

OPERATION

Note

If time and date are incorrect,

reset the clock/calendar.

1. When the sterilizer is plugged in and

the controls are off, the time and date

will be displayed.

2. Press Controls ON switch to turn on

the control panel. The cycle

temperature, exposure time and drying

time will be displayed and the Standby

Mode will begin. During the Standby

Mode, the heater turns on to warm the

chamber to approximately 38°C. The

heater then cycles ON and OFF to

maintain the warm temperature.

3. Turn ON the optional printer (see

Printer section).

Power On/Controls On

17

Loading...

Loading...