HARVEY Gyro Air G-1000, Gyro Air G-800 Operation Manual

Index of Contents

1. Foreword

2. Machine Description

2.1 Feature Identification

2.2 Specification

2.3 Electrical Power Requirement

3. Safety Regulations................................................................................................................................7

3.1 General Safety Instructions

3.2 Specific Safety Instructions for the Dust Processor

4. Installation of the Machine

4.1 Transportation of Machine

4.2 Positioning the Machine

4.3 Assembly...................................................................................................................................... 10

4.3.1 Unpacking

4.3.2 Removing the Pallet

4.3.3 Connection

4.3.4 Power Supply

4.3.5 Air Supply

5. Function and Operation.................................................................................................................... 13

5.1 Control Panel and Operation Instruction

5.1.1 Touch Screen Operation Instruction

5.1.2 Supplementary Instruction for Dust Cleaning

5.2 Instructions for Remote Control

5.3 Instructions for Synchronous Control

5.4 Pulse Controller Use and Control............................................................................................. 19

5.5 Use of Dust Bin

5.6 Use of Dust Box

6. Maintenance

6.1 Cleaning Dust Bin

6.2 Cleaning Dust Box

6.3 Cleaning or Changing the Filters.............................................................................................. 21

6.4 Full Dust Bin or Pressure Drop Alarm

6.5 Convertor Error and Alarm

..................................................................................................................................................

.............................................................................................................................

....................................................................................................................

...................................................................................................................................

.....................................................................................................

.........................................................................................................

.................................................................

..................................................................................................................

...........................................................................................................

.............................................................................................................

.................................................................................................................................

................................................................................................................

................................................................................................................................

............................................................................................................................

..................................................................................................................................

.................................................................................

.....................................................................................

......................................................................

................................................................................................

.......................................................................................

............................................................................................................................

..........................................................................................................................

.........................................................................................................................................

.......................................................................................................................

......................................................................................................................

......................................................................................

.........................................................................................................

10

10

10

11

11

12

13

14

18

18

18

20

20

21

21

21

22

22

2

3

3

4

5

7

8

9

9

1

1. Foreword

This original instruction was developed as an integral part of this machine. It contains basic

information for qualified operating staff. It also contains all necessary information for the correct

and safe operation of this machine. These regulations, however, cannot cover all safety aspects.

The operator must peruse and make sense of this manual before starting to use the machine.

This manual should be put in a convenient place. If you lose this manual, please contact your

distributor for a new one.

We maintain the right to modify specifications, designs, operation and maintenance instructions

without advance notice.

We offer a two-year warranty based on the purchase date. Defective parts will be repaired or

replaced by Harvey at no charge.

We do not offer the warranty service for the following reasons:

Misuse

Lack of proper maintenance;

Not using genuine Harvey parts;

Consumable parts;

Force majeure, fire or explosion

Every machine we produce is fitted with a name plate with its serial number. The number

is also punched on the machine.

An exact description of the machine model and serial number will facilitate rapid and

effective replies from our after-sales service.

2

2. Machine Description

This product uses the Gyro Air dust processing technology, which effectively separates the dust

from the air flow before the filter. This machine has the following features:

Reduces filter clogging:

The Gyro Air technology efficiently separates 99.7% of the dust from the air flow BEFORE the

filter, providing the benefit of a lower capacity load on the filter and a longer filter life. The air flow

levels are also maintained for a longer time during normal operation.

Clean emission:

Emission concentration<0.05mg/m³, better than the CE standard of 0.1mg/m³. .

Intelligent control:

Real time monitoring of dust levels in the dust bin, filter clogging, convertor and motor status for

auto-dust cleaning; auto-start; remote-start; delayed dust cleaning.

Flow Cruise

Intelligent speed control which maintains consistent air flow speed in the flow cruise mode.

Remarkable designs:

Heavy duty casters for easy positioning at the dust source; no need for specially designed

pipeline; easy connection; low cost for building dust collection system.

Easy maintenance:

Easily-to-change tool-less filters; exhaust air by internal circulation, low maintenance cost.;

Safety Standards:

CE (CONFORMITE EUROPEENNE).

:

This product is suitable for dry dust process, and can be used in the field of metal grinding, metal

cutting, wood machining, plastic machining, graphite machining, fiberglass machining, stone

cutting and surface polishing.

2.1 Feature Identification (Fig.1)

1. Cabinet 10. Filter

2. Flow Duct 11. Oil Water Separator

3. Separator 12. Disconnect switch

4. Inlet 13. Fan Motor

5. Dust bin 14. Power C able

6. Operation Panel 15. Gas storage tank

7. Dust Box 16. Directional wheel

8. Swivel Wheel 17. Electrical box

9. Foots

Fig.1

3

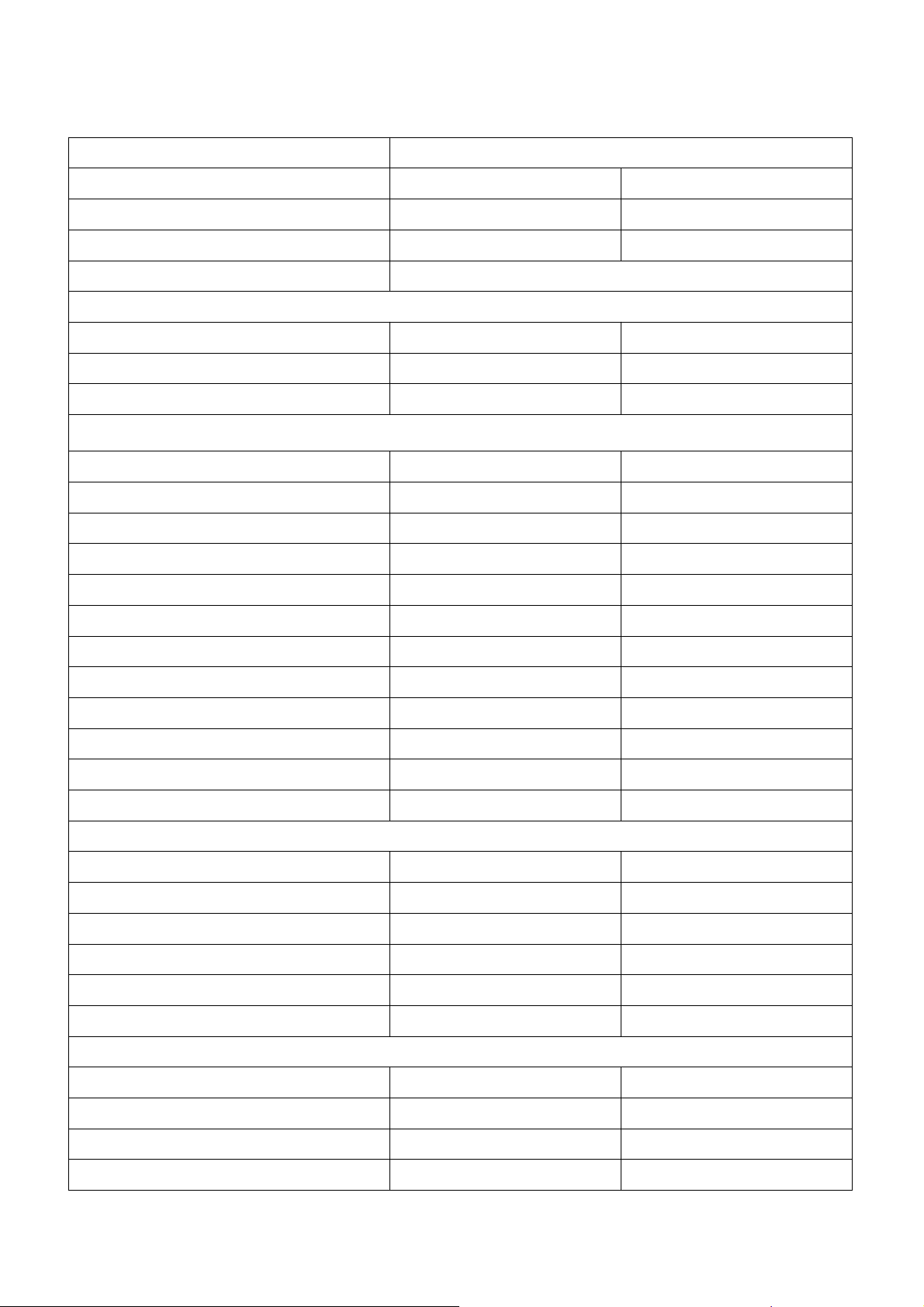

2.2 Specification

Specification G-1000

Electrical Metric Imperial

Power Source 380-480V 50Hz 3-phase 380-480V 60Hz 3-phase

Main motor 3KW 4HP

Frequency Converter Siemens V20

Dimensions & Weights

Overall Dimension 1870x 940 x 1500 mm 73-3/5X37X59 in.

Packing Size 2140x1100x1730mm 84-1/4X43-1/4X68-1/8 in.

Net Weight/Gross Weight 445/545 Kg 980/1200 lbs

Performance

Inlet Size Φ

Max. Air Flow

Max. Static Pressure 6200Pa 25 inch water

Vacuum@22m/s 2200Pa @ Φ140mm /

Blower Speed 2400-4200rpm 2400-4200rpm

Impeller Size Φ360mm 14-1/8”

Filter Efficiency 99.95%@0.3μm 99.95%@0.3μm

Emission 0.05mg/m³ 0.05mg/m³

Filter Area

Number of Filters 3 3

Noise Level 61-72dB(A) 61-72dB(A)

Dustbin Capacity 150L 40Gal

Features

Smart Jet-Pulse Filter Cleaning Standard Standard

Dust Full Monitor Standard Standard

160mm and Φ140mm

2700m³/h

12.6

㎡ 136SF

6“

1600CFM

Filter Monitor Standard Standard

Flow Cruise Standard Standard

Wireless Remote Control Standard Standard

Wireless Synchronized Control Standard Standard

Optional Accessories

Remote Control(RC-800/1000)

Synchronized Control(SC-800/1000)

Y-Adapter(YA-150-2x100) NO YES

Dust Bag(DB-1000)

YES YES

YES YES

YES YES

4

2.3 Electrical Power Requirement

Power requirement: AC380-480V 3-phase

Breaker Size: 20A

The machine needs no further electrical installation.

For the North American market, the equipment comes with a cable (4 cords).

For the European market, the machine is equipped with an industrial socket (5 cords).

The input power supply of the machine is 3-phase, AC380-480V. The steady-state AC power

supply is 0.9-1.1 times of the rated value.

2.3.1 Equipment grounding

This machine must be grounded. If it should malfunction or breakdown, grounding provides a

path of least resistance for the electric current to reduce the risk of electric shock. This appliance

is equipped with a cord having an equipment-grounding conductor and grounding plug. The plug

must be inserted into an appropriate outlet that is properly installed and grounded in accordance

with all local building codes and ordinances.

WARNING

electric shock. Check with a qualified electrician or service person if you are in doubt as to

whether the outlet is properly grounded.

– Improper connection of the equipment-grounding conductor can result in a risk of

2.3.2 Cable Inspection and Extension

Before using, you need to check the cable to see if there is any damage. If any, it should be

immediately repaired or replaced.

Extension cables cause a voltage drop, which may damage electrical components and shorten

the motor life. Voltage drop increases as the extension cable size gets longer and the cable size

gets smaller.

Minimum Gauge Size ........................... 2.5mm2(14 AWG)

Maximum Length (Shorter is Better).......15m (50 ft).

5

2.3.3 Electrical diagram

(Fig.2)

Fig.2

6

3. Safety Regulations

3.1 General Safety Instructions

1. Read and understand the owner’s manual and labels affixed to the machine. Learn its

application and limitations as well as its specific potential hazards.

2. The power supply socket or terminals need reliable grounding.

3. Keep the machine in good working order, properly adjusted and aligned. Cluttered areas and

benches may invite accidents. Make sure the floor is clean and not slippery due to wax and

sawdust build-up.

4. WARNING! – To reduce the risk of electric shock:

Do not expose the machine to water or moisture.

Operators shall be adequately instructed on the use of these machines.

5. CAUTION! – This machine is for indoor use only.

This machine shall be stored indoors only.

6. Do not use this machine within the designated safety areas of flammable liquid storage or in

areas where there may be volatile gasses. Keep the work area clean, dry, and well-lit.

7. Keep children away from this machine.

8. Don’t force the machine or the attachment to do a job for which it was not designed.

9. Do not wear loose clothing, gloves, neckties or jewelry (rings, watch) because they could get

caught in moving parts. Non-slip footwear is recommended. Wear protective hair covering to

contain long hair. Roll up long sleeves above the elbows.

10. Do not use this machine if you are tired, your attention is wandering or you are distracted.

11. If the work operation appears to be excessively noisy, it’s advisable to wear ear protection.

12. Always wear safety glasses or a face shield when operating or observing machinery to

reduce the risk of eye injury or blindness from flying particles. Everyday eyeglasses are not

approved safety glasses.

13. WARNING! – To reduce the risk of electric shock:

Always unplug the machine during servicing.

14. WARNING! – To reduce the risk of injury from moving parts:

Always unplug the machine before servicing.

15. Make sure the power switch is in the “OFF” position before plugging it into an electrical outlet.

16. When turning the power ‘’OFF’’, do not leave the machine unattended until it comes to a

complete stop.

17. Regularly inspect the machine for damaged parts, loose bolts or any other conditions that

may effect safe operation. Always repair or replace damaged parts before operating machine.

18. Keep the machine clean. This will enable you to easily see any damage that may have

occurred. If need be, clean the machine with a damp soapy cloth. Do not use any solvents or

cleaners as these may cause damage to any plastic parts or to the electrical components.

7

Loading...

Loading...