HARVEY Chemiclave EC5500, Chemiclave EC6000 Service Manual

BARNSTEAD THERMOLYNE CORPORATION

®

Harvey

Chemiclave

EC Series Sterilizers

SERVICE MANUAL

LT1121X2 • 11/13/00

1

Table of Contents

Introduction ................................................................................................................................................................. 4

General Specifications ................................................................................................................................................ 5

General Description .................................................................................................................................................... 6

Controls and Features............................................................................................................................................... 6

Power Switch .......................................................................................................................................................... 6

Control Panel .......................................................................................................................................................... 6

Chemi-Filter............................................................................................................................................................. 8

Door ........................................................................................................................................................................ 8

Drain........................................................................................................................................................................ 8

Pressure Relief Valve.............................................................................................................................................. 8

Piping Components ................................................................................................................................................... 8

Reservoir ................................................................................................................................................................. 8

Metering Valve ........................................................................................................................................................ 8

Chamber ................................................................................................................................................................. 9

Pressure Gauge ...................................................................................................................................................... 9

Pressure Relief Valve.............................................................................................................................................. 9

Condenser............................................................................................................................................................... 9

Condensate Tank .................................................................................................................................................... 9

Drain........................................................................................................................................................................ 9

Exhaust ................................................................................................................................................................. 10

Chemi-Filter........................................................................................................................................................... 10

Electrical Components ............................................................................................................................................ 10

Printed Circuit Boards ........................................................................................................................................... 10

Power Cord ........................................................................................................................................................... 11

Power Switch ........................................................................................................................................................ 11

Control Panel ........................................................................................................................................................ 11

Heater ................................................................................................................................................................... 11

Thermostat ............................................................................................................................................................ 11

Overtemp Switch ................................................................................................................................................... 12

Valve Shaft Switch ................................................................................................................................................ 12

Pressure Switch .................................................................................................................................................... 12

Sterilant Level Switch ............................................................................................................................................ 12

Principles of Operation .............................................................................................................................................. 13

Chemiclave Cycle (EC5500 & 6000)....................................................................................................................... 13

Filling the Reservoir .............................................................................................................................................. 13

Power ON.............................................................................................................................................................. 13

Warm Up ............................................................................................................................................................... 13

Ready/Load ........................................................................................................................................................... 13

Pressurization ....................................................................................................................................................... 13

Exposure ............................................................................................................................................................... 14

Depressurization ................................................................................................................................................... 14

Purge..................................................................................................................................................................... 14

Complete ............................................................................................................................................................... 14

Wiring Diagrams........................................................................................................................................................ 24

Troubleshooting ........................................................................................................................................................ 26

Maintenance and Servicing ....................................................................................................................................... 28

Piping Components ................................................................................................................................................. 28

Leaks..................................................................................................................................................................... 28

Metering Valve ...................................................................................................................................................... 30

2

TABLE OF CONTENTS

Pressure Gauge .................................................................................................................................................... 33

Pressure Relief Valve............................................................................................................................................ 33

Condenser............................................................................................................................................................. 34

Condensate Tank .................................................................................................................................................. 34

Door ...................................................................................................................................................................... 34

Purge Pump .......................................................................................................................................................... 35

Air Filter ................................................................................................................................................................. 36

Check Valve .......................................................................................................................................................... 36

Electrical Components ............................................................................................................................................ 36

Fuses .................................................................................................................................................................... 36

Printed Circuit Boards (PCBs)............................................................................................................................... 37

Timer ..................................................................................................................................................................... 41

Power Switch ........................................................................................................................................................ 41

Heater ................................................................................................................................................................... 42

Chamber Temperature .......................................................................................................................................... 43

Thermostat ............................................................................................................................................................ 43

Overtemp Switch ................................................................................................................................................... 44

Pressure Switch .................................................................................................................................................... 45

Sterilant Level Switch ............................................................................................................................................ 45

Check Valve .......................................................................................................................................................... 46

Electrical Components ............................................................................................................................................ 46

Recommended Spare Parts .................................................................................................................................... 47

General Maintenance ................................................................................................................................................ 48

Daily ........................................................................................................................................................................ 48

Cleaning the Door Gasket ..................................................................................................................................... 48

Draining the Waste Tank....................................................................................................................................... 49

Weekly .................................................................................................................................................................... 50

Cleaning the Chamber and Trays ......................................................................................................................... 50

Monthly.................................................................................................................................................................... 50

Checking the Pressure Relief Valve...................................................................................................................... 50

When Required ....................................................................................................................................................... 51

Replacing the Chemi-Filter.................................................................................................................................... 51

Finding the Replacement Date ............................................................................................................................. 51

Replacing the Door Gasket ................................................................................................................................... 52

Door Adjustment ................................................................................................................................................... 53

Recommended Spare Parts .................................................................................................................................... 54

Two Year Limited Warranty....................................................................................................................................... 55

3

Introduction

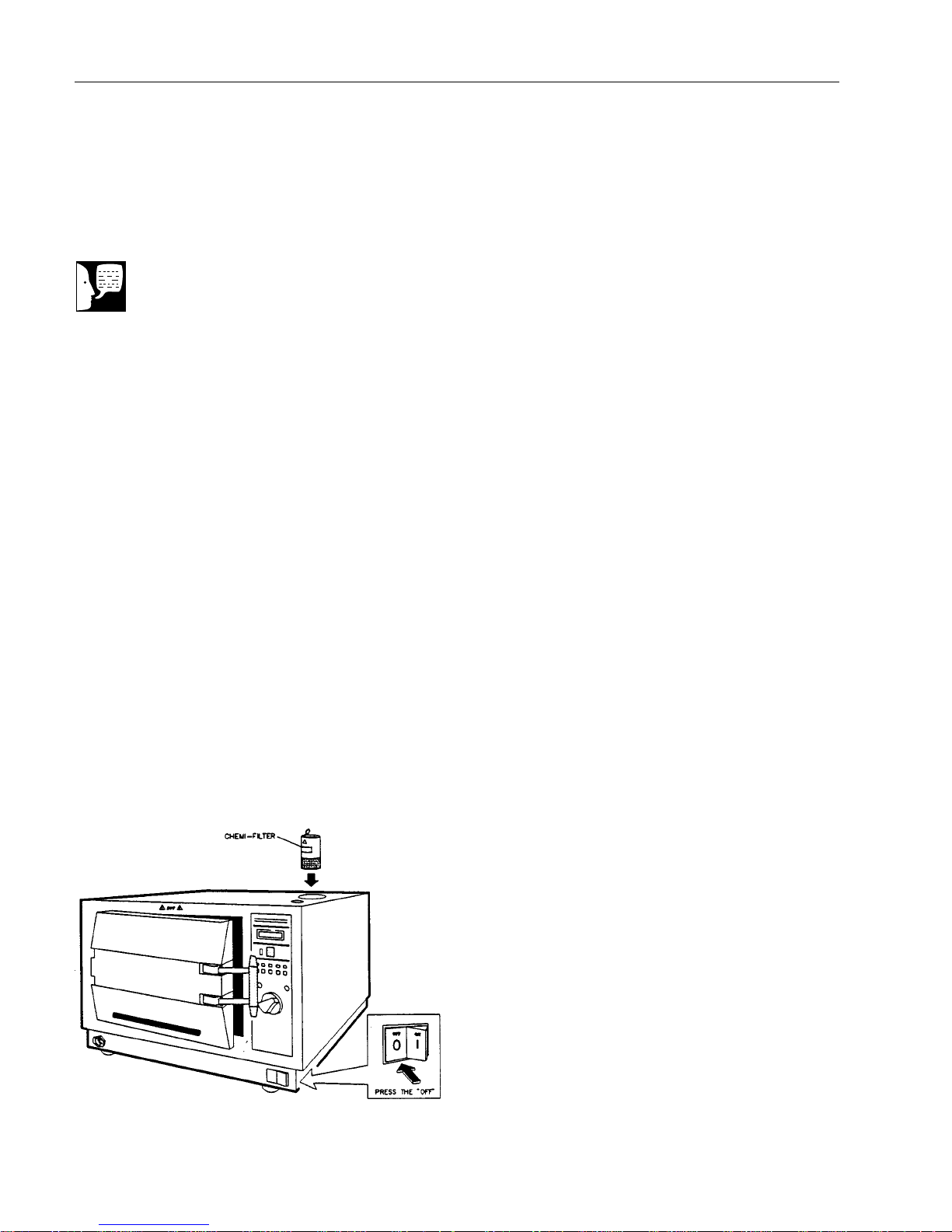

Note

To save space, most figures in this

manual show only one of the models.

This is usually the EC5500. Both

models contain similar or identical

components and operate in a similar

way.

The Harvey® Chemiclave sterilizer is a safe, fast and

effective sterilizer for use in medical and dental offices,

hospitals, clinics and other health care facilities.

To sterilize goods, Chemiclave sterilizers use an unsaturated chemical vapor process. The active ingredient in

Vapo-Steril, the liquid sterilant, is formaldehyde.

Two models of the EC Series are available: the EC5500 (8”

chamber diameter) and the EC6000 (10” chamber diameter).

The model with a larger chamber (EC6000) can process a

larger load. Features of each model are summarized in

Figures 1 and 12 and in “General Specifications.”

Figure 1: EC Series Chemiclave Sterilizers

4

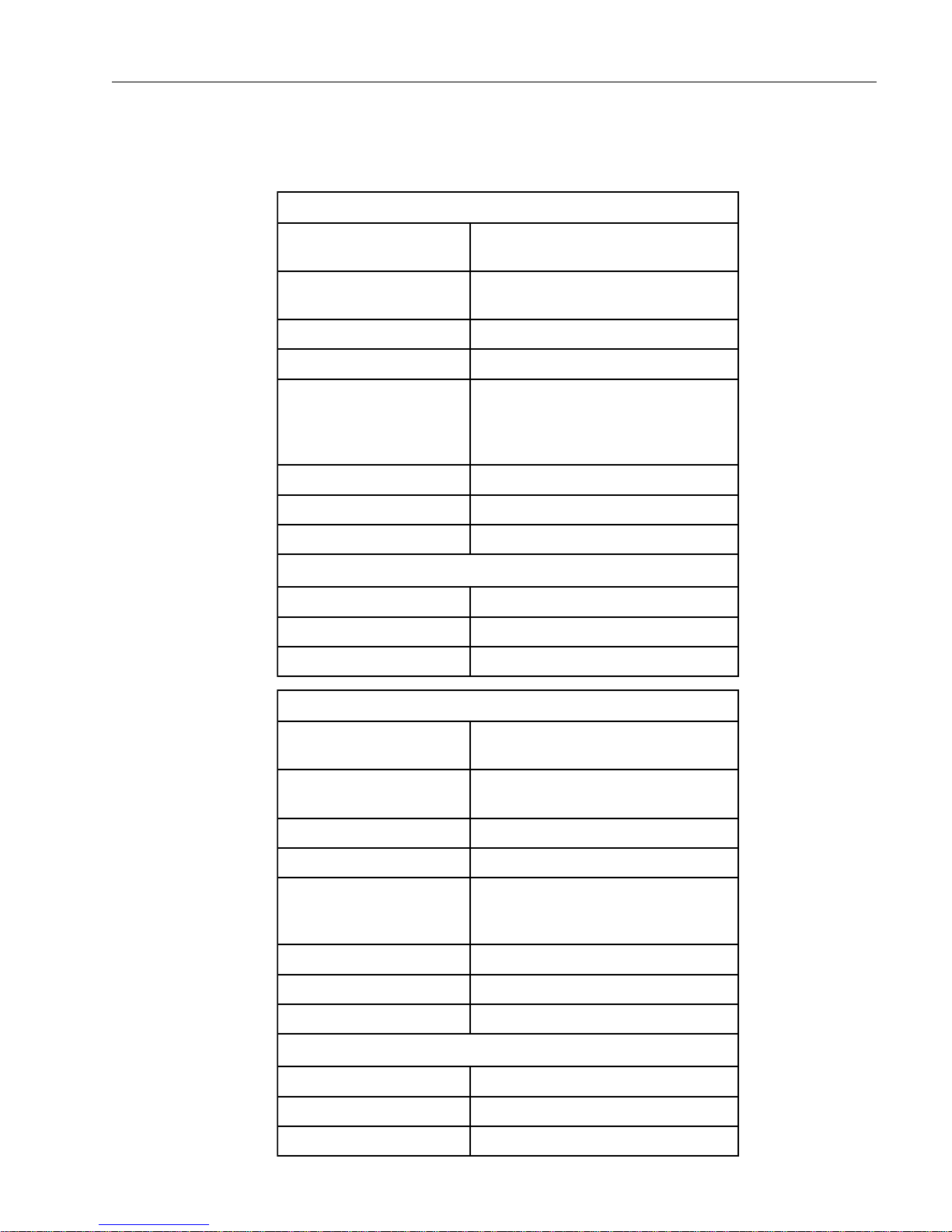

General Specifications

0055CEledoM

eziStenibaC

eziSrebmahC

thgieW)gk8.62(.sbl95

egattaWretaeHW008

gnitaRlacirtcelE

erusserPgnitarepO)aPk672-831(gisp04-02

erutarepmeTnoitarepO231 ° 072(C ° )F

evlaVfeileRerusserP)aPk013(gisp54

seiticapaCdiulF

riovreseRnoituloS).zo.lf73(sretil1.1

knaTetasnednoC).zo.lf73(sretil1.1

rebmahCtohS).zo.lf10.1(lm03

D"5.81xH"31xW"57.61

)mm074xmm033xmm524(

peed"52.31xretemaid"8

)mm733xmm302(

spmA01,zH05,CAV001

spmA01,zH06,CAV001

spmA8,zH06,CAV511

spmA4,zH05,CAV032

0006CEledoM

eziStenibaC

eziSrebmahC

thgieW)gk4.45(.sbl021

egattaWretaeHW0021

gnitaRlacirtcelE

erusserPgnitarepO)aPk672-831(gisp04-02

erutarepmeTnoitarepO231 ° 072(C ° )F

evlaVfeileRerusserP)aPk013(gisp54

seiticapaCdiulF

riovreseRnoituloS).zo.lf73(sretil1.1

knaTetasnednoC).zo.lf73(sretil1.1

rebmahCtohS).zo.lf30.2(lm06

D"5.02xH"5.61xW"52.91

)mm125xmm914xmm984(

peed"61xretemaid"01

)mm604xmm452(

spmA31,zH06,CAV001

spmA21,zH06,CAV511

spmA6,zH05,CAV032

5

General Description

Controls and Features

Power Switch

The power switch on the front of the sterilizer turns power

to the sterilizer ON (I) or OFF (O). See Figure 1.

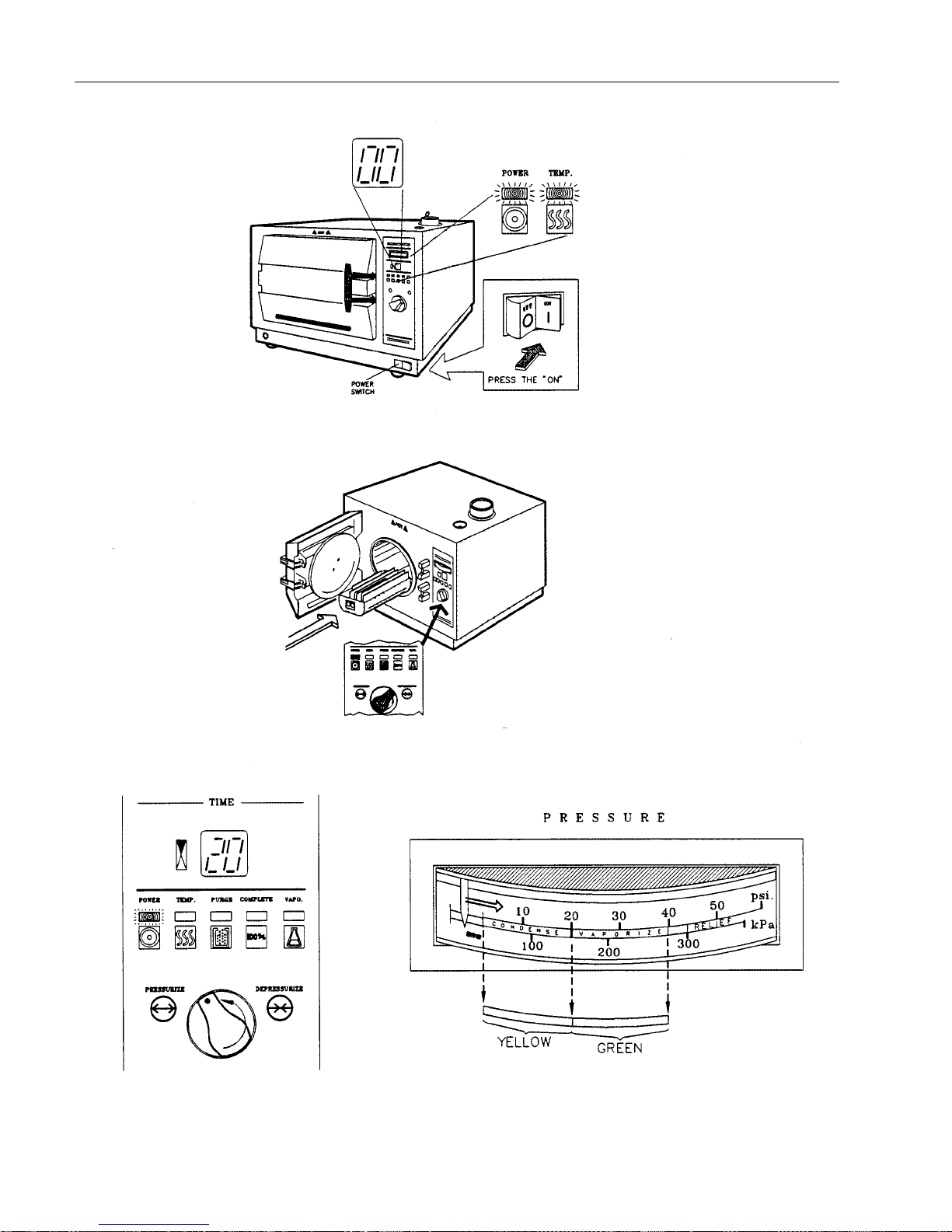

Control Panel

Pressure Gauge

Displays the chamber pressure. See Figure 2.

Timer

Times the 20 minute exposure phase and the purge phase

for models EC5500 and EC6000.

Indicators

POWER: Lights when power to the unit is ON.

TEMP: Turns on and off as the chamber heaters cycle on

and off.

COMPLETE: Lights when the exposure phase is complete.

PURGE: Lights when the chamber is being emptied of

vapors.

VAPO: Signals when the reservoir must be filled with VapoSteril solution. The indicator will remain lit until solution is

added.

CONTROL KNOB: Attached to the valve shaft, this knob

controls the metering valve. Turning the control knob to

PRESSURIZE introduces VAPO-Steril into the chamber

and enables a cycle to begin. Turning the knob to DEPRESSURIZE permits vapors to exhaust from the chamber.

Figure 2: Control Panels—EC Series

6

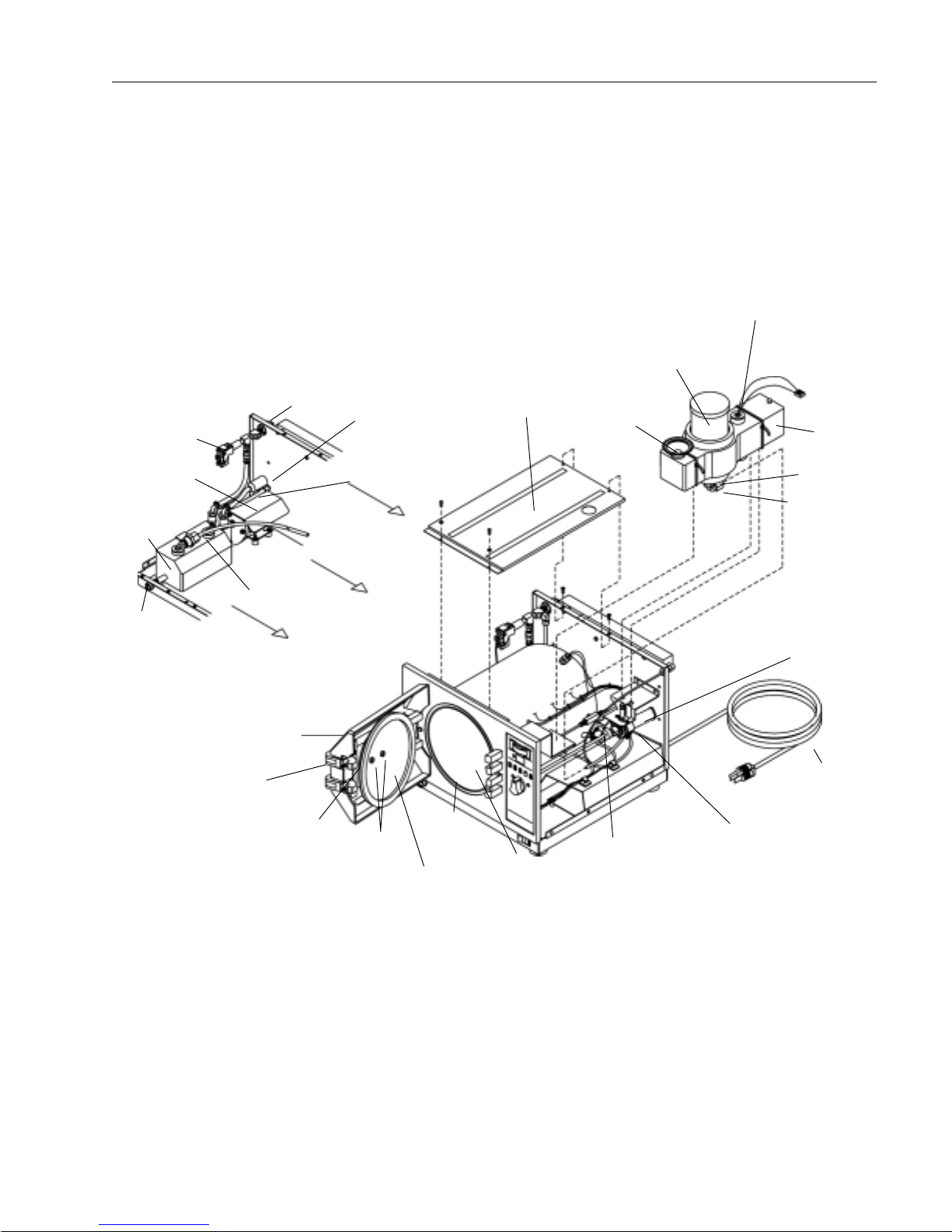

GENERAL DESCRIPTION

Sterilant

Level Switch

Pressure

Switch

Pump

Condensate

Tank

Drain

Exhaust to

Chemi-filter

Door

Cover

Door

Handle

Pressure

Relief Valve

Door

Latch

Air filter

From

Condenser

Seal

Screws

Door

Door

Gasket

Baffle Plate

Chamber

Chemi-filter

Filling

Cup

Valve Shaft

Switch

Reservoir

Filter Housing

Exhaust to

Chemi-filter

Metering

Valve

Power

Cord

Main fuse

holder

Figure 3: Major Components

7

GENERAL DESCRIPTION

Chemi-Filter

The Chemi-Filter is placed in the top of the sterilizer. It

removes chemicals from the exhaust.

Door

The door latch secures the door. It is opened by the door

handle. The handle mechanism prevents the door from

being opened while there is pressure in the chamber.

Drain

A drain valve below the sterilizer door is provided to drain

used Vapo-Steril from the condensate tank.

Caution

Be sure you are using only Harvey

Vapo-Steril solution. Other solutions will

cause damage to the Chemiclave and

will void all warranties.

Pressure Relief Valve

A safety valve on the rear of the sterilizer relieves excess

chamber pressure (see Figure 3).

Piping Components

See Figure 3 for major components and Figure 12 for

detailed component locations.

Reservoir

The reservoir holds about 1 liter of Vapo-Steril solution (see

“Technical Specifications” for exact amounts). The filling

cup has a spring-loaded valve. When the reservoir is full,

the valve stops the flow of solution from the filling bottle.

The reservoir contains a STERILANT LEVEL SWITCH.

This switch lights the VAPO indicator on the control panel

when the level of solution is low.

Metering Valve

8

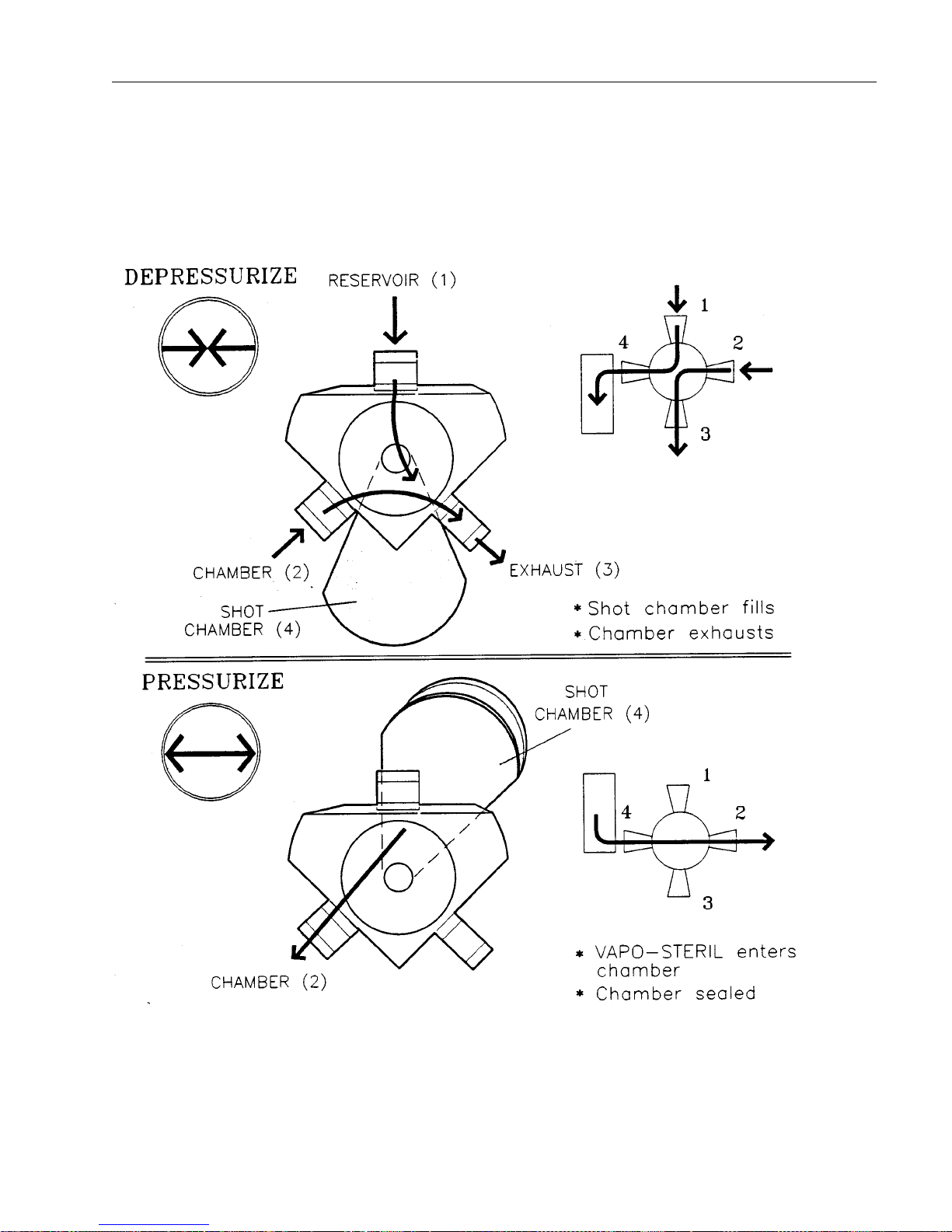

Operated by the control knob, the valve has four ports

(including the shot chamber) and two settings, DEPRESSURIZE and PRESSURIZE.

GENERAL DESCRIPTION

With the control knob at DEPRESSURIZE, Vapo-Steril

can enter through the fill port and fill the shot chamber,

while the chamber itself connects through the exhaust

port to the exhaust line.

With the control knob at PRESSURIZE, the fill port and

exhaust port are closed. The valve connects the shot

chamber to chamber. The measured amount of VapoSteril from the shot chamber can enter the chamber. The

chamber can build pressure to run a sterilizing cycle.

Chamber

Pressure vessel where loads of instruments are sterilized. The pressure for a typical sterilizing cycle is 20 - 40

psig (138 - 276 kPa).

Pressure Gauge

Displays the chamber pressure.

Pressure Relief Valve

The pressure relief valve will open to relieve the chamber

pressure if it exceeds the pressure rating of the valve.

This valve is on the rear of the sterilizer.

Condenser

The condensing coils on the back of the sterilizer liquefy

the vapors that exit from the chamber.

Condensate Tank

The condensate tank collects the liquefied vapors from

the condenser. Any remaining vapors proceed through

the exhaust line to the Chemi-Filter.

Drain

The drain includes a valve in the chassis and a separate

fitting with plastic tubing. The operator inserts the fitting

into the valve to empty liquid waste from the condensate

tank.

9

GENERAL DESCRIPTION

Exhaust

Vapors from the chamber that do not liquefy in the condenser proceed to the exhaust connection on the filter

housing. They exit through the Chemi-Filter into the atmosphere.

Chemi-Filter

The Chemi-Filter traps the formaldehyde from the exhaust

vapors before releasing them to the atmosphere. The

Chemi-Filter should be installed before the sterilizer is

operated. It must be replaced regularly.

Pump

Propels air into the chamber during the purge phase, which

forces vapors out of the chamber through the vent port.

Air Filter

Removes contaminants from intake air before the pump

propels it into the chamber.

Check Valve

Prevents chamber back pressure from contacting the pump

and the air filter.

Electrical Components

Printed Circuit Boards (PCBs)

Power Supply Board

Transforms line power into working voltages. Acts as “input/

output” board for heater and pump.

10

GENERAL DESCRIPTION

Display Control Board

Contains logic circuits and display components, including

the timer and the buzzer.

• Timer: On Display/Control Board. Counts to

time the exposure and purge phases. For the

exposure phase, the timer operates only if the

valve shaft switch is closed and the pressure

switch is closed. For the purge phase, the

timer is actuated when the control knob is

turned to DEPRESSURIZE and valve shaft

switch changes from closed to open. After a 1minute delay, the timer begins to count down

the preset purge valve.

• Buzzer: On Display/Control Board. Signals the

end of the exposure and purge phases.

Power Cord

The power cord connects the unit to the voltage supply.

Power Switch

The POWER switch turns ON and OFF the electrical

power for the unit.

Control Panel

The control panel contains the indicators, pressure gauge

and the control knob.

Heater

The chamber is heated by a band-type heater that wraps

completely around the outside of the chamber. Wattage

for the heater is listed in “Technical Specifications.”

Caution

Refer to “Thermostat Adjustment” in the

“Maintenance and Servicing” section of

this manual before adjusting the

thermostat.

Thermostat

Turns heater on and off to maintain chamber temperature.

11

GENERAL DESCRIPTION

Overtemp Switch

Opens to cut power to the heaters if chamber temperature

reaches (163°C ± 4) 325°F. Overtemp switch has to be

manually reset.

Valve Shaft Switch

Engaged by the cam on the valve shaft, this switch is

closed only when the control knob is set to PRESSURIZE.

For the exposure phase, the timer will not operate if either

this switch or pressure switch is open. For the purge phase,

this switch must change from the closed state to the open

state. After a 1-minute delay, the timer begins to count

down the preset purge value.

Pressure Switch

Closes when chamber pressure reaches the minimum

exposure pressure of (138 kPa) 20 psi. Opens whenever

chamber pressure is less than that value. For the exposure

phase, the timer will not operate if either this switch or value

switch is open.

Sterilant Level Switch

The sterilant level switch in the reservoir lights the VAPO

indicator when the sterilant level is low. This switch is

preset to actuate when one liter of Vapo-Steril can be

poured into the reservoir. The float level is not adjustable.

12

Principles of Operation

Warning

Do not reuse Vapo-Steril solution

removed from the waste tank. This

liquid may be contaminated or

chemically altered and may damage

the sterilizer.

Caution

Use only harvey Vapo-Steril solution in

the Chemiclave. Do not dilute, alter or

otherwise change Vapo-Steril in any

way. Use of other solutions may cause

mechanical damage to components of

the sterilizer and may result in nonsterile loads.

Chemiclave Cycle

(EC5500 & EC6000)

Filling the Reservoir

This is a manual function. When the sterilant reservoir is

filled, Vapo-Steril can flow through the metering valve to

fill the shot chamber. The metering valve is open to the

shot chamber when the control knob is set to DEPRESSURIZE (see Figure 4).

Power On

Control knob is set to DEPRESSURIZE before turning

the power ON. This vents any sterilant vapors into the

condensate tank. Electrical power is applied to the unit

when POWER switch is turned ON. When the power is

turned ON all the indicator (LED’s) should light for

approximately two seconds then extinguish, except for

the POWER and TEMP indicators which should remain

ON.

Warm Up

The heater that surrounds the chamber is turned on

when the power is turned ON. It stays active until the

setpoint temperature is reached. As long as the heater is

active, the TEMP indicator lights (see Figure 5).

Ready/Load

When the setpoint temperature is reached, the heater

cycles off and the TEMP indicator goes out. The chamber

is ready to be loaded (see Figure 6). The heater is

controlled to maintain chamber temperature. TEMP light

cycles on and off with heater.

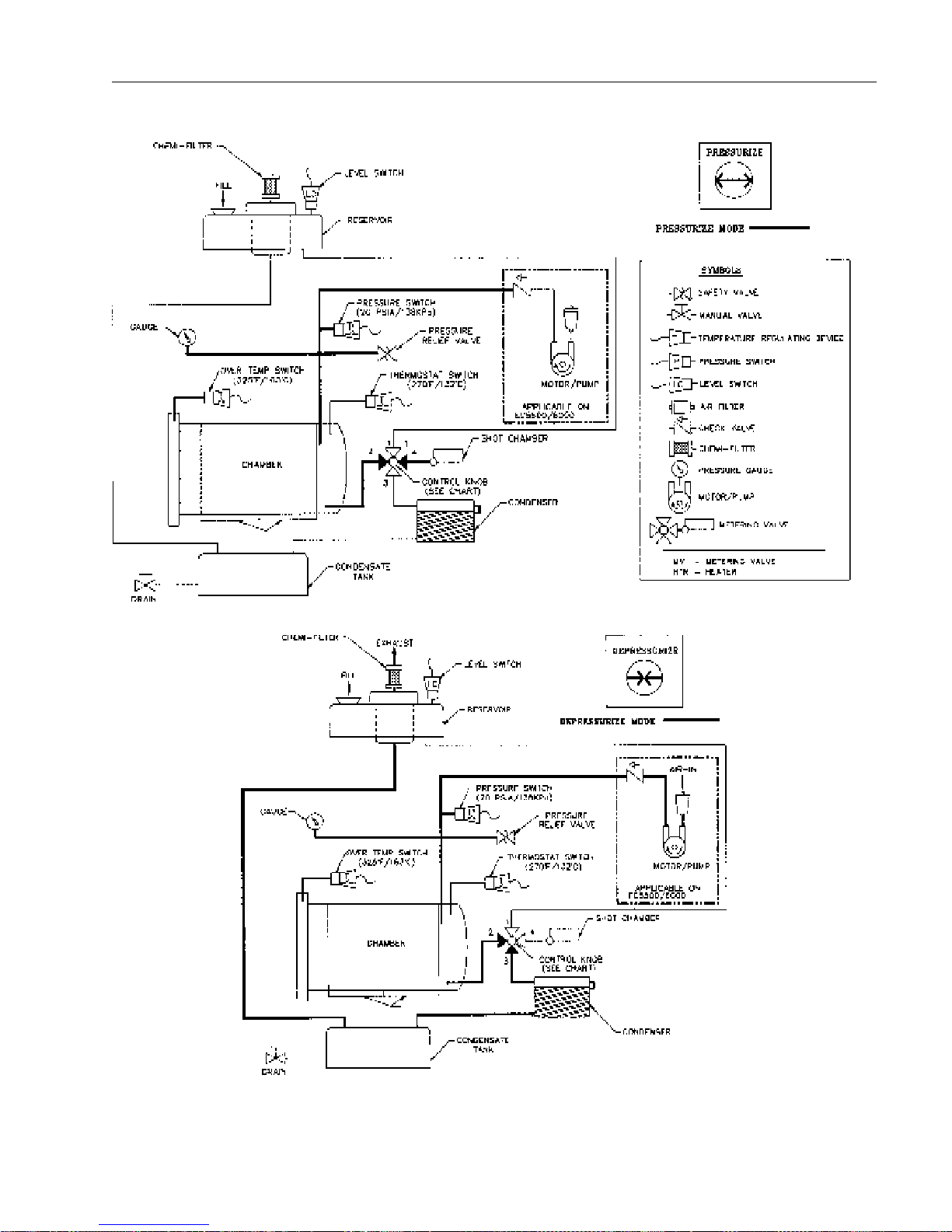

Pressurization

When the operator sets control knob to PRESSURIZE,

sterilant flows by gravity into the chamber from the shot

chamber of the metering valve (see Figure 7, PRESSURIZE mode). Chamber pressure begins to increase. The

timer displays “20” minutes.

13

PRINCIPLES OF OPERATION

Exposure

This timed function begins when chamber pressure reaches

20 psig (138 kPa). Pressure switch is then energized. The

timer counts down the exposure time of 20 minutes. The

decimal point flashes when the timer is active. Chamber

pressure is displayed continually on the pressure gauge. If

pressure goes below 20 psig (138 kPa), the pressure

switch is de-energized. This stops the timer countdown and

the flashing decimal point until pressure returns to 20 psig

(138 kPa) or above.

Note

Exposure conditions are maintained

until the control knob is set to depres-

surize.

Exposure Complete

When the exposure is complete, the timer displays “00” and

a tone sounds. The COMPLETE indicator lights. The

PURGE indicator flashes briefly (see Figure 9).

Depressurization

Begins when the operator sets the control knob to DEPRESSURIZE (see Figure 4). This vents the chamber

through the metering valve to the condensate tank (see

Figure 8, DEPRESSURIZE mode). Pressure switch is deenergized. The COMPLETE indicator stays on. The

PURGE indicator continues to flash as the chamber

depressurizes for one minute.

Purge

Begins automatically after Depressurization (approximately

1 minute delay before pump starts). See Figure 10. Timer

displays “07” (EC5500) or “09” (EC6000). The COMPLETE

indicator goes out. The PURGE indicator lights. Purge

pump forces sterilant vapor from the chamber until the timer

counts down to “00.”

14

Complete

After Purge, the pump stops and the PURGE indicator goes

out. A tone sounds. The pressure gauge reads less than 2

psig (14 kPa). The cycle is complete. The COMPLETE light

stays lit for one minute, then goes out. Heater remains

controlled as long as the POWER switch remains ON. The

POWER indicator is lit and he TEMP indicator cycles on

and off with the heater. To unload, the operator opens the

door (see Figure 11).

PRINCIPLES OF OPERATION

Figure 4: Metering Valve Function

15

PRINCIPLES OF OPERATION

Figure 5: Warm-Up

Figure 6: Ready/Load

Figure 7: Pressurization

16

PRINCIPLES OF OPERATION

Figure 8: EC5500/EC6000 Operation

17

Loading...

Loading...