HARVEY C200, C200-30 Operating Instructions Manual

Contents

1. Foreword

2. Warranty Information

3. Machine Description

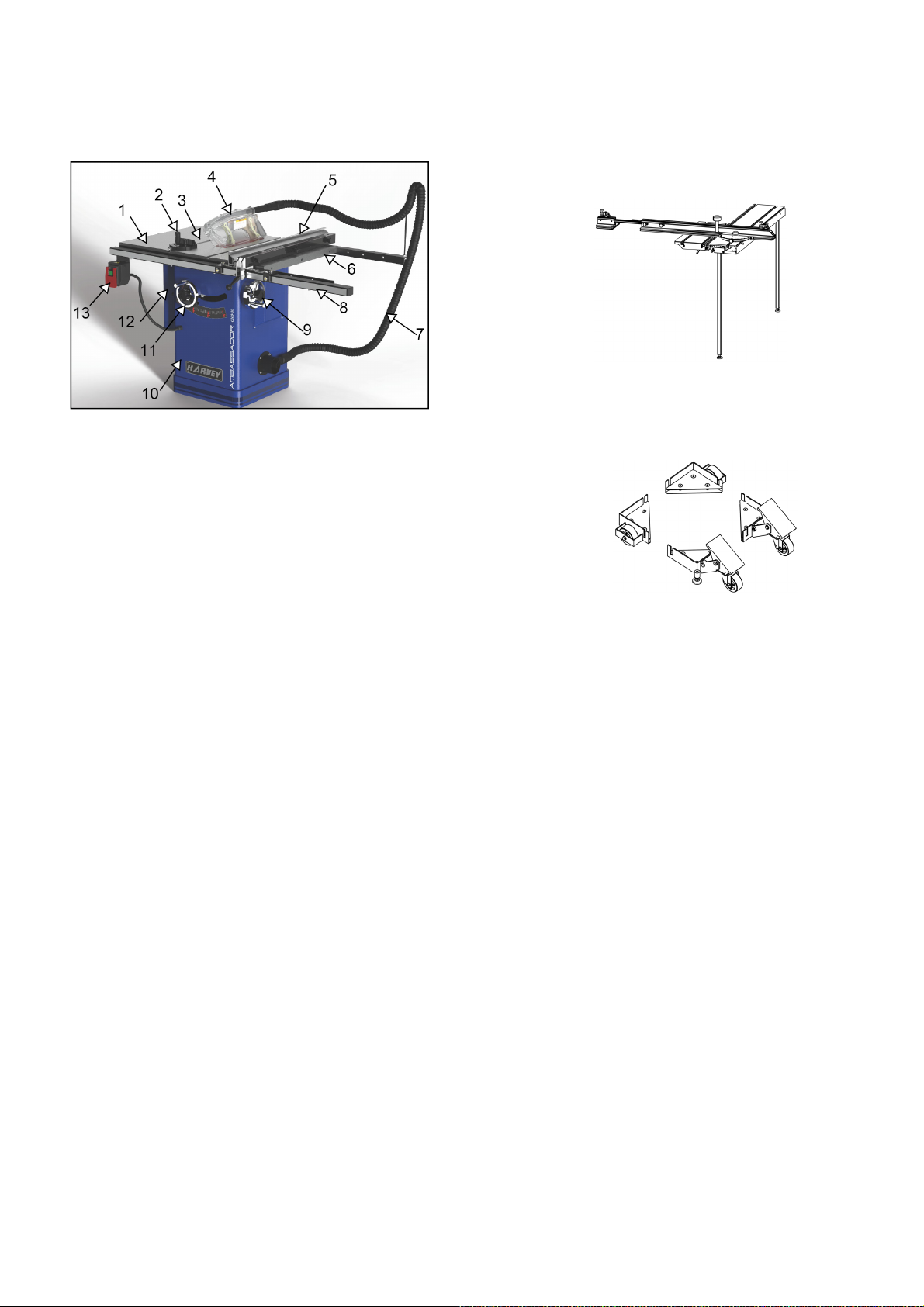

3.1 Technical Parameters

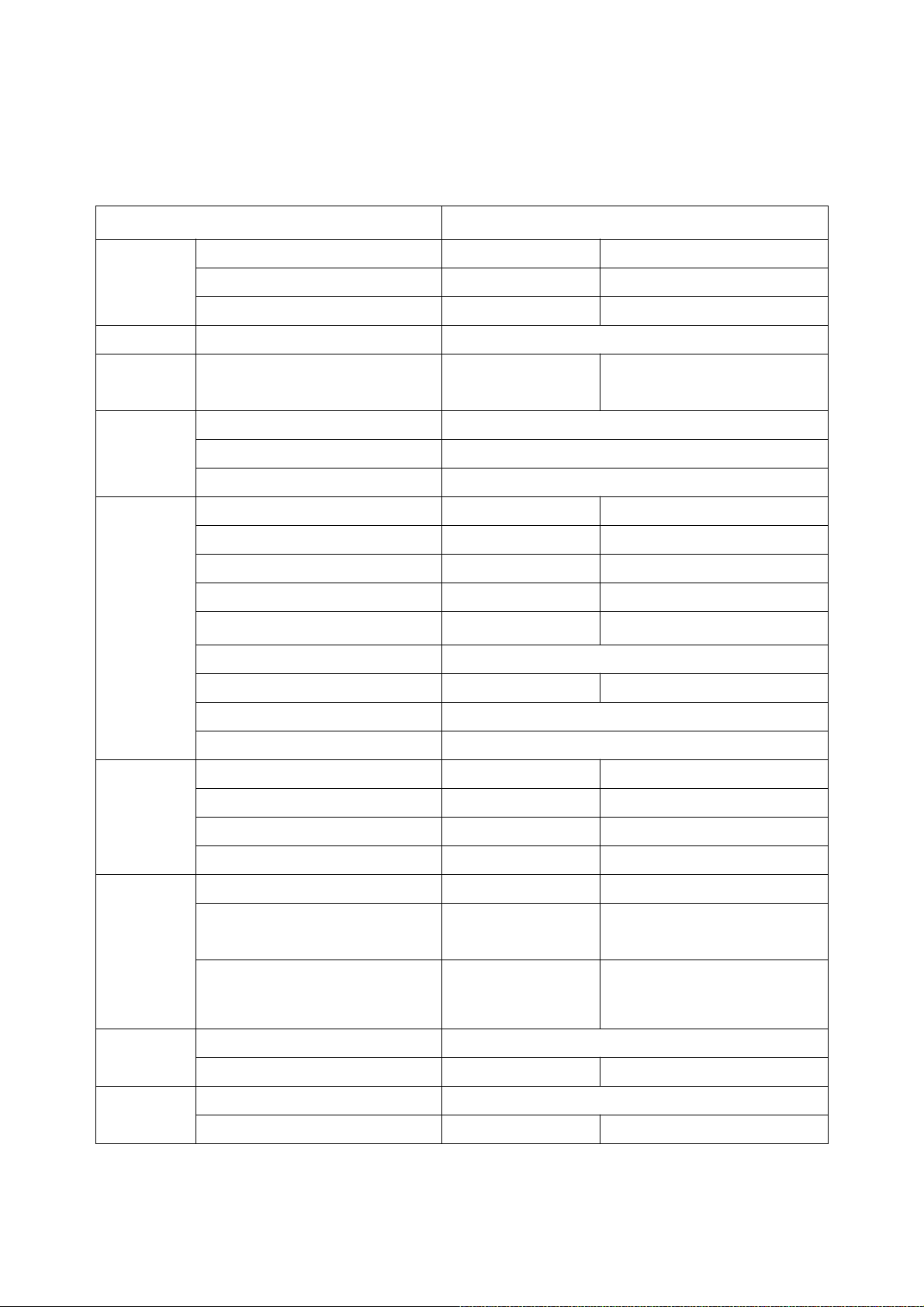

3.2 Features Identification

3.3 Optional Equipments

3.4 Intended Use

3.5 Requirements of Electrical Power

4. Safety Regulations

4.1. General Safety Instructions

4.2. Specific Safety Instructions for Sliding Table Saw

4.3. Residual Risks

4.4.Safety Equipments

5. Installation of the Machine

5.1 Transportation of Machines

5.2 Unpacking

5.3 Contents of C200-30

5.4 Safety Measure before Installation

5.5 Installation

6. Adjustment

6.1 Blade Elevation and Tilting Mechanism

6.2 Adjusting Rip Fence

6.3 Aligning Table T-slot Parallel with Blade

6.4 Adjusting 45°and 90°Positive Stops

6.5 Aligning Blade Guard Splitter or Riving Knife with Blade

7. Operations

7.1 Electrical Operation

7.2 Safety Precautions before Operations

7.3 Operation

7.4 Crosscutting

7.5 Ripping

8. Maintenance

9. Trouble Shooting

10. Exploded View and Parts List

...............................................................................................................................................

.........................................................................................................................

..........................................................................................................................

.................................................................................................................

.................................................................................................................

...................................................................................................................

................................................................................................................................

.............................................................................................

.............................................................................................................................

.......................................................................................................

............................................................................................................................

......................................................................................................................

...............................................................................................................

........................................................................................................

.....................................................................................................................................

...................................................................................................................

...........................................................................................

...................................................................................................................................

.........................................................................................................................................

.................................................................................

..................................................................................................................

...............................................................................

.......................................................................................

..........................................................................................................................................

...................................................................................................................

...................................................................................

....................................................................................................................................

................................................................................................................................

........................................................................................................................................

.......................................................................................................................................

..............................................................................................................................

.....................................................................................................

................................................................

....................................................

1

1

2

2

3

3

4

4

5

5

5

6

6

7

7

8

9

9

10

15

15

15

15

16

16

17

17

17

17

17

17

18

19

20

1. Foreword

2. Warranty Information

This machine contains basic information for

qualified operators and describes the intended

uses of the machine. It contains all of the

information necessary for correct and safe

operation. The machine is equipped with various

safety features which will protect the operator

under normal operating conditions. This

information cannot cover all possible safety

aspects and that is why the operator needs to

review this manual and insure familiarity with it and

its functions before operating it.

Limited Warranty

Two year.

Proof of Purchase

Please keep your dated proof of purchase for

warranty and servicing purposes.

Limited Tool Warranty

We make every effort to ensure that this product

meets high quality and durability standards. We

offer a two-year limited warranty based on the

purchase date. Defective parts will be repaired or

replaced by Harvey at no charge. Warranty does

not apply to defects due directly or indirectly to

misuse, abuse, normal wear and tear, negligence

or accidents, repairs done by an unauthorized

service center, alterations and/or lack of

maintenance. We shall in no event be liable for

death, injuries to persons or property or for

incidental, special or consequential damages

arising from the use of our products. To take

advantage of this limited warranty, contact us at

888-211-0397 or info@harveywoodworking.com.

We will either repair or replace the product if any

part or parts covered under this warranty, after

examination, proves to be defective in

workmanship or material during the warranty

period.

Notice to California Residents: This product can

expose you to wood dust, which is known to the

State of California to cause cancer. For more

information, go to www.P65Warnings.ca.gov.

1

3. Machine Description

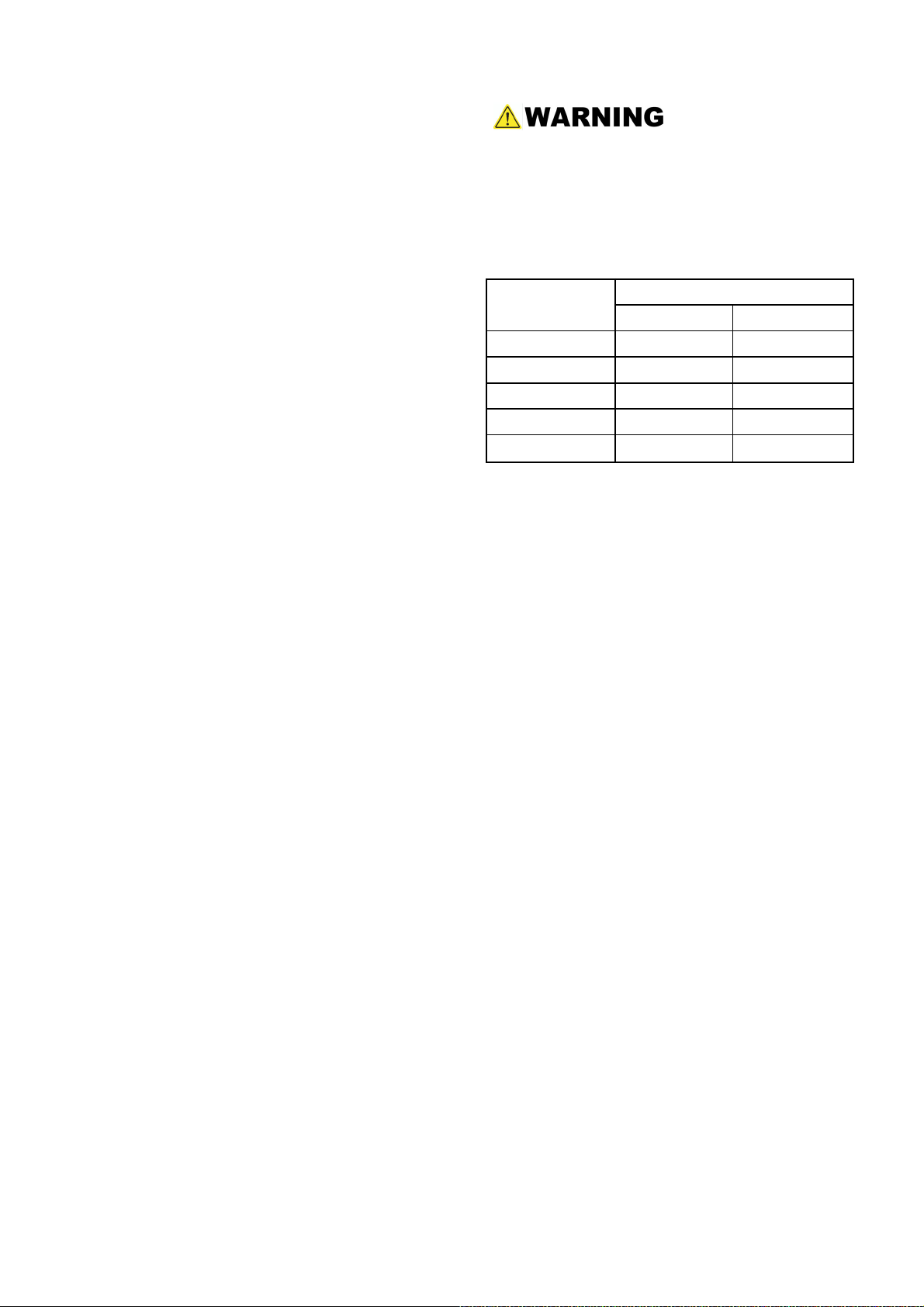

3.1 Technical Parameters

Model: C200-30

ITEM C200-30

Product

Dimensions

Electrical Switch Magnetic with Thermal Overload Protection

Power

Supply

Motor

Blade

Information

Weight 180Kg 396 lbs

Length/Width/Height 1570x985x1060 mm 61-13/16"×38-3/4"×41-3/4"

Footprint 514x498 mm 20-1/4"×19-5/8"

Horsepower, Voltage,

Frequency, Phase, Amps

Type TEFC, Capacitor Start, Induction

Speed 3500 RPM

Power Transfer V-Ribbed Belt Drive

Maximum Blade Diameter 254 mm 10”

Riving Knife Thickness 2.5 mm 0.1”

Available Blade Plate Thickness 1.8-2.4 mm 0.071”-0.094”

Available Blade Kerf Thickness 2.6-3.2 mm 0.102”-0.126”

Maximum Width of Dado 20.6 mm 13/16"

Blade Tilt Left 0-45°

Arbor Diameter at Blade 15.875 mm 5/8”

1.65 kW, 230 V,

50 Hz, 1 PH, 8 A

2.0 HP, 115 V (230 V), 60 Hz,

1PH,16A(8A)

Cutting

Capacities

Table

Information

Miter

Gauge

Other

Information

Arbor Speed 3850 RPM

Arbor Bearings Sealed and Permanently Lubricated

Maximum Depth of Cut at 90° 79.4 mm 3-1/8”

Maximum Depth of Cut at 45° 56 mm 2-3/16”

Maximum Rip, Right of Blade 800 mm 31-1/2"

Maximum Rip, Left of Blade 288 mm 11-3/8"

Height 867 mm 34”

Main Table -

512x685x40 mm 20"×27"×1-1/2"

Length/Width/Thickness

TableSizeWithExtension

1016x685 mm 40"×27"

Wings--Length/Width

Miter Gauge Slot Type T-Shape

Miter Gauge Size - Width/Height 19x9.5 mm 3/4” x 3/8”

Finish Powder Coated

Dust Port Size 100 mm 4”

Note: For correct option of power supply, please refer to the specifications label on the product.

2

3.2 Features Identification

Refer to Fig. 1.

Fig. 1

3.3 Optional Equipments

Sliding table

Model: ST-1400S

Fig. 1-1

Universal Mobile Base

Model: MB-600

1 Left Extension Table

2MiterGauge

3 Main Table

4 Blade Guard

5 Fence

6 Right Extension Table

7Flexiblehose

8 Rail & Tube

9 Blade Elevation Hand Wheel

10 Cabinet

11 Blade Tilt Hand Wheel

12 Motor Cover

13 On/Off Switch

Fig. 1-2

3

3.4 Intended Use

The table saw and the fence supplied with it are

intended to be used exclusively for the following

purposes:

● Laminated and unlaminated board materials (e.g.

chipboard, coreboard, MDF board, ...)

● Solid wood

● Gypsum plasterboard, Cardboard, Veneer with a

suitable clamping device

● Dimensionally stable plastics (thermoset plastics,

thermoplastics). Sawing these materials does not

normally involve any risks in respect of dust, chips,

and thermal degradation products.

Too ls:

● The chosen saw blade must be suitable both for

the specific work cycle and for the specific material.

●Only circular blades which are solid chrome

vanadium (CV) or tungsten carbide tipped (TCT)

andhaveadiameterof

( 15.875mm ) ,aswellasamaximumwidthof

13/16"(

● Saw blades and their fixing devices shall conform

to EN 847-1:2005.

10”(254mm), arbor size 5/8”

20.6mm)are allowed for the main saw

The machine is prohibited to be used in a

potentially explosive atmosphere!

3.5 Requirements of Electrical Power

List of the motor using & pre-wired voltage

Item

2HP 1.65kW

Voltage(V) 115(230 V) 230 V

Phase 1 PH 1 PH

Freq.(Hz) 60Hz 50Hz

Rated current A 16(8)A

Prewired 115 V/1 PH 230 V/1 PH

Note: For correct option of power supply, please

refer to the specifications Label on the product.

The recommended amperage of the power supply

line is 20 A.

The steady-state AC power supply is 0.9 -1.1 times

of the rated value.

Motor

8A

Site of installation/use:

● The machine is not suitable for use outdoors, or in

rooms that are subject to moisture or the risk of

explosions.

●The intended use of the machine involves

connection to a suitably dimensioned chip and dust

extraction system .

● Intended use also involves compliance with our

specified operat ing, maintenance and repair

conditions and the safety information contained in

the operating instructions.

● The table saw may only be used, set up and

maintained by persons who are familiar with the

machine and aware of the dangers.

● The pertinent accident prevention regulations as

well as any other generally recognized technical and

industrial safety rules must be observed.

● Repair work must be carried out by our own

customer service or by an organization that we have

authorized to repair tools. Only original spare parts

are allowed. We will assume no warranty for any

damage that is caused by using non-original spare

parts.

Electrical Protection

End user should provide protection device against

overvoltage due to lightning and short-circuited

protection device at the power supply.

Ingress P rotection at the Inlet of Incoming

Power Cable

The method of the incoming cable should ensure

IP54 protection class when installation is finished.

4

4. Safety Regulations

4.1 General Safety Instructions

1. KNOW YOUR MACHINE.

Read and understand the owners manual and

labels affixed to the machine. Learn its application

and limitations as well as its specific potential

hazards;

2. GROUND THE MACHINE.

In the event of an electrical short, grounding

reduces the risk of electrical short;

3. KEEP THE BLADE GUARDS IN PLACE.

Keep in good working order, properly adjusted and

aligned;

4. REMOVE THE ADJUSTING TOOLS

Form a habit of checking that the key and adjusting

wrenches are removed from the machine before

turning it on;

5. KEEP THE WORK AREA CLEAN.

Cluttered areas and benches invite accidents.

Make sure the floor is clean and not slippery due to

wax and sawdust build-up;

6. AVOID A DANGEROUS ENVIRONMENT.

Don’t use machines in damp or wet locations or

expose them to rain. Keep the work area well lit

and provide adequate surrounding work space;

7. KEEP CHILDREN AWAY.

All visitors should be kept a safe distance from

work area;

8. MAKE WORKSHOP CHILD-PROOF.

With padlocks, master switches or by removing

starter keys;

9. USE THE PROPER SPEED.

A machine will do a better and safer job when

operated at the proper speed;

10. USE THE RIGHT MACHINE.

Don’t force the machine or the attachment to do a

job for which it was not designed;

11. WEAR THE PROPER APPAREL.

Do not wear loose clothing, gloves, neckties or

jewelry (rings, watch) because they could get

caught in moving parts. Non-slip footwear is

recommended. Wear protective hair covering to

contain long hair. Roll up long sleeves above the

elbows;

12. MAINTAIN PROPER FOOTING.

Keep proper footing and balance at all time. Do

not over-reach to perform an operation;

13. MAINTAIN THE MACHINE WITH CARE.

Keep tools sharp and clean for the best and safest

performance;

14. DISCONNECT MACHINES.

Before servicing, when changing accessories or

attachments;

15. AVOID ACCIDENTAL STARTING.

Make sure the switch is in the “OFF” position

before plugging in;

16. USE RECOMMENDED ACCESSORIES.

Consult the manual for recommended accessories.

Follow the instructions that accompany the

accessories. The use of improper accessories may

cause hazards;

17. NEVER STAND ON THE MACHINE.

Serious injury could occur if the machine tips over.

Do not store materials such that it is necessary to

stand on the machine to reach them;

18. CHECK FOR DAMAGED PARTS.

Before further use of the machine, a guard or other

parts that are damaged should be carefully

checked to ensure that they will operate properly

and perform their intended function. Check for

alignment of moving parts, breakage of parts,

mounting, and any other conditions that may affect

its operation. A guard or other parts that are

damaged should be properly repaired or replaced;

19. NEVER LEAVE THE MACHINE RUNNING

UNATTENDED.

Turn the power to "off". Do not walk away from the

machine until it comes to a complete stop;

20. ADEQUATE LIGHT

Ensure that adequate general or localized lighting

is provided in work area;

4.2 Table Saw Safety Instructions

1. ALWAYS USE A GUARD.

Always use a guard 、 splitter and anti-kickback

fingers on all “thru-sawing” operations.

Thru-sawing operations are those when the blade

cuts completely through the work piece as in

ripping or crosscutting;

2. ALWAYS HOLD THE WORK.

Always hold the work firmly against the miter

gauge or fence;

3. ALWAYS USE A PUSHSTICK OR PUSH

BLOCKS.

Push blocks or push sticks shall be used when

cutting small workpieces and in circumstances

where it is necessary to push the workpiece

against the fence;

4. NEVER PERFORM UNSAFE OPERATIONS.

Never perform any operations “free-hand” which

means using your hands to support or guide the

work piece. Always use either the fence or the

miter gauge to position and guide the work piece;

5

5. STAND TO THE SIDE WHEN FEEDING

MATERIAL.

Never stand or have any part of your body in line

withthepathofthesawblade;

6. USE CAUTION WHEN REACHING FOR

OBJECTS.

Never reach behind or over the cutting tool with

either hand for any reason;

7. SAFE CROSSCUTTING OPERATIONS.

Move the rip fence out of the way when

crosscutting;

8. ENSURE CORRECT FEEDING OF MATERIAL.

Feed the work into the blade against the direction

of rotation;

9. CORRECT USAGE WITH THE FENCE.

Never use the fence as a cut-off gauge when you

are cross-cutting;

10. ALWAYS TURN THE POWER TO THE "OFF"

POSITION.

When attempting to free a stalled saw blade,

always turn the saw to the "off" position and

disconnect it from the power source.

11. PROVIDE ADEQUATE SUPPORT.

To the rear and sides of the table saw for wide or

long work pieces;

12. AVOID KICKBACKS.

Avoid kickbacks (work thrown back towards you)

by keeping the blade sharp, by keeping the rip

fence parallel to the saw blade, by keeping the

splitter and anti-kickback fingers and guard in place

and operating, by not releasing work before it is

pushed all the way past the saw blade, and by not

ripping work that is twisted or warped or does not

have a straight edge to guide along the fence;

13. AVOID AWKWARD OPERATIONS.

Avoid awkward operations and hand positions

where a sudden slip could cause your hand to

move into the spinning blade;

14. BLADE REQUIREMENTS.

Only correctly sharpened saw blades

manufactured in accordance with the requirements

of EN 847-1:2005 shall be used;

15. CORRECT SAW BLADE USAGE.

No saw blade shall be used where the maximum

marked speed is lower than the maximum

rotational speed of the saw spindle;

16. CHIP AND DUST.

The mac hine shall be connected to an external

chip and dust extraction system;

The dust extraction equipment is to be switched on

before commencing machining;

17. CHECK

Periodically check the brake function to make sure

the completed stop time of the saw blade is less

than 10 seconds.

4.3 Residual Risks

1. Take precautions to reduce the hazard of

inhalation of harmful dusts (e.g. wearing a dust

mask);

2. Wear ear protection to prevent hearing loss;

3. Always wear safety glasses. Also use a face

or dust mask if t he cutting operation is dusty;

4. Protect against the hazard of handling saw

blades when doing maintenance;

5. Do not attempt to remove chips while the

blade is still moving;

6. Do not use the machine unless all of the

guards and other safety devices necessary for

machining are in good working order;

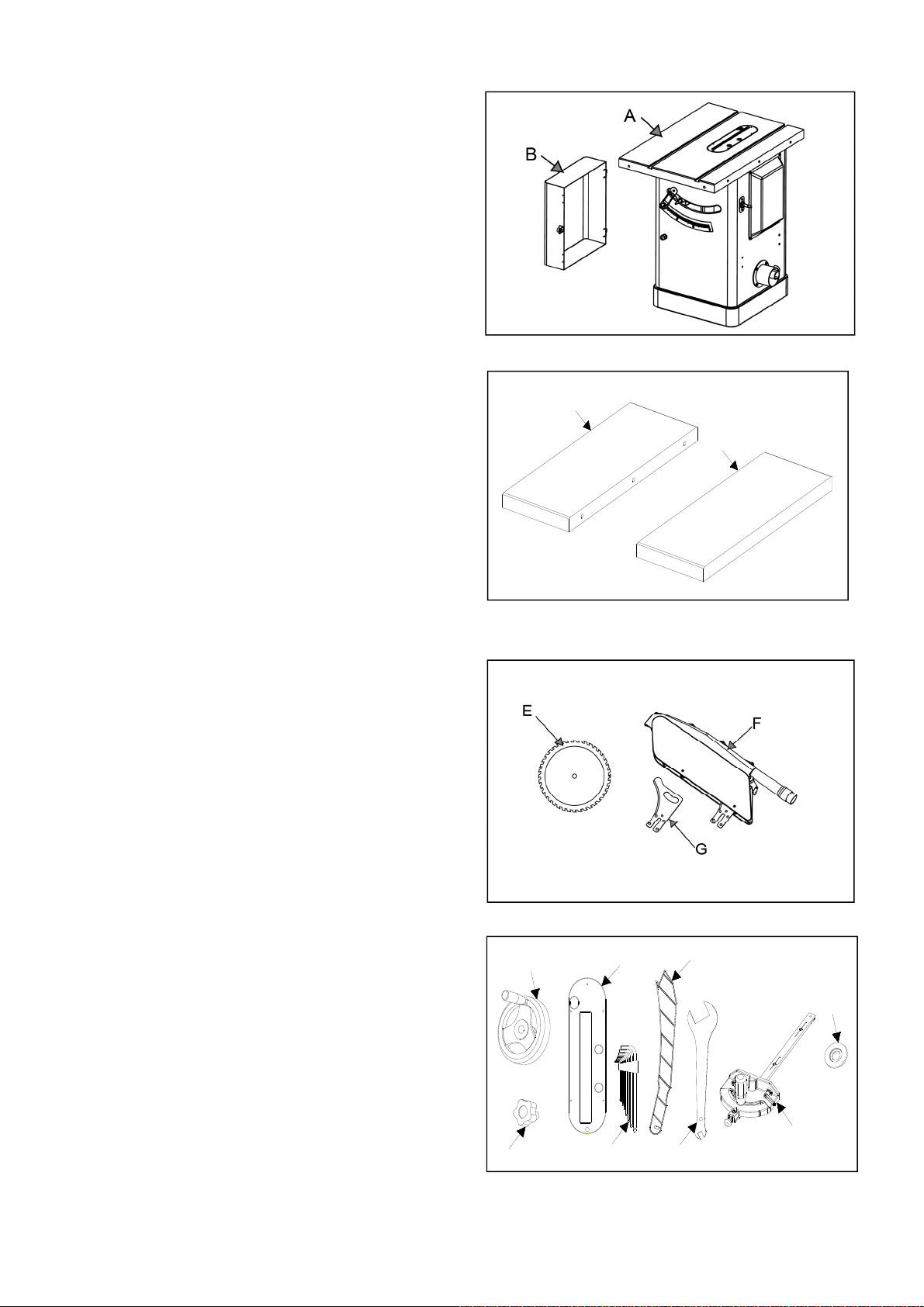

4.4 Safety Equipments

Apushblock(Fig. 2) and A push stick (Fig. 3)

must be used

Fig. 2

Fig. 3

If the workpieces is less then 120 mm, you

must use the push stick to prevent your hands

from getting too close to the saw blade.

Push block must be used to cut narrow

workpieces and, when necessary, to push the

workpiece against the fence. A push block can

be easily made by the operator as shown in Fig.

2.

6

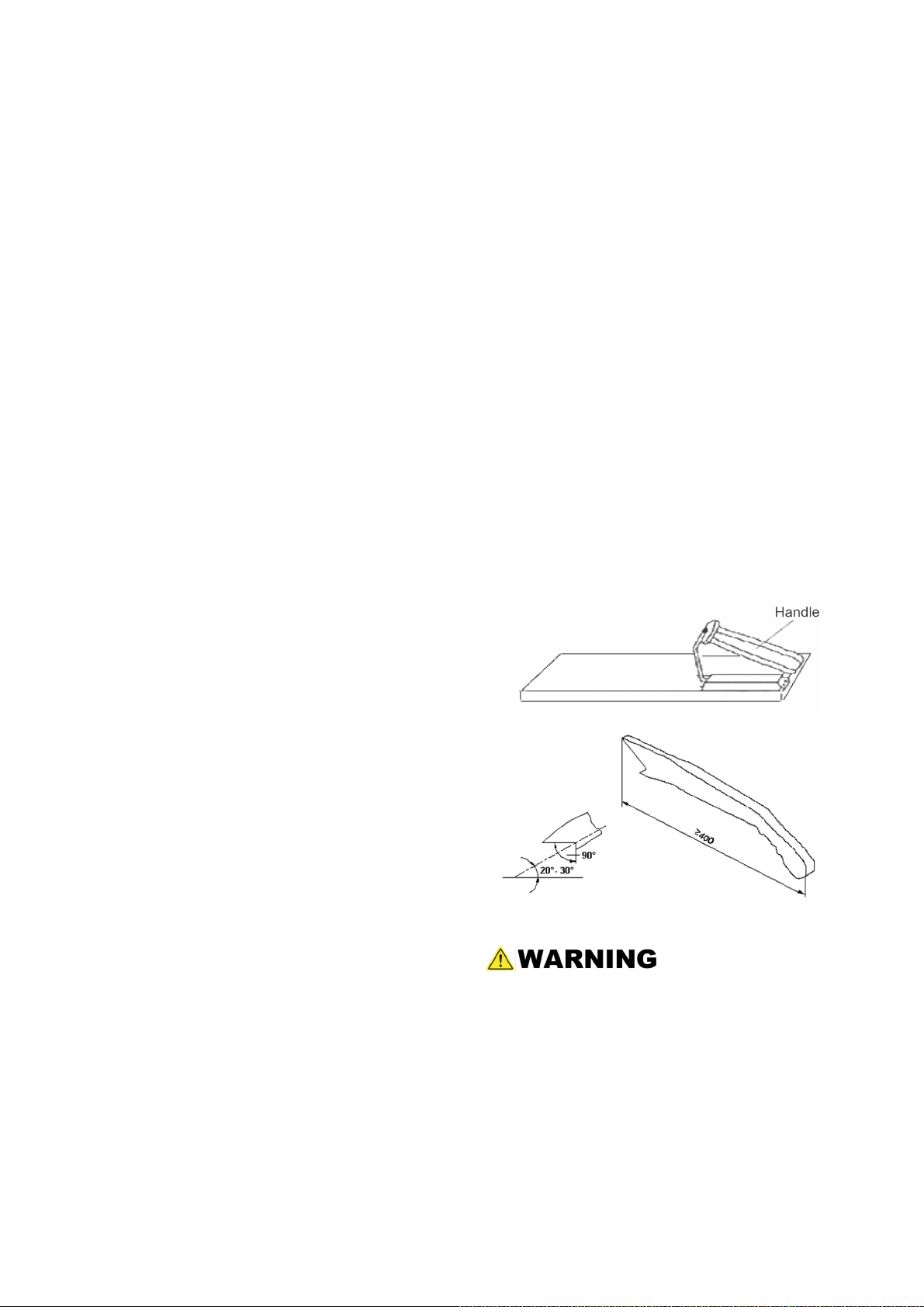

5. Installation of the Machine

5.1 Transportation of Machines

5.1.1 Transportation and Storage

Anti-rust and shock-proofing measures were taken

during packaging. The machine is able to endure

temperature variations of -13 to 130 degrees F. Do

not expose the machine to rain and avoid

damaging the packaging during transportation and

storage.

5.2 Unpacking

Your machine was carefully packaged for safe

transportation. R emove the packaging materials

from around your machine and inspect it. If you

discover the machine is damaged, please

immediately call Customer Service for advice.

Save the containers and all packing materials for

possible inspection by the carrier or its agent.

Otherwise, filing a freight claim can be difficult.

While transporting or handling the machine, be

careful and let the activity be done by qualified

personnel especially trained for this kind of

activity!

While the machine is being loaded or unloaded,

make sure that no person or subject gets

injured by the machine!

Select proper transportation device according

to the weight of the machine. Make sure the

lifting capacity of the transportation device is

competent for the weight of the machine.

5.1.2 Transportation before unpacking

As standard, the machine is packed in a robust

cardboard box. Fig. 4 shows the tool can be used

to transport the packing box.

Note: If you can't find an item on this list, check

the mounting location on the machine or

examine the packaging materials carefully.

Occasionally we pre-install certain components

for shipping purposes, or in other packing;

Fig. 4

7

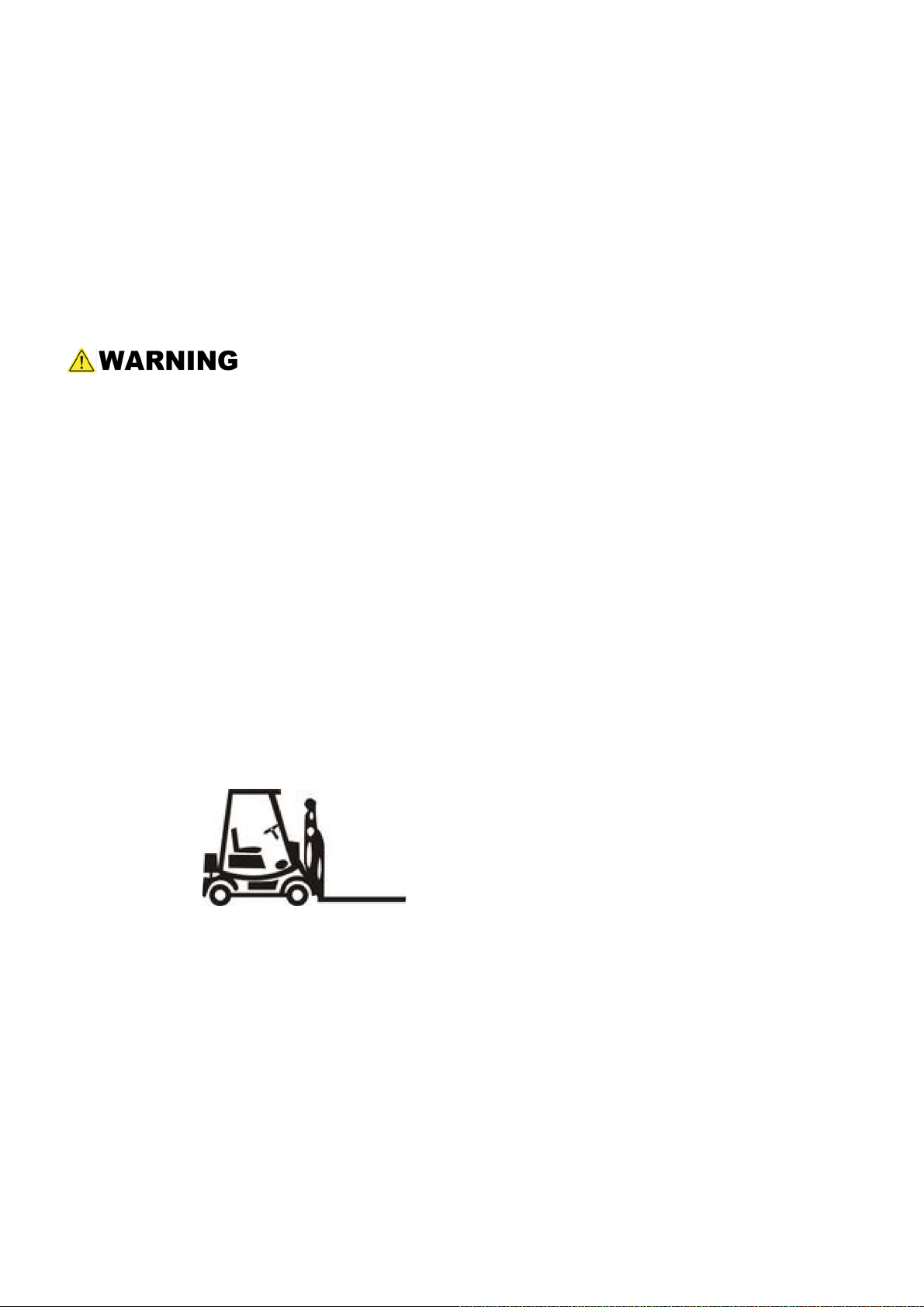

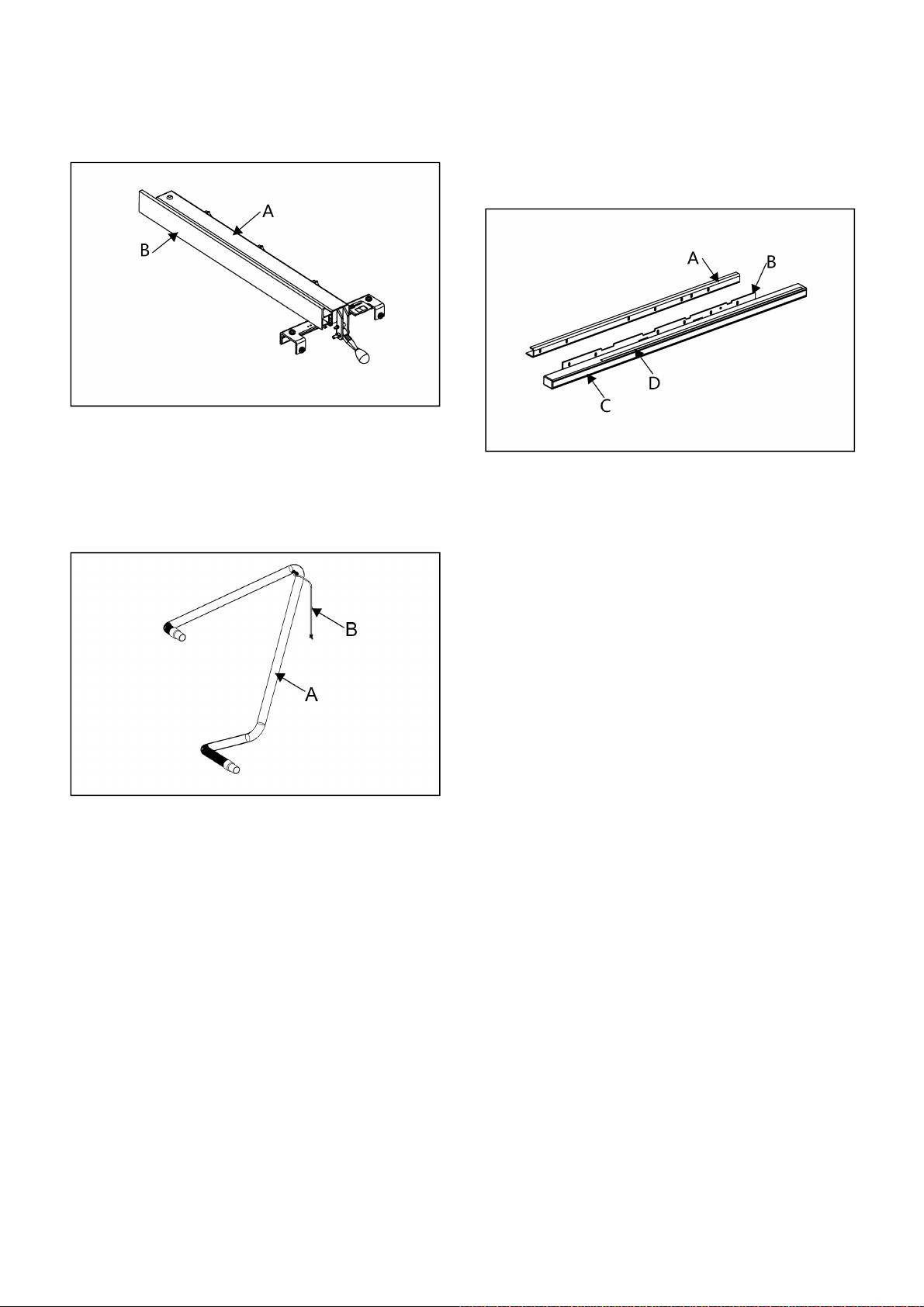

5.3 Contents of C200-30

Main machine box contents:

(Fig. 4-1-----Fig. 4-4)

A. Main table saw unit……..………..………1

B. Motor cover……….……..………..………1

C. Left extension table……..………………1

D. Right extension table…………………1

E. Saw blade…………………………………1

F. Blade guard assembly…………………1

G. Rivin g knife…….. ……….. …….. ……… 1

H. Hand wheel……………..………..………1

I. Lock knob..….. ………..………..………1

J. Hex wrench set (eight pieces)…..…1

K. Wrench open-end 17/23 mm…..………1

L. Miter gauge…..………..…..…..………1

M. Dado Blade Flange…………………….1

N. Push stick…..…… .. …..……… ..……… 1

O. Dado table insert……..………..……… 1

Fig. 4-1

C

D

Fig. 4-2

Fig. 4-3

H

O

N

M

8

I

Fig. 4-4

L

J

K

Fence box contents:(Fig. 4-5)

A. Fence body…..…..……………… ..……1

B. Fence………………………………..…..1

Fig. 4-5

Rail box contents:(Fig. 4-7)

A. Rear rail…………… ..……………..…… 1

B. Front rail…………….…………..………1

C. Front rail rectangular tube………...…1

D. Front rail tape scale………………….…1

Flexible hose box contents:(Fig. 4-6)

A. Flexible hose (length 2.5 m)…………...1

B. Hose bracket ……………………………..1

Fig. 4-6

Fig. 4-7

5.4 Safety Measure before Installation

It is important to maintain a free area of 2.5 ft.

around the machine, which is required for the

working place. If any long material is machined, it is

necessary to have a sufficient room in front of the

machine as well behind it in the places of material

input and output.

9

Loading...

Loading...