Harvest TEC 720 Owner's Manual

Model 720 Dew Simulator Owner’s Manual -18

5/18

Owner’s Manual

Model 720 Dew Simulator

Natural Dew Simulation Machine

1

(intentionally blank)

2

Model 720 Dew Simulator Table of Contents

Page

Introduction

5

Requirements

5

Safety

6

Safety Decal Definitions

6

Safety Decal Locations

7

Setup

8-12

Unloading the Machine

8

Connecting the Reel

9

Connecting Hoses

10

Connecting Perimeter Nozzle Hoses

10

Preparing the Water Supply Trailer

11

Hooking up Tractor, Dew Sim & Trailer Tank

12

Machine Setup

13-18

Installing Tines & Tips

13

Tine Assemblies

13

Tip Rate Chart – MW5 & MW11 Tips

14

Drive Chain

15

Trip Sections

16

Adjusting Trip Sections

16-17

Operating Perimeter Nozzles

17

Perimeter Nozzle GPM

18

Description of Electronic Valves and Sensors

18-19

2Way Valve

18

Warming Valve

18

Arm Switch

19

Installing Controls

20

Wiring Diagram

20

Initial Operation

21-22

Turning on the Dew Simulator

21

Priming the System

21

Determining Operation Settings

21-22

Setting Pressures

22

Warming Up Systems

22

Operating

22-28

Control Box

23

Screen Definitions

23

Field Setup Screen Steps

24

Minimum and Maximum Levels

24

Main Screen

25

Heater #1 & #2

26

Arm Override

26-27

Warming Valve

27

Operating Temp Status

27

Target PSI

28

Target GPM

28

Operation of the Dew Simulator

28-31

Removal of the Ground Drive Chain

29

Field Operation

29

Using Surfactant

30

Maintenance

30

3

Maintenance Schedule

30

Preventative Maintenance

30

Maintenance Details

30

Heater Coil Descaling Procedure

31

Winterizing Procedures

32

Troubleshooting

33-36

Pin Outs

36-41

Parts Breakdown

42-59

Tine Assembly

42

Valve Assembly

42

Valve Exploded View

43

Valve Trip Assembly

43

Cross Tube Assembly

44

Trip Assembly

44

Cam Mount Assembly

45

Reel Dumbbell Assembly

45

X-Tube Bearing Assembly

46

Perimeter Nozzle Pump Assembly

46

Perimeter Nozzle Pump Feed

47

Perimeter Nozzle Assembly

47

Reel Assembly

48

Lift Arm Assembly

49

Lift Arm Support Assembly

49

Perimeter Nozzle Manifold Assembly

50

Hydraulic Cylinder Assembly

50

Limit Switch Assembly

51

Pump Assembly

51

Cart Assembly

52

Flow Switch Assembly

53

Pump Discharge Front

53

Pump Discharge Rear

54

Pump Intake

54

Hi Temp Dump Valve Assembly

55

Heater Skid Assembly – Front View

56

Filter Bracket Assembly

56

Heater Skid Assembly – Rear View

57

Burner Motor Replacement Parts

58

Trailer Parts

59

Tractor Parts

59

Notes

62-63

Warranty Statement

64

4

Introduction

The new Model 720 Dew Simulator allows for the precise addition of hot water mist to windrowed alfalfa. The

windrow will be as soft as if it had just received the ideal amount of dew. By spraying into the windrow prior to

baling, moisture is added to all of the plant material. The hot water mist softens the hay, giving the hay the

appearance and test of hay made with natural dew.

Right and Left sides are determined by facing in the direction of forward travel.

Requirements

Tractor size and horsepower

o Min 80 horse power, Approximately 9,000lbs, 1000 rpm PTO

o 90A alternator, strong 12V battery & charging system

o System at max draws approximately 40-50 Amps @ 13VDC. Reduced voltage will cause reduced

heater performance

Suggested trailer and tank

o Tandem axle 1,000 gallon water trailer

Below is an example of a water tank, Dew Simulator and tractor setup.

5

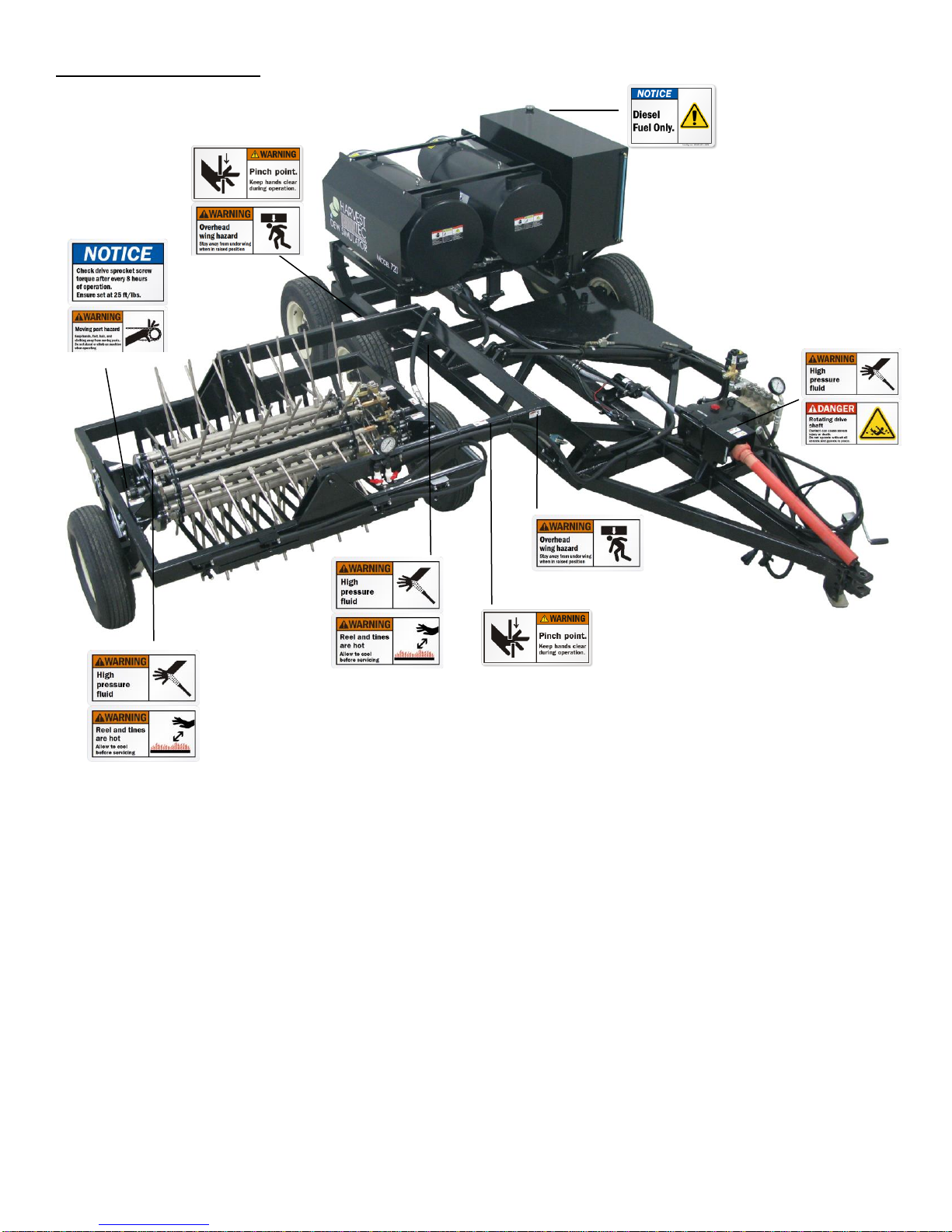

Safety

DCL-720-03

DCL-720-06

DCL-720-04

DCL-720-05

DCL-720-07

DCL-720-08

DCL-720-09

DCL-720-10

DCL-720-11

DCL-Yellow Reflector

2” x 9”

DCL-Red Reflector

2” x 9”

Carefully read all the safety signs in this manual and on the equipment before use. Keep signs clean and in

clear view. Replace missing or damaged safety signs. Replacement signs are available from your local

authorized dealer. Keep your Dew Simulator in proper working condition. Unauthorized modifications to the

system may impair the function and/or safety of the machine. Carefully read and understand all of the safety

signs before installing or servicing the 720 Dew Simulator.

Safety Decal Definitions

6

Safety Decal Locations

7

Setup

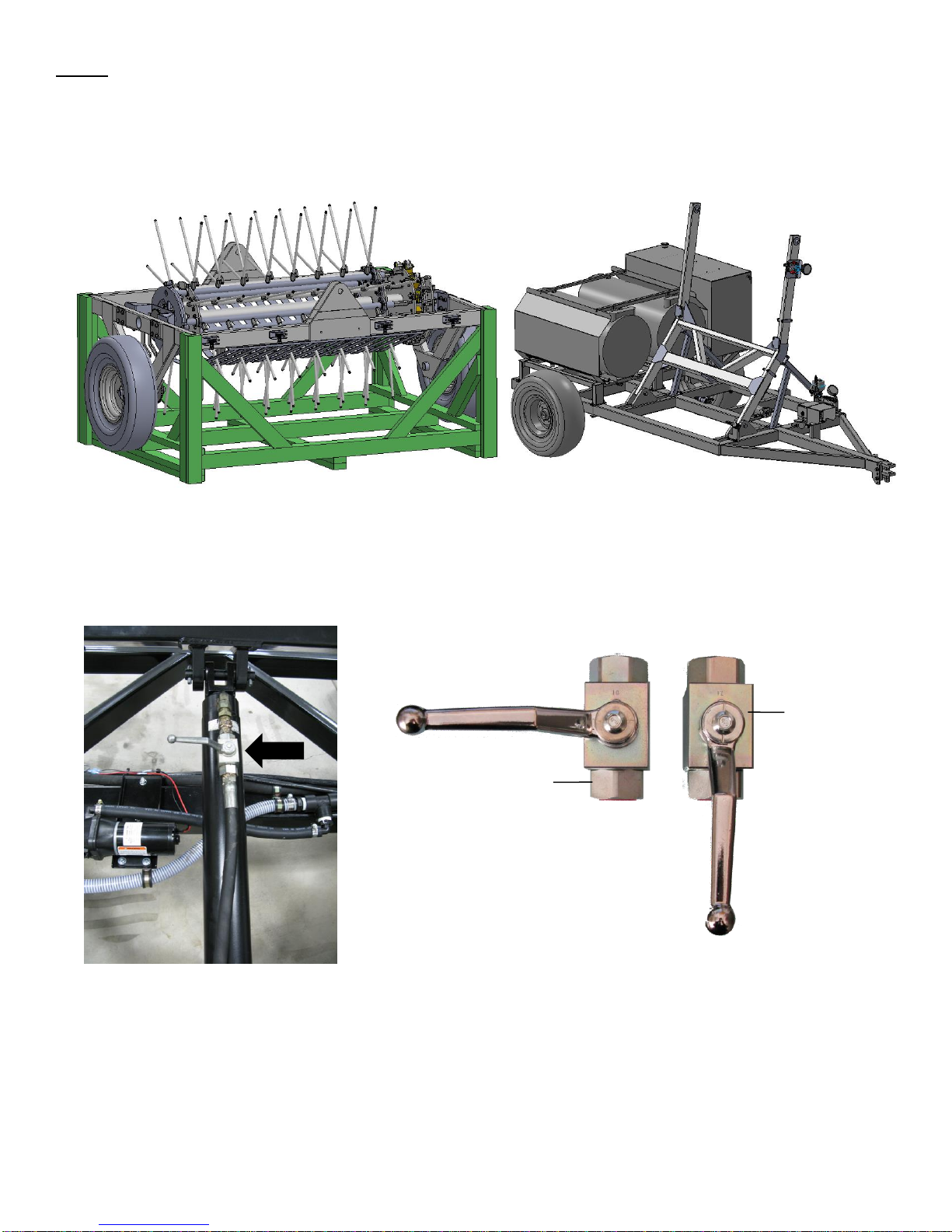

Reel Skid Assembly

Cart Assembly

Open

Closed

Unloading the machine

1. Unload the reel skid assembly and the cart assembly shown below and remove packaging. The reel skid is

designed to be handled from the front side (valves to right side) with pallet forks.

2. Attach the cart assembly to a tractor and connect the hydraulic couplers

3. Turn the hydraulic valve to the unlocked position

8

Connecting the Reel

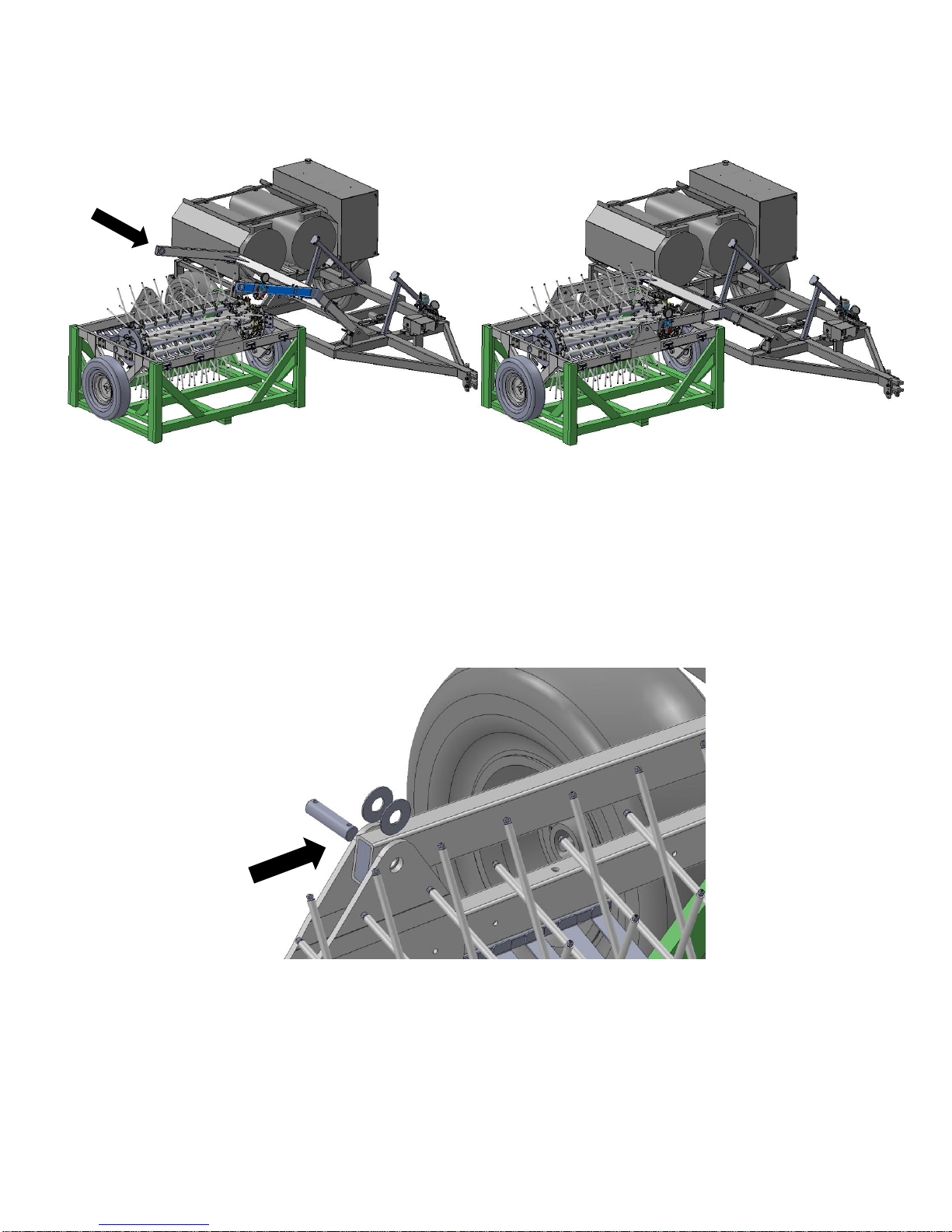

Reel & Cart assemblies w/ lift arm being lowered

Reel & Cart assembly aligned

1. Position the reel skid assembly next to the cart assembly and lower the lift arm partial with the hydraulics

and position the reel so it is aligned, *side with valves goes towards the cart (below left).

2. Align the holes in the lift arms with the holes in the reel frame (above right).

3. Install the Pins & bushings (found in the cart parts box) see below. The bushings are located between the

inside of the reel frame brackets and the lift arm on the front and back side of the lift arm. After the pins and

bushings have been installed, cut the banding attaching the reel to the skid and lift the now connected reel

assembly into the full transport position so the lift arm is resting against the stops. Remove the reel

shipping skid.

9

Connecting Hoses

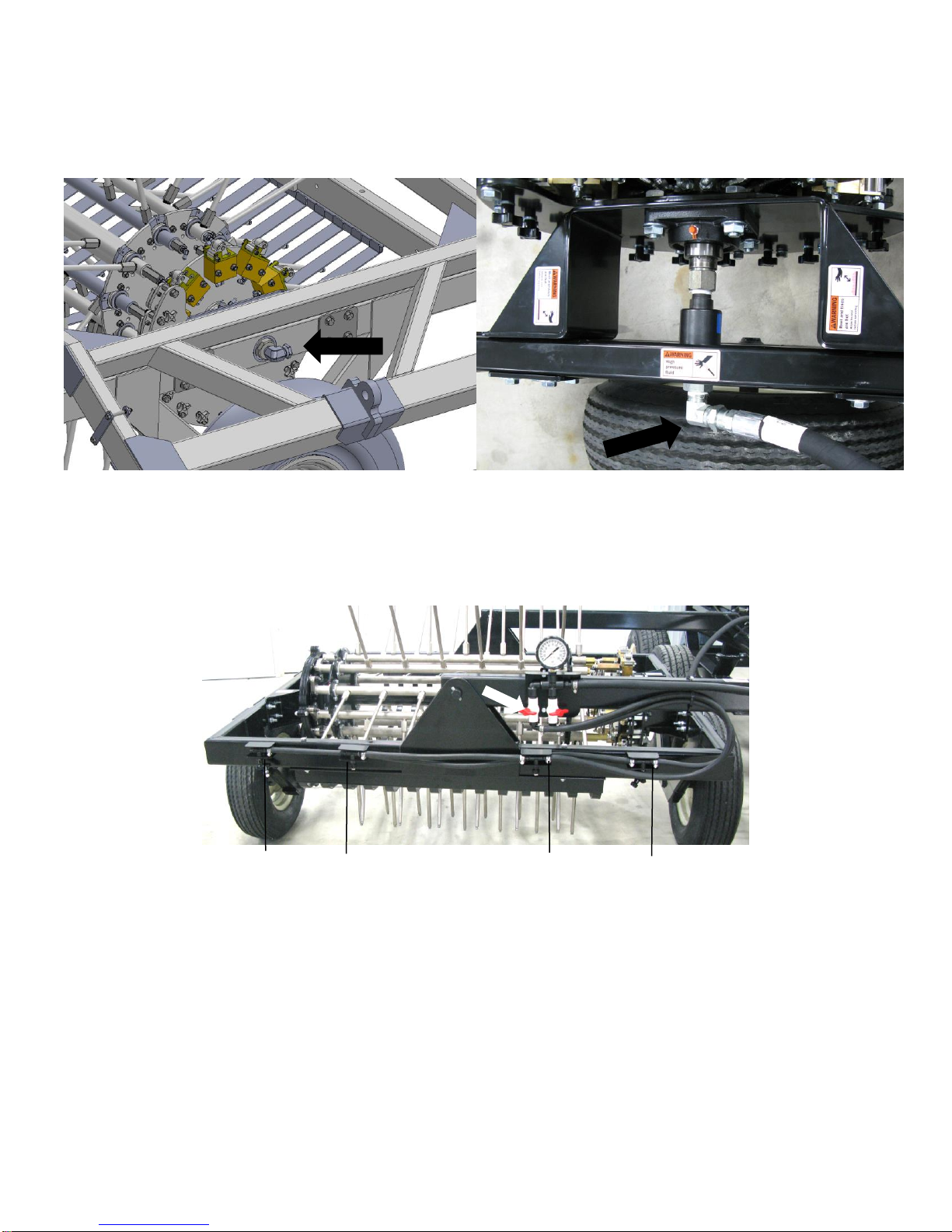

Connection location on the reel assembly

Above view of the water line reel connection

Outside tip

Outside tip

Inside tip

Inside tip

Lower the reel from the transport position to the field operating position so both reel tires are on the ground.

Connect the stainless steel 3/4” water line attached to the back of the lift arm to the elbow attached to the

swivel (below). Secure hose to reel frame with supplied Jiffy clip.

Connecting the Perimeter Nozzle Hoses

1. Locate the gauge & valve manifold on the front of the lift arm attached to the reel assembly (below).

2. Following the routing path shown above connect the black 1/2” hose from the valve on the right to the

outside tip manifold straight fitting, cut to length and secure with hose clamp. On the opposite side of the

manifold route the hose to the other outside tip straight fitting on the left side of the reel assembly. The

hose and corresponding fitting are marked with color coded cable ties.

3. Following the routing path shown above connect the black 1/2” hose from the valve on the right to the

inside tip manifold straight fitting, cut to length and secure with hose clamp. The hose and corresponding

fitting are marked with color coded cable ties.

10

Preparing the Water Supply Trailer

The 720 Dew Simulator will require a water supply trailer (not included). The following step will explain the

installation of the supply, return fittings and hoses.

1. Install the 2” bulkhead (connector in the bottom of the tank. Then install the 2” elbow (003-EL2020) fitting in

the bulk head.

2. Attach the 2” hose (provided) to the 2” elbow fitting, route to front of trailer, cut hose to length and install 2”

valve/coupler.

3. Install 1/2” stainless steel bulkhead in bottom of the tank, or front side towards the bottom of tank, install

the steel 1/2” NPT x 3/4” Elbow (003-DSEL1234) and black green stripe hose. Route hose to rear of Dew

Simulator and cut hose to length, attach to the aluminum coupler (002-2204B). Locate the ¾” On/Off valve

with hose barb fittings attached between the coupler at the hitch and fitting at the bottom of the tank.

Secure the green stripe hose to each fitting and secure with the provided hose clamps. *Note that water

returning to the tank through this line will approach 200 F.

4. Install 3/4” plastic bulkhead on the front side of the tank near the top, or on the top side of the tank. Install

the 3/4” plastic elbow. Attach green stripe hose to the 3/4” plastic elbow and route hose to the rear of the

dew simulator. Cut hose to length and install the plastic male coupler. Secure the hoses with hose

clamps.

11

Hooking up Tractor, Dew Sim, and Trailer Tank

2” Valve Coupler

Trailer Light

Connection

3/4” Aluminum Coupler

3/4” Plastic Coupler

1. Connect the tractor to the cart assembly with a 1-1/4” draw pin (below).

2. Adjust the front hitch position to level the cart assembly to the tractor drawbar. The cleats can be moved up

or down as needed.

3. Connect the water trailer to the rear of the cart assembly with a 1-1/4” draw pin (shown above).

4. Adjust the rear hitch position to level the water trailer to the cart assembly

5. Connect the 2” valve/couple to the coupler at the rear of the Dew Simulator

6. Connect the metal valve assembly female coupler to the aluminum male coupler at the rear of the Dew

Simulator.

7. Connect the 3/4” plastic male coupler to the plastic female coupler at the rear of the Dew Simulator

8. Connect the trailer lighting connector to the rear of the Dew Simulator. See trailer wiring schematic for

additional information.

12

Machine Setup

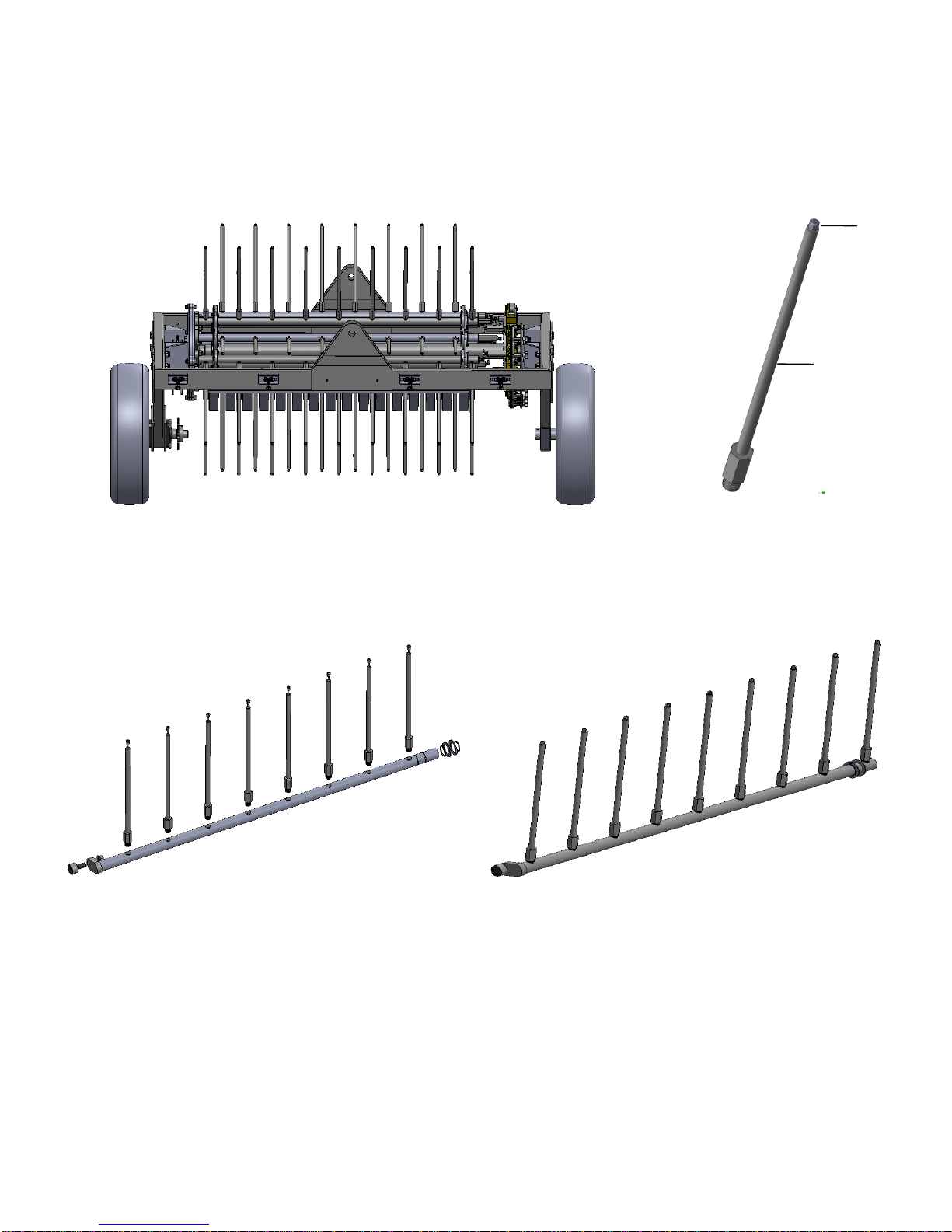

Reel Assembly

Tine / Tip Assembly

8-Tine Cross Tube Assembly (x5)

9-Tine Cross Tube Assembly (x5)

Tine

Tip

Installing Tines & Tips

The reel assembly is shipped with 65 tines installed each with a size MW11 tip (below left). There are 20 plugs

installed on the reel assembly as well that can be removed by using a 3/8” Allen wrench and replaced with

additional tines & tips (below right).

Tine Assemblies

Below are illustrations of the 8 and 9 Tine Cross Tube Assemblies located on the reel assembly. There are five

of each cross tube assemblies (below).

Each cross tube has two holes with a plug in the tube. If the width of the windrow is wider than 45.5” covered

by the initial 65 tine & tip assembles installed, adding additional tips will be necessary. Remove the plugs using

a 3/8” Allen and add in the new tine & tip assemblies. Each additional set of 10 tips will increase the width of

coverage by 6.5” with a maximum increase of 13”. Tighten to approximately 150ft/lbs, recommend that Teflon

tape or liquid thread sealant not be used, but that a drop of high strength locktite or equivalent be used on each

thread. Do not use Teflon tape or tocktite on the tips.

Tip and tine assemblies can also be removed and replaced with plugs to reduce the coverage for thin, light, or

narrow windrows.

13

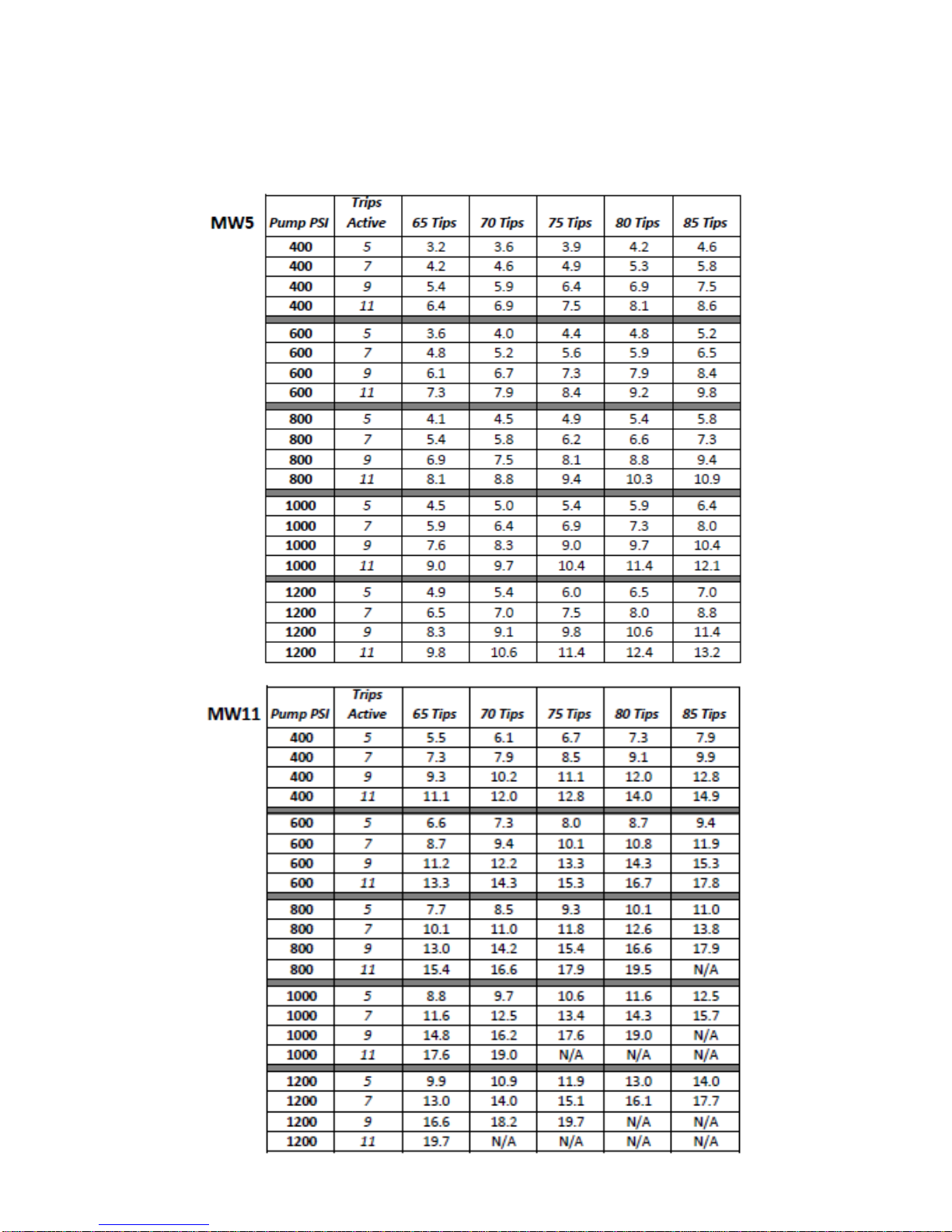

Tip Rate Chart

Use the chart below to determine the output (GPM) required by the dew simulator based on the field (ton/acre,

swath width, desired speed) and windrow (# of trips active) conditions. If tips need to be changed, a 7/16”

wrench or socket will be required to remove the tip currently installed. MW5 and MW11 tips, as well as

additional tines, can be purchased as spare parts from Harvest Tec.

14

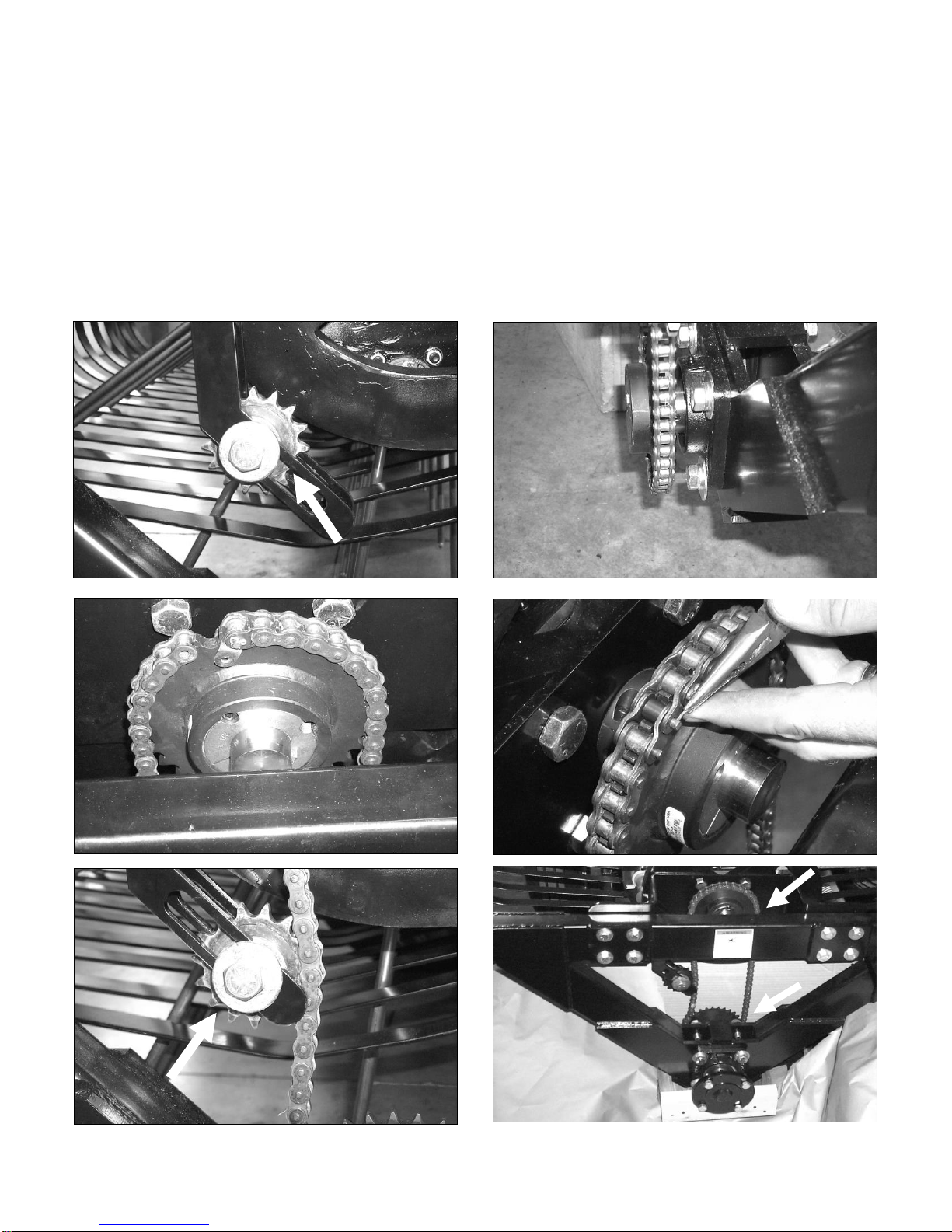

Drive Chain

1 2 3

4

5

6

The Model 720 Dew Simulator comes with a drive chain installed, which allows the reel to be ground driven at

a rate where rotation of the reel matched forward movement. This gearing allows the tines to enter and exit the

windrow without significant disturbance or movement of the windrowed material. In heavier windrows, or

windrows that have been raked tightly or raked multiple times, it is possible to run the machine without the

drive chain installed, letting the windrow turn the reel. This is recommended in most conditions.

In windrow conditions where the hay is either thin or the windrow is matted down and there is not enough

windrowed material to turn the reel, the drive chain will need to be installed. To reinstall the drive chain, begin

by loosening and sliding up the idler sprocket. Install the drive chain and complete the installation by moving

the idler down against the backside of the chain until it is tight and tighten the idler bolt.

15

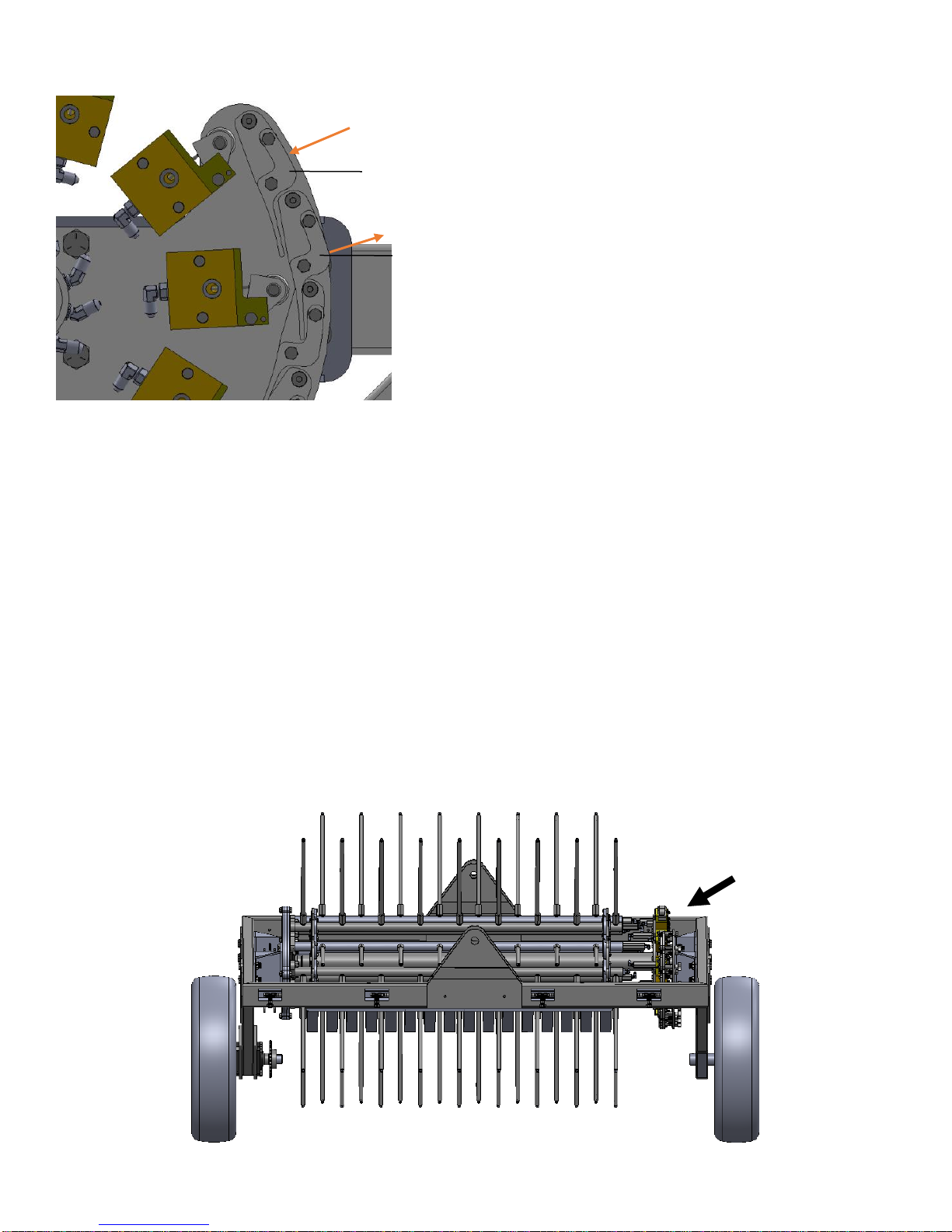

Trip Sections

Trip active

Trip inactive

The trip sections shown (left) will determine when each cross

tube section will spray as the reel assembly rotates.

Adjusting Trip Sections

Adjust trip sections that are active based on windrow size/shape/and condition.

If the windrow is tall and fluffy, adjust the sections so the tines turn on as soon as they enter the

windrow.

If the windrow is shorter, shut off the leading trip sections so the tines do not turn on until they are about

to enter the hay.

If less water is required to be added to the windrow, turn off rear trip sections so the tines don’t spray

the entire time they’re in the windrow.

If there is moisture in the bottom of the windrow but the top 2/3 of the windrow is dry, turn off trip

sections at the bottom of the arc so the tines turn on as they enter the windrow and turn off for the

bottom 1/3, then turn back on until they exit the windrow.

To activate, loosen the adjustment bolt on the backside of the valve plate by loosening with a 3/8” wrench.

Slide the assembly up in the slot and retighten the bolt. To deactivate sections, loosen the bolt and slide down

in the slot away from the valves and tighten in position.

16

Adjusting Trip Sections (continued)

Front View Reel Trip Section

Reverse View Reel Trip Section

-Loosen and raise in slot, tighten to activate section

-Loosen and slide down in slot to deactivate section

Operation of Perimeter Nozzles

Adjustment

Bolts

On

Off

The perimeter nozzles are used to apply ambient temperature (non-heated) water in a course spray as a

supplement to the heated reel spray when evaporative conditions are high, either due to extremely low

humidity or the presence of wind. The perimeter nozzle spray is selectable, the spray can be focused on the

sides of the windrow, top of the windrow, or both, based on the valve settings on the perimeter nozzle

manifold. See picture below.

Left Valve – Inside Nozzles

Right Valve – Outside Nozzles

The perimeter nozzles operate off of a separate pump that is controlled by the switch and dial on the cab

controller. The toggle switch turns the pump on, and the dial is used to increase or decrease the pressure of

the tips. The chart below provides an estimate of the GPM for 2 and 4 tips at varying pressures. The perimeter

nozzle pump will automatically turn off when the Arm Switch is not activated and the Arm Override is not

activated.

17

Perimeter Nozzle GPM

PSI

XR11008VS

(x2)

XR11008VS

(x4)

10

0.80

1.60

15

0.98

1.96

20

1.13

2.26

25

1.26

2.53

30

1.39

2.77

35

1.50

2.99

40

1.60

3.20

45

1.70

3.39

50

1.79

3.58

Description of Electric Valves and Sensors

2Way Valve

The 2way valve is located on the pressurized side of the pump outlet at the rear

of the pump. When inactive, this valve is normally open. In its normally open

state, fluid from the outlet of the pump is returned to the tank. When it is closed,

fluid is forced through the front outlet manifold through the heaters and either

back to the tank or to the reel.

Warming Valve

The 2way warming valve is located towards the rear of the machine in between the heaters. The valve is on

the outlet side of heater #2 and is normally closed. When activated on the main screen of the control, it opens

and allows pressurized flow that has gone through the heaters to be returned to the supply tank. When the

heaters are activated and heating water, the warming valve, when opened, will allow heated water to be

bypassed back to the supply tank until the water temperature reaches 200F. Once the water temp reaches

200F, the warmup valve will automatically close and shut off on the main screen, forcing the heated

pressurized water out to the reel. The warmup valve is uses for initial priming (allowing bypass water back to

tank) and for initial heating of the system so water does not need to be sprayed on the ground until after the

temperature has reached 200F. The warmup valve will also automatically open to vent hot water back to the

tank if the output temperature rises above 270F and the flow stops. When this occurs, the green indicator light

for the warmup valve will illuminate to indicate that the valve is in the open position.

18

Arm Switch

Located towards the front of the machine on the right side of the lift arm (shown below). This is a mechanical

switch that senses when the reel lift arm is in the field operating position. The arm switch is active when it

senses the lift arm. The arm switch must be active for the 2way valve to close, thus directing flow out to the

heaters. When the arm switch is deactivated (normally open), flow from the pump is recirculated through the

pump.

For instance, if you are treating a windrow and raise the reel 12” off the ground, either when turning at the

headland or stopping in the windrow, the arm switch becoming deactivated will cause the 2way valve to open

and divert flow to the tank, shutting off flow to the reel. Similarly, for the heaters to run, the arm switch must be

active, so when the reel is raised the heaters will automatically turn off. Additionally, the system must also be

seeing a flow rate (GPM) from the flow meter before the heaters will run.

**For system priming and diagnostics, the arm switch can be overridden by the “ARM OVERRIDE” button on

the controller. Activating that button will cause the 2way valve to close and allow flow to go through the heaters

regardless of the lift arm position.

19

Loading...

Loading...