Harvest TEC 600RBC, 600RB Installation Manual

Installation Manual

Model 600RBC

Moisture Sensor Kit for Roll-Belt Round Balers

600RBC-16-INST-Imp&Metric

5/18

2

DECLARATION OF INCORPORATION

MANUFACTURER: Harvest Tec Inc.

2821 Harvey St.

P.O. Box 63

Hudson, WI 54016, U.S.A.

REPRESENTATIVE ESTABLISHED IN COMMUNITY: Profitable Farming Company

Middle Barlington, Roborough

Winkleigh, Devon, EX19 8AG

ENGLAND

The person above certifies and declares that:

VIRTUAL MACHINE: Equipment mounted on a farm press and for the application of innoculants onto forage crops.

MODEL: 600RBC-INST-17-Imp&Metric

BRAND: Harvest Tec

SERIAL NUMBER:

This application preservatives for hay Harvest Tec system meets the Directive 2006/42/EC of the European Parliment and

the Council of 17 May 2006 and other applicable European Directives including Directive 2004/108/EC on the

Electromagnetic compatability.

The application of preservatives for hay Harvest Tec system will be turned on after being installed on a farm press has been

declard in conformity with the Machinery Directive.

Person in the community authorized to provide information on the partly completed machinery and making this statement:

Richard Snell, President, Profitable Farming Company

Signed on May 21, 2011: Middle Barlington, Roborough

Winkleigh, Devon, EX19 8AG

ENGLAND

3

600RBC Installation Manual Table of Contents

Page

Introduction

4

System Requirements

4

Tools Needed

4

Installation of Moisture Sensor

5-7

Installation of Dual Channel Processor (DCP)

5

Installation of Moisture Sensor Pads

6-7

Installation of Bale Rate Timer Sensor

7

Wiring Diagram

8

Pin Outs

9-10

Common Questions

11

Troubleshooting

11

Parts Breakdown

12-15

600RBC Control and Harnesses

12

Moisture Pads

13

Optional iPad Mini Mounting Kit (030-2012MK)

14

Optional iPad Display Kit (030-2670DK)

15

Notes

16-18

Warranty

19

4

Introduction

Thank you for purchasing a Harvest Tec Model 600RBC Moisture Monitor System. This 600RBC Moisture

Monitoring System has been designed to be operated through an Apple iPad (not included) using the Hay App.

As well as the option to plug directly into most tractors that have an ISOBUS Monitor. The 600RBC Moisture

Monitoring System offers these advantages by operating through an Apple iPad:

1. Large bright, clear, colorful display

2. More durable and can be read in bright sunlight

3. Wireless connection in cab

4. Can be used for multiple other uses than just the applicator display

5. Option to tie-into the tractor ISOBUS system

The 600RBC Moisture Monitor kit includes the following parts: Dual Channel Processor (DCP), Moisture

Sensors, Harnesses, Bluetooth receiver and Miscellaneous Hardware. For your convenience a parts break

down for the 600RBC Moisture Monitoring System is included in the back of this manual. If you do have

questions please bring this manual into the dealership.

Right and Left sides are determined by facing in the direction of forward travel.

System Requirements

*iPad Mini or iPad 3rd Generation (2012) or newer, running the current iOS operating system

or one version previous required for iPad option

If choosing to operate the unit though the ISOBUS monitor, part number 006-6670A

will need to be ordered through your local equipment dealer.

Tools Needed:

- Standard wrench set

- Electric drill and bits

- Side cutter

- Standard nut driver set

- Standard socket set

- Hammer

- Center punch

5

Installation of Dual Channel Processor (DCP)

Figure 1

Figure 2

Figure 3

1. Locate mounting bolts on support bar of right side of baler (Figure 1).

2. Install DCP mounting bracket 001-4703XI as shown (Figure 2).

3. Install DCP onto mounting bracket 001-4703XI and secure (Figure 3).

4. Cover with DCP Shield 001-5650X (not shown).

6

Installation of Moisture Sensing Pads

1. Open rear tail gate of baler and lock in the up position. Refer to baler manual to lock door open.

2. Remove bale shaping discs on each side of chamber by grinding welds. Once removed grind any

remaining welds so sides of bale chamber are smooth.

3. Place plastic isolator (006-4641FX) in the same spot that the shaping disc had been. There should be a

hole in the baler that matches up with the hole in the plastic isolator. If not, use the isolator as a

template and mark the hole. Center punch the hole and drill it to 3/4" (19mm) (Note: before drilling

make sure you are not drilling into sensitive equipment on the outside of the baler). Drill through the

complete square tube. About two inches. Repeat for other side of the baler.

4. Insert plastic bushing (006-4641G) from the outside of baler. Make sure it is flush with the outside of the

baler frame. Go to the inside of the baler and mark amount that protrudes into the chamber. Remove

and cut off excess material. Repeat for other side.

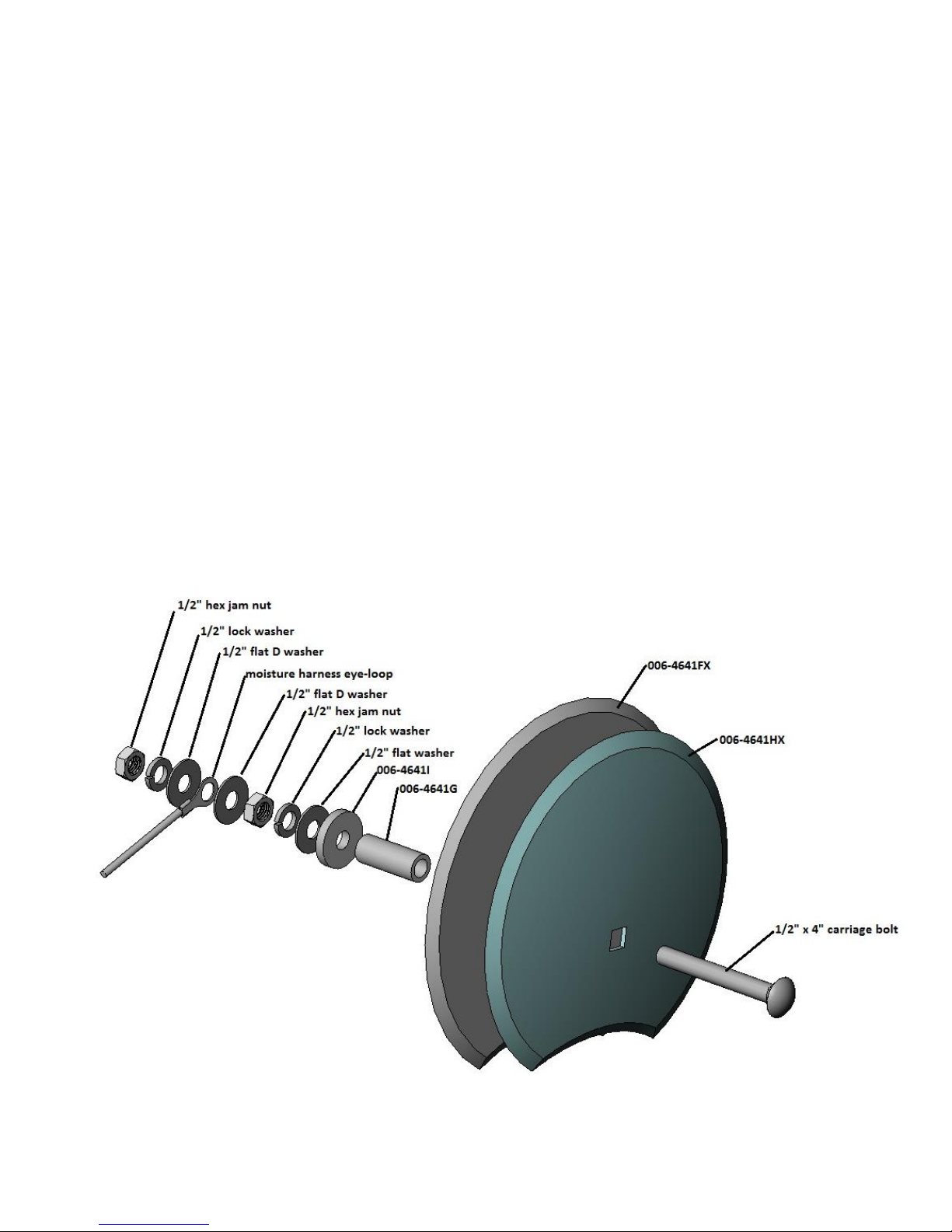

5. Using 4” carriage bolt slide the parts on in following order: metal disc (001-4641HX), plastic isolator

(006-4641FX) and shortened plastic bushing (006-4641G).

6. Insert disc assembly into 3/8” (10mm) hole from inside of bale chamber. Secure to outside of baler by

attaching to the protruding carriage bolt in the following order: small isolator (006-4641), 1/2” D shaped

washer, 1/2” lock washer, 1/2” jam nut. Tighten down and repeat for the other side. Make sure no part

of the bolt or hardware makes contact with the frame of baler-no metal to metal.

7. Route moisture harness (006-4640G3E) from processor down to the carriage bolt on each side. Make

sure it does not come in contact with any moving parts. Secure with cable ties.

8. Attach moisture cable to moisture carriage bolt by placing items in the following order: 1/2” D shaped

washer, Ring terminal of moisture harness (006-4640G3E), second 1/2” D washer, 1/2” lock washer,

1/2” Jam Nut. Tighten down and repeat for other side. Make sure none of the hardware comes in

contact with the frame of the baler.

Loading...

Loading...