Harvest Right SCIENTIFIC Freeze Dryer OWNER’S MANUAL

SCIENTIFIC Freeze Dryer

OWNER’S MANUAL

The Essential Guide for Every

Scientific Freeze Dryer Owner

CONTENTS

UNPACKING

Unpacking Your Freeze Dryer.................................. ..................................................1

Important Information About Your First Batch………..............................................1

IMPORTANT SAFEGUARDS

Safety Information.......…………...…………………......................................................2

Never Operate the Freeze Dyer if it Appears Damaged.......................................3

Be Careful About What You Put in Your Freeze Dryer...........................................3

Vacuum Pump Runs Hot........................................................................................3

Recommended Operating Temperatures..............……..........................................3

Oil Free Vacuum Pump..........................................................................................4

freeze dryer set up

Major Components.............……………………………..……………….......................…...5

Freeze Dryer Assembly & Vacuum Test...……………………………....................……..5

Your First Batch......................................................................................................9

OPERATIONAL OVERVIEW

1. Login Screen….……………………………...................................................……...11

2. Main Operations Screen................................................................................13

3. Creating/Editing a Profile..............................................................................15

4. Loading a Profile..........................................................................................25

5. Settings........................................................................................................26

5.1 – Settings – Manage Profiles.............................................................28

5.2 – Settings – User Accounts...............................................................28

5.3 – Settings – Watlow RM Configuration.............................................29

5.3.1 – Settings – Watlow RM Configuration – Analog Inputs......... ....30

5.3.2 – Settings – Watlow RM Configuration – Digital I/O....................31

5.3.3 – Settings – Watlow RM Configuration – Limit............................31

5.3.4 – Settings – Watlow RM Configuration – Vacuum Input

Linearization................................................................................32

5.3.5 – Settings – Watlow RM Configuration – Control Loop..............33

5.4 – Settings – Graph Legend and Settings.........................................35

5.5 – Settings – Network and Touchscreen...........................................36

5.6 – Settings – Save Datalogs to USB..................................................37

CONTENTS

A CLOSED SYSTEM

What is a Closed System?.............…………..……………………….....................……..38

Possible Leak Points on the Vaccuum Pump..…..……………….......................…...38

Possible Leak Points on the Freeze Dryer.......…..…………….…...................……..38

care and cleaning

Cleaning the Interior and Exterior of Your Freeze Dryer............................……...39

Moving or Long Absences......................…..……………….............................……...39

TROUBLESHOOTING

Frequently Asked Questions......................…..…………..…….....................…........39

warranty................................................................................................................................41

Returns......................................................…..………………............................…....42

U.S. Patent 9,459,044

1.800.700.5508 HarvestRight.com

UNPACKING

UNPACKING Your Freeze Dryer

You should have taken the box o the freeze dryer and inspected for damage

at the time you received your unit, before you signed the Shipper’s Bill.

You should have received the following items:

• Harvest Right Freeze Dryer

• Vacuum Pump

• Power Cord

• Vacuum Hose

• Shelving Unit

• Trays

• Owner’s Manual

• Insulator Door Pad

• Other materials, not listed here, may have been included

1. Remove Harvest Right Freeze Dryer, vacuum pump, vacuum hose, and

power cord from packaging.

2. Inspect all items.

3. Remove the vacuum pump from its packaging and place it beside or

behind the freeze dryer.

4. If there is a problem, call Harvest Right Customer Support at

1-800-865-5584.

CAUTION: Do not lift the freeze dryer from the bottom of the

door. Doing this may cause misalignment and inability to achieve

proper vacuum, and voids the warranty. Always lift the freeze

dryer from the base.

Important Information about your first batch

Before using your freeze dryer, please note the following:

1. New freeze dryers need to have a one batch burn in period. That means,

you should fill the freeze dryer with moist bread slices and freeze dry it. After

the bread is finished, test it for dryness and throw it away. This way you can

make sure your freeze dryer is working properly and it will help remove any

manufacturing smell that is kind of like or similar to a “new car” smell.

2. Please check each batch of food to make sure it is completely dry. If just a few

pieces are not dry, when you package the food, they will spoil the whole batch;

everything in the bag will turn soft.

1 | Unpacking

IMPORTANT SAFEGUARDS

Safety INFORMATION

Read all instructions carefully before using your Harvest Right Freeze Dryer.

Following these instructions will help prevent injuries, damage to the freeze dryer,

and will ensure that you have the best possible experience with your freeze dryer.

Save these instructions.

When using this appliance always exercise basic safety precautions, including the

following:

• Use this product only for its intended purpose as instructed in this Owner’s

Manual.

WARNING Do not use an extension cord when plugging your freeze dryer

into your power source. Many extension cords cannot handle a sucient

draw of power and may melt or deform causing a fire or other damage.

• Do not use surge protectors or plug your freeze dryer into a GFI outlet.

These sources are very sensitive and may cause your freeze dryer to

unnecessarily trip the power breaker.

• Do not allow children to climb, stand on the freeze dryer, or hang on the

door or shelves. They could damage the freeze dryer and injure themselves.

• After your freeze dryer is in operation, do not touch the cold surfaces during

the freezing cycle, particularly when hands are damp or wet. Skin may

adhere to these extremely cold surfaces.

• Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of the freeze dryer.

• Keep fingers out of “pinch point areas”. Clearances between the doors and

closing mechanism are necessarily small. Be careful closing doors when

children are in the area.

• Unplug your freeze dryer before cleaning or making repairs. We strongly

advise that service be done by a qualified individual.

• Refrigerants: All refrigeration products contain refrigerants, which under

federal law must be removed prior to product disposal. If you choose to

dispose of an old refrigeration product, check with the company handling

the disposal about what to do.

• This appliance is not intended for use by small children or infirm persons

without capable, adult supervision. Children should be supervised when

using the appliance.

Important Safeguards | 2

• Do not use a wet or damp cloth when cleaning the plug at the end of the

power cord. Remove any dust or foreign matter from the power plug pins. A

dirty power plug can increase the risk of fire.

• Do not block vent air holes. If the air holes are blocked, the freeze dryer could

overheat. Keep vents clean.

• Never unplug your freeze dryer by pulling on the power cord. Always grip the

power plug firmly and pull straight out from the outlet. Pulling on the power

cord could cause a fire and/or electric shock. A damaged power cord must be

replaced by the manufacturer, a certified service agent or qualified certified

service personnel.

• Use caution when putting your hands under the appliance. Any sharp edges

may cause personal injury.

• Do not insert the power plug with wet hands. It may cause electric shock. In

general, power consumption will average 8-10 amps of power and spike near 16

amps. Usage of a dedicated 20 amp circuit will help prevent power outages and

allow for proper freeze drying (Power consumption will vary between models).

• Do not defrost your freeze dryer with a blow dryer or other heating device. There

is a thermal cuto that protects the machine and the material inside the chamber

from overheating. If the thermal cuto gets too hot, it will eliminate all power to

your shelf heaters until the appropriate parts have been replaced.

NEVER OPERATE THE FREEZE DRYER IF IT APPEARS DAMAGED

If it is dropped or damaged in any way, call Harvest Right Customer Support

immediately at 1.800.865.5584 for examination, repair, electrical or mechanical

adjustment, or possible replacement of parts.

BE CAREFUL ABOUT WHAT YOU PUT IN YOUR FREEZE DRYER

The freeze dryer is designed to freeze dry materials or products that contain water.

Freeze drying other materials may void the warranty and could damage the

freeze dryer.

VACUUM PUMP RUNS HOT

Use caution when running your freeze dryer as the vacuum pump that sits

external can reach 160˚F during operation. Keep your vacuum pump out of

the reach of children as it may cause injury if touched. Your vacuum pump

is built to run hot. Use care and caution in order to prevent injury.

RECOMMENDED OPERATING TEMPERATURES

Your Harvest Right Freeze Dryer is designed to work in a wide variety of

environmental temperatures, but extreme heat and cold will aect performance.

The recommended temperature range for operation is 35-90°F. The most ecient

temperature range is between 45-75°F. Although safe, operating your freeze dryer

3 | Important Safeguards

in temperatures above 90˚F will increase batch times and have an adverse eect

on the condensing unit (freezer). As the temperature rises where your freeze

dryer operates, so does the length of time it takes to finish. This happens because

with hotter operating temperatures it is harder to reach the extreme cold required

for freeze drying.

For example: a batch that normally takes 24 hours to finish in a 75°F environment

could take over 40 hours to complete in hot temperatures.

Oil-Free Vacuum Pump

For optimum performance of your vacuum pump DO NOT reduce the freeze time

or bypass the freezing cycle of your freeze dryer! For shorter freezing cycles you

may pre-freeze the products until they are frozen solid before placing them in

the freeze dryer but STILL DO NOT bypass the freezing cycle of your freeze dryer!

Freeze drying products that have even a little non-solid moisture in them will

reduce the performance and the life of the vacuum pump.

DO NOT overload the trays in the freeze dryer. Too much product will produce too

much evaporated moisture which may exceed the ice capacity inside the vacuum

chamber and cause the vacuum pump to suck in the excess moisture. This may

aect the performance and shorten the life of the vacuum pump.

Important Safeguards | 4

GENERAL INFORMATION

MAJOR COMPONENTS

Harvest Right Scientific Freeze Dryer

Power Switch: Located on the back of the freeze dryer (“0” is o, “I” is on).

Vacuum Chamber: This circular chamber includes a shelving unit for the trays.

Trays: These hold the product to be freeze dried. Do not overload trays or batch

times will be extra long.

Power and Display: The freeze dryer is powered by plugging the power cord into

the back of the freeze dryer (one receptacle is for the power cord and one is for

powering the vacuum pump) and a functioning 110-120 volt power outlet in the

wall of your house or garage (a dedicated 20 amp circuit is recommended for

Medium freeze dryers and required for Large freeze dryers).

Vacuum Pump: Connect the vacuum hose to the connection on the side of the

freeze dryer and to the appropriate fitting on the vacuum pump. The vacuum

hose should be tight. Be sure to tighten both ends of the vacuum hose to

properly connect the freeze dryer to the vacuum pump. Plug the vacuum pump

power cord into the receptacle on the back panel of the freeze dryer. Make sure

the vacuum pump “on/o” switch is set to the “ON” position (“O” is o, “I” is

on). It will not receive power until the freeze dryer completes the circuit at the

appropriate time in the freeze drying process.

Drain Line: This is a clear tube, located on the side,

toward the bottom-back of the freeze dryer. This tube

should be un-coiled and the open end placed in a drain

or a 5-gallon bucket (or similar container) to collect the

water removed during freeze drying (collects as ice on the

sides of the vacuum chamber). Don’t open the drain valve

with the open end of the clear hose in water or the water

will be sucked into the freeze dryer.

Before you start a freeze drying cycle make sure the valve

on the drain tube is closed. The small handle on the valve

should be perpendicular to the tube (See Figure 1).

FIGURE 1

FREEZE DRYER ASSEMBLY & VACCUM TEST

Wait 24 hours before running your freeze dryer in order to facilitate proper

settling of the refrigerant within the condensing unit.

5 | General Information

1. The ideal location for operating your freeze dryer is a cool, dry, clean

location. Dirty air will clog the cooling fins in the condensing coil and reduce

the life and eciency of the refrigeration system.

2. Place the freeze dryer on a level, stable surface and adjust the leveling feet

so that the front end of the freeze dryer is about ¼ to ½ inch taller than the

rear. This allows the ice water from the freeze dryer to exit through the drain

hole in the rear of the vacuum chamber. Make sure the translucent (clear)

drain line is placed in a 5-gallon bucket, drain or equivalent container to catch

the water.

3. Make sure the inside surface of the acrylic door is clean. Use only dry cotton

cloth and warm water, no cleaners. Check rubber door gasket and make

sure it’s clean.

4. Connect the large hose to the vacuum pump and to the freeze dryer, and

tighten (See Figure 2). Do not add any additional Teflon tape, or any type of

adhesive, when installing the vacuum hose. Doing this almost always

creates a vacuum leak.

FIGURE 2

5. Connect the freeze dryer power cord to the receptacle on the rear panel and

to a 110 to 120 volt ac outlet (power may vary between models). A dedicated

20 amp circuit is recommended for Medium freeze dryers and required for

Large freeze dryers.

6. Connect the power cord on the vacuum pump to the receptacle on the rear

panel of the freeze dryer.

7. Make sure the power switch on the vacuum pump is in the “ON” position.

(“O” is o, “I” is on). The power button is located on the rear of the vacuum

pump.

8. Pull out your drain hose. Make sure it is in the ‘OFF’ position (the small

handle on the valve should be perpendicular to the direction of the drain

tube). Place the open end in a 5-gallon bucket, drain, or similar container, to

collect the water that is removed during freeze drying. It is best to keep the

hose out of the water.

9. Ensure that the acrylic door makes contact with the rubber gasket by

General Information | 6

examining the door in the fully closed position. You will see a thin line in the

middle of the gasket as it presses up against the door. For the first couple

batches, when the pump turns on, make sure the door fully seals around the

gasket. The door has a two-staged handle. Stage 1 latches the door and Stage

2 compresses the door against the rubber gasket. Make sure it is turned all the

way to the right.

10. Turn on freeze dryer (On/O switch is located on the back of your freeze

dryer. Press the switch to the “ON” position (“0” is o, “I” is on). Next, in order

to perform a quick test and assure that your freeze dryer is set up properly,

please complete the following steps. To accomplish this task, your freeze

dryer chamber must be free of any damp or wet material such as water or

condensation. It needs to be completely dry.

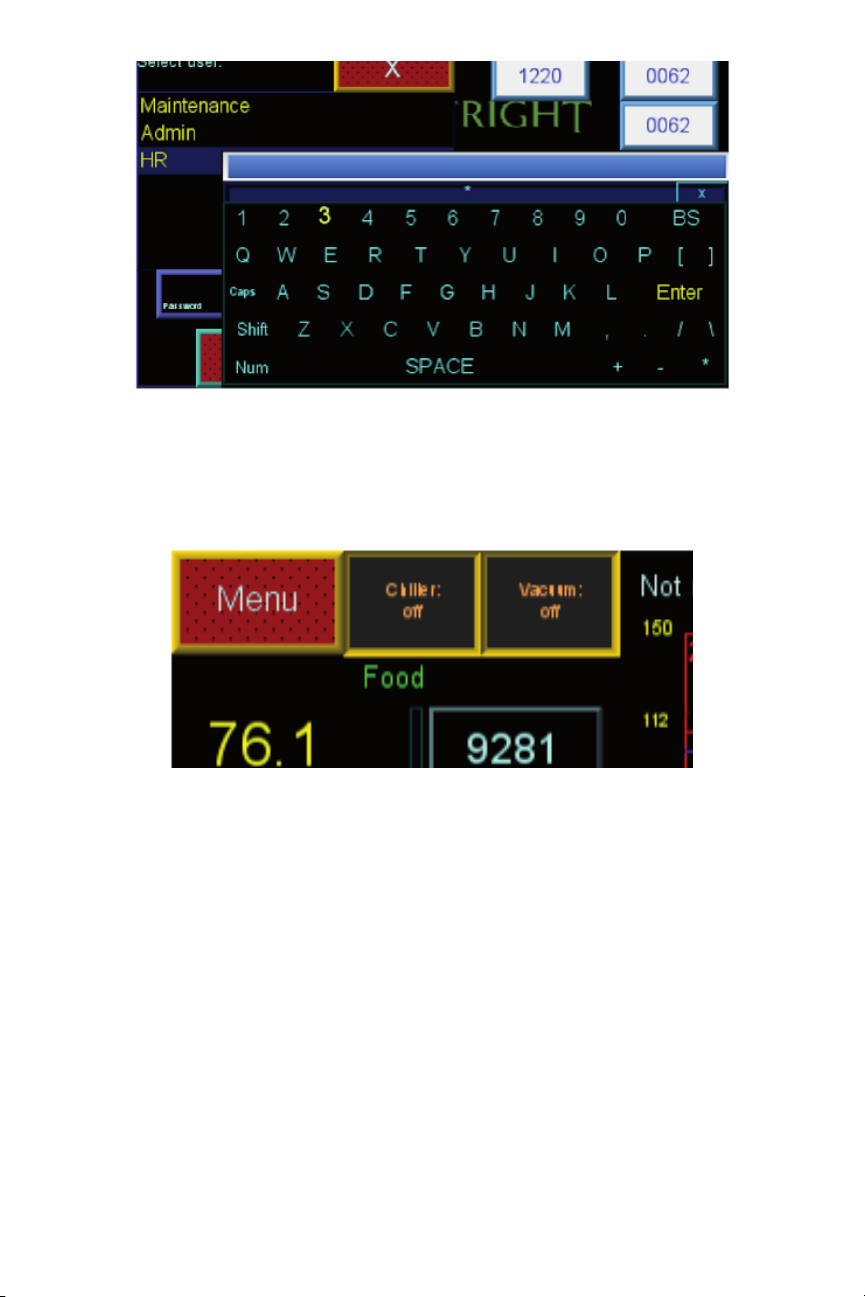

• Tap the “List” button and select the user HR, then tap the password box and

type in 3, then press enter, then select the “Continue” button.

7 | General Information

• Located at the top of the screen are three buttons. One is red and says

“Menu”, the next two are“Chiller” and “Vacuum”. These two button are

for manual control of the cooling system and the vacuum pump. Tap the

“Chiller” button. A box will appear, select Yes. Tap “Vacuum”, then tap Yes.

• When the vacuum pump first turns on, the display will read a 4-digit

number. Within 10-20 minutes the displayed pressure will begin to drop. This

number represents the vacuum pressure inside the freeze

dryer. A lower number represents a stronger vacuum pressure.

• Eventually, the pressure will go from the initial 4-digit number down to 500

mTorr and lower. If you see that this is the case, it means that your freeze

dryer has been set up properly and you are ready to start your first batch. If

you are unable to achieve a vacuum of 500 mTorr or lower after 20 minutes

(or if the screen still displays the same 4-digit number) check steps 3-11 of

this quick start guide to assure that there are no air leaks at any location of

your freeze dryer.

• Once you are able to see a pressure of 500 or lower, you are ready to start

your first batch!

• Turn o the “Chiller” and “Vacuum” by tapping the same buttons as before

and selecting Yes, then open the drain valve (located on the left side of your

freeze dryer). This will release the pressure and allow the door to be opened

General Information | 8

so that you can begin freeze drying your desired materials! Now that the

pressure has been released, close the drain valve again (or we will not be

able to achieve a vacuum when the freeze dryer is running.)

If 500 mTorr or lower is not reached, check for air leaks and repeat the

test.

1. Door must be properly closed.

2. Hose connecting the vacuum pump to the freeze dryer should be

securely tightened on both ends.

3. Drain valve must be closed

Once you are able to see a pressure of 500 mTorr or lower, you are ready

to start your first batch. Turn o your freeze dryer and open the drain valve.

This will release the pressure and allow the door to be opened.

If you are unable to successfully complete this test because the vacuum

pressure won’t go below 500 mTorr, please call Customer Support: 800-

865-5584.

11. You are now ready to load freeze drying material onto trays.

12. Prepare the material that you want to freeze dry and place it on the trays,

one layer thick, so that it can be uniformly warmed by the shelving unit.

Product that is prepared in uniform thickness will dry quicker.

1. Place trays in the shelving unit inside the freeze dryer. Insert insulator pad.

Close the acrylic door and turn the door latch clockwise as far as it will go,

compressing the door against the rubber gasket. Visually check to make

sure the door is sealed properly to the gasket. If the door is not latched

tight, there will be a vacuum leak.

14. Close the drain valve. In the closed position, the drain valve is perpendicular

to the hose. If the material profile is already selected, press and hold the

“Start Profile” button at the bottom right of the screen until it begins. If

this profile is not selected. Tap Menu > Load a Profile then tap Food, then

tap the green “Start Profile” button. If this profile doesn’t exist, follow the

instructions beginning on page 11 for complete detailed instructions.

15. It will then begin the profile by freezing the material for a set time. The

vacuum pump will turn on automatically once the freeze step is complete.

The buttons pressed before during the test will turn on and o automatically

during the profile and do not need to be changed manually. If the vacuum

pump doesn’t turn on, make sure it is plugged into the back of the freeze

dryer. Make sure the switch is turned “on” on the back of the vacuum pump.

16. When the vacuum pump comes on then it should reduce the pressure in the

vacuum chamber within about 10 minutes. If you can still open the door after

9 | General Information

30 seconds turn o the vacuum pump, release the pressure in the vacuum

chamber by opening the drain valve, open the door and check the cleanliness

of the rubber gasket. Close the door again and turn the vacuum pump “on”.

Wait for 1 minute and verify that the door cannot be opened.

17. Once the material being freeze dried is frozen and when adequate vacuum

pressure is reached (500 mTorr depending on set points), the heaters on

the shelves turn on to hold the temperature at the set point, then they will

turn o when the pressure raises to the upper limit (600 mTorr depending

on set points). This on and o cycle can repeat over and over if the rate of

sublimation exceeds what the pump can pull. This freeze dryer is designed to

maintain the set temperature as long as it doesn’t exceed the upper pressure

limit.

18. At the end of the freeze dry cycle, the heaters will stay on at the last set point

temperature until the profile is ended or the defrost cycle is started. Before

the profile is either ended or the defrost cycle is started, turn o the vacuum

pump manually be tapping the “Vacuum” button. Once o, open the drain

valve and check whether the product is completely freeze dried. If not, place

the product back inside, insert insulation pad, close and latch door, close drain

valve, then turn the vacuum pump back on by selecting the “Vacuum” button.

Make sure the door will not open after the vacuum pump is turned back on.

It will continue to freeze dry at the last set point temperature until turned o

by the user. Check the product again after a few hours. Once complete, either

tap “Just End Profile” or change the temperature for defrost to 120°F if not set

already and tap “Run Defrost”.

• Immediately package your freeze dried material so that it doesn’t rehydrate

from the natural humidity in the air. When packaging, you can use cans, Mylar

bags, and glass jars. Always use an appropriate oxygen absorber.

• Make sure all of the ice and water are removed from the vacuum chamber

before starting a new batch. Pressing the “Run Defrost” button turns on the

heaters in the shelving unit and accelerates melting the ice. Ambient air can

also melt the ice over time.

General Information | 10

0PERATIONAL OVERVIEW

1. Login Screen

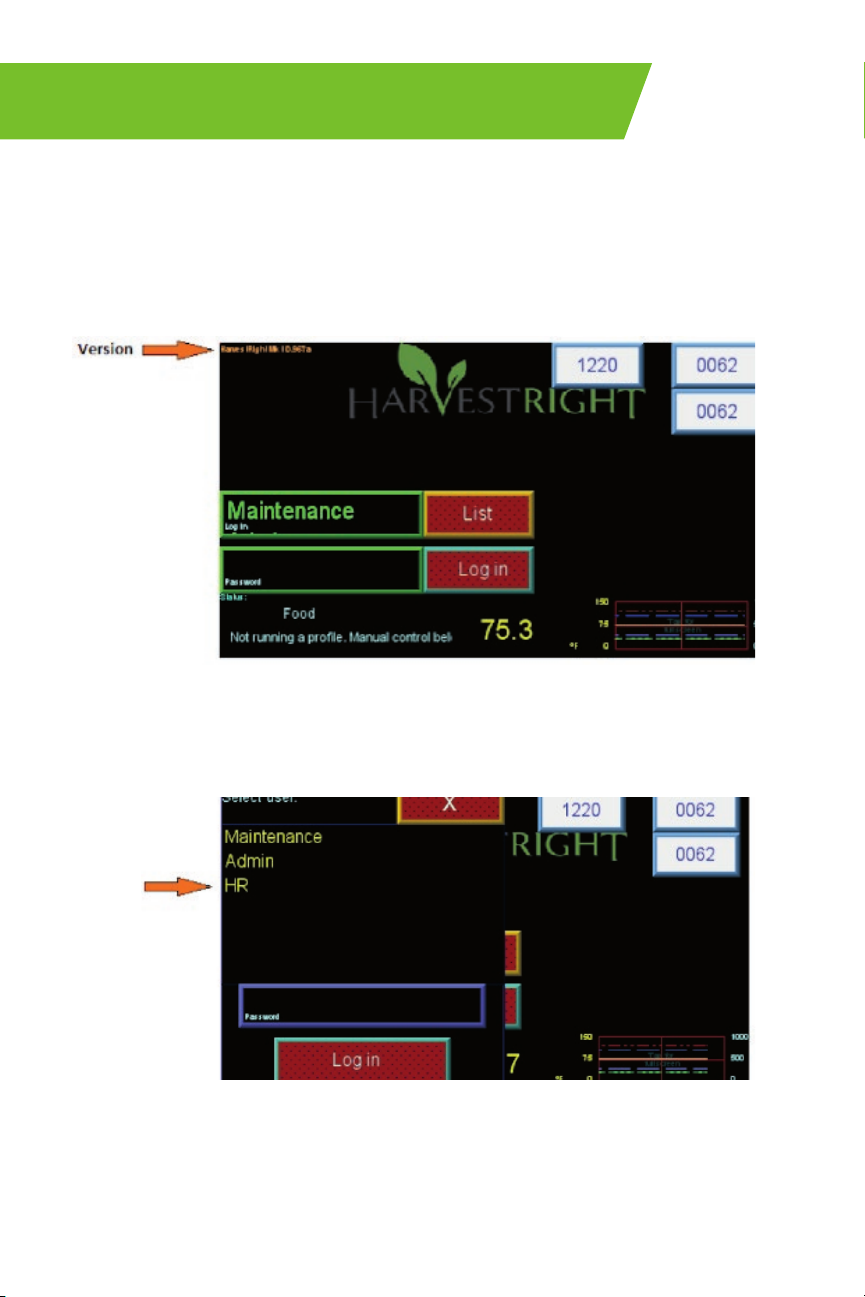

The login screen is the first screen to appear once the Scientific Freeze Dryer is

turned on. On this screen, the version is listed on the upper left of the screen. For

example, the version of the Scientific Freeze Dryer in this operations manual is

10.967a.

In order to login, a user needs to be selected. This can be done by tapping either

the green writing in the Log in box, in this case “Maintenance”, or the red button

“List”.

User: HR

Password: 3

11 | Operational Overview

Loading...

Loading...