Harvest Right Home Freeze Dryer Owner's Manual

1

Home Freeze Dryer

OWNER’S MANUAL

The Essential Guide for Every

Home Freeze Dryer Owner

HarvestRight.com | 1-800-700-55082

CONTENTS

QUICK SETUP ........................................................................................ 4

Vacuum Pump Maintenance Schedule......................................................7

IMPORTANT SAFEGUARDS .................................................................... 8

Safety Information ........................................................................................8

Never Operate the Freeze Dryer if it Appears Damaged ....................9

Be Careful About What You Put in Your Freeze Dryer ........................9

Vacuum Pump Runs Hot .............................................................................. 9

Recommended Operating Temperatures ................................................ 9

UNPACKING ........................................................................................ 10

Unpacking Your Freeze Dryer .................................................................. 10

Returns ........................................................................................................... 10

GENERAL INFORMATION BEFORE YOU BEGIN....................................... 12

Major Components ......................................................................................12

Freeze Dryer Assembly ...............................................................................13

Using the “Customize” Settings ............................................................... 16

Why Freeze Dry? .......................................................................................... 17

How to Freeze Dry .......................................................................................18

What Can be Freeze Dried? .......................................................................18

setup overview ............................................................................... 19

oPERATIONAL OVERVIEW ................................................................... 20

Main Points of Operation ..........................................................................20

The Freeze Dry Process .............................................................................20

Packaging and Storing Freeze-Dried Foods .........................................20

Pretreating Foods ........................................................................................20

Opening During Operation ........................................................................21

How Do I Know If My Food is Dry? .......................................................... 21

A CLOSED SYSTEM.............................................................................. 22

What is a Closed System? ..........................................................................22

Possible Leak Points on the Vacuum Pump .......................................... 22

Possible Leak Points on the Freeze Dryer.............................................22

3

Care + Cleaning ............................................................................... 23

Vacuum Pump Maintenance ..................................................................... 23

Cleaning the Interior and Exterior of Your Freeze Dryer .................25

Cleaning Cautions ....................................................................................... 25

Moving or Long Absences ......................................................................... 25

YOUR FIRST BATCH ............................................................................. 26

Final Check .................................................................................................... 26

Start Simple ..................................................................................................26

TROUBLESHOOTING ............................................................................ 27

Frequently Asked Questions ...............................................................27

Mist Coming Out of Pump Handle ..........................................................30

Pump isn’t Turning On During the Dry Cycle ......................................30

WARRANTY ........................................................................................ 30

FREEZE DRY TIMES ............................................................................. 32

TOUCH SCREEN INDEX ........................................................................ 34

HarvestRight.com | 1-800-700-55084

For a video tutorial, go to:

https://youtu.be/s0AfFFqMG08

1. Once your freeze dryer is

unpacked, make certain that the

bottom front feet are adjusted such

that the unit slopes from front to

back (the front of the freeze dryer

should be ¼ inch to ½ inch higher

than the back).

2. Make sure the rubber gasket is

clean both inside and out. Remove

gasket and run under water in order

to remove lint/dirt.

3. Make sure the inside surface of the

acrylic door is clean.

4. Follow the instructions for the vacuum

pump, add the right amount of oil (cover

the small circle in the center of the sight

glass window. See page 7, Figure 5).

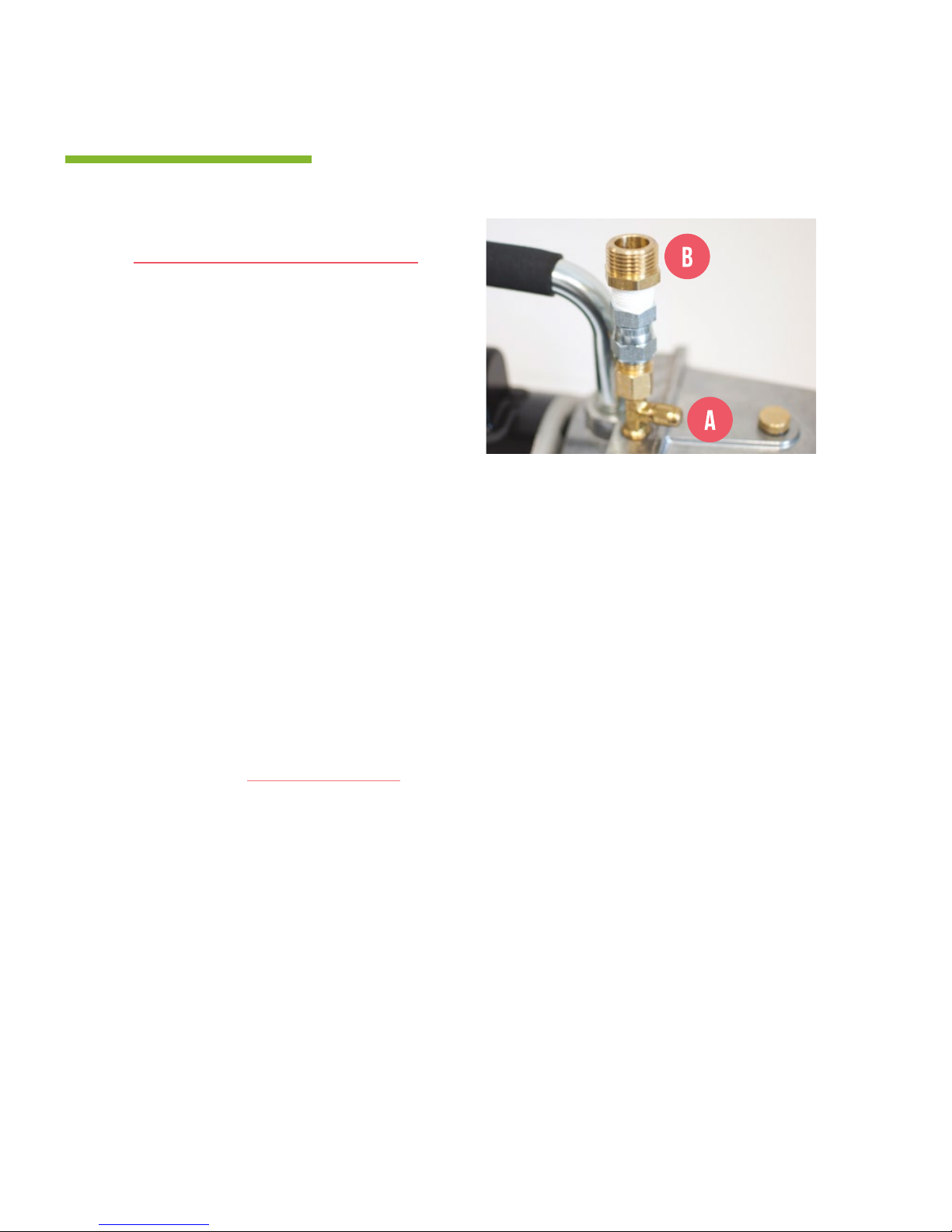

5. Make sure the brass cap located

near the port where your vacuum hose

connects is hand tight. See Figure 1, A.

6. Connect the large clear hose to the

vacuum pump and tighten hand tight,

then, if necessary, with a crescent

wrench, tighten an additional ¼

turn. See Figure 1, B. Do not add

any additional Teon tape, or any

type of adhesive, when installing

the vacuum hose. It almost always

creates a vacuum leak!

7. Plug the vacuum pump power cord

into the receptacle on the back of

the freeze dryer.

8. Make sure the power switch on

the vacuum pump is on (located on

the back of the vacuum pump).

9. Place the black insulator door pad

through the rubber gasket to plug

the gap between the shelving unit

and the back edge of the gasket.

Make sure your shelving unit is

pulled forward close to the rubber

door gasket so the pad will snuggly

t between the door and the shelf.

10. Secure the door latch to create

a good seal. There shouldn’t be any

gaps between the black circular

gasket and the door. If the door is not

latched tight, there will be a vacuum

leak which could damage your

vacuum pump, cause an oil spurt, and

FREEZE DRYER QUICK START GUIDE

Figure 1 - Vacuum Pump Connections

(A) Hand tighten vacuum hose (B) Connect large clear

tube, tighten with crescent wrench.

5

void the vacuum pump warranty. The

door latch is a two-staged handle.

Make sure you turn the handle as far

to the right as possible.

11. Make sure to close the drain

valve on the freeze dryer (located on

the left side of your freeze dryer). If

the drain valve is not closed, there

will be a vacuum leak which could

damage your vacuum pump, cause an

oil spurt, and void the vacuum pump

warranty.

12. As described in steps 6-11, it is

your responsibility to make sure

your door is closed properly, that the

drain valve is closed, and that the

hose connecting the vacuum pump

to the freeze dryer is connected

properly. If your freeze dryer doesn’t

pull a vacuum, an oil spurt will make

a mess as it may spray a cup (or

more) of oil out of the pump. Again,

it is your responsibility to make sure

that you have a good vacuum seal.

13. Turn on the freeze dryer (on the

back of your freeze dryer press the

switch to the “up” position). Next,

in order to perform a quick test and

assure that your freeze dryer is set

up properly, please complete the

following steps. To accomplish this

task, your freeze dryer chamber

must be free of any moist material,

water, or condensation. It needs to

be completely dry.

• Press “Start” on the touchscreen.

You will then be reminded to

“Please close drain valve.” Ensure

that this valve is closed.

• Initially, you will see “Freezing for

9 hours” appear on the display.

Now, press the small blue clock in

the top right corner of the display.

This will automatically turn your

vacuum pump on (the initial

vacuum will be a bit loud, but will

quickly settle to a hum that isn’t

too noticeable.)

• When the vacuum pump rst

turns on, the display will read

“>2500 mTorr”. Within 10-20

minutes the display will no longer

read “>2500 mTorr”, but will begin

to show a lower number (starting

with 2500 and moving down). This

number represents the vacuum

pressure inside the freeze dryer.

A lower number represents a

stronger vacuum pressure.

• Eventually, the pressure will go

from 2500 down to 500 mTorr,

and possibly lower. If you see

that this is the case, it means that

your freeze dryer has been set up

properly and you are ready to start

your rst batch. If you are unable

to achieve a vacuum of 500 mTorr,

Figure 2 - Freeze Dryer LCD Display

HarvestRight.com | 1-800-700-55086

or lower, after 30 minutes (or if the

screen still says “>2500 mTorr”)

check steps 2-11 of this Quick Start

Guide to assure that there are no

air leaks at any location on your

freeze dryer.

• Once you are able to see a

pressure of 500 or lower, you are

ready to start your rst batch.

Turn off your freeze dryer and

open the drain valve. This will

release the pressure and allow the

door to be opened so that you can

begin freeze drying your desired

product. Now that the pressure

has been released, close the drain

valve again (or you will not be able

to achieve a vacuum when the

freeze dryer is running.)

• If you are still unable to complete

this test, call Customer Support at

1-800-865-5584 for assistance in

setting up your freeze dryer.

14. Prepare the material that you

want to freeze dry and place it on

the trays, one layer thick, so that

it can be uniformly warmed by the

shelving unit. Food that is pre-frozen

should go into a cold chamber; To

accomplish this, run the freeze cycle

for 30 minutes before taking your

food out of the freezer and putting it

in the freeze dryer.

15. Turn the freeze dryer on. The

screen will now prompt you to press

‘Proceed’ or ‘Cancel’ within a limited

amount of time. Press ‘Cancel’. This

will return you to the home screen.

16. Place the trays in the shelving

unit inside the freeze dryer; insert

the black pad; close the door and

press “Start.”

17. The material will be frozen in

the freeze dryer for 9 hours. The

vacuum pump should then come on.

If it doesn’t, make sure it is plugged

into the back of the freeze dryer.

Make sure the power switch located

on the back of the vacuum pump is

turned on.

18. When the vacuum pump comes

on it should reduce the pressure in

the food chamber within about 10

minutes. If you can still open the door

after 30 seconds, turn off the vacuum

pump, release the pressure in the

food chamber by opening the drain

valve, open the door, and check the

cleanliness of the rubber gasket. Close

the door and turn the vacuum pump

on. Wait for 1 minute and verify that the

door cannot be opened. If your door is

out of adjustment the gasket may not

be able to make contact with the door.

Readjusting the door may be necessary.

19. Once the food is frozen, and

when adequate vacuum pressure is

reached (500 mTorr), the heaters on

the shelves turn on and stay on for

a few minutes, then they will turn

off when the pressure rises to 600

mTorr. Gradually the pressure will

again go down to 500 mTorr; the

heaters will turn on and the pressure

will rise to 600 mTorr when the

heaters will again shut off. This cycle

repeats until the food is dry.

7

*The number of batches is contingent on the food you freeze dry, the thickness, length of batches, etc.

20. Toward the end of the freeze

dry cycle, the heaters will stay on

for six hours and then the process is

complete. The freeze dryer will beep

when it is nished. See Figure 3.

For additional questions and setup

instructions, refer to the detailed Harvest

Right Owner’s Manual and User Guide,

beginning on page 8.

CHECKLIST: BEFORE EACH BATCH

• Drain valve closed

• Door clean

• Black rubber gasket (door seal)

clean. See Figure 4.

• Water drained from vacuum pump

oil (see page 27, How do I extend

the life of my vacuum pump oil?)

• Black insulator door pad in place

• Door closed, compressed tight,

and handle turned completely to

the right.

• Assure that oil level is above the

small circle in sight glass. See

Figure 5.

Figure 3 - Freeze Dryer LCD Display

Complete message.

Figure 5 - Vacuum

Pump Sight Glass

Fill oil above the small

circle in the center.

Figure 4 - Rinse

Rubber Gasket

Remove door rubber

gasket to rinse.

VACUUM PUMP MAINTENANCE SCHEDULE

MAINTENANCE

Drain off 1-2 tbsp of oil

Change oil

Power ush

Remove pump cover assembly

FREQUENCY

Beginning of every batch

Approx. 5-6 batches

*

Approx. 10-12 batches

*

Approx. 30-36 batches

*

INSTRUCTIONS

See pg 27, “How do I extend the

life of my vacuum pump oil?”

See pg 23, “Vacuum Pump

Maintenance, Oil Change”

See pg 24, “Vacuum Pump

Maintenance, Power Flush”

https://youtu.be/

ILVBXqg9oc8

https://youtu.be/

bOGTh9n3NpA

HarvestRight.com | 1-800-700-55088

IMPORTANT INFORMATION

Read all instructions carefully

before using your Harvest Right

Home Freeze Dryer. Following

these instructions will help prevent

injuries, damage to the freeze

dryer, and will ensure that you

have the best possible experience

with your freeze dryer. Save these

instructions.

1.1 SAFETY INFORMATION

When using this appliance always

exercise basic safety precautions,

including the following:

• Use this product only for its

intended purpose as instructed in

this Owner’s Manual.

• ⚠WARNING Do not use an

extension cord when plugging

your freeze dryer into your power

source. Many extension cords

cannot handle a sufcient draw

of power and may melt or deform

causing a re or other damage.

• Do not use surge protectors or

plug your freeze dryer into a GFI

outlet. These sources are very

sensitive and may cause your

freeze dryer to unnecessarily trip

the power breaker.

• Do not allow children to climb,

stand on the freeze dryer, or hang

on the door or shelves. They could

damage the freeze dryer and

injure themselves.

IMPORTANT SAFEGUARDS

• After your freeze dryer is in

operation, do not touch the cold

surfaces during the freezing

cycle, particularly when hands

are damp or wet. Skin may

adhere to these extremely cold

surfaces.

• Do not store or use gasoline

or other ammable vapors and

liquids in the vicinity of this or

any other appliance.

• Keep ngers out of “pinch point

areas”. Clearances between the

doors and closing mechanism

are necessarily small. Be careful

closing doors when children are

in the area.

• Unplug your freeze dryer before

cleaning or making repairs. We

strongly advise that all service be

done by a qualied individual.

• Refrigerants: All refrigeration

products contain refrigerants,

which under federal law must

be removed prior to product

disposal. If you choose to dispose

of an old refrigeration product,

check with the company handling

the disposal about what to do.

• This appliance is not intended

for use by small children or

inrm persons without capable,

adult supervision. Small children

should be supervised when using

the appliance.

• Do not use a wet or damp cloth

when cleaning the plug at the end

9

of the power cord. Remove any

dust or foreign matter from the

power plug pins. A dirty power

plug can increase the risk of re.

• Do not block vent air holes. If the

air holes are blocked, the freeze

dryer could overheat.

• Never unplug your freeze dryer by

pulling on the power cord. Always

grip the power plug rmly and

pull straight out from the outlet.

Pulling on the power cord could

cause a re and/or electric shock.

A damaged power cord must be

replaced by the manufacturer, a

certied service agent or qualied

certied service personnel.

• Use caution when putting your

hands under the appliance. Any

sharp edges may cause personal

injury.

• Do not insert the power plug

with wet hands. It may cause

electric shock.

• In general, power consumption

will average 8-10 amps of power

and spike near 16 amps. Usage of a

dedicated 20 amp circuit will help

prevent power outages and allow

for proper freeze drying.

1.2 NEVER OPERATE THE FREEZE

DRYER IF IT APPEARS DAMAGED

If it is dropped or damaged in any

way, call Harvest Right Customer

Support at 1-800-865-5584

immediately for examination, repair,

electrical or mechanical adjustment,

or possible replacement of parts.

1.3 BE CAREFUL ABOUT WHAT YOU PUT

IN YOUR FREEZE DRYER

This product is designed to freeze

dry materials or products that

contain water. Freeze drying other

materials voids the warranty and

may damage the freeze dryer.

1.4 VACUUM PUMP RUNS HOT

Use caution when running your

freeze dryer as the vacuum pump that

sits external to the unit will run hot.

Keep your vacuum pump out of reach

of children as it may cause injury if

handled improperly. Your high quality

vacuum pump is built to run hot. Use

care and caution in order to prevent

injury. Average operating temperature

is 160 degrees Fahrenheit.

1.5 RECOMMENDED OPERATING

TEMPERATURES

Your Harvest Right Freeze Dryer is

designed to work in a wide variety

of temperatures, but extreme heat

and cold will affect performance.

The recommended temperature

range for operation is 35-90 degrees

Fahrenheit. The most efcient

temperature range is between 45-80

degrees Fahrenheit.

Although safe, operating your

freeze dryer in temperatures

above 90 degrees Fahrenheit could

affect batch times and have an

adverse effect on the condensing

unit (freezer). As the temperature

rises where your freeze dryer

operates, so does the length of time

it takes to nish batches of food.

This happens because with hotter

HarvestRight.com | 1-800-700-550810

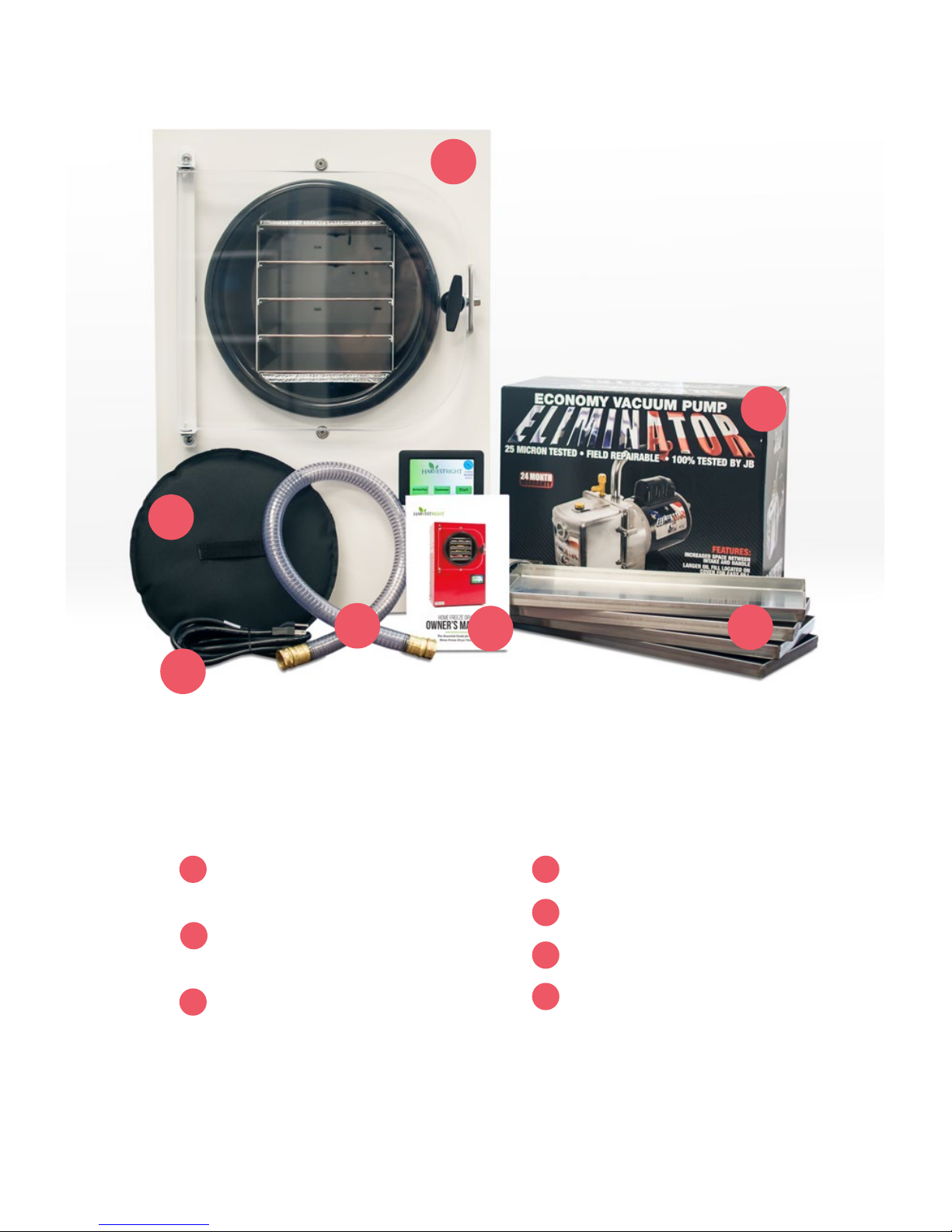

2.1 UNPACKING YOUR FREEZE DRYER

You should have received the

following items: see image on page 11.

• Harvest Right Home Freeze Dryer

• Vacuum pump with oil demister

• Power cord

• Vacuum hose

• Vacuum pump oil

• Shelving unit

• 4 food trays

• Owner’s Manual

• Black insulator door pad

• Other materials, not listed here,

may have been included.

1. Remove Harvest Right Freeze

Dryer, vacuum pump, vacuum hose

and power cord.

2. Inspect all items to ensure no

damage occurred during shipping.

3. If any damage has occurred, call

Harvest Right Customer Support

immediately at 1-800-865-5584.

operating temperatures it is harder

to reach the extreme cold required

for freeze drying.

For example: a batch that normally

takes 24 hours to nish in a 75°F

environment could take over

40 hours to complete in hot

temperatures.

UNPACKING

4. Remove the vacuum pump from

its packaging and place it beside or

behind the freeze dryer.

5. Unwind power cord.

2.2 RETURNS

Units may be returned if they have

not been used. The customer will

be charged a 15% restocking fee and

incur all shipping charges. Harvest

Right will issue a refund upon

examination of the unused freeze

dryer. If Harvest Right determines

that the returned unit has been

used, the freeze dryer will be sent

back to the customer, in which case

the customer will incur the cost of

freight for the returned unit.

CAUTION: Do not lift freeze dryer

from bottom of door. Doing this may

cause misalignment and inability to

achieve proper vacuum. Always lift

your freeze dryer appliance from the

base. Lifting the freeze dryer by the

door voids the warranty.

11

A

• Vacuum hose

• 4 food trays

• Owner’s Manual

• Black insulator door pad

What is in the box

You should have received the

following items:

• Harvest Right Home Freeze

Dryer with shelving unit

• Vacuum pump with oil demister

and vacuum pump oil

• Power cord

A

b

c

d

e

f

g

B

C

g

D

e

F

Other materials, not listed here, may have been included.

HarvestRight.com | 1-800-700-550812

before you begin...

3.1 MAJOR COMPONENTS

Harvest Right Home Freeze Dryer

• Power Switch: Located on the back

of the freeze dryer. Depressing the

toggle switch to the up position

turns the power on.

• Vacuum Chamber: This circular

chamber includes a shelving unit

for the food trays.

• Trays: You should have received

four of these to hold the food

items to be freeze dried.

• Power Unit and display: The

freeze dryer is powered by

plugging the power cord into

the back of the freeze dryer (one

receptacle is for the power cord

and the other is for powering the

vacuum pump) and a functioning

110-120 volt power outlet in the

wall of your house or garage.

• Vacuum Pump: Follow

the instructions from the

manufacturer of the vacuum

pump to get the vacuum pump

ready for operation. Connect the

vacuum hose to the connection

on the side of the freeze dryer

and to the appropriate tting on

the vacuum pump. The vacuum

hose should be hand-tightened,

and then tightened additionally

(1/4 turn), if needed, using a

crescent wrench, open-end

wrench, or pipe wrench. Be

sure to tighten both ends of

the vacuum hose to properly

connect the freeze dryer to the

vacuum pump. Plug the vacuum

pump power cord into the

receptacle on the back panel of

the freeze dryer. Make sure to

add the right amount of oil to the

vacuum pump as specied in the

manufacturer’s instructions (see

image on page 7, gure 5). Make

sure the vacuum pump “on/off”

switch is set to the “on” position.

It will not receive power until

the freeze dryer completes the

circuit at the appropriate time in

the freeze drying process.

• Oil Demister: This attaches to the

rear of the handle on the vacuum

pump and the holes in the white

cap point upward.

• Drain Line: This is a clear tube

beneath the left rear of the freeze

dryer. You will need to pull this

tube out from beneath the freeze

dryer. It should easily t in the

notch provided. This tube should

be un-coiled and the open end

placed in a 5-gallon bucket, drain

or similar container, to collect

the water that is removed from

the food during freeze drying and

collects as ice on the sides of the

vacuum chamber. Generally two

people can easily tilt the freeze

dryer and reach beneath it to pull

out the drain hose.

• Before you start a freeze drying

GENERAL INFORMATION

13

cycle make sure the valve on

the drain tube is closed (the

small handle on the valve is

perpendicular to the direction

of the drain tube). If the drain

valve is not closed, there will be a

vacuum leak which could damage

your vacuum pump and void the

vacuum pump warranty.

3.2 FREEZE DRYER ASSEMBLY

1.

Wait 24 hours before running

your freeze dryer in order to

facilitate proper settling within the

refrigerator condensing unit. Waiting

24 hours will allow the oil in the

condensing unit to settle so that the

freeze dryer can get cold enough.

2. The ideal location for operating

your freeze dryer is a cool, dry, clean

location. Operating your freeze dryer

in temperatures higher than 80

degrees Fahrenheit may cause cycle

times to take longer.

3. Place the freeze dryer on a level,

stable surface and adjust the leveling

feet so that the front end of the

freeze dryer is about ¼ to ½ inch

taller than the rear. This allows

the water that accumulates in the

chamber of the freeze dryer to exit

through the drain hole in the rear

of the vacuum chamber. Make sure

the translucent (clear) drain line is

placed in a 5-gallon bucket, a drain,

or an equivalent container to catch

the water. Make sure the drain valve

is tilted slightly down and not at on

the table or cart.

4. Connect the freeze dryer power

cord to the receptacle on the rear

panel and to a 110 to 120 volt ac

power supply (most homes power

outlets provide this power).

5. Connect the power cord on the

vacuum pump to the receptacle on

the rear panel of the freeze dryer.

6. Make sure the power switch on

the vacuum pump is in the “on”

position. The power button is

located above the power cord on the

rear of vacuum pump. The control

circuit in the freeze dryer will

control when to turn “on” and “off”

the vacuum pump.

7. Connect the large clear hose to

the freeze dryer (see Figure 6) and to

the vacuum pump (see image on page

4, gure 1, B) and tighten hand tight,

then, if necessary, with a crescent

wrench tighten an additional ¼ turn.

8. Make sure all other caps and ports

on the vacuum pump are closed

tightly (hand tightened only).

9. Install oil de-mister. This attaches

to the rear of the handle on the

Figure 6 - Freeze Dryer Connection for Vacuum

Pump Large Clear Tube

See Figure 1 on pg 4.

HarvestRight.com | 1-800-700-550814

vacuum pump and the holes in the

white cap point upward. Tighten

snuggly so that the white cap faces

upward. Suggestion: Place a small

sock or cloth over the white cap. This

will help control possible oil misting

and oil spurts.

10. Pull off the rubber gasket that

comes into contact with the acrylic

door and clean with water inside

and out. Assure that there are no

particulates inside the gasket. If the

gasket is not clean inside and out,

the freeze dryer may have a hard

time pulling a low vacuum. They are

generally clean. Just look to make

sure. Do not stretch the gasket

apart too far while trying to clean

the inside. Stretching too far could

damage the gasket creating a crack

that prevents achieving a proper seal.

11. Ensure that the acrylic door has

a tight t against the rubber gasket

by examining the door in the fully

closed position. Check to make sure

there are no small gaps or spaces

between the acrylic door and the

rubber seal. You will see a thin line

around the entire gasket as it presses

up against the door. If there is a gap

at any portion of the seal between

the door and rubber gasket, call

Harvest Right Customer Support at

1-800-865-5584 for assistance.

12. You are now ready to load freeze

drying material onto trays. It is

best to freeze dry materials that are

somewhat similar in moisture content.

13. Place the trays that have the

material on them in the shelving

unit. Make sure the trays are fully

supported by the heated shelf with no

part of the tray extending out of the

shelving unit. The trays are heated by

the shelving unit and must t well in

order to receive the appropriate heat

to drive off the moisture.

14. Place the black insulator door

pad in the opening of the vacuum

chamber (within the opening of the

black rubber gasket). This insulates

the acrylic door from the extreme

cold in the chamber and prevents the

cold from forming ice on the door.

15. Close the acrylic door and turn

the door latch clockwise as far as it

will go. This will compress the door

closed against the rubber gasket.

Visually check the seal to make sure

the door is sealed properly to the

gasket. If the door is not latched tight,

there will be a vacuum leak which

might damage your vacuum pump

and void the vacuum pump warranty.

16. Close the drain valve. In the

closed position, the drain valve is

perpendicular to the hose.

17. Power on your unit (press the

switch on the back of your freeze

dryer to the up position). Now, press

the “Start” button. You will then

be reminded to “Please close drain

valve...” Once you have done this, the

word “Freezing…” will be displayed

on the touch screen.

Loading...

Loading...