Harvestec 630 Operator's Manual

2003 1.321.219

.

INTRODUCTION

Dear Customer,

The following is some useful information provided to help ensure efficient and safe

operation of this corn head.

Read this manual carefully to learn how to operate and service your machine

correctly. Failure to do so could result in personal injury or equipment damage.

This manual should be considered a permanent part of your machine and should

remain with the machine when you sell it.

Since the corn head is universal type, carefully read your combine specifications and

follow the combine manufacturer's recommendations for usage, set-up and operation

of the combine.

TABLE OF CONTENTS

3

TABLE OF CONTENTS

SAFETY .................................................................................................................................... 4

IDENTIFICATION, TECHNICAL DATA ........................................................................... 10

1. Identification ..............................................................................................................................10

2. Technical data ............................................................................................................................11

SHIPPING CONDITIONS .................................................................................................... 12

MOUNTING THE CORN HEAD ON THE COMBINE ..................................................... 14

RUN-IN PROCEDURE ......................................................................................................... 21

SETUP PROCEDURE AND ADJUSTMENT OF THE CORN HEAD ............................. 22

HARVESTING ....................................................................................................................... 33

ROW SPACING ADJUSTMENT .......................................................................................... 36

MOUNTING TO ANOTHER TYPE OF COMBINE ........................................................... 39

MAINTENANCE AND LUBRICATION ............................................................................. 40

TROUBLE SHOOTING ........................................................................................................ 47

OFF-SEASON STORAGE OF YOUR CORN HEAD ......................................................... 48

WARRANTY, SERVICE, SPARE PARTS ORDER ............................................................. 48

LUBRICATION CHART ....................................................................................................... 49

4

SAFETY

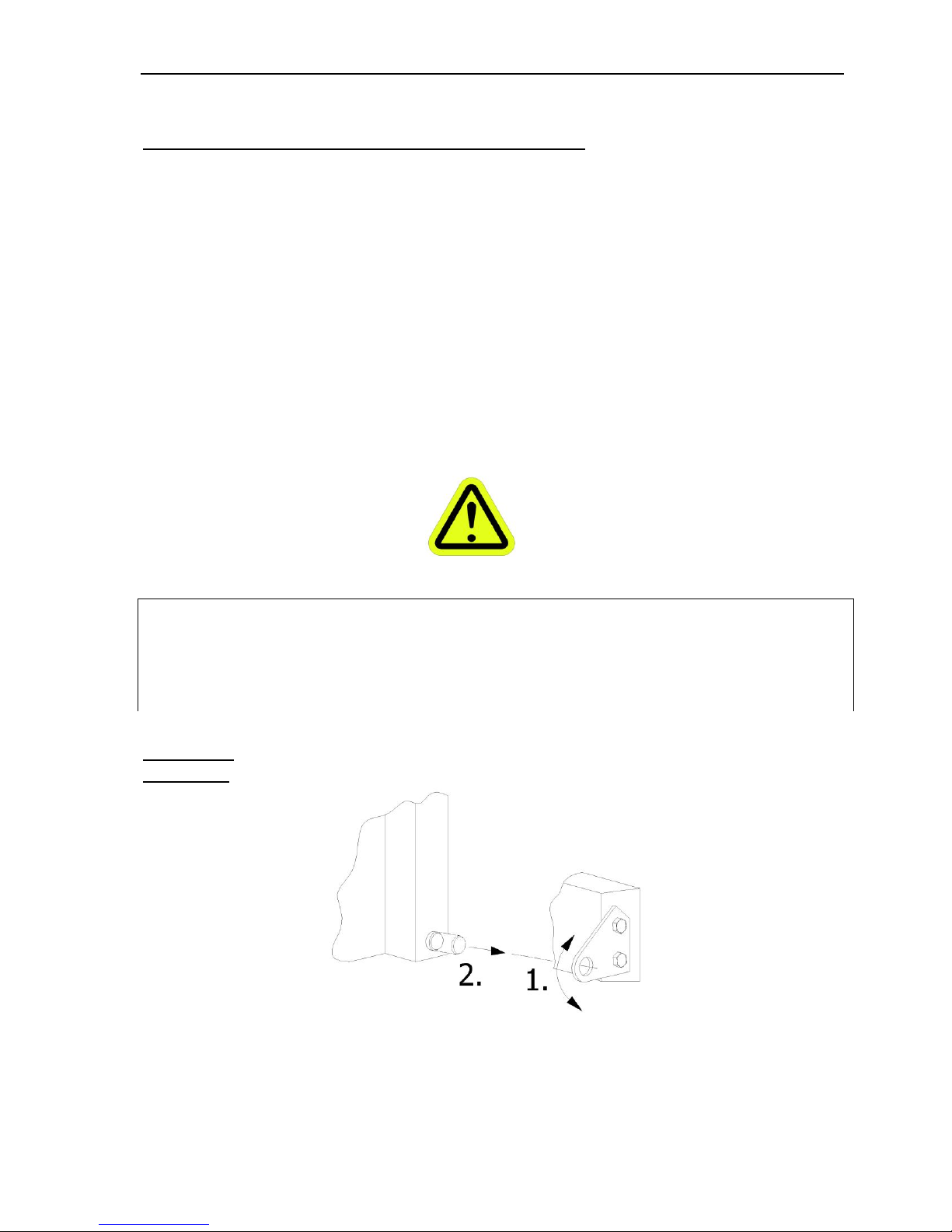

This is the safety-alert symbol. When you see this symbol on your machine or in this

manual carefully read the message that follows, and be alert to the possibility of

personal injury or death.

Follow recommended precautions and safe operating procedures.

UNDERSTAND SIGNAL WORDS

SAFETY

A signal word – DANGER, WARNING, or CAUTION – is used with the safety-alert

symbol. DANGER identifies the most serious hazards.

DANGER or WARNING safety signs are located near specific hazards. General

precautions are listed on CAUTION safety signs. CAUTION also calls attention to

safety messages in this manual.

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual and on your machine safety signs.

Keep safety signs in good condition. Replace missing or damaged safety signs. Be sure

new components and repair parts include current safety signs.

SAFETY

5

GENERAL SAFETY GUIDELINES

1. ALLOW ONLY trained and experienced operators to operate your machine. Operating

this equipment safely requires the full attention of the operator. Do not wear

entertainment headphones while operating this machine.

2. ALWAYS DISENGAGE header drive, shut off the engine and remove key before

servicing, adjustment, maintenance and lubrication to your corn head.

3. STAY CLEAR of the header when it is in operation.

4. DO NOT OPEN safety shields or covers while your corn head is running.

5. ENGAGE the lock on the feeder lift cylinder before doing any work under or around the

corn head.

6. CHOPPER KNIVES must not be installed without security locking pins.

7. WORN or DAMAGED CHOPPER KNIVES must be replaced before operation of the

corn head. Radial clearance between knife and bushing must be properly maintained. See

details in this manual.

8. It is FORBIDDEN to remove the warning lables from the machine. If they become

damaged or illegible they have to be ordered as shown in the Figures.

9. It is FORBIDDEN! to remove the safety hydraulic valve of the folding corn head located

on the upper support.

10. It is FORBIDDEN! to close or open the folding corn head when it is in operation.

6

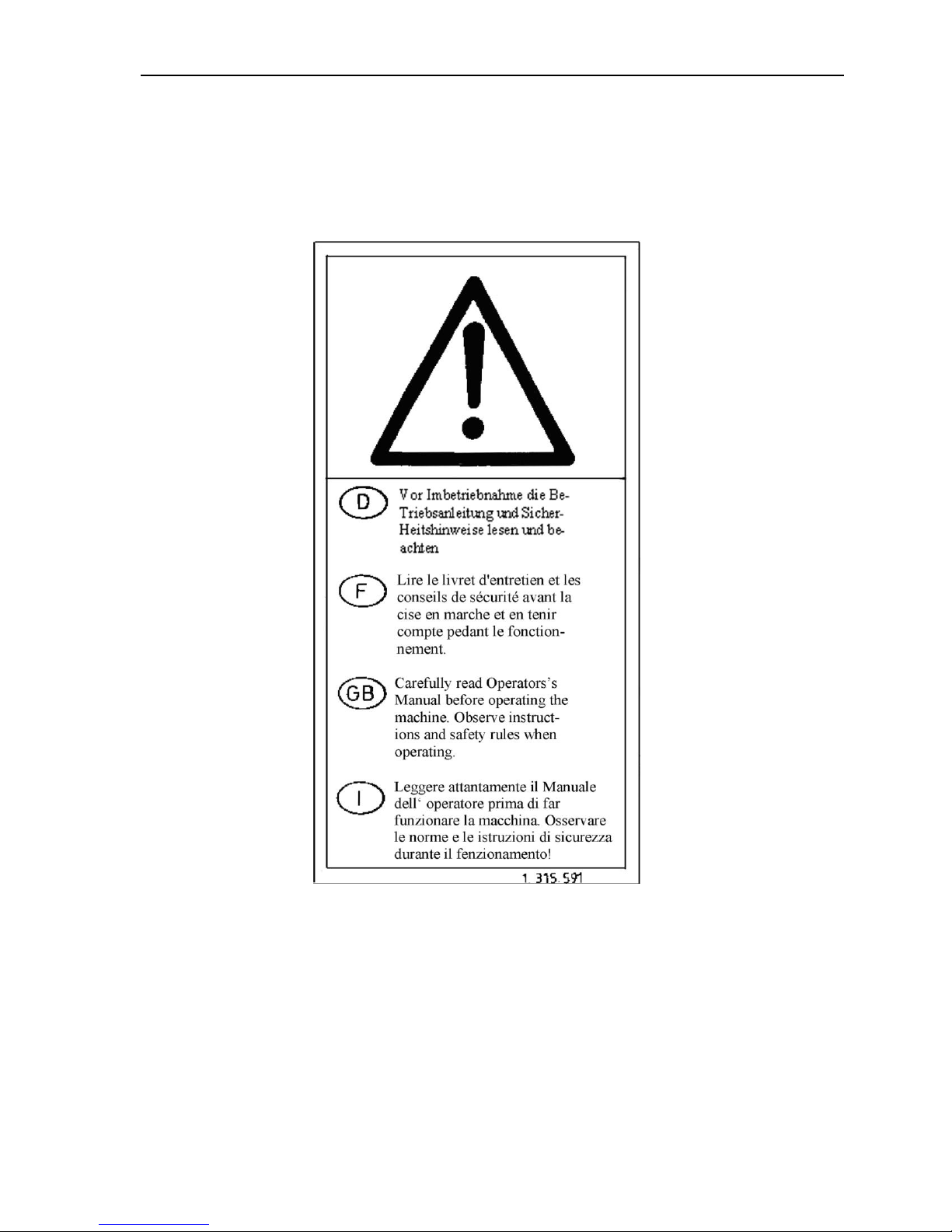

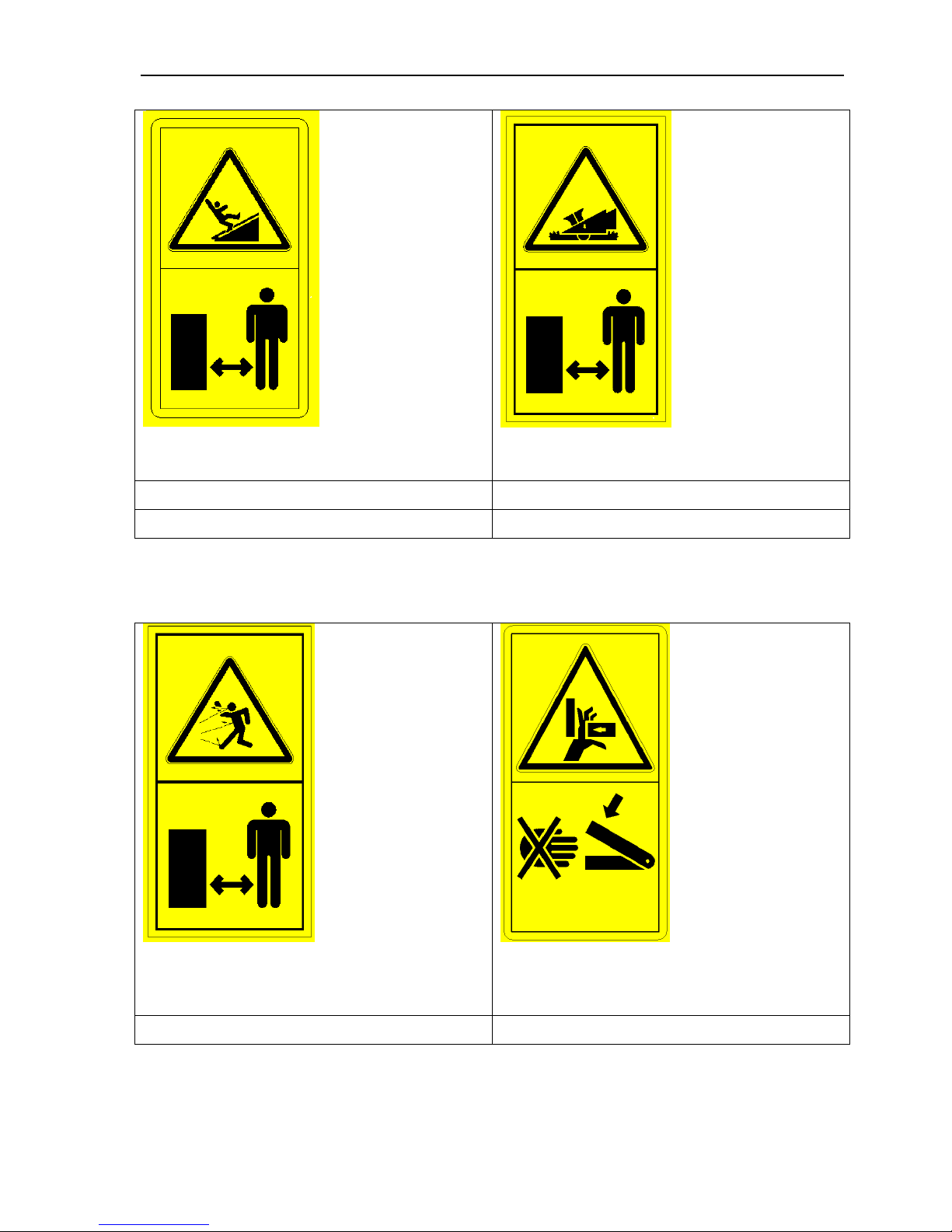

SAFETY DECAL

SAFETY

Carefully read Operator‟s Manual before handling the machine. When operating observe

safety instructions.

1.315.591

SAFETY

7

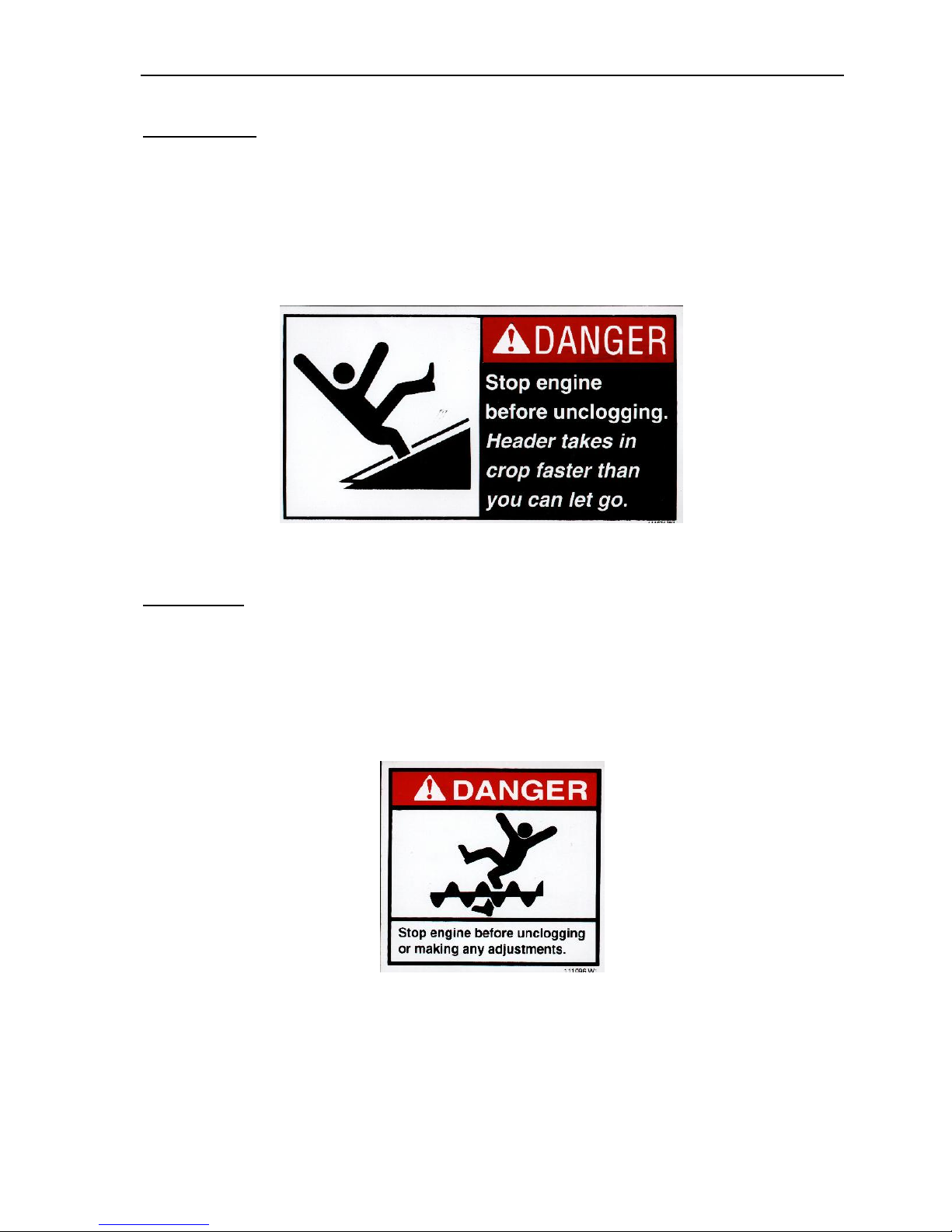

FRONT SIDE

Two reflecting strips are located at the ends on the front of the top beam facing forwards.

Fig A: Two decals are located on the front side of the header rear sheet (on each side of the

feeder opening).

FIG A

REAR SIDE

Two red reflector strips are located at the ends on the rear of the end shields facing rearward.

FIG B. Two decals are located on the rear side of the header back sheet (on each side of

the feeder opening).

FIG B

SAFETY

8

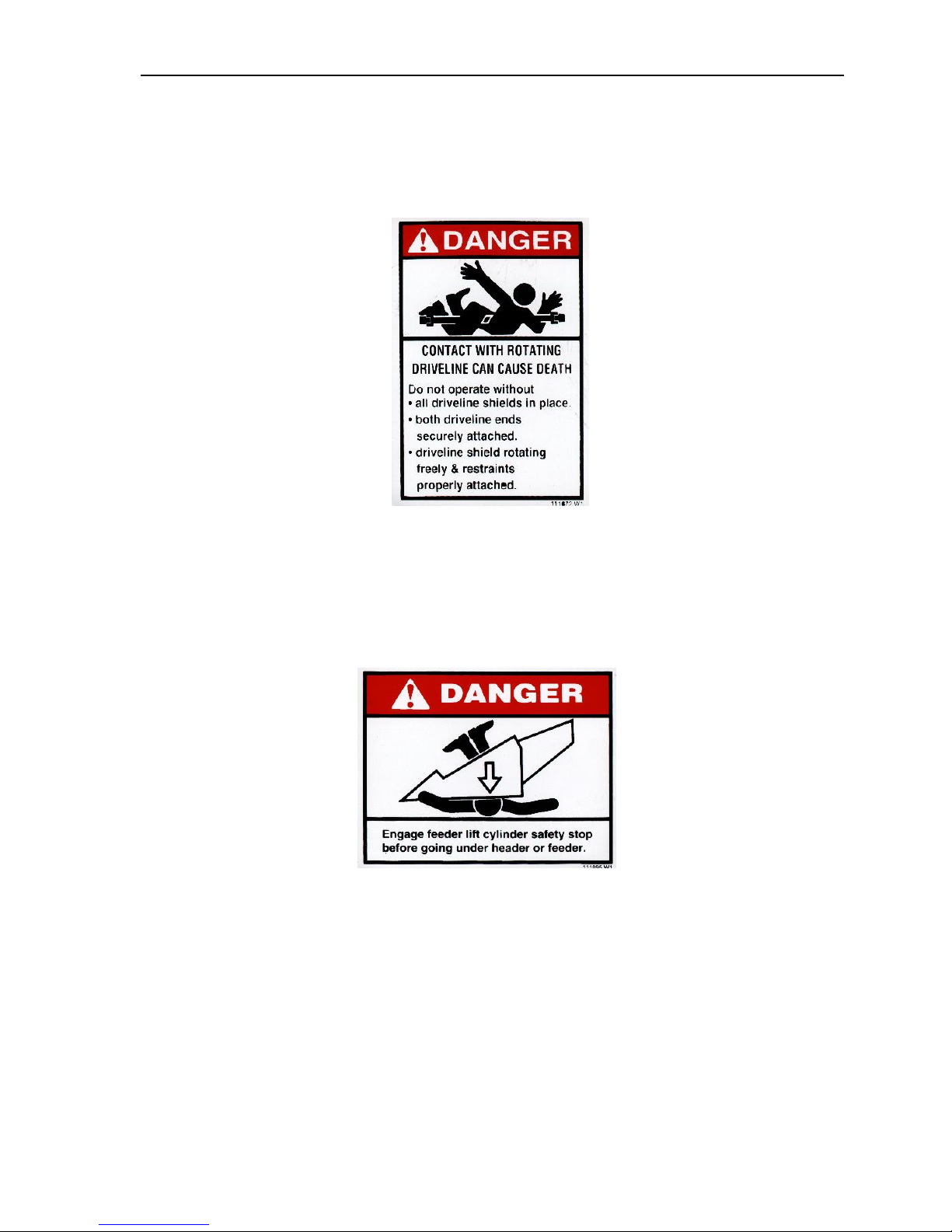

FIG. C: Two decals are located on the rear of the end shields.

NOTE: Four-row Corn Head will have one or two decals depending on the quantity of drive

shafts.

FIG C

FIG D: Two decals are located at the ends on the rear side of the header back panel above the

drive shafts.

FIG D

SAFETY

9

1.315.438 2 Decals

1.315.439 2 Decals

1.315.440 2 Decals

1.315.590 2 Decals

IDENTIFICATION, TECHNICAL DATA

10

IDENTIFICATION, TECHNICAL DATA

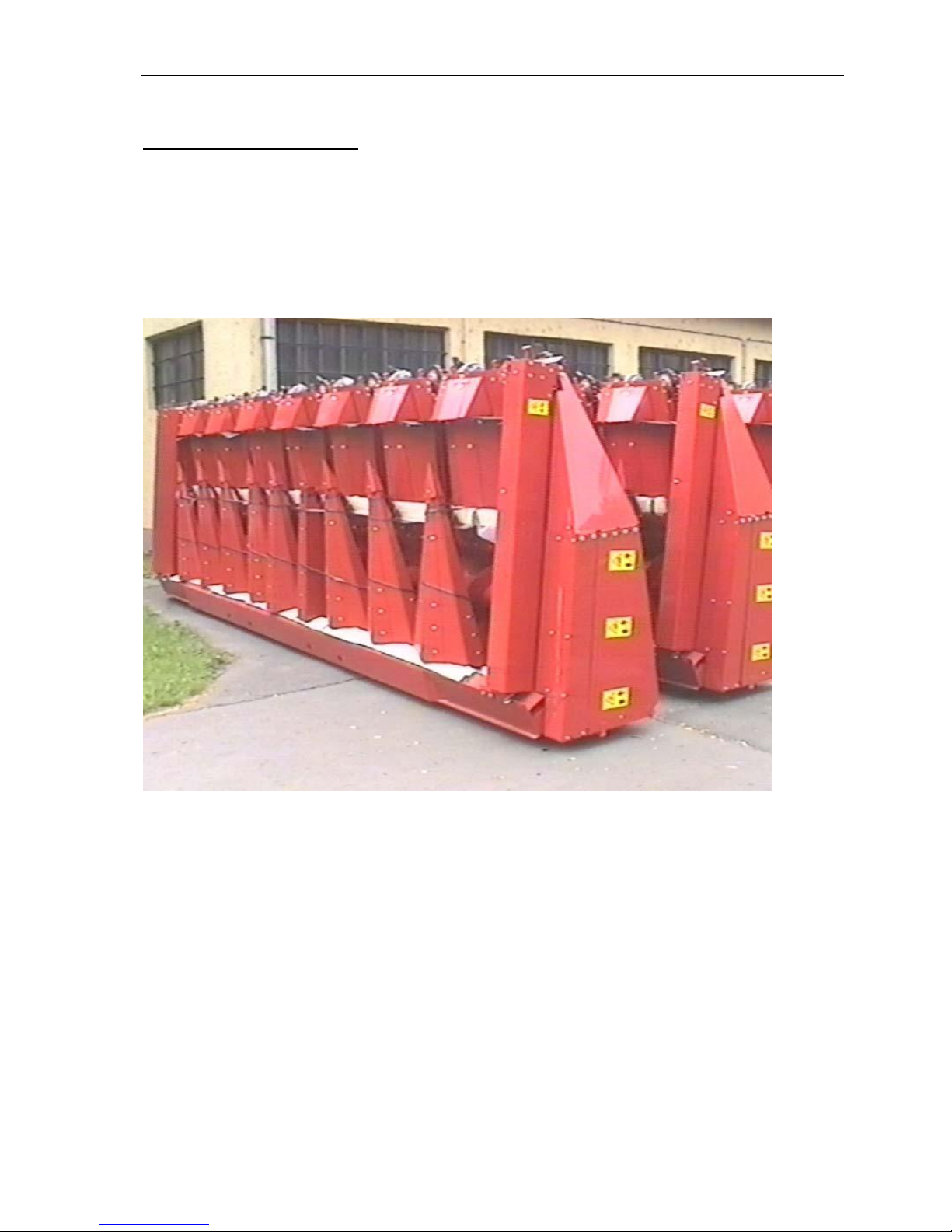

1. Identification

The corn head mounting is universal, so it can be assembled on specific combine types with

the appropriate mounting kit. A mounting kit is assembled to the corn head at the factory

when a machine is ordered. A data plate is provided located on the left side of the machine's

upper support.

The model number refers to the following: for example: HARVESTEC 630

Universal corn head

630 6-row fix frame corn head with 30” row spacing

HSA provided with stalk shredder located under the snapping roll

IDENTIFICATION, TECHNICAL DATA

11

Width(mm)

Length(mm)

Height(mm)

6-row 28-32"

4720

2950

1100

6-row 36-40"

5720

2950

1100

8-row 28-32"

6320

2950

1100

8-row 36-40"

7720

2950

1100

Width(mm)

Length(mm)

Height(mm)

6-row 28-32"

4720

950

2170

6-row 36-40"

5720

950

2170

8-row 28-32"

6320

950

2170

8-row 36-40"

7720

950

2170

Corn Head with

Steel

Snouts/Dividers

(less chopper)

Corn Head with

Plastic

Snouts/Dividers

(less chopper)

Corn Head with

Steel

Snouts/Dividers

(with chopper)

Corn Head with

Plastic

Snouts/Dividers

(with chopper)

4-row

1650 kg

1490 kg

1780 kg

1620 kg

6-row

2000 kg

1775 kg

2195 kg

1970 kg

8-row

2650 kg

2360 kg

2910 kg

2620 kg

6-row folding

2250 kg

2025 kg

2445 kg

2220 kg

8-row folding

3205 kg

2915 kg

3465 kg

3180 kg

2. Technical data

2.1. Dimensions (in operating condition)

2.2. Dimensions (in shipping condition)

2.3. Weight:

2.4. Lubrication specification: SAE 90 standard lubricating grease.

2.5. Pitch of the gathering auger is 450 mm.

2.6. Input shaft speed of the snapping unit drive: 550-620 rpm

2.7. Length of chopped stalk:

HSA = average 70 mm, depending on crop conditions.

2.8. Adjustment of the snapping plate is centrally electrical in-cab control switch.

2.9. Adjustable for row spacing

28"-30"-32"-(70 cm-76.2 cm-80 cm)

36"-38"-40"-(90 cm- 96.2 cm-100 cm)

SHIPPING CONDITIONS

12

SHIPPING CONDITIONS

Your corn head is delivered with gearboxes filled with oil, and packaged on a shipping skid.

Oil levels should be checked before putting the Corn Head into operation.

SHIPPING CONDITIONS

13

The corn head can be lifted with a suitable crane or forklift. When choosing lifting equipment

consider the weight as detailed in the Chapter 1, point 2.3. When lifting with a cable or chain,

the included angle should not exceed 90°.

Max 90°

The minimum cable length „L‟ to not exceed the max. 90° angle:

for 6-row fixed and folding frame and 8-row fixed frame is 1100 mm

The cable length should be equal on each side.

Use only a cable, which has capacity for the weight of the machine.

MOUNTING ON THE COMBINE

14

After the above operation and with the specified mounting kit securely attached to the Corn

Head, engage and securely attach the Corn Head to the combine according to Combine

Manufacturer‟s instructions and engage the feeder lift cylinder safety stop and secure the

lower latches.

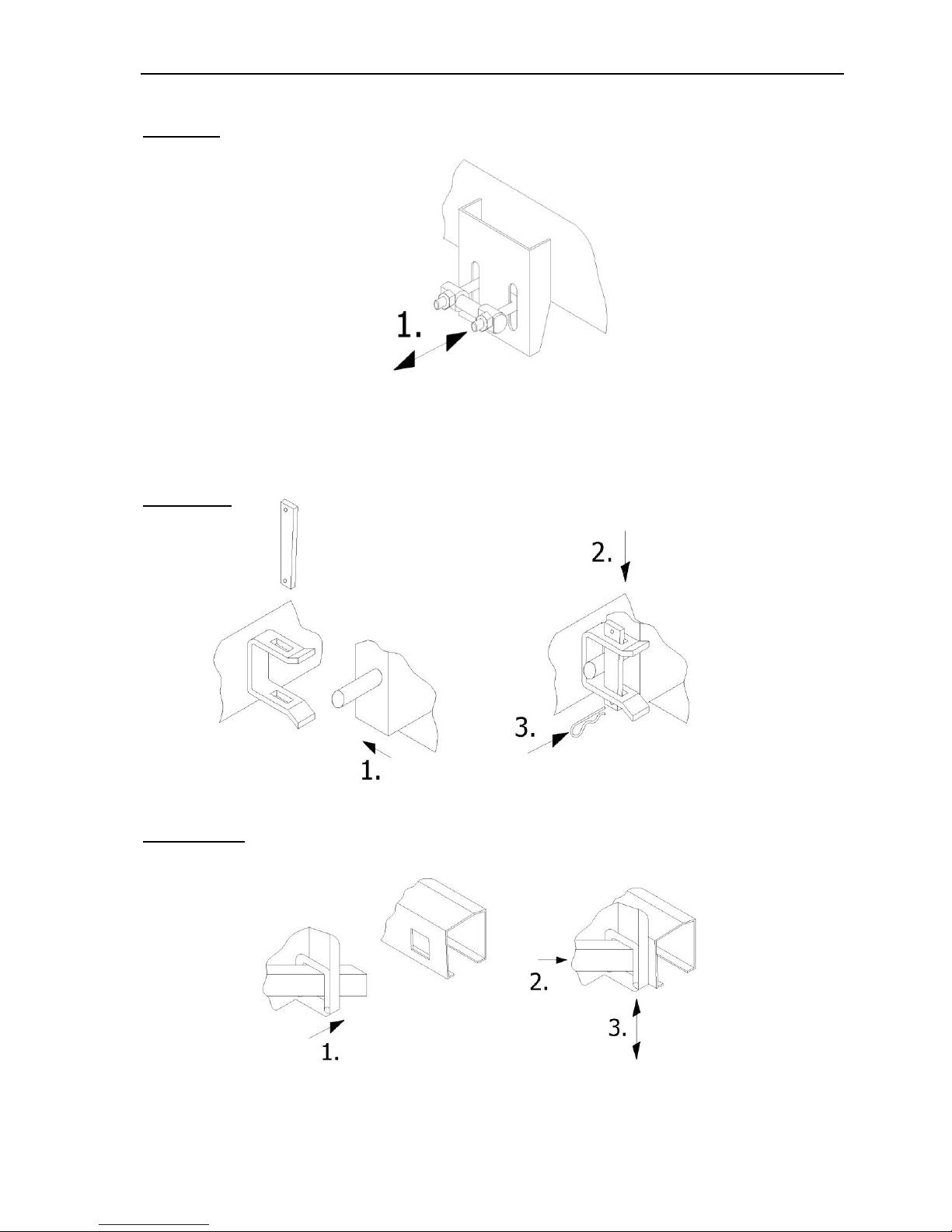

MOUNTING THE CORN HEAD ON THE COMBINE

After removing the Corn Head from the shipping container, and while on shipping stand

Remove the parking stands and snouts from their stored shipping position

Install parking stands in their retracted (transport) position

Carefully lower the machine to horizontal position with a cable attached to lifting hooks.

Disassemble the transport skid after the machine is resting securely in horizontal position.

The corn head is shipped from the factory with mounting kit installed as ordered. If the corn

head will be mounted to a different combine than ordered for, remove the factory installed

mounting kit and install the required mounting kit as recommended for your combine.

John Deere

9000 series

Insert the spring pivot pin of the feeder house into the hole of the secure plate, which is

assembled on the lower support. If it is required adjust the shaft alignment.

MOUNTING ON THE COMBINE

15

CASE IH

If necessary, adjust the nuts on the U-bolts to get the required force on the latches. Refer to

the combine Operator‟s Manual for the correct adjustments and latching methods.

Deutz-Fahr

Fiat-Laverda

Loading...

Loading...