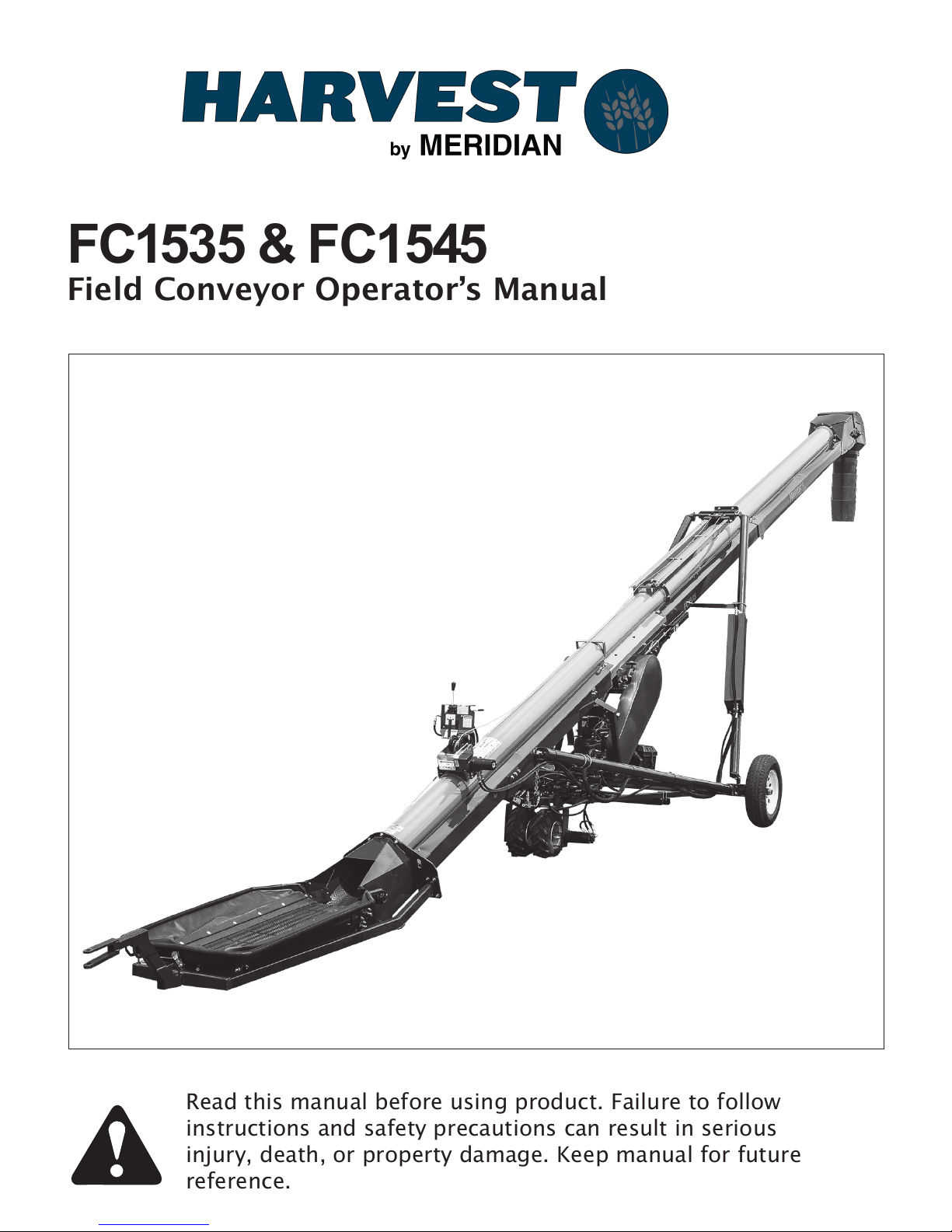

HARVEST FC1545, FC1535 Operator's Manual

Read this manual before using product. Failure to follow

instructions and safety precautions can result in serious

injury, death, or property damage. Keep manual for future

reference.

FC1535 & FC1545

This product has been designed and constructed according to general engineering

standards

a

. Other local regulations may apply and must be followed by the operator.

We strongly recommend that all personnel associated with this equipment be trained

in the correct operational and safety procedures required for this product. Periodic

reviews of this manual with all employees should be standard practice. For your

convenience, we include this sign-off sheet so you can record your periodic reviews.

!

Date

Employee Name

Employee

Signature

!2

!

!

TAB LE O F CO NT EN TS

1. Introduction 4

2. Safety First 5

2A General Safety 6

2B Transport Safety 7

2C Operation Safety 9

2D Maintenance Safety 10

2E Grain Storage Safety 10

3. Operation 11

3A Machine Break-In and Operation 12

3B Pre-Operation Checklist 13

3C Placement 13

3D Discharge Hood Adjustment 14

3E Gas Engine Drive & Lockout 15

3F Full Load Operation 15

3G Cold Weather Operation 16

3H Oilseed & Fertilizer Operation 16

3I Conveyor Shut Down 17

3J Clean Up & Storage 17

3K Transport Procedure 18

4. Service 18

4A Fluids & Lubricants 18

4B Lubrication 18

4C Service Intervals 19

4D Conveying Belt Tension 19

4E Belt Replacement 21

4F Lacing Inspection 21

5. Maintenance 22

5A Maintenance Schedule 22

23

24

25

39

!

!

!

!

!3

6. Harvest by Meridian Conveyor Specs

7. Troubleshooting

8. Parts Book

9. Warranty Policy & Forms

!

1. Introduction

Congratulations on your choice of a Harvest by Meridian conveyor to complement

!4

your agricultural operation. This equipment has been designed and manufactured to

meet the needs of the discriminating buyer for the efficient movement of grain,

pulse crops, fertilizer, and most other granular materials.

Safe, efficient, and trouble-free operation of your conveyor requires that you, and

anyone else who will be operating or maintaining the conveyor, read and understand

the safety, operation, maintenance, and troubleshooting information in this manual.

Equipment is available in various combinations. In most cases, the following

instructions will apply to all machines. However, some will vary according to certain

options and accessories.

Keep this manual handy for frequent reference and to pass on to new operators or

owners. Call your Harvest by Meridian distributor or dealer if you need assistance,

information, or additional copies of the manual.

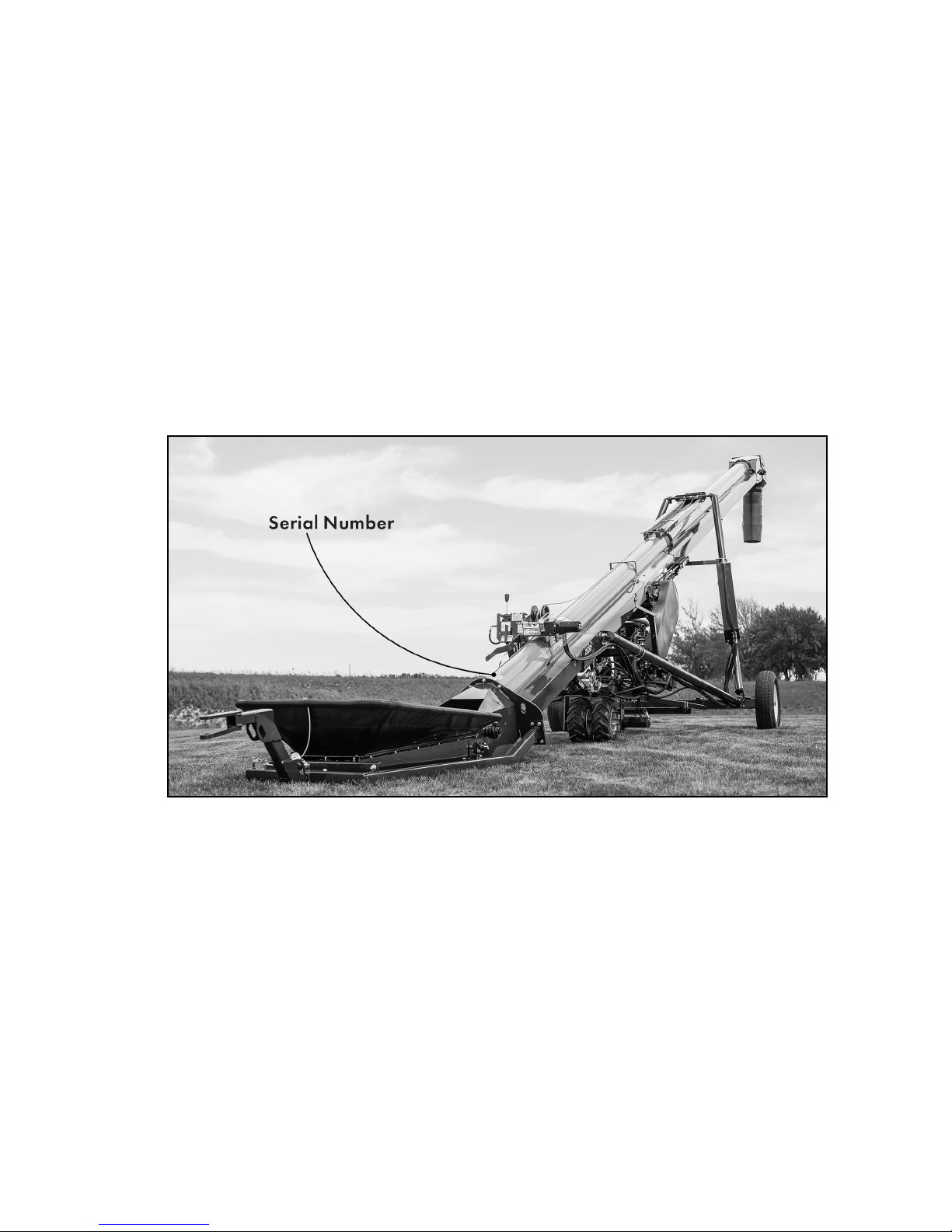

Always give your dealer the serial number of your Harvest by Meridian Grain

Conveyor when ordering parts or requesting service or information.

The serial number decal is located where indicated by arrow in image above. Please

mark the number in the space provided below for easy reference.

Model Number:_____________________________________

Serial Number:______________________________________

Production Year:_____________________________________

!

2. Safety First

Safety is a priority in your everyday work habit, especially if you work with

machinery. Whether you are an owner, an operator, or an employee, it is your

responsibility to know the operational requirements and safety precautions of

the machinery.!

!

Why is safety important to you?!

!

1. Accidents disable and kill.

2. Accidents cost.

3. Accidents can be avoided.

!

SIGNAL WORDS:!

Note the use of the signal words DANGER, WARNING, CAUTION, and NOTICE

with the safety messages. The safety alert symbol identifies imminent and

potential hazards to personal health and safety. The appropriate signal word for

each message has been selected using the definitions below as a guideline:!

!

!

DANGER: indicates an imminently hazardous situation that, if not

avoided, will result in serious injury or death.!

!

!

!

!

WARNING: Indicates a hazardous situation that, if not avoided,

could result in serious injury or death.!

!

!

!

!

CAUTION: Indicates a hazardous situation that, if not avoided, may

result in minor or moderate injury.!

!

!

!

NOTICE: Indicates a potentially hazardous situation that, if not

avoided, may result in property damage.

!

!

!5

!

2A General Safety _

Important: The general safety section includes instructions that apply to all safety practices. Any

instructions specific to a certain safety practice (e.g. assembly safety), can be found in the

appropriate section. Always read the complete instructional sections and not just these safety

summaries before doing anything with the equipment.

You are responsible for the safe use and maintenance of your equipment. Yo u must ensure that you and

anyone else who is going to work around the equipment understands all procedures and related safety

information contained in the manual.

Remember, you are the key to safety. Good safety practices not only protect you, but also the people

around you. Make these practices a working part of your safety program.

•

It is the equipment owner and the operator’s responsibility to read and understand all

safety instructions, safety decals, and manuals, and to follow them before assembling,

operating, or maintaining the equipment. All accidents can be avoided.

•

Equipment owners must give instructions and review the information initially and annually

with all personnel before allowing them to operate this product. Untrained users/operators

expose themselves and bystanders to possible serious injury or death.

•

Ensure the conveyor is in good working order with all safety shields in place.

•

Always have at least 2 people present when operating the machine.

•

Use this equipment for its intended purposes only.

•

Do not modify the equipment in any way. Unauthorized modification may impair the

function and/or safety, and could affect the life of the equipment. Any modification to the

equipment voids the warranty.

•

Do not allow children, spectators, or bystanders within the work area.

•

Have a first-aid kit available for use should the need arise, and know how to use it.

•

Provide a fire extinguisher for use in case of an accident. Store in a highly visible place.

•

Do not allow riders on the machine.

•

Wear appropriate protective gear. This list includes, but is not limited to: hard hat,

protective shoes, protective goggles, heavy gloves, wet weather gear, hearing protection,

filter mask or respirator.

•

Before servicing, adjusting, or repairing powered equipment, place all controls in neutral,

stop the engine, set the park brake, remove ignition key, wait for all moving parts to come

to a complete stop, and remove the PTO shaft from the tractor (if applicable).

•

Know where overhead electrical lines are located and stay away from them. Electrocution

can occur without direct contact.

•

Pay attention to the safety decals on the machine! They contain important alerts and

precautions which are to be followed at all times.

•

Keep all loose clothing and long hair away from the rotating driveline. PTO shafts can cause

entanglement and serious injury or death.

!6

!

2B Transport Safety _

•

Make sure the hitch on the towing vehicle is rated for the gross weight of the

towed machine.

•

Check with local authorities regarding transport of agricultural equipment on

public roads. Obey all applicable laws and regulations.

•

Always travel at a safe speed, never exceeding 20 mph (32 km/h). Reduce speed

on rough surfaces. Use caution when turning corners or meeting traffic.

•

Make sure the SMV (slow moving vehicle) emblem and all the lights and reflectors

that are required by local authorities are in place, are clean, and can be seen by

all over-taking and oncoming traffic. Always use hazard-warning flashers on

tractor/towing vehicle when transporting unless prohibited by law.

•

Do not allow riders on the machine, towing vehicle, tractor, or skid steer during

transport.

•

Stay away from overhead obstructions and power lines when operating and

transporting. Electrocution can occur without direct contact.

•

Fully lower conveyor before transporting, making sure the conveyor lifting slide is

firmly pressed against the transport stop. Keep light tension on the lifting cable.

•

When transporting, use a clevis-to-tongue connection. Never use a clevis-to-clevis

or tongue-to-tongue connection as this can lead to hitching failure.

•

Attach a conveyor to towing vehicle with a 3/4”pin and retainer. Always attach

safety chain(s).

•

The conveyor is not equipped with brakes. Make sure the tow vehicle has sufficient

braking capacity for the extra load. The conveyor may not exceed 1.5 times the

towing vehicle weight.

•

Check the tires for cracks and make sure they are inflated to 30 psi.

•

Do not transport conveyor on slopes greater than 20 degrees.

•

Only move your conveyor with a tractor/towing vehicle. Never move by hand.

!

! 7

!

!

!

!

!

!

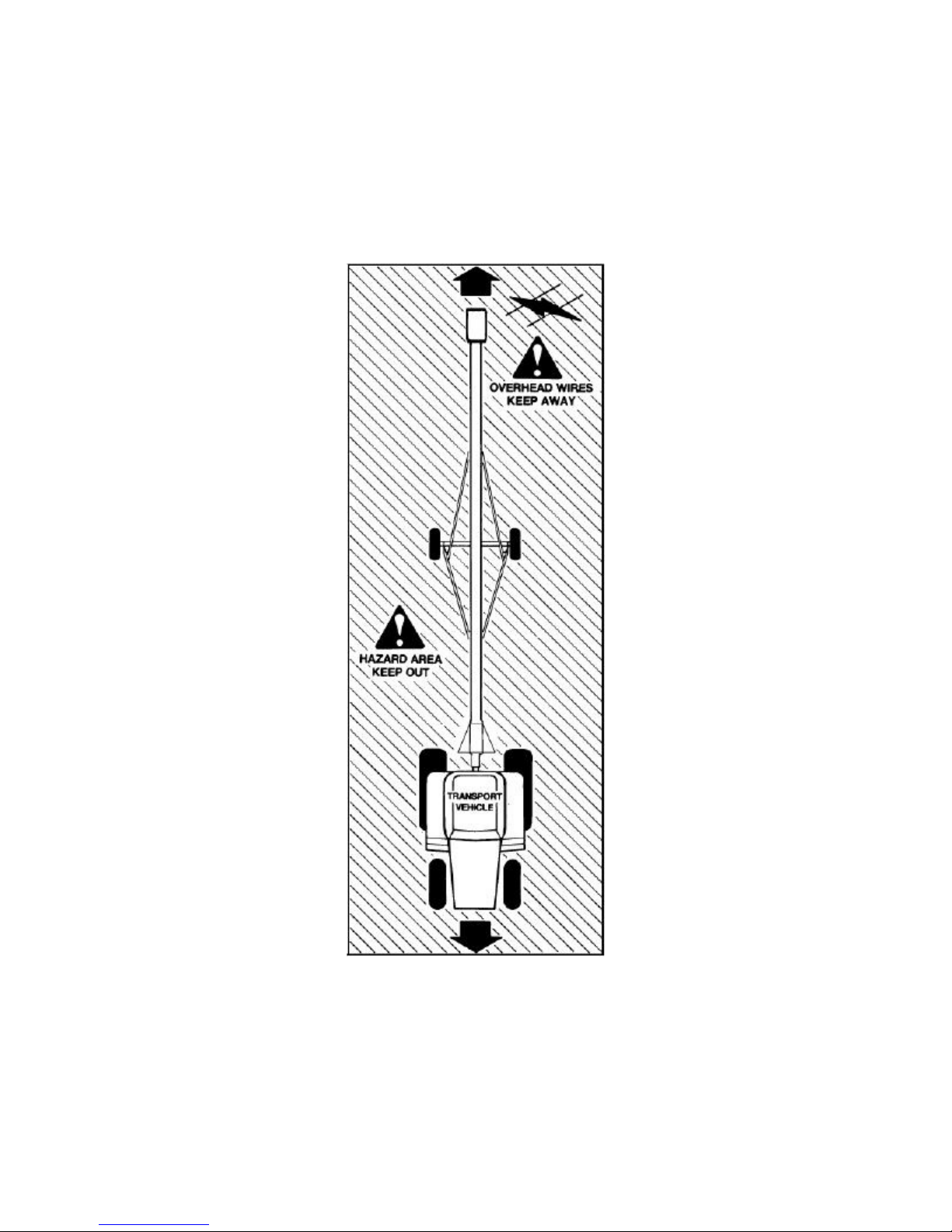

Figure 2: Transport Safety Zones

!

! 8

!

2C Operation Safety _

•

Keep hands, feet, hair, clothing, and jewelry away from all moving and/or rotating

parts.

•

Inspect the machine before operating. Ensure condition of belts, gearboxes,

drivelines, etc. are sufficient for operation and repair or replace if necessary.

•

Stay away from overhead obstructions and power lines; electrocution may occur

without direct contact.

•

Do not operate with any of the guards removed.

•

Clear area of all bystanders, especially children, before operation.

•

Keep all workers away from the intake of conveyor while machine is running.

•

When cleaning out corners of truck box, do not lean over the conveyor intake. Do

not use hands or feet to clean out intake hopper.

•

Do not use downspout as a support. Stay clear of discharge end.

•

The machine is closely balanced. Do not move grain unless the intake end is

anchored or the discharge end is supported to prevent upending.

•

Set park brake on tractor before starting.

•

Use extreme caution when running conveyor at maximum height. Conveyor should

always be transported at lowest position, never at maximum height.

•

Operate conveyor on level ground free of debris. If ground is uneven, anchor the

conveyor to prevent tipping or upending.

•

Always work with a second person around conveyor in case of accident.

•

Do not run conveyor at high speeds when it is empty.

•

Be familiar with the machine hazard area shown in Figure 3. If anyone enters the

hazard area, shut down the machines immediately. Clear the area before

restarting.!

!9

!

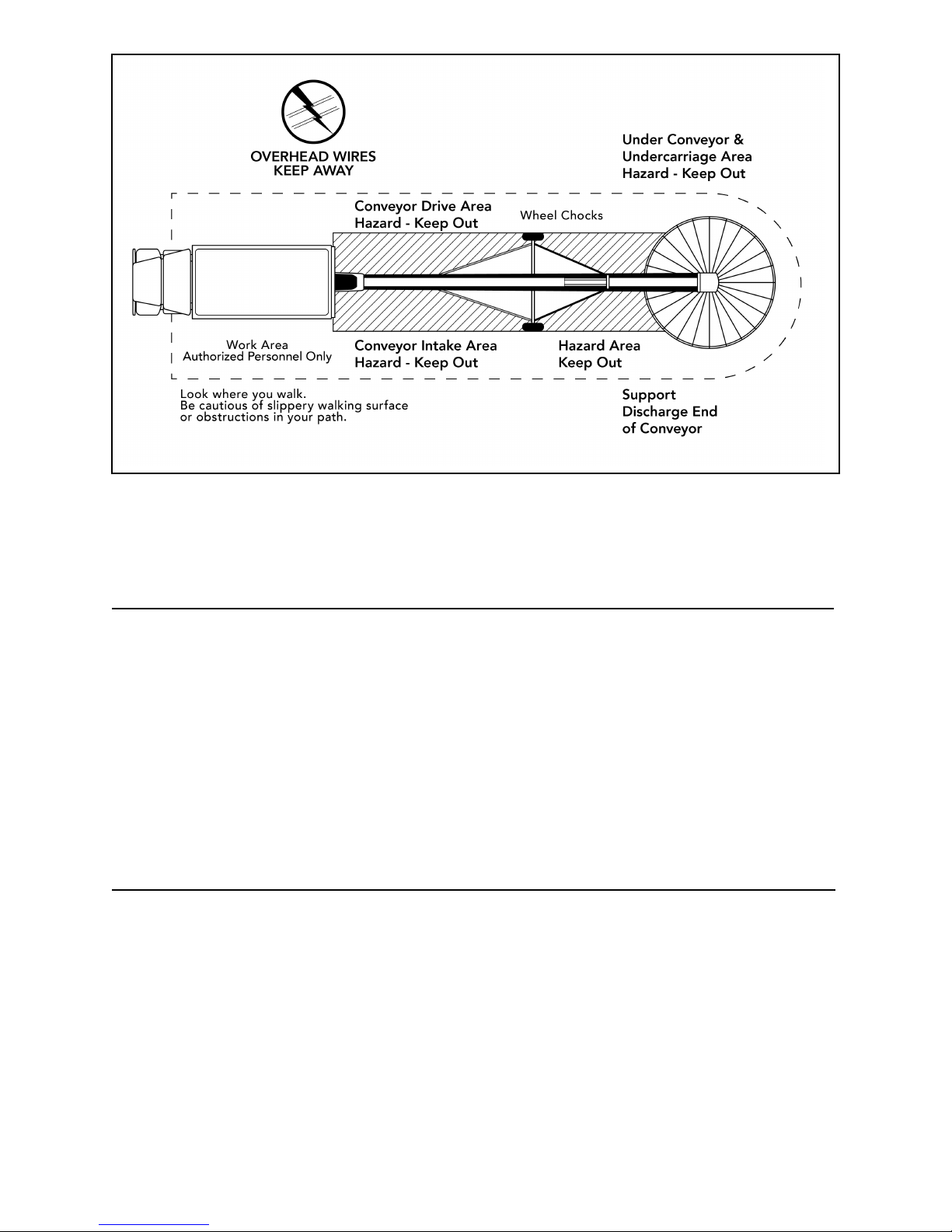

Figure 3: Workplace Hazard Area (Gas Engine Drive)

!

2D Maintenance Safety _

•

Before servicing the conveyor, always disengage power and ensure all moving parts

have stopped.

•

Support the machine with blocks or stands when working underneath the conveyor.

•

Keep service area dry and clean. Be sure electrical tools are properly grounded. Use

adequate light for the job at hand and use personal protective equipment.

•

Use only tools, jacks, and hoists of sufficient capacity for the job.

•

Replace all shields before operating. Check that all fittings are tight.

2E Grain Storage Safety _

•

Never enter a grain bin unless at least two people are present. Have one person

outside the bin solely to shut the conveyor down in case of emergency.

•

Always ensure an escape route exists before entering the bin.

•

Only walk on top of grain bin if equipped with safety line and another person is

present.

•

Do not place intake of conveyor near or between your feet when standing on top of

grain. There is a risk of being pulled into the grain pile causing suffocation.

!10

!

3. Operation

Before operating the conveyor, all operators should familiarize themselves with the location

and function of the components and controls.

Warning: Before continuing, please reread the safety information relevant to this section at

the beginning of this manual. Failure to follow the safety instructions can result in serious

injury, death, or property damage.

!

!

!

! 11

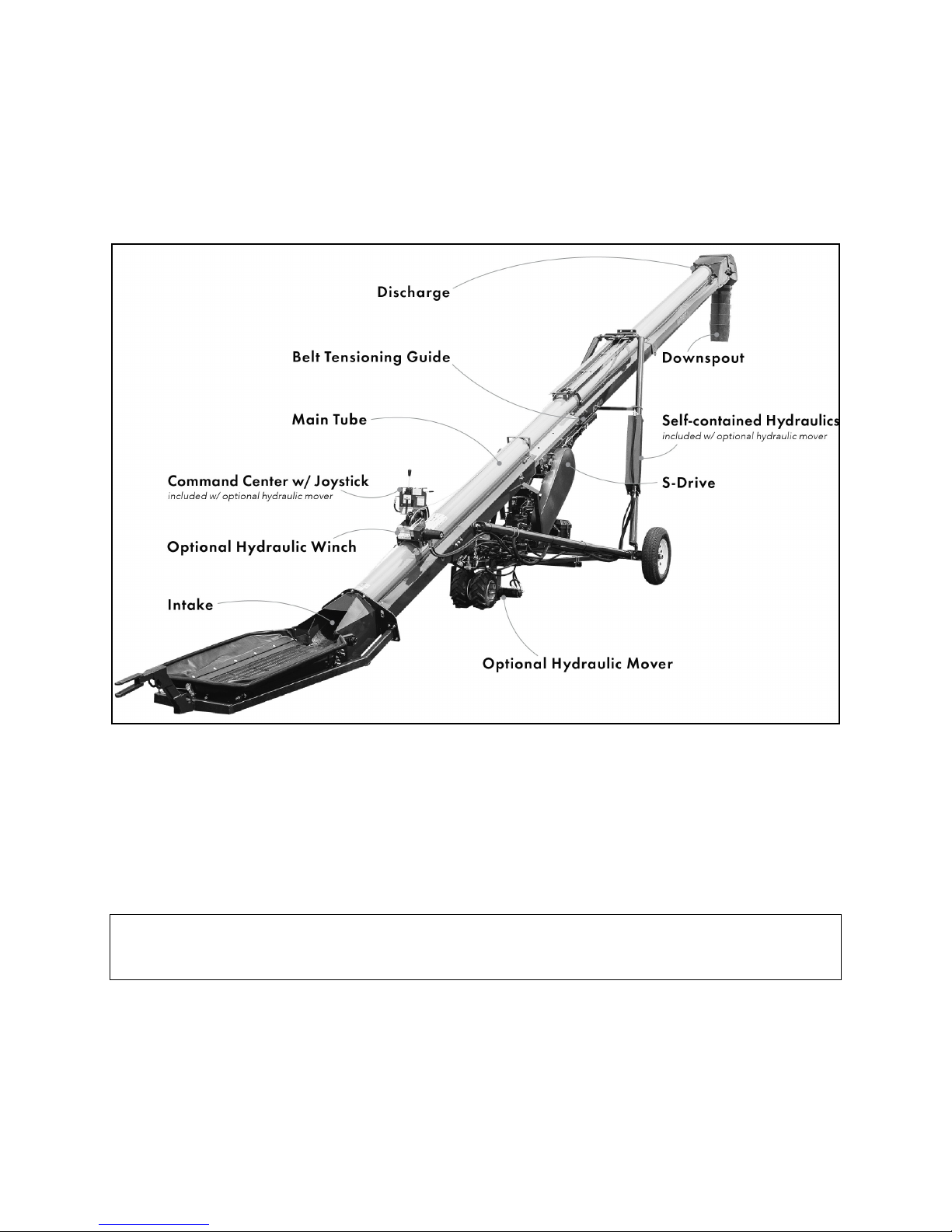

The Harvest by Meridian Conveyor is powered by a gas engine drive. Power is transferred to

the conveyor belt through an S-Drive mounted to the bottom of the main tube. The conveyor

utilizes a belt tensioning guide that allows the operator to know the belt tension at all times.

Options include: Hydraulic Mover & Hydraulic Winch.

!

!

3A Machine Break-in and Operation _

BEFORE STARTING:

1. Read the conveyor operation manual.

2. Tighten wheel bolts to specified torque.

3. Check all fasteners and ensure they are tightened to specified torque levels.

4. Check that all guards are in place, secure, and functional.

5. Check winch and cable for security and operation. There should be at least three

complete wraps of cable around the winch drum in the full down position. The

cable anchor on the winch drum must be tight.

6. The FC1545 Conveyor is designed to have a belt speed of 600 FPM with the gas

engine drive (using a 26 HP engine @ 3600 RPM).

7. During the first 15 minutes of operation, check the conveyor belt alignment to

ensure preset alignment does not vary under loaded conditions. See Maintenance

section 8.3.5

NOTE: A new belt will ear at edges and throw small pieces of belting for the first 5 minutes of

use. This is normal. Check tension and alignment closely during this time. A slower belt speed

is gentler on the product, whereas a higher belt speed increases capacity but may increase

product damage.

!

AFTER OPERATING OR TRANSPORTING FOR 5 MINUTES:

1. Re-torque all fasteners and hardware.

2. Check conveyor belt and drive belts for tension and alignment.

AFTER OPERATING OR TRANSPORTING FOR ½ HOUR:

1. Re-torque all the wheel bolts.

2. Re-torque fasteners and hardware.

3. Check the drive and conveyor belt tension and alignment. Tension or align as

required. See “Maintenance” section.

AFTER OPERATING FOR 5 AND 10 HOURS:

1. Re-torque all wheel bolts, fasteners, and hardware.

2. Check the drive and conveyor belt tension and alignment. Tension or align as

required.

!12

!

3B Pre-Operation Checklist _

BEFORE OPERATING THE CONVEYOR EACH TIME:

•

Service the machine per the schedule outlined in the Maintenance section of this

manual.

•

The conveyor belt should slide freely inside the tube.

•

All guards and shields should be in place.

•

Check tires for proper inflation and ensure they are in safe road condition.

•

Check the conveyor belt for tension, alignment, and condition.

•

Check the condition of the belt lacing and the lacing pin.

•

Check drive belt for tension, alignment, and condition.

•

Check and clear the conveyor of any obstructions at intake or discharge end.

•

Check winch cable for fraying. Replace immediately if there is any fraying.

•

Check winch brake. Repair if necessary.

•

Anchor intake end of support discharge end of conveyor when in position.

!

3C Placement _

Moving the Conveyor with a Towing Vehicle into or out of the Working Area

1. Clear the area of all debris.

2. Always use a vehicle when moving the conveyor. When raising from or attaching to

vehicle, test the intake end for downward weight. Lift slowly and keep intake end

no higher than the tow vehicle’s hitch. Be sure all product is emptied from

conveyor before lifting.

!

WARNING: Never move the conveyor by hand. Do not push on the conveyor

undercarriage.

!

3. Conveyor must be on level surface attached to vehicle with wheels free to move.

4. If conveyor must be raised before placement, ensure the entire area above the

conveyor and in the line of travel is clear of obstructions and electrical wires.

!

! 13

Loading...

Loading...