Hart Sceintific 9113 User Manual

Model 9113

Portable Furnace

User Manual

HART

SCIENTIFIC

Rev. 721801

© Copyright,1991 All rights reserved

Hart Scientific

799 E. Utah Valley Drive

American Fork, Utah 84003-9775

Telephone (801) 763-1600 • Fax (801) 763-1010

Internet: http://www.hartscientific.com

2

WARNING

To ensure the safety of operating personnel, and to avoid damage to this equipment:

DO NOT operate this unit without a properly grounded, properly polarized power cord.

DO NOT connect this unit to a non-grounded, non-polarized outlet.

DO USE a ground fault interrupt device.

WARNING

HIGHVOLTAGE

is used in the operation of this equipment.

SEVERE INJURY OR DEATH

may result if personnel fail to observe safety precautions.

Before working inside the equipment, turn power off and disconnect power cord.

WARNING

HIGH TEMPERATURES PRESENT

in this equipment

FIRES AND SEVERE BURNS

may result if personnel fail to observe safety precautions.

WARNING

To ensure the safety of personnel, and to avoid damage to equipment:

DO NOT use this unit for any application other than calibration work.

DO NOT use this unit in environments other than those listed in the user’s manual.

Continuous use of this equipment at high temperatures for extended periods of time

requires caution.

Completely unattended high temperature operation is not recommended for

safety reasons.

Components and heater lifetimes can be shortened by continuous high temperature operation.

Follow all safety guidelines listed in the user’s manual.

c

WARNING

THIS EQUIPMENT SHOULD ONLY BE USED BY TRAINED PERSONNEL.

d

Table of Contents

1 Introduction ................................7

2 Specifications and Environmental Conditions .............8

2.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Safety Guidelines ............................ 10

4 Quick Start ................................ 11

4.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Installation ................................ 12

5.1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.3 “Dry-out” Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.4 Equilibration Block Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 Parts and Controls ........................... 13

6.1 Top Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.1.1 Temperature Controller ................................... 13

6.1.1.1 Temperature Adjustment Up/Down Keys ..................... 13

6.1.2 Power Switch ........................................ 14

6.1.3 Fan Light Indicator ...................................... 14

6.1.4 Probe Cooling Tubes .................................... 14

6.1.5 Handles ........................................... 14

6.1.6 Cooling Vents ........................................ 15

6.2 Equilibration Block Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2.1 Temperature Control and Cut-out Sensors ......................... 15

6.3 Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.3.1 Power Cable ......................................... 15

6.3.2 Fuse ............................................. 15

6.3.3 RS-232 Port (Optional) ................................... 15

7 General Operation ............................ 18

7.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.2 Operating the Temperature Controller . . . . . . . . . . . . . . . . . . . . . . 18

v

7.2.1 Over Temperature Cut-out ................................. 19

8 Digital Communications Interface (optional) .............20

8.1 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.2 Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

9 Test Probe Calibration .........................21

9.1 Calibration Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

9.1.1 Direct Calibration ...................................... 21

9.1.2 Comparison Calibration ................................... 21

9.1.3 Calibration of Multiple Probes ................................ 22

9.2 Furnace Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

9.2.1 Vertical Gradient ...................................... 22

9.2.2 Stabilization and Accuracy ................................. 22

10Maintenance ...............................23

11TroubleShooting ............................24

11.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

11.2 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figures and Tables

Table 1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 1 Top Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 2 Temperature Controller (enlarged view) . . . . . . . . . . . . . . . . . . . 14

Figure 3 Equilibration Block Assembly . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 4 Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 5 Serial Communications Wiring Diagram . . . . . . . . . . . . . . . . . . . 20

Figure 6 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

vi

1 Introduction

Introduction

The model 9113 Portable Calibration Furnace was

designed specifically for calibrating PRT’s, fiber optic

sensorsandthermocouples atthe highertemperature

ranges up to 1100°C. The furnace utilizes an equilibration block capable of making comparison measurements.Temperaturestabilityisbetterthan ±0.75°C

throughout the range and the gradient between wells

at full insertion is less than 1.0°C (±0.25°C).

The temperature control system utilizes a digital controller with a type K thermocouple control sensor.An

RS-232 interface is optional. The controller displays

thesettemperature andtheactualtemperaturesimultaneously.Thedisplaysshow temperature to the nearest degree in °C or °F (normally shipped in °C, may

be changed to °F). The temperature is set with convenient up and down buttons on the front panel.

The furnace is protected from excessivetemperature

with an over-temperature cut-out.The cut-out is relay

operated and independent from the temperaturecontroller to protect against the possibility of thermal

runaway due to a shorted solid state relay which

controls the heater.

9113 Portable Furnace Manual Rev. 721801 7

Specifications and Environmental Conditions

2 Specifications and Environmental

Conditions

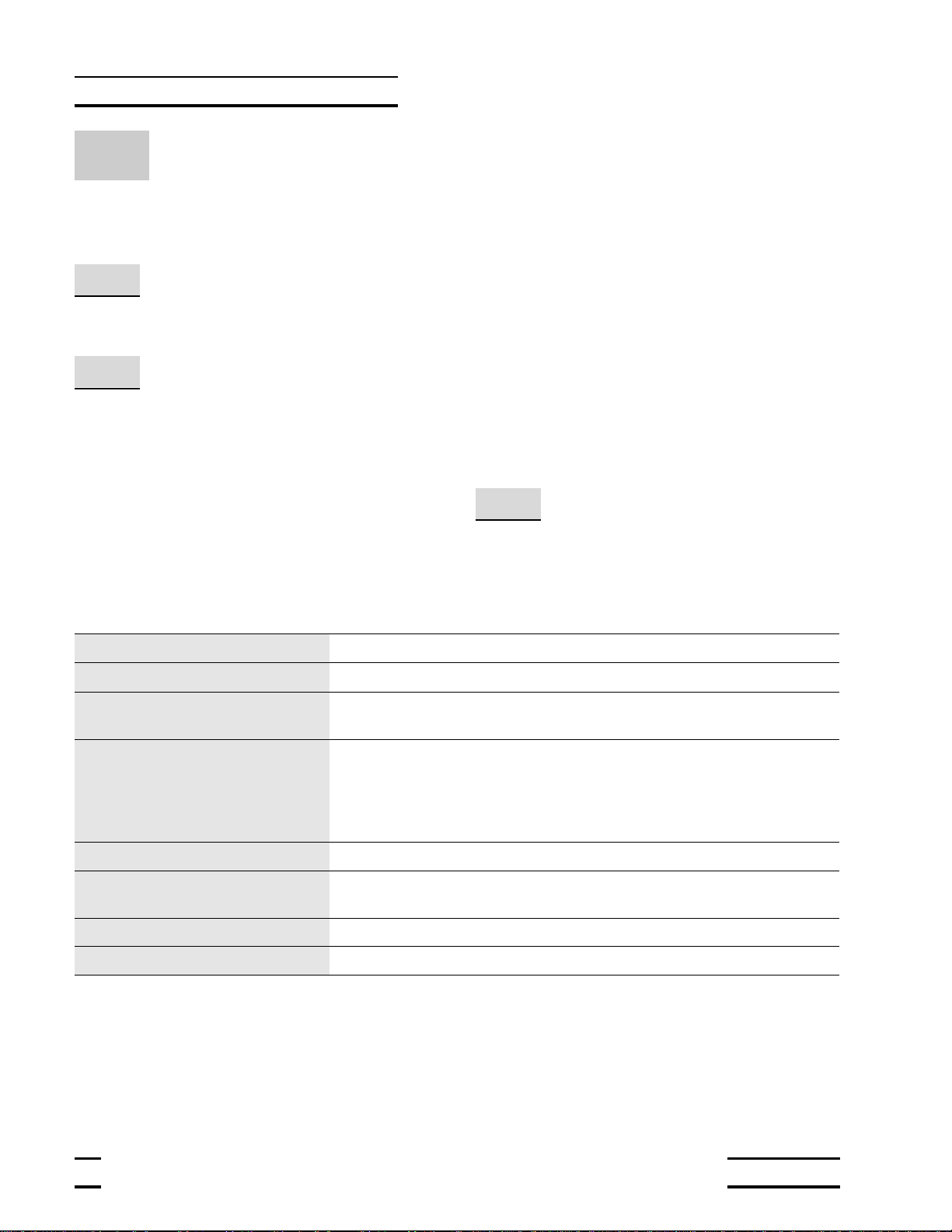

2.1 Specifications

See Table 1.

2.2 Environmental Conditions

Although the instrument has been designed for optimum durability and trouble-free operation, it must be

handled with care. The instrument should not be

operatedinan excessivelydustyor dirtyenvironment.

Maintenance and cleaning recommendations can be

found in the Maintenance Section of this manual.

The instrument operates safely under the following

conditions:

Table 1

Operating Range: 200°C to 1100°C

Stability:

TestWell: 1.3" Dia.X 10.5" Deep.Availableinserts size the well for best thermal

Specifications

±0.75°C

contact with the probe.

• temperature range: 5–50°C (41–122°F)

• ambient relative humidity:15–50%

• pressure: 75kPa–106kPa

• mains voltage within ±10% of nominal

• vibrations in the calibration environment

should be minimized

• altitude does not effect the performance or

safety of the unit

2.3 Warranty

The 9113 calibration furnace is covered by a 1 year

warranty that takes effect 10 days after the product is

Inserts: Special high temperature alloy.Standard inserts include a reference

and a test hole.One insert is included with the 9113 with 1 hole for

0.25" dia.probes and one for 0.28" dia. standard. Additional custom

drilled inserts are available with holes sizes starting at 3/16" (probe

size fit).Insert block dimension is 1.25" dia. X 6" long.

Interface: Optional, RS-232 serial interface for computer controlled operation

Cooling: Built in fan keeps enclosure cool and assists cool down after high

temperatue use

Size: 17.5 H X 13" W X 7" D

Weight: 22 lb.

8 Manual Rev. 721801 Hart Scientific

Loading...

Loading...