Hart and Cooley TLC Installation Instructions Manual

Model TLC

PLEASE READ AND UNDERSTAND THE REQUIREMENTS BEFORE PROCEEDING

Installation Instructions

All-Fuel Chimney - 5” to 8”

Factory-Built Type HT Insulated Chimney - Tested to UL103

Type of Appliances

Your Model TLC chimney is intended for venting gas,

liquid, or solid fuel-fired, residential-type appliances and

building heating appliances or as defined in NFPA 211, in

which the maximum continuous flue gas temperatures do

not exceed 1000°F. It has been tested and approved to

withstand temperatures of up to 2100°F for three

10-minute intervals.

Pre-Installation Guidelines

If you choose to have your product installed by

others, we recommend these products be installed by

professionals who are certified by NFI (National Fireplace

Institute) or equivalent.

Your Model TLC chimney and connecting stovepipe

diameter should be sized in accordance with the

appliance manufacturer’s recommendations.

Plan the installation of your appliance and chimney in

such a way that both your chimney and your stovepipe

run as short and straight as possible. By having too long

and/or multiple-bend installations, you can reduce system

draft that can affect the operation and/or performance

of your appliance and/or chimney system. The chimney

should be located within the building in order to avoid

cutting or altering load-bearing members, such as joists,

rafters, studs, etc. If you have to cut or alter an existing

load-bearing member, special reframing methods are

required, which often include doubling of adjacent

members. If such a case arises, contact your local

Building Code Official regarding local regulations and

proper installation methods.

Sections of the Model TLC chimney that pass through

accessible areas of the building, such as through closets,

storage areas, occupied spaces, or any place where the

surface of the chimney could be contacted by persons

or combustible materials, must be enclosed in a chase

to avoid personal contact and damage to the chimney.

The chase may be fabricated using standard building

materials. Drywall mounted on 2” x 4” studs is typically

used in this situation. The space between the outer wall

of the chimney and the enclosure must be at least a

minimum of 2 inches.

MAINTAIN A 2-INCH MINIMUM AIRSPACE

CLEARANCE BETWEEN INSULATED CHIMNEY

SECTIONS AND COMBUSTIBLE MATERIALS.

WARNING: A MAJOR CAUSE OF CHIMNEY-RELATED

FIRES IS FAILURE TO MAINTAIN REQUIRED

CLEARANCES (AIRSPACES) TO COMBUSTIBLE

MATERIALS. IT IS OF UTMOST IMPORTANCE

THAT THIS CHIMNEY BE INSTALLED ONLY IN

ACCORDANCE WITH THESE INSTRUCTIONS.

Please read all instructions before beginning your installation.

Failure to install this system in accordance with these instructions will

void the conditions of certification and the manufacturer’s warranty.

Keep these instructions in a safe place for future reference.

Hart & Cooley, Inc.

1

Model TLC All-Fuel Chimney - 5” to 8” Installation Instructions

WARNING: DO NOT PLACE ANY INSULATING MATERIALS

OR RUN ANY ELECTRICAL WIRING WITHIN

THE REQUIRED AIR CLEARANCE SPACE

SURROUNDING THE CHIMNEY.

Before beginning the installation, ensure that you obtain

any necessary building permits, and that your installation

will conform with all federal and municipal building code

requirements.

CONTACT LOCAL BUILDING OR FIRE

OFFICIALS ABOUT RESTRICTIONS AND

INSTALLATION INSPECTION IN YOUR AREA.

The National Fire Protection Association Standard 211

states: Factory-built chimneys that pass through floors of

buildings requiring the protection of vertical opening shall

be enclosed with approved walls having a fire-resistance

rating of not less than one hour where such chimneys are

located in a building less than four stories in height, and

not less than two hours where such chimneys are located

in a building four or more stories in height.

WEAR SAFETY GLOVES WHEN HANDLING

SHEET METAL PARTS WITH SHARP EDGES.

The chimney must extend not less than 3 feet above

the highest point where it passes through the roof of a

building and not less than 2 feet above any portion of the

building within 10 feet (Figure 1). See Chart 2 - Chimney

Height Above the Roof on page 17 of these instructions.

The use of Locking Bands at all chimney joints is

required for added safety, stability when exposed to high

winds, and as a precaution against accidental unlocking

of lengths when the system is inspected and swept.

The ideal location for your chimney system is within the

building envelope. In cold climates, the use of external

chimneys may result in operational problems, such

as poor draft, excessive condensation of combustion

products, and rapid accumulation of creosote. Under

these circumstances, the installation of the chimney within

the building is strongly recommended.

If the chimney must be installed on an exterior wall, it

is recommended that the chimney be enclosed below

the roof line to protect the chimney from cold outdoor

temperatures; this may help reduce condensation,

creosote formation, and enhance draft. Provide an

access door by the tee cap for chimney inspection and

cleaning. The exterior enclosure may be insulated,

maintaining the required minimum airspace clearance

of 2 inches to any part of the chimney. Consult local

building codes for cold-climate application.

Do not install the chimney directly at the outlet of the

appliance. Interconnecting stovepipe is required, unless

the appliance is specifically approved for that type of

installation.

Use only with an appliance listed by a recognized testing

authority, such as Underwriters Laboratories, Inc. or

Intertek Testing Services.

2

The flue diameter of gas or oil-fired appliance should

comply with the appropriate NFPA or ANSI Installation

Codes, NFPA 54, ANSIZ223.1, and NFPA31.

YOUR CHIMNEY HAS BEEN TESTED AND LISTED,

USING ALL OF THE SUPPORTS, SHIELDS, ETC.,

DESCRIBED HEREIN. DELETION OR MODIFI-

CATION OF ANY OF THE REQUIRED PARTS OR

MATERIALS MAY SERIOUSLY IMPAIR THE SAFETY

OF YOUR INSTALLATION AND VOID THE CERTIFI-

CATION AND/OR WARRANTY OF THIS CHIMNEY.

Hart & Cooley, Inc.

Installation Instructions Model TLC All-Fuel Chimney

Installation Instructions Model TLC All-Fuel Chimney

Tools

Your Model TLC chimney system is designed for

installation using standard building materials and

procedures. The following tools/equipment may be

required, as well as some others, depending on the

location and structure in which the chimney is to be

installed.

•

Safety Gloves

•

Screwdriver and Pliers

•

Safety Goggles

•

Plumb Line and Level

•

Hammer and Nails

•

Square

•

Tin Snips

•

Keyhole Saw or Power Jigsaw

•

Tape Measure

•

Caulking Gun

Framing Details

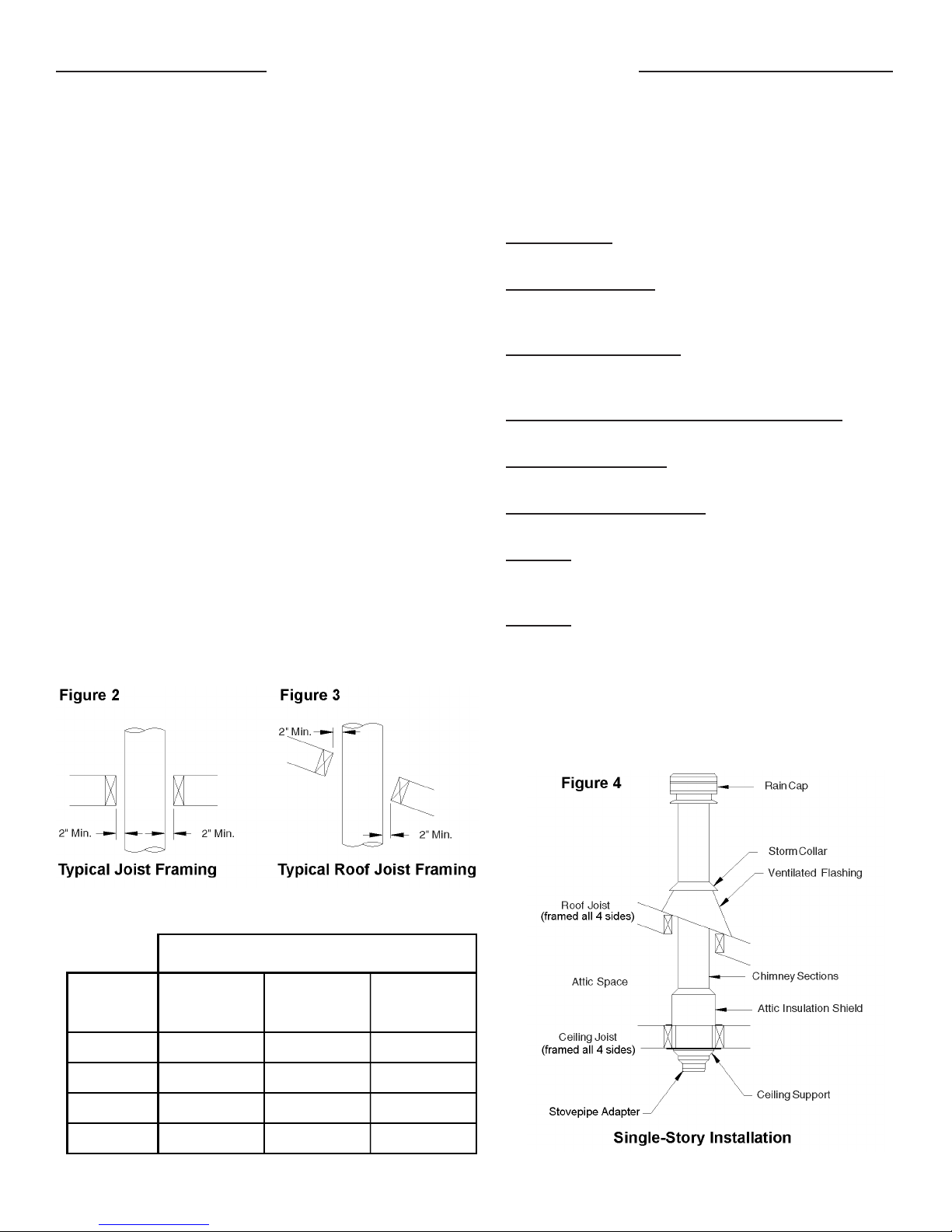

Plan your installation carefully. If possible, position the

stove so that the flue outlet is between joists or rafters.

Drop a plumb line to the center of the flue outlet, and mark

this center point on the ceiling. Lay out and frame in all

openings, ensuring the specified 2-inch clearance to

combustibles is maintained. Refer to Table 1 for framing

dimensions, and mark the appropriate cutting lines around

the center point. All openings should be square (all four

sides), plumb, and in perfect alignment with each other

(Figure 2).

For sloping roofs, ensure that the framing dimension is

measured in the horizontal plane (Figure 3).

Installation Procedures

Ceiling Support Installation

To complete a proper ceiling support installation, the

following parts will or may be required.

• Ceiling Support: Required when supporting a chimney

through a flat level ceiling. Also acts as a firestop.

• Attic Insulation Shield: Required where a chimney

passes from a lower living space into an unoccupied

attic space.

• Firestop Radiation Shield: Required where a chimney

passes from a lower living space into an upper living

space or occupied attic space.

• Roof Flashing Assembly (including Storm Collar):

Required when the chimney penetrates a roof.

• Rafter Radiation Shield: Required when the chimney is

enclosed immediately below the roof.

• Suitable Lengths of Chimney: The chimney diameter

(ID) should be sized to suit the appliance.

• Elbow Kit: To avoid cutting of joists and clear other

obstructions. Kit includes 2 elbows, 1 offset support,

and 4 locking bands.

• Rain Cap: Deluxe model.

The Model TLC ceiling support will support up to 50 feet

of chimney sections, all of which must be installed above

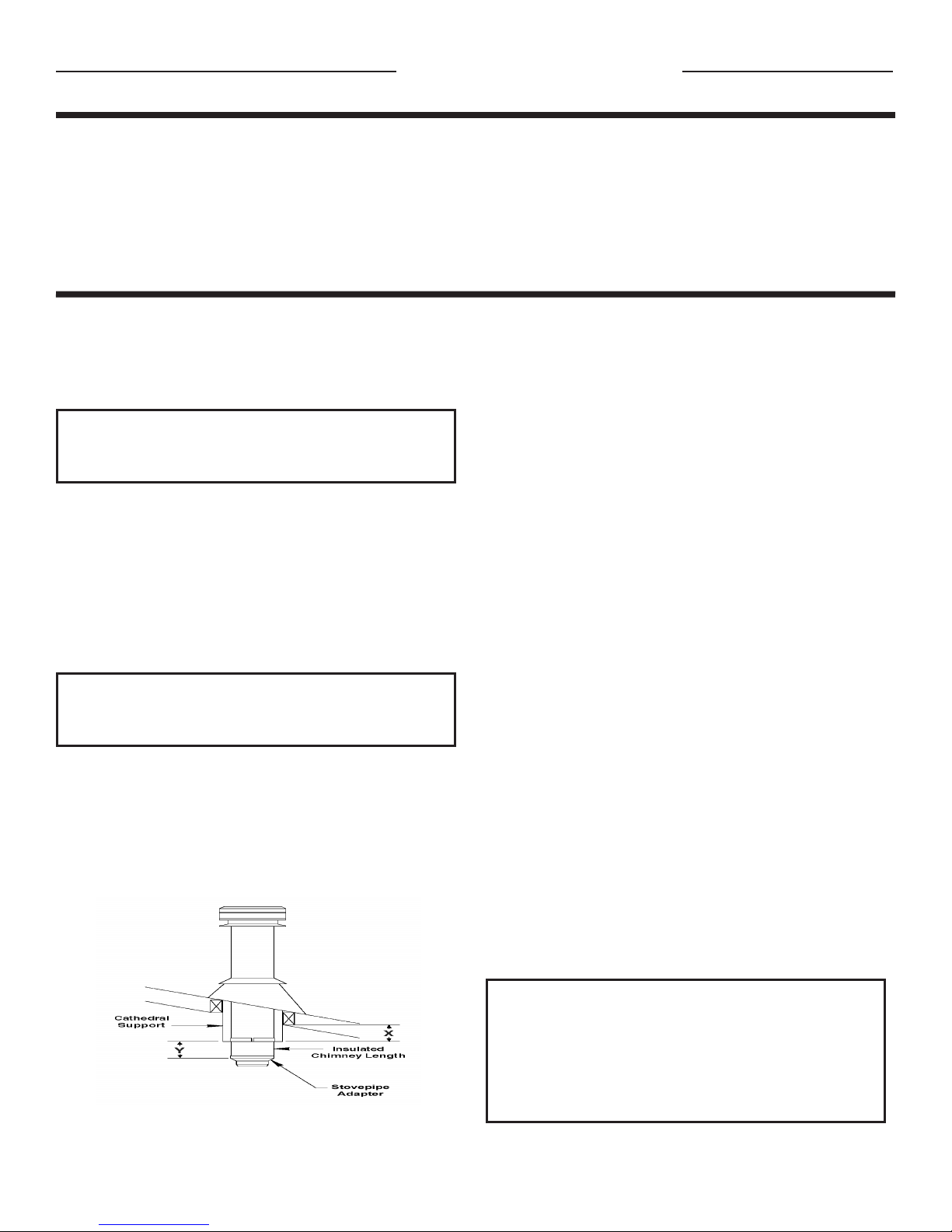

the support. Figures 4 and 6 show the two most common

types of ceiling support installation. Frame (all four sides)

a level square opening to the dimensions specified in the

Framing Dimensions (Table 1).

Table 1

Chimney

Diameter

Support*

Wall

Thimble*

All

Framing

Tools

Your Model TLC chimney system is designed for

installation using standard building materials and

procedures. The following tools/equipment may be

required, as well as some others, depending on the

location and structure in which the chimney is to be

installed.

• Safety Gloves

• Safety Goggles

• Hammer and Nails • Square

• Tin Snips

• Tape Measure

Framing Details

•

Screwdriver and Pliers

•

Plumb Line and Level

•

Keyhole Saw or Power Jigsaw

•

Caulking Gun

Plan your installation carefully. If possible, position the

stove so that the flue outlet is between joists or rafters.

Drop a plumb line to the center of the flue outlet, and

mark this center point on the ceiling. Lay out and frame

in all openings, ensuring the specified 2-inch clearance to

combustibles is maintained. Refer to Table 1 for framing

dimensions, and mark the appropriate cutting lines around

the center point. All openings should be square (all four

sides), plumb, and in perfect alignment with each other

(Figure 2).

For sloping roofs, ensure that the framing dimension is

measured in the horizontal plane (Figure 3).

Installation Procedures

Ceiling Support Installation

To complete a proper ceiling support installation, the

following parts will or may be required.

• Ceiling Support: Required when supporting a chimney

through a flat level ceiling. Also acts as a firestop.

• Attic Insulation Shield: Required where a chimney

passes from a lower living space into an unoccupied

attic space.

• Firestop Radiation Shield: Required where a chimney

passes from a lower living space into an upper living

space or occupied attic space.

• Roof Flashing Assembly (including Storm Collar):

Required when the chimney penetrates a roof.

• Rafter Radiation Shield: Required when the chimney is

enclosed immediately below the roof.

• Suitable Lengths of Chimney: The chimney diameter

(ID) should be sized to suit the appliance.

• Elbow Kit: To avoid cutting of joists and clear other

obstructions. Kit includes 2 elbows, 1 offset support,

and 4 locking bands.

• Rain Cap: Deluxe model.

The Model TLC ceiling support will support up to 50 feet

of chimney sections, all of which must be installed above

the support. Figures 4 and 6 show the two most common

types of ceiling support installation. Frame (all four sides)

a level square opening to the dimensions specified in the

Framing Dimensions (Table 1).

Framing Dimensions (in inches)

Flue

5" 123/8 x 123/

6" 123/8 x 123/

7" 133/8 x 133/

8" 143/8 x 143/

* When cutting the inside "finished" surface of your wall or

ceiling, cut a "round hole" to the framing dimension.

Ceiling

(Support)

14 x 14 11 x 11

8

14 x 14 12 x 12

8

14 x 14 13 x 13

8

14 x 14 14 x 14

8

Othe r

3

Model TLC All-Fuel Chimney - 5” to 8” Installation Instructions

Table 2

Framing Dimensions

for Attic Insulation Shield

Chimney Flue

Diameter

Slide the trim ring onto the ceiling support, and slide the

assembly into the framed opening from below. Ensure

that the finishing ring is flush with the underside of the

ceiling and the assembly is level and plumb. Secure

the ceiling support in place, using at least three 8-penny

(2½”) nails through each of the four straps or through

the twelve prepunched holes in the support. You may

substitute, in lieu of nails, twelve #8 x 2” wood screws.

Stovepipe Adapter Installation

The stovepipe adapter is installed by twisting-locking it

to the bottom end of the chimney section that enters the

ceiling support. Lower the assembly down into the ceiling

support so that the stovepipe adapter sleeve is protruding

through the support and into the living space.

Attic Insulation Shield Installation

An attic insulation shield must be installed where

the chimney enters an attic space. (It also acts as a

firestop when properly framed.) An attic insulation

shield should keep insulation from coming into contact

with the chimney and will allow a depth of insulation of

10 inches plus the depth of the ceiling joist. Where height

restrictions will not permit the use of the attic insulation

shield, an enclosure from the attic joist to the roof joist will

be sufficient. All chimney enclosures must maintain the

required minimum airspace clearance of 2 inches to the

chimney. When enclosing the chimney below the roof

line, a rafter radiation shield at the roof level and a firestop

radiation shield at the ceiling level must be installed.

inches

The crimped end (stub) of the stovepipe adapter is

intended to fit inside the flue pipe from a solid-fuel

appliance, thus preventing condensate drips at the

chimney connection. Install interconnecting flue pipe

by following the appliance manufacturer’s installation

instructions and appropriate building code requirements,

keeping in mind that the flue pipe run should be as short

and straight as practical. Generally, for a wood-burning

appliance installation, an 18-inch minimum clearance to

combustibles must be maintained for a single-wall flue

pipe.

5" 11 x 11

6" 12 x 12

7" 13 x 13

8" 14 x 14

Install additional chimney sections and lock together by

turning clockwise until the two sections lock together

tightly. Install required locking bands. Continue adding

chimney lengths until a height of about 2 feet below the

next ceiling level is achieved.

4

Hart & Cooley, Inc.

Installation Instructions Model TLC All-Fuel Chimney

For proper installation, the attic opening must be fully

framed at 2 inches of clearance to the chimney pipe

with framing material of the same dimension as the

ceiling joists, per Table 2 (Framing Dimensions for

Attic Insulation Shield). The tabs on the plate of the

attic insulation shield are inserted in the framed opening

around the chimney. Nail the attic insulation shield base

to the framing dimensions with at least two per side, using

2d 1” spiral nails or 1” x #8 wood screws.

When an attic insulation shield is required above the

ceiling support into an attic as shown in Figure 4, ensure

that the base of the shield is flush with the top of the joist

framing, and nail in place. The telescoping portion of

the attic insulation shield will eliminate the need to trim

the bottom, when installed immediately above the ceiling

support. When fully extended, the attic insulation shield

will provide joist shielding when installed in a two-story

main floor application (Figure 6).

If insulation is blown in and adheres to the chimney pipe,

it must be brushed off to eliminate any possible contact of

this material with the chimney surface.

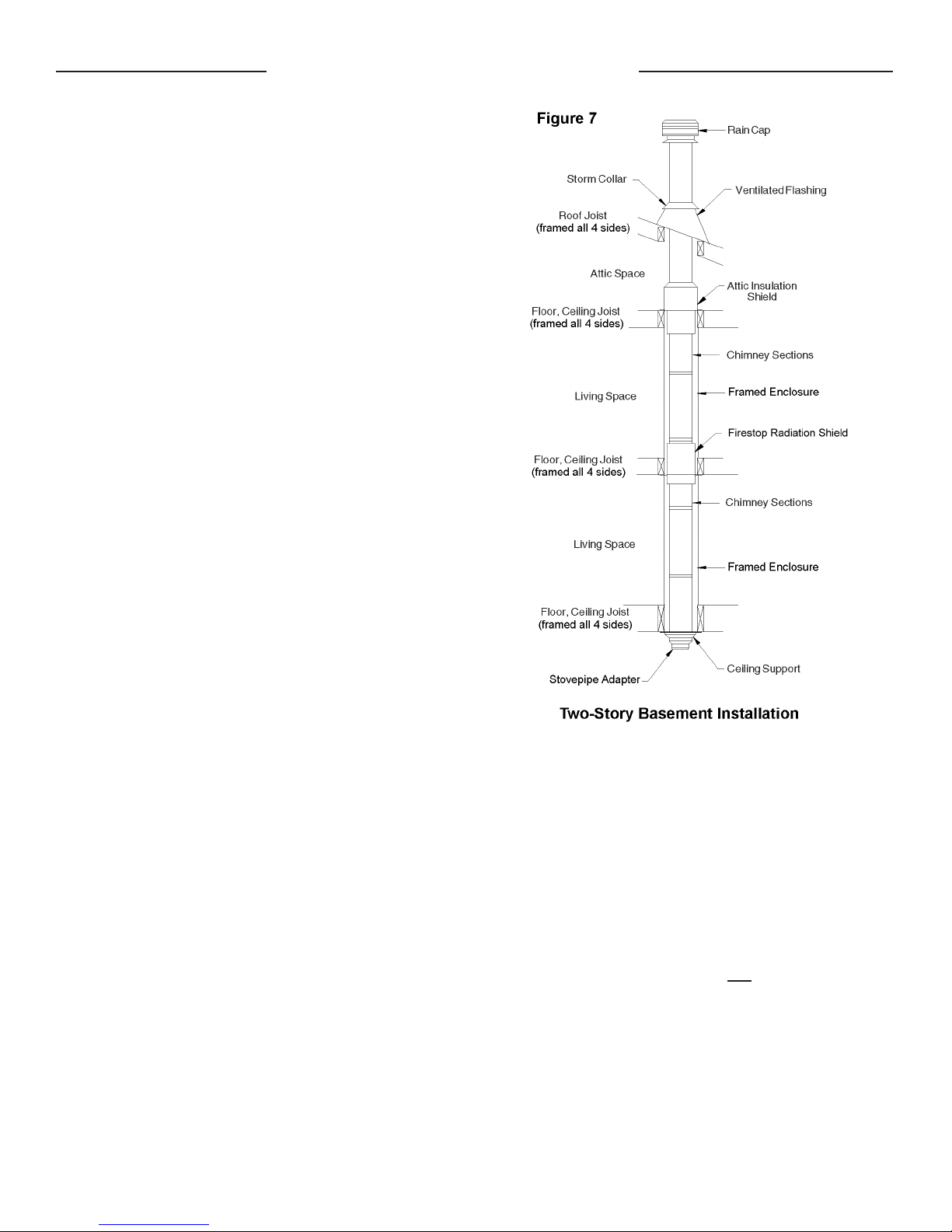

Firestop Radiation Shield Installation

A firestop radiation shield must be installed where the

chimney passes from one living space to another living

space, as shown in Figure 7. It is designed to provide

proper firestopping between floors and to keep direct

radiation from the chimney away from the joist framing.

Install the firestop radiation shield from below the joist

framing, and nail in place using 1” spiral nails. Ensure no

insulation is within the 2-inch airspace clearance around

the chimney. This includes the airspaces between the

firestop radiation shield and the joist framing.

When the chimney is enclosed in the attic area, a firestop

radiation shield must be installed at the ceiling level. If

the base of the firestop radiation shield does not fit flush

with the ceiling frame, measure the distance that the base

is sitting below the framing, and trim that amount off the

top of the firestop radiation shield before securing into

place.

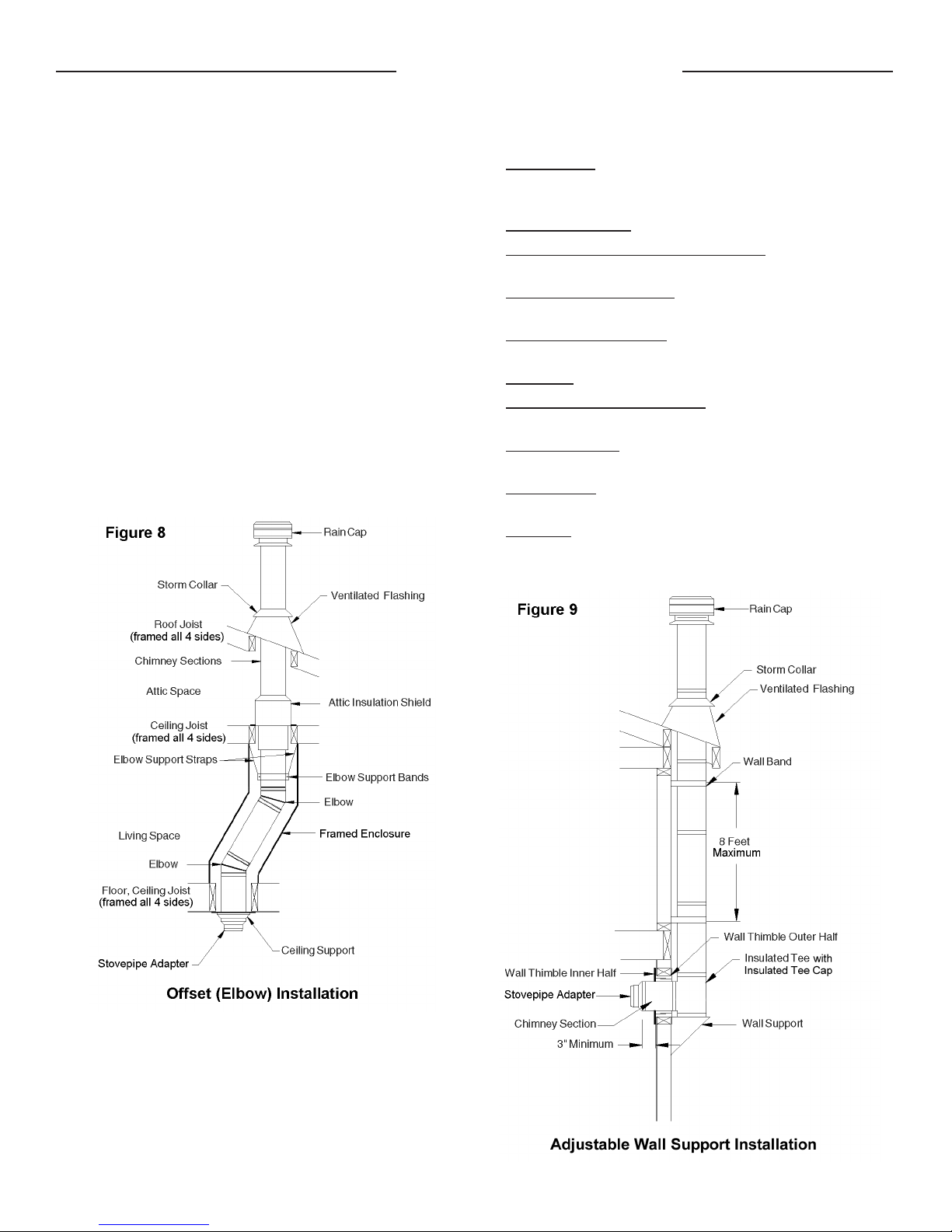

Elbow Installation

Two elbows may be used in an interior installation to

provide an offset, in order to avoid cutting of joists and

to clear other obstructions. Each elbow support will

support 15 feet of chimney, and the maximum length of

chimney allowed between elbows is 6 feet. Forty-five-

degree (45°) elbows may be used only with oil or gas

appliances. See Chart 1 - Offset Chimney Installation

on page 16 of these instructions for details.

The female end of the elbows are not embossed; this

ensures that proper alignment of the chimney system

is maintained. Locking bands must be installed at all

chimney joints, forming an offset.

Hart & Cooley, Inc.

Install the insulated offset elbow on the vertical chimney

length, and position the elbow in the required direction.

Fasten the elbow to the chimney length with the supplied

locking band.

5

Model TLC All-Fuel Chimney - 5” to 8” Installation Instructions

Place the required offset chimney length(s) as per the

Offset Chimney Installation chart for appropriate

length(s). Turn it clockwise to lock it in place and fasten

in place with the supplied locking band.

Install the remaining offset elbow to turn the chimney

back to the vertical position and fasten in place with the

supplied locking band.

During installation, provide supplementary support for the

offset section to avoid undue stress on connected elbows.

Install an elbow support just above the highest elbow.

Attach the support band to the chimney with four of the

nuts and bolts, and then install the four stainless steel

sheet metal screws through the prepunched holes. Attach

the support straps to the support band assembly, and

nail the support straps to the framing using 6d 2” nails or

#8 x 1½” wood screws. See Figure 8.

Never install an elbow in a joist area. Chimney sections

must pass vertically through framed joist areas.

To complete a proper wall support installation, the

following parts will or may be required.

•

Wall Support: Intended for a through-the-wall

installation where the chimney has a horizontal

connection.

•

Stovepipe Adapter: Transition from chimney to flue pipe.

•

Insulated Tee with Insulated Tee Cap: Allowing a

horizontal connection to the chimney.

•

Roof Flashing Assembly: Required when the chimney

penetrates a roof or a roof overhang.

•

Rafter Radiation Shield: Required when the chimney is

enclosed immediately below the roof.

•

Wall Band: Required to provide lateral support to chimney.

•

Suitable Lengths of Chimney: The chimney diameter

should be sized to suit the appliance.

•

Chimney Length: Appropriate length for connection to

tee branch.

•

Wall Thimble: Required to pass though a combustible

wall. It also acts as a firestop.

•

Rain Cap: Deluxe model.

Note: Never offset an exterior chimney.

Note: Never offset an exterior chimney.

Adjustable Wall Support Installation

As previously mentioned, the ideal location for your

chimney system is within the building envelope. A wall

support installation is required when the above-mentioned

location is not possible.

6

Hart & Cooley, Inc.

Installation Instructions Model TLC All-Fuel Chimney

Installation Instructions Model TLC All-Fuel Chimney

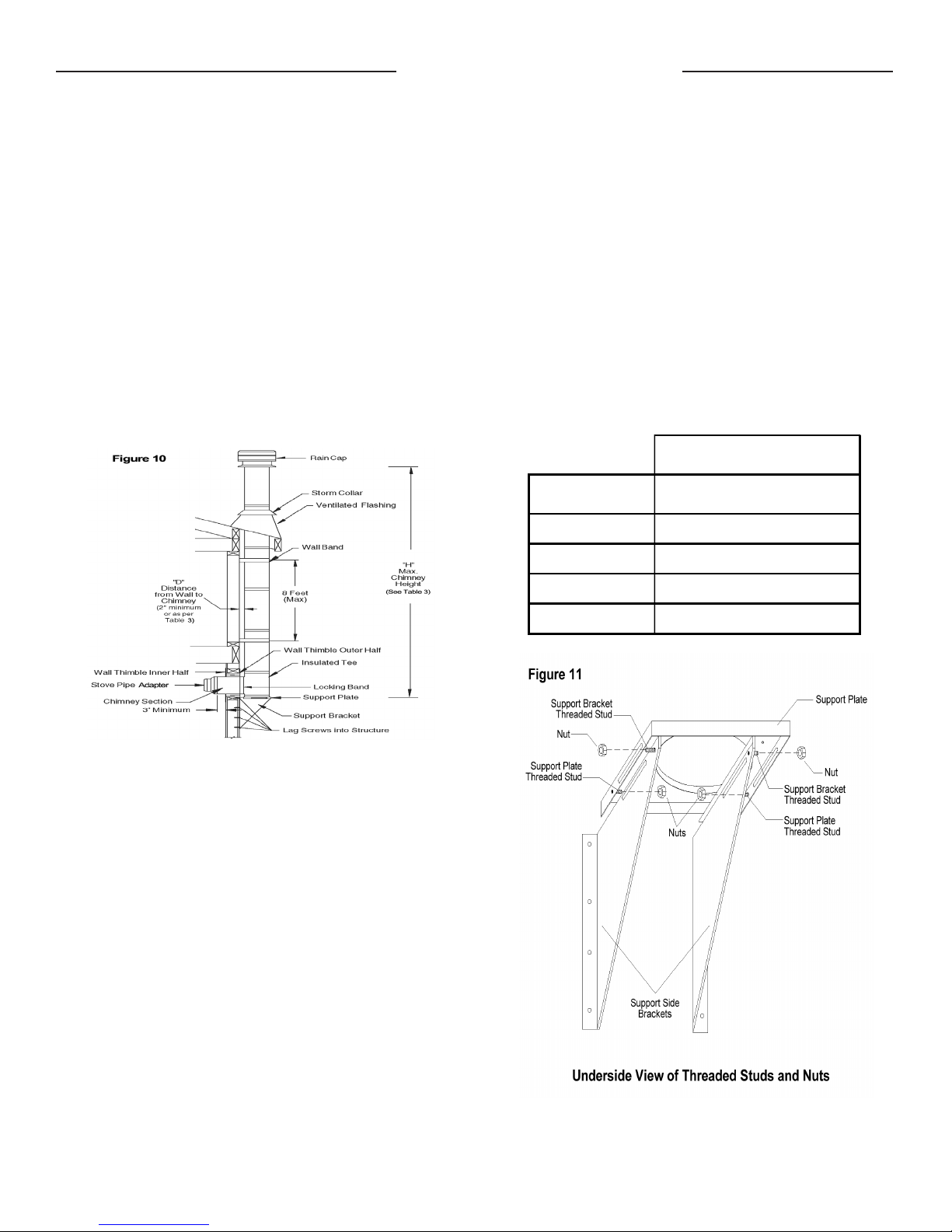

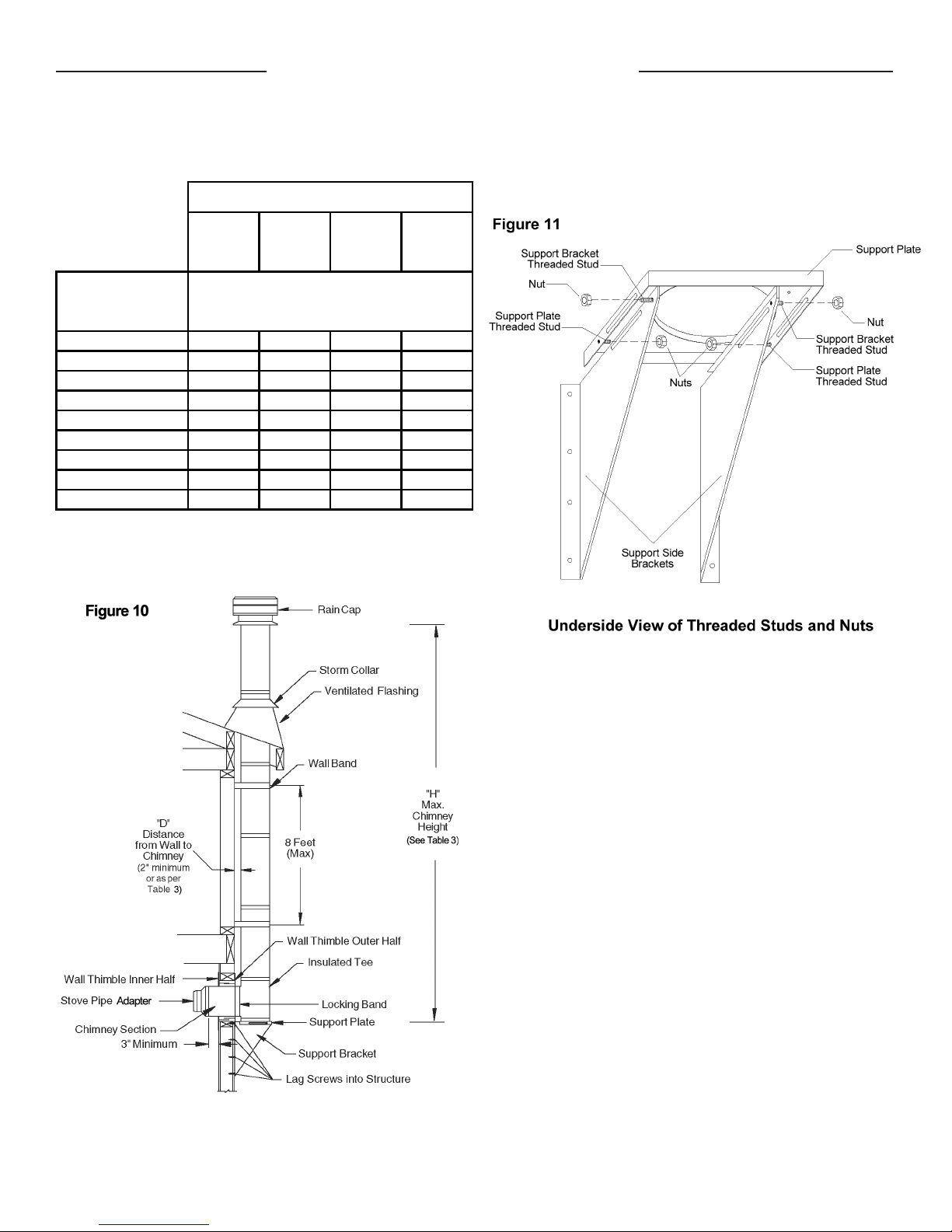

The maximum chimney height above a wall support is

indicated in Table 3 and illustrated in Figure 10, all of

which must be above the support.

The wall support will allow for an adjustment of 2" to 6"

from a vertical wall. Threaded studs are factory-installed

on both side brackets and the support plate for fast and

easy assembly. See Figure 11.

Table 3

D (inches)

Wall to Chimney

H (feet)

Height

The maximum chimney height above a wall support is

indicated in Table 3 and illustrated in Figure 10, all of

which must be above the support.

Wall Support Chimney Height Chart

5" ID

Chimney

Distance from

2 74 63 56 49

2.5 73 62 55 48

3 71 60 53 47

3.5 69 59 51 46

4 66 56 49 44

4.5 62 53 46 42

5 58 50 43 39

5.5 52 45 38 35

6 45 39 34 30

D - Distanc e from wall to the chimney

H - Height of chimney in feet

See Figure 10 also

6" ID

Chimney

Maximum

7" ID

Chimney

8" ID

Chimney

The wall support will allow for an adjustment of 2” to 6”

from a vertical wall. Threaded studs are factory-installed

on both side brackets and the support plate for fast and

easy assembly. See Figure 11.

Ensure that the wall support brackets are bolted securely

to the wall.

The following steps will assist you in the installation of

the wall thimble and of the wall support. Figure 10 shows

a typical wall support installation through a combustible

wall.

1. Determine the centerline of the horizontal connection

(chimney length through the wall), and frame an

opening to the dimensions for the wall thimble in a

combustible wall. See Table 4 Section A and Figure

12(A).

- Use a stud finder to roughly locate the wall studs.

Mark the outline of the hole and drill a pilot hole in

its center.

- Break out part of the wall covering within the

outline to confirm that the hole will be centered

between studs and that no electrical wires could

be cut by the saw.

2. For a noncombustible wall (concrete block or poured

foundation), cut a hole 3/16” greater in diameter than

the outside diameter of the chimney as per Table 4.

See Table 3 for maximum chimney heights based on

chimney diameter and distance from wall.

Hart & Cooley, Inc.

7

Model TLC All-Fuel Chimney - 5” to 8” Installation Instructions

Model TLC All-Fuel Chimney - 5" to 8" Installation Instructions

5" 6" 7" 8"

Wall Thimble

for Combustible Wall

Support Brackets

for Bracing

Table 4

Chimney SizeFraming Dimensions

Wall Thimble & Support Brackets

Section

A

B

Minimum Round Hole Diameter

for Noncombustible Wall

Minimum Framed Opening

Minimum Framed Opening

3

7

14" x 14" 14" x 14" 14" x 14" 14" x 14"

91/4"9

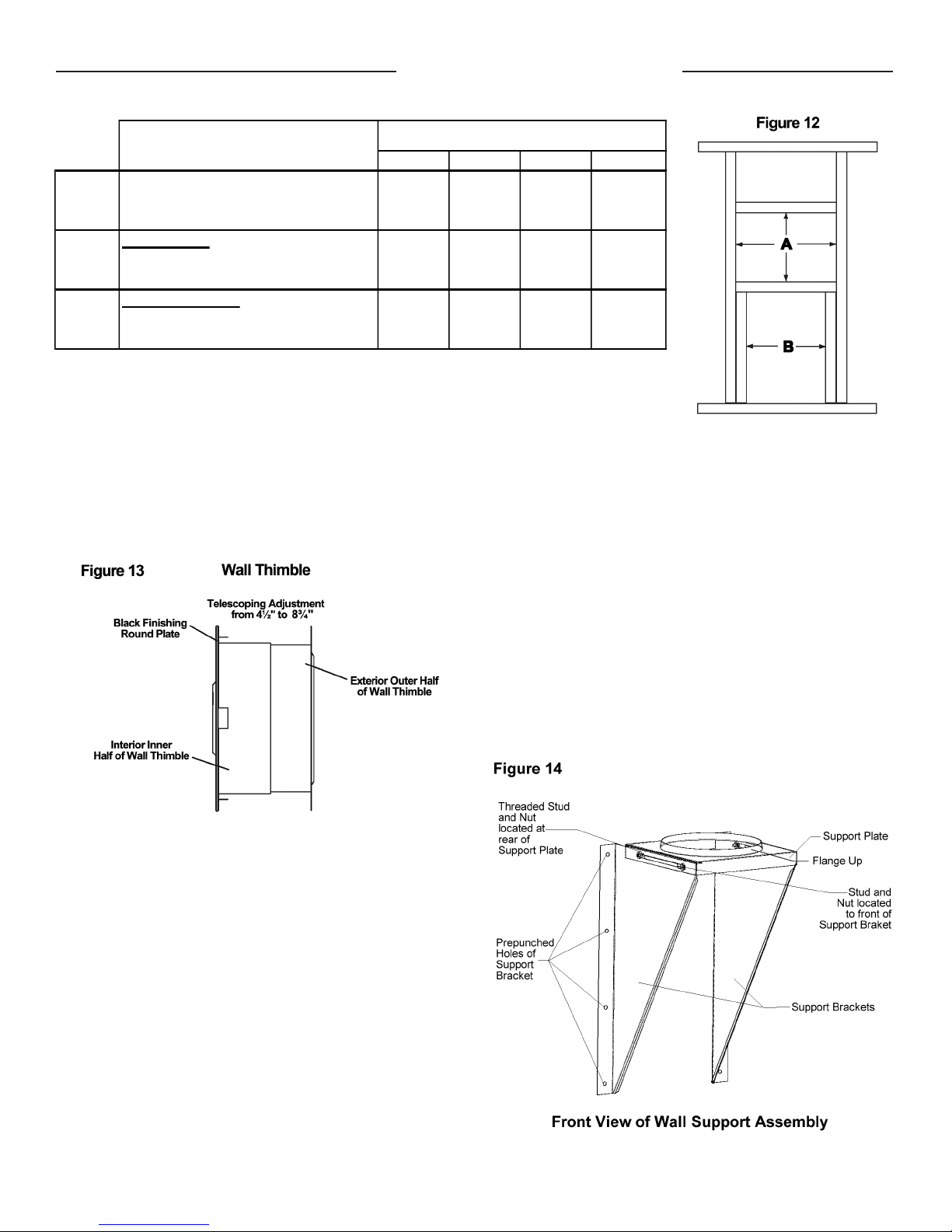

3. After framing in your opening to the dimensions

specified to the Framing Tables 1 or 3, install the

outer half (with the unfinished square plate) of the wall

thimble into the outside wall opening. Secure in place

using appropriate fasteners through the prepunched

holes.

/16"83/16"93/16" 103/16"

1

/4" 101/4" 111/4"

threaded studs into the oblong slots. See Figures

11 and 14. Install the supplied nuts on the threaded

studs until snug. Do not tighten at this time, as

adjustments may be required. Set aside and prepare

the support bracing to secure the side brackets as per

Framing Dimensions Table 4 Section B and Figure

12(B).

Two options are described hereafter for the installation of

the wall support and the insulated tee assembly. Follow

Method A if inserting an assembled insulated chimney

length and insulated tee into the wall thimble prior to

the wall support. Follow Method B if securing of the

wall support to the wall prior to the insulated tee and the

insulated chimney length.

4. Install the inner half (with round plate) of the wall

thimble into the inside wall opening, ensuring that the

shield slides over the shield of the outer half. Once

in place and flush against the wall, install the black

finishing trim plate onto the wall surface and fasten

in place with appropriate fasteners through the four

prepunched holes.

Note: To stop cold air infiltration into the dwelling,

you can install the optional universal shielding

insulation into the wall thimble. See separate

installation instructions packaged with the

universal shield insulation.

5. Assemble the two side brackets (point of triangle

facing down) to the support plate (flange up and

threaded stud toward the wall) by inserting the

8

Hart & Cooley, Inc.

Loading...

Loading...