Harsh RL-J100, RL-J100N Spare Parts & Maintenance Manual

HARSH Hookloader

Spare Parts & Maintenance Manual

Edition 2017

SPARE PARTS

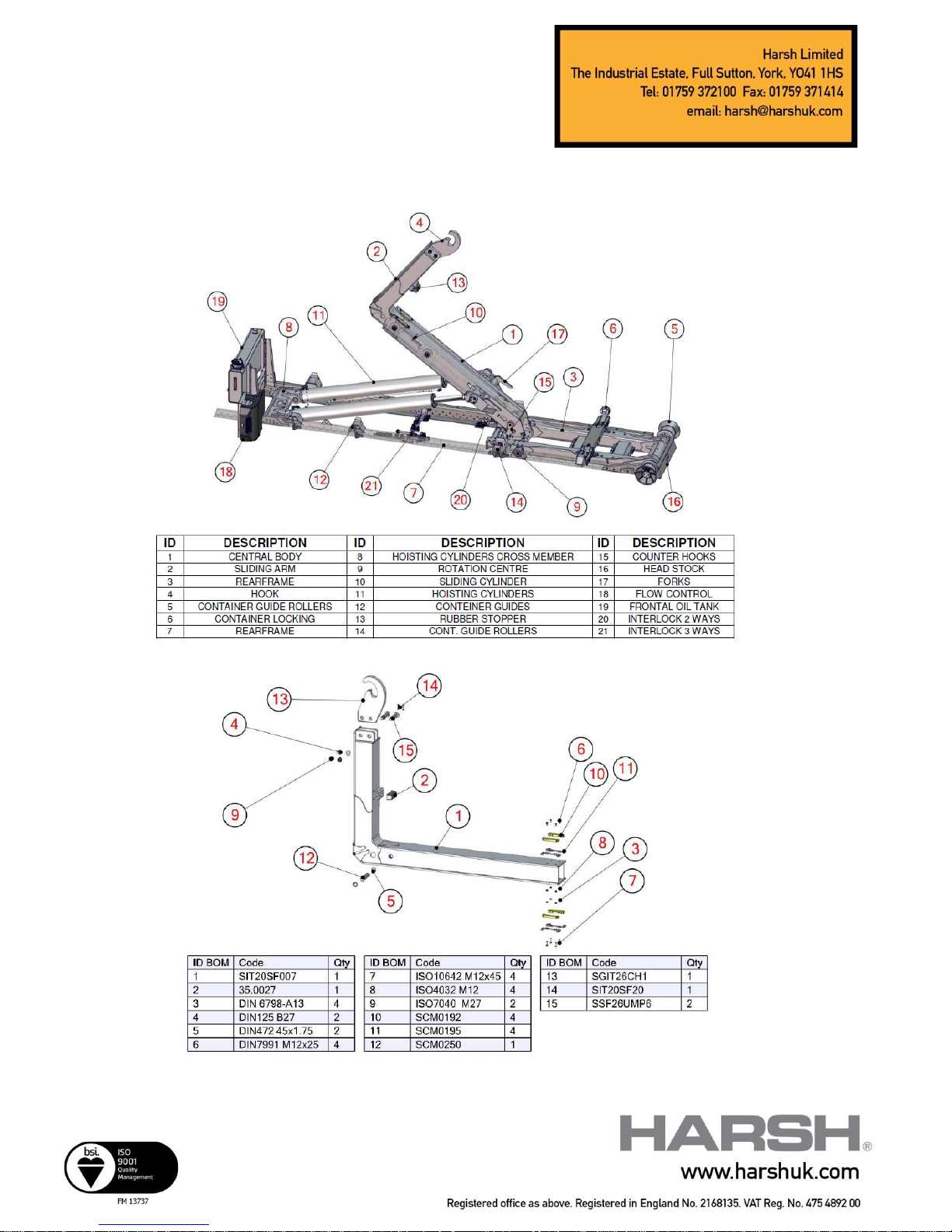

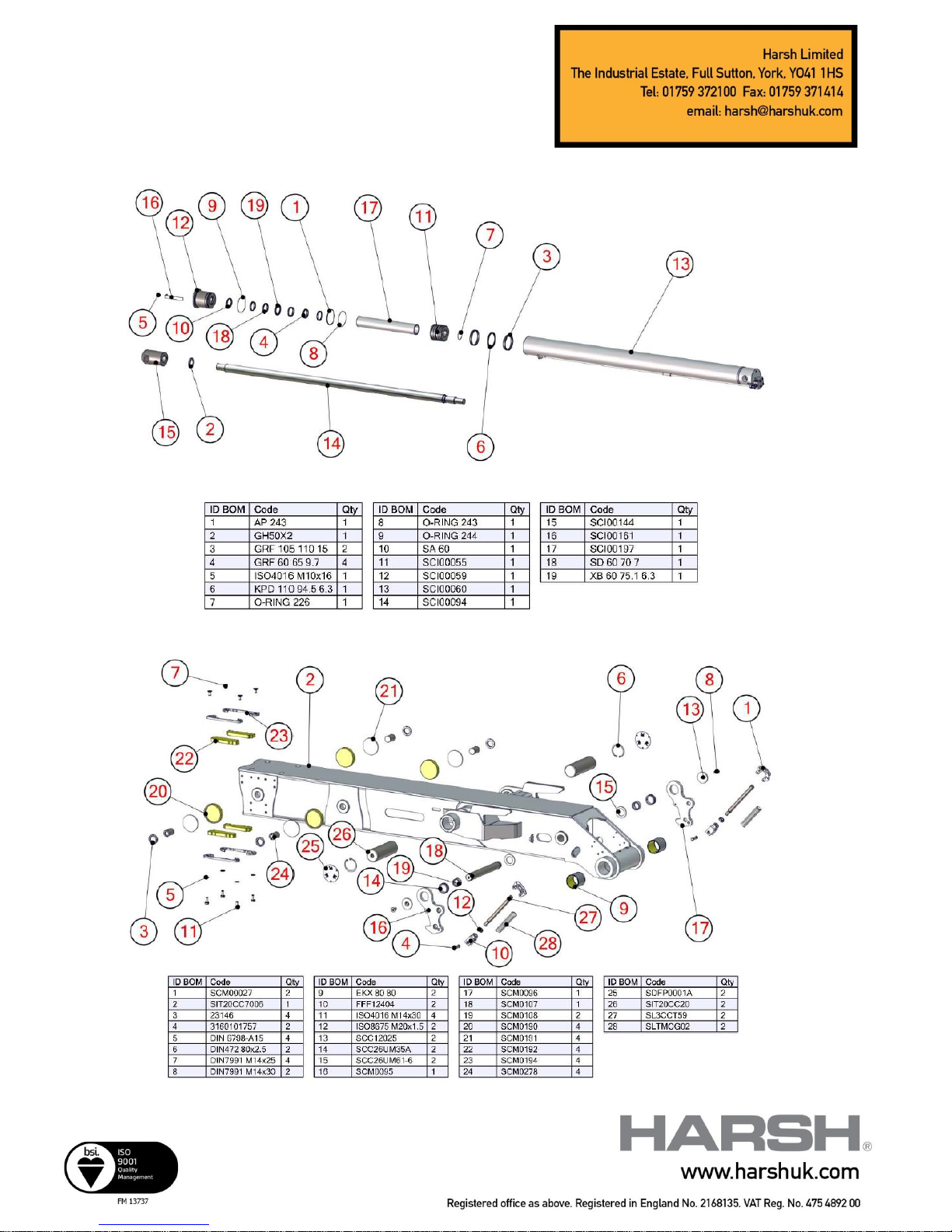

Spare Parts Identification

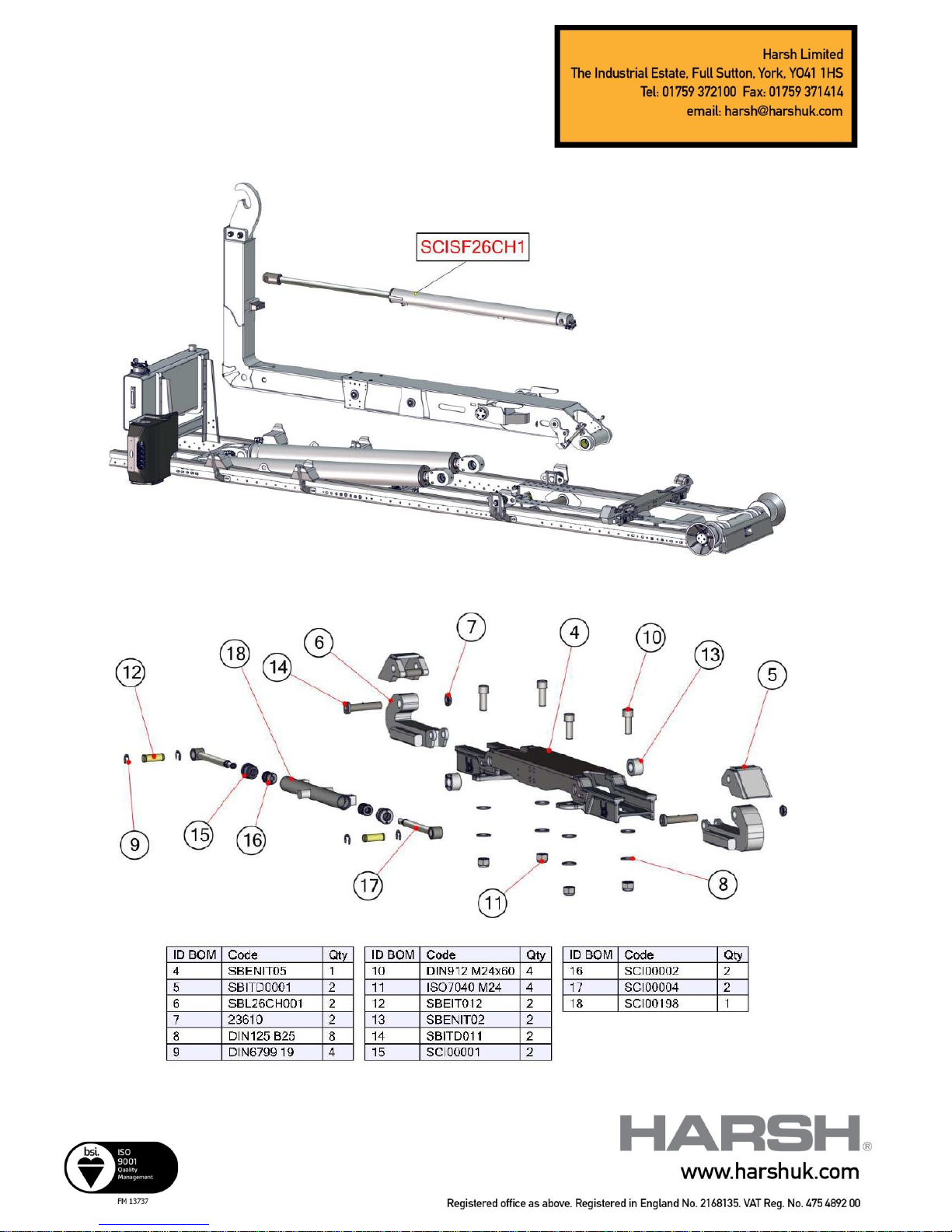

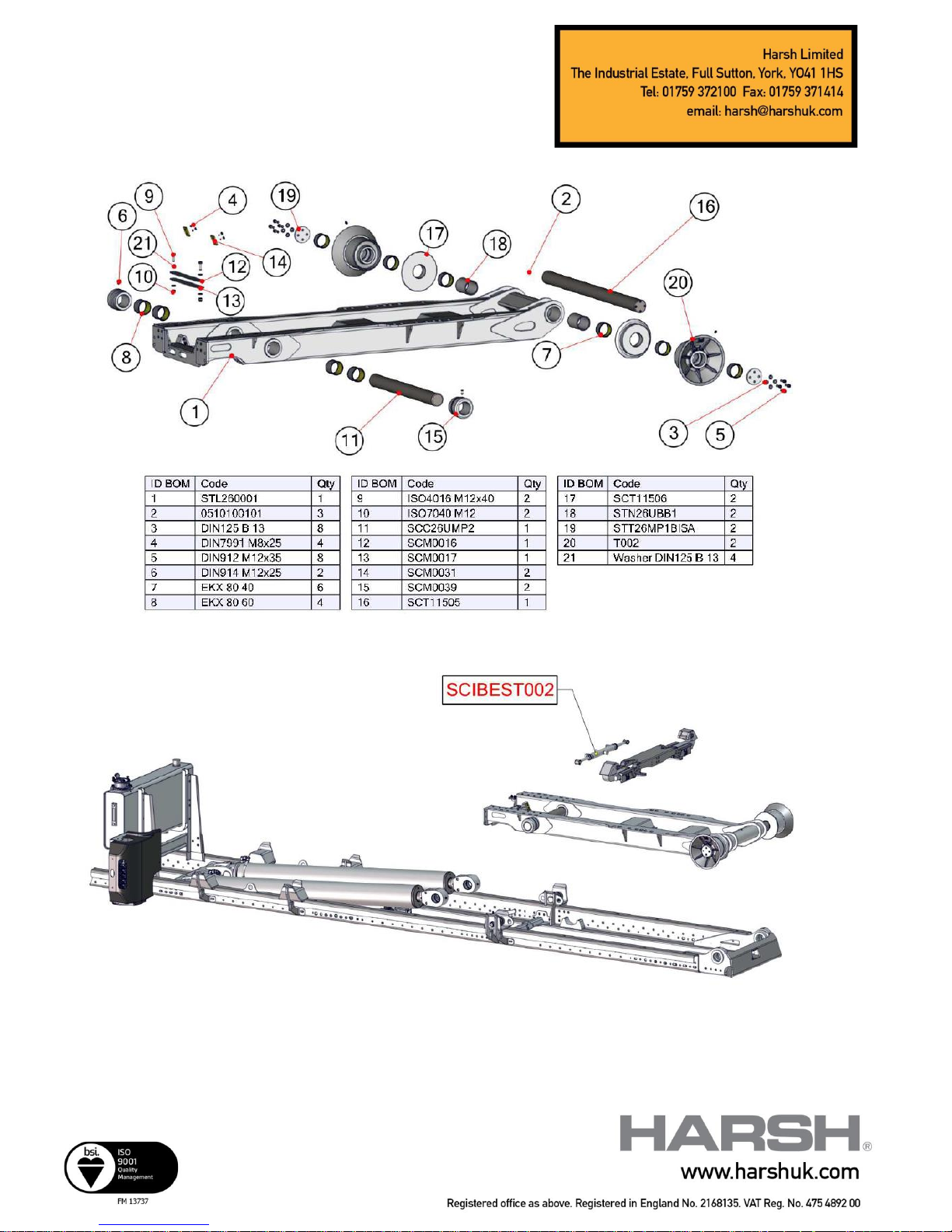

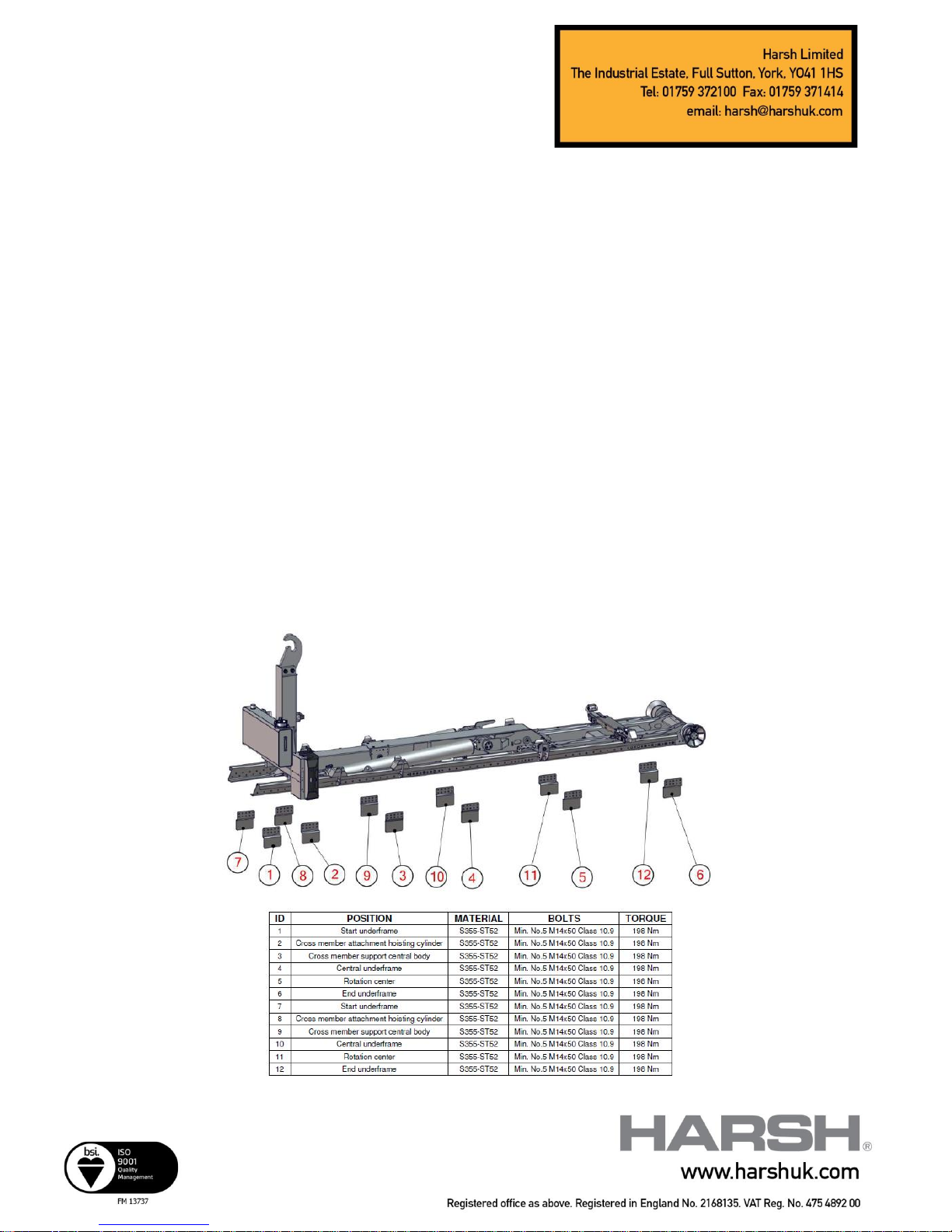

Parts denomination diagram for HH26 model

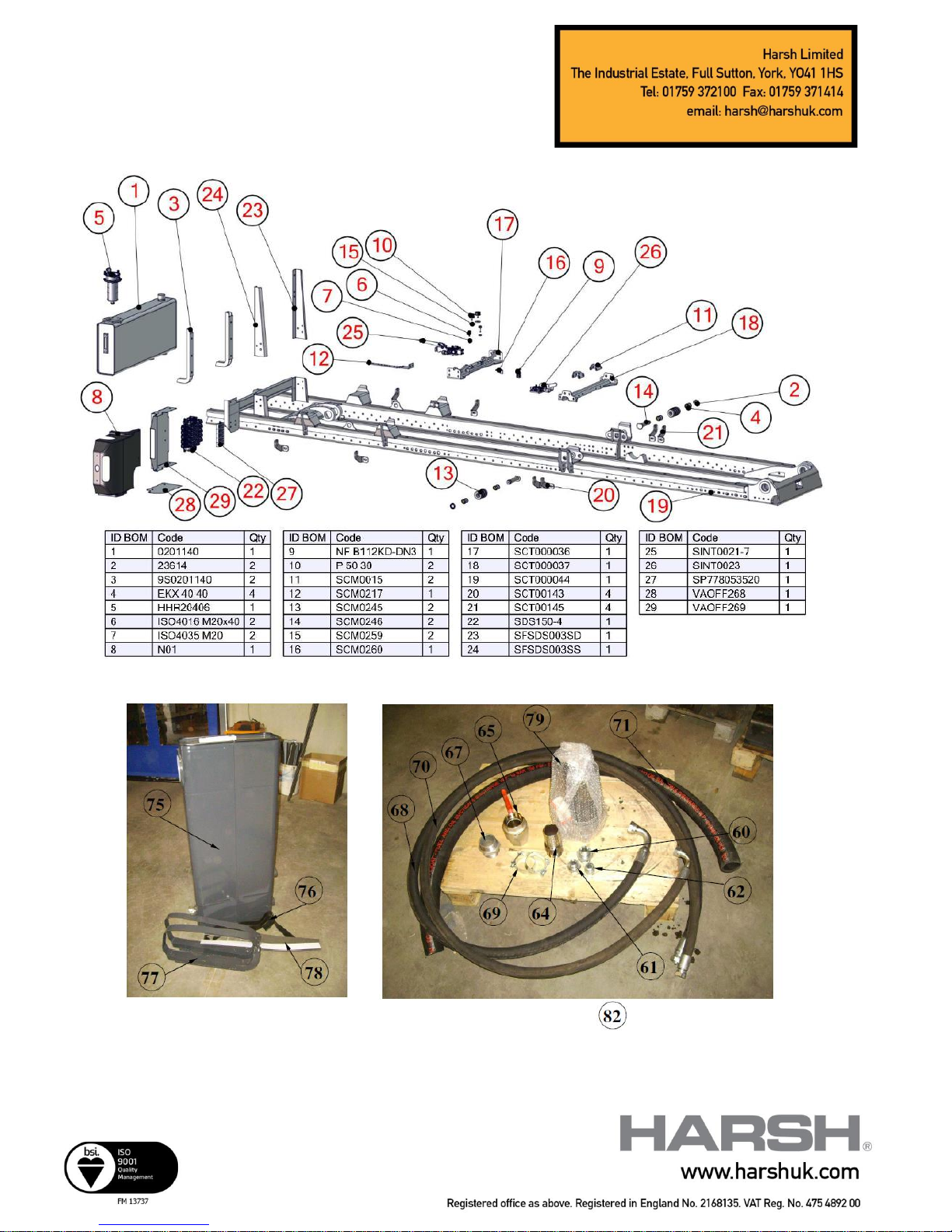

Front Oil Tank

MAINTENANCE

Maintenance should be carried out by trained professionals only and all health and safety checks listed in this manual

along with site health and safety processes should be adhered to at all times. It is imperative before works are

carried out on the Hooklift equipment safe and the environment is secure.

Routine Maintenance

Routine maintenance should be carried out by a trained competent professional and adhere strictly to all

health and safety procedures and risk assessments.

The routine maintenance guide provided is calculated for a single person in a standard workshop for the entire

maintenance cycle. It is anticipated the total time to carry out the routine maintenance listed should be

between 60-90 minutes.

What to check for on Routine Maintenance

This section provides a helpful guide on the items to check when maintaining the HH26 Hookloader

equipment.

Chassis to Hooklift connecting/mounting plates

After the first 30-40 working hours perform a complete check on the fixation plates, bolts and nuts with specific

attention to the front cylinders cross member connection plate.

Required time 10-15 minutes.

Loading...

Loading...