Harsco Industrial SC-1500, SC-2000, SC-3000, SC-4000, SC-1500GG Installation & Owner's Manual

...

&

P-K SONIC® GAS FIRED BOILER

w/ NURO® CONTROL SYSTEM

Natural Gas or Propane Gas

SC-1500/SC-2000/SC-3000/SC-4000

Dual Fuel

SC-1500GG/SC-2000GG

SC-3000GG/SC-4000GG

Part # 1004905978

C.S.A Design-Certified

Complies with ANSI Z21.13/CSA 4.9

Gas-Fired Low Pressure Steam and Hot Water Boilers

ASME Code, Section IV

Certified by Patterson-Kelley

C.S.A Design-Certified

Complies with ANSI Z21.13/CSA 4.9

Gas-Fired Low Pressure Steam and Hot Water Boilers

Model Number:

Serial Number:

Start-Up Date:

Harsco Industrial, Patterson-Kelley

155 Burson Street

East Stroudsburg, PA 18301

Telephone: 570.476.7261

Toll Free: 877.728.5351

Fax: 570.476.7247 www.harscopk.com

Released June 2, 2017

INSTALLATION

&

OWNER’S

MANUA

L

INSTALLATION

&

OWNER’S

MANUA

L

INSTALLATION

&

OWNER’S

MANUA

L

INSTALLATION

&

OWNER’S

MANUA

L

INSTALLATION

&

OWNER’S

MANUA

L

INSTALLATION

&

OWNER’S

MANUA

L

INSTALLATION

&

OWNER’S

MANUA

L

INSTALLATION

&

OWNER’S

MANUA

L

The information in this manual is the property of Harsco Industrial Patterson-Kelley. The descriptions and specifications contained in this

manual were in effect at the time this manual was approved for publication. While Harsco Industrial Patterson-Kelley will continue to

support earlier model boilers to within a reasonable time limit, we reserve the right to discontinue models and replacement parts at any

HARSCO Industrial, Patterson-Kelley 2017: All Rights Reserved.

time or change specifications or design without notice and without incurring any obligation.

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

General

P-K SONIC® SC-1500, SC-2000, SC-3000 and SC-4000

All P-K SONIC® SC-1500, SC-2000, SC-3000 and SC-4000

Gas-Fired Boilers must be:

• Installed, operated, and serviced in accordance with

instructions contained in this manual and other supplemental

manuals.

• Installed by qualified personnel in accordance with designs

prepared by qualified facility engineers including: structural,

mechanical, electrical, and other applicable disciplines.

• Operated and serviced in accordance with a comprehensive

safety program determined and established by the customer.

Do not attempt to operate or service until such a program

has been established.

• Operated and serviced by experienced, qualified, and

properly trained personnel in accordance with all applicable

codes, laws, and regulations.

Safety Precautions

Provide a suitable location for the boiler, away from normal

personnel traffic, with adequate working space, adequate

clearances, proper ventilation and lighting, with a structure

sufficiently strong and rigid to support the weight of the boiler, all

piping, and accessories.

NOTICE!

Each safety device must be

maintained and checked per the

recommended schedule. Refer to

Maintenance.

SAFETY FEATURES

It is the responsibility of the

customer to ensure external

safety provisions, such as but not

limited to: guards, safety labels,

safety controls, interlocks, lockout

devices are in place and operable.

SAFETY LABELS

The following words are used in

this manual to denote the degree

of seriousness of the individual

hazards.

Indicates an imminently

hazardous situation which,

if not avoided, will result in

death or serious injury. This

signal word is to be limited

to the most extreme

situations.

Indicates a potentially

hazardous situation which, if

not avoided, could result in

death or serious injury.

Indicates a potentially

hazardous situation which, if

not avoided, may result in

minor or moderate injury. It

may also be used to alert

against unsafe practices.

NOTICE/NOTE - NOTICE

The preferred signal word to

address practices not related to

personal injury. The safety alert

symbol is not used with this signal

word.

Safety

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

NOTICE!

The safety labels shown below are

affixed to your boiler. Although the

labels are of high quality, they may

become dislodged or unreadable

over time. Contact Harsco

Industrial, Patterson-Kelley at

570.476.7261 or toll-free at

877.728.5351 for replacements.

Gas may lose its odor. Proper gas

sensing equipment and procedures

should be used for leak checks.

Failure to detect gas leaks could

result in injury or death.

Training

Proper training is the best protection against accidents. It is

essential to read, understand, and follow the recommendations

of this manual before installing, operating, or servicing this

equipment. Failure to do so could result in fire or explosion and

serious injury, death, and/or property damage.

Operating and service personnel must be thoroughly familiar with

the basic construction of the P-K SONIC® SC-1500, SC-2000,

SC-3000 and SC-4000 boilers, the use and locations of th e

controls, the operation of the boilers, adjustment of their various

mechanisms, and all applicable safety precautions. If any of the

provisions of this manual are not fully and completely

understood, contact Harsco Industrial, Patterson-Kelley Technical

Service at 570.476.7261 or toll free at 877.728.5351.

Hazard Warnings

Electrical Hazards

Shock Hazard! Properly Lockout/Tagout the

electrical service and all other energy sources

before working on or near the boiler.

Shock Hazard! Do not spray water directly on

this boiler or any electrical components.

Electrical Hazard! Do not alter wiring

connections.

Crush Hazards

Lifting Hazards! Use properly rated lifting

equipment to lift and position the boiler. The

load is unbalanced. Test the balance before

lifting off the floor. Do not allow personnel

beneath the lifted load. Refer to the

approximate weights in the table below.

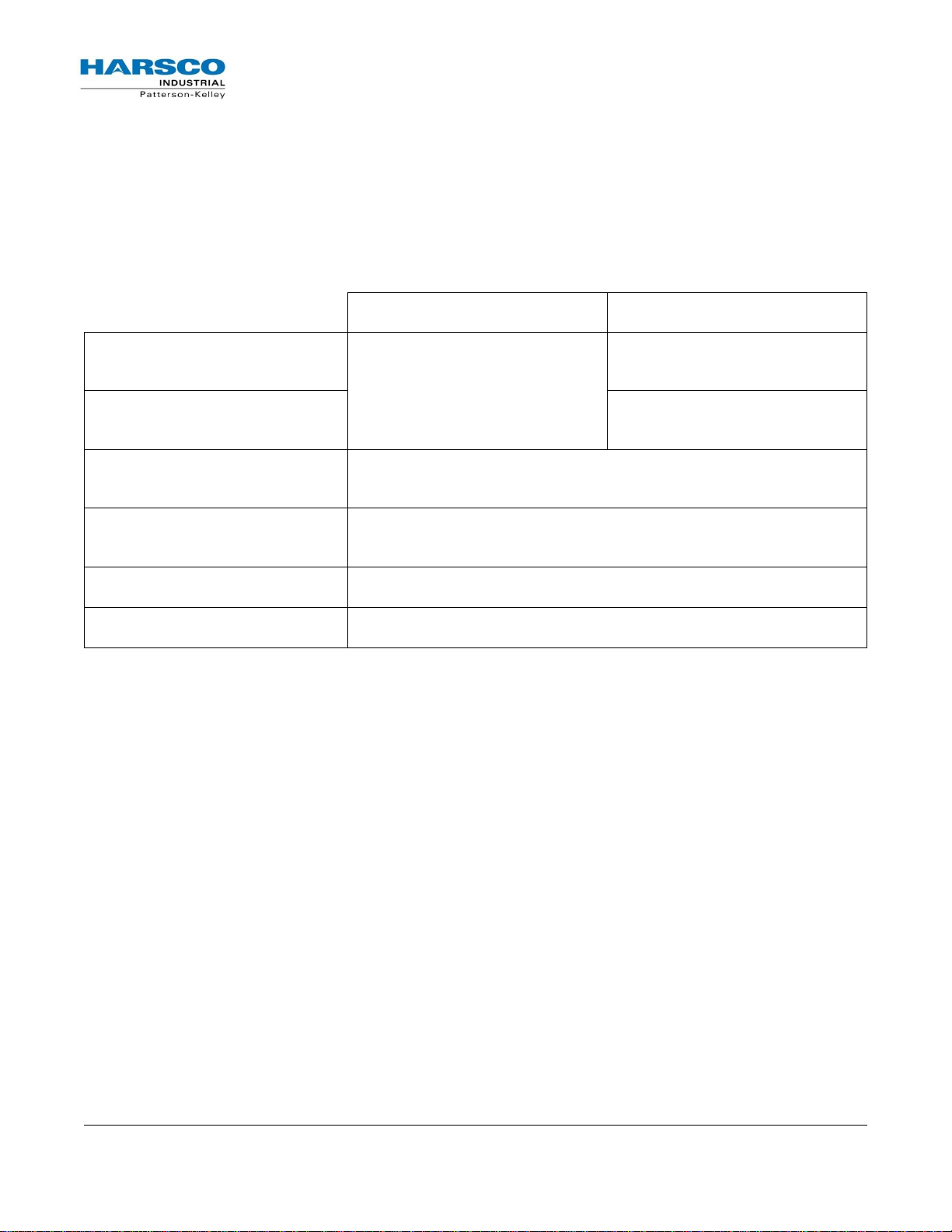

Boiler Model

Weight in

Pounds

Dual Fuel

Model

Weight in

Pounds

SC-1500

1,450 lbs.

SC-1500GG

1,550 lbs.

SC-2000

1,450 lbs.

SC-2000GG

1,550 lbs.

SC-3000

1,850 lbs.

SC-3000GG

2,000 lbs.

SC-4000

1,900 lbs.

SC-4000GG

2,000 lbs.

Bump Hazard from Overhead Ductwork and Piping

Pressure Hazards

Injury Hazard! Install components with adequate vertical clearance.

Pressure Hazard! Hot fluids. Install isolation valves on boiler water inlet and outlet.

Make sure isolation valves are closed before servicing boiler.

Pressure Hazard! Hot fluids. Annually test safety relief valve(s) for proper operation.

Do not operate boiler with faulty relief valve(s).

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Slip, Fall Hazards

Tripping Hazard! Do not install piping on floor surfaces. Maintain a clear path around

the boiler.

Slip and Fall Hazard! Use a drip pan to catch water while draining the boiler. Maintain

dry floor surfaces.

Slip and Fall Hazard! Do not locate intake or exhaust terminations above a walkway;

dripping of condensate can cause icing of the walking surface. Refer to 2.5.5 for more

information.

Fall Hazard! Do not stand on boiler.

Chemical Hazards

Chemical Hazards from Cleaning Products. Use

caution when cleaning the system. The use of

professional assistance is recommended. Use safe

procedures for the disposal of all cleaning solutions.

Combustion Condensate – An acidic pH of

approximately 3.0 to 5.0 can be expected. Use PVC,

CPVC, or other corrosion resistant piping for drainage. Collection and disposal must be in accordance

with all applicable regulations. A condensate neutralization kit is available. Please contact your local

Harsco Industrial, Patterson-Kelley representative for more information.

Burn, Fire and Explosion Hazards

Burn, fire, and explosion hazards! Installation must be in strict conformance to all applicable codes

and standards including NFPA 54, ANSI Z223.1 and CAN/CSA B.149. Install all required

vent lines for gas devices. Refer to 3.4 and 3.5 for more information.

Hazard from Incorrect Fuels! Possible fire, explosion, overheating, and damage. Do not

use any fuels except the design fuels for the unit.

Overfire Hazards! High pressure in gas supply could result in overfiring of this or other

devices supplied from the same source.

Fire and Explosion Hazards! Close the main gas shutoff before servicing boiler.

Fire and Explosion Hazards! Do not store or use gasoline or other flammable vapors or

liquids in the vicinity of this or any other gas fired appliance.

Burn hazard! Possible hot surfaces. Do not touch gas vent during firing operation. Use

only factory recommended vent components.

Burn Hazard! Pipes, vents, and boiler components could be hot. Do not touch piping or stack surfaces

during operation or immediately after shutdown of the boiler.

Burn Hazard! Hot flue! Use caution when servicing or draining boiler.

Fire and Explosion Hazards! Use caution when servicing burner. Propane (LPG) is heavier than air

and may linger in the combustion chamber, vent lines, or elsewhere.

Gas Leak Hazard! Make sure the burner is installed correctly and blower/transition is securely fastened

following any maintenance performed on them. These connections may leak gas if assembled

incorrectly.

Gas Leak Hazard! All threaded gas connections must be made using a pipe compound that is resistant

to liquefied petroleum gas. Do not use Teflon™ tape on threaded ga s piping.

Gas Leak Hazard! Check entire gas train for leaks after installation. If there is a smell of gas, shut down

the boiler and obtain immediate assistance from trained service personnel and/or your local fire

department.

Overfire Hazard! Possible fire and explosion from excess gas pressure. Make sure that gas inlet

pressure does not exceed 14 inches W.C.

Overfire Hazard! Possible fire and explosion. Possible malfunction of regulators and/or gas safety shut

off/control valves. Maintain all gas train components in good condition. Do not alter wiring connections.

Annual inspection by factory-trained personnel for proper set-up and operation is recommended.

Overfire and Underfire Hazards! Possible fire, explosion, overheating, and component failure. Do not

attempt to adjust firing rate of the boiler. The firing rate must be adjusted only by factory trained

personnel.

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page v

Table of Contents

1 INTRODUCTION .......................................................................................................................... IX

1.1 PURPOSE OF THIS DOCUMENT .................................................................................................. 1

1.2 COMMON ABBREVIATIONS ........................................................................................................ 1

2 SITE PREPARATION .................................................................................................................... 2

2.1 INITIAL INSPECTION UPON RECEIVING ........................................................................................ 2

2.2 STORAGE PRIOR TO INSTALLATION ............................................................................................ 2

2.3 COMPLIANCE WITH CODES ........................................................................................................ 3

2.4 LOCATION SETUP ..................................................................................................................... 4

Foundation ......................................................................................................................... 4

Clearances ......................................................................................................................... 5

2.5

2.6 GAS PIPING CONSIDERATIONS ................................................................................................ 11

2.7 WATER QUALITY STANDARD ................................................................................................... 11

3 INSTALLATION ........................................................................................................................... 11

I

NLET AIR AND EXHAUST VENTING CONSIDERATIONS

.................................................................. 6

Applicable Codes and Standards ........................................................................................ 6

Combustion Air Inlet Planning (United States and Canada Considerations) ....................... 6

Category II/IV Flue Gas Exhaust Vent Planning ................................................................. 7

Venting Materials for Flue/Exhaust Systems ....................................................................... 8

Required Clearances .......................................................................................................... 9

3.1 OVERVIEW ............................................................................................................................. 11

3.2 APPLIANCE CONNECTIONS ...................................................................................................... 11

Appliance Connections (SC-1500 & SC-2000) ................................................................. 12

Appliance Connections (SC-3000 & SC-4000) ................................................................. 12

3.3 ELECTRICAL CONNECTIONS .................................................................................................... 13

Power Requirements (SC-1500 & SC-2000) ..................................................................... 13

Single Phase Power Supply Connection (SC-1500 & SC-2000) ....................................... 13

Power Requirements (SC-3000 & SC-4000) ..................................................................... 14

Three Phase Power Supply Connection (SC-3000 & SC-4000) ........................................ 14

High Voltage (TB2) Terminal Block (SC1500 & SC2000) ................................ .................. 16

High Voltage (TB2) Terminal Block (SC3000 & SC4000) ................................ .................. 18

Low Voltage (TB1) Terminal Block .................................................................................... 20

3.4 COMBUSTION AIR ................................................................................................................... 22

Air Inlet Requirements – United States ............................................................................. 22

Air Inlet Requirements - Canada ....................................................................................... 23

P-K SONIC® Combustion Air Requirements ................................................................ ..... 24

Direct Vent / Sealed Combustion Installations .................................................................. 24

Motorized Combustion Air Dampers ................................................................................. 25

3.5 FLUE GAS / EXHAUST VENTING ............................................................................................... 27

Category II or IV Venting Installation................................................................................. 27

Vent Termination ............................................................................................................... 28

Venting for Multiple Boilers................................................................................................ 29

Sealed Combustion/Direct Vent Systems .......................................................................... 30

Inlet Duct Connection to Boiler .......................................................................................... 30

Intake Duct Materials and Sizes ....................................................................................... 30

Category II Installations .................................................................................................... 30

Category IV Installations ................................................................................................... 32

Stainless Steel Venting ..................................................................................................... 32

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page vi

CPVC Vent System Installation..................................................................................... 32

3.6 REMOVING AN EXISTING BOILER ............................................................................................. 33

3.7 PIPING ................................................................................................................................... 34

Gas Piping Overview ........................................................................................................ 34

Natural Gas Piping ........................................................................................................... 35

Propane Gas Piping ......................................................................................................... 35

Pressure Testing the Gas Piping ...................................................................................... 35

Boiler Water Piping ........................................................................................................... 36

Boiler Inlet and Outlet Connections ................................................................................... 36

Boiler Water Piping (for Installer) ...................................................................................... 37

3.8 WATER QUALITY .................................................................................................................... 38

3.9 PRE-START CHECKLIST .......................................................................................................... 39

3.10 SAFETY CHECKS ................................................................................................................... 39

Ignition Safety System Test .......................................................................................... 39

Low Water Cut-Out Test ................................................................ ............................... 39

Manual Reset High Temperature Limit Test ..................................................................... 40

Gas Pressure Switch Tests ........................................................................................... 40

3.11 FUEL/AIR ADJUSTMENTS ........................................................................................................ 41

Gas Pressure Adjustment ............................................................................................. 41

Manual Control Mode for High and Low Fire Adjustment .............................................. 42

Adjusting High Fire ....................................................................................................... 43

Adjusting Low Fire ........................................................................................................ 43

Checking Flame Signal ................................................................................................. 43

3.12 INITIAL NURO CONTROL SETUP AND ADJUSTMENT .................................................................. 44

Startup .......................................................................................................................... 44

Home Screen ................................................................................................................ 45

Information Screen ....................................................................................................... 45

Setup Wizard ................................................................................................................ 46

TYPICAL BOILER OPERATING CONDITIONS ............................................................................... 46

3.13

4 DUAL FUEL BOILER OPERATION ............................................................................................ 47

4.1 OVERVIEW ............................................................................................................................. 47

4.2 CHANGING FUEL TYPES .......................................................................................................... 47

4.3 P-K SONIC SC1500GG & SC2000GG .................................................................................. 48

Natural Gas Train and Propane Gas Train Locations (SC1500GG & SC2000GG) ........... 48

Fuel Selector Switch Location........................................................................................... 49

4.4 P-K SONIC SC3000-SC4000................................................................................................ 50

Natural Gas Train and Propane Gas Train Locations (SC3000GG & SC4000GG) ........... 50

Fuel Selector Switch Location........................................................................................... 51

5 OPERATIONS ................................................................ ............................................................. 52

5.1 NURO

®

CONTROL PANEL ....................................................................................................... 52

NURO Touch Screen Interface ................................................................ ......................... 52

Factory Tests .................................................................................................................... 52

5.2 NORMAL LIGHTING AND SHUT-DOWN PROCEDURES ................................................................. 53

Normal Lighting Procedures ............................................................................................. 53

Normal Shut Down Procedures ......................................................................................... 53

5.3 EMERGENCY SHUT-OFF ......................................................................................................... 53

6 MAINTENANCE .......................................................................................................................... 54

6.1 PREVENTATIVE MAINTENANCE ................................................................................................ 54

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page vii

Daily Preventative Maintenance ....................................................................................... 54

Weekly Preventative Maintenance .................................................................................... 54

Monthly Preventative Maintenance ................................................................................... 55

Semi-Annually .................................................................................................................. 55

Annually ........................................................................................................................... 55

6.2 MAINTENANCE AND INSPECTION SCHEDULE ............................................................................. 56

6.3 CLEANING THE BURNER & COMBUSTION CHAMBER .................................................................. 56

6.4 AFTER REPAIRS OR MAINTENANCE.......................................................................................... 58

6.5 SEQUENCE OF OPERATIONS ................................................................................................... 59

6.6 TROUBLESHOOTING ............................................................................................................... 60

Loss of Power ................................................................................................................... 60

Loss of Water Level .......................................................................................................... 60

Low Gas Pressure ............................................................................................................ 60

High Gas Pressure ........................................................................................................... 60

High Water Temperature ................................................................................................... 60

Low Air ............................................................................................................................. 60

Flame Failure ................................................................................................................... 61

Flame Error ...................................................................................................................... 61

Flue Problem .................................................................................................................... 61

7 PARTS/TECHNICAL SUPPORT ................................................................................................. 62

7.1 TERMINAL BLOCK ASSIGNMENTS ............................................................................................. 63

Terminal Block Assignments — Low Voltage (TB1) Terminal Block .................................. 63

Terminal Block Assignments — High Voltage (TB2) Terminal Block .................................. 64

7.2 WIRING DIAGRAMS ................................................................ ................................................. 65

SC-1500 & SC-2000 Natural Gas or Propane Gas ........................................................... 65

SC-1500 & SC-2000 Dual Fuel ......................................................................................... 67

Wiring Diagram – Power Box (SC-3000 and SC-4000 Only) ............................................ 70

SC-3000 & SC-4000 Control Transformer Diagrams ........................................................ 71

SC-3000 & SC-4000 240V Natural Gas or Propane Gas .................................................. 73

SC-3000 & SC-4000 240V Dual Fuel ................................................................................ 75

SC-3000 & SC-4000 480V Natural Gas or Propane Gas .................................................. 78

SC-3000 & SC-4000 480V Dual Fuel ................................................................................ 80

7.3 BOILER PARTS IDENTIFICATION (SC-1500 & SC-2000) ............................................................ 83

Main Boiler Assembly (SC-1500 & SC-2000) .................................................................... 83

NURO Control Panel (SC-1500 & SC-2000) ..................................................................... 84

Heat Exchanger Assembly (SC-1500 & SC-2000) ............................................................ 85

Natural Gas Train, Burner & Blower Assembly (SC-1500 & SC-2000) .............................. 86

Propane Gas Train, Burner & Blower (SC-1500 & SC-2000) ............................................ 87

7.4 BOILER PARTS IDENTIFICATION (SC-3000 & SC-4000) ............................................................ 88

Main Boiler Assembly (SC-3000 & SC-4000) .................................................................... 88

NURO Control Panel (SC-3000 & SC-4000) ..................................................................... 89

Main Power Box (SC-3000 & SC-4000) ............................................................................ 90

Heat Exchanger Assembly (SC-3000 & SC-4000) ............................................................ 91

Natural Gas Train, Burner & Blower Assembly (SC-3000 & SC-4000) .............................. 92

Propane Gas Train (SC-3000 & SC-4000) ........................................................................ 93

8 P-K SONIC® SPECIFIC LIMITED WARRANTY ........................................................................... 94

9 BOILER FIRE-TEST REPORT .................................................................................................... 96

APPENDIX A – MAINTENANCE LOG ................................................................................................ 97

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page viii

APPENDIX B – BOILER ALTITUDE DERATE SCHEDULE ................................ ............................... 98

APPENDIX C – WATER QUALITY STANDARDS QUALITY STANDARDS FOR HYDRONIC

BOILERS IN MULTI-METAL SYSTEMS ............................................................................................. 99

APPENDIX D – BEST PRACTICES FOR NEW & RETROFIT SYSTEMS ........................................ 100

APPENDIX E – INSTALLATION AND QUICK REFERENCE ........................................................... 102

FUEL/GAS SUPPLY .......................................................................................................................... 102

ELECTRICAL/POWER SUPPLY ........................................................................................................... 102

EXHAUST VENTING .......................................................................................................................... 102

APPLIANCE CONNECTIONS (SC-1500 & SC-2000) ............................................................................ 103

APPLIANCE CONNECTIONS (SC-3000 & SC-4000) ............................................................................ 103

HYDRONICS/WATER FLOW ............................................................................................................... 104

PROPYLENE GLYCOL FLOW .............................................................................................................. 105

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page ix

If the information in this manual

is not followed, fire or explosion

may result causing property

damage, personal injury, or loss

of life.

Do not store or use gasoline or other

flammable vapors or liquids in the

vicinity of this or any other

appliance. Installation and service

must be performed by a qualified

installer, service agency, or the gas

supplier.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any

appliance.

Do not touch any electrical

switch; do not use any phone in

your building.

Immediately call your gas

supplier from a neighbor’s

phone. Follow the gas

supplier’s instructions.

If you cannot reach your gas

supplier, call the fire department.

It is essential to read,

understand, and follow the

recommendations of this manual

before installing, operating or

servicing this equipment. Failure

to do so could result in personal

injury or death.

Installation and service must be

performed by a qualified and

knowledgeable individual who

has been certified on the P-K

SONIC® boiler. The features

which permit this boiler to

achieve high-efficiency

performance can be misused

which could result in personal

injury or death.

NOTICE! This manual covers single fuel P-K SONIC®

boilers (Natural Gas –or– Propane Gas) AND dual fuel P-K

SONIC boilers (Natural Gas –and– Propane Gas).

1 Introduction

This manual describes the installation and operation of the

following P-K SONIC® boilers featuring NURO® controls.

SC-1500 & SC-2000:

Natural Gas, 208-240V (single phase)

Propane Gas, 208-240V (single phase)

SC-1500GG & SC-2000GG:

Dual Fuel, 208-240V (single phase)

SC-3000 & SC-4000:

Natural Gas, 208-240V (three phase)

Propane Gas, 208-240V (three phase)

Natural Gas, 440-480V (three phase)

Propane Gas, 440-480V (three phase)

SC-3000GG & SC-4000GG:

Dual Fuel, 208-240V (three phase)

Dual Fuel, 440-480V (three phase)

Individual differences between boiler models will be called out

and defined in separate sections and the titles of these sections

will include the boiler model number. If the boiler model numbers

are not listed in the section title, that section is common to all

boiler models.

If you have any questions on the information contained within, or

do not fully and completely understand the content, please

contact Harsco Industrial, Patterson-Kelley Technical Service at

570.476.7261 or toll free at 877.728.5351.

The P-K SONIC® gas-fired boiler is fully modulating using a

variable speed combustion blower, sophisticated microprocessor

controls, modulating gas safety shut off / control valves and a

unique stainless steel heat exchanger capable of operating in a

fully condensing mode to provide maximum efficiency in a

minimum amount of space. The high-quality materials and

design of the boiler should provide years of trouble-free service if

the instructions in this manual are followed carefully.

The boiler is only a part of the complete heating system. This

boiler may be fully operational but because of poor circulation,

improper control, or other site related characteristics, not deliver

heat to the desired location. Additional equipment such as

temperature sensors, pumps, flow switches, balancing valves,

and check valves will be required for satisfactory operation of any

system. Harsco Industrial, Patterson-Kelley cannot be

responsible for the design or operation of such systems and a

qualified engineer or contractor must be consulted.

While details may differ slightly, basic operation is the same for all

models. Boilers may be built to operate with natural gas or liquefied petroleum gas (propane). Check the

rating plate for correct fuel usage and gas pressures.

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page 1

Abbreviation

Description

AMP

Ampere or Amperage

ANSI

American National Standards Institute

ASME

American Society of Mechanical Engineers

AWG

American Wire Gauge

BTU

British Thermal Unit

CH

Comfort Heat

CO2

Carbon Dioxide

CSA

Canadian Standards Association

CSD-1

Controls and Safety Devices

CPVC

Chlorinated Polyvinyl Chloride

DHW

Domestic Hot Water

HWR

Heating Water Return / Hot Water Return (From Building)

HWS

Heating Water Supply / Hot Water Supply (To Building)

ID

Inside Diameter

MBH

Thousands of BTU / Hour

MODBUS

A serial communication protocol (not an abbreviation)

NFPA

National Fire and Protection Agency

NTC

Negative Temperature Coefficient

O2

Oxygen

OD

Outside Diameter

OEM

Original Equipment Manufacturer

SCFM

Standard Cubic Feet per Minute

SMACNA

Sheet Metal and Thermoplastic Duct Construction Manual Air Conditioning

Contractors National Association

TB<#>

Terminal Block (1, 2, 3 etc.)

VAC

Volts Alternating Current

VDC

Volts Direct Current

1.1 Purpose of this Document

It is the purpose of this Installation and Owner’s Manual is to provide complete documentation support

for P-K SONIC

®

boilers featuring NURO controls. Harsco Industrial, Patterson-Kelley is constantly

seeking ways to produce high quality HVAC products. Our operation is based on the premium quality

control program and insures that Harsco Industrial manufactures quality products.

The primary concern of all Harsco Industrial, Patterson-Kelley equipment installation procedures is

Safety. Safety instructions and considerations are presented and repeated throughout the document

as needed. If you have any questions on the information contained within, or do not fully and

completely understand the content, please contact Harsco Industrial, Patterson-Kelley Technical

Service at 570.476.7261 or toll free at 877.728.5351.

1.2 Common Abbreviations

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page 2

Installation and service must be

performed by a qualified

installer, service agency, or gas

supplier. Failure to install the

equipment in accordance with

this manual could result in an

unsafe operating condition.

NOTICE!

Controls and other equipment that

are damaged or fail due to

weather exposure are not covered

by warranty.

The boiler is heavy and requires

additional technicians to

support and move the unit(s)

during installation. Use

extreme caution to avoid

dropping the boiler or cause

any bodily injury while lifting or

handling. When positioning

this boiler, maintain positive

control of it at all times. Do not

attempt to move the boiler on

surfaces that are not level.

Failure to heed this warning

could result in personal injury

or death.

NOTICE!

The boiler may be installed on a

combustible floor; however, the

boiler must never be installed on

carpeting.

Bumping hazard from overhead

ducts! Install all components

with adequate vertical

clearances. Insufficient

clearance can restrict the

service access, increasing the

possibility of injury.

NOTICE! Note any damage, suspected potential damage,

or shortage of materials on the freight bill and immediately

notify the carrier. File all claims for shortage or damage with

the carrier. Claims for hidden damages must be filed with

your carrier within 7 days. The carton is equipped with a

“Tip (N) Tell”. If the “Tip (N) Tell” arrow point is blue, that

indicates the package has been on its side or tipped over in

transit.

NOTICE! Controls and other equipment that are damaged

or fail due to weather exposure are not covered by warranty.

2 Site Preparation

2.1 Initial Inspection upon Receiving

Upon receiving the boiler, inspect it for signs of shipping

damage. Some damage may be hidden. Unpack the boiler,

open the front and side doors and inspect the boiler. Verify that

the total number of pieces shown on the packing slip agrees

with those actually received.

2.2 Storage Prior to Installation

If the boiler is not installed immediately, it must be stored in a

location adequately protected from the weather, preferably

indoors. If this is not possible, then it should remain in the

shipping container and be covered by a tarpaulin or other

waterproof covering.

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page 3

SC-1500 & SC-2000

SC-3000 & SC-4000

Code of Construction

(Boiler)

ASME Section IV – “H”

(Latest Edition)

ASME Section IV – “H”

(Latest Edition)

Code of Construction

(Economizer)

ASME Section VIII – Div. 1 –

“U” (Latest Edition)

Maximum Allowable Working

Pressure

160 PSIG

Maximum Allowable Design

Temperature

210° F

Hi-Limit Setpoint

200° F

Maximum Setpoint

185° F

2.3 Compliance with Codes

Each P-K SONIC® boiler with standard components complies with American National Standard/CSA

Standard ANSI Z21.13/CSA 4.9, latest edition for Gas-Fired Low Pressure Steam and Hot Water

Boilers.

The P-K SONIC® SC-1500, SC-2000, SC-3000 and SC-4000 heat exchangers are constructed and

stamped in accordance with ASME Boiler and Pressure Vessel Code, Section IV for 160 psig maximum

pressure and 210°F maximum temperature. Other codes or approvals which apply will be labeled on

the boiler.

Installation of the boiler must conform to all the requirements of all national, state and local codes

established by the authorities having jurisdiction or, in the absence of such requirements, to the

National Fuel Gas Code, ANSI Z223.1/NFPA 54 latest edition in the U.S. In Canada, the equipment

shall be installed in accordance with the current Installation Code for Gas Burning Appliances and

Equipment, CAN/CSA-B.149, latest edition, and applicable Provincial Regulations for the class, which

should be carefully followed in all cases. Authorities having jurisdiction should be consulted before

making any installation.

Where required by local codes, the installation must conform to American Society of Mechanical

Engineers Safety Code for Controls and Safety Devices for Automatically Fired Boilers (ASME CSD-1).

In the Commonwealth of Massachusetts (a) this unit must be installed by

a licensed pipe fitter/plumber,

(b) field installed gas cocks must be “T” handle type, (c) piping of condensate shall conform to the State

Plumbing Code, and (d) refer to the Massachusetts Supplement for further details.

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page 4

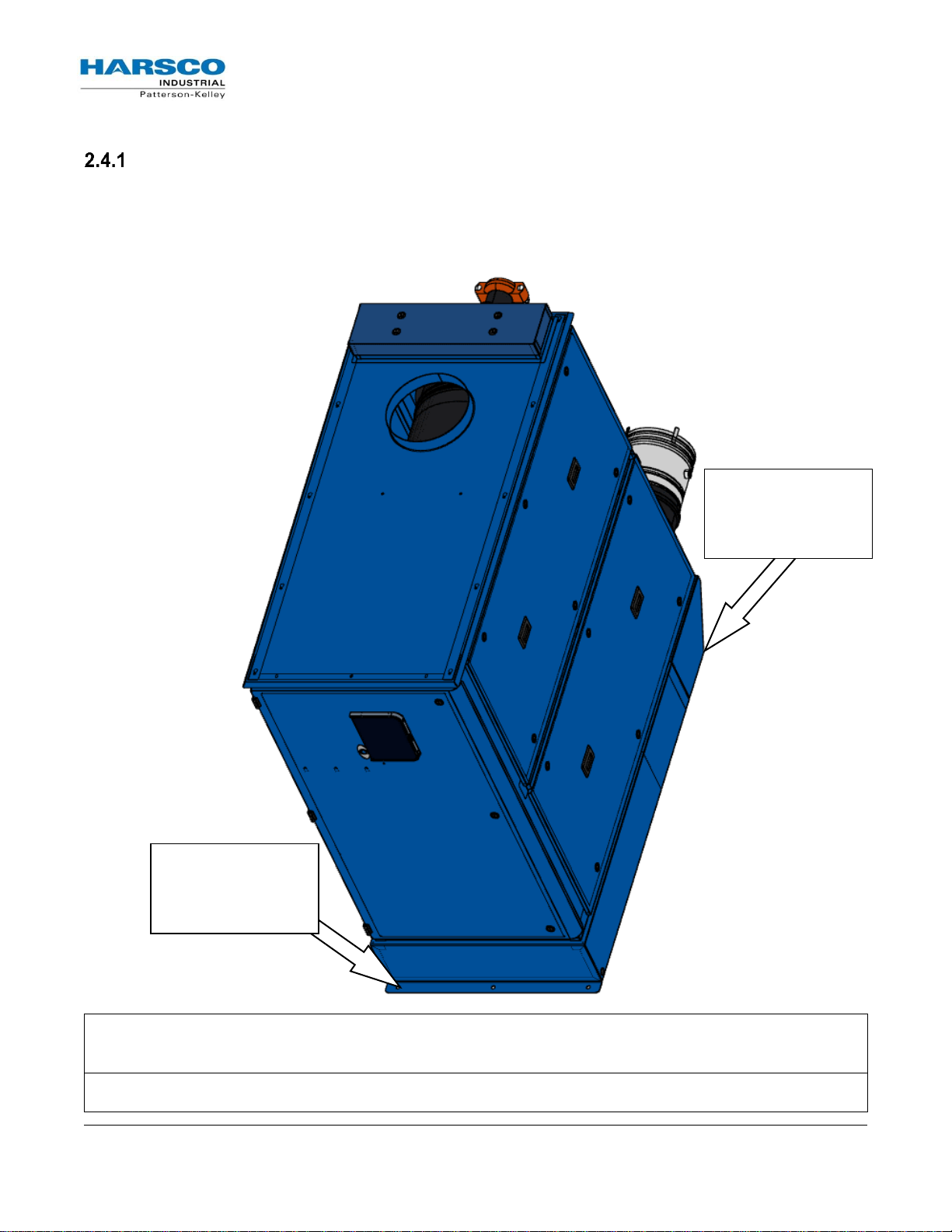

NOTICE! The appliance may be installed on a combustible floor; however, the appliance must

NEVER be installed on carpeting.

NOTICE! This appliance is certified for INDOOR use only!

QTY 3: 9/16” Holes

for

Anchor/Lag Bolts

(REAR)

QTY 3: 9/16” Holes

for

Anchor/Lag Bolts

(FRONT)

2.4 Location Setup

Foundation

Provide a firm, level foundation, preferably made of concrete. The P-K SONIC® boilers must be level

and upright to function properly. There are s

1/2" anchor bolts. Once the boiler is installed on the foundation and furnished with anchor/lag bolts,

use a bubble level and adjust the anchor nuts until the appliance is secure and level.

ix 9/16” holes in the base which may be used for 3/8” or

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page 5

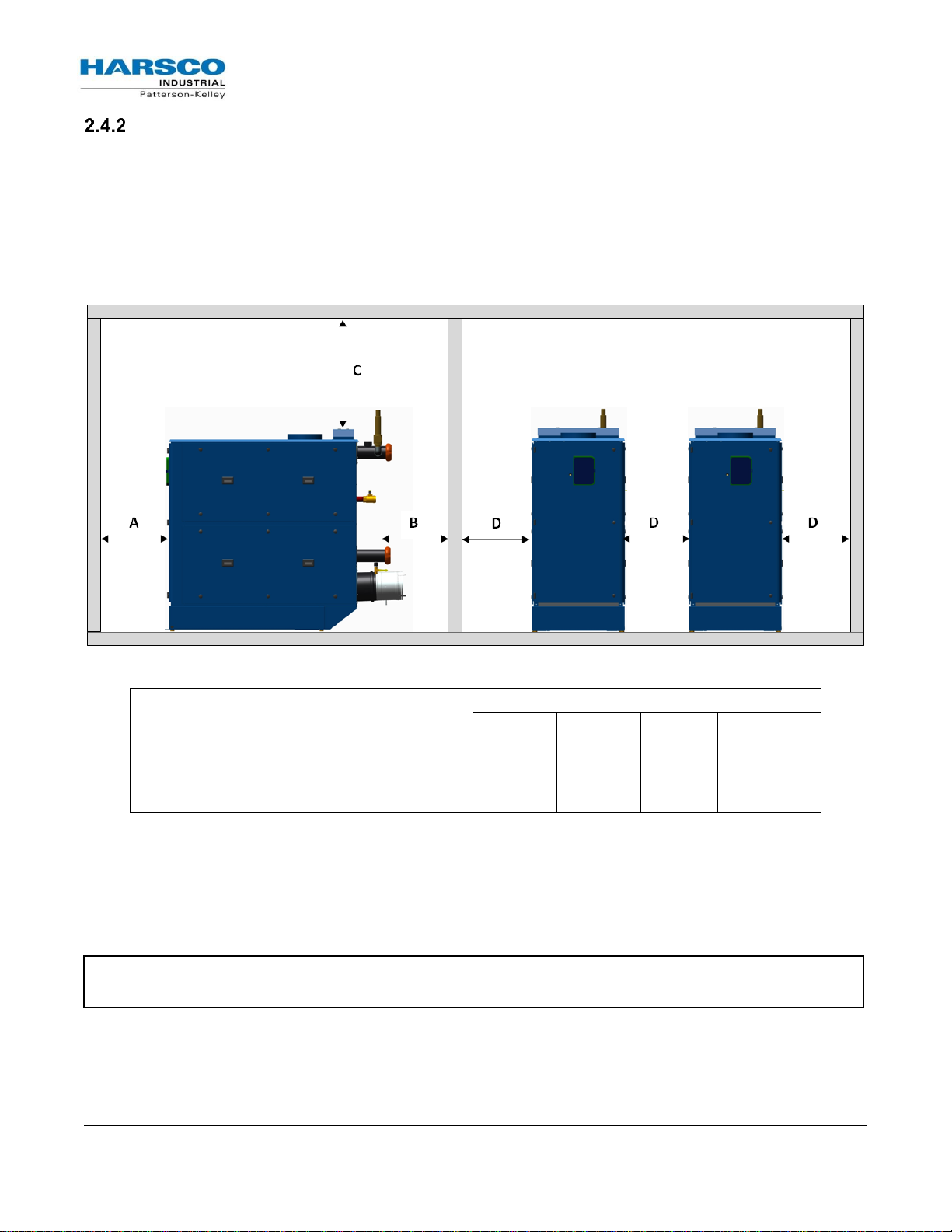

Type of Surface

Dimensions (inches)

A B C†

D

CSA Minimum Clearances to Combustibles

18

6*

12†

6**

Clearance to Non-Combustible Surfaces

0 0 0

0

Recommended Service Clearances

32

12*

12†

12**

Note: Failure to provide recommended service clearances may make it difficult to perform service

on the boiler(s).

Clearances

If the boiler is to be installed near combustible surfaces, the minimum clearances are shown in the

illustration below. Failure to provide adequate service clearances, even with non-combustible surfaces,

may present problems during routine maintenance of the boiler. Maintain a clearance from the vent to

combustible surfaces of 24” or as specified in the vent manufacturer’s listed installation instructions.

The boiler must be installed in a space large in comparison to the boiler as described in the National

Fuel Gas Code, NFPA 54/ANSI Z223.1, Latest Edition.

* “B” Clearance depends upon exhaust vent configuration.

† “C” Space required for pipes, ducts, etc. in this area above the boiler.

** Do not put pipes, ducts, vents, etc. in this space. Electrical conduit must be installed vertically so that

the side doors can be opened.

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page 6

Design and installation of

venting systems should be

done only by qualified and

knowledgeable venting systems

personnel and in accordance

with vent system

manufacturer’s installation

instructions. Installing a boiler

or vent system using improper

installation methods or

materials can result in serious

injury or death due to fire or

asphyxiation.

Before connecting a boiler to a

venting system, it must be

determined whether the boiler

is to be installed in a

conventional or direct vent

configuration. In the US,

provisions for combustion air

must be in accordance with

NFPA 54/ANSI Z223.1, National

Fuel Gas Code, latest edition, or

applicable provisions of local

building codes. In Canada,

combustion and ventilation air

openings shall comply with

CAN/CSA B-149.1 Natural Gas

and Propane Installation Code.

For correct installation of a vent

system, read all of these

instructions and refer to the

vent manufacturer’s

instructions.

Failure to use a proper vent

system (types and materials), as

described in this manual will

void the boiler warranty and

may result in rapid deterioration

of the venting system, creating

a health or life safety hazard.

Faulty vent installation can

allow toxic fumes to be released

into living areas. This may

cause property damage, injury,

or death.

NBIC – Part I

National Board Inspection Code Installation

NFPA 54/ANSI Z223.1

National Fuel Gas Code

NFPA/ANSI 211

Chimneys, Fireplaces, Vents and Solid

Fuel Burning Appliances

CAN/CSA B149.1

Installation Codes for Gas Burning

Equipment

UL 441 / ULC S605

Standard for Gas Vents

UL 1738

Venting Systems for Gas-Burning

Appliances, Categories II, III and IV

ULC S636-95

Standard for Type BH Venting System

Sheet Metal and Thermoplastic Duct

Construction Manual Air Conditioning

Contractors National Association

(SMACNA)

2.5

Inlet Air and Exhaust Venting Considerations

Applicable Codes and Standards

United States Installation Codes:

Canada Installation Codes:

Flue Gas Exhaust Vent Standards:

These codes and standards contain information for the venting of

gas fired appliances, including, but not limited to vent sizing,

location, clearance to combustibles, and safe installation practices.

The installation must comply with both the above Federal Codes

and with state, provincial, and local codes.

Combustion Air Inlet Planning (United States and

Canada Considerations)

Air inlet requirements for the U.S. are established by NFPA

54/ANSI Z223.1 & NFPA/ANSI 211.

Air inlet requirements for Canada are established by

CAN/CSA B149.1.

Refer to see section 3.4, for more details on combustion air inlet

requirements in the United States and Canada.

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page 7

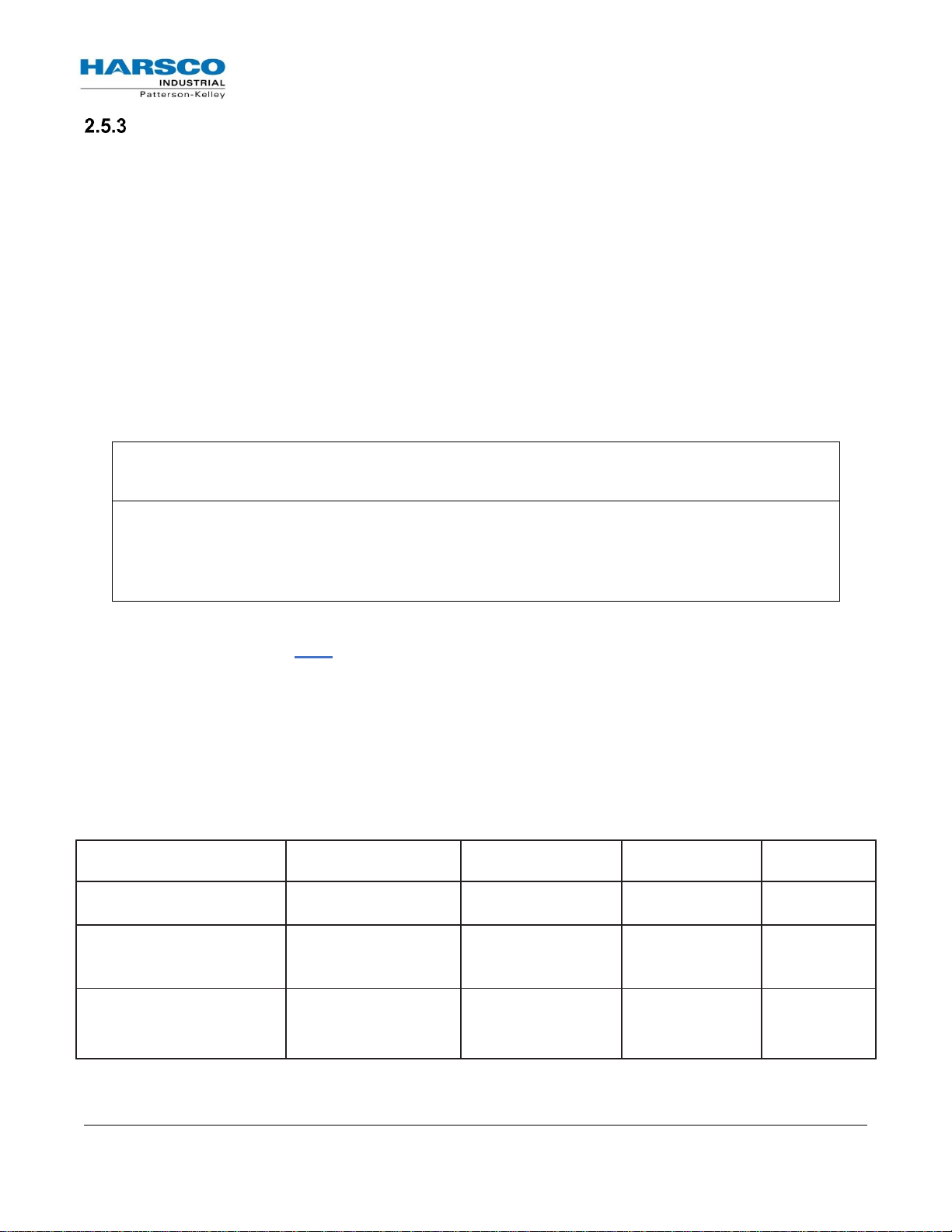

NOTE: For Category II installations, ensure the flue venting system is designed to maintain a

slightly negative exhaust pressure between -0.01” W.C. and -0.05” W.C.

NOTE: For Category IV installations, ensure the flue venting system is designed to maintain a

slightly positive exhaust pressure which MUST BE in the following ranges:

+0.01” W.C. and +0.22” W.C. (Direct Vent / Sealed Combustion)

+0.01” W.C. and +0.4” W.C. (Exhaust Only)

P-K SONIC® Boiler Model

Draft

Stack Temperature

CO2

Natural Gas

CO2

Propane Gas

SC-1500, SC-2000,

SC-3000, SC-4000

Category II

-0.01” to -0.05” W.C.

220 °F (gross)

9.2%

10.4%

SC-1500, SC-2000,

SC-3000, SC-4000

Category IV

(Sealed Combustion)

+0.01” to +0.22” W.C.

220 °F (gross)

9.2%

10.4%

SC-1500, SC-2000,

SC-3000, SC-4000

Category IV

(Exhaust Only)

+0.01” to +0.4” W.C.

220 °F (gross)

9.2%

10.4%

Category II/IV Flue Gas Exhaust Vent Planning

Several codes and standards have categorized appliances in accordance with the flue gas temperature

and pressure produced by the appliance. The applicable categories are defined as follows:

Category II: An appliance that operates with a non-positive vent static pressure and with a vent

temperature that may cause excessive condensate production in the vent.

Category IV: An appliance that operates with a positive vent static pressure and with a vent

temperature that may cause excessive condensate production in the vent.

Direct Vent: An appliance that is constructed and installed so that all air for combustion is

derived directly from outdoors and all flue gases are discharged to the outdoors.

All P-K SONIC® boilers are dual-certified as Category II or IV appliances, as defined in ANSI

Z21.13/CSA 4.9, latest edition. The P-K SONIC® series boilers are capable of operating with slightly

negative to slightly positive exhaust pressure. It is critical to ensure the flue vent material is certified for

Category II or IV operation.

The vent material to be used for US and Canada is listed in the Table of Acceptable Materials for

Venting Systems located in 2.5.4.

Vent installations shall be in accordance with NFPA 54/ANSI Z223.1, the National Fuel Gas Code, or

CAN/

CSA-B149.1, the Natural Gas and Propane Installation Code, or applicable provisions of the local

building codes.

Vent Sizing for Category II / IV Operation

The vent must be sized in accordance with the ASHRAE Systems and Equipment handbook (Chapter

30) or according to the vent manufacturer’s recommendations. When using manufactured venting

systems, consult your vent supplier for correct sizing and structural support requirements.

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page 8

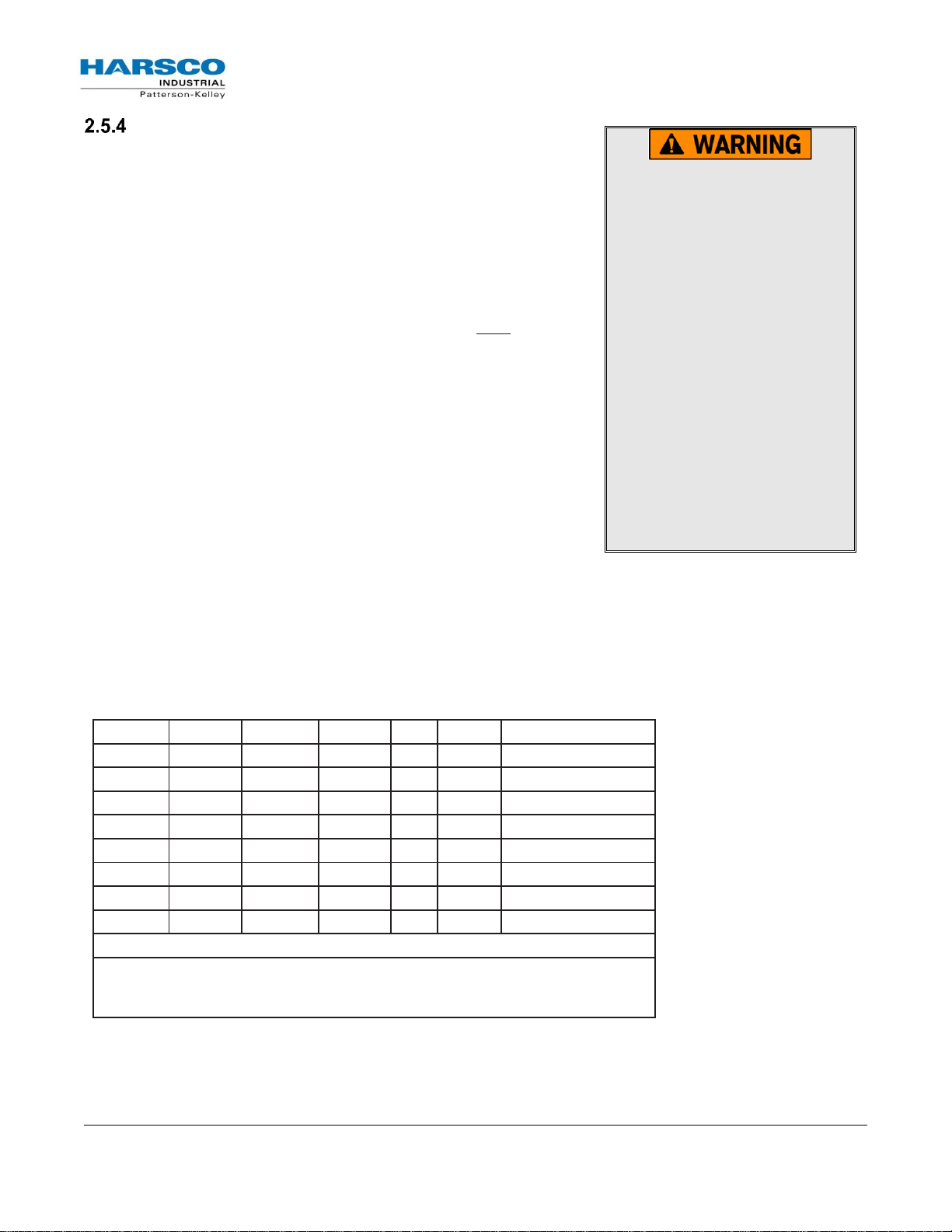

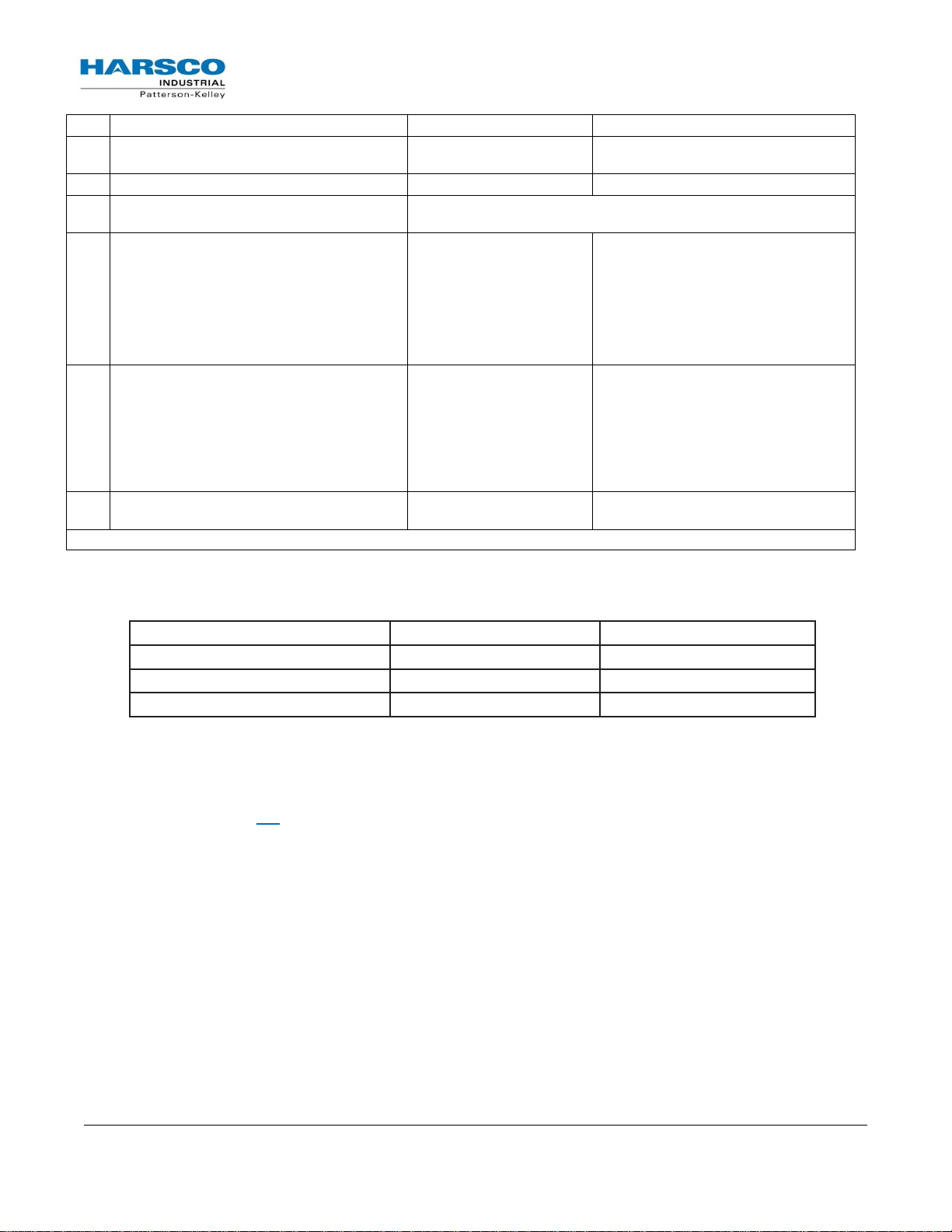

Model

Country

AL29-4C

316L SS

PVC

CPVC

POLYPROPYLENE

SC-1500

US

Yes

Yes

No

Yes

Note 2

SC-2000

US

Yes

Yes

No

Yes

Note 2

SC-3000

US

Yes

Yes

No

Yes

Note 2

SC-4000

US

Yes

Yes

No

Yes

Note 2

SC-1500

Canada

Yes

Yes

No

Note 1

Note 1

SC-2000

Canada

Yes

Yes

No

Note 1

Note 1

SC-3000

Canada

Yes

Yes

No

Note 1

Note 1

SC-4000

Canada

Yes

Yes

No

Note 1

Note 1

NOTE 1: When this material is used for venting, it must be listed to ULC-S636.

NOTE 2: When this material is used for venting, it must be listed to either UL-

1738 or ULC-S636 (depending on the local requirements). Consult the local

boiler codes for more information.

The venting materials listed are

intended for the venting of gas

burning appliances only. Do

not use these venting materials

for venting liquid or solid fuel

(such as oil, kerosene, wood,

or coal) appliances.

Maintain clearances to

combustibles as listed in the

vent manufacturer’s

installation instructions or as

set forth in the codes and

standards listed in this section.

Do not use these vent pipes for

incinerators of any sort!

This boiler is not certified for

use with PVC venting. Use of

PVC venting may result in vent

failure and possible serious

injury or death.

Venting Materials for Flue/Exhaust Systems

The P-K SONIC boilers are dual certified as a Category II and

Category IV appliances, which vents with a temperature that is likely to

cause condensation in the vent. Therefore, any venting system used

with the P-K SONIC® boiler must comply with the requirements for

either Category II or Category IV venting systems as specified in th e

latest edition of NFPA 54/ANSI Z223.1 in the US or th e latest edition of

CAN/CSA B-149.1 in Canada.

CPVC Venting

US: CPVC pipe conforming to ASTM F441. Sch. 80 fittings

conforming to ASTM F439. Joints are to be sealed with

solvent conforming ASTM 493.

Canada: CPVC Pipe, Fitting and Sealant listed and

labeled to ULC S-636 Standard for Type BH Venting

Systems.

Polypropylene Venting

US and Canada: Polypropylene such as InnoFlue® from

Centrotherm or PolyPro® from DuraVent or other listed

manufacturers. When used, the same manufacturer's

material must be used throughout the system. It is not

permissible to use material from different manufacturers

within the same system.

As per ANSI Z21.13b-2012 * CSA 4.9b-2012:

The use of cellular core PVC, CPVC, and Radel® as venting materials is prohibited.

The use of external insulation on plastic vent pipe is prohibited.

Acceptable Venting Materials

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page 9

The boiler vent should not be

connected into any portion of

another mechanical draft system

without consulting the vent

manufacturer. The boiler shall

not be connected to any part of

a vent system serving a

Category I appliance, nor shall a

Category I appliance be

connected to any part of the

vent system serving this

appliance. For Category II

common venting, refer to local

venting codes. Improper

interconnection of venting

systems may result in leakage of

flue gases into occupied spaces.

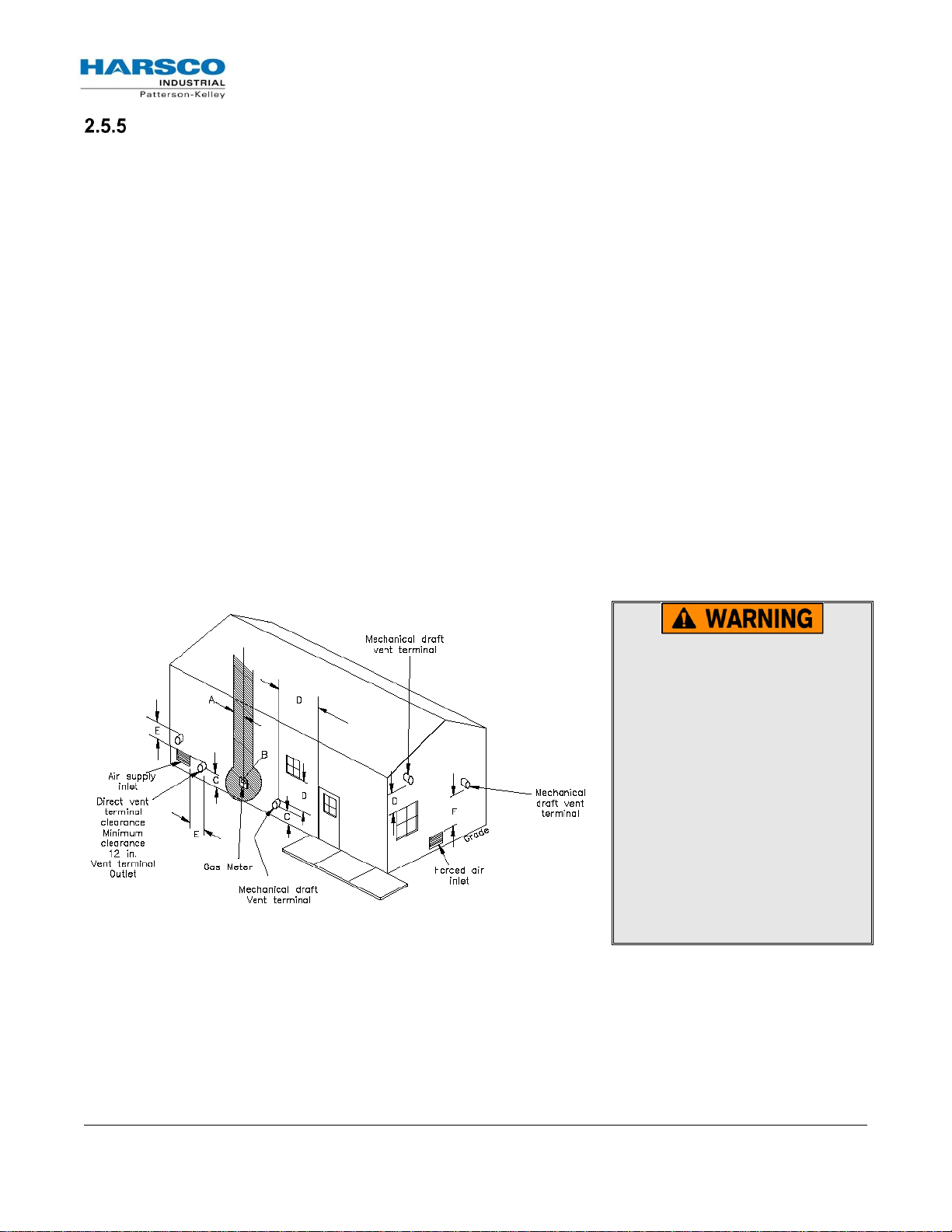

Required Clearances

Conventional Vent Systems Clearances

The following termination clearance requirements are for conventional non direct vent installations:

The vent system shall terminate at least 3 ft. above a forced air inlet located within 10 ft.

horizontally.

The vent system shall terminate at least 4 ft. below, 4 ft. horizontally from, or 1 ft. above any

door, operable window or gravity inlet into any building. The bottom of the vent terminal shall be

at least 12 in. above grade or highest expected snow line (if applicable).

Through the wall terminations shall not terminate over public walkways or over an area where

condensate or vapor could create a nuisance or hazard or could be detrimental to the operation

of regulators, relief valves, or other equipment.

Direct Vent (Sealed Combustion) Systems Clearances

The vent terminal shall be located at least 12 in. from any air opening into a building. The

bottom of the vent terminal shall be at least 12 in. above grade. Both the vent and air intake

terminals must be at least 12 in. above the highest expected snow line.

Through the wall terminations shall not terminate over public walkways or over an area where

condensate or vapor could create a nuisance or hazard or could be detrimental to the operation

of regulators, relief valves, or other equipment.

When multiple direct vent appliances are adjacent, the exhaust must terminate at least 10 ft.

horizontally or 3 ft. vertically from the air intake of another appliance.

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page 10

Mark

Description

US Installations

Canadian Installations

A

Clearance to each side of center line

extended above meter/regulator

3 ft. (91 cm) within a height of 15 ft. (4.6

m) above the meter/regulator assembly

B

Clearance to service regulator vent outlet

3 ft. (91 cm)

C

Clearance above grade, porch, deck,

veranda, or balcony

12 in

D

Clearance to window or door that may be

opened

4 ft. (1.2 m) below or to side

of opening

1 ft. (300 mm) above

opening

6 in (15 cm) for appliances ≤ 10,000

Btuh (3 kW)

12 in (30 cm) for appliances > 10,000

Btuh (3 kW) and ≤ 100,000 Btuh (30

kW)

36 in (91 cm) for appliances > 100,000

Btuh (30 kW)

E

Clearance to non-mechanical air supply inlet

to building or the combustion air inlet to any

other appliance

4 ft. (1.2 m) below or to side

of opening

1 ft. (300 mm) above

opening

6 in (15 cm) for appliances ≤ 10,000

Btuh (3 kW)

12 in (30 cm) for appliances > 10,000

Btuh (3 kW) and ≤ 100,000 Btuh (30

kW)

36 in (91 cm) for appliances > 100,000

Btuh (30 kW)

F

Clearance to a mechanical air supply inlet

3 ft. (91 cm) above if within

10 ft. (3 m) horizontally

6 feet (1.83 m)

For clearances not specified maintain clearance in accordance with local installation codes and the requirements of the gas supplier

Material

Combustible

Non-Combustibles

Unlisted single wall metal pipe

Do NOT Use

Do NOT Use

Single wall PVC pipe

Do NOT Use

Do NOT Use

UL 1738 listed Category IV vent

Per manufacturer’s listing

Per manufacturer’s listing

Interior Component Clearances

All vent system components shall be installed so as to maintain the following minimum clearances:

Flue Connection

The connection from the appliance to the vent should be as direct as possible and the upward slope of

any horizontal breaching should be at least 1/4 inch per linear foot. Examples of the complete exhaust

system with drain is in 3.5. The appliance connector should incorporate provisions to drain condensate

formed in the vent system. The connector should include an appropriate drain section (not provided).

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page 11

Supplying a fuel other than that shown on the appliance’s

nameplate can lead to over firing of the appliance. This can

cause damage to the equipment which could result in serious

injury and/or death.

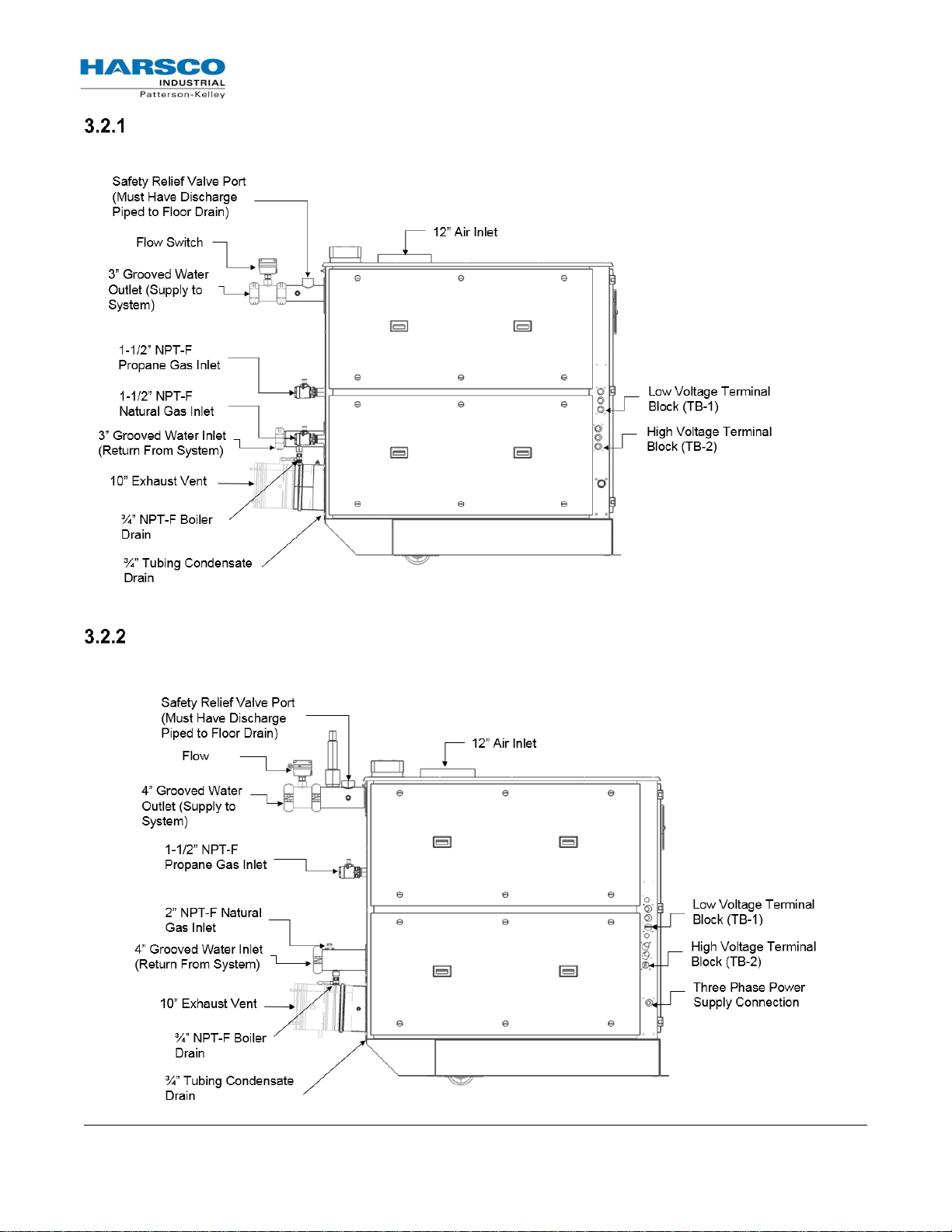

Boiler Model

SC-1500 & SC-2000

SC-3000 & SC-4000

Power Requirement

208-240/1/60 VAC

208-240/3/60 VAC -or-

440-480/3/60 VAC

Air Intake Connection

12”

Nominal Exhaust Vent

Connection

10”

Condensate Drain

3/4" Flexible Tubing

Heat Exchanger Drain

3/4" NPT-F

Natural Gas Shutoff Valve

1-1/2” NPT-F

2” NPT-F

Propane Gas Shutoff Valve

1-1/2” NPT-F

1-1/2” NPT-F

HWR Connection

3” Grooved (Stainless Steel)

4” Grooved (Stainless Steel)

HWS Connection

3” Grooved (Stainless Steel)

4” Grooved (Stainless Steel)

NOTE: Failure to maintain the water quality according to the requirements of the multi-metal

systems water quality standards can void the heat exchanger warranty.

2.6 Gas Piping Considerations

Before making the gas hook-up, make sure the boiler is being supplied with the type of fuel shown on

the boiler nameplate.

The boiler shall be installed such that gas ignition system components are protected from water

(dripping, spraying, rain, etc.) during appliance operation and service (circulator replacement, control

adjustment, etc.).

2.7 Water Quality Standard

The P-K SONIC® boiler’s heat exchanger is made of stainless steel. The heat exchanger requires

proper water conditions to remain efficient and function properly. For more information, refer to Harsco

Industrial, Patterson-Kelley’s Water Quality Standards for Hydronic Boilers in Multi-Metal Systems in

Appendix C – Water Quality Standards Quality Standards for Hydronic Boilers in Multi-Metal

Systems, as this applies to the warranty of your heat exchanger.

3 Installation

3.1 Overview

For site preparation follow the guidelines established in Section 2. Section 3 details the installation

requirements for electrical connections, combustion air, and flue vent piping, hydronic piping, etc.

3.2 Appliance Connections

The table below summarizes the appliance connections to the P-K SONIC® series boilers:

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page 12

Appliance Connections (SC-1500 & SC-2000)

All connections must be in compliance with national, state, and local code requirements.

Appliance Connections (SC-3000 & SC-4000)

All connections must be in compliance with national, state, and local code requirements.

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page 13

TB2 Terminal 1 = HOT L1

TB2 Terminal 2 = HOT L2

TB2 Terminal 3 = NEUTRAL

TB2 Terminal 4 = GROUND

Do not over-tighten the terminal screws.

Maximum tightening torque = 6 in-lbs!

NOTE: These terminals can accommodate maximum 10 AWG wire.

3.3 Electrical Connections

Power Requirements (SC-1500 & SC-2000)

The SC-1500 and SC-2000 boiler models require 208-240 VAC, single phase, 60 hertz electrical

service. The MCA and MOCP are indicated on the boiler’s rating nameplate. Before starting the boiler,

check to ensure that the proper electrical service is connected to the boiler.

An external electrical disconnect and overload protection (not supplied with the boiler) are required.

Refer to 7.1 for proper wiring and configuration of the electrical connections. The electrical service to

the boiler must be installed and grounded in accordance with local codes or in the absence of such

requirements, in the U.S. with National Electrical Codes, ANSI/NFPA No. 70 latest edition or, in

Canada, to the current Canadian Electrical Code, Part I, CSA C22.1 latest edition. Installed conduit

must not block any of the boiler’s openings and must allow the front door to be opened.

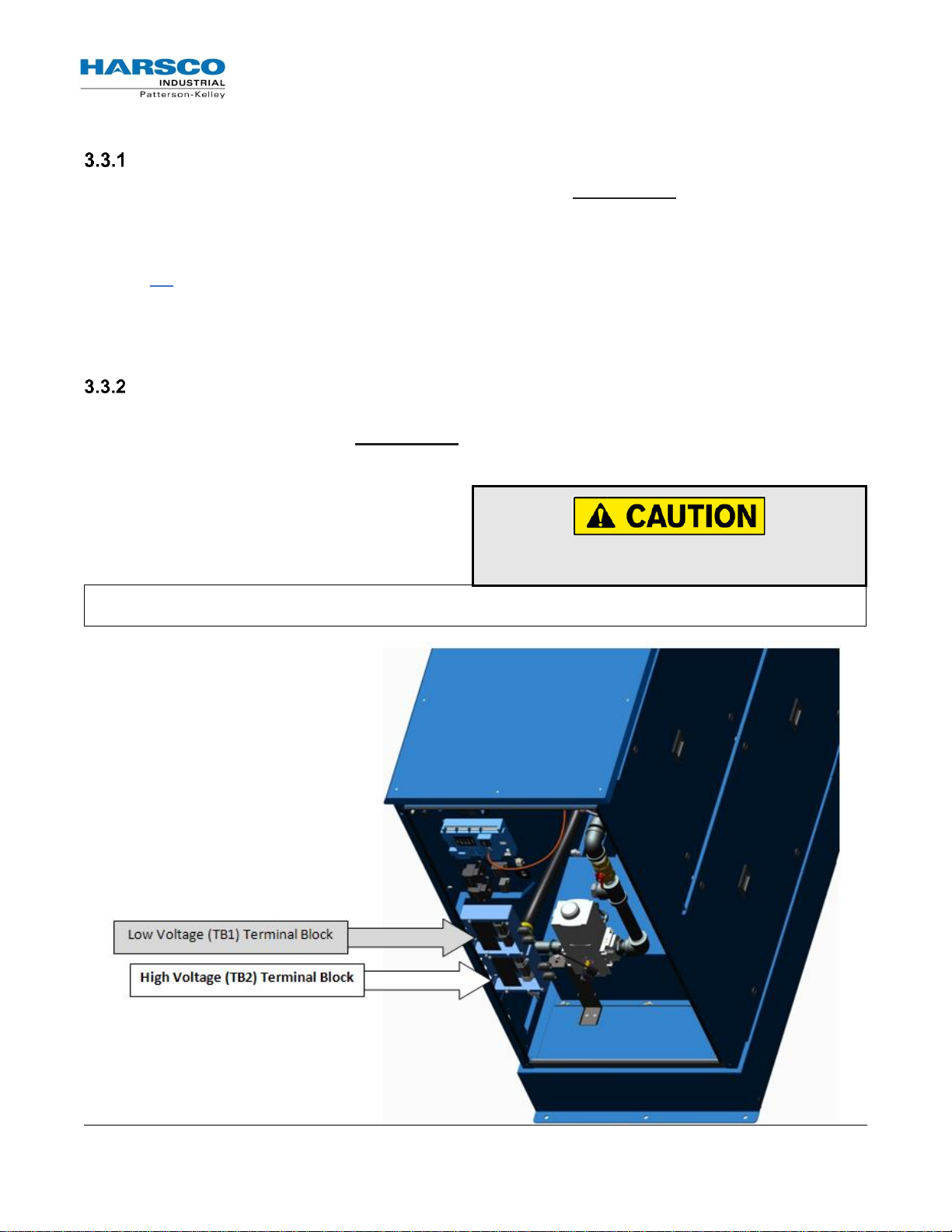

Single Phase Power Supply Connection (SC-1500 & SC-2000)

The SC-1500 and SC-2000 models feature four dedicated power terminals on the High Voltage (TB2)

terminal block for the 208-240VAC, single phase, and 60 hertz electrical supply. The image below

shows the location of the Low Voltage (TB1) and High Voltage (TB2) terminal blocks with the front

door hidden for clarity:

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page 14

NOTE: The SC-3000 & SC-4000 boiler models MUST be ordered to the correct voltage! IT IS NOT

POSSIBLE to convert an SC-3000 or SC-4000 between the 240V and 480V configurations in the

field!

NOTICE: If 208 VAC three phase power is supplied to the boiler, the internal control transformer

must be re-wired for operation at this lower voltage. The wire in terminal X3 on the load side of the

internal control transformer must be moved to terminal X4. This supplies 110 VAC power to the

NURO® control from the 208 VAC main voltage. Refer to Section 7.1, for proper wiring and

configuration of the internal control transformer.

Power Requirements (SC-3000 & SC-4000)

The SC-3000 and SC-4000 boilers can be manufactured for 208-240 VAC, three phase, 60 hertz

electrical service OR 440-480VAC, three phase, 60 hertz electrical service. The total operating

amperage is indicated on the rating nameplate and the SC-3000 & SC-4000 boiler models require less

than 20 Amps at full load. Before starting the boiler, check to ensure that the proper electrical service is

connected to the boiler.

An external electrical disconnect and overload protection (not supplied with the boiler) are required.

Refer to Section 7.1, for proper wiring and configuration of the electrical connections. The electrical

service to the boiler must be installed and grounded in accordance with local codes or in the absence of

such requirements, in the U.S. with National Electrical Codes, ANSI/NFPA No. 70 latest edition or, in

Canada, to the current Canadian Electrical Code, Part I, CSA C22.1 latest edition. Installed conduit

must not block any of the boiler’s openings and must allow the front door to be opened.

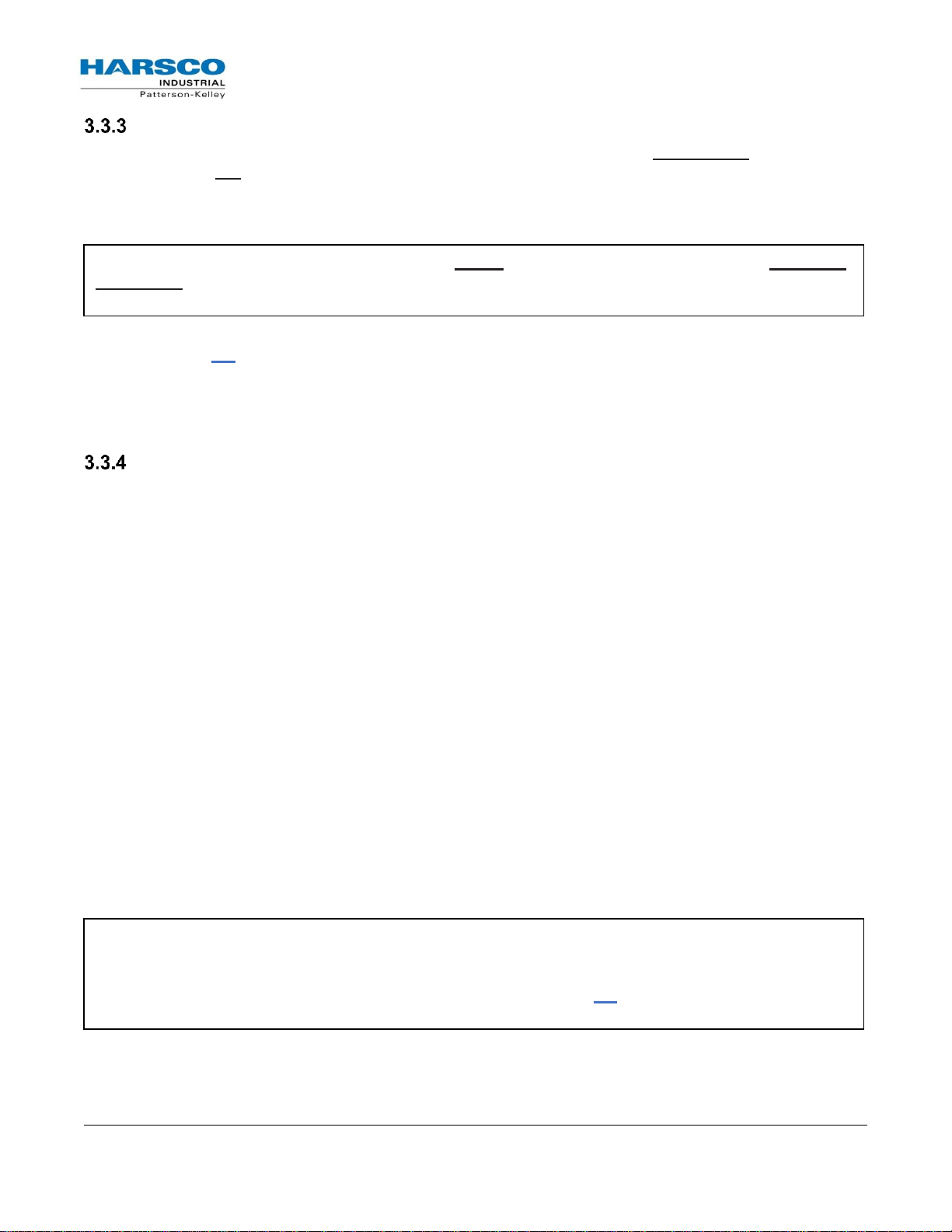

Three Phase Power Supply Connection (SC-3000 & SC-4000)

Main Power Connection Box

Always check the rating nameplate of the SC-3000 or SC-4000 boiler to determine the required

electrical service:

208-240VAC, three phase, 60 hertz

440-480VAC, three phase, 60 hertz

The incoming three phase power for the SC-3000 & SC-4000 boilers is connected to the over-current

safety device (rated for 20 Amps) and the Ground terminal located in the main power connection box.

The image on the next page shows the Low Voltage (TB1) and High Voltage (TB2) terminal blocks,

plus the Main Power Connection Box on the SC-3000 & SC-4000 with the front door hidden for

clarity:

Terminal 1 = HOT L1

Terminal 3 = HOT L2

Terminal 5 = HOT L3

Terminal G = GROUND

Control Transformer

The Main Power Connection Box features a Control Transformer which steps down two hot leads

from the incoming three-phase power in order to supply 110-120VAC single phase power to the

NURO® control system. Be aware that SC-3000 & SC-4000 boilers ordered in the 240V configuration,

are pre-wired from the factory for operation with 240 VAC three phase incoming power.

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page 15

Do not over-tighten the hot lead terminal screws. Maximum tightening torque = 13 in-lbs!

NOTE: The hot lead terminals can accommodate maximum 12AWG wire. The ground terminal can

accommodate maximum 8AWG wire.

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page 16

Be sure to check the

nameplate on the boiler

before connecting the

electrical supply.

NOTICE!

A dedicated earth ground

(green wire) is required to

avoid nuisance shutdowns.

Do not ground through the

conduit!

The high voltage (TB2)

terminal block on the SONIC

SC-1500 and SC-2000 with

NURO controls contains two

hot leads (HOT L1 & HOT L2),

a neutral lead (NEUTRAL) and

a ground lead (GROUND) for

208- 240 VAC, single phase

60Hz electrical supply. This

terminal block (TB2) also

contains dry-contact relays

with a maximum voltage

rating of 240VAC and 1/2 Amp

maximum current capacity.

Incorrect wiring can result in

equipment damage, injury, or

death.

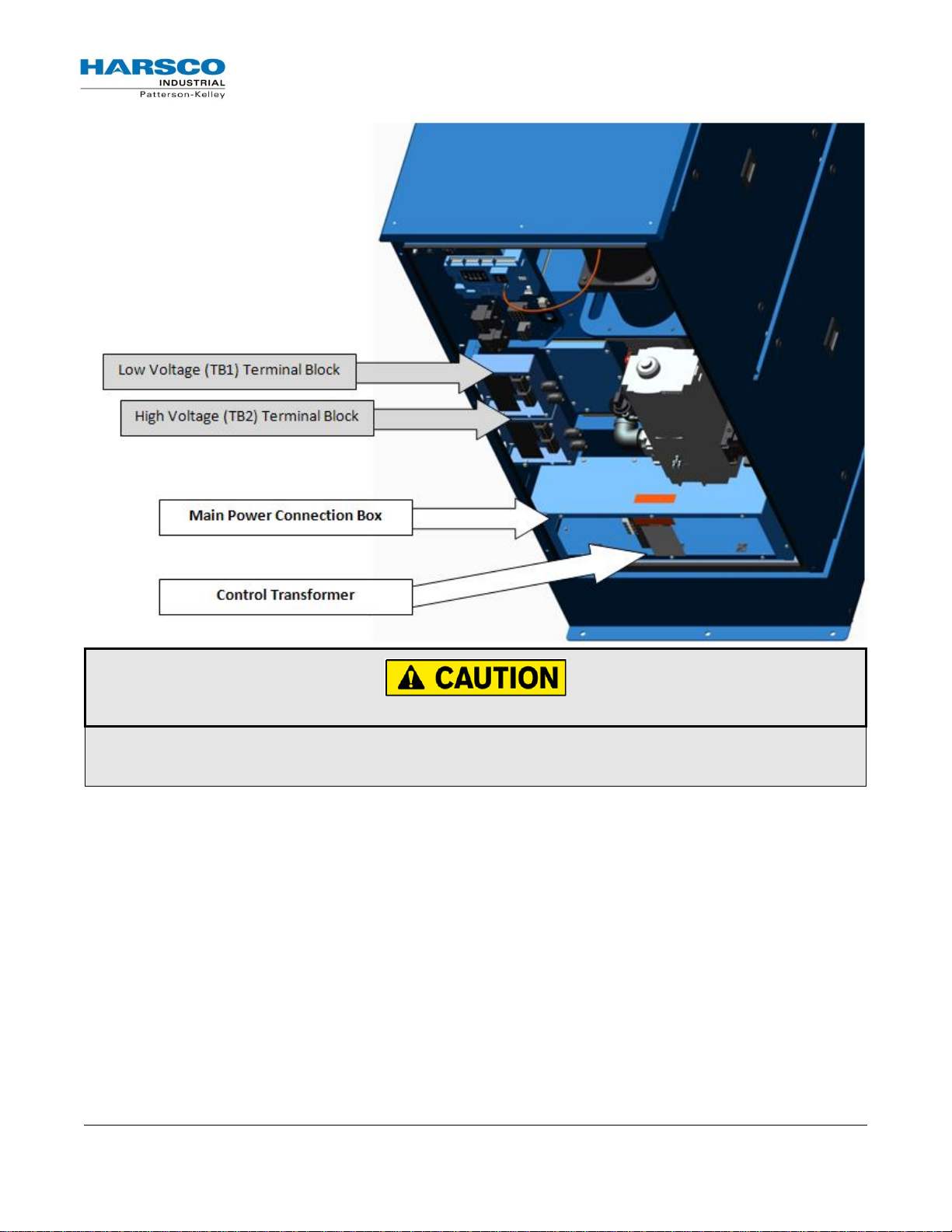

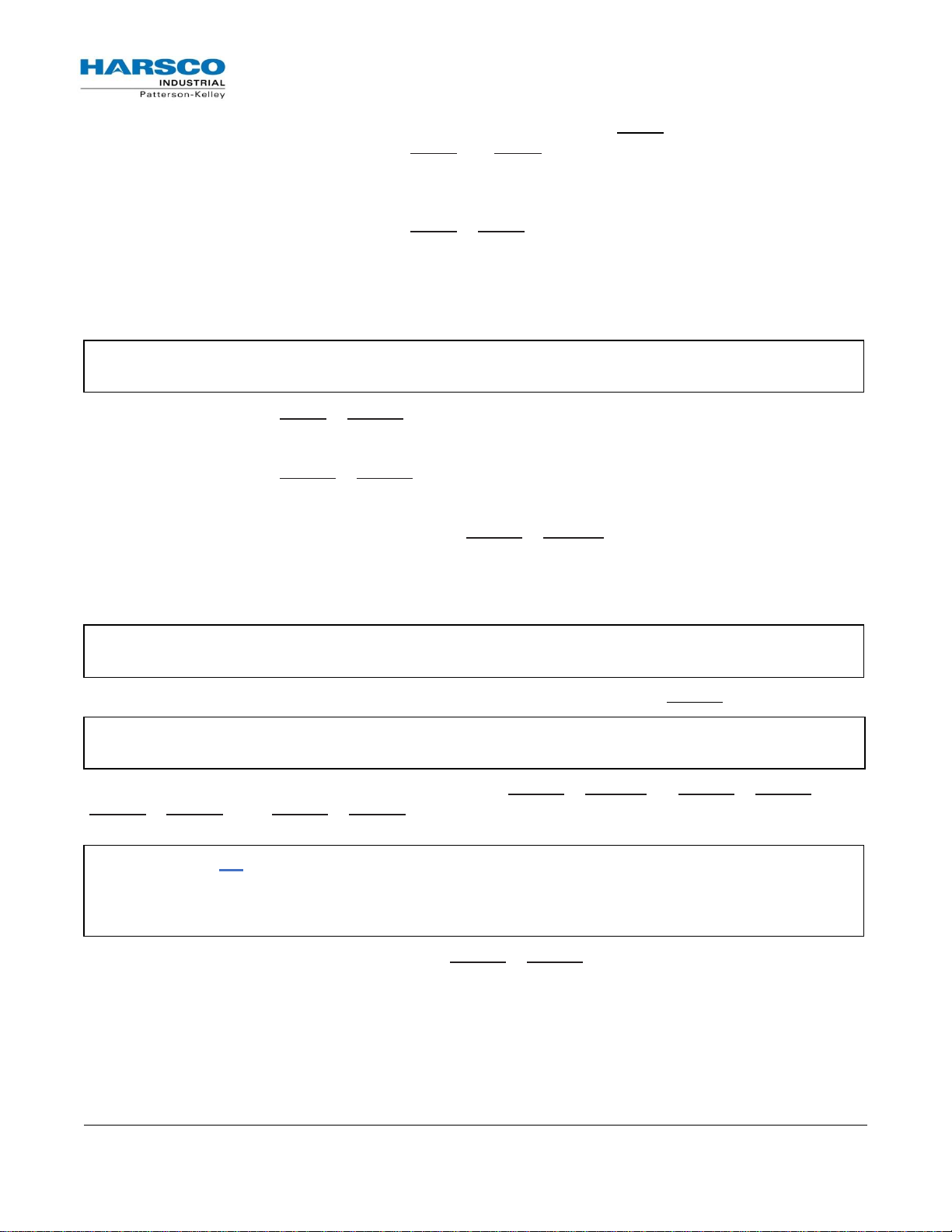

High Voltage (TB2) Terminal Block (SC1500 & SC2000)

TB2-1 terminal.

HOT L2 – Connect the 2nd hot lead of the 208-240VAC, single phase, 60Hz electrical service to the

TB2-2 terminal.

NEUTRAL – Connect the neutral lead of the 208-240VAC, single phase, 60Hz electrical service to the

TB2-3 terminal.

HOT L1 – Connect the 1st hot lead of the 208-240VAC, single phase, 60Hz electrical service to the

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page 17

NOTE: The Start Interlock circuit must close within 5 minutes of a call for heat. Failure to close the

Start Interlock circuit will cause the appliance to lockout on alarm.

NOTE:

The boiler ships with a factory-installed jumper across the Air Damper Interlock terminals.

Remove the jumper if connecting a motorized air damper with end limit switch.

NOTE: This ground terminal is connected to the TB2 sheet metal and is not common with the

appliance’s electrical service ground.

NOTE: Refer to 7.1, for proper wiring and configuration of the electrical connections. Relays A

through D can be user-configured through the NURO® touch screen interface to control devices

such as the Comfort Heat (CH) pump, Domestic Hot Water (DHW) Pump, Air Damper, System

Pump, etc.

GROUND – Connect the ground lead from the electrical service to the TB2-4 terminal.

Start Interlock #2 –

The Start Interlock #2 TB2-5 and TB2-6 terminals are in series with Start Interlock

#1 and provide additional connection points for auxiliary safety devices. This circuit is energized with

120VAC, so the contacts on any auxiliary safety devices must be rated for minimum 120VAC.

Start Interlock #1 –

The Start Interlock #1 TB2-7 & TB2-8 terminals can be used for auxiliary safety

devices such as damper limit switches, control valve limit switches, emergency stop buttons, and low

water cutoff devices. This circuit is energized with 120VAC, so the contacts on any auxiliary safety

devices must be rated for a minimum of 120VAC. The appliance ships with a factory-installed jumper

across Start Interlock #1 and Start Interlock #2 terminals. Remove the jumper(s) if using any auxiliary

safety devices.

Auxiliary Input #2 –

energized with 120VAC

Auxiliary Input #1 –

energized with 120VAC

Air Damper Interlock – The Air Damper Interlock TB2-13 & TB2-14 terminals

The TB2-9 & TB2-10 terminals are reserved for future use. This circuit is

.

The TB2-11 & TB2-12 terminals are reserved for future use. This circuit is

.

allow for proof of open

end limit switch on a motorized air damper. This circuit is energized with 120VAC, so the contacts on

the end limit switch must be rated for minimum 120VAC. The appliance ships with a factory-installed

jumper across the Air Damper Interlock terminals. Remove the jumper if connecting a motorized air

damper with end limit switch.

Ground – Grounding connection for auxiliary safety/limit devices on terminal TB2-15.

Relay A, B, C & D – User-configurable relay outputs A (TB2-22 & TB2-23), B (TB2-20 & TB2-21), C

(TB2-18 & TB2-19) & D (TB2-16 & TB2-17). The normally-open contacts on these relays have a

maximum voltage rating of 240VAC and maximum current capacity of 1/2 Amp.

Master Alarm Relay – The Master Alarm Relay TB2-24 & TB2-25 terminals are normally-open dry

contacts that close in the event of an alarm output from the NURO control. The normally-open contacts

on this relay have a maximum voltage rating of 240VAC and maximum current capacity of 1/2 Amp.

P-K SONIC® Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: June 2, 2017

Released: June 2, 2017

HARSCO Industrial, Patterson-Kelley 2017

All Rights Reserved.

1004905978 P-K SONIC NURO Installation and

Owners Manual (Rev F Jun-2017).docx

Page 18

Be sure to check the

nameplate on the boiler

before connecting the

electrical supply.

NOTICE!

A dedicated earth ground

(green wire) is required to

avoid nuisance shutdowns.

Do not ground through the

conduit!

The high voltage (TB2)

terminal block on the SONIC

SC-3000 & SC-4000 with

NURO controls contains dry-

contact relays with a

maximum voltage rating of

240VAC and 1/2 Amp

maximum current capacity.

Incorrect wiring can result in

equipment damage, injury, or

death.

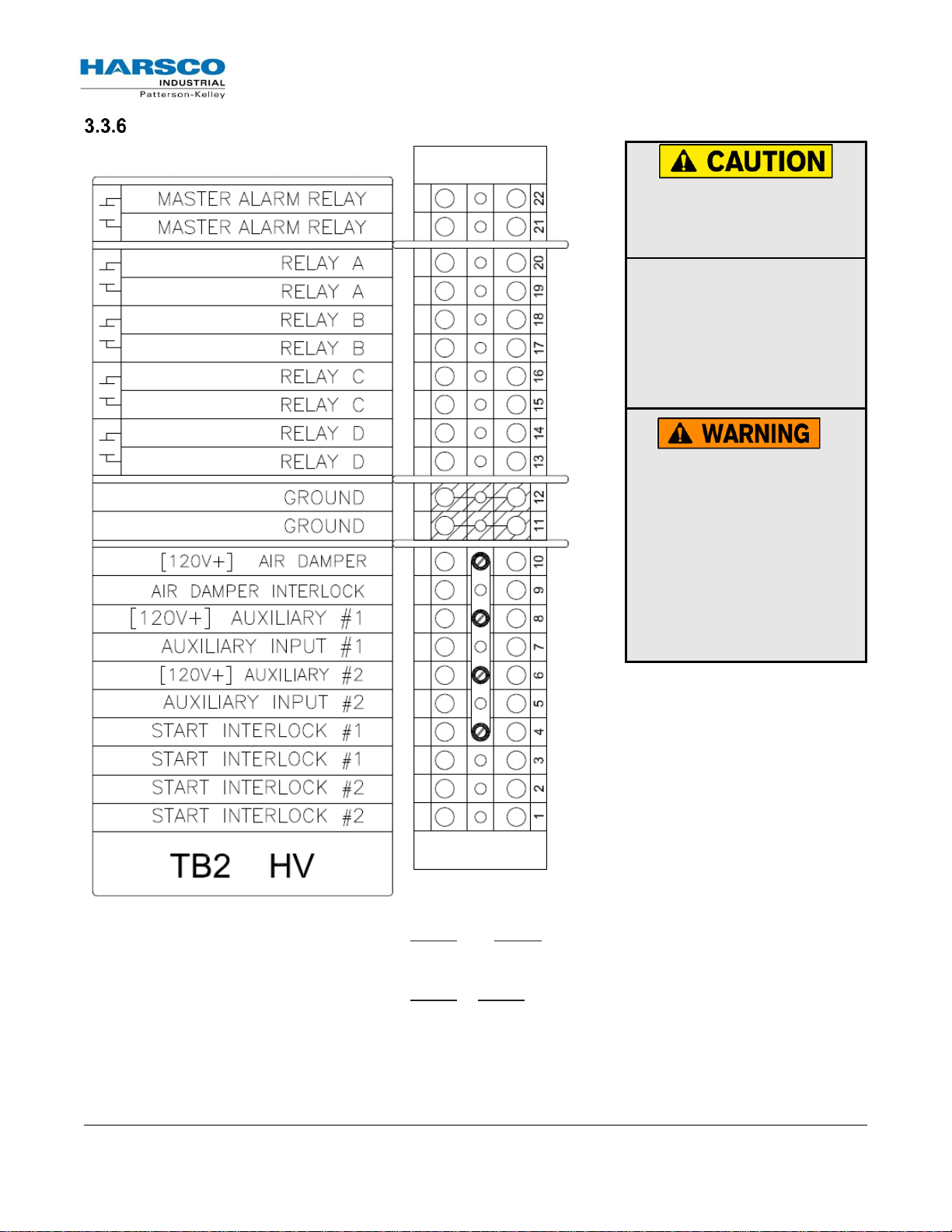

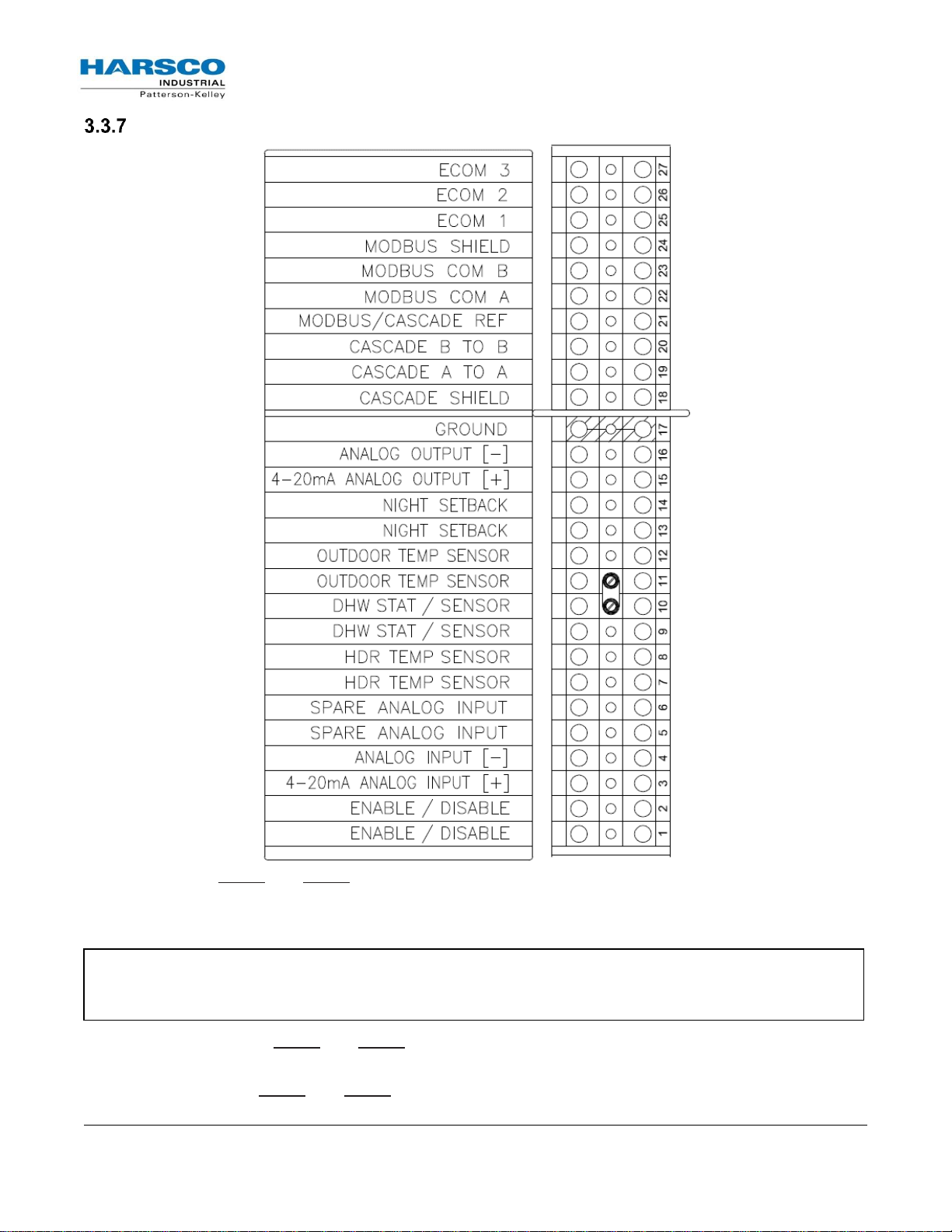

High Voltage (TB2) Terminal Block (SC3000 & SC4000)

Start Interlock #2 –

The Start Interlock #2 TB2-1 and TB2-2 terminals are in series with Start Interlock

#1 and provide additional connection points for auxiliary safety devices. This circuit is energized with

120VAC, so the contacts on any auxiliary safety devices must be rated for minimum 120VAC.

Start Interlock #1 –

The Start Interlock #1 TB2-3 & TB2-4 terminals can be used for auxiliary safety

devices such as damper limit switches, control valve limit switches, emergency stop buttons, and low

water cutoff devices. This circuit is energized with 120VAC, so the contacts on any auxiliary safety

devices must be rated for a minimum of 120VAC. The appliance ships with a factory-installed jumper