&

&

&

&

&

&

&

&

&

Revised Januar y 13, 2015

INSTALLATION

OWNER ’ S

P-K SONIC™ GAS FIRE D BOILER

SC-2000/SC-3000/SC-4000

Natural Gas/Propane/Dual Fuel

Part # 1004 90 59 78

C.S.A Design-Certified

Complies with ANSI Z21.13/CSA 4.9

Gas-Fired Low Pressure Steam and Hot Water Boilers

ASME Code, Section IV

Certified by Patter son-Kelley

M A N

U

A L

INSTALLATION

OWNER ’ S

M A N

U

A L

INSTALLATION

OWNER ’ S

M A N

U

INSTALLATION

OWNER ’ S

M A N

U

INSTALLATION

OWNER ’ S

A L

A L

CERTIFIE D

Model Number:

Serial Number:

Start-Up Date:

Harsco Industrial , Patterson-Kelley

155 Burson Street

East Stroudsburg, PA 18301

Telephone: 570.476.7261

Toll Free: 877.728.5351

Fax: 570.476. 7247

www .harscopk.com

©2015 Harsco Industrial, Patterson-Kelley

Released: 1/13/15

C.S.A Design-Certified

Complies with ANSI Z21.13/CSA 4.9

Gas-Fired Low Pressure Steam and Hot Water Boilers

M A N

U

A L

INSTALLATION

OWNER ’ S

M A N

U

A L

INSTALLATION

OWNER ’ S

M A N

U

A L

INSTALLATION

OWNER ’ S

M A N

U

A L

INSTALLATION

OWNER ’ S

M A N

U

A L

Gaass FFiirreedd BBooiilleerr

Installation and Operation Quick Reference

Fuel/Gas Supply

• Refer to Section 3.6 for information on proper sizing of the gas supply piping. Undersized gas

piping with too much pressure drop will negatively impact the boiler’s performance.

• Install a lock-up type gas regulator to supply an appropriate gas pressure as described below:

Natural Gas Propane Gas

Minimum In let Pressure = 4.0” w.c.

Maximum Inlet P ress ur e = 14.0” w.c.

Minimum In let Pressure = 7.0” w.c.

Maximum Inlet P ress ur e = 14.0” w.c.

• NOTE: Harsco Industrial, Patterson-Kelley recommends installing an individual lock-up type gas

regulator in the gas supply piping to each boiler. For installations where one master lock-up type

gas pressure regulator will service multiple boilers, Patterson-Kelley recommends contacting the

local regulator representative for application assistance specifying the appropriate lock-up type

regulator and gas pipe sizing.

Electrical/Power Supply

• Carefully inspect the boiler’s nameplate labels which describe the power supply requirements.

• Provide an appropriate power feed to the boiler with overcurrent protection:

Boiler Model Power Supply Requirements

SC-2000 (240V)

SC-3000 / SC-4000 (240V)

SC-3000 / SC-4000 (480V)

208-240VAC, single phase, 60Hz sized for 15 Amps.

208-240VAC, three phase, 60Hz sized for 20 Amps.

460-480VAC, three phase, 60Hz sized for 20 Amps.

• NOTE: The SC-3000 & SC-4000 MUST be ordered to the correct voltage! IT IS NOT

POSSIBLE to convert an SC-3000 or SC-4000 between the 240V and 480V configurations in

the field.

• Prior to startup, carefully check all electrical connections for tightness as

connections can come lose during shipping.

Exhaust Venting

• The P-K SONIC boilers are dual-certified as Category II & Category IV appliances,

capable of oper atin g with slightly negative to slightly positive exhaust pressure. It is

critical to ensure the flue venting material is suitable for use with the boiler.

• For Category II installations, ensure the flue venting system is designed to maintain

a slightly negative exhaust pressure which does not exceed -0.04” w.c.

• For Category IV installations, ensure the flue venting system is designed to maintain

a slightly positive exhaust pressure which does not exceed +0.22” w.c.

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

2

Gaass FFiirreedd BBooiilleerr

Hydronics/Water Flow (SC-2000)

• The chart below represents the pressure drop (Ft of Head) versus the water flow rate (GPM) for

the SONIC SC-20 00. This information is useful to help size an appropriate circulatio n pump.

Keep in mind this pressure drop represents the boiler only, additional consideration is needed for

any connected piping, valves, strainers, couplings, flanges, etc.

• The table below summarizes the minimum and maximum flow restrictions for the SC-2000:

Flow Condition Boiler Operation Flow Rate Approximate ∆T

Maximum Flow High Fire 192 GPM 20°F

Minimum Flow Ignition 48 GPM 20°F

Minimum Flow Low Fire 38 GPM 20°F

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

3

Gaass FFiirreedd BBooiilleerr

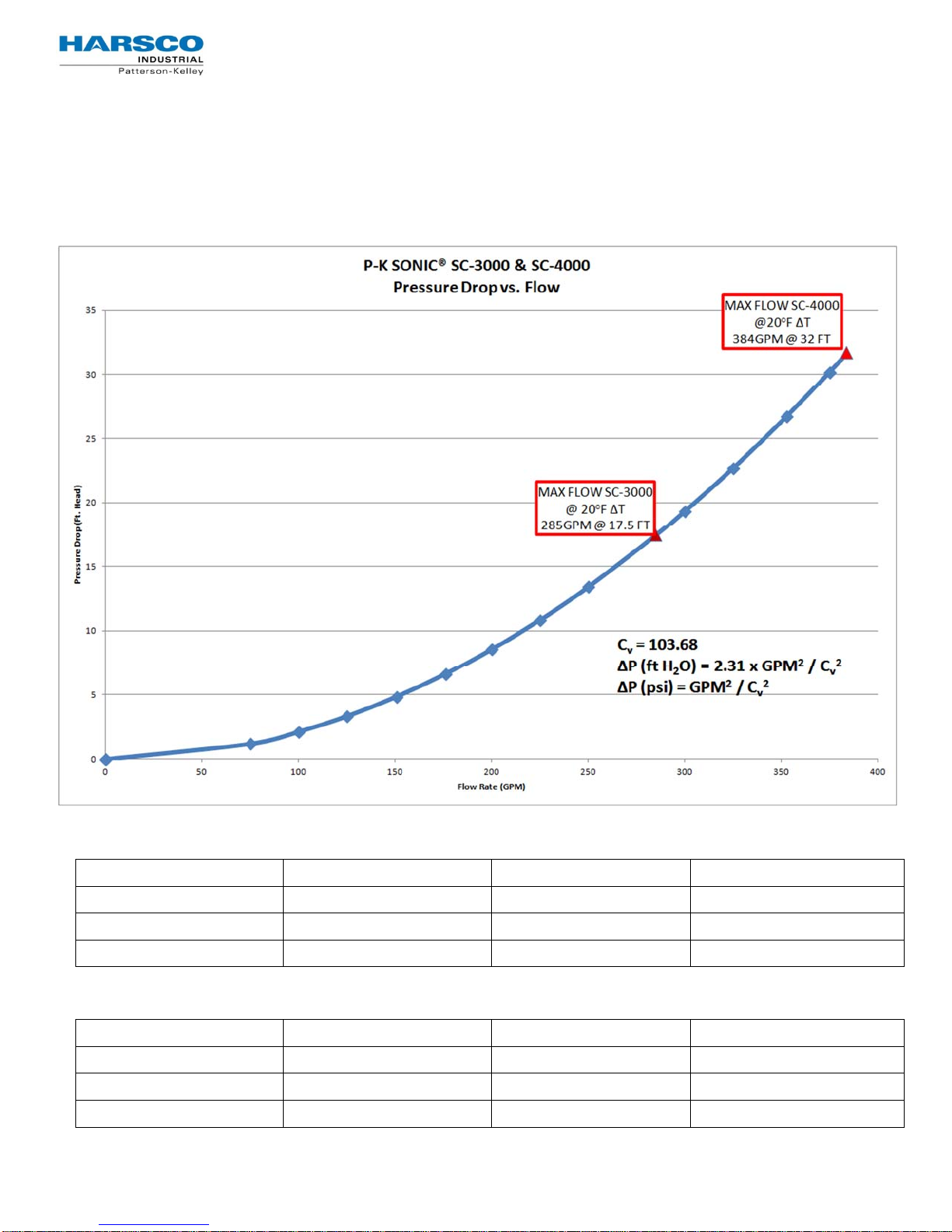

Hydronics/Water Flow (SC-3000 & SC-4000)

• The chart below represents the pressure drop (Ft of Head) versus the water flow rate (GPM) for

the SONIC SC-3000 & SC-4000. This information is useful to help size an appropriate circulation

pump. Keep in mind this pressure drop repres ents the boiler only, additional consideration is

needed for any connected piping, valves, strainers, couplings, flanges, etc.

• The table below summarizes the minimum and maximum flow restrictions for the SC-3000:

Flow Condition Boiler Operation Flow Rate Approximate ∆T

Maximum Flow High Fire 285 GPM 20°F

Minimum Flow Ignition 72 GPM 20°F

Minimum Flow Low Fire 57 GPM 20°F

• The table below summarizes the minimum and maximum flow restrictions for the SC-4000:

Flow Condition Boiler Operation Flow Rate Approximate ∆T

Maximum Flow High Fire 384 GPM 20°F

Minimum Flow Ignition 98 GPM 20°F

Minimum Flow Low Fire 76 GPM 20°F

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

4

Gaass FFiirreedd BBooiilleerr

Table of Contents

1 Introduction 6

2 Safety 8

2.1 General 8

2.2 Safety Prec autions 8

2.3 Training 9

2.4 Hazard Warnings 9

3 Installation 11

3.1 Receiving and Storage 11

3.2 Compliance with Codes 11

3.3 Setup 12

3.4 Electric al Connec tions 13

3.5 Inlet Air and Exhaust V enting 17

3.6 Gas Piping 27

3.7 Boiler Wat er Piping 28

3.8 Pre-St art Chec kli st 30

3.9 Safety Checks 30

3.10 Initial NURO Control Setup & Adjustment 32

3.11 Fuel/Air A djusment 34

4 Operations 36

4.1 General 36

4.2 Normal Lighting and Shut-down Procedures 37

4.3 Emergency S hut-Of f 37

4.4 Typical Boiler Operating Conditions 37

5 Maintenance 38

5.1 Maintenance and I nspect ions Schedule 38

5.2 Cleaning the Burner & Combustion Chamber 39

5.3 After Repai r s or Maintenance 40

5.4 Sequence of Operat ion 41

5.5 Troubl eshooting 42

6 Parts/Tech Support 44

6.1 Wiring Diagrams 44

6.2 Boiler Part s Identif ication (SC-2000) 55

6.3 Boiler Part s Identif ication (SC-3000 & SC-4000) 59

7 Warranty 65

Boiler Fire-Test Report

66

Appendix 1: Maintenance Log 67

Appendix 2: Boiler Altitude Derate Sch. 68

Appendix 3: Water Quality Standards

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

69

5

WARNING: If the information

in this manual is not

followed, a fire or explosion

may result causing property

damage, personal injury or

loss of life.

Do not store or use gasoline or

other flammable vapors or

liquids in the vicinity of this or

any other appliance.

Installation and service must be

performed by a qualified

installer, service agency, or the

gas supplier.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electrical switch;

do not use any phone in your

building.

Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

If you cannot reach your gas

supplier, call the fire department.

It is essential to read, understand,

and follow the recommendations of

this manual before installing,

operating or servicing this

equipment. Failure to do so could

result in personal injury or death.

Installation and service must be

perform ed by a qu al ified and

knowledgeable individual who has

been certified on the P-K Sonic™

Boiler. The feature s which permit

this boiler to achieve highefficiency performance can be

misused which could result in

personal injury or death.

Gaass FFiirreedd BBooiilleerr

1 INTRODUCTION

This manual describes the installation and operation of the

following

SC-2000:

Natural Gas, 208-240V (single phase)

Propane Gas, 208-240V (single phase)

SC-3000:

Natural Gas, 240V (three phase)

Natural Gas, 480V (three phase)

Propane Gas, 240V (three phase)

Propane Gas, 480V (three phase)

SC-4000:

Natural Gas, 240V (three phase)

Natural Gas, 480V (three phase)

Propane Gas, 240V (three phase)

Propane Gas, 480V (three phase)

If you have any questions on the information contained within,

or do not fully and completely understand the content, please

contact Harsco Industrial, Patterson-Kelley Technical Service at

570.476 .7 26 1 or tol l free at 877. 72 8. 5351.

The

variable speed combustion blowers, sophisticated

microprocessor controls, modulating gas safety shut off/control

valves and a unique stainless steel heat exchanger capable of

operating in a fully condensing mode to provide maximum

efficiency in a minimum amount of space.

While specific details may differ slightly, basic operation is the

same for all models. Check the rating plate for correct fuel

usage and gas pressur es .

The boiler is only a part of the complete heating system. This

boiler may be fully operational and yet because of poor

circulation, control, or other operating characteristics may not

deliver heat to the desired location. Additional equipment such

as temperature sensors, pumps, flow switches, balancing

valves, and check valves will be required for satisfactory

operation of any system. Harsco Industrial, Patterson-Kelley

cannot be responsible for the design or operation of such

systems and a qualified engineer or contractor must be

consulted.

P-K SONIC™ boilers featuring NURO controls:

P-K SONIC™ gas fired boilers are fully modulating using

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

6

REVISION NOTES:

1/13/2015 – Revised flame signal information.

12/10/14 – Revised to include SC-2000 & NURO controls.

07/8/14 – Edited text, made grammar corrections.

Gaass FFiirreedd BBooiilleerr

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

7

r

2 S

AFETY

2.1 General

The SC-2 0 00, SC-3000 and SC-4 00 0 gas-fired boilers must be:

• Instal led, operated, and serviced in ac c or danc e with instructions

contained i n this manual and other supplemental manuals.

• Instal led by qualified personnel in accordanc e with designs prepared by

qualified facility engineers includi ng: str uc tural, mechanical, electrical, and

other applicable disciplines.

• Operat ed and serviced in accordance with a comprehensive safety

program det ermined and established by the customer. Do not attempt to

operate or servic e until such a pr ogr am has been established.

• Operat ed and serviced by experienced, qualif ied, and properly trained

personnel in accor danc e with all applicable codes, laws, and regulations.

2.2 Safety Precautions

Provide a suitable location for the boiler, away from normal personnel

traffic, with adequate working space, adequate clearances, proper

ventilation and lighting, with a structure sufficiently strong and rigid to

support the weight of the boiler, all piping, and accessories.

Gas Fired Boile

N

OTICE

Each safety device must be

maintai ne d an d chec ked per the

recommended schedule. Refer to

Section 5. 1 of this manual.

!

Safet y Feat ur es

It is the responsibility of the

customer to ensure external safety

provisions, such as but not limited

to: guards, safety labels, safety

controls, interlocks, lockout devices,

are in place and operable.

Safet y Labe ls

The following words are used in this

manual to denote the degree of

seriousness of the individual

hazards.

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury. This

signal word is to be limited to the

most extreme situations.

Indicates a potentially hazardous

situation which, if not avoided, coul d

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

8

N

OTICE/NOTE - NOTICE

Is the preferred signal word to

address pr acti ces not rela ted to

personal injury. The safety alert

symbol is not used with this signal

word.

r

Gas Fired Boile

NOTICE!

The safety labels shown below are

affixed to your boi ler. Although the

labels are of high quality, they may

become dis l o dg ed or unr e adable

over time. Contact Harsco

Industrial, Patterson-Kelley at

570. 476.7261 or toll-f r ee at

877.728. 5 35 1 for repl ac ements.

Gas may lose its odor. Proper gas

sensing eq ui pment and pr ocedures

should be used for leak checks.

Failure to detect gas leaks could

result in injury or death.

2.4.4 Press u re Haz a rd s

Pressure Hazard! Hot fl uids. Install isolation valves on boi ler water inlet and outlet. Make sure

isolati on valves are closed before servicing boiler .

Pressure Hazard! Hot fl uids. Annually test safety relief v alve(s) for proper operation. Do not operate

boiler with faulty relief valve(s).

2.3 Traini ng

Proper training is the best protection against accidents. It is

essential to read, understand, and follow the recommendations of

this manual before installing, operating, or servicing this

equi pm en t. Fa il ur e to do s o coul d res ult in fir e or ex pl osi on a nd

serious injury , death, and/or property damage.

Operating and service personnel must be thoroughly familiar with

the basic construction of the SC-2000,

boilers, the use and locations of the controls, the operation of the

boilers, adjustment of their various mechanisms, and all applicable

safety precautions. If any of the provisions of this manual are not

fully and completely understood, contact Harsco Industrial,

Patt er s on- K ell ey Tec hni c al Ser v i ce at

877.728.5351.

2.4 Hazard Warnings

2.4.1 Elect rical Hazard s

Shock Hazard! Properly lockout/tagout the electrical

service and all other energy sources before working on

2.4.2 Crush Hazards

or near the boiler .

Shock Hazard! Do not spray water directly on this

boiler or any electrical components.

Electrical Haz ard! Do not alter wiring connections.

Lifting Hazards! Use properly rated lifting equipm ent

to lift and position the boiler. The load is unbalanced.

Test the balanc e before lifting off the floor. Do not

allow personnel beneath the lifted load. Refer to the

approxim ate weights in the table.

Boiler Model Weight in Pounds

SC-2000 1,450 lbs

SC-3000 1,850 lbs

SC-4000 1,900 lbs

2.4.3 Bump Hazard from Overhead Ductwork and Piping

Injury Hazard ! Install c om ponents with adequate

vertical clearance.

SC-3000 and SC-4000

570.476.7261 or toll free at

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

9

r

2.4.5 Slip, Fall Hazards

Tripping Hazard! Do not install piping on floor surfaces. Maintai n a clear pat h ar ound the boiler.

Slip and Fall Hazard ! Use a drip pan to catch water while draining the boil er. Maintain dry floor surfaces.

Slip and Fall Hazard ! Do not locate intake or exhaust terminati ons di r ectly above a walkway; dripping of

condensate can cause ic ing of the walking surface. Refer to Section 3.5.

Fall Hazard! Do not stand on boiler.

2.4.6 Chemical Hazards

Chemical Hazard s from Clean in g Product s. Use

caution when cleaning the system. The use of

professional assistanc e is recommended. Use safe

procedures for t he disposal of all cleaning soluti ons.

Combustion Condensate – An acidic pH of

approxim ately 3. 0 to 5.0 can be ex pec t ed. Use PVC, CPVC, or other c or r osi on r esi stant piping for

drainage. Coll ection and disposal must be in accordance with all applicable regulations. A condensate

neutralizati on ki t is available. Please contact your loc al Har sco I ndustr ial, Patterson-Kelley representative

for more i nfor matio n.

2.4.7 Burn, Fire and Explosion H azards

Burn, fire, and ex pl osi on hazar ds! Installation must be in s tric t con fo r mance to a ll applicable codes

standards including NFPA 54, AN SI Z223.1 and CAN/CSA B.1 49. Install all required vent lines for gas

devices. Refer to Section 3.5 .

Hazard from Incorrect Fuels! Possible fire, e xplosion, overheating, and d amage. Do not use any fu e ls

except the design fuels for the unit.

Overfire Hazar ds! H igh pressure in gas s upply could result in o ver firing o f th is or o ther devices supplied

from the same source.

Fire a n d E x plo s i on Ha z ar ds! Clos e the ma in gas s hut o f f before ser vicing boiler.

Fire and Explosion Hazards! Do not store or use gaso line or o ther fla m mab le vapors or liquids in the

vicinity of this or any other gas fired appliance.

Burn hazard! Possible hot sur faces . Do not touch gas vent during firing op era tion. Us e only factory

recommended vent componen ts.

Burn Hazard! Pipes, vents, a nd bo iler co mpon ents could be hot. Do not touch p iping or stack surfa ces

during operation or im med iat e ly afte r shutdown of the boiler.

Burn Hazard! Hot flue! Use caution when ser vicing or d r aining boiler.

Fire and Explosion Hazards! Use caution when ser vicing bur ner. P rop ane ( LP G) is heavier than air and

may linger in the combustion chamber , vent lines, or elsewhere .

Gas Leak Hazard! Make sure the burner is installed correctly and blower/trans ition is securely fastened

following any maintenance perfor med on them. These conne ctions may leak gas if assembled incorrectly.

Gas Leak Hazard! A ll threaded gas connections must be made using a pipe compound that is resistant to

liquefied petro leum gas . Do not use Teflon™ tape on thr eaded g as piping.

Gas Leak Hazard! Check entire gas tra in for leaks after insta llation. If there is a s me ll of gas, sh ut d ow n the

boiler and obtain immediate assistance from trained ser vice personnel and/or your local fire department .

Overfire Hazard! Poss ible fire and explosion from excess gas pressure. Make sure that gas inlet pressure

does not exceed 14 inches w .c.

Overfire Hazard! Possible fire and explosion. Possible malfunction of regulators and/or gas safety shut

off/control valves. Maintain all gas train components in good condition. Do not alter wiring connections.

Annual inspec tion by facto r y-t ra ined pe rs onne l for pr oper set-up and opera t ion is recommended.

Overfire and Underfire Hazards! Poss ible fire, explosio n, overheating, and compon ent failure. Do not

attempt to adjust firing ra te o f the bo iler. The firing rate mus t be adjus ted on ly by fac to ry trained personnel.

Gas Fired Boile

and

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

10

r

3

I

NSTALLATION

Gas Fired Boile

Installation and service must be

performed by a qualified installer,

service agency, or gas supplier.

Failure to install the equipment in

accordance with this manual could

result in an unsafe operating

condition.

NOTICE!

Controls and other equipment that

are damaged or fail due to weather

exposure are not covered by

warranty.

The wheels provided with this

boiler are for positioning purposes

only. When positioning this boiler,

maintain positive control of it at all

times. Do not attempt to move the

boiler on surfaces that are not

level. Failure to heed this warning

could result in personal injury or

death.

NOTICE!

The boiler may be installed on a

combustible floor; however, the

boiler must never be installed on

carpeting.

Bumping hazard from overhead

ducts! Install all components with

adequate vertical clearances.

Insufficient clearance can restrict

the service access, increasing the

possibility of injury.

3.1 Receiving and Storage

3.1.1 Initial Inspection

Upon receiving the boiler, inspect it for signs of shipping damage.

Some damage may be hidden. Unpack the boiler, open the front

and side doors and inspect the boiler. Verify that the total number

of pieces shown on the packing slip agrees with those actually

received.

3.1.2 Storage Prior t o In s t all at ion

If the boiler is not installed immediately, it must be stored in a

location adequately protected from the weather, preferably indoors.

If this is not possible, then it should remain in the shipping container

and be covered by a tarpaulin or other waterproof covering.

3.2 Compliance with Codes

The boiler with standard components and with many options

complies with American National Standard/CSA Standard ANSI

Z21.13/CSA 4.9, latest edition, Gas-Fired Low Pressure Steam and

Hot Water Boilers.

The SC-2000 heat exchanger is constructed and stamped in

accordance with ASME Boiler and Pressure Vessel Code, Section

IV (160 psig maximum operating pressure).

The SC-3000 and SC-4000 contain two separate heat exchangers

constructed and stamped in accordance with ASME Boiler and

Pressure Vessel Code, Section IV, and Section VIII – Division 1

(160 psig maximum operation pressure).

Installation of the boiler must conform to all the requirements of all

national, state and local codes established by the authorities having

jurisdiction or, in the absence of such requirements, to the National

Fuel Gas Code, ANSI Z223.1/NFPA 54 latest edition in the U.S. In

Canada, the equipment shall be installed in accordance with the

current Installation Code for Gas Burning Appliances and

Equipment, CAN/CSA-B.149, latest edition, and applicable

Provincial Regulations for the class, which should be carefully

followed in all cases. Authorities having jurisdiction should be

consulted before making any installation.

Where required by local codes, the installation must conform to

American Society of Mechanical Engineers Safety Code for

Controls and Safety Devices for Automatically Fired Boilers (ASME

CSD-1).

In the Commonwealth of Massachusetts (a) this unit must be

installed by

cocks must be “T” handle type, (c) piping of condensate shall

conform to the State Plumbing Code, and (d) refer to the

Massachusetts Supplement for further details.

a licensed pipe fitter/plumber, (b) field installed gas

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

11

r

Gas Fired Boile

3.3 S

etup

3.3.1 Foundation

Provide a firm, level foundation, preferably of concrete. Lifting the front of the boiler slightly will allow the boiler

to be rolled off the shipping skid onto the concrete foundation. Once in position, the wheel bolts may be removed

allowing the wheels to recess up into the boiler. The base will sit flat on the provided foundation. If the boiler is

to be pulled out for maintenance, the wheels may be left attached.

3.3.2 Plac ement

The boiler must be level to function properly. Six 9/16” holes in the base may be used for 3/8” anchor bolts.

3.3.3 Clearances

If the boiler is to be installed near combustible surfaces, the minimum clearances shown in Table 3.3.3 and

Figure 3.3.3. must be maintained. Failure to provide for the service access clearances, even with non-

combustible surfaces, may cause future problems servicing the boiler. Maintain a clearance from the vent to

combustible surfaces of 24” or as specified in the vent manufacturer’s listed installation instructions. The boiler

must be installed in a space large enough in comparison to the boiler as described in the National Fuel Gas

Code, ANSI Z223.1, latest edition.

Table 3.3.3

Type of Surface Dimensions (inches)

Combustible Surfaces Minimum Clearances 30 12* 24† 12**

Recommended Clearances for Service Access

Figure 3.3.3

A B C D

30 12* 24† 12**

* “B” Clearance depends upon exhaust vent configuration.

† “C” Space required for pipes, ducts, etc. in this area above the boiler.

** Do not put pipes, ducts, vents, etc in this space. Electrical conduit must be installed

vertically so that the side doors can be opened.

NOTE: Annual maintenance items can be accessed from the front of the boiler.

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

12

r

Gas Fired Boile

3.4 Electrical Connections

The SC-2000 boiler requires 208-240 VAC, single phase, 60 hertz electrical service. The total operating amperage

is indicated on the rating nameplate and the SC-2000 requires less than 15 Amps at full load. Before starting

the boiler, check to ensure that the proper electrical service is connected to the boiler.

SC-3000 and SC-4000 boilers can be manufactured for 208-240 VAC, three phase, 60 hertz electrical service

The

440-480VAC, three phase, 60 hertz electrical service. The total operating amperage is indicated on the rating

OR

nameplate and the SC-3000 & SC-4000 boilers require less than 20 Amps at full load. Before starting the boiler,

check to ensure that the proper electrical service is connected to the boiler.

NOTE: The SC-3000 & SC-4000 MUST be ordered to the correct voltage! IT IS NOT POSSIBLE to convert

an SC-3000 or SC-4000 between the 240V and 480V configurations in the field.

An external electrical disconnect (not supplied with the boiler) i s required. Refer to Section 6.1 for proper wiring

and configuration of the electrical connections. The boiler electrical service must be installed and grounded in

accordance with local codes or in the absence of such requirements, in the U.S. with National Electrical Codes,

ANSI/NFPA No. 70 latest edition or, in Canada, to the Canadian Electrical Code, Part I,

Installed conduit must not block any of the boiler’s openings and must allow the side doors to be opened.

3.4.1 Single Phase Power Supply Connection (SC-2000 Only)

High Voltage (TB2) Terminal Block

The SC-2000 must be supplied with 208-240VAC, single phase, 60 hertz electrical service. The SC-2000

features four dedicated power terminals on the High Voltage (TB2) terminal block. Figure 3.4.1 shows the

Low Voltage (TB1) and High Voltage (TB2) terminal blocks on the SC-2000 with the front door hidden for

clarity:

CSA C22.1, latest edition.

TB2 Terminal 1 = HOT L1

TB2 Terminal 2 = HOT L2

TB2 Terminal 3 = NEUTRAL

TB2 Terminal 4 = GROUND

NOTE:Theseterminalscan

accommodatemaximum10AWG

wire.

CAUTION:Donotover‐tighten

theterminalscrews.Maximum

tighteningtorque=6in‐lbs!

LowVoltage(TB1)TerminalBlock

HighVoltage(TB2)TerminalBlock

Figure3.4.1

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

13

r

3.4.2 Three Phase Power Supply Connection (SC-3000 & SC-4000 Only)

Main Power Connecti on Box

Check the rating nameplate of the SC-3000 or SC-4000 boiler to determine the required electrical service:

208-240VAC, three phase, 60 hertz

440-480VAC, three phase, 60 hertz

The incoming three phase power for the SC-3000 & SC-4000 boilers is connected to the over-current safety

device (rated for 20 Amps) and the Ground terminal located in the main power connection box. Figure 3.4.2

shows the Low Voltage (TB1) and High Voltage (TB2) terminal blocks, plus the Main Power Connection Box

on the SC-3000 & SC-4000 with the front door hidden for clarity:

Terminal 1 = HOT L1

Terminal 3 = HOT L2

Terminal 5 = HOT L3

Terminal G = GROUND

The Main Power Connection Box features a Control Transformer which steps down two hot leads from the

incoming three-phase power in order to supply 110-120VAC single phase power to the boiler’s control system.

Be aware that SC-3000 & SC-4000 boilers ordered in the 240V configuration, are pre-wired from the factory for

operation with 240 VAC three phase incoming power.

If 208 VAC three phase power is supplied to the boiler, the internal control transformer must be re-wired for

operation at this lower voltage. The wire in terminal X3 on the load side of the internal control transformer must

be moved to terminal X4. This supplies the 120 VAC power to the controls from the 208 VAC main voltage.

Refer to Section 6.1.4 for proper wiring and configuration of the internal control transformer.

Gas Fired Boile

NOTE:Thehotleadterminalscan

accommodatemaximum12AWG

wire.Thegroundterminalcan

accommodatemaximum8AWG

wire.

CAUTION:Donotover‐tightenthe

hotleadterminalscrews.Maximum

tighteningtorque=13in‐lbs!

LowVoltage(TB1)TerminalBlock

HighVoltage(TB2)TerminalBlock

MainPowerConnectionBox

ControlTransformer

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

Figure3.4.2

14

r

Gas Fired Boile

3.4.2 Hi gh Voltage (TB 2) Terminal Blo ck

Be sure to check the nameplate on

the boiler before connecting the

electrical supply.

N

OTICE

!

A dedicated earth ground (green

wire) is required to avoid nuisance

shutdowns. Do not ground through

the conduit!

The high voltage (TB2) terminal

block on the SONIC SC-2000 with

NURO controls contains two hot

leads (

lead (

(

GROUND

HOT L1 & HOT L2

NEUTRAL

) and a ground lead

) for 208- 240 VAC,

), a neutral

single phase 60Hz electrical

supply. This terminal block (TB2)

also contains dry-contact relays

with a maximum voltage rating of

240VAC

and

1/2 Amp

maximum

current capacity. Incorrect wiring

can result in equipment damage,

injury or death.

The high voltage (TB2) terminal

block on the SONIC SC-3000 &

SC-4000 with NURO controls

contains dry-contact relays with a

maximum voltage rating of

and

1/2 Amp

maximum current

240VAC

capacity. Incorrect wiring can

result in equipment damage, injury

or death.

Start Inter lock #1 – The Start Interlock #1 terminals can be used

for auxiliary safety devices such as damper end limit switches,

control valve end limit switches, emergency stop buttons, and low

water cutoff devices. This circuit is energized with

120VAC

contacts on any auxiliary safety devices must be rated for a

minimum of

120VAC

.

Start Inter lock #2 – The Start Interlock #2 terminals are in series

with Start Interlock #1 and provide additional connection points for

auxiliary safety devices. This circuit is energized with

120VAC

the contacts on any auxiliary safety devices must be rated for

minimum

120VAC

.

The boiler ships with a factory-installed jumper across Start

Interlock #1 and Start Interlock #2 terminals. Remove the

jumper(s) if using any auxiliary safety devices.

NOTE: Both the Start Interlock #1 and Start Interlock #2 circuits

must close within 5 minutes of a call for heat. Failure to close

the Start Interlock circuit will cause the boiler to lockout on

alarm.

Auxiliary Input #1 – These terminals are reserved for future use.

This circuit is energized with

120VAC

.

Auxiliary Input #2 – These terminals are reserved for future use.

This circuit is energized with

120VAC

.

Air Damper Interlock – The Air Damper Interlock provides

dedicated terminals for proof of open end limit switch on a

motorized air damper. This circuit is energized with

120VAC

contacts on the end limit switch must be rated for minimum

The boiler ships with a factory-installed jumper across the Air

Damper Interlock terminals. Remove the jumper if connecting

a motorized air damper with end limit switch.

Relay A – User-configurable relay output #1. The normally-open

contacts on this relay have a maximum voltage rating of

and maximum current capacity of

Relay B – User-configurable relay output #2. The normally-open

1/2 Amp

.

contacts on this relay have a maximum voltage rating of

and maximum current capacity of

Relay C –

User-configurable relay output #3. The normally-open

1/2 Amp

.

contacts on this relay have a maximum voltage rating of

and maximum current capacity of

1/2 Amp

.

, so the

, so

, so the

120VAC

240VAC

240VAC

240VAC

.

Relay D –

rating of

User-configurable relay output #4. The normally-open contacts on this relay have a maximum voltage

240VAC

and maximum current capacity of

NOTE: Relays A thru D can be user-configured through the NURO touch screen interface to control devices

such the Comfort Heat (CH) Pump, Domestic Hot Water (DHW) Pump, Air Damper, System Pump, etc.

Mast er A l arm Rel ay – The Master Alarm Relay terminals are normally-open dry contacts that close in the event

of an alarm output from the boiler control.

Refer to Section 6.1 for proper wiring and configuration of the electrical connections.

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

1/2 Amp

15

.

r

3.4.3 Low V o lt age (TB 1) Term in al Blo ck

Gas Fired Boile

Enable/Disable –

TB1-1 and TB1-2 can be used to remotely enable or disable the boiler. The functionality of

these terminals is user-configurable through the NURO controls, but generally closure of the Enable/Disable

circuit provides a call for heat to the boiler. Opening this circuit prevents the boiler from running.

The boiler ships with a factory-installed jumper across the Enable/Disable terminals. This circuit is energized

with a

4-20mA Analog Input –

24VAC potential, so the contacts on any remote enable devices must be rated for minimum 24VAC.

TB1-3 and TB1-4 can be used to provide a remote analog 4-20mA control signal to the

boiler. This analog signal can be used to change the boiler’s operating setpoint or firing rate.

Spare Analog Input –

TB1-5 and TB1-6 are reserved for future use.

HDR Temp Sensor – TB1-7 and TB1-8 can be used to connect a remote header temperature sensor, installed

in the primary hydronic system piping, downstream of all the boilers. This temperature sensor must be a 2-wire

12kΩ NTC thermistor. This circuit is energized by the boiler with a

DHW Stat/Sensor –

TB1-9 and TB1-10 can be used to connect either an aquastat or remote DHW temperature

5VDC potential.

sensor installed in a domestic hot water storage tank. If using an aquastat, use a SPST normally-closed, break

on rise type with either a fixed or adjustable deadband above and below the setpoint.

Alternatively, if using a temperature sensor, it must be a 2-wire 12kΩ NTC thermistor and be of sufficient length

to measure an accurate storage tank temperature. This circuit is energized by the boiler with a

Outdoor Temp Sensor –

TB1-11 and TB1-12 can be used to connect an outdoor air temperature sensor which

5VDC potential.

allows the NURO control to be programmed to run an outdoor air schedule. The outdoor air temperature sensor

must be a 2-wire 12kΩ NTC thermistor and should be installed on the North face of the building and shielded

from direct sunlight exposure. This circuit is energized by the boiler with a

5VDC potential.

Night Setback –

TB1-13 and TB1-14 can be used to connect a day/night or occupancy timer. Closure of the

Night Setback circuit enables the Night Setback mode which reduces the boiler’s operating setpoint. Opening

this circuit resumes normal operation. This circuit is energized by the boiler with a

on the day/night timer must be rated for minimum

4-20mA Analog Output –

TB1-15 and TB1-16 provide a 4-20mA analog output signal which tracks the boiler’s

5VDC.

5VDC potential, so the contacts

firing rate. When operating at full power (maximum firing rate), the boiler will provide a 20mA output. When

operating at mimimum power (minimum firing rate), the boiler will provide a 4mA output.

Ground –

TB1-17 provides an equipment (frame) ground connection for input, output, or communication

connections. For independently powered control devices, it may be necessary to create a common ground.

Cascade Shield & Cascade –

TB1-18, TB1-19 and TB1-20 can be used to setup a cascade system with multiple

SONIC boilers with NURO controls. Terminals TB1-19 and TB1-20 are reserved for the cascade communication

between the master and member boilers. Terminal TB1-18 should be used to connect the cascade

communication wiring shield between all boilers. The cascade and shielding must be wired from the master

boiler to each individual member boiler in a daisy-chain fashion. NOTE: Only ground the shield at the master

boiler.

MODBUS COM & MODBUS Shield –

TB1-22, TB1-23 and TB1-24 can be used to integrate the boiler with a

Building Management System (BMS), Protocol Converter, or other device capable of RS-485 2-wire MODBUS

communication. Terminals

TB1-22 and TB1-23 are reserved for MODBUS and terminal TB1-18 provides a

connection for the MODDBUS communication wire shield. NOTE: Only ground the shield at the master boiler.

ECOM 1, 2 & 3 –

TB1-25, TB1-26 and TB1-27 can be used to connect a wireless outdoor air temperature sensor.

The wireless receiver should be installed at or near the boiler, and the wireless temperature sensor should be

installed on the North face of the building and shielded from direct sunlight exposure.

Refer to Section 6.1 for proper wiring and configuration of the electrical connections.

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

16

r

Design and installation of venting

systems should be done only be

qualified and knowledgeable

venting systems personnel and in

accordance with vent system

manufacturer’s installation

instructions. Installing a boiler or

vent system using improper

installation methods or materials

can result in serious injury or death

due to fire or asphyxiation.

Before connecting a boiler to a

venting system, it must be

determined whether the boiler is to

be installed in a conventional or

direct vent configuration. In the

US, provisions for combustion air

must be in accordance with NFPA

54/ANSI Z223.1, National Fuel

Gas Code, latest edition, or

applicable provisions of the local

building codes. In Canada,

combustion and ventilation air

openings shall comply with

CAN/CSA B-149.1 Natural Gas

and Propane Installation Code.

For correct installation of vent

system, read all of these

instructions and refer to vent

manufacturer’s instructions.

Failure to use a proper vent system

(types and materials), as described

in this manual will void the boiler

warranty and may result in rapid

deterioration of the venting system,

creating a health or life safety

hazard.

Faulty vent installation can allow

toxic fumes to be released into

living areas. This may cause

property damage, injury or death.

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

Gas Fired Boile

3.5

Inlet Air and Exhaust Venting

3.5.1 A ppli cabl e Cod es and Stand ards

Codes

Unit ed St at es :

Canada:

Standards

These codes and standards contain information for the venting of

gas fired appliances, including, but not limited to vent sizing,

location, clearance to combustibles, and safe installation practices.

The installation must comply with both the above Federal Codes

and with state, provincial and local codes.

Table 3.5.1

Required Stainless Steel Vent Adapters and Category II Motorized

Dampers

Boiler Size Nom.

SC-2000 10” 2640000133 10” 12” 1004906946 12”

SC-3000 10” 2640000133 10” 12” 1004906946 12”

SC-4000 10” 2640000133 10” 12” 1004906989 14”

NOTE: This table is for information only. Combustion air dampers

and vent adapters are listed for use of design and may or may not

be specific to your application.

NFPA 54/ANSI Z223.1 National Fuel Gas Code

NFPA/ANSI 211 Chimneys, Fireplaces, Vents and Solid

Fuel Burning Appliances

CAN/CSA B149.1 Installation Codes for Gas Burning

Equipment

UL 1738 Venting Systems for Gas-Burning

Appliances, Categories II, III and IV

ULC S636-95 Standard for Type BH Venting System

Sheet Metal and Thermoplastic Duct

Construction Manual Air Conditioning

Contractors National Association

(SMACNA)

vent

Size

Stainless

Vent

Adapter

Vent

adapter

size

Boiler

Combustion

Air inlet

Combustion air

N.C. Motorized

Damper

Size

17

r

Gas Fired Boile

A normally-closed motorized combustion air damper with end limit switch is required for Category II vent

installations, and is optional for Category IV vent installations.

120VAC motorized dampers with end limit switches

are available for purchase from Harsco Industrial, Patterson-Kelley. Other damper motor voltages are

acceptable, provided they do not exceed

always

120VAC which is sourced from the boiler itself. All end limit switches must be rated for a minimum 120VAC.

240VAC. The Air Damper Interlock circuit for the end limit switch is

Motorized dampers must be powered from an external power supply

other than the boiler. Figure 3.5.1 shows a sample installation in

which Relay C is user-selected to operate a

120VAC motorized air

damper. Relay C is normally-open, so when the boiler is in standby,

the combustion air damper remains closed. Once a call for heat is

received, Relay C closes the

120VAC circuit (external power supply)

which provides power to the damper motor, opening the damper.

N

OTICE

!

Relay A, Relay B and Relay C are

rated for a maximum voltage of

240VAC and a maximum current

capacity of

1/2 Amp. Connecting a

motorized damper which exceeds

Once the motorized damper is fully-open, its end limit switch

completes the Air Damper Interlock circuit (

120VAC) which allows the

boiler to proceed to ignition.

the voltage or current capacity of

the relay could cause permanent

damage to the relay.

NOTE: The NURO control allows the user to allocate Relay A, B or C for use with a motorized combustion air

damper. Figure 3.5.1 shows Relay C in use for the motorized combustion air damper. Depending on the

user-configuration, Relay A, Relay B, or Relay C can be selected to operate the combustion air damper.

Figure 3.5.1

External power supplies are required for Relay A, Relay B and Relay C. Because power is provided from an

external source, the power is still present when the boiler is turned off. Check all voltage sources have been

disconnected prior to servicing. Failure to do so could result in electrocution, injury, or death.

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

18

r

Gas Fired Boile

3.5.1.1 Gas Vent Categories

Several codes and standards have categorized appliances in accordance with the flue gas temperature and

pressure produced by the appliance. The applicable categories are defined as follows:

• Category II: An appliance that operates with a non-positive vent static pressure and with a vent

temperature that may cause excessive condensate production in the vent.

• Category IV: An appliance that operates with a positive vent static pressure and with a vent temperature

that may cause excessive condensate production in the vent.

• Direct Vent: An appliance that is constructed and installed so that all air for combustion is derived directly

from outdoors and all flue gases are discharged to the outdoors.

3.5.1.2 Venting Materials for Flue/Exhaust Systems

The P-K SONIC™ boilers are dual certified as a Category II and Category

IV appliances, which vents with a temperature that is likely to cause

condensation in the vent. Therefore, any venting system used with the

K SONIC™

boiler must comply with the requirements for either Category II

or Category IV venting systems as specified in the latest edition of

54/ANSI Z223.1

in the US or the latest edition of CAN/CSA B-149.1 in

P-

NFPA

Canada.

CPVC Venting

US: CPVC pipe conforming to ASTM F441. Sch 80 fittings

conforming to ASTM F439. Joints are to be sealed with solvent

conforming ASTM 493.

Canada: CPVC Pipe, Fitting and Sealant listed and labeled to ULC

S-636 Standard for Type BH Venting Systems.

Polypropylene Venting

US and Canada: Polypropylene such as InnoFlue from Centrotherm or

PolyPro from DuraVent or other listed manufacturers. When used, the same

manufacturer's material must be used throughout the system. It is not

permissible to use material from different manufacturers within the same

system.

As per ANSI Z21.13b-2012 * CSA 4.9b-2012:

• The u se of cellu lar core PVC, CPVC and Radel as venting materials is

prohibited.

• The use of external insulation on plastic vent pipe is prohibited.

Acceptable Venting Materials

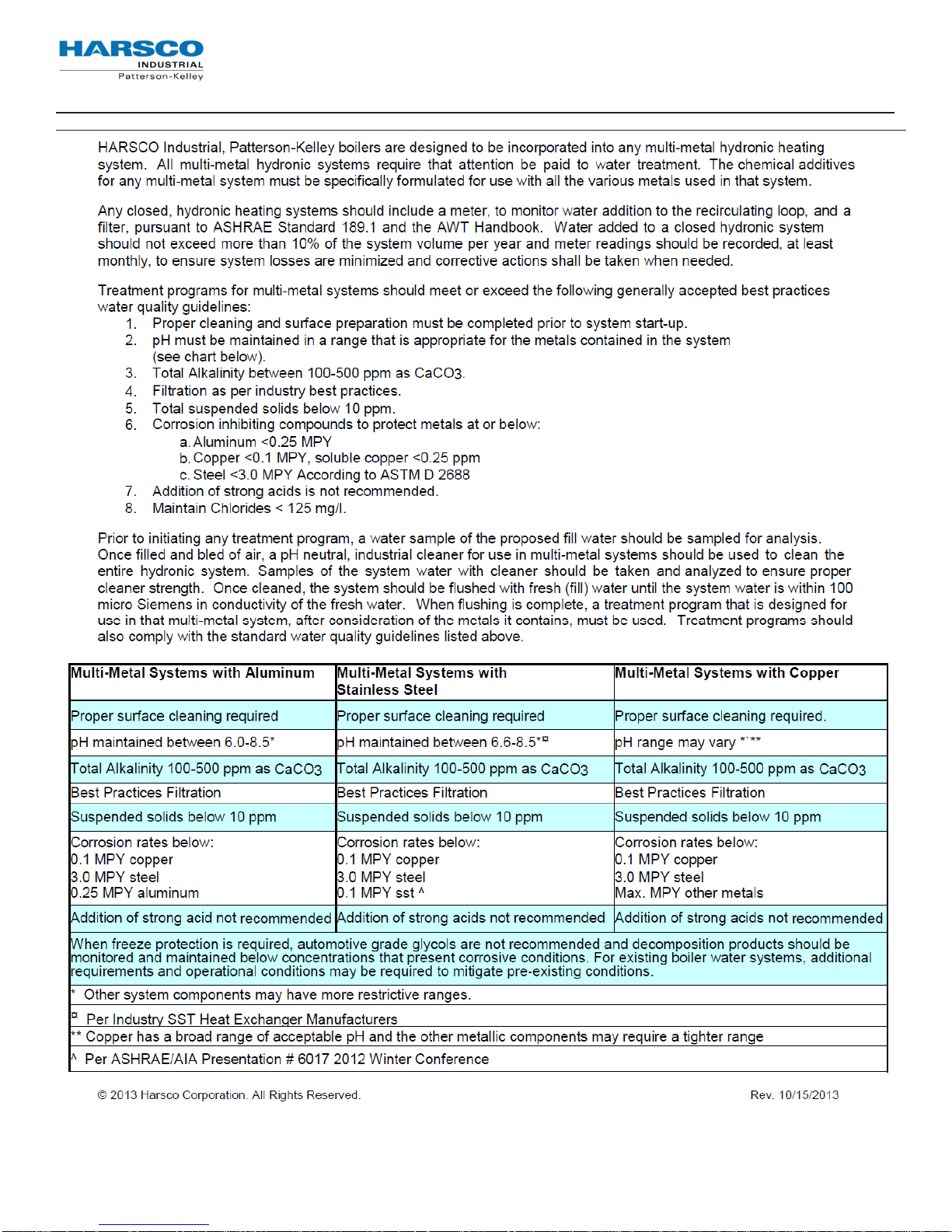

Table 3.5 .1.2

Model Country AL29-4C 316L SS PVC CPVC POLYPROPYLENE

SC-2000 US Yes Yes No Yes Note 2

SC-3000 US Ye s Yes No Yes Note 2

SC-4000 US Ye s Yes No Yes Note 2

SC-2000 Canada Yes Yes No Note 1 Note 1

SC-3000 Canada Ye s Yes No Note 1 Note 1

SC-4000 Canada Ye s Yes No Note 1 Note 1

The venting materials listed are

intended for the venting of gas

burning appliances only. Do not

use these venting materials for

venting liquid or solid fuel (such as

oil, kerosene, wood or coal)

appliances.

Maintain clearances to

combustibles as listed in the vent

manufacturer’s installation

instructions or as set forth in the

codes and standards listed in this

section.

Do not use these vent pipes for

incinerators of any sort!

This boiler is not certified for

use with PVC venting. Use of

PVC venting may result in vent

failure and possible serious

injury or death.

Note 1: When this material is used for venting, it must be listed to ULC-S636.

Note 2: When this material is used for venting, it must be listed to UL-1738.

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

19

r

Gas Fired Boile

3.5.2 Combustion Air Materials and Sizes

The air intake duct can be fabricated from PVC, CPVC, single wall galvanized steel, or other suitable materials.

The duct must be rigid enough to maintain the full required cross sectional area under all operating conditions.

Proper sealing of the intake ductwork is necessary to prevent infiltration of air from conditioned space. Joints in

PVC or CPVC must be cemented. For galvanized duct, wrap each joint and seam with adhesive aluminum tape

or other sealant. The installation of a bird screen on the intake termination is recommended. Ensure that the

screen does not become blocked with snow, ice, insects etc. Combustion air duct should be designed with

maximum 0.22” w.c. friction loss.

Combustion air must be free from dust, lint, etc. The presence of such materials in the air supplied to the burner

could cause nuisance "Low Air" shutdowns or premature burner failure. The boiler should not be operated during

construction while the possibility of drywall dust, demolition dust, etc. exists.

The combustion air supply must be completely free of chemical fumes which may be corrosive when burned in

the boiler. Common chemicals which must be avoided are fluorocarbons and other halogenated compounds,

most commonly present as refrigerants or solvents, such as Freon®, trichloroethylene, perchloroethylene,

chlorine, etc. These chemicals, when burned, form acids which quickly attack the boiler and the boiler stack. The

result is improper combustion and premature boiler failure.

Refer to Table 3.5.2 below which summarizes the combustion air requirements for the SONIC boilers. Ensure

the combustion air piping is of sufficient size (and acceptable equivalent length) in order to carry the required

SCFM with a maximum friction loss of 0.22” w.c.

Table 3.5.2

P-K SONIC™ Boiler Model Required SCFM

SC-2000 420

SC-3000 629

SC-4000 839

Acceptable Materials for Venting Systems

Manufactured Venting Systems

US and Canada:

AL29-4C Stainless Steel Vent Systems listed and labeled to UL1738 Venting Systems for Gas-Burning

Appliances, Categories II, III, and IV

316L Stainless Steel where certified and warranted by the vent manufacturer for venting of Category II, III, or IV

appliances

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

20

r

Gas Fired Boile

3.5.2.1 Air Inlet Requirements — United States (NFPA 54/ANSI Z223.1 & NFPA/ANSI 211)

When air is supplied from inside the building, the total required volume

Under no circumstances shall

the boiler room ever be under a

negative pressure. Particular

care should be taken when

exhaust fans, compressors, airhandling units or other equipment

may rob air from the boiler. Note

that this equipment might be in

rooms other than the boiler room.

This applies to both sealed

combustion and atmospheric room

combustion air applications.

N

OTE

:

1. The required size of openings for

combustion and ventilation air shall

be based on the net free area of the

opening.

2. Screens shall be not smaller than ¼”.

3. Motorized louvers shall be

interlocked with the appliance so that

they are proven open prior to main

burner ignition and operation.

When using two permanent openings, one opening shall commence within

shall be the sum of the required volume for all the appliances located

in the mechanical room. Adjacent rooms furnished with fixed openings

communicating directly with the mechanical room are considered part

of the required volume. The minimum volume is 50 ft

3

(4.8 m

/kW) of installed appliance input capacity.

3

per 1000 Btu/hr

Openings used to connect indoor spaces to obtain the required

minimum volume shall be sized as follows:

• When rooms are on the same floor, each opening shall have an area

2

equal to 1 square inch for each 1000 Btu/hr (2200 mm

appliance input capacity, but not less than 100 square inches. One

opening should commence less than 12 inches above the floor and the

other less than 12 inches below the ceiling. The minimum dimension of air

openings shall be 3 inches.

/kW) of installed

• When rooms are on different floors, each opening shall have an area

2

equal to 2 square inches for each 1000 Btu/hr (4400 mm

appliance input capacity.

When combustion air is supplied from outside the building, the boiler

room shall be provided with one or two openings to ensure adequate

combustion air and proper ventilation.

When using one permanent opening, the opening shall commence

within 12 inches of the ceiling and shall communicate directly with the

outdoors or through a vertical or horizontal duct that communicates to

the outdoors.

Minimum free area of the opening is 1 square inch for each 3000

Btu/hr (700 mm

2

/kW) of installed appliance input capacity, and not less

than the sum of the areas of all vent connectors in the room.

12 inches above the floor and the other

/kW) of installed

within 12 inches below the ceiling, preferably on opposite walls. The openings shall communicate directly, or by way

of ducts, with free outdoor air. The minimum net free area of the openings shall be calculated in accordance with the

following:

• When air is taken directly from outside the building, each opening (minimum of two, as outlined above), 1 square

inch for each 4,000 Btu per hour (550 mm

• When air is taken from the outdoors through a vertical duct into the mechanical room, 1 square inch per 4,000 Btu

2

per hour (550 mm

/kW) of total boiler input is required.

• When air is taken from the outdoors through a horizontal duct into the mechanical room, 1 square inch per 2,000 Btu

2

per hour (1100 mm

/kW) of total boiler input is required.

Table 3.5.2.1 US Minimum area of ventilation openings per boiler (sq inches)

P-K SONIC™

Boiler Model

SC-2000 2000 4000 667 500 500 1000

SC-3000 3000 6000 1000 750 750 1500

SC-4000 4000 8000 1334 1000 1000 2000

INDOOR AIR SUPPLY OUTDOOR A IR SUPPLY

SAME FLOOR DIFF FLOORS ONE OPEN ING

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

2

/kW) of total boiler input is required.

AIR SOURCE

DIRECT VERT DUCT HORIZ DUCT

21

TWO OPENIN GS

r

Gas Fired Boile

3.5.2.2 Air Inlet Requirements – Canada (CAN/CSA B149.1)

A. Ventilation of the space occupied by fuel burning appliance(s) or equipment shall be supplied by a

ventilation opening at the highest practicable point communicating with the outdoors. The total cross sectional

area of the ventilation opening must be either 10% of the net free area required for combustion air or 10 sq. in.

(6500 mm

2

), whichever is greater.

B. Use the following opening calculation for P-K SONIC™

boilers:

When combustion air is supplied for a forced draft burner by natural airflow

N

OTE

from the outdoors and there is no draft regulator or draft hood in the same

space, there shall be a permanent opening with a cross sectional area not

2

less than 1 sq. in/30,000 Btu/Hr (70 mm

/kW) of the total rated input to the

burner(s). This opening must not interfere with the ventilation air opening

defined in paragraph A.

C. Use the following opening calculation for P-K THERMIFIC®

boilers or other natural draft or fan-assist appliances:

When combustion air is supplied for natural or fan-assisted burners by

natural airflow from the outdoors, there shall be a permanent opening with

a cross sectional area not less than 1 sq. in/7000 Btu/Hr (321 mm

to and including 1,000,000 Btu/Hr plus 1 sq. in./14,000 Btu/Hr (155 mm

2

/kW) up

2

/kW)

1. The free area of a combustion air

supply opening is calculated by

deducting the blockage area of any

fixed louvers, grilles or screens from

the total area of the opening.

2. Screens shall be not smaller than ¼”.

3. Motorized louvers shall be

interlocked with the appliance so that

they are proven open prior to main

burner ignition and operation.

:

in excess of 1,000,000 Btu/Hr. This opening must be either located at or

ducted to a point not more than 18 in. (450 mm) or less than 6 in. (150 mm)

above floor level. This opening is in addition to the ventilation air opening

defined in paragraph A.

D. When combustion air is supplied by natural airflow into a space containing both types of appliance described

in paragraphs B and C, the cross sectional area of the opening shall not be less than the sum of the cross

sectional areas for all appliances in the space as calculated by the applicable method. This opening is in addition

to the ventilation air opening defined in paragraph A.

E. When a duct is used to meet the requirement for combustion air supply, as described in paragraphs A through

D, above, the opening of the duct shall be located so there is no possibility of cold air affecting steam or water

piping, electrical equipment or mechanical equipment.

F. When combustion air is supplied by mechanical means, an airflow-sensing device must be installed. It must

be wired into the pre-ignition limit c to prevent the burner from starting or to stop an operating burner in case of

air supply failure.

G. When all combustion air is supplied through a make-up air heater, and the appliance is interlocked to the

heater, the requirements of paragraphs A through F do not apply.

Table 3.5.2.2 Canadian Minimum Area of Combustion and Ventilation Air Openings

P-K SONIC™ Boiler Required Combustion Air Opening Ventilation Air Opening

Model Input (Btu/Hr) in

SC-2000 2,000,000 667 43,032 67 4,303

SC-3000 3,000,000 100 64,516 10 6,452

SC-4000 4,000,000 134 86,451 13.4 8,645

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

2

mm

2

in

2

mm

2

22

r

Gas Fired Boile

3.5.3 Flue Venting

This boiler is not certified for use with Type "B" vent nor with

P-K SONIC™ boilers are dual certified as a Category II and Category IV appliances, as defined in ANSI

Z21.13/CSA 4.9

Venting Systems in

, latest edition. The vent material must be as listed in the Table of Acceptable Materials for

Sectio n 3.5 .1.2 above. The exhaust vent can be run horizontally or vertically.

PVC venting.

Vent installations shall be in accordance with NFPA54/ANSI Z223.1, the National Fuel Gas Code, or CAN/

CSA-B149.1

codes.

, the Natural Gas and Propane Installation Code, or applicable provisions of the local building

3.5.3.1 V en t Sizing

The vent must be sized in accordance with the

ASHRAE Systems and Equipment handbook, Chapter 30 or

according to the vent manufacturer’s recommendations. When using manufactured venting systems, consult

your vent supplier for correct sizing and structural support requirements.Table 3.5.3.1 Vent Design

Parameters

P-K SONIC™ Boiler Model Frictional Resistance Stack Temperature CO2 Natural Gas CO2 LP Gas

SC-2000/SC-3000/SC-4000 0.22” wc 220 °F 9.2% 10.4%

3.5.3.2 Required Clearances

Conventional Vent Systems Clearances

The following termination clearance requirements are for

conventional non direct vent installations:

• The vent system shall terminate at least 3 ft. above a forced air inlet

located within 10 ft. horizontally.

• The vent system shall terminate at least 4 ft . below, 4 ft. horizontally

from or 1 ft. above any door, operable window or gravity inlet into any

building. The bottom of the vent terminal shall be at least 12 in. above

grade or highest expected snow line (if applicable).

• Through the wall terminations shall not terminate over public walkways

or over an area where condensate or vapor could create a nuisance or

hazard or could be detrimental to the operation of regulators, relief valves

or other equipment.

Direct Vent (Sealed Combustion) Systems Clearances

• The vent terminal shall be located at least 12 in. from any air opening

into a building. The bottom of the vent terminal shall be at least 12 in.

above grade. Both the vent and air intake terminals must be at least 12

in. above the highest expected snow line.

• Through the wall terminations shall not terminate over public walkways

or over an area where condensate or vapor could create a nuisance or

hazard or could be detrimental to the operation of regulators, relief valves

or other equipment.

• When multiple direct vent appliances are adjacent, the exhaust must

terminate at least 10 ft. horizontally or 3 ft. vertically from the air intake of

another appliance.

Do not locate intake or exhaust

terminations directly above a

walkway; dripping of condensation

can cause icing of the walking

surface. Maintain a minimum

clearance of 6 ft (1.83 m)

horizontally from any electric or

gas meter, regulator or relief

equipment.

OTICE

N

Make sure that the weight of the

vent is not supported by the boiler

vent collar. The collar is not

designed to support the weight

of the vent. Horizontal vent

sections shall be supported in a

manner to prevent sags or low

spots where condensate can

collect. Structural supports must

be connected to building elements

of sufficient strength to withstand

the weight of the vent system and

any bending forces imposed by the

venting system.

!

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

23

r

Gas Fired Boile

Interior Component Clearances

All vent system components shall be installed so as to maintain the following required minimum clearances:

Table 3.5 .3.2

Unlisted single wall metal pipe Do NOT Use Do NOT Use

Single wall PVC pipe Do NOT Use Do NOT Use

UL 1738 listed Category IV vent Per manufacturer’s listing Per manufacturer’s listing

Combustible Non-Combustibles

Figure 3.5.3.2

The boiler vent should not be

connected into any portion of

another mechanical draft system

without consulting the vent

manufacturer. The boiler shall not

be connected to any part of a vent

system serving a Category I

appliance, nor shall a Category I

appliance be connected to any part

of the vent system serving this

appliance. For Category II

common venting, refer to local

venting codes. Improper

interconnection of venting systems

may result in leakage of flue gases

Reference: NFPA 54/ANSI Z223.1 National Fuel Gas Code

3.5.3.3 Flue Connection

Figure 3.5.3.3

into occupied spaces.

OTE

!

N

The condensate formed from

combustion flue gases is acidic.

The condensate shall be drained in

accordance with local code

requirements. A condensate

neutralizer may be required by

local code.

The complete exhaust with drain system is shown in the figure. The

boiler connector (provided) is designed to accept a 10”

OD nominal

flue pipe. This connector incorporates provisions to drain

condensate formed in the vent system using a 3/4”

OD drain stub.

This drain stub should be connected with the condensate drain on

the boiler. The condensate drains shall have a 4” tall trap to prevent

the passage of flue gases through the condensate system.

4” Tall Condensate Trap

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

24

r

Gas Fired Boile

3.5.3.4 Vent Termination

The vent shall extend at least three (3) feet above the roof, or at least two (2) feet above the highest part of any

structure within ten (10) feet of the vent. This is illustrated in the following diagram.

Additionally the boiler vent shall terminate

Figure 3.5.3.4

at least 3 ft above a forced air inlet located

within 10 ft.

To prevent the possible re-circulation of flue

gases, the vent designer must take into

consideration such things as prevailing

winds, eddy zones, building configurations,

etc. Harsco Industrial, Patterson-Kelley

cannot be responsible for the effects

such adverse conditions may have on

the operation of the boilers.

Dimensions listed above are minimums

and may not be sufficient for conditions at

a specific job site.

Vertical vents are allowed to be terminated

with a variety of ends, including plain

straight pipe, elbow or vent tee. Horizontal

vents must be terminated as illustrated in

Section 3.5.5. A bird screen with 1” x 1”

openings is recommended for the

termination. Harsco Industrial, PattersonKelley does not recommend using a vent

rain cap of any type.

Reference: NFPA 54/ANSI Z223.1 National Fuel Gas Code

3.5.4 Venting for Multiple Boilers

While the vent design parameters outlined in S ect ion 3.5.3 still apply, achieving those same parameters in a

combined vent system, adds a significant degree of complexity. Therefore, venting systems for multiple boilers

shall be designed by experienced and knowledgeable venting professionals. The venting system shall be

designed to prevent backflow of exhaust gas through idle boilers. For combined breeching installations, please

follow recommendations of a qualified venting engineer/manufacturer.

Harsco Industrial, Patterson-Kelley recommends that common venting systems be designed for a

maximum continuous exhaust pressure of -0.04” w.c. when measured in the common vent. Locking

inline dampers are recommended on the discharge of each boiler in order to maintain a slightly positive

exhaust pressure within the boiler and upstream of the damper. The -0.04” w.c. in the common flue will

help make sure the exhaust gases from an online boiler does not backflow through offline boiler(s). In

addition, Harsco Industrial, Patterson-Kelley also recommends the use of motorized dampers in the

combu s ti o n air int ake d uct to h elp prev en t the backflo w o f f l u e g as es f r om onli n e bo i lers t hr ough offline

boilers.

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

25

r

Gas Fired Boile

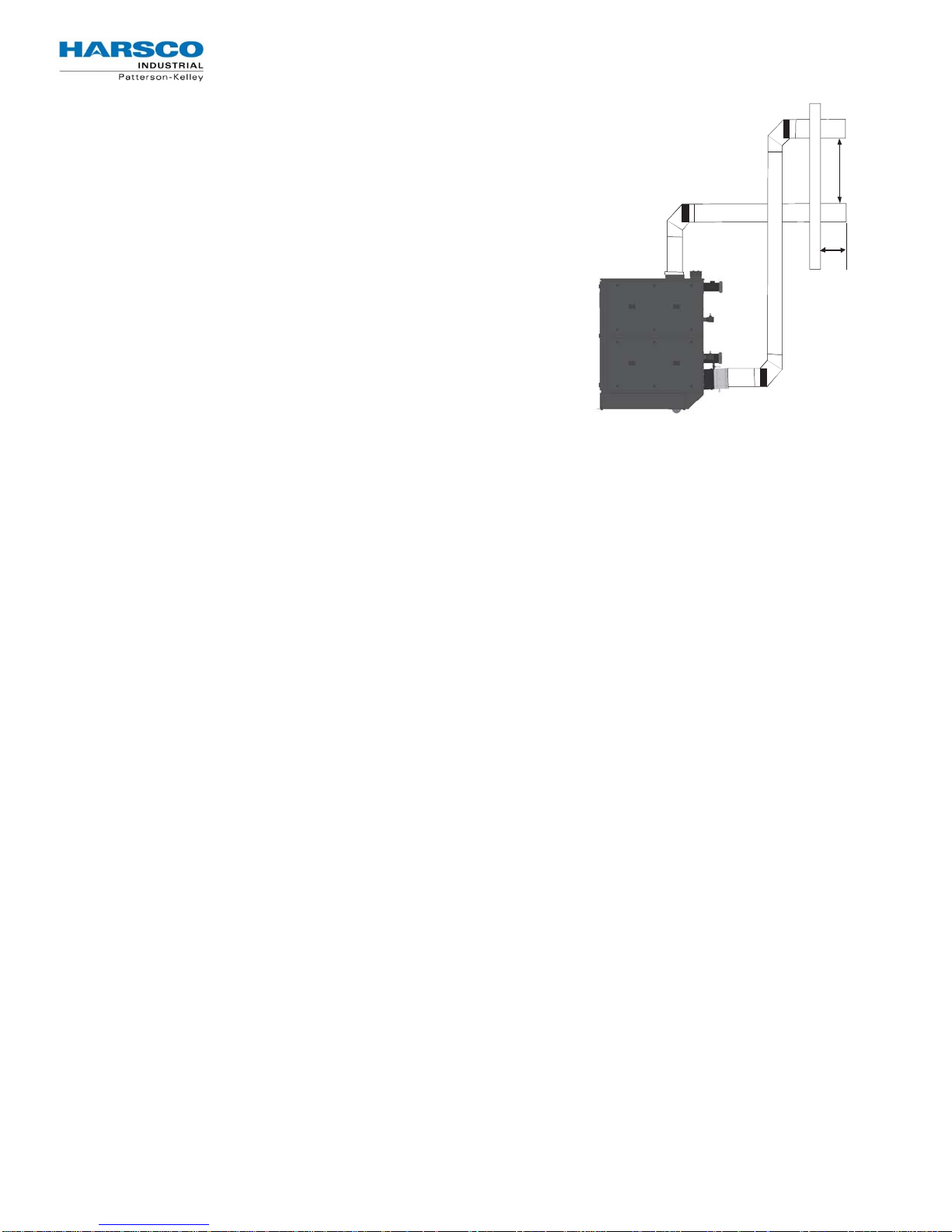

3.5.5 Sealed Combustion/Direct Vent Systems

These boilers are also certified for operation with a sealed

Figure 3.5.5

combustion air and pressurized venting system. Such a system

employs a sealed combustion air intake duct leading from outdoors

and a sealed exhaust vent terminating outdoors. Air flow through the

36”

Minimum

system is maintained by the combustion air fan. Allowable

configurations of vent and air intake terminations are illustrated to the

right.

NOTE: Drains have been omitted for clarity.

12” Minimum

The combined pressure drop of the air supply duct and exhaust vent

must not exceed 0.44” wc. This pressure drop includes both the

inlet and exhaust duct friction loss.

NOTE: The inlet air duct loss should not exceed 0.22” w.c.

If the air inlet and the exhaust vent terminate on the same wall of the

building they must utilize the same type of termination fitting.

Allowable termination fittings are either 90° elbows or tees.

This boiler may be installed with sidewall vent using room air. (Refer to air inlet requirements Section 3.5.2.1)

Figure 3.5 .5 shows the sidewall penetration requirements. The exhaust vent must be at least 3 feet above the air

intake. The air intake and exhaust vent must extend 6" to 12" from the exterior wall and be offset.

3.5.5.1 Inlet Duct Connection to Boiler

Connect the air supply duct to the inlet air collar on the boiler. The air inlet collar is 11.875”

inlet duct to the collar with sheet metal screws at 90° angles and seal with aluminum tape or sealant.

3.5.5.2 Intake Duct Materials and Sizes

The air intake duct can be fabricated from

PVC, CPVC, single wall galvanized steel, or other suitable materials.

OD. Fasten the air

The duct must be rigid enough to maintain the full required cross sectional area under all operating conditions.

Proper sealing of the intake ductwork is necessary to prevent infiltration of air from conditioned space. Joints in

PVC or CPVC must be cemented. For galvanized duct, wrap each joint and seam with adhesive aluminum tape

or other sealant. The installation of a birdscreen on the intake termination is recommended. Ensure that the

screen does not become blocked with snow, ice, insects, etc.

3.5.6 Removing an Existing Boiler

When an existing boiler is removed from a common venting system, the common venting system is likely to be

too large for proper venting of the appliances remaining connected to it.

At the time of removal of an existing boiler, while the other appliances remaining connected to the common

venting system are not in operation, the following steps should be followed with each appliance remaining

connected to the common venting system placed in operation:

1. Seal any unused openings in the common venting system.

2. Visually inspect the venting system for proper size and horizontal pitch and determine that there is no blockage or

restriction, leakage, corrosion or other deficiency which could cause an unsafe condition.

3. Insofar as is practical, close all building doors and windows and all doors between the space in which the appliance

remaining connected to the common venting system are located and other spaces of the building. Turn on clothes

dryers and any appliances not connected to the common venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will operate at maximum speed. Do not operate a summer exhaust fan. Close

fireplace dampers.

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

26

r

4. Place the appliance being inspected in operation. Follow the lighting

instructions. Adjust the thermostat so that the appliance will operate

continuously.

5. Test for spillage at the draft hood relief opening after 5 minutes of main

burner operation. Use the flame of a match or candle or smoke from a

cigarette, cigar or pipe.

6. After it has been determined that each appliance remaining

connected to the common venting system properly vents when tested

as outlined above, return doors, windows, exhaust fans, fireplace

dampers and any other gas-burning appliance to their previous

conditions of use.

Any improper operation of the common venting system should be

corrected so the installation conforms to the National Fuel Gas

Code,

ANSI Z223.1 and CSA B149 Installation Code. When resizing

any portion of the common venting system, the common vent

system should be resized to approach the minimum size as

determined using the appropriate tables in part 11 of the National

Fuel Gas Code,

ANSI Z223.1/NFPA 54 and/or CAN/CSA B149.1

Natural Gas and Propane Installation Code.

3.6 Gas Piping

Before making the gas hook-up, make sure the boiler is being

supplied with the type of fuel shown on the boiler nameplate.

The boiler shall be installed such that the gas ignition

system components are protected from water (dripping,

spraying, rain, etc.) during appliance operation and

service (circulator replacement, control adjustment, etc.)

Figure 3.6: Simplified Gas Piping

Gas Fired Boile

All threaded connections must be

made using a pipe compound that

is resistant to the action of liquefied

petroleum gases. Do not use

Teflon tape on gas line threads!

N

OTICE

See Pipe Capacity for Natural Gas

chart on the following page for

required pipe size, based on

overall length of pipe from the

meter plus equivalent length of all

fittings. Approximate sizing may

be based on 1 cubic foot of natural

gas per 1,000 Btu per hour input,

i.e., 3,000,000 Btu/hr requires

about 3,000 cubic feet per hour.

(See “Typical Boiler Operating

Conditions,” Sec ti o n 4.4 for more

information.)

!

The boiler is factory fire-tested and adjusted for proper

combustion. The gas train components are certified to

handle a maximum inlet pressure of 14" w.c. (1/2 psig).

Typical gas pressure supply for natural gas is 7" w.c. (11"

w.c. for propane). If the available gas pressure exceeds

14" w.c., a suitable additional intermediate gas pressure

regulator of the "lock up" type must be provided to reduce

the pressure to less than 14" w.c. Refer to boiler label

for minimum inlet gas pressure.

Install a sediment trap (drip leg) and a union connection ahead of the primary manual shutoff valve on the boiler.

A gas piping schematic is shown above. Gas piping should be installed in accordance with National Fuel Gas

Code,

ANSI Z223.1, latest edition, and any other local codes which may apply; in Canada see CAN/CSA-B.149.1,

latest edition. In the Commonwealth of Massachusetts, the gas cock must be a “T-handle type.”

Table 3.6: Pipe Capacity for Natural Gas

Nominal

Iron Pipe

Size

(Inches)

2 2.067 5.17 10.3 2750 - - - - - -

2.5 2.469 6.16 12.3 4350 3000 2400 - - - -

3 3.068 7.67 15.3 7700 5300 4300 3700 - - -

Internal

Diameter

(Inches)

Equivalen t Pipe

Length

90o Ell

(Feet)

Tee

(Feet)

Maximum Capacity in Cubi c Feet of Natural Gas Per Hour Pressure

Drop of 0.5 inch Water Column/Equivalent Length of Pipe (in feet)

20 40 60 80 100 150 200

4 4.026 10.1 20.2 15800 10900 8800 7500 6700 5500 4600

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

27

r

N

OTICE

The SC-2000 boiler is furnished

with 3” grooved connections and

Victaulic Style 75 couplings. The

SC-3000 and SC-4000 boilers are

furnished with 4” grooved

connections and Victaulic Style 75

couplings. These couplings must

be used with the EPDM Victaulic

seals. Isolating valves must be

installed in both the inlet and outlet

water connections.

N

OTICE

The Condensate Trap must be

piped to a drain in accordance with

all national, state and local codes.

If installed outdoors and the local

requires freeze protection, it must

be field heat traced.

!

!

Gas Fired Boile

3.6.1 Gas Supply Pipi ng by Ins taller

The boiler and all gas piping connections should be pressure-tested

and must be checked for leaks before being placed into service. Test

with compressed air or inert gas if possible.

The boiler must be disconnected at the boiler’s manual shut-off valve

(located at the end of the supplied gas train) from the gas supply piping

system during any pressure testing of the system at pressures in

excess of 1/2 psig (14" w.c.).

During any pressure testing of the gas supply piping system at

pressures equal to or less than 1/2 psig (14" w.c.), the boiler must be

isolated from the gas supply piping system by closing the manual shutoff.

Some leak test solutions, including soap and water, may cause

corrosion of the carbon steel gas pipe fittings. These leak test solutions

should be cleaned off after testing is complete.

3.7 Boiler Water Piping

3.7.1.1 Pi p ing wit h Ref r i g erat ion Lines

When installed in a two-pipe system that provides both chilled and hot

water, the control system should be configured so as to limit the time

rate of change of temperature at the boiler. Consult your authorized

Harsco Industrial, Patterson-Kelley boiler representative for application

guidance.