Harris RF Communications Division XG 100LPA User Manual

Rhein Tech Laboratories, Inc. Client: Harris Corporation

360 Herndon Parkway Model: XG-100LPA

Suite 1400 IDs: AQZ-XG-100LPA /122D-XG100LPA

Herndon, VA 20170 Standards: FCC Part 90/ICRSS-119

http://www.rheintech.com Report #: 2014152

Appendix N: Manuals

Please refer to the following pages for the Installation Manual and the Product Safety Manual.

35 of 49

Installation Manual

14221-1200-4010

Rev. B, Jan/15

Unity® Mobile

VHF Low Band Amplifier

XG-100LPA

14221-1200-4010, Rev. B

REV.

DATE

REASON FOR CHANGE

-

Nov/14

Initial Release.

A

Jan/15

Changed RF cable part from W90-0223-003 to W90-0223-001 and corrected antenna

element part numbers.

B

Jan/15

Corrected Industry Canada Standard reference and deleted AN-025127-100 antenna

option.

This product conforms to the European Union WEEE Directive 2012/19/EU. Do not dispose of this product in a

public landfill. Take it to a recycling center at the end of its life.

This manual is published by Harris Corporation without any warranty. Improvements and changes to this manual

necessitated by typographical errors, inaccuracies of current information, or improvements to programs and/or equipment,

may be made by Harris Corporation at any time and without notice. Such changes will be incorporated into new editions of

this manual. No part of this manual may be reproduced or transmitted in any form or by any means, electronic or mechanical,

including photocopying and recording, for any purpose, without the express written permission of Harris Corporation.

Copyright© 2014, 2015 Harris Corporation

MANUAL REVISION HISTORY

Harris Corporation, Public Safety and Professional Communications (PSPC) Business, continually evaluates its technical

publications for completeness, technical accuracy, and organization. You can assist in this process by submitting your

comments and suggestions to the following:

Harris Corporation fax your comments to: 1-434-455-6851

PSPC Business or

Technical Publications e-mail us at: PSPC_TechPubs@harris.com

221 Jefferson Ridge Parkway

Lynchburg, VA 24501

ACKNOWLEDGEMENT

This device is made under license under one or more of the following US patents: 4,590,473; 4,636,791; 5,148,482;

5,185,796; 5,271,017; 5,377,229; 4,716,407; 4,972,460; 5,502,767; 5,146,497; 5,164,986; 5,185,795; 5,226,084; 5,247,579;

5,491,772; 5,517,511; 5,630,011; 5,649,050; 5,701,390; 5,715,365; 5,754,974; 5,826,222; 5,870,405; 6,161,089; and

6,199,037 B1. DVSI claims certain rights, including patent rights under aforementioned U.S. patents, and under other U.S.

and foreign patents and patents pending. Any use of this software or technology requires a separate written license from

DVSI.

CREDITS

Harris, assured communications, and Unity are registered trademarks of Harris Corporation.

All other brand and product names are trademarks, registered trademarks, or service marks of their respective holders.

NOTICE!

The material contained herein is subject to U.S. export approval. No export or re-export is permitted without written approval

from the U.S. Government. Rated: EAR99 in accordance with U.S. Dept. of Commerce regulations 15CFR774, Export

Administration Regulations.

Information and descriptions contained herein are the property of Harris Corporation. Such information and descriptions may

not be copied or reproduced by any means, or disseminated or distributed without the express prior written permission of

Harris Corporation, PSPC Business, 221 Jefferson Ridge Parkway, Lynchburg, VA 24501.

Repairs to this equipment should be made only by an authorized service technician or facility designated by the supplier. Any

repairs, alterations, or substitutions of recommended parts made by the user to this equipment not approved by the

manufacturer could void the user's authority to operate the equipment in addition to the manufacturer's warranty.

2

14221-1200-4010, Rev. B

TABLE OF CONTENTS

Section Page

1. REGULATORY AND SAFETY INFORMATION .................................................................... 7

1.1 SAFETY SYMBOL CONVENTIONS ................................................................................................. 7

1.2 RF ENERGY EXPOSURE AWARENESS AND CONTROL INFORMATION FOR FCC

OCCUPATIONAL USE REQUIREMENTS ........................................................................................ 7

1.2.1 Federal Communications Commission Regulations ............................................................... 8

1.3 COMPLIANCE WITH RF EXPOSURE STANDARDS ...................................................................... 8

1.3.1 Mobile Antennas .................................................................................................................... 9

1.3.2 Approved Accessories ............................................................................................................ 9

1.3.3 Contact Information .............................................................................................................. 10

1.4 RADIO FREQUENCY INTERFERENCE ......................................................................................... 10

1.4.1 FCC Part 15 .......................................................................................................................... 10

1.4.2 Industry Canada .................................................................................................................... 10

1.5 OCCUPATIONAL SAFETY GUIDELINES AND SAFETY TRAINING INFORMATION............ 10

1.6 COMMON HAZARDS ...................................................................................................................... 11

1.7 SAFE DRIVING RECOMMENDATIONS ........................................................................................ 12

1.8 OPERATING RULES REGULATIONS ............................................................................................ 12

1.9 OPERATING TIPS ............................................................................................................................. 13

2. SPECIFICATIONS ...................................................................................................................... 14

2.1 GENERAL .......................................................................................................................................... 14

2.2 TRANSMITTER ................................................................................................................................ 15

2.3 REGULATORY ................................................................................................................................. 15

3. INTRODUCTION ........................................................................................................................ 16

3.1 GENERAL INFORMATION ............................................................................................................. 16

3.2 EQUIPMENT MOUNTING ............................................................................................................... 16

3.3 CONTROL HEADS ........................................................................................................................... 16

3.3.1 General Information ............................................................................................................. 16

3.3.2 CH-100 Control Head ........................................................................................................... 17

3.3.3 CH-721 Control Head ........................................................................................................... 17

3.4 OPERATING POWER ....................................................................................................................... 18

3.5 RADIO PROGRAMMING ................................................................................................................. 18

3.6 RELATED PUBLICATIONS ............................................................................................................. 20

4. CUSTOMER SERVICE .............................................................................................................. 21

4.1 TECHNICAL SUPPORT.................................................................................................................... 21

4.2 TECH-LINK ....................................................................................................................................... 21

4.3 CUSTOMER CARE ........................................................................................................................... 21

5. UNPACKING AND CHECKING THE EQUIPMENT ........................................................... 22

5.1 MATERIALS...................................................................................................................................... 22

6. PLANNING THE INSTALLATION ......................................................................................... 29

3

14221-1200-4010, Rev. B

TABLE OF CONTENTS

Section Page

6.1 GENERAL INFORMATION ............................................................................................................. 29

6.2 TOOLS REQUIRED ........................................................................................................................... 29

6.3 LOCATING COMPONENTS............................................................................................................. 30

7. MOUNTING THE RADIO EQUIPMENT ............................................................................... 33

7.1 INSTALL THE MOUNTING BRACKETS ........................................................................................ 33

7.2 MOUNT THE EQUIPMENT INTO THE BRACKETS ..................................................................... 37

7.2.1 MRU and LBPA Mounting ................................................................................................... 37

8. ANTENNA INSTALLATION .................................................................................................... 40

8.1 ANTENNA MOUNTING LOCATIONS ............................................................................................ 40

8.1.1 Direct Center or Center-Rear of Rooftop for MRU Antenna ................................................ 40

8.1.2 Center of Trunk Lid for LBPA Antenna ............................................................................... 40

8.1.3 Rear Deck Lid for GPS Stand-Alone GPS Receive Antenna ............................................... 42

8.2 ANTENNA INSTALLATION PROCEDURES ................................................................................. 43

8.2.1 Installing NMO Antenna Mounts AN-125001-001, -002, -003 and -004 ............................. 43

8.2.2 Installing NMO Magnetic Antenna Mounts AN-125001-007 and -008 ............................... 46

8.2.3 Installing all Other Antenna Mounts ..................................................................................... 46

8.2.4 Attaching NMO Antenna Elements ...................................................................................... 46

8.2.5 Connecting the Mobile Antennas .......................................................................................... 48

8.2.6 Connect RF Cable between Unity Mobile MRU and Low Band PA .................................... 49

9. DC POWER INSTALLATION .................................................................................................. 50

9.1 OVERVIEW OF ON/OFF POWER WIRING CONFIGURATIONS ................................................. 50

9.2 POWER INSTALLATION PROCEDURE ......................................................................................... 51

9.2.1 Radios DC Power Cables and Main Fuse Holders Installation ............................................. 51

10. CONTROL HEAD INSTALLATION ....................................................................................... 55

10.1 SELECTING THE MOUNTING LOCATION ................................................................................... 55

10.2 GENERAL INFORMATION ON THE CH-100 CONTROL HEAD ................................................. 56

10.3 GENERAL INFORMATION ON THE CH-721 CONTROL HEAD ................................................. 58

10.4 CONTROL HEAD MECHANICAL INSTALLATION ..................................................................... 60

10.5 CONTROL HEAD-TO-RADIO CAN CABLE CONNECTIONS ...................................................... 61

10.5.1 General Information .............................................................................................................. 61

10.5.2 Make CAN Link Terminations and Cable Connection ......................................................... 63

10.6 CONTROL HEAD POWER CABLE INSTALLATION .................................................................... 63

10.6.1 Install DC Power Cable and Make Power and Ground Connections .................................... 64

10.6.2 Connect DC Power Cable’s White Wire ............................................................................... 65

11. SPEAKER INSTALLATION ..................................................................................................... 67

12. MICROPHONE ATTACHMENT ............................................................................................. 67

13. OPTIONAL CABLES ................................................................................................................. 68

13.1 SERIAL PROGRAMMING CABLE CA-013671-020 ....................................................................... 68

13.2 CH-100/CH-721 OPTION CABLE CA-011854-001 .......................................................................... 69

13.3 CH-721 SERIAL PROGRAMMING CABLE CA-104861 ................................................................. 70

4

14221-1200-4010, Rev. B

TABLE OF CONTENTS

Section Page

13.4 CH-721 MIC CONNECTOR PROGRAMMING CABLE CA-103541-001 ...................................... 70

13.5 OPTION CABLE 14002-0174-01 ....................................................................................................... 71

14. GPS NMEA-FORMATTED SERIAL DATA CONNECTION ............................................... 75

15. MOBILE DATA CONNECTION .............................................................................................. 75

16. INITIAL POWER-UP TEST ...................................................................................................... 76

17. PERFORMANCE TESTS ........................................................................................................... 78

17.1 REQUIRED TEST EQUIPMENT ...................................................................................................... 79

17.2 MRU TRANSMITTING INTO A 50-OHM LOAD/TERMINATOR ................................................ 80

17.3 MRU TRANSMITTING INTO ITS ANTENNA ................................................................................ 82

17.4 LOW BAND PA TRANSMITTING INTO A 50-OHM LOAD/TERMINATOR............................... 85

17.4.1 For a 100 Watt Output Configuration ................................................................................... 85

17.5 LOW BAND PA TRANSMITTING INTO ITS ANTENNA ................................................................. 87

17.6 TEST PERFORMANCE DATA FORM ............................................................................................. 90

18. COMPLETE THE INSTALLATION ........................................................................................ 92

19. WARRANTY REGISTRATION ............................................................................................... 92

20. CLEANING THE RADIO EQUIPMENT ................................................................................. 93

20.1 LIGHT-DUTY CLEANING PROCEDURE....................................................................................... 93

20.2 HEAVY-DUTY CLEANING PROCEDURE ..................................................................................... 93

21. WIRING DIAGRAM ................................................................................................................... 95

5

14221-1200-4010, Rev. B

LIST OF FIGURES

Figure Page

Figure 3-1: Simplified Block Diagram Unity Low Band PA .............................................................................. 17

Figure 3-2: Setting Unity Low Band PA in RPM Personality ............................................................................. 19

Figure 6-1: Unity XG-100LPA Low Band Power Amplifier - Front and Rear Views ........................................ 31

Figure 6-2: Unity XG-100M Remote-Mount Mobile Radio - Front and Rear Views ......................................... 31

Figure 6-3: XG-100LPA/XG-100M Front-Side View......................................................................................... 32

Figure 6-4: XG-100LPA/XG-100M Rear View .................................................................................................. 32

Figure 7-1: Base Bracket 1000003678 (Part of XM-ZN2G Installation Kit) ...................................................... 34

Figure 7-2: Base Bracket FM103111V1 in Bracket Kit KT23117 ...................................................................... 35

Figure 7-3: Extension Bracket FM-018205 (Part of XM-ZN2G Installation Kit) ............................................... 36

Figure 7-4: Assembly into Stack Brackets (Exploded View) .............................................................................. 38

Figure 7-5: Assembly into Separate Brackets (Exploded Views) ........................................................................ 39

Figure 8-1: Required Unity mobile MRU Antenna Mounting Location with Antenna Part Numbers ................ 41

Figure 8-2: Required LBPA Antenna Mounting Location with Antenna Part Numbers ..................................... 42

Figure 8-3: Installing a Standard ¾-Inch NMO Antenna Mount ......................................................................... 45

Figure 8-4: Installing a Thick-Roof NMO Antenna Mount ................................................................................. 45

Figure 8-5: Cutting Charts for Antenna Element AN-225006-001 ..................................................................... 47

Figure 8-6: Crimping Instructions for TNC RF Connector (Dimensions in Inches) ........................................... 48

Figure 10-1: CH-100 Control Head Front Panel .................................................................................................. 56

Figure 10-2: CH-100 Control Head Rear Panel (shown with Standard Mounting Bracket)................................ 56

Figure 10-3: CH-100 Control Head Dimensions ................................................................................................. 57

Figure 10-4: CH-721 System Model Control Head Front Panel.......................................................................... 58

Figure 10-5: CH-721 Control Head Rear Panel ................................................................................................... 58

Figure 10-6: CH-721 Control Head Dimensions (System Model Shown) .......................................................... 59

Figure 10-7: Standard U-Shaped Control Head Mounting Bracket for CH-721 Control Head ........................... 60

Figure 10-8: CAN Link Connections for a Single Control Head Installation ...................................................... 62

Figure 10-9: CAN Link Connections for a Dual Control Head Installation ........................................................ 62

Figure 13-1: Serial Data Cable CA-013671-020 ................................................................................................. 68

Figure 13-2: CH-100/CH-721 Option Cable CA-011854-001 ............................................................................ 69

Figure 13-3: Programming Cable CA-104861 .................................................................................................... 70

Figure 13-4: CH-721 Serial Programming Cable CA-103541-001 ..................................................................... 70

Figure 13-5: Option Cable 14002-0174-01 ......................................................................................................... 71

Figure 17-1: Wattmeter Connections for Unity mobile MRU Antenna Tests ..................................................... 80

Figure 17-2: Wattmeter Connections for LBPA Antenna Tests .......................................................................... 85

LIST OF TABLES

Table Page

Table 1-1: Recommended Minimum Safe Lateral Distance from Transmitting Antenna for VHF Low Band

Antennas (XG-100LPA Transmit/Receive Antenna) .................................................................... 9

Table 5-1: Catalog and Part Numbers for Unity XG-100M Mobile Radio with XG-100LPA ............................ 23

Table 5-2: Installation Kit XM-ZN2G for XG-100LPA ...................................................................................... 23

Table 5-3: Installation Kit XMZN9A for XG-100M with CH-100 Control Head ............................................... 24

Table 5-4: Installation Kit XMZN7R for XG-100M with CH-721 Control Head ............................................... 26

Table 5-5: XG-100LPA Antenna Elements and Mount Options ......................................................................... 27

Table 5-6: XG-100M Antenna Elements and Mount Options ............................................................................. 28

Table 13-1: Option Cable 14002-0174-01 Interconnections ............................................................................... 72

Table 17-1: Test Equipment Required for Performance Tests............................................................................. 79

6

14221-1200-4010, Rev. B

The WARNING symbol calls attention to a procedure, practice, or the like, which, if

not correctly performed or adhered to, could result in personal injury. Do not proceed

beyond a WARNING symbol until the conditions identified are fully understood or

met.

The CAUTION symbol calls attention to an operating procedure, practice, or the like,

which, if not performed correctly or adhered to, could result in damage to the equipment or

severely degrade equipment performance.

NOTE

The NOTE symbol calls attention to supplemental information, which may improve system

performance or clarify a process or procedure.

This radio is intended for use in occupational/controlled conditions, where users have

full knowledge of their exposure and can exercise control over their exposure to

remain below RF exposure limits. This radio is NOT authorized for general

population, consumer, or any other use.

Changes or modifications not expressly approved by Harris could void the user's authority

to operate the equipment.

1. REGULATORY AND SAFETY INFORMATION

1.1 SAFETY SYMBOL CONVENTIONS

The following conventions are used in this manual to alert the user to general safety precautions that must

be observed during all phases of operation, service, and repair of this product. Failure to comply with

these precautions or with specific warnings elsewhere violates safety standards of design, manufacture,

and intended use of the product. Harris® assumes no liability for the customer's failure to comply with

these standards.

1.2 RF ENERGY EXPOSURE AWARENESS AND CONTROL INFORMATION FOR FCC OCCUPATIONAL USE REQUIREMENTS

Before using the mobile two-way radio, read this important RF energy awareness and control

information to ensure compliance with RF exposure guidelines.

This two-way radio uses electromagnetic energy in the radio frequency (RF) spectrum to provide

communications between two or more users over a distance. It uses RF energy or radio waves to send and

receive calls. RF energy is one form of electromagnetic energy. Other forms include, but are not limited

to, electric power, sunlight, and x-rays. RF energy, however, should not be confused with these other

7

14221-1200-4010, Rev. B

forms of electromagnetic energy, which, when used improperly, can cause biological damage. Very high

levels of x-rays, for example, can damage tissues and genetic material.

Experts in science, engineering, medicine, health, and industry work with organizations to develop

standards for exposure to RF energy. These standards provide recommended levels of RF exposure for

both workers and the general public. These recommended RF exposure levels include substantial margins

of protection. All two-way radios marketed in North America are designed, manufactured, and tested to

ensure they meet government-established RF exposure levels. In addition, manufacturers also recommend

specific operating instructions to users of two-way radios. These instructions are important because they

inform users about RF energy exposure and provide simple procedures on how to control it. Please refer

to the following websites for more information on what RF energy exposure is and how to control

exposure to assure compliance with established RF exposure limits:

http://www.fcc.gov/oet/rfsafety/rf-faqs.html

http://www.osha.gov./SLTC/radiofrequencyradiation/index.html

1.2.1 Federal Communications Commission Regulations

Before it was marketed in the United States, the Unity® mobile Low Band P Power Amplifier (LPA) was

tested to ensure compliance with FCC RF energy exposure limits for mobile two-way radios. When twoway radios are used as a consequence of employment, the FCC requires users to be fully aware of and

able to control their exposure to meet occupational requirements. Exposure awareness can be facilitated

by the use of a label directing users to specific user awareness information. The radio has an RF exposure

product label. Also, this Installation, the Product Safety Manual, and the applicable Operator’s Manual

include information and operating instructions required to control RF exposure and to satisfy compliance

requirements.

1.3 COMPLIANCE WITH RF EXPOSURE STANDARDS

The UnityXG-100 LPA mobile Low Band Power Amplifier System is designed and tested to comply with

a number of national and international standards and guidelines regarding human exposure to RF

electromagnetic energy. This radio complies with the IEEE and ICNIRP exposure limits for

occupational/controlled RF exposure environment at duty-cycle times of up to 50% (50% transmit, 50%

receive) for the Unity mobile radio equipment, and up to 100% for the LBPA radio equipment. The radio

equipment is authorized by the FCC for occupational use. In terms of measuring RF energy for

compliance with the FCC exposure guidelines, the radio’s antenna radiates measurable RF energy only

while it is transmitting (talking), not when it is receiving (listening), or in standby mode.

The Unity mobile low band VHF amplifier complies with the following RF energy exposure standards

and guidelines:

United States Federal Communications Commission (FCC), Code of Federal Regulations; 47

CFR § 2 sub-part J.

American National Standards Institute (ANSI)/Institute of Electrical and Electronic Engineers

(IEEE) C95.1-2005.

Institute of Electrical and Electronic Engineers (IEEE) C95.1-2005.

IC Standard RSS-102, Issue 4, 2010: Spectrum Management and Telecommunications Radio

Standards Specification. Radiofrequency Exposure Compliance of Radio communication

Apparatus (All Frequency Bands).

8

14221-1200-4010, Rev. B

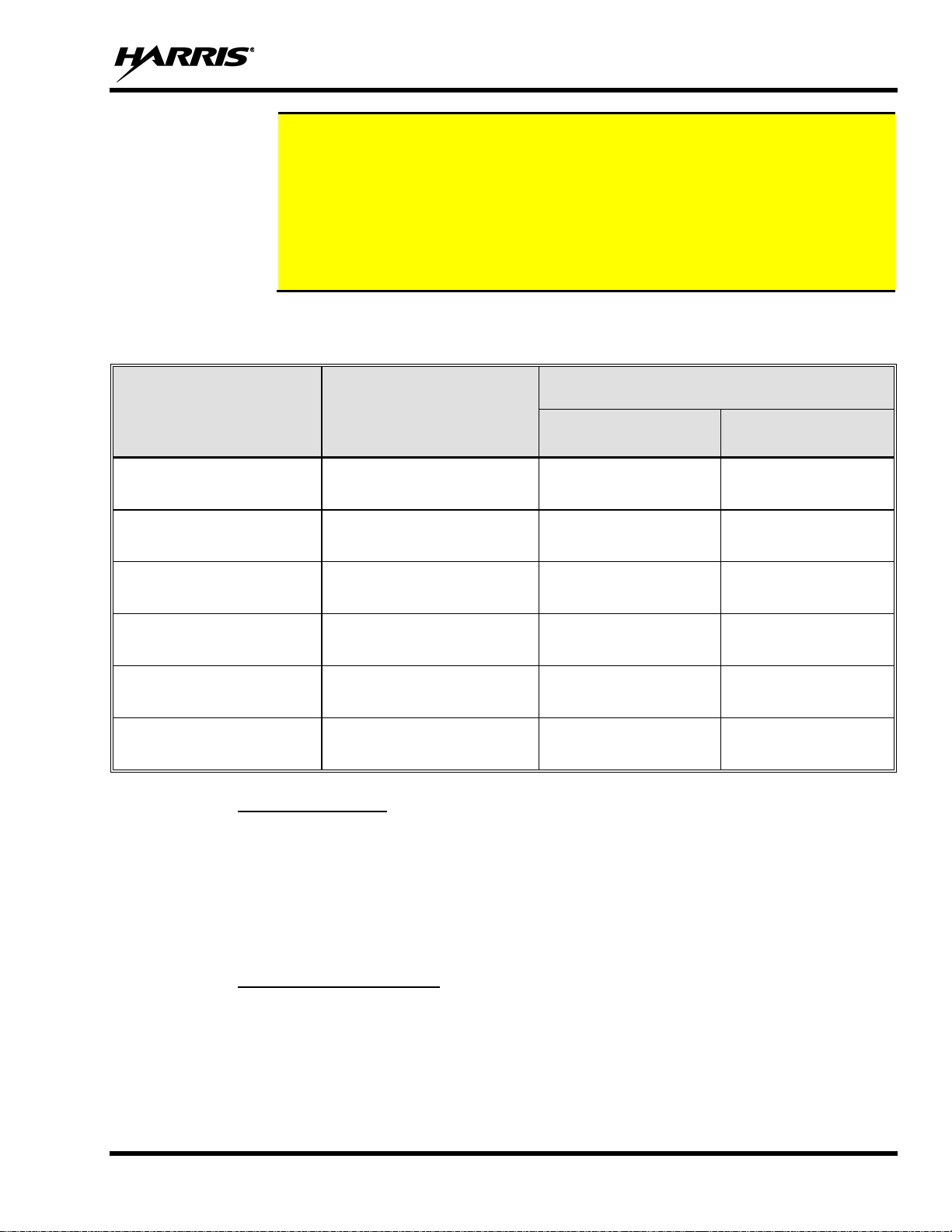

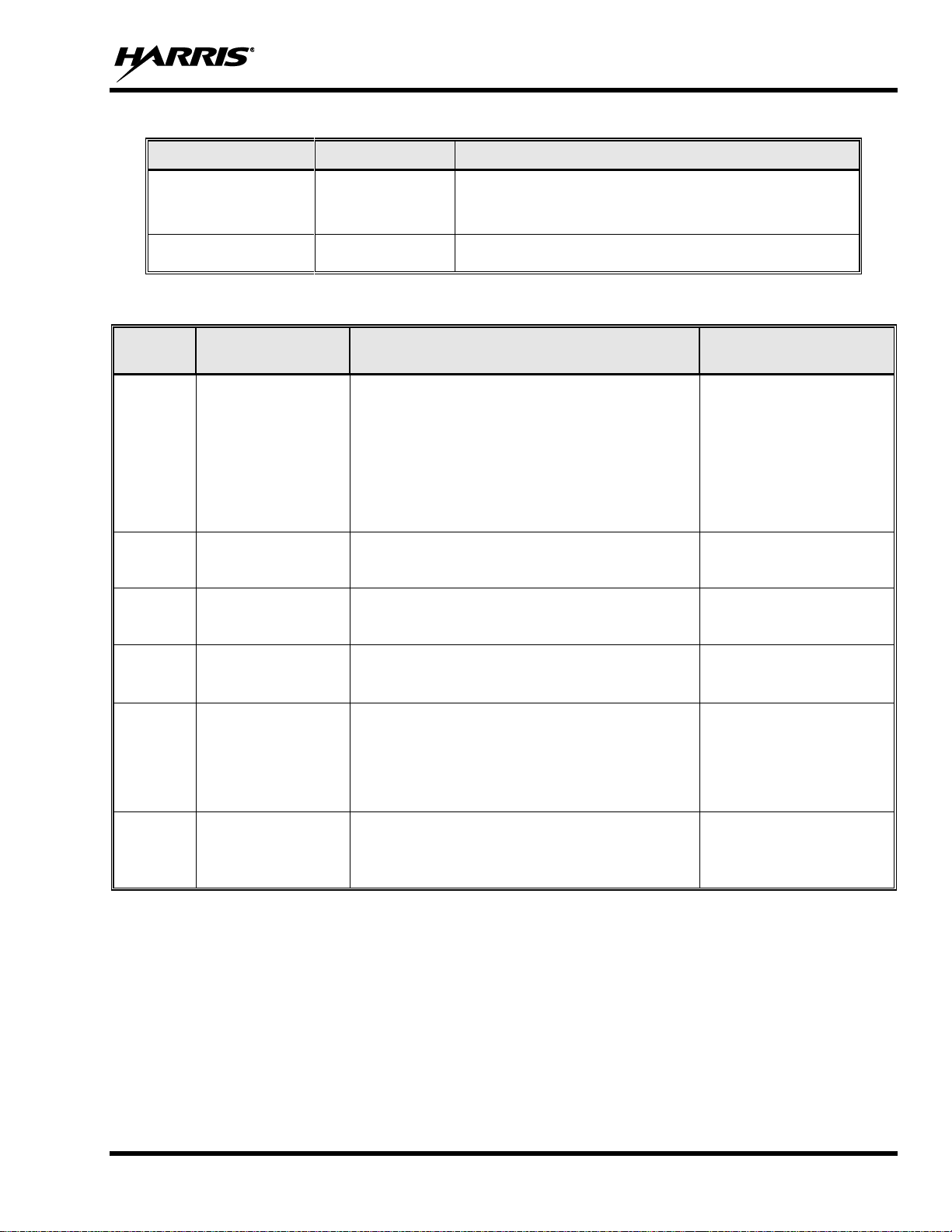

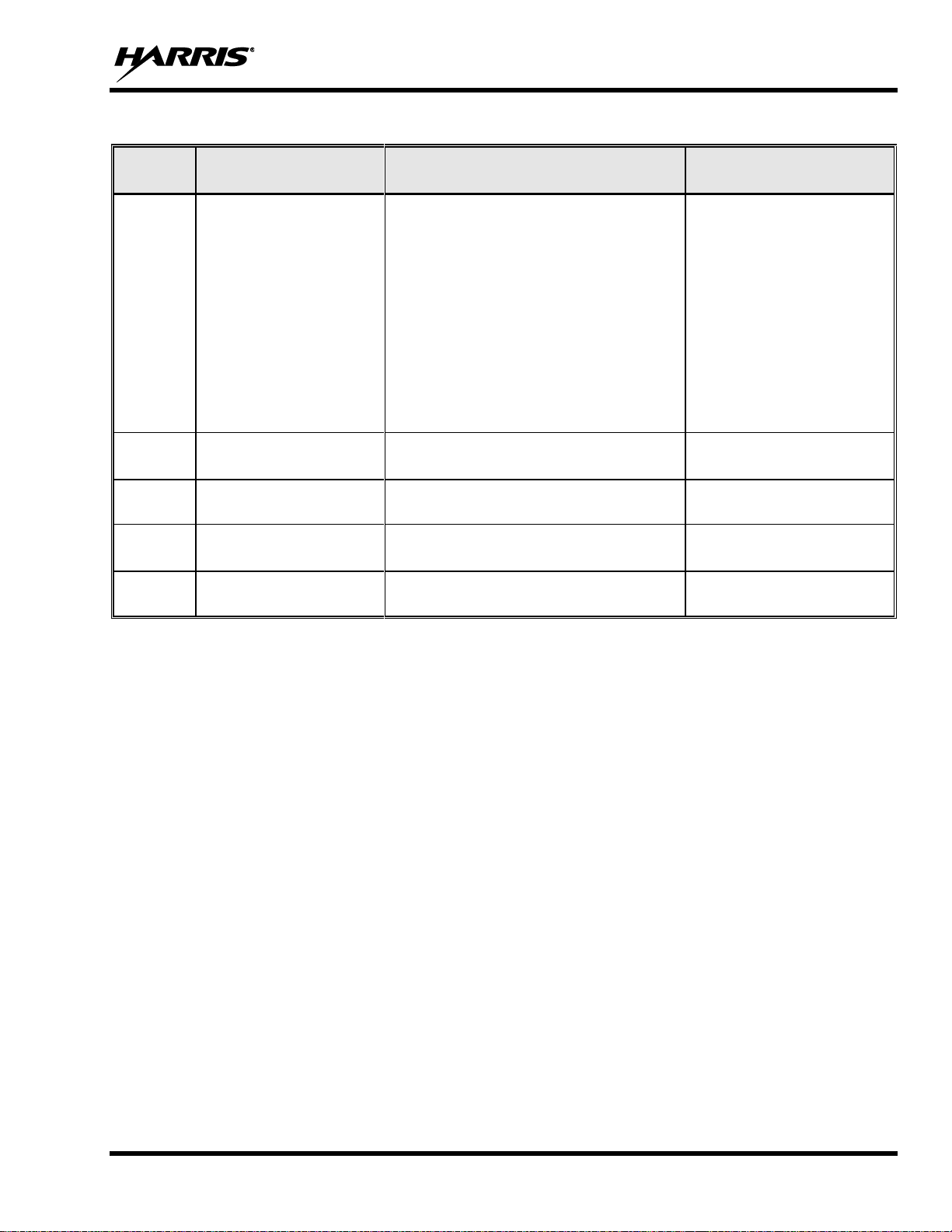

Table 1-1 lists the recommended minimum safe lateral distances for a controlled

environment and for unaware bystanders in an uncontrolled environment, from

transmitting antennas (i.e., monopoles over a ground plane, or dipoles). Table 1-1 has

the distances for the LBPA on a per antenna basis. This data is based upon the mobile

radio installed in a motor vehicle with the radio transmitting at its rated RF power

level. Transmit only when unaware bystanders are at least the uncontrolled

recommended minimum safe lateral distance away from the mobile radio’s transmitting

antenna.

Table 1-1: Recommended Minimum Safe Lateral Distance from Transmitting Antenna for VHF Low

Band Antennas (XG-100LPA Transmit/Receive Antenna)

(This table applies to Unity Mobile Low Band PAs only)

ANTENNA

PART NUMBER

ANTENNA DESCRIPTION

RECOMMENDED MINIMUM LATERAL HUMAN

BODY DISTANCE FROM TRANSMITTING ANTENNA

CONTROLLED

ENVIRONMENT

UNCONTROLLED

ENVIRONMENT

AN-125001-002 (mount) with

AN-025127-101 (element)

Low Band Mobile Antenna 30–35

MHz NMO DC ground

38.2 Inches

(97.0 Centimeters)

85.4 Inches

(217 Centimeters)

AN-125001-002 (mount) with

AN-025127-102 (element)

Low Band Mobile Antenna 34–37

MHz NMO DC ground

38.2 Inches

(97.0 Centimeters)

85.4 Inches

(217 Centimeters)

AN-125001-002 (mount) with

AN-025127-103 (element)

Low Band Mobile Antenna 37–40

MHz NMO DC ground

38.2 Inches

(97.0 Centimeters)

85.4 Inches

(217 Centimeters)

AN-125001-002 (mount) with

AN-025127-104 (element)

Low Band Mobile Antenna 40–47

MHz NMO DC ground

38.2 Inches

(97.0 Centimeters)

85.4 Inches

(217 Centimeters)

AN-125001-002 (mount) with

AN-025127-105 (element)

Low Band Mobile Antenna 45–48

MHz NMO DC ground

38.2 Inches

(97.0 Centimeters)

85.4 Inches

(217 Centimeters)

AN-125001-002 (mount) with

AN-025127-106 (element)

Low Band Mobile Antenna 47–50

MHz NMO DC ground

38.2 Inches

(97.0 Centimeters)

85.4 Inches

(217 Centimeters)

1.3.1 Mobile Antennas

The antenna(s) for the radios must be installed in accordance with Section 8 in this manual. Installation

guidelines presented in Section 8 are limited to metal-body motor vehicles or vehicles with appropriate

ground planes.

Use only the Harris-approved/supplied antenna(s) or an approved replacement antenna. Unauthorized

antennas, modifications, or attachments can cause the FCC RF exposure limits to be exceeded.

1.3.2 Approved Accessories

The radio has been tested and meets FCC RF guidelines when used with accessories supplied or

designated for use with it. Use of other accessories may not ensure compliance with the FCC’s RF

exposure guidelines, and may violate FCC regulations. For a list of approved accessories refer to Section

4 in this manual (begins on page 21) and/or the Products and Services Catalog.

9

14221-1200-4010, Rev. B

1.3.3 Contact Information

For additional information on RF exposure and other information, contact Harris using one of the contact

links listed in Section 4 on page 21.

1.4 RADIO FREQUENCY INTERFERENCE

1.4.1 FCC Part 15

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause undesired

operation.

1.4.2 Industry Canada

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the

following two conditions: (1) this device may not cause interference, and (2) this device must accept any

interference, including interference that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de

licence. L'exploitation est autorisée aux deux conditions suivantes : (1) l'appareil ne doit pas produire de

brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d'en compromettre le fonctionnement.

1.5 OCCUPATIONAL SAFETY GUIDELINES AND SAFETY TRAINING INFORMATION

To ensure bodily exposure to RF electromagnetic energy is within the FCC allowable limits for

occupational use. Always adhere to the following basic guidelines:

The push-to-talk button should only be depressed when intending to send a voice message.

The radio should only be used for necessary work-related communications.

The radio should only be used by authorized and trained personnel. It should never be operated by

children.

Do not attempt any unauthorized modification to the radio. Changes or modifications to the radio may

cause harmful interference and/or cause it to exceed FCC RF exposure limits. Only qualified

personnel should service the radio.

Always use only Harris-authorized accessories (antennas, control heads, speakers/mics, etc.). Use of

unauthorized accessories can cause the FCC RF exposure compliance requirements to be exceeded.

The information listed above provides the user with information needed to make him or her aware of a RF

exposure, and what to do to assure that this radio operates within the FCC exposure limits of this radio.

10

14221-1200-4010, Rev. B

The operator of any mobile radio should be aware of certain hazards common to the

operation of vehicular radio transmissions. Possible hazards include but are not

limited to:

1.6 COMMON HAZARDS

Explosive Atmospheres — Just as it is dangerous to fuel a vehicle with its engine running, be sure to

turn the radio OFF while fuelling the vehicle. If the radio is mounted in the trunk of the vehicle, DO

NOT carry fuel containers in the trunk.

Areas with potentially explosive atmosphere are often, but not always, clearly marked. Turn the radio

OFF when in any area with a potentially explosive atmosphere. It is rare, but not impossible that the

radio or its accessories could generate sparks.

Interference To Vehicular Electronic Systems — Electronic fuel injection systems, electronic anti-

skid braking systems, electronic cruise control systems, etc., are typical of the types of electronic

devices that can malfunction due to the lack of protection from radio frequency (RF) energy present

when transmitting. If the vehicle contains such equipment, consult the dealer for the make of vehicle

and enlist the dealer’s aid in determining if such electronic circuits perform normally when the radio

is transmitting.

Electric Blasting Caps — To prevent accidental detonation of electric blasting caps, DO NOT use

two-way radios within 1000 feet (305 meters) of blasting operations. Always obey the “Turn Off

Two-Way Radios” (or equivalent) signs posted where electric blasting caps are being used (OSHA

Standard: 1926.900).

Radio Frequency Energy — To prevent burns or related physical injury from radio frequency

energy, do not operate the transmitter when anyone outside of the vehicle is within the minimum safe

distance from the antenna as specified in Table 1-1 (as applicable). Refer to Section 1.2 for additional

information.

Vehicles Powered By Liquefied Petroleum (LP) Gas — Radio installation in vehicles powered by

liquefied petroleum gas, where the LP gas container is located in the trunk or other sealed-off space

within the interior of the vehicle, must conform to the National Fire Protection Association standard

NFPA 58. This requires:

The space containing the radio equipment must be isolated and sealed from the space containing

LP gas containers and their fittings.

Outside filling connections must be used for the LP gas container.

The LP gas container space shall be vented to the outside of the vehicle.

Vehicles Equipped with Airbags — For driver and passenger safety, avoid mounting the radio’s

control head (or any other component) above or near airbag deployment areas. In addition to driverside and passenger-side front-impact airbags, some vehicles may also be equipped with side-impact

airbags. For occupant safety, verify the location of all airbags within the vehicle before installing the

radio equipment.

11

14221-1200-4010, Rev. B

Under U.S. law, operation of an unlicensed radio transmitter within the jurisdiction of the

United States may be punishable by a fine of up to $10,000, imprisonment for up to two (2)

years, or both.

1.7 SAFE DRIVING RECOMMENDATIONS

The American Automobile Association (AAA) advocates the following key safe driving recommendations:

Read the literature on the safe operation of the radio.

Keep both hands on the steering wheel and the microphone in its hanger whenever the vehicle is in

motion.

Place calls only when the vehicle is stopped.

When talking from a moving vehicle is unavoidable, drive in the slower lane. Keep conversations

brief.

If a conversation requires taking notes or complex thought, stop the vehicle in a safe place and

continue the call.

Whenever using a mobile radio, exercise caution.

1.8 OPERATING RULES REGULATIONS

Two-way radio systems must be operated in accordance with the rules and regulations of the local,

regional, or national government.

In the United States, this Unity mobile low band VHF amplifier must be operated in accordance with the

rules and regulations of the Federal Communications Commission (FCC). Operators of two-way radio

equipment must be thoroughly familiar with the rules that apply to the particular type of radio operation.

Following these rules helps eliminate confusion, assures the most efficient use of the existing radio

channels, and results in a smoothly functioning radio network.

When using a two-way radio, remember these rules:

It is a violation of FCC rules to interrupt any distress or emergency message. The radio operates in

much the same way as a telephone “party line.” Therefore, always listen to make sure the channel is

clear before transmitting. Emergency calls have priority over all other messages. If someone is

sending an emergency message – such as reporting a fire or asking for help in an accident, do not

transmit unless assistance can be offered.

The use of profane or obscene language is prohibited by Federal law.

It is against the law to send false call letters or false distress or emergency messages. The FCC

requires keeping conversations brief and confined to business. Use coded messages whenever

possible to save on-the-air time.

Using the radio to send personal messages (except in an emergency) is a violation of FCC rules. Send

only essential messages.

It is against Federal law to repeat or otherwise make known anything overheard on the radio.

Conversations between others sharing the channel must be regarded as confidential.

12

14221-1200-4010, Rev. B

In areas where transmission or reception is poor, communication improvement may

sometimes be obtained by moving a few yards in another direction, or moving to a higher

elevation.

NOTE

The FCC requires self-identification at certain specific times by means of call letters. Refer to the

rules that apply to the particular type of operation for the proper procedure.

No changes or adjustments shall be made to the equipment except by an authorized or certified

electronics technician.

1.9 OPERATING TIPS

The following conditions tend to reduce the effective range of two-way radios and should be avoided

whenever possible:

Operating the radio in areas of low terrain, or while under power lines or bridges.

Obstructions such as mountains and buildings.

13

14221-1200-4010, Rev. B

2. SPECIFICATIONS1

2.1 GENERAL

Dimensions (Height x Width x Depth):

XG-100LPA: 2.68 x 8.8 x 9.3 inches (6.81 x 22.4 x 23.6 centimeters)

(Includes bracket but not space required for cables)

XG-100LPA and XG-100M: 7.3 x 8.8 x 9.3 inches (18.5 x 22.4 x 23.6 centimeters)

(Includes bracket but not space required for cables)

Control Head, CH-100: 3.3 x 7.0 x 2.8 inches (8.4 x 17.8 x 7.1 centimeters)

(Does not include bracket and mounting screws)

Control Head, CH721: 2.4 x 6.9 x 3.9 inches (6 x 17.5 x 10 centimeters)

(Does not include bracket and mounting screws)

Weights

XG-100LPA and XG-100M: 13.6 pounds (6.17 kilograms), does not include bracket

Control Head, CH-100: 1.20 pounds (0.54 kilograms), does not include bracket

Control Head, CH-721: 1.25 pounds (0.57 kilograms), does not include bracket

Mounting Brackets: 1.25 pounds (0.57 kilograms) each

Cable, Interface: 1.25 pounds (0.57 kilograms)

Operating Ambient Temperature Range: -22 to +140° Fahrenheit (-30 to +60° Celsius)

Storage Temperature Range: -40 to +185° Fahrenheit (-40 to +85° Celsius)

Altitude

Operating: 15,000 feet (4572 meters) maximum

Storage/Shipment: 50,000 feet (15,240 meters) maximum

DC Supply Voltage Operating Range

For Full Performance: +13.6 Vdc ±10% (Normal range per TIA-603)

Overall Operating Range: +10.8 to +16.6 Vdc

Continuous without Damage: 0 to +17 Vdc

DC Supply Current (less control head and Unity mobile)

XG-100LPA

Receive: 1.1 amps maximum

Transmit at 30 Watts, VHF-Low: 7.25 amps typical, 10 amps maximum

Transmit at 100 Watts, VHF-High: 15 amps typical, 25 amps maximum

Quiescent/Off Current: 2 milliamps maximum

1

These specifications are primarily intended for the use of the installation technician. See the appropriate Specifications

Sheet for the complete specifications.

14

14221-1200-4010, Rev. B

DC Supply Current with CH-100 or CH-721 Control Head

With ½-Watt Speaker Output Power: 0.9 amps maximum

With 10-Watts Speaker Output Power: 2.0 amps maximum

With 15-Watts Speaker Output Power: 2.4 amps maximum

Standby Current (Muted): 0.6 amps maximum

Quiescent/Off Current: 100 microamps maximum

2.2 TRANSMITTER

Frequency Range: 33-48 MHz

Frequency Stability: ±0.5 ppm

Rated Power Output: 30 or 100 Watts (user selectable)

RF Output Impedance: 50 Ohms

Modulation Deviation: ±5 kHz

FM Hum and Noise: 50 dB

Spurious and Harmonic Emissions: -15 dBm

Adjacent Channel Power: >70 dBc

2.3 REGULATORY

FCC Identification Numbers:

XG-100MLPA AQZ-XG-100LPA

50-Watt XG-100M: AQZ-XG-100M00

Applicable FCC Rules: Part 80, Part 90, and Part 15

Industry Canada Certifications:

XG-100MLPA 122D-XG100LPA

50-Watt XG-100M: 122D-XG100M00

Applicable Industry Canada Rules: RSS-119

15

14221-1200-4010, Rev. B

The XG-100M/XG-100LPA combination for VHF Low Band operation requires XGP

Release R4A (or later) firmware.

NOTE

3. INTRODUCTION

This manual contains product safety and installation-related procedures for the XG-100M Unity mobile

with its companion XG-100LPA VHF Low Band Power Amplifier. Installation procedures cover the

mounting and cabling of the equipment, as well as the basic testing of the mobile radio and control head.

An interconnection wiring diagram is included at the rear of this manual. Important product safety-related

information is presented in Section 1.

3.1 GENERAL INFORMATION

The XG-100LPA VHF Low Band Power Amplifier extends the versatility and interoperability of the

Unity XG-100M mobile by adding efficient transmission capability at 33 to 48 MHz. With 100 Watts of

power, user safety is ensured by broadening the coverage area of the mobile radio. Expanded

interoperability allows responders to communicate with multiple jurisdictions and agencies operating on

multiple frequencies and systems. The rugged mechanical package provides reliable performance in harsh

environments. The PA includes the following features:

Expands the versatility of the Unity XG-100M into VHF low band

Additional hardware module for low band transmit operation

User-selectable transmit power of 100 or 30 Watts

Durable construction meets the same MIL-STD-810G specifications as the Unity XG-100M

mobile

Designed to have the same dimensions as the chassis of the Unity XG-100M mobile

Stacks on the mobile to reduce the footprint required in constrained vehicular spaces

Provides three connections: power, radio, and antenna

3.2 EQUIPMENT MOUNTING

The XG-100M Unity mobile with its companion XG-100LPA VHF Low Band Power Amplifier is

designed for remote mounting in a motor vehicle’s trunk, or some other preferably unoccupied section in

a vehicle, such as a fire truck’s equipment shelf. Detailed radio equipment mounting procedures are

presented in Section 7 of this manual. Detailed control head mounting procedures are presented in Section

10 of this manual.

3.3 CONTROL HEADS

3.3.1 General Information

XG-100M Unity mobile with its companion XG-100LPA Low Band Power Amplifier is compatible with

either the CH-721 System model control head or the CH-100 touch screen control head. This equipment

provides the interface for the radio’s operator/user.

16

14221-1200-4010, Rev. B

A 3-wire Controller Area Network (CAN) cable provides radio-to-control head(s) interconnection. One

end of the CAN cable connects to a CAN port on the rear of the Unity mobile radio unit (MRU) and the

other end connects to a CAN port on the rear of the control head. Between the radio and the control head,

the CAN link carries digitized microphone and speaker audio and controlling data such as button presses

and radio messages. For proper operation, the CAN link must be terminated appropriately on each end.

The control head provides the user/operator interface for the XG-100M Unity mobile with its companion

XG-100LPA VHF Low Band Power Amplifier.

Figure 3-1: Simplified Block Diagram Unity Low Band PA

3.3.2 CH-100 Control Head

The CH-100 control head features a 4.3-inch touch screen high-contrast sunlight-readable LCD color

display, providing an easy-to-use menu-driven operator interface. The front panel of the CH-100 head

features an easy-to-use on/off/volume control and group/channel selection controls, an emergency button,

a home button, a USB programming port, a transmit/receive busy indicator, and a microphone connector.

The CH-100 also features a Bluetooth® wireless interface for connection of optional equipment and it

provides support for radio and control head programming via the wireless connection.

The front panel of the CH-100 is shown in Figure 10-1 on page 56 and its rear panel is shown in Figure

10-2. Connectors located on the rear panel include a DC power connector, two (2) CAN port connectors

used for CAN link interconnections, an external speaker connector, a 9-pin serial port connector for

connecting optional equipment such as a mobile data terminal, and a 25-pin multi-function accessory

connector.

3.3.3 CH-721 Control Head

The CH-721 control head, shown in Figure 10-4, features a large 3-line graphical vacuum-fluorescent

display, front panel controls, and buttons for user control of the mobile radio, an internal high-power

audio amplifier to drive an externally-connected speaker, and a front panel microphone connector. It

17

14221-1200-4010, Rev. B

Harris recommends the buyer use only a Harris-authorized representative to install

and service this product. The warranties provided to the buyer under the terms of sale

shall be null and void if this product is installed or serviced improperly, and Harris shall

have no further obligation to the buyer for any damage caused to the product or to any

person or personal property.

Radio Personality Manager Release R11A or later is required to program the XG100M/XG-100LPA radio for VHF Low Band transmit operation.

NOTE

features a 12-key numeric keypad that provides Dual-Tone Multi-Frequency (DTMF) keypad

functionality and operator system/group selection control, three (3) preset buttons, and an

emergency/home button.

Shown in Figure 10-5 on page 58, the CH-721 System model control head has several connectors located

on its rear panel. These connectors include a DC power connector, two (2) CAN port connectors used for

CAN link interconnections, an external speaker connector, a 9-pin serial port connector for connecting

optional equipment such as a mobile data terminal, and a 25-pin multi-function accessory connector.

3.4 OPERATING POWER

The XG-100M Unity mobile radio with its companion XG-100LPA VHF Low Band Power Amplifier is

powered by an external +13.6-volt (nominal) DC power source. In mobile applications, the motor

vehicle’s electrical system is used as the source of DC power. The Unity mobile radio and its companion

XG-100LPA are separately fused. For detailed specifications, see Section 2 of this manual which begins

on page 14.

The control head(s) connected to the radio is powered by the same DC power source, but fused separately

from the XG-100M and XG-100LPA. When the control head is powered-up by the operator, it “wakes

up” the MRU radio by transmitting data to the radio over the CAN link.

3.5 RADIO PROGRAMMING

Unless otherwise stated, all radio installation and test procedures presented in this manual assume the

radio has been programmed by radio network administration personnel before it is delivered to radio

installation personnel. Programming instructions are beyond the scope of this manual.

The Radio Personality Manager (RPM) software application TQS3385 (part number SK-104768-001) is

used to program the XG-100M/XG-100LPA for VHF Low Band conventional operation. RPM can also

be used to flash program new operating software (i.e., firmware) into an XG-100M mobile radio. Refer to

the radio’s maintenance manual for additional information.

For additional RPM information, refer to its built-in online help and/or RPM Software Release Notes,

publication number MS-012550-001(TQS3385).

An XG-100M radio with a CH-100 control head can use a TIA/EIA/RS-232C serial cable connection, a

USB serial cable connection, or a Bluetooth wireless connection for programming operations. The

TIA/EIA/RS-232C serial cable connects to the 9-pin D-subminiature (DB-9) connector on the rear of the

radio. For USB and Bluetooth links, the CH-100 control head provides the connection path.

18

14221-1200-4010, Rev. B

A USB or a Bluetooth link is the preferred connection method for an XG-100M radio with a

CH-100 control head. These links support programming of up to ten (10) personalities/mission

plans into the radio. Only one personality/mission plan is active at a time.

An XG-100M radio with a CH-721 control head can only have one (1) personality/mission

plan. It is always active.

A personality/mission plan loaded into the radio via a TIA/EIA/RS-232C serial link cannot be

extracted (read back) via a USB or Bluetooth link.

NOTE

An XG-100M radio with a CH-721 control head must use a TIA/EIA/RS-232C serial cable connection for

programming. The serial cable connects to the 9-pin D-subminiature (DB-9) connector on the rear of the

radio.

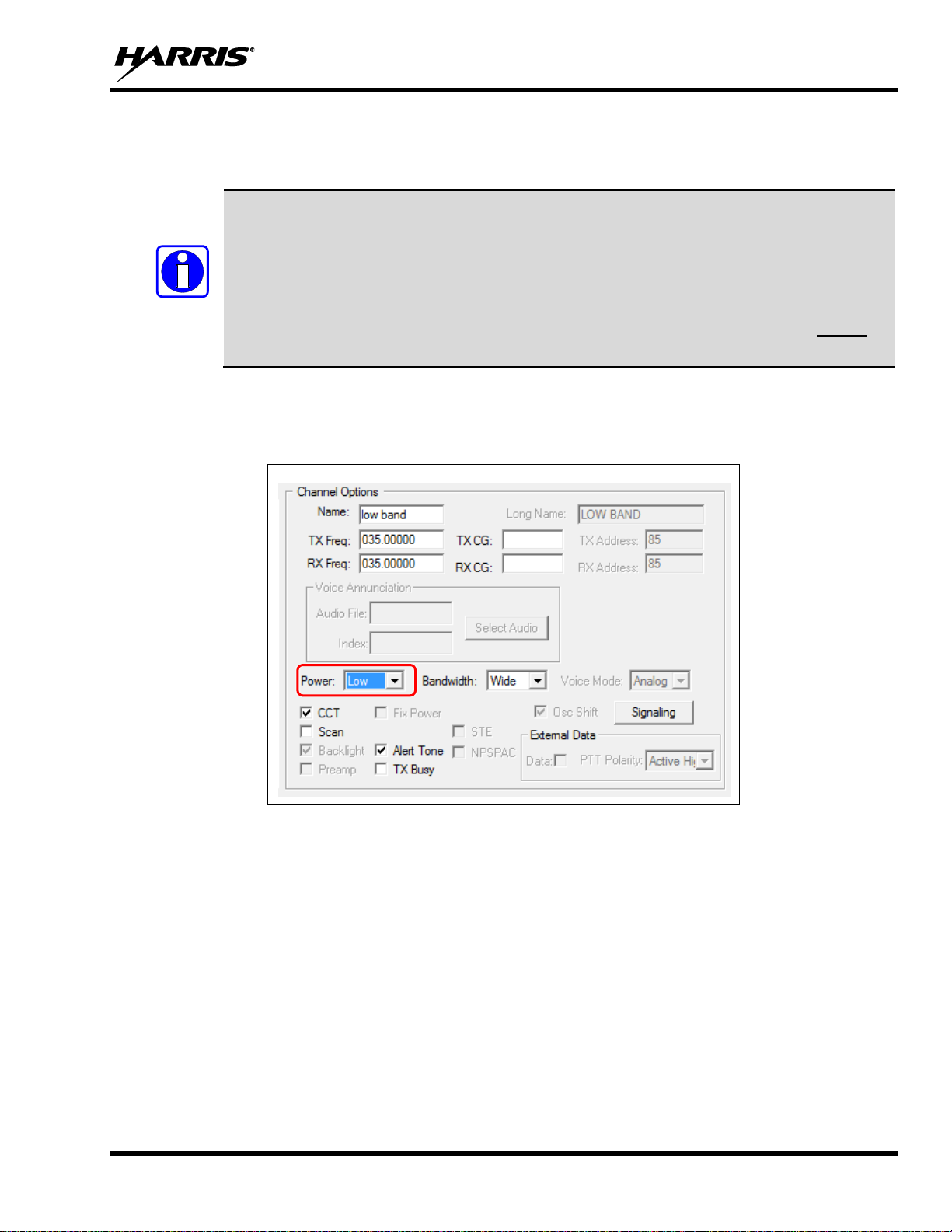

Personality for the VHF Low Band power output is setup in RPM by selecting the Sets->Conventional

Frequency Set controls and select the Conventional Frequency Set tab. In the Channel Options

section, set Power to either Low (30 Watts) or High (100 Watts).

Figure 3-2: Setting Unity Low Band PA in RPM Personality

19

14221-1200-4010, Rev. B

Quick Guide for Unity XG-100M Mobile Radio

with CH-100 Control Head:

14221-1200-1010

Quick Guide for Unity XG-100M Mobile Radio

with CH-721 Control Head:

14221-1200-1000

Operator’s Manual for Unity XG-100M Mobile Radio

with CH-100 Control Head:

14221-1200-2010

Operator’s Manual for Unity XG-100M Mobile Radio

with CH-721 Control Head:

14221-1200-2000

Installation Manual for XG-100M:

14221-1200-4440

Maintenance Manual for XG-100M

14221-1200-5000

3.6 RELATED PUBLICATIONS

The following publications contain additional information about this radio equipment:

The Product Safety Manual and Quick Guides (for radio operators) are included with each mobile radio

equipment package when the package ships from the factory. The Operator’s Manuals and the Quick

Guides are also available online at http://pspc.harris.com/Products/Mobile/unitymobile.aspx without a

login. All other XG-100M and XG-100LPA related mobile radio publications can be obtained from

www.pspc.harris.com via an Information Center login (i.e., a user name and password are required). The

publications are in Tech-Link’s Technical Manual Library.

20

14221-1200-4010, Rev. B

4. CUSTOMER SERVICE

4.1 TECHNICAL SUPPORT

The Harris Technical Assistance Center (TAC) resources are available to help you with overall system

operation, maintenance, upgrades, and product support. TAC is your point of contact when you need

technical questions answered.

Product specialists, with detailed knowledge of product operation, maintenance, and repair, provide

technical support via a toll-free telephone number (in North America). Support is also available through

mail, fax, and e-mail.

For more information about technical assistance services, contact your sales representative, or call the

Technical Assistance Center directly at:

North America: 1-800-528-7711

International: 1-434-385-2400

Fax: 1-434-455-6712

E-mail: PSPC_tac@harris.com

4.2 TECH-LINK

For more information about this and other Harris PSPC products, check out our Tech-Link service at:

https://premier.pspc.harris.com/

Tech-Link is a one stop link to Technical Documentation (downloadable PDFs), Software Revisions,

Feature Encryption, pictorials of parts and accessories, and other information pertaining to our products.

This is information that will enhance your service efforts; 24 hours a day and 7 days a week.

4.3 CUSTOMER CARE

If any part of the system equipment is damaged on arrival, contact the shipper to conduct an inspection

and prepare a damage report. Save the shipping container and all packing materials until the inspection

and the damage report are completed. In addition, contact the Customer Care center to make

arrangements for replacement equipment. Do not return any part of the shipment until you receive

detailed instructions from a Harris representative.

Contact the Customer Care center at http://www.pspc.harris.com/CustomerService or:

North America:

Phone Number: 1-800-368-3277

Fax Number: 1-321-409-4393

E-mail: PSPC_CustomerFocus@harris.com

International:

Phone Number: 1-434-455-6403

Fax Number: 1-321-409-4394

E-mail: PSPC_InternationalCustomerFocus@harris.com

21

14221-1200-4010, Rev. B

After removal from the carton, examine the mobile radios, control head, and other

components for broken, damaged, loose, or missing parts. If any are noted, contact the

Customer Care center (see page 21) immediately to discuss and arrange the return of the

equipment to Harris for replacement. Any unauthorized attempts to repair or modify this

equipment will void the warranty and could create a safety hazard.

5. UNPACKING AND CHECKING THE EQUIPMENT

Upon receipt of the Harris equipment, carefully unpack the equipment and verify that the order is

complete. Inspect the equipment for any shipping damage. If there is any damage to the equipment,

contact the carrier immediately and have their representative verify the damage. If you fail to report the

shipping damage immediately, you may forfeit any claim against the carrier.

When unpacking the equipment, check the contents against the packing list. Contact your Harris

representative and the carrier if any discrepancies are noted.

After verifying all equipment is accounted for, proceed with the installation.

5.1 MATERIALS

A typical set of installation materials for a Unity XG-100M mobile radio with XG-100LPA VHF Low

Band Amplifier includes:

Unity XG-100M Mobile Radio -refer to Table 5-1.

Unity XG-100LPA 100W Low Band Power Amplifier -refer to Table 5-1.

CH-100 Control Head [12099-1200-01; catalog number XMCP9R].

or

CH-721 System Control Head [part number CU23218-0004; catalog number MAMW-NCP9F].

Standard Microphone [part number MC-101616-041; part of catalog number MAMW-NMC7Z].

Installation Kits:

Unity XG-100LPA – contents listed in Table 5-2.

XG-100M with Remote CH-100 Control head - contents listed in Table 5-3.

XG-100M with Remote CH-721 System Control head - contents listed in Table 5-4.

Two (2) or Three (3) Antennas - refer to Table 5-5 for VHF Low Band antennas and Table 5-6 for

other XG-100M antenna options.

22

14221-1200-4010, Rev. B

CATALOG NUMBER

PART NUMBER

DESCRIPTION

XM-100F or

XM-100F-D01 or

XM-100F-D02

12099-1000-01

Unity XG-100M Mobile Radio, 136-870 MHz

Unity XG-100M Mobile Radio, 136-520 MHz

Unity XG-100M Mobile Radio, 136-174, 762-870 MHz

XM-100LPA

12099-3500-02

100W VHF Low Band Power Amplifier

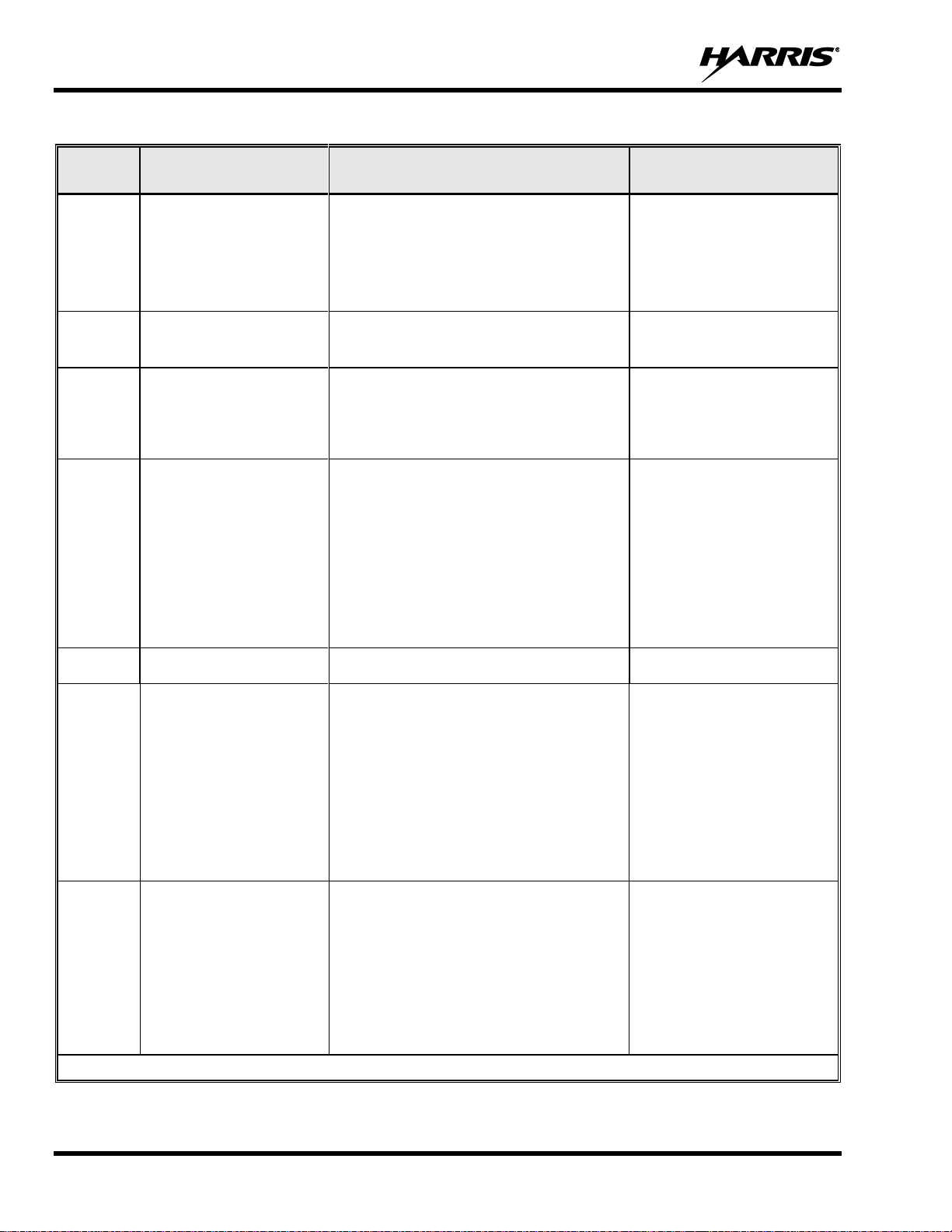

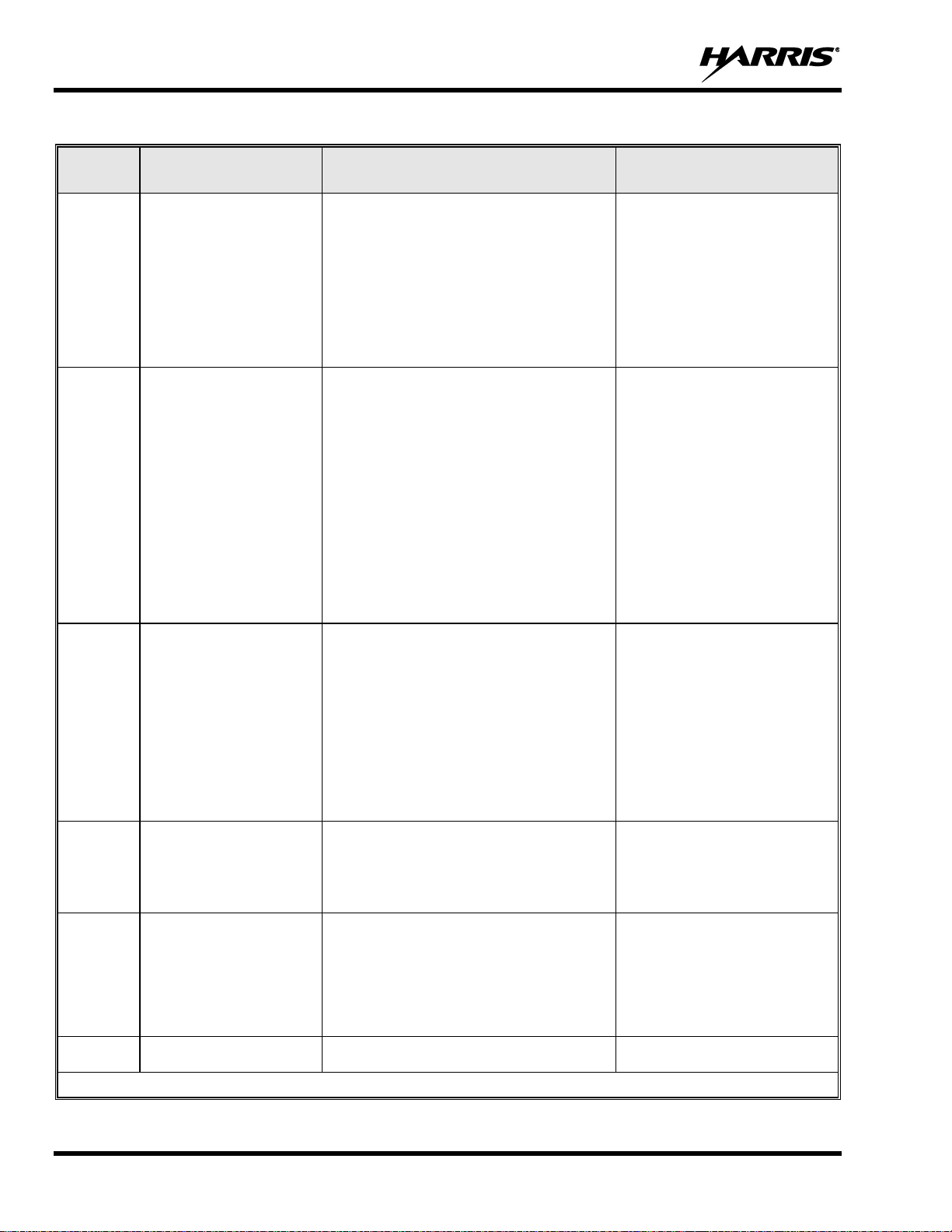

Table 5-2: Installation Kit XM-ZN2G for XG-100LPA

QTY

PER KIT

PART NUMBER

DESCRIPTION

ILLUSTRATION

1

14002-0167-01

Cable, DC Power for High-Power Applications,

Includes:

(1) DC Power Cable with a 20-Foot Red Wire,

(1) water-resistant inline HEB-BB fuse holder,

(2) 30-amp BAF-30 fuses,

(2) ring terminals, and

(4) heat-shrink tubing, 50mm long

1

W90-0223-001

Cable, RF; BNC Male to BNC Male, 12"

1

AD00006

Screws: #8-32 Pan-Head (Package of 4

screws)

1

SC-018424

Screws: M5 x 10 mm Philips-Head SEMS

Screws (Package of 12 screws)

1

1000003678

Bracket, Base

2

FM-018205

Extension Bracket

Table 5-1: Catalog and Part Numbers for Unity XG-100M Mobile Radio with XG-100LPA

23

14221-1200-4010, Rev. B

Table 5-3: Installation Kit XMZN9A for XG-100M with CH-100 Control Head

QTY

PER KIT

PART NUMBER

DESCRIPTION

ILLUSTRATION

1

12099-1500-01

Kit, Swivel Mounting, includes:

(1) U-Shaped Swivel-Mount Bracket,

(2) Socket-Head Cap Screws, M4x8mm,

(2) Flat Washers, and

(2) Lock Washers

1

MAMROS0034-NN006

Cable, Speaker; 6-Inch, Straight

Connector

1

CA-009562-030

Cable, CAN; 30 feet, Right-Angle-toStraight Connectors

1

LS102824V10

Speaker, External Mobile; 4 Ohm,

20-Watt (with 4.6-foot cable)

2

CD-014027-001

Terminator, CAN; 3-Pin, Straight Body

1

CA-012616-001

Cable, DC Power for CH-100, Includes:

(1) DC Power Cable with straight

connector,

(2) waterproof inline HFB-type fuse

holders,

(1) 3-amp AGC fuse,

(1) 5-amp AGC fuse

(2) ring terminals, and

(1) spade terminal

1

KT23117

Kit, Bracket. Includes Base Bracket

FM103111V1 and M5 hardware

Continued…

24

14221-1200-4010, Rev. B

Table 5-3: Installation Kit XMZN9A for XG-100M with CH-100 Control Head

QTY

PER KIT

PART NUMBER

DESCRIPTION

ILLUSTRATION

1

CA-012365-001

Cable, DC Power for XG-100M,

Includes:

(1) DC Power Cable with straight

connector,

(2) waterproof inline HFB-type fuse

holders,

(1) 3-amp AGC fuse,

(1) 15-amp AGC fuse, (radio Application)

(1) 20-amp AGC fuse, (not used)

(2) ring terminals, and

(1) spade terminal

1

FM-104859-001

Cap, Waterproof (For control head’s DB-9

serial port connector)

1

FM-104859-002

Cap, Waterproof (For control head’s DB-25

connector)

1

FM-104859-003

Cap, Waterproof (For radio’s DB-9

connector)

1

FM-104859-004

Cap, Waterproof (For radio’s DB-25

connector)

25

14221-1200-4010, Rev. B

Table 5-4: Installation Kit XMZN7R for XG-100M with CH-721 Control Head

QTY

PER KIT

PART NUMBER

DESCRIPTION

ILLUSTRATION

1

KT23117

Kit, Bracket. Includes Base Bracket

FM103111V1 and M5 hardware

1

CA-012365-001

Cable, DC Power for XG-100M,

Includes:

(1) DC Power Cable with straight

connector,

(2) waterproof inline HFB-type fuse

holders,

(1) 3-amp AGC fuse,

(1) 15-amp AGC fuse, (radio

Application)

(1) 20-amp AGC fuse, (not used)

(2) ring terminals, and

(1) spade terminal

1

CA-012616-001

Cable, DC Power for CH-721, Includes:

(1) DC Power Cable with straight

connector,

(2) waterproof inline HFB-type fuse

holders,

(1) 3-amp AGC fuse,

(1) 5-amp AGC fuse

(2) ring terminals, and

(1) spade terminal

1

CA-009562-030

Cable, CAN; 30 feet, Right-Angle-toStraight Connectors

1

KT-008608

Kit, CH-721 Mounting Bracket. Includes

(1) U-Shaped Mounting Bracket, (2)

¼-Inch #8-32 stainless-steel screws, (2)

stainless-steel flat washers and (2)

stainless-steel lock washers

2

CD-014027-001

Terminator, CAN; 3-Pin, Straight Body

Continued…

26

14221-1200-4010, Rev. B

Table 5-4: Installation Kit XMZN7R for XG-100M with CH-721 Control Head

QTY

PER KIT

PART NUMBER

DESCRIPTION

ILLUSTRATION

1

LS102824V10

Speaker, External Mobile; 20-Watt (with

4.6-foot cable)

1

MAMROS0034-NN006

Cable, Speaker; 6-Inch, Straight

Connector

1

FM-104859-001

Cap, Waterproof (For control head’s DB-9

serial port connector)

1

FM-104859-002

Cap, Waterproof (For control head’s

DB-25 connector)

1

FM-104859-003

Cap, Waterproof (For radio’s DB-9

connector)

1

FM-104859-004

Cap, Waterproof (For radio’s DB-25

connector)

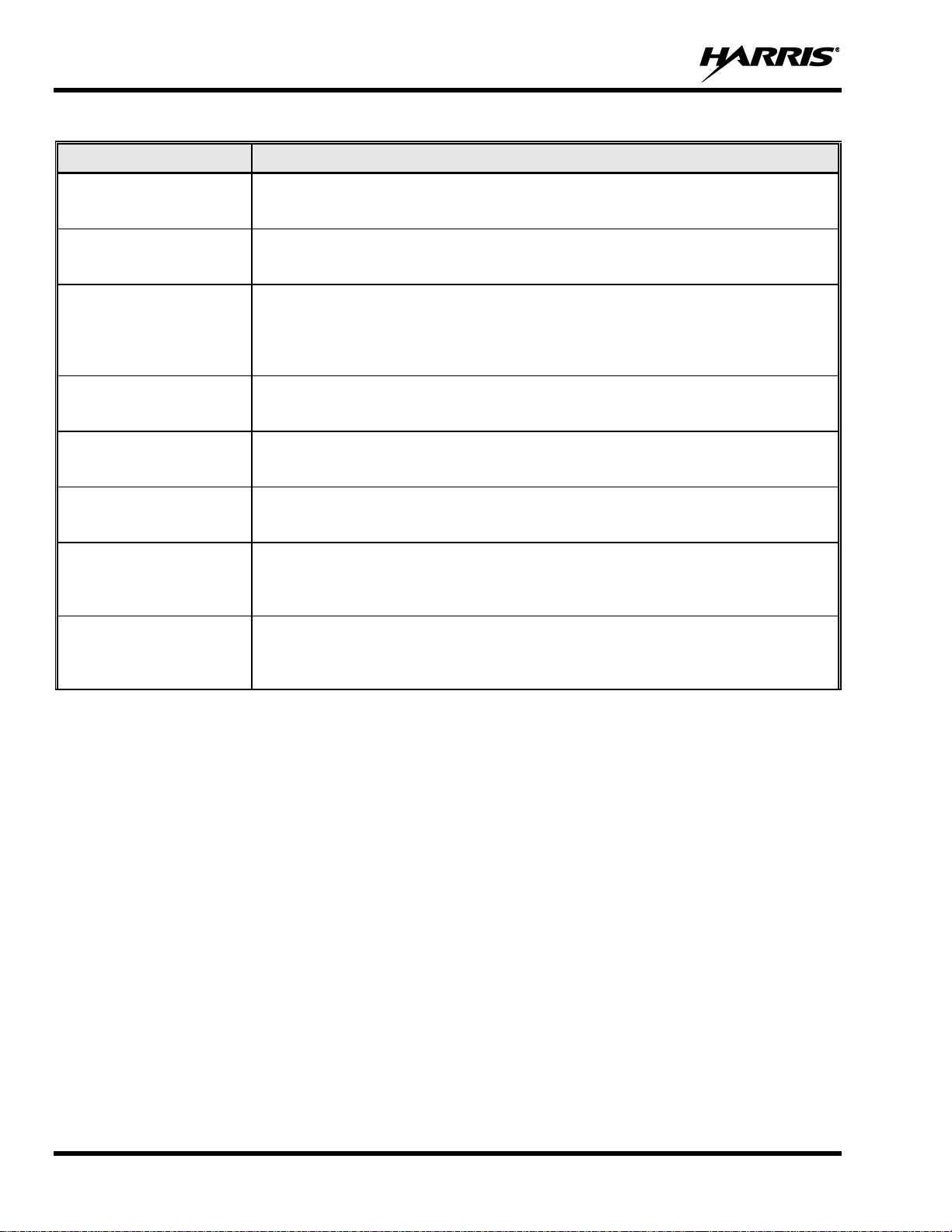

Table 5-5: XG-100LPA Antenna Elements and Mount Options

PART NUMBER

DESCRIPTION

AN-125001-002

Antenna Mount: Standard Rooftop, NMO Mounting Base, 15-foot (4.6-meter)

RF-195 (or equivalent) Low-Loss RF Cable, Male TNC RF Connector.

AN-025127-101

Antenna Element: Low Band Mobile Antenna 30–35 MHz NMO DC ground.

AN-025127-102

Antenna Element: Low Band Mobile Antenna 34–37 MHz NMO DC ground.

AN-025127-103

Antenna Element: Low Band Mobile Antenna 37–40 MHz NMO DC ground.

AN-025127-104

Antenna Element: Low Band Mobile Antenna 40–47 MHz NMO DC ground.

AN-025127-105

Antenna Element: Low Band Mobile Antenna 45–48 MHz NMO DC ground.

AN-025127-106

Antenna Element: Low Band Mobile Antenna 47–50 MHz NMO DC ground.

27

14221-1200-4010, Rev. B

Table 5-6: XG-100M Antenna Elements and Mount Options

PART NUMBER

DESCRIPTION

AN-125001-002

Antenna Mount: Standard Rooftop, NMO Mounting Base, 15-foot (4.6-meter)

RF-195 (or equivalent) Low-Loss RF Cable, Male TNC RF Connector.

AN-125001-004

Antenna Mount: Thick Rooftop, NMO Mounting Base, 15-foot (4.6-meter) RF-195

(or equivalent) Low-Loss RF Cable, Male TNC RF Connector.

AN-125001-006

Antenna Mount: GPS Combo Rooftop, NMO Mounting Base, 17-foot (5.1-meter)

RF-195 (or equivalent) Low-Loss RF Cable, Male TNC RF Connector; 17-foot

(5.1-meter) RG174/U (or equivalent) GPS RF Cable with Male SMA RF Connector

(attached); 2.7 to 3.3 Vdc or 4.8 to 5.2 Vdc Bias.

AN-125001-008

Antenna Mount: Magnetic, NMO Mounting Base, 15-foot (4.6-meter) RF-195 (or

equivalent) Low-Loss RF Cable, Male TNC RF Connector.

12099-0310-01

(Cat. No. XMAN6H)

Antenna Element: Multi-Band (136 to 174 MHz, 380 to 520 MHz, and 762 to 870

MHz), NMO, Factory Tuned.

12099-0330-01

(Cat. No. XMAN6J)

Antenna Element: Multi-Band (136 to 174 MHz/3 dBi, 380 to 520 MHz/3 dBi, and

762 to 870 MHz/6 dBi), NMO, Factory Tuned, 100-Watt.

AN-025187-001

(Cat. No. XMAN5F)

Antenna: GPS Receive-Only, Roof-Mount, 17-foot (5.2-meter) RG174/U (or

equivalent) RF Cable with Male SMA RF Connector (attached); 2.7 to 3.3 Vdc or

4.8 to 5.2 Vdc Bias.

AN-025187-003

(Cat. No. XMAN3L)

Antenna: GPS Receive-Only, Magnetic-Mount, 17-foot (5.2-meter) RG174/U (or

equivalent) RF Cable with Male SMA RF Connector (attached); 2.7 to 3.3 Vdc or

4.8 to 5.2 Vdc Bias.

28

14221-1200-4010, Rev. B

A professional radio installer should perform the installation!

Crimp Tool for Non-Insulated Terminals:

Thomas & Betts WT-111-M

Crimp Tool for Insulated Terminals: Klein

1005

Crimp Tool for 35/50-Watt Radio

Installations (Fuse Holder): Thomas & Betts

– WT-112M or California Terminal Products

No. 1250 or Channelock No. 909

Crimp Tool for 110-Watt Radio Installations

(Fuse Holder and 6-AWG Ring Terminals):

Molex 64001-3900 or 3M TH-450.

3-Blade Coax Cable Stripper for RG-58 Cable

similar to Tyco Electronics 1490490-1

(includes blades)

Ratcheting Hex-Crimp Tool for 50-Ohm TNC

and BNC RF Connectors and RG-58 Cable

similar to Tyco Electronics 58433-2 (includes

Crimper 354940-1 and Die Set 58436-1) or

Emerson Network Power 24-9960P

Non-Metallic Fish Tape, 25-Foot: Klein-Lite

50156

Two Pairs of Soft-Jaw Pliers: Tessco 450520

or equivalent

Flush-Cut and Large Wire Cutters

Phillips-Head Screwdrivers, #1 and #2

Flat-Blade Screwdrivers, ⅛ and ¼-inch tips

⅛-Inch Hex Key Wrench (Allen Wrench)

5

/

16

-Inch Combination or Open-End Wrench

Socket and/or Nut Driver Sets

¾-Inch or ⅜-Inch Hole Saw with Depth

Protection: ¾-Inch = Ripley HSK 19 or

Antenex HS34; ⅜-Inch = Antenex HS38

Clutch-Type (i.e., with torque limit) Cordless

Drill with Drill Bits and Driver Bits

Deburring Tool (for ⅜-inch and smaller

holes)

Tie Wraps: 6-inches or larger

Various Fasteners (e.g., machine screws and

nuts, Tek screws, etc.)

6. PLANNING THE INSTALLATION

6.1 GENERAL INFORMATION

Before beginning the radio installation, plan it carefully so it will meet the following requirements:

The installation is safe for the operator and passengers within the vehicle.

The equipment is installed away from the airbag deployment areas.

The installation allows for convenient access by the operator, as applicable (i.e., the control head).

The equipment is protected from water damage.

The installation is neat and allows easy service access.

The radio is mounted in a location assuring the vehicle occupant’s safety and out of the way of

passengers and auto mechanics.

See Section 6.3 on page 30 for additional requirements on equipment locations.

6.2 TOOLS REQUIRED

The following list of equipment is recommended for the installation. Equivalents may be used unless

otherwise specified:

29

Loading...

Loading...