Page 1

TECHNICAL MANUAL

888-2595-001

ZX Series FM

Transmitter

ZX Series

FM Transmitters

ZX2500, ZX3750, ZX5000, ZX7.5, & ZX10

T.M. No. 888-2595-001

© Copyright Harris Corporation 2009, 2010, 2011

All rights reserved

Dec 20, 2011

Rev: J

Page 2

ii 888-2595-001 12/20/11

WARNING: Disconnect primary power prior to servicing.

Page 3

Technical Assistance

Technical and troubleshooting assistance for HARRIS Transmission products is available from

HARRIS Field Service (factory location: Quincy , Illinois, USA) during normal business hours (8:00

AM - 5:00 PM US Central T ime, UTC-6 ). Telephone +1-2 17-222-8200 to contact the Field Service

Department; FAX +1-217-221-7086; or E-mail questions to tsupport@harris.com.

Emergency service is available 24 hours a day, seven days a week, by telephone only.

Other on-line assistance, including technical manuals, white papers, software downloads, and

service bulletins, is available at www.support.harris.broadcast.com (log-in required).

Address written correspondence to Field Service Department, HARRIS Broadcast Communications

Division, P.O. Box 4290, Quincy, Illinois 62305-4290, USA. For other global service contact

information, please visit: http://www.broadcast.harris.com/contact.

NOTE: For all service and parts correspondence, you will need to provide the Sales Order number,

as well as the Serial Number for the transmitter or part in question. For future reference, record

those numbers here: ___________________/____________________

Please provide these numbers for any written request, or have these numbers ready in the event you

choose to call regarding any service or parts requests. For warranty claims they will be required, and

for products out of warranty, they will help us to best identify what specific hardware was shipped.

Replaceable Parts Service

Replacement parts are available from HARRIS Service Parts Department from 7:00 AM to 11:00

PM US Central Time (UTC-6), seven days a week. Telephone +1-217-222-8200 or email

servicepartsreq@harris.com to contact the Service Parts Department.

Emergency replacement parts are available by telephone only , 24 hours a day , seven days a week

by calling +1-217-222-8200.

Unpacking

Carefully unpack the equipment and perform a visual inspection to determine if any apparent

damage was incurred during shipment. Retain the shipping materials until it has been verified that

all equipment has been received undamaged. Locate and retain all PACKING CHECK LISTs. Use

the PACKING CHECK LIST to help locate and identify any components or assemblies which are

removed for shipping and must be reinstalled. Also remove any shipping supports, straps, and

packing materials prior to initial turn on.

Returns And Exchanges

No equipment can be returned unless written approval and a Return Authorization is received from

HARRIS Broadcast Communications Division. Special shipping instructions and coding will be

provided to assure proper handling. Complete details regarding circumstances and reasons for

return are to be included in the request for return. Custom equipment or special order equipment is

not returnable. In those instances where return or exchange of equipment is at the request of the cus

tomer, or convenience of the customer, a restocking fee will be charged. All returns will be sent

freight prepaid and properly insured by the customer. When communicating with HARRIS Broad

cast Communications Division, specify the HARRIS Order Number or Invoice Number

-

-

12/20/11 888-2595-001 iii

WARNING: Disconnect primary power prior to servicing.

Page 4

iv 888-2595-001 12/20/11

WARNING: Disconnect primary power prior to servicing.

Page 5

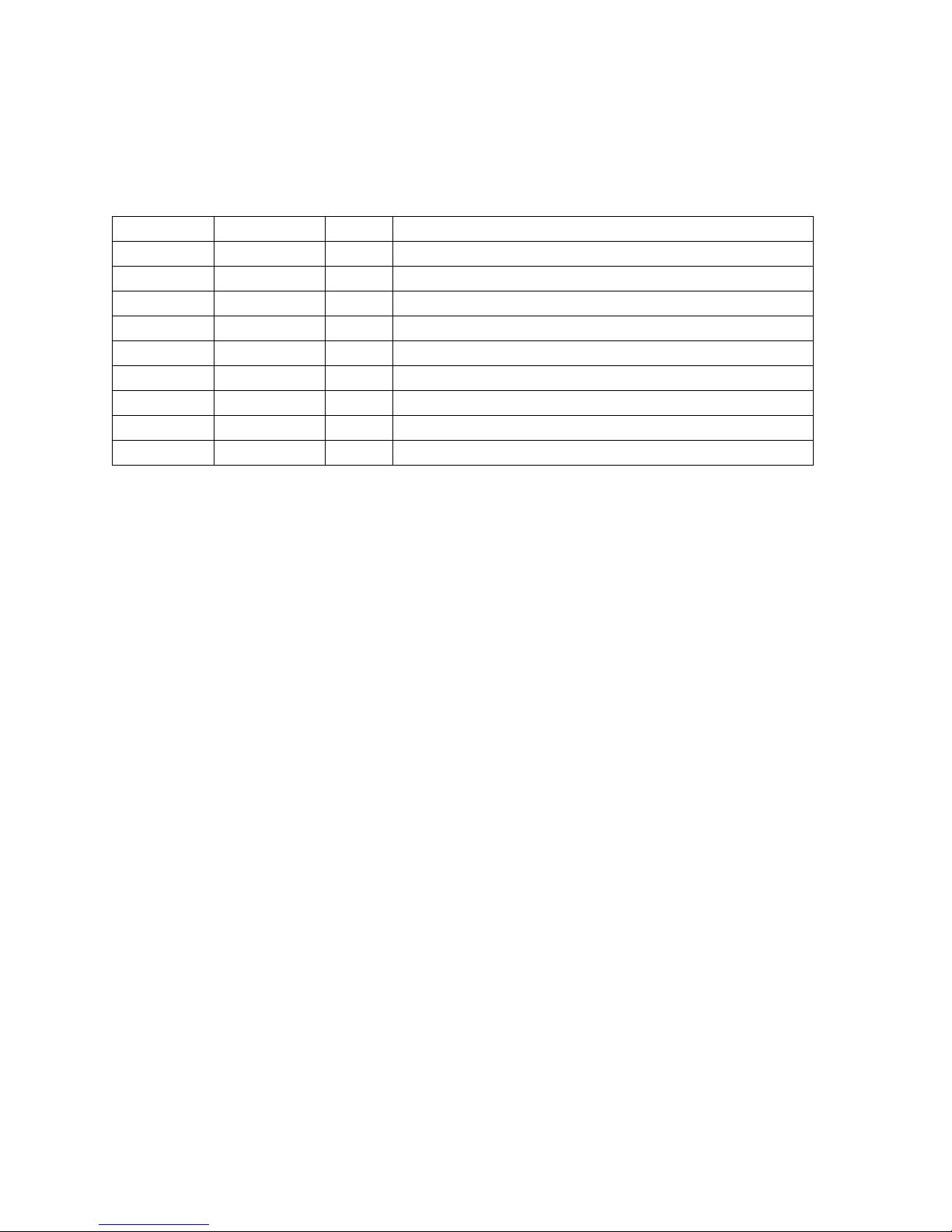

Manual Revision History

ZX Series FM Transmitter Manual

REV. DATE ECN Pages Affected

A 2009 June

B 2009 July P44299 Added service revisions.

C 2009 Dec 58482 Revised Title Page, MRH1, TOC, added Appendix-A

D 2010 Jan 58572 Revised Title Page, MRH1, Sheets 2-15 and 2-16

E 2010 May 58978 Revised to include 7.5 and 10 kW models

F 2010 Aug 59394 Revised Title Page, MRH1, Sheet 4-2

G 2010 Sep 59487 Revised Title Page, MRH, Table 2-2 on Page 2-14

H 2011 Jan 59870 Updated Appendix A-Web Remote Option

J 2011 Dec 61074 Revised Titl Page, MRH, Sheet 4-8

12/20/11 888-2595-001 MRH-1

WARNING: Disconnect primary power prior to servicing.

Page 6

MRH-2 888-2595-001 12/20/11

WARNING: Disconnect primary power prior to servicing.

Page 7

Guide to Using Harris Parts List Information

Transmitter

994 9283 001

Control Cabinet

992 9244 002

Controller Board

992 8344 002

PA Cabinet

992 9400 002

PA Amplifier

992 7894 002

PA Amplifier Board

992 7904 002

Output Cabinet

992 9450 001

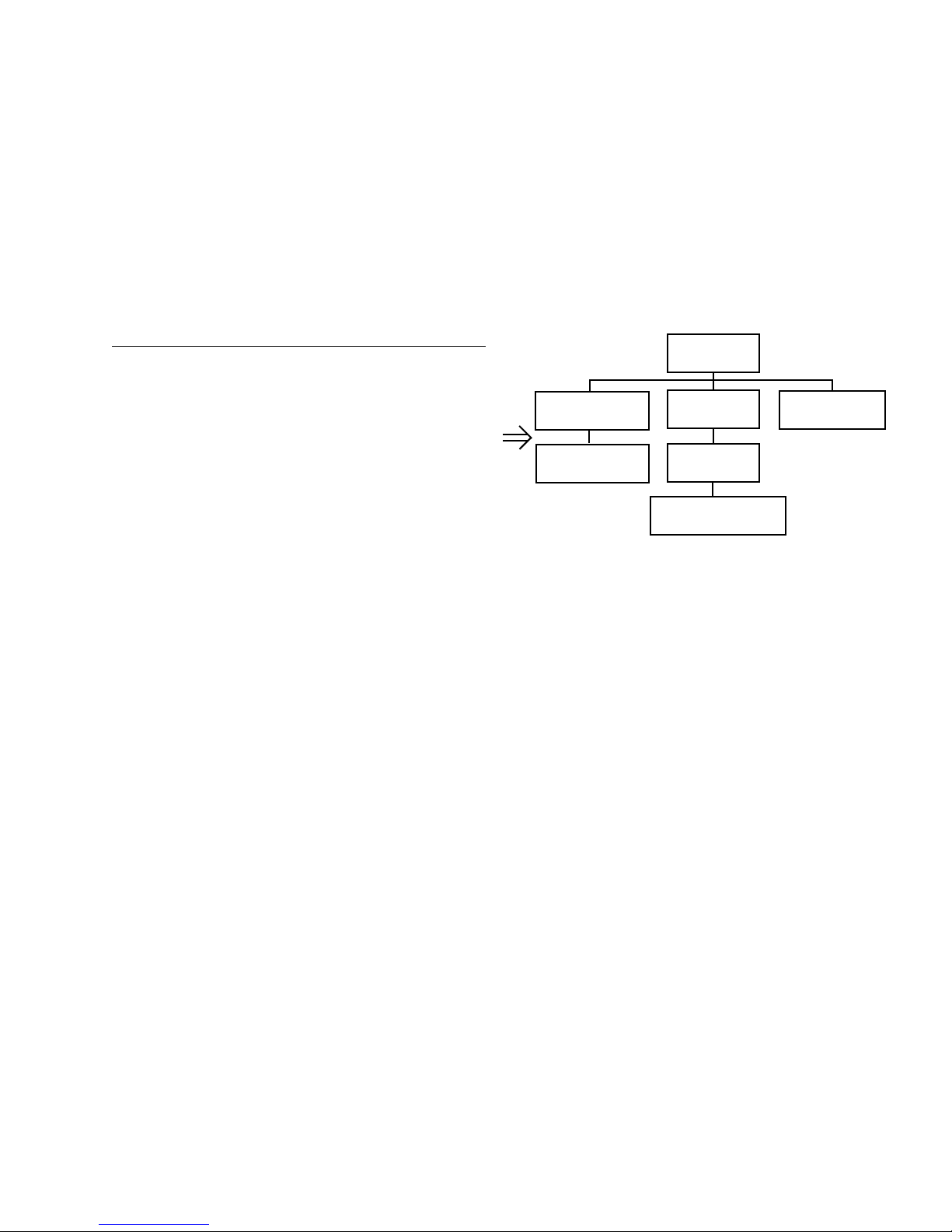

The Harris Replaceable Parts List Index portrays a tree structure with the major items being leftmost in the index.

The example below shows the Transmitter as the highest item in the tree structure. If you were to look at the bill

of materials table for the Transmitter you would find the Control Cabinet, the PA Cabinet, and the Output

Cabinet. In the Replaceable Parts List Index the Control Cabinet, PA Cabinet, and Output Cabinet show up one

indentation level below the Transmitter and implies that they are used in the Transmitter. The Controller Board is

indented one level below the Control Cabinet so it will show up in the bill of material for the Control Cabinet.

The tree structure of this same index is shown to the right of the table and shows indentation level versus tree

structure level.

Example of Replaceable Parts List Index and equivalent tree structure:

Replaceable Parts List Index Part Number Page

Table 7-1. Transmitter 994 9283 001 7-2

Table 7-2. Control Cabinet 992 9244 002 7-3

Table 7-3. Controller Board 992 8344 002 7-6

Table 7-4. PA Cabinet 992 9400 002 7-7

Table 7-5. PA Amplifier 994 7894 002 7-9

Table 7-6. PA Amplifier Board 992 7904 002 7-10

Table 7-7. Output Cabinet 992 9450 001 7-12

The part number of the item is shown to the right of the description as is the page in the manual where the bill for

that part number starts. Inside the actual tables, four main headings are used:

NOTE: Inside the individual tables some standard conventions are used:

The term “SEE HIGHER LEVEL BILL” in the description column implies that the reference designated part

• Table #-#. ITEM NAME - HARRIS PART NUMBER - this line gives the information that corresponds

to the

• Replaceable Parts List Index entry;

• HARRIS P/N column gives the ten digit Harris part number (usually in ascending order);

• DESCRIPTION column gives a 25 character or less description of the part number;

• REF. SYMBOLS/EXPLANATIONS column 1) gives the reference designators for the item (i.e., C001,

R102, etc.) that corresponds to the number found in the schematics (C001 in a bill of material is equiva

lent to C1 on the schematic) or 2) gives added information or further explanation (i.e., “Used for 208V

operation only,” or “Used for HT 10LS only,” etc.).

• A # symbol in front of a component such as #C001 under the REF. SYMBOLS/EXPLANATIONS col-

umn means that this item is used on or with C001 and is not the actual part number fo r C001.

• In the ten digit part numbers, if the last three numbers are 000, the item is a part that Harris has pur-

chased and has not manufactured or modified. If the last three numbers are other than 000, the item is

either manufactured by Harris or is purchased from a vendor and modified for use in the Harris product.

• The first three digits of the ten digit part number tell which family the part num ber belongs to - for

example, all electrolytic (can) capacitors will be in the same family (524 xxxx 000). If an electrolytic

(can) capacitor is found to have a 9xx xxxx xxx part number (a number outside of the normal family of

numbers), it has probably been modified in some manner at the Harris factory and will therefore show

up farther down into the individual parts list (because each table is normally sorted in ascending order).

Most Harris made or modified assemblies will have 9xx xxxx xxx numbers associated with them.

number will show up in a bill that is higher in the tree structure. This is often the case for components

that may be frequency determinant or voltage determinant and are called out in a higher level bill

structure that is more customer dependent than the bill at a lower level.

-

12/20/11 888-2595-001 vii

WARNING: Disconnect primary power prior to servicing.

Page 8

viii 888-2595-001 12/20/11

WARNING: Disconnect primary power prior to servicing.

Page 9

12/20/11 888-2595-001 ix

WARNING: Disconnect primary power prior to servicing.

Page 10

x 888-2595-001 12/20/11

WARNING: Disconnect primary power prior to servicing.

Page 11

!

WA RN IN G:

THE CURRENTS AND VOLTAGES IN THIS EQUIPMENT ARE DANGEROUS.

!

WA RN IN G:

!

WA RN IN G:

!

WA RN IN G:

PERSONNEL MUST AT ALL TIMES OBSERVE SAFETY WARNINGS, INSTRUC

TIONS, AND REGULATIONS.

-

This manual is intended as a general guide for trained and qualified personnel who are aware

of the dangers inherent in handling potentially hazardous electrical/electronic circuits. It is not

intended to contain a complete statement of all safety precautions which should be observed

by personnel in using this or other electronic equipment.

The installation, operation, maintenance, and service of this equipment involves risks both to

personnel and equipment, and must be performed only by qualified personnel exercising due

care. HARRIS CORPORATION shall not be responsible for injury or damage resulting from

improper procedures or from the use of improperly trained or inexperienced personnel

performing such tasks. During installation and operation of this equipment, local building

codes and fire protection standards must be observed.

The following National Fire Protection Association (NFPA) standards are recommended as

reference:

- Automatic Fire Detectors, No. 72E

- Installation, Maintenance, and Use of Portable Fire Extinguishers, No. 10

- Halogenated Fire Extinguishing Agent Systems, No. 12A

ALWAYS DISCONNECT POWER BEFORE OPENING COVERS, DOORS, ENCLOSURES, GATES, PANELS, OR SHIELDS. ALWAYS USE GROUNDING STICKS

AND SHORT OUT HIGH VOLTAGE POINTS BEFORE SERVICING. NEVER MAKE

INTERNAL ADJUSTMENTS, PERFORM MAINTENANCE, OR SERVICE WHEN

ALONE OR WHEN FATIGUED.

Do not remove, short-circuit, or tamper with interlock switches on access covers, doors,

enclosures, gates, panels, or shields. Keep away from live circuits, know your equipment and

don’t take chances.

IN CASE OF EMERGENCY, ENSURE THAT POWER HAS BEEN DISCONNECTED.

IF OIL FILLED OR ELECTROLYTIC CAPACIT ORS ARE UTILIZED IN YOUR

EQUIPMENT, AND IF A LEAK OR BULGE IS APPARENT ON THE CAPACITOR

CASE WHEN THE UNIT IS OPENED FOR SERVICE OR MAINTENANCE, ALLOW

THE UNIT TO COOL DOWN BEFORE ATTEMPTING TO REMOVE THE DEFEC

TIVE CAP ACITOR. DO NOT ATTEMPT TO SERVICE A DEFECTIVE CAPACITOR

-

12/20/11 888-2595-001 xi

WARNING: Disconnect primary power prior to servicing.

Page 12

WHILE IT IS HOT DUE TO THE POSSIBILITY OF A CASE RUPTURE AND SUBSEQUENT INJURY.

xii 888-2595-001 12/20/11

WARNING: Disconnect primary power prior to servicing.

Page 13

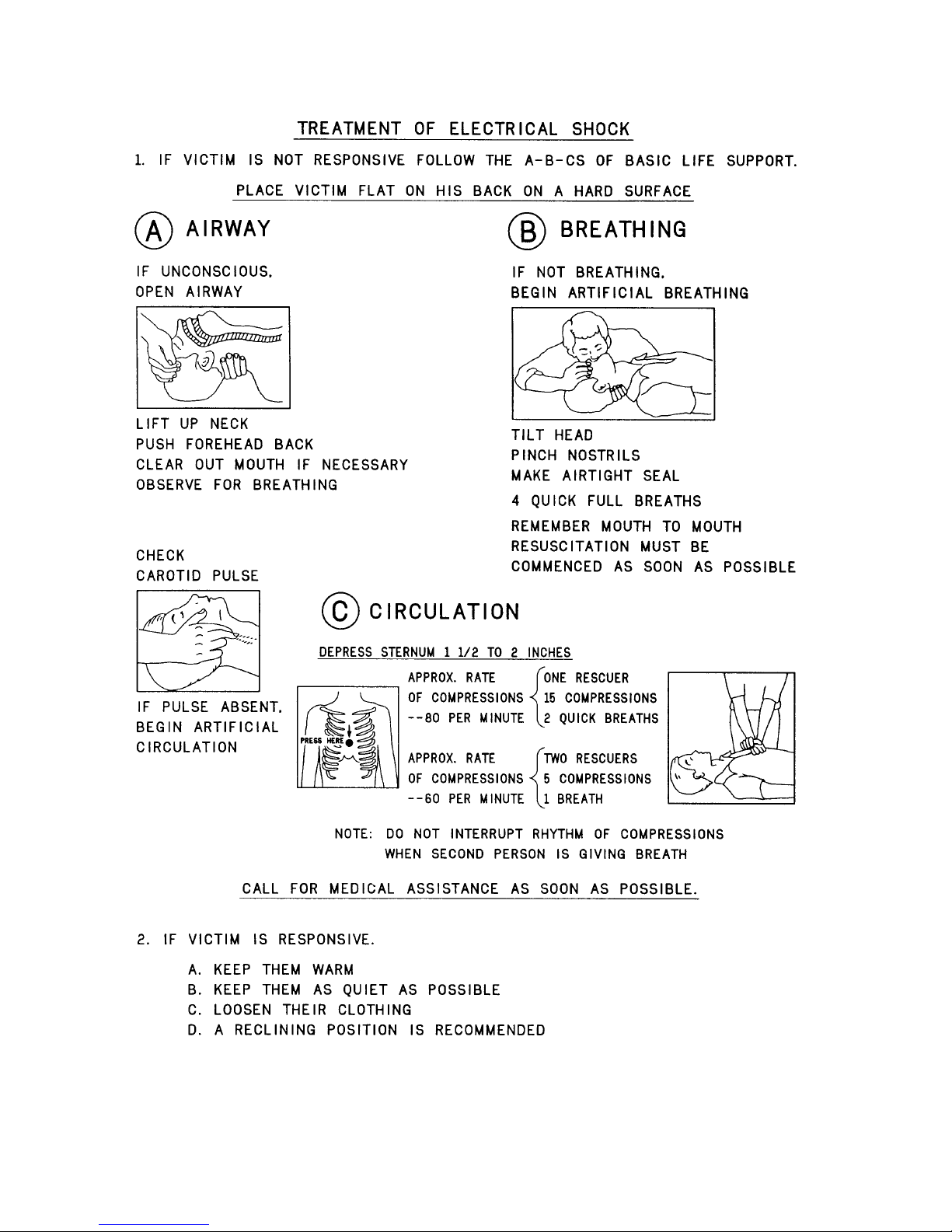

FIRST-AID

NOTE:

Personnel engaged in the installation, operation, maintenance, or servicing of this equipment

are urged to become familiar with first-aid theory and practices. The following information is

not intended to be complete first-aid procedures; it is brief and is only to be used as a

reference. It is the duty of all personnel using the equipment to be prepared to give adequate

Emergency First Aid and thereby prevent avoidable loss of life.

Treatment of Electrical Burns

1. Extensive burned and broken skin

a. Cover area with clean sheet or cloth. (Cleanest available cloth

article.)

b. Do not break blisters, remove tissue, remove adhered particles of

clothing, or apply any salve or ointment.

c. Treat victim for shock as required.

d. Arrange transportation to a hospital as quickly as possible.

e. If arms or legs are affected keep them elevated.

If medical help will not be available within an hour and the victim is conscious and

not vomiting, give him a weak solution of salt and soda: 1 level teaspoonful of salt

and 1/2 level teaspoonful of baking soda to each quart of water (neither hot or

cold). Allow victim to sip slowly about 4 ounces (a half of glass) over a period of

15 minutes. Discontinue fluid if vomiting occurs. (Do not give alcohol.)

2. Less severe burns - (1st & 2nd degree)

a. Apply cool (not ice cold) compresses using the cleanest available

cloth article.

b. Do not break blisters, remove tissue, remove adhered particles of

clothing, or apply salve or ointment.

c. Apply clean dry dressing if necessary.

d. Treat victim for shock as required.

e. Arrange transportation to a hospital as quickly as possible.

f. If arms or legs are affected keep them elevated.

REFERENCE:

ILLINOIS HEART ASSOCIATION

AMERICAN RED CROSS ST ANDARD FIRST AID AND PERSONAL SAFETY

MANUAL (SECOND EDITION)

12/20/11 888-2595-001 xiii

WARNING: Disconnect primary power prior to servicing.

Page 14

xiv 888-2595-001 12/20/11

WARNING: Disconnect primary power prior to servicing.

Page 15

Table of Contents

Section 1

Introduction

Manual Contents . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Features / Benefits. . . . . . . . . . . . . . . . . . . . . . . . . 1-2

General Product Description. . . . . . . . . . . . . . . . . 1-3

Exciter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Transmitter Nomenclature. . . . . . . . . . . . . . . . . . . 1-4

Tri-mode Operation. . . . . . . . . . . . . . . . . . . . . . . . 1-5

ZX Transmitter General Construction. . . . . . . . . . 1-5

Simplified Block Diagrams. . . . . . . . . . . . . . . . . . 1-8

Major Subassemblies. . . . . . . . . . . . . . . . . . . . . . 1-13

Transmitter Accessories . . . . . . . . . . . . . . . . . . . 1-18

Customized Rack Integration . . . . . . . . . . . . . . 1-18

AC Distribution & Signal Monitor Chassis . . . 1-18

Directional Coupler or Wattmeter . . . . . . . . . . 1-18

Dual-Drive / Main-alternate Switcher . . . . . . . 1-19

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Section 2

Installation

Field Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Returns and Exchanges . . . . . . . . . . . . . . . . . . . . . 2-2

Transmitter Documentation. . . . . . . . . . . . . . . . . . 2-2

Installation and Outline Drawings . . . . . . . . . . . 2-3

Site Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

AC Mains Requirements. . . . . . . . . . . . . . . . . . . . 2-4

Transmitters with AC Distribution Chassis. . . . 2-4

Transmitters without AC Distribution Chassis. . 2-5

Surge Suppression Devices. . . . . . . . . . . . . . . . . . 2-7

Ground Requirements . . . . . . . . . . . . . . . . . . . . . . 2-7

Overview of RF Grounding Practices . . . . . . . . 2-8

Cooling System Requirements . . . . . . . . . . . . . . . 2-9

Personnel and Equipment Protection . . . . . . . . . 2-11

Safety circuits. . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Remote Control Installation . . . . . . . . . . . . . . . . 2-12

Exciter Connections . . . . . . . . . . . . . . . . . . . . . 2-17

System Bus Connections. . . . . . . . . . . . . . . . . . . 2-20

Initial Start-up Procedure . . . . . . . . . . . . . . . . . . 2-20

Section 3

Operation

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Controls and Indicators. . . . . . . . . . . . . . . . . . . . . .3-1

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Controller board . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Internal LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

System Metering Assembly . . . . . . . . . . . . . . . . . .3-7

Basic Operational Procedures. . . . . . . . . . . . . . . . .3-8

ON/OFF Procedure . . . . . . . . . . . . . . . . . . . . . . .3-8

Power Raise/Lower Procedure. . . . . . . . . . . . . . .3-9

Switch Operating Mode Procedure

(FlexStar HDX Exciter) . . . . . . . . . . . . . . . . . . . .3-9

Basic Functional Check Procedure . . . . . . . . . .3-10

Section 4

Theory of Operation

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

RF Interconnect Wiring Diagram . . . . . . . . . . . . . .4-1

Output Assembly . . . . . . . . . . . . . . . . . . . . . . . . . .4 -2

AC-DC Interconnect Wiring Diagram . . . . . . . . . .4-4

PA Backplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

PA Reverse Power Alarm. . . . . . . . . . . . . . . . . . .4-5

PA Temperature Alarm. . . . . . . . . . . . . . . . . . . . .4-6

PA Current Alarm. . . . . . . . . . . . . . . . . . . . . . . . .4-6

Socket Interlock Module Fault Sensor. . . . . . . . .4-7

IPA Backplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

I/O Filter PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

8X PS Interface PCB . . . . . . . . . . . . . . . . . . . . . . .4-9

5X Fan Monitor PCB . . . . . . . . . . . . . . . . . . . . . .4-10

16X Load PCB . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

PA, IBOC PCB . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Transmitter Controller PCB . . . . . . . . . . . . . . . . .4-12

On/Off Control. . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Auto Restart. . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

APC Circuit and Power Level Adjust . . . . . . . .4-14

Operating Mode and Bias Level Control . . . . . .4-16

Metering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Fault and Status Signaling . . . . . . . . . . . . . . . . .4-19

Load Temperature Fault Sensor . . . . . . . . . . . . .4-20

Ambient Temperature Sensor. . . . . . . . . . . . . . .4-20

Drain Voltage Adjust . . . . . . . . . . . . . . . . . . . . .4-20

System Metering Assembly . . . . . . . . . . . . . . . . .4-20

1

Page 16

Table of Contents (Continued)

System Interconnect (multi-PA chassis

transmitters). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Command Sharing. . . . . . . . . . . . . . . . . . . . . . . 4-21

Power Control Sharing . . . . . . . . . . . . . . . . . . . 4-23

Section 5

Maintenance and Alignments

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

General Maintenance Guidelines. . . . . . . . . . . . . . 5-2

Personnel Training . . . . . . . . . . . . . . . . . . . . . . . 5-2

Recommended Tools and Equipment . . . . . . . . . 5-3

Spares Holding . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . 5-5

Transmitter Logbook. . . . . . . . . . . . . . . . . . . . . . 5-6

Maintenance Logbook. . . . . . . . . . . . . . . . . . . . . 5-6

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . 5-7

MTBF Estimates . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Basic Maintenance Procedures . . . . . . . . . . . . . . . 5-8

Power Amplifier (PA) Module Swap

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Power Supply (PS) Module Swap Procedure . . 5-10

Air Filter Replacement Procedure. . . . . . . . . . . 5-11

PA Module Cleaning Procedure . . . . . . . . . . . . 5-12

Advanced Maintenance Procedures. . . . . . . . . . . 5-13

Advanced Functional Check . . . . . . . . . . . . . . . 5-13

Forward Power Meter Calibration . . . . . . . . . . 5-16

Precision Directional Coupler . . . . . . . . . . . . 5-17

Reverse Power Meter Calibration. . . . . . . . . . . 5-18

Set Transmitter Power Level (Case 1:

internal transmitter APC control) . . . . . . . . . . . 5-19

Set Transmitter Power Level (Case 2:

exciter APC control with FlexStar HDX). . . . . 5-21

APC Setup for Multiple PA Chassis . . . . . . . . . 5-23

Set User Reverse Power Foldback Threshold

(ZX2500 / ZX3750 / ZX5000). . . . . . . . . . . . . 5-24

Set User Reverse Power Foldback Threshold

(ZX7.5, ZX10) . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Periodic Cleaning and Inspection. . . . . . . . . . . 5-26

Service one PA chassis while transmitter is

on air (ZX7.5/ZX10). . . . . . . . . . . . . . . . . . . . . 5-28

Check balance by disconnecting load

(ZX7.5/ZX10) . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Special Part Replacement Notes . . . . . . . . . . . . . 5-30

PA Module (992-9992-041G or otherwise) . . . 5-30

PA Amplifier Assembly (PWA, PA)

(992-9992-021G or otherwise) . . . . . . . . . . . . . 5-30

PS Module (736-0445-000) . . . . . . . . . . . . . . . 5-32

Transmitter Controller PCB (901-0203-541) . . 5-33

PA Backplane PCB (901-0203-381). . . . . . . . . 5-33

IPA Backplane PCB (901-0203-581) . . . . . . . . 5-33

PS Interface PCB (901-0203-531) . . . . . . . . . . 5-33

RF Output Assembly

(971-0023-026/027/028). . . . . . . . . . . . . . . . . . 5-34

Output Assembly Ballast Load

(700-1225-000). . . . . . . . . . . . . . . . . . . . . . . . . 5-38

RF Splitter (901-0203-511/561/571) . . . . . . . . 5-39

I/O Filter PCB (901-0203-551). . . . . . . . . . . . . 5-40

Web Remote PCB (901-0203-391T) . . . . . . . . 5-40

Fan Monitor PCB (901-0203-441) . . . . . . . . . . 5-40

Cooling Fans (430-0458-000). . . . . . . . . . . . . . 5-40

Front Panel Multimeter (632-1201-000). . . . . . 5-40

AC Mains Filter

(476-0528-000 or 609-0125-000). . . . . . . . . . . 5-41

Front Panel Filter (943-5567-408) . . . . . . . . . . 5-41

2X IPA Splitter (901-0203-591) . . . . . . . . . . . . 5-41

Input 3dB Attenuator (971-0023-050) . . . . . . . 5-41

System Metering Assembly . . . . . . . . . . . . . . . 5-41

Output Combiner (3dB Hybrid) . . . . . . . . . . . . 5-41

2.5 kW RF Load . . . . . . . . . . . . . . . . . . . . . . . . 5-42

Section 6

Troubleshooting

Contacting Harris Service . . . . . . . . . . . . . . . . . . . 6-1

Troubleshooting Table. . . . . . . . . . . . . . . . . . . . . . 6-2

Section 7

Parts List

ZX5000 Replaceable Parts List. . . . . . . . . . . . . . . 7-2

ZX10 Replaceable Parts List. . . . . . . . . . . . . . . . . 7-7

Appendix A - FM Web Remote

Option

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

General Product Description. . . . . . . . . . . . . . . .A-1

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Internet Security . . . . . . . . . . . . . . . . . . . . . . . . .A-3

2

Page 17

Table of Contents

Installation Procedure. . . . . . . . . . . . . . . . . . . . . A-4

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Access main page . . . . . . . . . . . . . . . . . . . . . . . . A-5

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . A-11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Access Configuration Page. . . . . . . . . . . . . . . . A-12

Perform Simple Reset. . . . . . . . . . . . . . . . . . . . A-17

Perform Expert Reset . . . . . . . . . . . . . . . . . . . . A-18

Change Clock Battery. . . . . . . . . . . . . . . . . . . . A-19

Calibrate Clock Speed . . . . . . . . . . . . . . . . . . . A-20

Use Microchip Discoverer Utility . . . . . . . . . . A-20

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . A-22

USB Flash Drive. . . . . . . . . . . . . . . . . . . . . . . . . A-23

3

Page 18

Table of Contents (Continued)

4

Page 19

ZX Series

NOTE:

Section 1

Introduction

1.1 Manual Contents

This technical manual addresses the following Harris ZX series of solid-state radio

transmitters:

• ZX2500 – 2.5 kW FM transmitter

• ZX3750 – 3.75 kW FM transmitter

• ZX5000 – 5 kW FM transmitter

1

• ZX7.5 – 7.5 kW FM transmitter

• ZX10 – 10 kW FM transmitter

This manual does not address the ZX transmitter models listed below:

• ZX500 – 500W FM transmitter

• ZX1000 – 1000W FM transmitter

• ZX2000 – 2000W FM transmitter

• ZX3500 – 3500W FM transmitter

These transmitters are addressed in Instruction Book (888-2594-001).

This manual contains the following sections:

• Section 1: Introduction, identifies the versions of the product available and the possi-

ble options.

• Section 2: Installation, details the procedures to receive, install, and commission the

transmitter for use, including an initial turn-on procedure.

12/20/11 888-2595-001 1-1

WARNING: Disconnect primary power prior to servicing.

Page 20

Section 1 Introduction

• Section 3: Operation, describes operation of the equipment and is intended to be the

primary section referenced by operating personnel.

• Section 4: Theory of Operation, is included to help service personnel to understand

the inner workings of the transmitter.

• Section 5: Maintenance, lists and explains alignments and adjustments that could be

required to maintain the transmitter once in operation.

• Section 6: Troubleshooting, is included as a servicing aid to be used along with Sec-

tions 4 and 5 by qualified service personnel to identify and correct an equipment malfunction.

• Section 7: Parts List, is a comprehensive listing of the components that may be

replaced in the field.

• Appendix A: FM WEB remote option, proivdes information about the optional

WEB remote interface card.

1.2 Features / Benefits

ZX Series

The Harris ZX Series of transmitters offers the following useful features and benefits:

• HD Radio capable with on-the-fly switching between FM, FM+HD, or HD mode

when used with FlexStar exciter.

• Broadband design to eliminate tuning adjustments from 87.5 MHz through 108 MHz

(N+1 capable). Frequency change can be done electronically in seconds with MicroMax or FlexStar exciter or Digit exciter with external controller.

• Redundant hot-plug RF amplifier modules allow module replacement while transmit-

ter is in operation.

• Redundant hot-plug power supplies modules allow module replacement while trans-

mitter is in operation, including transmitter logic supplies. (each PS module has both

50V and 5V logic supplies)

• Redundant cooling fans allow transmitter to operate at full power for extended peri-

ods with a fan failure, while fan tachometer alarm notifies service personnel of failure condition.

• Three independent AC mains inputs per amplifier chassis and regulated power sup-

plies allow transmitter to accept a wide range of single or three phase mains power

without concern for line balance or rotation.

• Redundant IPA amplifiers and PA splitters eliminate a single point of failure.

• Non software-based controller for simple, repeatable operation. Does not require

UPS or battery to retain settings during AC mains failures.

• EIA rack mounting for easy installation with only 16RU height for 5000W amplifier .

1-2 888-2595-001 12/20/11

WARNING: Disconnect primary power prior to servicing.

Page 21

ZX Series

(Flexstar HDX exciter shown)

[002] Amplifier

[001] Exciter

[001]

[002]

• Optional air plenum available for interface to an external ducted air system.

• Precision directional RF sample port provided for customer use.

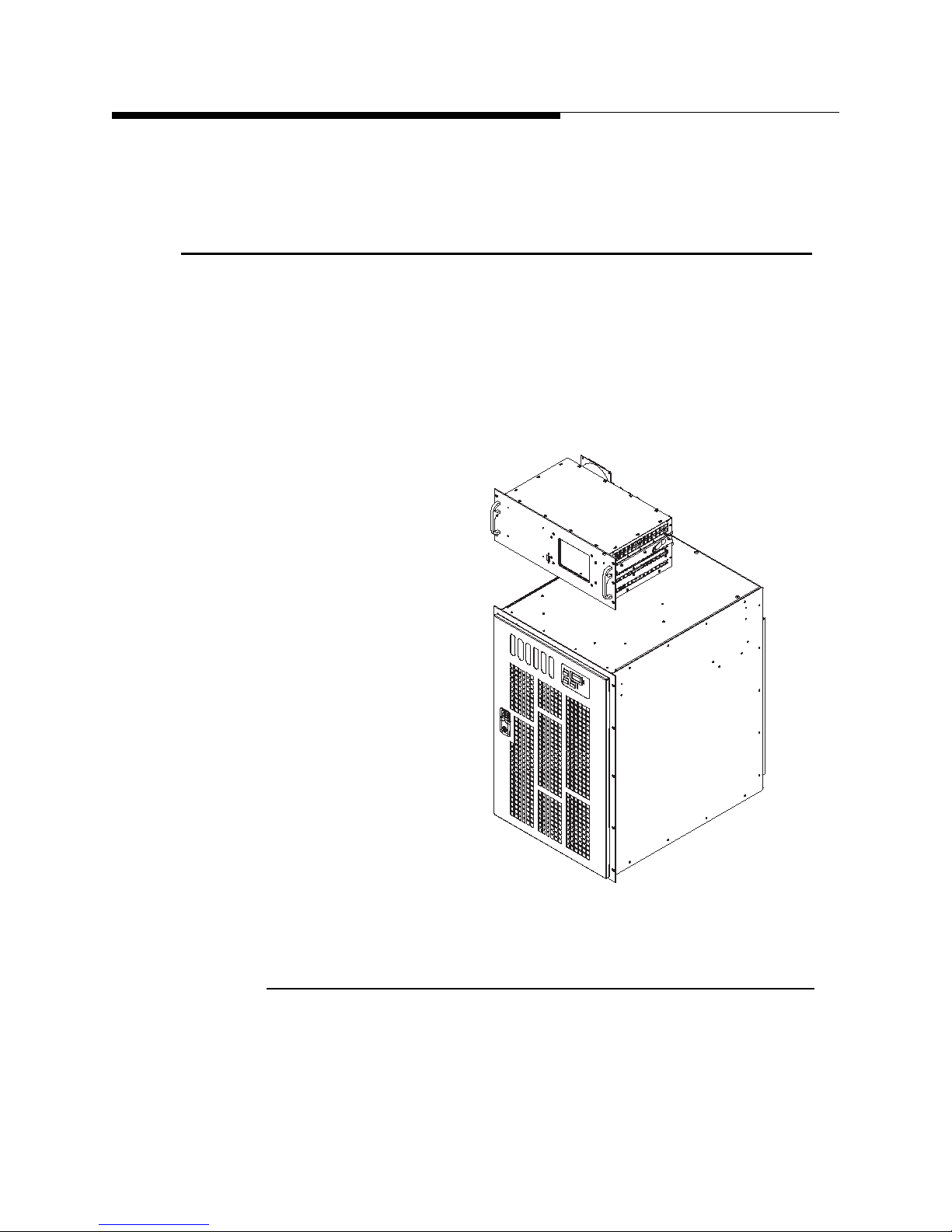

1.3 General Product Description

The ZX series of solid state transmitters is designed to synthesize and amplify

radiofrequency signals in the FM broadcast band (87.5MHz -108MHz).

The complete ZX transmitter consists of one or more of each of two major assemblies:

an FM exciter and the ZX amplifier chassis. These are shown in Figure 1-1.

Section 1 Introduction

12/20/11 888-2595-001 1-3

1.3.1 Exciter

The exciter accepts an audio signal in either analog or digital format and modulates it

onto an RF carrier. Depending on the format of modulation, digital HD Radio or

traditional FM, the exciter may be any one of these Harris exciters:

Figure 1-1 Major subassemblies of ZX series transmitter

WARNING: Disconnect primary power prior to servicing.

Page 22

Section 1 Introduction

NOTE:

• Micromax FM – FM exciter with analog modulator.

• Digit CD – Digitally synthesized FM exciter.

• FlexStar HDX - Tri-mode exciter capable of either traditional FM or digital HD

Radio transmissions.

1.3.2 Amplifier

The amplifier chassis accepts a low level on-channel RF signal from the exciter and

amplifies it to the desired output level for transmission. The transmitter models

addressed in this manual have five standard FM power levels: 2500W, 3750W, 5000W,

7.5kW & 10kW.

This manual chiefly addresses the ZX amplifier chassis and the operation of the

transmitter as a whole. A manual dedicated to the exciter is provided separately.

1.4 Transmitter Nomenclature

ZX Series

The complete ZX transmitter is named according to the particular combination of

exciter and amplifier chassis being employed. The number following the ZX prefix

indicates the full nominal FM power level,either in watts for power levels below

5000W or in kilowatts for power levels above 5000W. A suffix of FM, CD, FLX, or

HD+ is assigned according to the exciter type.

For example:

ZX5000 = 5000W amplifier with no exciter

ZX5000MX = 5000W amplifier with MicroMax

ZX5000CD = 5000W amplifier with DIGIT CD

ZX5000FLX = 5000W amplifier with FlexStar

only, no HD Radio)

ZX5000HDPL (HD plus) = 5000W amplifier with FlexStar

exciter (both FM and HD Radio capable)

FM exciter

(TM)

digital FM exciter

(TM)

HDX-FM digital FM exciter (FM

(TM)

HDX-FM digital FM

(TM)

In addition, the FlexStar exciter may have one or two RF outputs, depending on

the model number. The use of dual RF outputs is advantageous in certain appli

cations.

1-4 888-2595-001 12/20/11

WARNING: Disconnect primary power prior to servicing.

-

Page 23

ZX Series

FLX-11 = single FM output

FLX-12 = dual FM outputs

HDPL-21 = single tri-mode output (FM, FM+HD, HD)

HDPL-22 = dual tri-mode outputs

1.5 Tri-mode Operation

All ZX transmitters are designed to operate in any one of three different modes:

1. FM mode = traditional FM modulation

2. FM+HD mode = hybrid mode with analog and digital HD Radio simulcast

3. HD mode = digital HD Radio modulation only

The determination of operating mode is made by the exciter. To transmit a digital HD

Radio signal, an HD Radio exciter, such as the FlexStar HDX exciter is required. The

ZX amplifier can switch on-the-fly between all three operating modes, as commanded

by the exciter through an exciter interface cable.

Section 1 Introduction

1.6 ZX Transmitter General Construction

The ZX transmitter features all solid-state construction and utilizes a series of FETbased power amplifier (PA) modules to amplify the RF signal. In addition to RF drive

power from the exciter, these PA modules utilize 50V DC power supplied by

switchmode power supply (PS) modules. Both the PA and PS modules are hotpluggable and may be inserted and removed from the transmitter while it is on the air.

12/20/11 888-2595-001 1-5

WARNING: Disconnect primary power prior to servicing.

Page 24

Section 1 Introduction

NOTE:

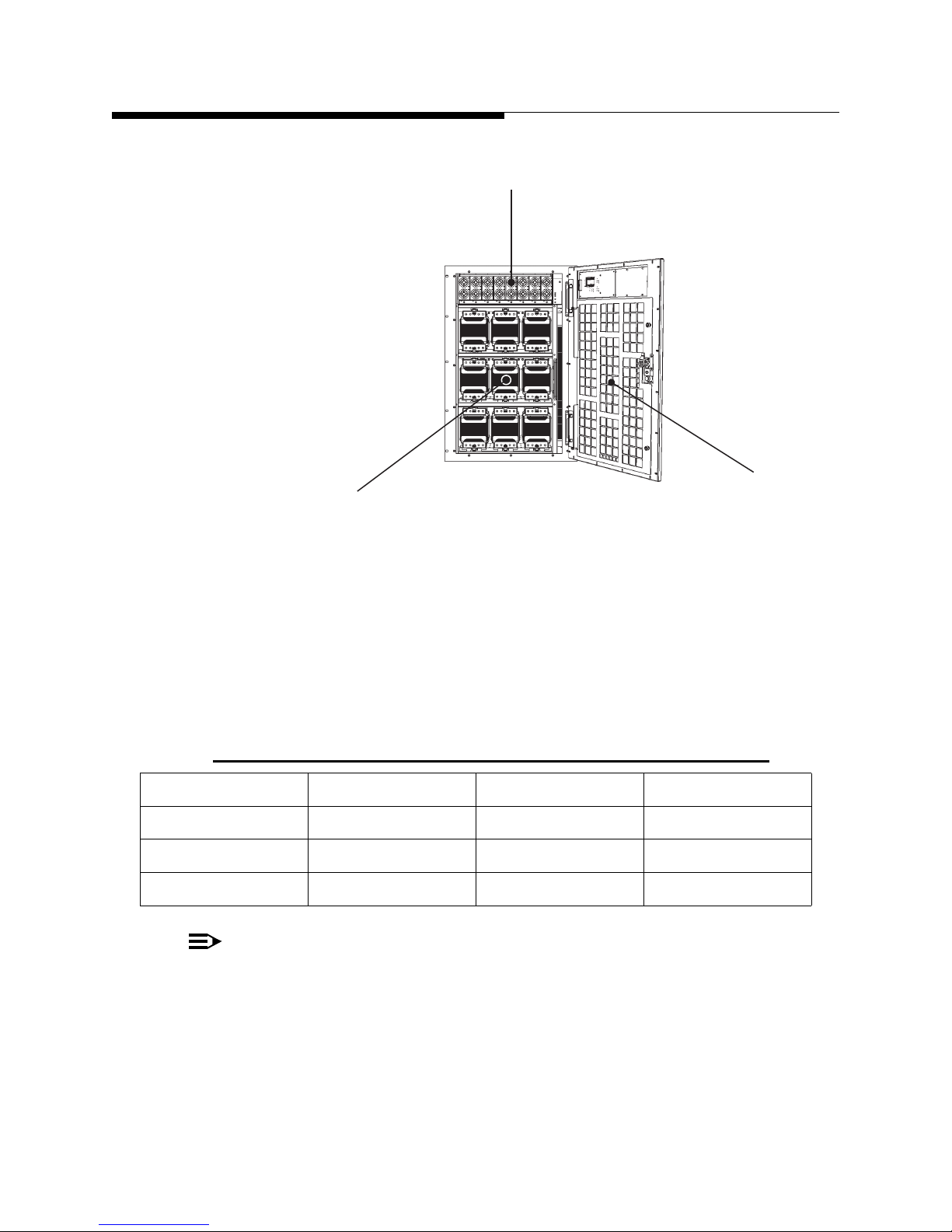

[101]

[102]

[103]

[101] Power supply (PS) module

[102] Front door

[103] Power amplifier (PA) module

ZX Series

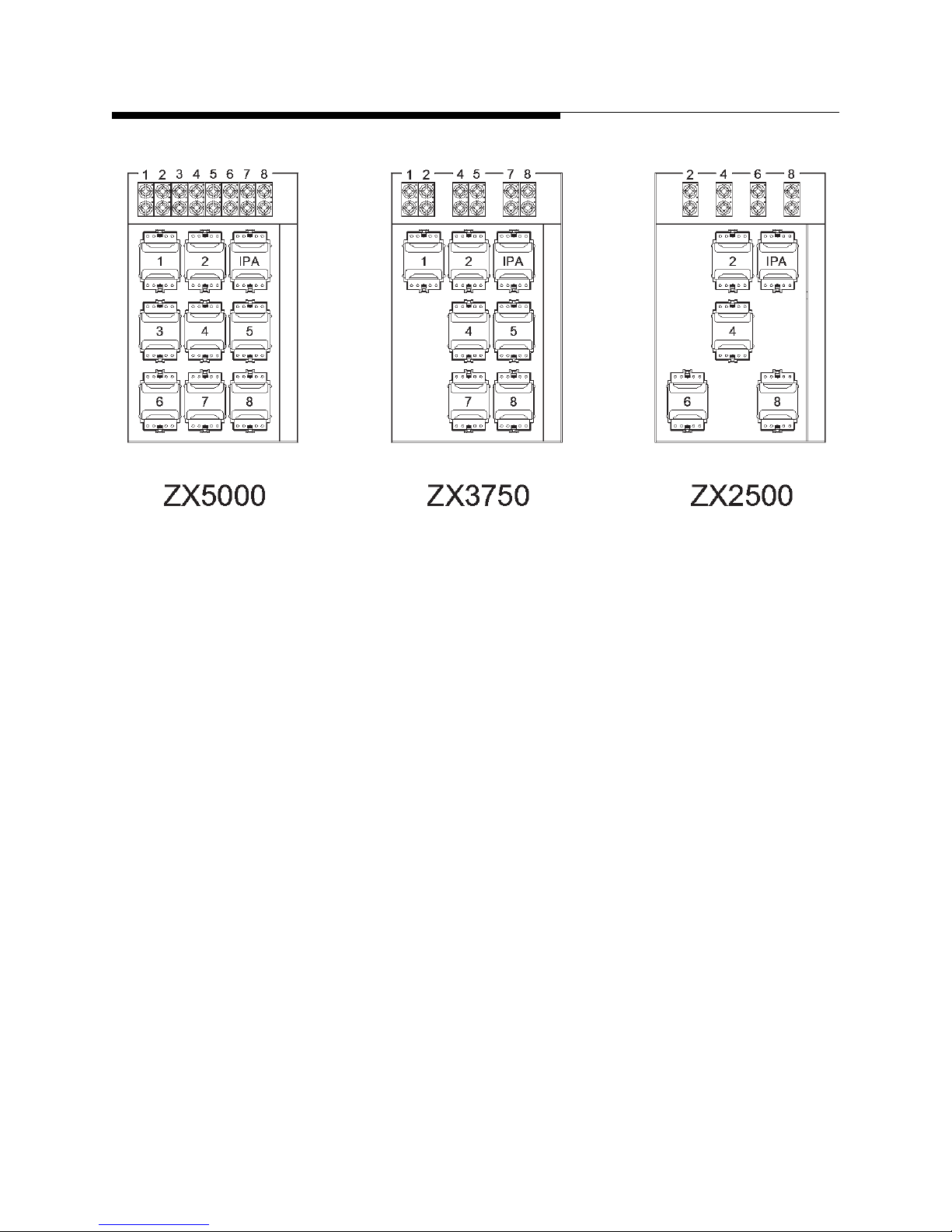

The number of PA and PS modules, size, weight, and other important parameters vary

according to the transmitter model and desired power level. Information on the number

of PA and PS modules as a function of transmitter model for power levels of 5000W

and below is given below in Table 1-1 and Figure 1-3.

Table 1-1 Complement of Modules vs Transmitter Model

Model PA Modules* PS Modules Cooling Fans

ZX5000 8 + 1 8 5

ZX3750 6 + 1 6 5

ZX2500 4 + 1 4 5

Figure 1-2 PA and PS modules in ZX series amplifier

“+1” designation indicates an IPA module: a PA module installed in the IPA position.

1-6 888-2595-001 12/20/11

WARNING: Disconnect primary power prior to servicing.

Page 25

ZX Series

Section 1 Introduction

Figure 1-3 Positions of PA and PS modules in various ZX series transmitter models

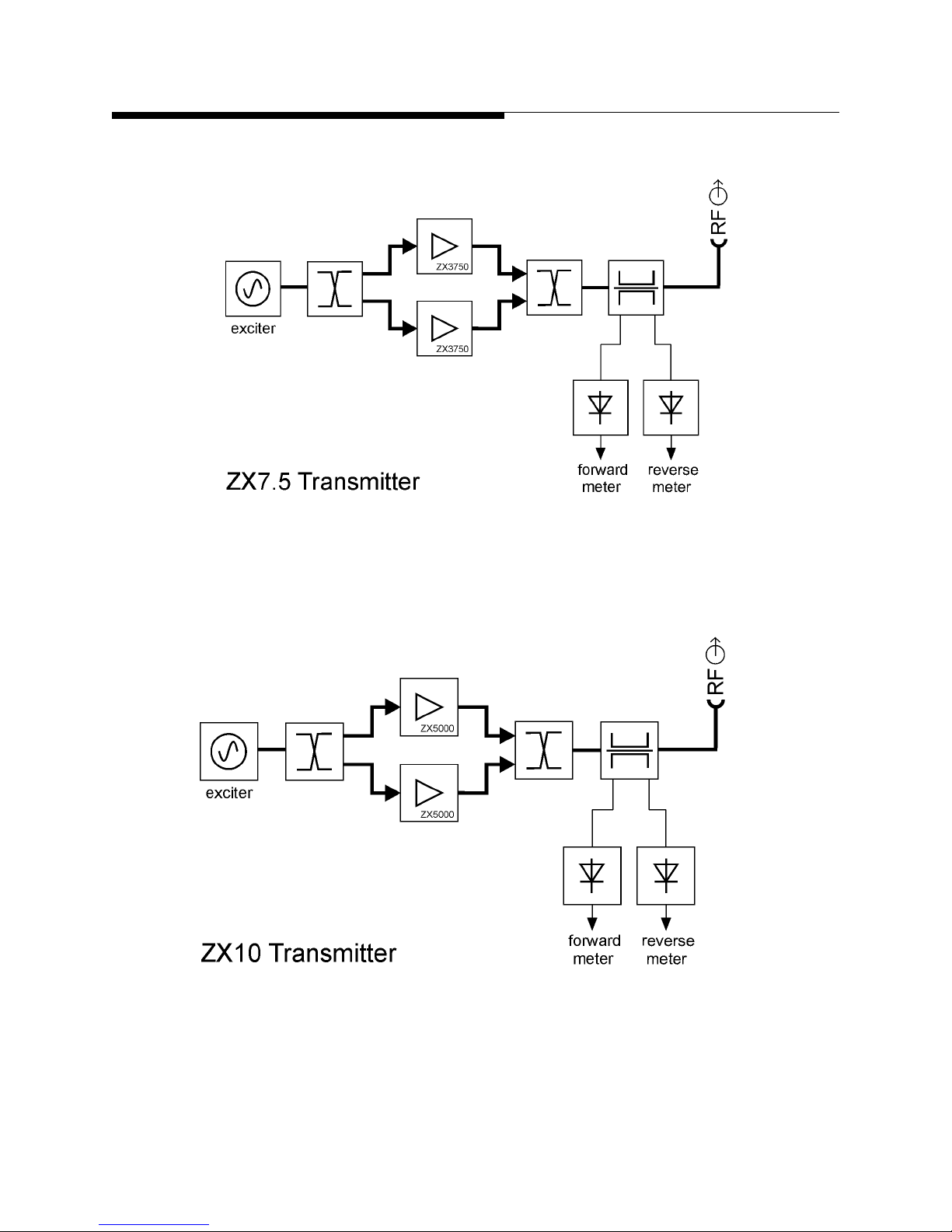

The transmitter models at 7.5kW and above are made by combining the outputs of

multiple ZX3750 or ZX5000 amplifier chassis in an integrated system. The number of

amplifier chassis per model is as follows:

ZX7.5 = 2 x ZX3750

ZX10 = 2 x ZX5000

Additional information on important transmitter parameters, such as size, weight, and

power consumption, may be found in drawing 839-8464-033 Outline Drawing, ZX

Transmitters in the drawing package accompanying this manual.

12/20/11 888-2595-001 1-7

WARNING: Disconnect primary power prior to servicing.

Page 26

Section 1 Introduction

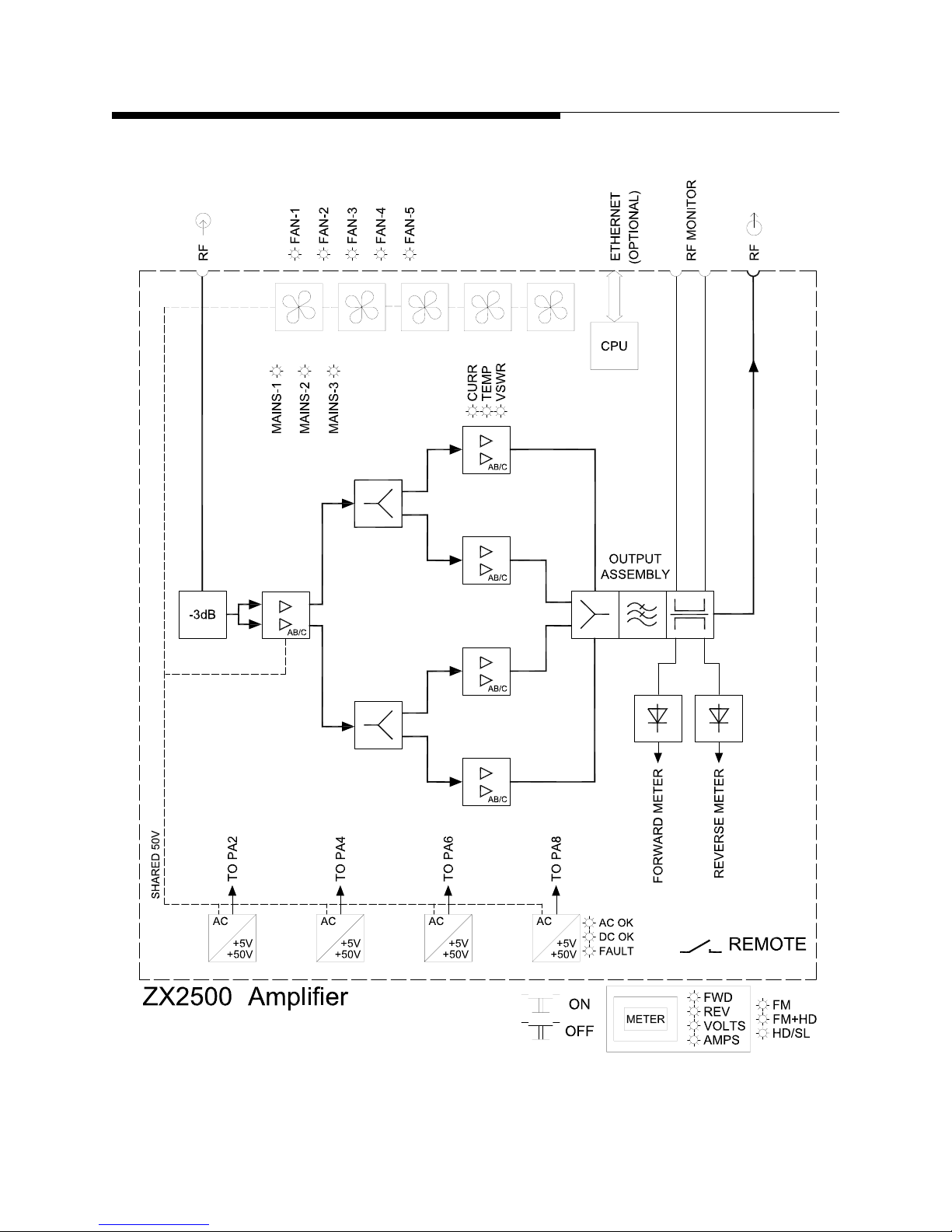

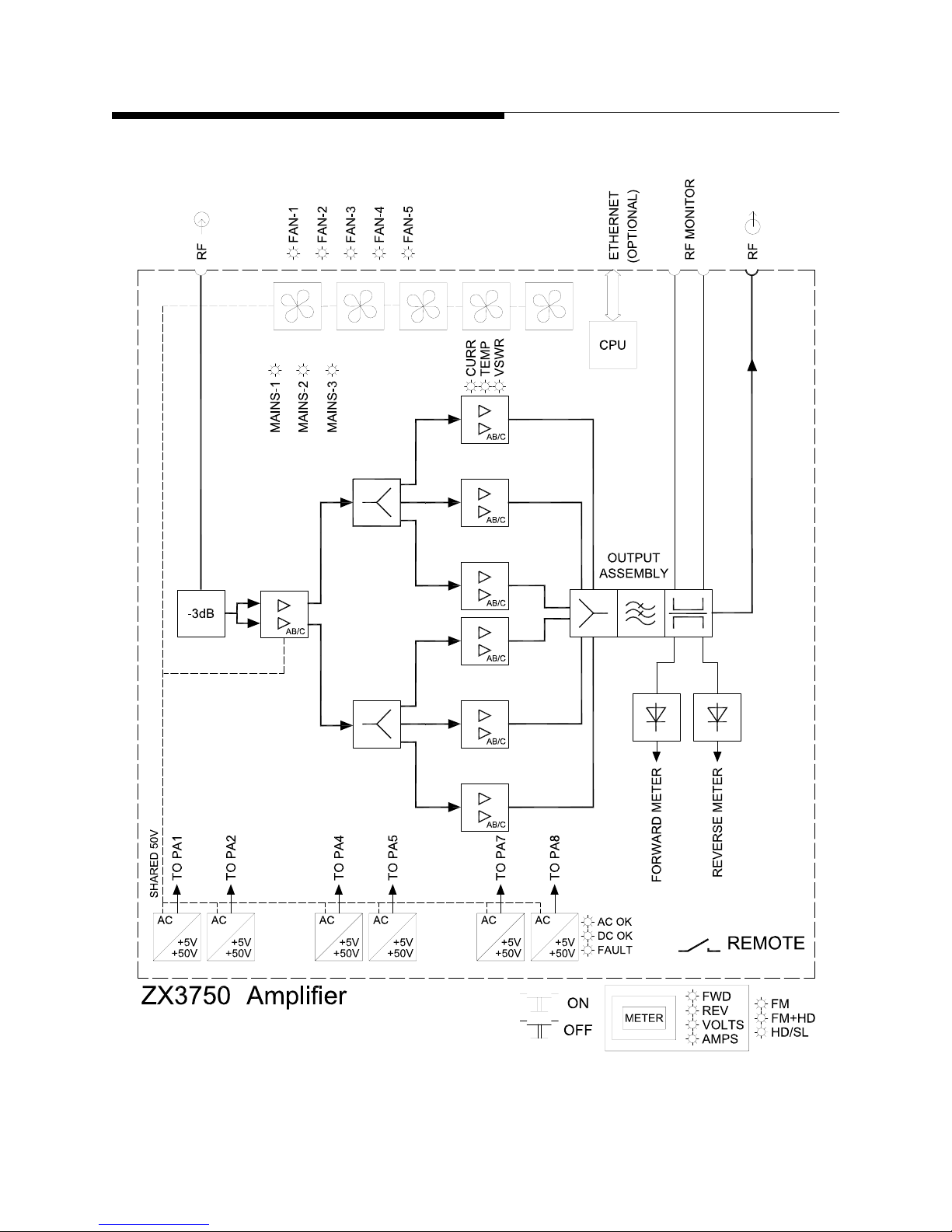

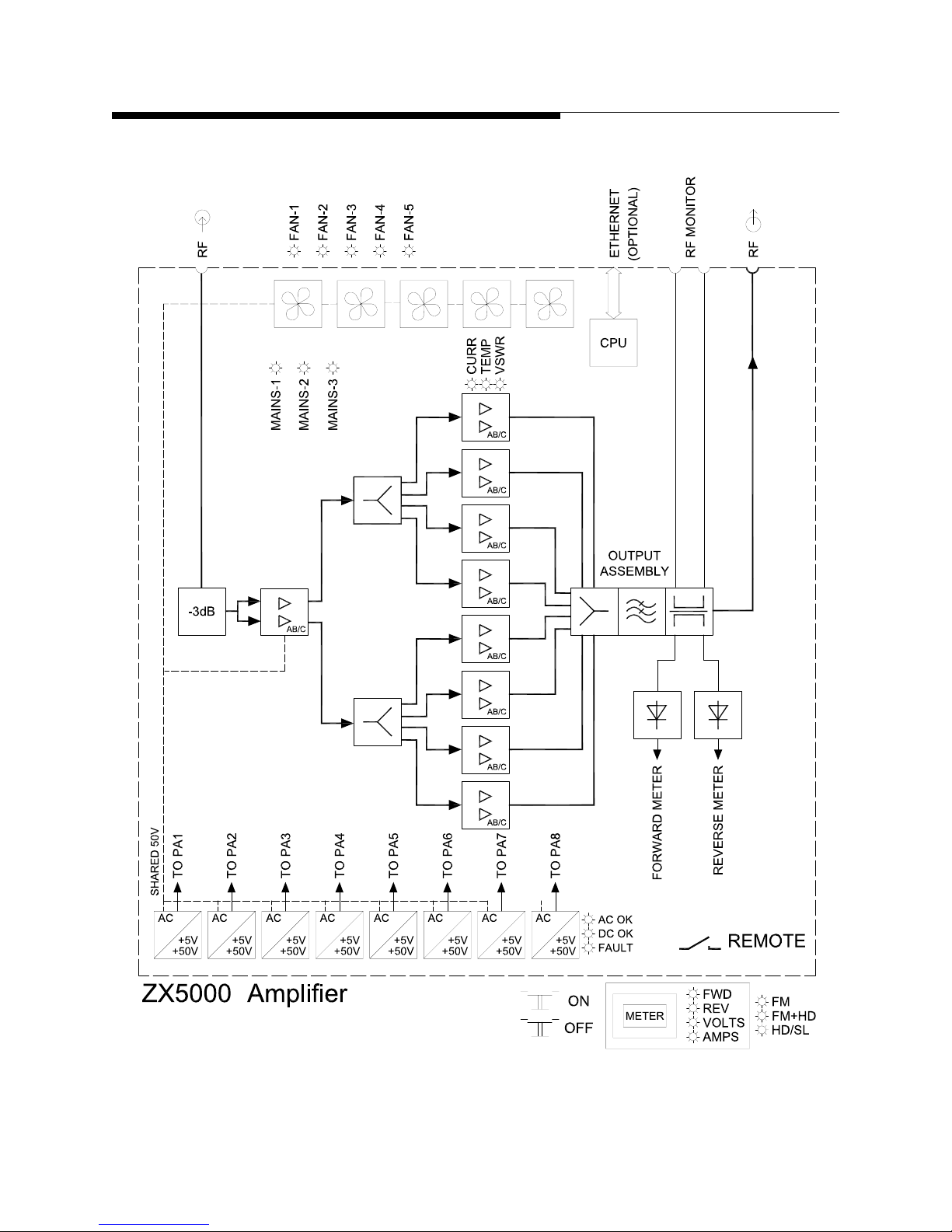

1.7 Simplified Block Diagrams

Figures 1-4 through 1-6 provide simplified block diagrams of the amplifier models

discussed in this manual. Figures 1-7 and 1-8 provide a simplified block diagram of the

ZX7.5 and ZX10 model transmitters. Consult the exciter manual for a block diagram of

the exciter.

ZX Series

1-8 888-2595-001 12/20/11

WARNING: Disconnect primary power prior to servicing.

Page 27

ZX Series

Section 1 Introduction

Figure 1-4 ZX2500 amplifier simplified block diagram

12/20/11 888-2595-001 1-9

WARNING: Disconnect primary power prior to servicing.

Page 28

Section 1 Introduction

ZX Series

Figure 1-5 ZX3750 amplifier simplified block diagram

1-10 888-2595-001 12/20/11

WARNING: Disconnect primary power prior to servicing.

Page 29

ZX Series

Section 1 Introduction

Figure 1-6 ZX5000 amplifier simplified block diagram

12/20/11 888-2595-001 1-11

WARNING: Disconnect primary power prior to servicing.

Page 30

Section 1 Introduction

ZX Series

Figure 1-7 ZX7.5 similified block diagram

Figure 1-8 ZX10 simplified block diagram

1-12 888-2595-001 12/20/11

WARNING: Disconnect primary power prior to servicing.

Page 31

ZX Series

[002]

[003]

[004]

[005]

[006]

[001]

[001] PS module

[002] Controller board

[003] Filter door and air filter

[004] Hex key to open rear door

[005] Air intake plenum leading to

output assembly heatsink

[006] PA module

1.8 Major Subassemblies

Figures 1-7 through 1-9 identify some of the major subassemblies contained the ZX

series amplifier. Figures 1-10 through 1-14 indentify the major subassemblies found in

full-cabinet transmitters with output powers of 7.5kW and above.The role of these

subassemblies is discussed in detail in Section 4 – Theory of Operation.

Section 1 Introduction

Figure 1-9 ZX5000 amplifier front view with front face removed

12/20/11 888-2595-001 1-13

WARNING: Disconnect primary power prior to servicing.

Page 32

Section 1 Introduction

[203]

[204]

[205]

[206]

[207]

[201]

[202]

[201] User interface subpanel:

RF forward monitor port (SMA-M)

RF reverse monitor port (SMA-M)

RF input port (BNC–F)

[202] User interface subpanel:

Ethernet port (RJ-45)

Exciter interface port (D-sub 15)

System interface port (D-sub 15HD)

Remote control port (D-sub 25)

[203] AC mains inputs:

PowerCon NAC3MPA (ZX5000)

IEC C20 (ZX2500, ZX3750)

[204] Individual fan alarm LEDs

[205] Chassis cooling fan

[206] Hex key latch to open rear door

[207] EIA 1-5/8 flangeless RF output

ZX Series

Figure 1-10 ZX5000 amplifier rear view

1-14 888-2595-001 12/20/11

WARNING: Disconnect primary power prior to servicing.

Page 33

ZX Series

[301]

[302]

[303]

[304]

[305]

[306]

[307]

[301] AC mains filters (ZX5000)

[302] 8X PS interface board

[303] 2X IPA splitter board

[304] 3dB attenuator assembly

[305] 8X splitter board

[306] PA backplane board

[307] Output assembly (combiner, harmonic filter, and directional

couplers)

Section 1 Introduction

Figure 1-11 ZX5000 exploded interior view

12/20/11 888-2595-001 1-15

WARNING: Disconnect primary power prior to servicing.

Page 34

Section 1 Introduction

[101] Air exhaust ports

[102] RF output flange

[103] ZX5000 amplifier chassis

[104] ZX5000 amplifier chassis

[105] AC distribution chassis

[106] System metering assembly

[107] Exciter

Exciter switcher: 1RU drawer between

upper and lower exciter

[108] Exciter

[201] RF output flange

[202] Exciters

[203] ZX5000 amplifier chassis

[204] ZX5000 amplifier chassis

[205] 2X hybrid combiner

[206] RF directional couplers

[207] Access door, exciter air

compartment

ZX Series

Figure 1-12 ZX10 transmitter front view

Figure 1-13 ZX10 transmitter rear with cabinet removed

1-16 888-2595-001 12/20/11

WARNING: Disconnect primary power prior to servicing.

Page 35

ZX Series

[301] 2.5kW RF load

[302] Component panel (side wall)

[303] Cabinet rear door

[401] Coaxial transfer relay

[402] Reserve exciter RF test load

[403] 2X splitter RF load

[404] 2X splitter (700W hybrid)

[405] Remote terminal board

[406] 5X HD15 divider board

(system interface bus)

[407] 5X DB15 divider board

(exciter interface bus)

Section 1 Introduction

Figure 1-14 ZX10 transmitter with rear door removed

Certain components shown in Figure 1-15 (above) will not be present in certain

transmitter models.

Figure 1-15 ZX10 component panel in rear cabinet

12/20/11 888-2595-001 1-17

WARNING: Disconnect primary power prior to servicing.

Page 36

Section 1 Introduction

1.9 Transmitter Accessories

The exciter and one or more ZX amplifier chassis form the basic ZX transmitter. In

addition to these devices, various add-on options are available and may be present in a

ZX transmitter system. Inasmuch as these accessories do not significantly change the

functioning of the core transmitter itself, it is understood that this manual addresses

customized transmitter configurations that may contain one or more of these options.

In the case of a relatively high level of customization, this manual may also be

accompanied by a supplemental “customer-special” manual. In the case where

conflicting information is presented in the two manuals, the information given by the

customer-special manual supersedes any information contained in this manual.

1.9.1 Customized Rack Integration

ZX transmitters up to the 5000W power level are often purchased as stand-alone units

and mounted in an equipment rack provided by the customer. Alternatively, Harris

sometimes provides a complete rack integration package, especially for customers

requiring ducted output and/or input air. Transmitters at the 7.5kW level and above are

furnished with racks as part of an integrated system.

ZX Series

1.9.2 AC Distribution & Signal Monitor Chassis

A customized AC distribution chassis is sometimes supplied to provide in-rack AC

mains distribution with front panel circuit breaker switching. This chassis may also

feature a set of front-panel SMA connectors for signal monitoring and/or an emergency

off button. One or more AC distribution chassis (as required) are provided as standard

equipment for transmitters at the 7.5kW level and above.

1.9.3 Directional Coupler or Wattmeter

Each amplifier chassis features a precision on-board directional coupler, which may be

used to calibrate power meters with an average power meter . Alternately , a through-line

wattmeter capable of measuring the output power directly may be supplied as an option.

Optional external couplers may also be provided to provide additional sample ports for

test and monitoring equipment.

1-18 888-2595-001 12/20/11

WARNING: Disconnect primary power prior to servicing.

Page 37

ZX Series

Section 1 Introduction

1.9.4 Dual-Drive / Main-alternate Switcher

A second exciter and exciter switchover controller are sometimes provided. The

operation of the main alternate switcher is addressed in a separate manual.

12/20/11 888-2595-001 1-19

WARNING: Disconnect primary power prior to servicing.

Page 38

Section 1 Introduction

Title: SPEC, ZX TRANSMITTER FAMILY Sheet 1 of 7 Rev: B Dwg: 817-2350-085

HARRIS CORPORATION

BROADCAST SYSTEM

P.O. BOX 4290

QUINCY, IL 62305

THIS DOCUMENT CONTAINS PROPRIETARY DATA OF

HARRIS CORPORATION. NO DISCLOSURE,

REPRODUCTION, OR USE OF ANY PART THEREOF MAY

BE MADE EXCEPT BY WRITTEN PERMISSION.

REVISIONS

Rev: Date: Dftm: Eng: ECO Number: Rev: Date: Dftm: Eng: ECO Number:

A 06/03/09 DS DS P43867 B 02/13/10 DS DS P46612

New Drawing Add ZX7.5, ZX10

APPROVALS

Drawn By: D SPARANO

03/14/09

Eng: D SPARANO Proj: D SPARANO Mfg: W OLSON

SPECIFICATIONS FOR ZX TRANSMITTER FAMILY (ZX2500, ZX3750, ZX5000, ZX7.5, ZX10)

Overview: The present document provides a controlled source for specifications for the ZX10, ZX7.5, ZX5000,

ZX3750, and ZX2500 models of FM transmitter. This information mirrors some of the information contained in

outline drawing 839-8464-033. Many of the exciter-dependent parameters are derived from the data sheets of the

respective exciters and are subject to change according to any changes in the exciter design.

ZX Transmitters Specifications – FM models

GENERAL

FM power output range:

1

ZX2500: 625 W – 2750 W

ZX3750: 950 W – 4125 W

ZX5000: 1250 W – 5500 W

ZX7.5: 1900 W – 8250 W

ZX10: 2500 W – 11000 W

RF output connector:

2

ZX2500: EIA 1-5/8” flangeless, 50 ohms

ZX3750: EIA 1-5/8” flangeless, 50 ohms

ZX5000: EIA 1-5/8” flangeless, 50 ohms

ZX7.5: EIA 1-5/8” flanged, 50 ohms

ZX10: EIA 1-5/8” flanged, 50 ohms

Excitation: Harris Micromax analog FM exciter.

RF amplifers: MOSFET, broadband (no-tune), hot plug

modular, universal (same type all tx models), 4.5 kg.

Power supplies: Switchmode, auto-ranging, hot plug modular,

universal, 2.5 kg.

Frequency range: 87.5 MHz - 108 MHz, in 10 kHz increments.

Frequency stability: +/- 3 ppm, 0

o

C to 50o C (4-minute

stabilization period).

Power stability: +/- 0.25 dB.

Reverse power: Protected against open or short circuit, all

phase angles. Capable of operation into infinite VSWR

with user-adjustable foldback threshold. Threshold set to

2.5% of FM nameplate power level at factory.

Harmonic / spurious output: Meets or exceeds FCC,

Canadian, CE, and Chinese requirements.

Modulation type: Direct carrier frequency modulation.

Modulation capability: +/- 350 kHz.

1

VSWR 1.2:1 or less. De-rate to nameplate rating for VSWR

up to 1.5:1.

2

EIA 3-1/8” flanged available as option, ZX7.5 and ZX10.

Asynchronous AM S/N ratio: 50 dB minimum below

equivalent 100% amplitude modulation by 400 Hz using 75

µs de-emphasis (no FM modulation present).

Synchronous AM S/N ratio: 40 dB below equivalent 100%

amplitude modulation with 75 µs de-emphasis and 400 Hz

highpass filter (FM deviation +/- 75 kHz by a 1 kHz sine

wave). Higher ratios are obtainable. Refer to Harris

Application Note # APN-115-TA.

AC mains requirement: 90 - 264 V

3

, 47 - 63 Hz, IEC C14

inlet for exciter and following connections to power

amplifier:

ZX2500/3750: 190 - 264 V

4

, 47 - 63 Hz, triple IEC

C20 inlets. Configurable on-site for single or threephase connection: 190 - 264 V single phase, 190264 V delta, 190 - 264 V wye, or 330 - 450 V wye.

ZX5000: Same as 3750 W model except triple

PowerCon NAC3MPA inlets.

ZX7.5 and ZX10:

Screw terminal connections.

Option: 190 - 264 V, 47 - 63 Hz, delta

Option: 330 - 450 V, 47 - 63 Hz, wye

Option: 190 - 264 V, 47 - 63 Hz, dual single-phase

(top and bottom amplifiers)

Power consumption: (FM mode at nameplate power level)

ZX2500: 4700 W max; 4300 W typical

ZX3750: 7000 W max; 6350 W typical

ZX5000: 9300 W max; 8500 W typical

ZX7.5: 14000 W max; 12700 W typical

ZX10: 18600 W max; 17000 W typical

Power factor (displacement): 0.98 typical.

Phase rotation/balance: all AC inputs independent.

Observation of correct phase rotation and balance not required.

3

Certified to 100-240 V nominal range +/- 10% testing margin.

4

Certified to 208-240 V nominal range +/- 10% testing margin.

1.10 Specifications

ZX Series

1-20 888-2595-001 12/20/11

WARNING: Disconnect primary power prior to servicing.

Page 39

ZX Series

Title: SPEC, ZX TRANSMITTER FAMILY Sheet 2 of 7 Rev: B Dwg: 817-2350-085

Mains restart: > 80% output power in less than 5 seconds after

AC mains failure.

Altitude: 3000 m elevation above mean sea level.

Ambient temperature range: 0 - 50

o

C at sea level, upper limit

de-rated 2

o

Centigrade per 300 m elevation AMSL.

Humidity: 95%, non-condensing.

Dimensions: Standard 19” (48.3 cm) EIA rack; 1RU = 4.45 cm

(1.75”)

ZX2500: 16 RU amp + 1 RU exciter, 62 cm (25”) depth

ZX3750: 16 RU amp + 1 RU exciter, 62 cm (25”) depth

ZX5000: 16 RU amp + 1 RU exciter, 62 cm (25”) depth

ZX7.5: 44 RU rack, 96 cm (38”) depth

ZX10: 44 RU rack, 96 cm (38”) depth

Weight, less exciter (all modules installed):

ZX2500: 67 kg (148 lbs) approx.

ZX3750: 81 kg (179 lbs) approx.

ZX5000: 95 kg (210 lbs) approx.

ZX7.5: 225 kg (500 lbs) approx.

ZX10: 250 kg (550 lbs) approx.

Air cooling: Air input with built-in filter at front. Air exhaust

with built-in DC fans at rear. Ducted air exhaust and/or

input available as option.

ZX2500: 17 m3/min (600 cfm) approx.

ZX3750: 17 m3/min (600 cfm) approx.

ZX5000: 17 m3/min (600 cfm) approx.

ZX7.5: 34 m3/min (1200 cfm) approx.

ZX10: 34 m3/min (1200 cfm) approx.

Ambient noise: Worst case, 1 m from front face, 1 m above

ground. Mounted in rack, no ducted air input or exhaust.

Figures in parentheses are for ducted air input and exhaust

option.

ZX2500: < 73 dBA (65 dBA)

ZX3750: < 73 dBA (65 dBA)

ZX5000: < 73 dBA (65 dBA)

ZX7.5: < 73 dBA (65 dBA)

ZX10: < 73 dBA (65 dBA)

REMOTE CONTROL

Parallel remote: D-sub 25 female.

Status: open collector, 24 V @ 500 mA max.

Command: active low with internal pull-up.

Telemetry: 0 - 2 V, 2k source impedance.

Security: RF mute and external interlock lines.

ZX7.5, ZX10: D-sub 25 female to each amp chassis and Dsub 9 with screw terminal breakout for system.

Ethernet (optional): RJ45, twisted pair.

WIDEBAND COMPOSITE PERFORMANCE

Inputs: Selectable, balanced/unbalanced, female BNC

connector.

Input impedance: Selectable 10k ohms or 50 ohms nominal

(resistive).

Input level: 3.5 V p-p (1.24 V rms) nominal for +/- 75 kHz

deviation.

FM signal to noise ratio: 80 dB below +/- 75 kHz deviation at

400 Hz with 75 µs de-emphasis, 22 Hz to 500 kHz

bandwidth.

Amplitude response: +/- 0.1 dB, 30 Hz to 53 kHz.

Total harmonic distortion (THD+N): 0.02%, 30 Hz to 100

kHz with 75 µs de-emphasis.

Intermodulation distortion: SMPTE: 0.03% (60 / 7000 Hz

1:1) CCIF: All distortion products down 74 dB (reference

14 kHz / 15 kHz tone pair).

Transient intermodulation distortion (DIM): 0.05%, 2.96

kHz square wave / 14 kHz sine wave modulation.

Phase response variation: +/- 0.5

o

from linear phase, 30 Hz to

53 kHz, limited by measurement equipment (see stereo

separation below).

Stereo separation: 50 Hz to 300 Hz: 40 dB; 300 Hz to 15 kHz:

50 dB (as limited by external stereo generator).

MONAURAL MODE (STANDARD)

Input: XLR (female) connector, 600 ohms, balanced, resistive,

transformerless.

Input sensitivity: -8 dBm to +12 dBm for +/- 75 kHz deviation

at 400 Hz, adjustable.

Amplitude response: +/- 0.5 dB with respect to pre-emphasis

curve. Selectable pre-emphasis: flat, 25, 50 or 75 µs.

Harmonic distortion: (THD+N): 0.02%, 30 Hz to 15 kHz with

75 µs de-emphasis.

Intermodulation distortion: SMPTE: 0.03%, 60 Hz / 7 kHz

tone pair, 4:1 ratio, 75 µs pre-/de-emphasis; CCIF: All

distortion products down 74 dB (reference 14 kHz / 15 kHz

tone pair).

Transient intermodulation distortion: DIM: 0.05%, 2.96 kHz

square wave / 14 kHz sine wave modulation (flat).

FM signal to noise ratio: 80 dB below +/- 75 kHz deviation at

400 Hz with 75 µs de-emphasis, 22 Hz to 500 kHz

bandwidth.

SCA/RBDS/RDS INPUTS (STANDARD)

Number of inputs: Three, female BNC.

Input impedance: 10k ohms, unbalanced.

Input sensitivity: 1.5V p-p (nominal) for 10% injection.

Subcarrier frequency range: 57 kHz to 92 kHz (25 kHz to 92

kHz in monaural operation).

Amplitude response: +/- 0.3 dB, 20 kHz to 100 kHz.

COMPLIANCE

RoHS 2002/95/EC compliant: Yes.

R&TTE 1999/5/EC compliant: Yes.

All specifications referenced to any single output frequency

(87.5 - 108 MHz), nominal rated output power, and 50 ohm,

isolated, non-reactive load.

Specifications defined in a laboratory environment with highgrade source and demodulation equipment. Standard factory

measurement does not include all listed items. Specifications

subject to change without notice.

Section 1 Introduction

12/20/11 888-2595-001 1-21

WARNING: Disconnect primary power prior to servicing.

Page 40

Section 1 Introduction

Title: SPEC, ZX TRANSMITTER FAMILY Sheet 3 of 7 Rev: B Dwg: 817-2350-085

ZX Transmitter Specifications – CD Models

GENERAL

FM power output range:

1

ZX2500: 625 W – 2750 W

ZX3750: 950 W – 4125 W

ZX5000: 1250 W – 5500 W

ZX7.5: 1900 W – 8250 W

ZX10: 2500 W – 11000 W

RF output connector:

2

ZX2500: EIA 1-5/8” flangeless, 50 ohms

ZX3750: EIA 1-5/8” flangeless, 50 ohms

ZX5000: EIA 1-5/8” flangeless, 50 ohms

ZX7.5: EIA 1-5/8” flanged, 50 ohms

ZX10: EIA 1-5/8” flanged, 50 ohms

Excitation: Harris DIGIT

R

CD digital FM exciter.

RF amplifers: MOSFET, broadband (no-tune), hot plug

modular, universal (same type all tx models), 4.5 kg.

Power supplies: Switchmode, auto-ranging, hot plug modular,

universal, 2.5 kg.

Frequency range: 87.5 - 108 MHz, digitally programmable in

50 Hz increments.

Frequency stability: +/- 150 Hz, 0

o

C to 50o C ambient

temperature range (using internal frequency reference).

Power stability: +/- 0.25 dB.

Reverse power: Protected against open or short circuit, all

phase angles. Capable of operation into infinite VSWR

with user-adjustable foldback threshold. Threshold set to

2.5% of FM nameplate power level at factory.

External frequency control: Capable of locking to an external

10 MHz reference for use in FM synchronous applications

when fitted with optional DIGIT CD Sync Board (9929850-001). Sync input requirement: 2.82 V p-p or TTL

level. Sync input connector: BNC female.

Harmonic / spurious output: Meets or exceeds FCC,

Canadian, CE, and Chinese requirements.

Modulation type: Direct digital synthesis (DDS) using a 32-bit

NCO (numerically controlled oscillator).

Modulation capability: 208% (+/- 75 kHz reference standard).

Factory programmable in 6 dB increments to +/- 468 kHz.

PLL/AFC overload characteristics: Immune to carrier

dropouts caused by high energy, low frequency modulation

(program audio is not applied to the VCO).

Modulation indication: Digitally generated peak reading,

0.25% accuracy (at 150% modulation setting), color-coded

LED display with baseband over-modulation indicator.

Asynchronous AM S/N ratio: 55 dB minimum below

equivalent 100% amplitude modulation by 400 Hz using 75

ȝs de-emphasis (no FM modulation present).

Synchronous AM S/N ratio: 50 dB minimum below

equivalent 100% amplitude modulation with 75 ȝs deemphasis and 400 Hz highpass filter (FM deviation +/- 75

kHz by a 1 kHz sine wave).

1

VSWR 1.2:1 or less. De-rate to nameplate rating for VSWR

up to 1.5:1.

2

EIA 3-1/8” flanged available as option, ZX7.5 and ZX10.

AC mains requirement: 90 - 264 V

3

, 47 - 63 Hz, IEC C14

inlet for exciter and following connections to power

amplifier:

ZX2500/3750: 190 - 264 V

4

, 47 - 63 Hz, triple IEC

C20 inlets. Configurable on-site for single or threephase connection: 190 - 264 V single phase, 190264 V delta, 190 - 264 V wye, or 330 - 450 V wye.

ZX5000: Same as 3750 W model except triple

PowerCon NAC3MPA inlets.

ZX7.5 and ZX10:

Screw terminal connections.

Option: 190 - 264 V, 47 - 63 Hz, delta

Option: 330 - 450 V, 47 - 63 Hz, wye

Option: 190 - 264 V, 47 - 63 Hz, dual single-phase

(top and bottom amplifiers)

Power consumption: (FM mode at nameplate power level)

ZX2500: 4700 W max; 4300 W typical

ZX3750: 7000 W max; 6350 W typical

ZX5000: 9300 W max; 8500 W typical

ZX7.5: 14000 W max; 12700 W typical

ZX10: 18600 W max; 17000 W typical

Power factor (displacement): 0.98 typical.

Phase rotation/balance: all AC inputs independent.

Observation of correct phase rotation and balance not

required.

Mains restart: > 80% output power in less than 5 seconds after

AC mains failure.

Altitude: 3000 m elevation above mean sea level.

Ambient temperature range: 0 - 50

o

C at sea level, upper limit

de-rated 2

o

Centigrade per 300 m elevation AMSL.

Humidity: 95%, non-condensing.

Dimensions: Standard 19” (48.3 cm) EIA rack; 1RU = 4.45 cm

(1.75”)

ZX2500: 16 RU amp + 1 RU exciter, 62 cm (25”) depth

ZX3750: 16 RU amp + 1 RU exciter, 62 cm (25”) depth

ZX5000: 16 RU amp + 1 RU exciter, 62 cm (25”) depth

ZX7.5: 44 RU rack, 96 cm (38”) depth

ZX10: 44 RU rack, 96 cm (38”) depth

Weight, less exciter (all modules installed):

ZX2500: 67 kg (148 lbs) approx.

ZX3750: 81 kg (179 lbs) approx.

ZX5000: 95 kg (210 lbs) approx.

ZX7.5: 225 kg (500 lbs) approx.

ZX10: 250 kg (550 lbs) approx.

Air cooling: Air input with built-in filter at front. Air exhaust

with built-in DC fans at rear. Ducted air exhaust and/or

input available as option.

ZX2500: 17 m3/min (600 cfm) approx.

ZX3750: 17 m3/min (600 cfm) approx.

ZX5000: 17 m3/min (600 cfm) approx.

ZX7.5: 34 m3/min (1200 cfm) approx.

ZX10: 34 m3/min (1200 cfm) approx.

Ambient noise: Worst case, 1 m from front face, 1 m above

ground. Mounted in rack, no ducted air input or exhaust.

Figures in parentheses are for ducted air input and exhaust

option.

3

Certified to 100-240 V nominal range +/- 10% testing margin.

4

Certified to 208-240 V nominal range +/- 10% testing margin.

ZX Series

1-22 888-2595-001 12/20/11

WARNING: Disconnect primary power prior to servicing.

Page 41

ZX Series

Title: SPEC, ZX TRANSMITTER FAMILY Sheet 4 of 7 Rev: B Dwg: 817-2350-085

ZX2500: < 73 dBA (65 dBA)

ZX3750: < 73 dBA (65 dBA)

ZX5000: < 73 dBA (65 dBA)

ZX7.5: < 73 dBA (65 dBA)

ZX10: < 73 dBA (65 dBA)

REMOTE CONTROL

Parallel remote: D-sub 25 female.

Status: open collector, 24 V @ 500 mA max.

Command: active low with internal pull-up.

Telemetry: 0 - 2 V, 2k source impedance.

Security: RF mute and external interlock lines.

ZX7.5, ZX10: D-sub 25 female to each amp chassis and Dsub 9 with screw terminal breakout for system.

Ethernet (optional): RJ45, twisted pair.

COMPLIANCE

RoHS 2002/95/EC compliant: Yes.

R&TTE 1999/5/EC compliant: Yes.

STEREO PERFORMANCE with Digital Input Module

Input data format: AES3-1992 (reference standards: AES5-

1984, ANSI S4.28-1984, AES3-1985, ANSI S4.40-1992,

and AES3-1992).

Sample rate: Any in range 32 kHz to 56 kHz (32, 44.1 or

48kHz typically output from AES3 devices).

Digital stereo generator: Complete digital composite stereo

waveform generated in digital domain from incoming AES3

stereo audio data using a digital signal processor (DSP).

Digital baseband composite limiting: DSP “lookahead”

techniques for control of peaks before overmodulation can

occur. Active with on-board DSP stereo generator in stereo

or monaural mode; pilot carrier and SCA signals unaffected.

Limiter on/off and limit setting adjustable from 0 - 18 dB

either locally or by standard remote control systems.

Pre-emphasis: 0, 25, 50, or 75 ȝs, locally selectable.

Stereo separation (sine wave): 65 dB or greater, 10 Hz to 15

kHz.

Dynamic stereo separation (complex waveform): 55 dB or

greater, 10 Hz to 15 kHz.

Amplitude response (L or R): 10 Hz to 15 kHz +/- 0.2 dB

referenced to selected pre-emphasis curve.

FM signal to noise ratio (L or R): 83 dB below 100%

modulation at 400 Hz; measured in DC to 22 kHz

bandwidth with 75 ȝs de-emphasis and DIN “A” weighting.

Does not exhibit the subsonic noise associated with analog

exciters.

Stereo harmonic distortion: 0.005% or less for any

modulating frequency from 10 Hz to 15 kHz, measured in

DC to 22 kHz bandwidth with 75 ȝs de-emphasis.

Intermodulation distortion (L or R): CCIF: 0.02% (14/15

kHz 1:1); SMPTE: 0.025% (60/7000 Hz 1:1).

Transient intermodulation distortion (DIM) (L or R):

0.005% (2.96 kHz square wave / 14 kHz sine wave

modulation).

Linear crosstalk: L+R to L-R and L-R to L+R due to

amplitude and phase matching of L&R channels (DC - 15

kHz): 85 dB below 100% modulation reference.

Non-linear crosstalk: L+R to L-R and L-R to L+R due to

distortion products: 75 dB below 100% modulation

reference, DC - 15 kHz.

RBDS/RDS synchronizing signal: 19 kHz quasi-sine wave,

nominal 5.6 V p-p, AC coupled, 100 ohm output impedance

(unbalanced); for use by customer-supplied, external

generator. BNC female connector.

Stereo / monaural mode control: Selectable locally or by

standard remote control systems. Zero amplitude pilot in

monaural mode.

Emergency analog composite mode: Switchable locally or by

standard remote control systems to mute on-board DSP

stereo generator and accept analog composite stereo on

SCA Port #2. Nominal input sensitivity (all SCA ports in

this mode): 3.5 V p-p (1.24 V rms) for +/- 75 kHz

deviation. FM signal to noise ratio: 85 dB below 100%

modulation. Total composite harmonic distortion: 0.02%.

COMPOSITE INPUT PERFORMANCE with Analog Input

Module

Inputs: Two: XLR female balanced (switchable, composite, or

monaural), and BNC female unbalanced.

Input impedance: Balanced/unbalanced: 10k ohms nominal

(resistive).

Input level: 3.5 V p-p (1.24 V rms) nominal for +/- 75 kHz

deviation.

FM signal to noise ratio: 94 dB below +/- 75 kHz deviation at

400 Hz; measured in a DC to 100 kHz bandwidth with 75

ȝs de-emphasis; DIN “A” weighting. Does not exhibit the

subsonic noise associated with analog exciters.

Amplitude response: +/- 0.01 dB, DC to 53 kHz; +/- 0.25 dB,

53 to 100 kHz.

Total harmonic distortion: 94 dB or 0.002% THD over stereo

sub-band (DC to 53 kHz).

Intermodulation distortion: CCIF: 0.008% (14/15 kHz 1:1);

SMPTE: 0.008% (60/7000 Hz 1:1).

Transient intermodulation distortion (DIM): 0.005% (2.96

kHz square wave / 14 kHz sine wave modulation).

Slew rate: 9 V/ȝs, symmetrical.

Group delay variation: +/- 5 ns, DC to 53 kHz, +/- 50 ns, 53

to 100 kHz.

Phase response variation: +/- 0.1

o

from linear phase, DC to 53

kHz.

ANALOG STEREO and SCA PERFORMANCE

NOTE: Analog stereo and SCA performance with the DIGIT

TM

exciter is defined almost entirely by the program link and

external generators.

All specifications referenced to any single output frequency

(87.5 - 108 MHz), nominal rated output power, and 50 ohm,

isolated, non-reactive load. Specifications defined in a

laboratory environment with high grade source and

demodulation equipment. Standard factory measurement does

not include all listed items. Specifications subject to change

without notice.

Section 1 Introduction

12/20/11 888-2595-001 1-23

WARNING: Disconnect primary power prior to servicing.

Page 42

Section 1 Introduction

Title: SPEC, ZX TRANSMITTER FAMILY Sheet 5 of 7 Rev: B Dwg: 817-2350-085

ZX Transmitters Specifications – HD models

GENERAL

FM power output range:

1

ZX2500: 625 W – 2750 W

ZX3750: 950 W – 4125 W

ZX5000: 1250 W – 5500 W

ZX7.5: 1900 W – 8250 W

ZX10: 2500 W – 11000 W

FM+HD power output range:

2

(HD signal injection ratio -20

dB)

ZX2500: 500 W – 2050 W

ZX3750: 750 W – 3100 W

ZX5000: 1000 W – 4125 W

ZX7.5: 1500 – 6200 W

ZX10: 2000 W – 8250 W

HD power output range:

3

ZX2500: 250 W – 950 W

ZX3750: 375 W – 1450 W

ZX5000: 500 W – 1925 W

ZX7.5: 750 W – 2900 W

ZX10: 1000 W – 3850 W

RF output connector:

4

ZX2500: EIA 1-5/8” flangeless, 50 ohms

ZX3750: EIA 1-5/8” flangeless, 50 ohms

ZX5000: EIA 1-5/8” flangeless, 50 ohms

ZX7.5: EIA 1-5/8” flanged, 50 ohms

ZX10: EIA 1-5/8” flanged, 50 ohms

Excitation: Flexstar HDX Exciter.

RF amplifers: MOSFET, broadband (no-tune), hot plug

modular, universal (same type all tx models), 4.5 kg.

Power supplies: Switchmode, auto-ranging, hot plug modular,

universal, 2.5 kg.

Frequency range: 87.5 - 108.0 MHz, programmable in 10 kHz

steps.

Frequency stability: +/- 150 Hz, 0° to 50°C using high

accuracy internal (59.535 MHz) TCXO. 10 MHz input for

synchronization to external (GPS) reference. Automatic

switching to internal oscillator if external reference fails.

Power stability: +/- 0.25 dB.

Reverse power: Protected against open or short circuit, all

phase angles. Capable of operation into infinite VSWR

with user-adjustable foldback threshold. Threshold set to

2.5% of FM nameplate power level at factory.

Harmonic / spurious suppression: Internal harmonic filter

meets or exceeds all FCC, IC, CE, Chinese requirements.

Meets or exceeds standard NRSC-5A emission limits in all

modes.

1

VSWR 1.2:1 or less. De-rate to nameplate rating for VSWR

up to 1.5:1.

2

VSWR 1.2:1 or less. De-rate to 70% of nameplate rating for

VSWR up to 1.5:1.

3

VSWR 1.2:1 or less. De-rate to 35% of nameplate rating for

VSWR up to 1.5:1.

4

EIA 3-1/8” flanged available as option, ZX7.5 and ZX10.

Modulation types: FM digitally synthesized direct to channel,

HD digital direct to channel, FM+HD digital direct to

channel.

Operating modes: “On-the-Fly” switching between FM only,

HD only, FM+HD modes.

FM modulation capability: Greater than +/- 300 kHz.

Asynchronous AM S/N ratio: 50 dB minimum below

equivalent 100% amplitude modulation by 400 Hz using 75

ȝs de-emphasis (no FM modulation present).

Synchronous AM S/N ratio: 50 dB minimum below equivalent

100% amplitude modulation with 75 ȝs de-emphasis and

400 Hz high-pass filter (FM deviation +/-75 kHz by a 1 kHz

sine wave). Measured at wideband input.

AC mains requirement: 90 - 264 V

5

, 47 - 63 Hz, IEC C14

inlet for exciter and following connections to power

amplifier:

ZX2500/3750: 190 - 264 V

6

, 47 - 63 Hz, triple IEC

C20 inlets. Configurable on-site for single or threephase connection: 190 - 264 V single phase, 190264 V delta, 190 - 264 V wye, or 330 - 450 V wye.

ZX5000: Same as 3750 W model except triple

PowerCon NAC3MPA inlets.

ZX7.5 and ZX10:

Screw terminal connections.

Option: 190 - 264 V, 47 - 63 Hz, delta

Option: 330 - 450 V, 47 - 63 Hz, wye

Option: 190 - 264 V, 47 - 63 Hz, dual single-phase

(top and bottom amplifiers)

Power consumption: (FM mode at nameplate power level)

ZX2500: 4700 W max; 4300 W typical

ZX3750: 7000 W max; 6350 W typical

ZX5000: 9300 W max; 8500 W typical

ZX7.5: 14000 W max; 12700 W typical

ZX10: 18600 W max; 17000 W typical

Power Factor (displacement): 0.98 typical.

Phase rotation/balance: all AC inputs independent.

Observation of correct phase rotation and balance not

required.

Mains restart: > 80% output power in less than 5 seconds after

AC mains failure.

Altitude: 3000 m elevation above mean sea level.

Ambient temperature range: 0 - 50

o

C at sea level, upper limit

de-rated 2

o

Centigrade per 300 m elevation AMSL.

Humidity: 95%, non-condensing.

Dimensions: Standard 19” (48.3 cm) EIA rack; 1RU = 4.45 cm

(1.75”)

ZX2500: 16 RU amp + 1 RU exciter, 62 cm (25”) depth

ZX3750: 16 RU amp + 1 RU exciter, 62 cm (25”) depth

ZX5000: 16 RU amp + 1 RU exciter, 62 cm (25”) depth

ZX7.5: 44 RU rack, 96 cm (38”) depth

ZX10: 44 RU rack, 96 cm (38”) depth

Weight, less exciter (all modules installed):

ZX2500: 67 kg (148 lbs) approx.

ZX3750: 81 kg (179 lbs) approx.

ZX5000: 95 kg (210 lbs) approx.

ZX7.5: 225 kg (500 lbs) approx.

5

Certified to 100-240 V nominal range +/- 10% testing margin.

6

Certified to 208-240 V nominal range +/- 10% testing margin.

ZX Series

1-24 888-2595-001 12/20/11

WARNING: Disconnect primary power prior to servicing.

Page 43

ZX Series

Title: SPEC, ZX TRANSMITTER FAMILY Sheet 6 of 7 Rev: B Dwg: 817-2350-085

ZX10: 250 kg (550 lbs) approx.

Air cooling: Air input with built-in filter at front. Air exhaust

with built-in DC fans at rear. Ducted air exhaust and/or

input available as option.

ZX2500: 17 m3/min (600 cfm) approx.

ZX3750: 17 m3/min (600 cfm) approx.

ZX5000: 17 m3/min (600 cfm) approx.

ZX7.5: 34 m3/min (1200 cfm) approx.

ZX10: 34 m3/min (1200 cfm) approx.

Ambient noise: Worst case, 1 m from front face, 1 m above

ground. Mounted in rack, no ducted air input or exhaust.

Figures in parentheses are for ducted air input and exhaust

option.

ZX2500: < 73 dBA (65 dBA)

ZX3750: < 73 dBA (65 dBA)

ZX5000: < 73 dBA (65 dBA)

ZX7.5: < 73 dBA (65 dBA)

ZX10: < 73 dBA (65 dBA)

REMOTE CONTROL

Parallel remote: D-sub 25 female.

Status: open collector, 24 V @ 500 mA max.

Command: active low with internal pull-up.

Telemetry: 0 - 2 V, 2k source impedance.

Security: RF mute and external interlock lines.

ZX7.5, ZX10: D-sub 25 female to each amp chassis and Dsub 9 with screw terminal breakout for system.

Ethernet (optional): RJ45, twisted pair.

COMPLIANCE

RoHS 2002/95/EC compliant: Yes.

R&TTE 1999/5/EC compliant: Yes.

INPUT/OUTPUT SPECIFICATIONS

External frequency control: Parallel I/O control of up to 8

frequencies. Unlimited frequency selection via optional

N+1 controller.

AES3 audio inputs: (2) auto-switching AES3 inputs, female

XLR, 110 ohms balanced; -2.8 dBfs nominal; Adjustable

level from 0 dBfs to -15 dBfs in 0.1 dB steps for +/- 75 kHz

deviation; input sample rate 32 to 96 kHz.

Analog L/R inputs: Female XLR, >10K ohms, balanced,

resistive; default level +10 dBu for +/-75 kHz deviation.

Level adjustable from -10 dBV to +10 dBV.

Analog composite input: (2) BNC inputs (1 balanced, 1

unbalanced); Balanced impedance 10k ohms or 50 ohms

(selectable); Unbalanced 10k ohms; Input level: 3.5 V p-p

for +/-75 kHz deviation; Adjustable 2 V p-p to 5 V p-p.

SCA audio inputs: (2) inputs combined on one 5-pin XLR

female connector (mating male connector supplied); >10k

ohms balanced, resistive; +10 dBV nominal for +/- 6 kHz

deviation of FM sub-carrier.

External SCA inputs: (2) BNC female, unbalanced; >10k ohm;

1.5V p-p nominal for +/-7.5 kHz (10%) deviation of main

carrier; adjustable from 1 V p-p to 4 V p-p.

RBDS data input: D-sub 9-pin female RS-232.

External 10MHz clock input: BNC female, unbalanced, 50

ohm, -10 dBm to +10 dBm.

External 1 PPS clock input: BNC female, unbalanced, 50 ohm,

TTL level.

User remote interface: D-sub 25-pin female.

N+1 interface: D-sub 25-pin female.

RF sample out: BNC jack, -66 dBc, post harmonic filter.

19 kHz pilot sync output: BNC female, unbalanced, 50 ohms

resistive, sine wave, AC coupled, 4.5 V p-p nominal,

unterminated.

Exciter communication ports: (2) D-sub 9-pin female; RS232

protocol, RBDS or VT-100 data.

Exciter ethernet ports: (2) RJ-45 on main processor board; (2)

RJ-45 on Exgine board (HD version only); all Ethernet

ports 10/100; supports static or dynamic IP address.

Exciter USB port: Front panel USB type-A connector; USB 1.1

/ 2.0 compliant; supports configuration save/restore and

software updates via flash drive.

STEREO GENERATOR PERFORMANCE (AES3 OR

ANALOG INPUTS)

Modes: Stereo, Mono L+R, Mono L, and Mono R; remote

controllable.

Pre-emphasis: Selectable 0, 25, 50, or 75 microseconds.

Stereo pilot tone: 19 kHz +/- 0.03 Hz; injection adjustable 0%

to 12% in 0.05% steps; 9% nominal. 38 kHz, 57 kHz, 76

kHz, 95 kHz Suppression: 80 dB below +/- 75 kHz

deviation.

Stereo separation: 80 dB*

/60 dB, 10 Hz to 15 kHz.

Dynamic stereo separation: 80 dB*/60 dB, 10 Hz to 15 kHz*.

Stereo amplitude response: +/- 0.1 dB, 10 Hz to 15 kHz

referenced to selected pre-emphasis curve.

Stereo signal to noise ratio (L or R): 85 dB below 100%

modulation at 400 Hz; measured in a 10 Hz to 22 kHz

bandwidth with 75ȝs de-emphasis and DIN “A” weighting.

Stereo total harmonic distortion: 0.005%*/0.02%, any

modulating frequency 10 Hz to 15 kHz, in bandwidth 10 Hz

to 22 kHz with 75ȝs de-emphasis.

Stereo intermodulation distortion (L or R): CCIF:

0.005%*/0.02% Note 1; (14/15 kHz 1:1), SMPTE: 0.02%

(60/7000 Hz 1:1).

Transient intermodulation distortion (DIM):

0.008%*/0.02%; (2.96 kHz square wave / 14 kHz sine

wave modulation).

Linear crosstalk: 90 dB below 100% modulation reference

(AES3 Input); L+R to L-R or L-R to L+R due to amplitude

and phase matching of L&R channels (10 Hz - 15 kHz).

Non-linear crosstalk: 80 dB below 100% modulation

reference; L+R to L-R or L-R to L+R due to distortion

products.

Audio overshoot: Less than 0.16 dB.

MONO PERFORMANCE (AES3 OR ANALOG INPUT)

Pre-emphasis: Selectable 0, 25, 50 or 75 microseconds.

FM mono signal-to-noise ratio: 94 dB below 100%

modulation at 400 Hz; measured in a 10 Hz to 22 kHz

bandwidth with 75 ȝs de-emphasis and DIN “A” weighting.

Amplitude response: +/- 0.05 dB, referenced to selected pre-

emphasis curve (no low-pass filter).

Section 1 Introduction

12/20/11 888-2595-001 1-25

WARNING: Disconnect primary power prior to servicing.

Page 44

Section 1 Introduction

Title: SPEC, ZX TRANSMITTER FAMILY Sheet 7 of 7 Rev: B Dwg: 817-2350-085

Mono total harmonic distortion:

0.002%*/0.01% THD, 10 Hz

to 22 kHz bandwidth.

Mono intermodulation distortion: CCIF: 0.005% (14/15 kHz

1:1); SMPTE: 0.005% (60/7000 Hz 1:1).

Mono transient intermodulation distortion (DIM): 0.005%

(2.96 kHz square wave / 14 kHz sine wave).

WIDEBAND ANALOG INPUT PERFORMANCE

FM signal-to-noise ratio: 94 dB below +/-75 kHz deviation at

400 Hz; measured in 10 Hz to 100 kHz bandwidth with 75

ȝs de-emphasis and DIN “A” weighting.

Amplitude response: +/- 0.005 dB 20 Hz to 53 kHz; +/- 0.03

dB, 53 kHz to 100 kHz.

Total harmonic distortion: 0.002%*/.01% THD over stereo

sub-band (10 Hz to 53 kHz) with 75 ȝs de-emphasis.

Intermodulation distortion: CCIF: 0.005% (14/15 kHz 1:1);

SMPTE: 0.005% (60/7000 Hz 1:1).

Transient intermodulation distortion (DIM): 0.005% (2.96

kHz square wave / 14 kHz sine wave modulation).

Slew rate: 11.8 V/ȝs - symmetrical.

Phase response variation: +/- 0.05° from linear phase, 10 Hz

to 100 kHz.

Group delay variation: +/- 5 ns, 10 Hz to 53 kHz, +/- 30 ns, 53

kHz to 100 kHz.

EXTERNAL SCA, RBDS PERFORMANCE

SCA format: Externally generated, analog FM subcarriers

within range of 53 - 99 kHz.

SCA sub-band amplitude response: +/- 0.5 dB, 40 kHz to 100

kHz; high-pass filtered.

SCA channel FM signal-to-noise ratio: 80 dB below +/- 6 kHz

subcarrier deviation at 400 Hz with 150 ȝs de-emphasis.

Harmonic distortion: less than 0.2% in audio passband of SCA

generator.

Intermodulation distortion: SMPTE (60/7000 Hz, 1:1): 0.2%

or less, no pre/de-emphasis, SCA generator low-pass filter

bypassed.

Crosstalk, SCA to stereo: 80 dB below 100% modulation, L or

R channel with 75 ȝs de-emphasis.

Crosstalk, stereo to SCA: 80 dB below 100% modulation

referenced to +/- 6 kHz deviation and 150 ȝs de-emphasis.

Crosstalk, SCA to SCA: 80 dB below 100% modulation

(referenced to +/- 6 kHz deviation and 150 ȝs de-emphasis

per channel).

DUAL INTERNAL SCA PERFORMANCE

Pre-emphasis: Selectable: 150 ȝs, 75 ȝs, none.

Amplitude response: +/- 0.5 dB, 10 Hz to 7.5 kHz; selectable

4.3 kHz or 7.5 kHz low-pass filter.

Subcarrier frequency: 57 kHz to 99 kHz in 1 kHz steps.

Signal-to-noise ratio: 80 dB with 150 ȝs de-emphasis, 65 dB

without de-emphasis at +/- 6 kHz deviation.

Total harmonic distortion: 0.1% 10 Hz to 5 kHz.

SCA deviation capability: +/- 1 kHz to +/- 12 kHz; +/- 6 kHz

default.

Injection level: 2 to 20%, adjustable in 0.1% increments.

Spurious & harmonic performance: 2

nd

harmonic: better than

40 dB below sub-carrier; 3

rd

harmonic: better than 45 dB

below sub-carrier; All other components 50 Hz to 100 kHz: